A mold assembly tool for a single blade wax mold of a turbine guide

A turbine guider and single-blade technology, which is applied in the direction of casting and molding equipment, can solve the problems of high mold maintenance costs, small mold parts, and many sharp edges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

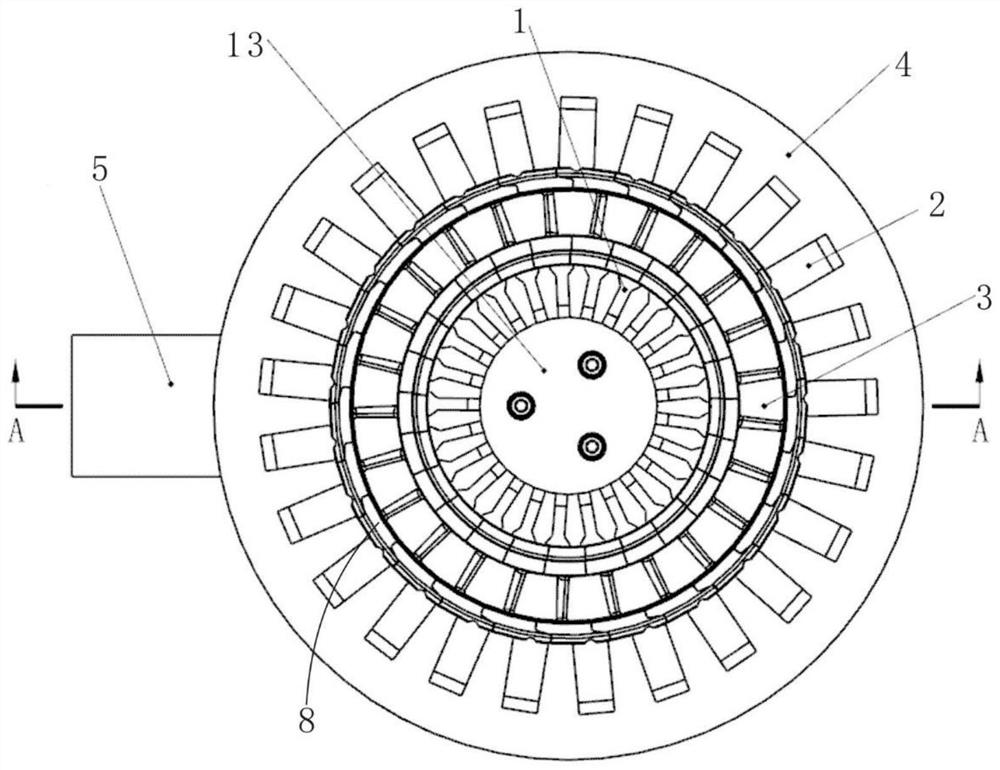

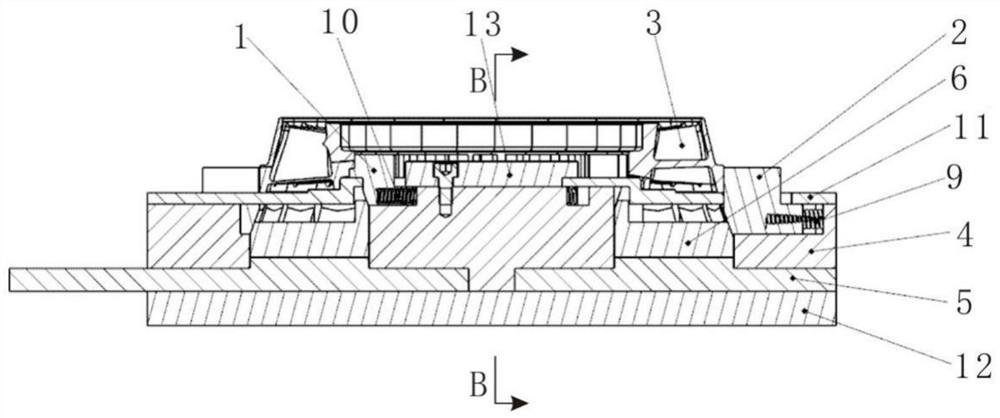

[0033] Such as figure 1 As shown, the mold assembly tooling of the single blade wax mold 3 of the turbine guider includes the wax mold 3 cooperatingly sandwiched between the inner positioning block 1 and the outer positioning block 2, and the wax mold is fixed by the inner positioning block 1 and the outer positioning block 2 respectively. The two ends of the mold 3 are clamped to complete the fixing of the position of the wax mold 3 .

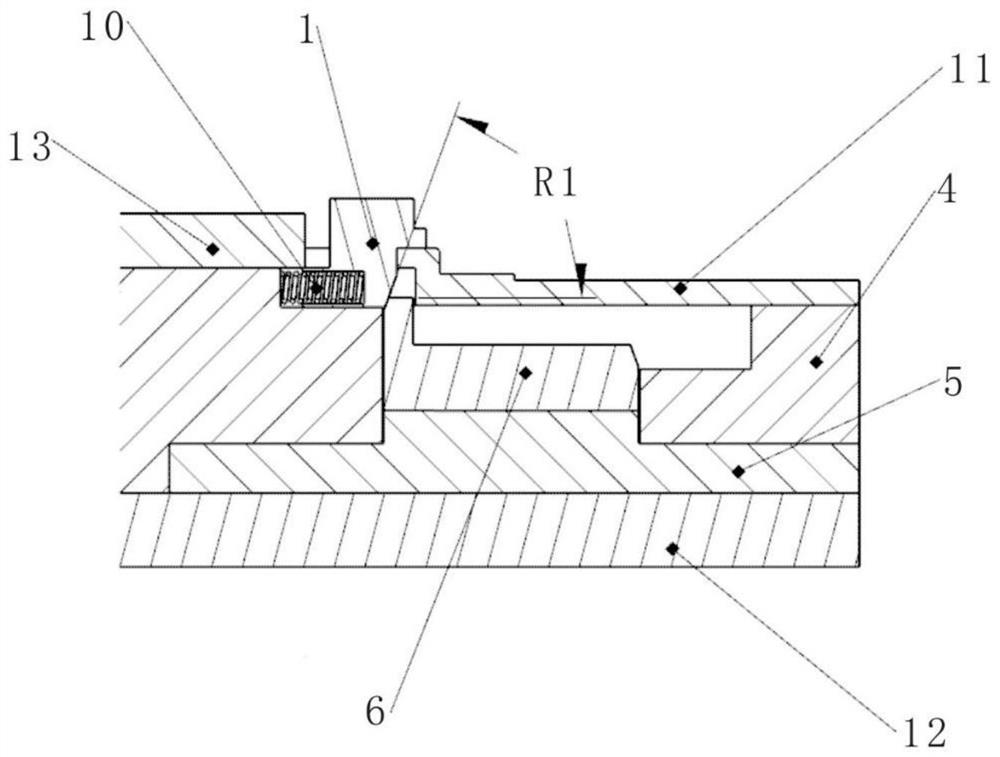

[0034] Wherein, the inner positioning block 1 and the outer positioning block 2 are installed on the track base 4, and can move horizontally relative to the track base 4, thereby realizing clamping, positioning and release of the wax mold 3. Preferably, a chute is installed on the track base 4 , and the length direction of the chute is set relative to the clamping direction of the wax model 3 .

[0035] The track base 4 has a guiding and limiting effect on the inner positioning block 1 and the outer positioning block 2. It adopts an integral ...

Embodiment 2

[0047] According to an embodiment of the present application, on the basis of the above embodiments, a U-shaped ring groove 7 is provided on the track base 4 .

[0048] Wherein, the ejection structure 6 is placed in the U-shaped ring groove 7, and moves up and down in the U-shaped ring groove 7. Through the setting of the U-shaped ring groove 7, the moving direction of the ejection structure 6 is limited. Only the degree of freedom in the vertical direction is left, so that in the process of rotating the handle 5, the up and down movement of the ejection structure 6 in the U-shaped ring groove 7 can be effectively driven, which provides a structural basis for use and stable performance.

[0049] It can be preferably designed that there are two helical surface projections at a distance of 180° at the top of the rotating handle 5, and the helical surface projections cooperate with the helicoid projections arranged at the bottom of the ejection structure 6, and the helical surfac...

Embodiment 3

[0052] The inner positioning block 1 and the outer positioning block 2 of the molding tooling of the single blade wax mold 3 of the turbine guide both clamp the wax mold 3 through the arc groove structure 8 .

[0053] Specifically, an inner ring positioning groove is arranged on the inner side of the wax mold 3, and an outer ring positioning groove is arranged on the outer side of the wax mold 3. The inner ring positioning groove of the wax mold 3 is aligned with the inner positioning block 1, and the wax The positioning groove of the outer ring of the mold 3 and the outer positioning block 2 are aligned and clamped.

[0054] There are multiple inner positioning blocks 1 and outer positioning blocks 2, and both the inner positioning blocks 1 and the outer positioning blocks 2 are distributed in a ring shape; during operation, place the rotation handle 5 at the limit position counterclockwise, and pull the outer positioning blocks outward 2. After putting the wax mold 3 in plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com