Patents

Literature

1036results about "Foundry moulding apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

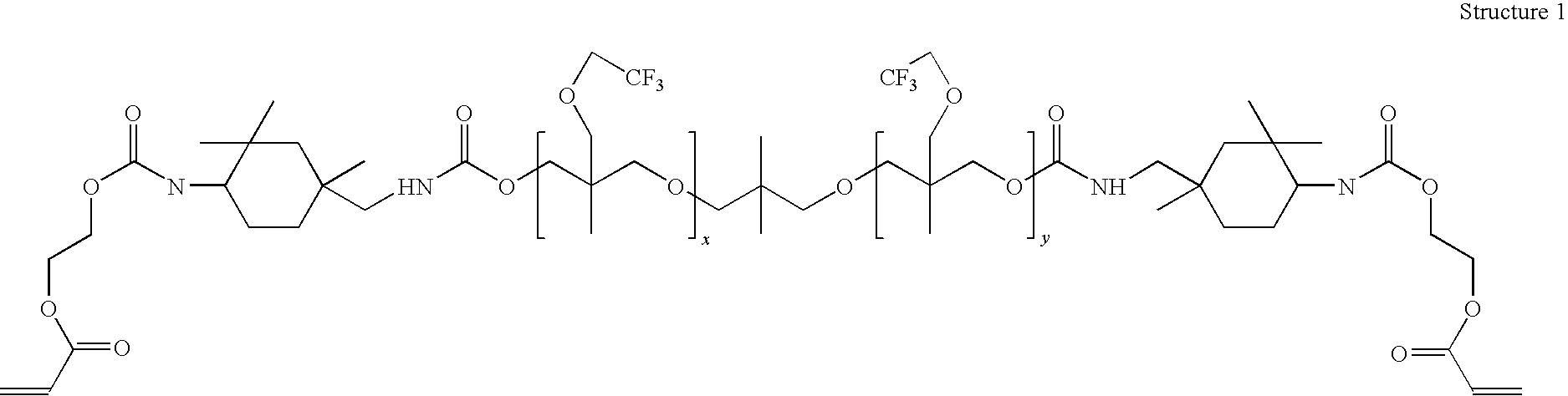

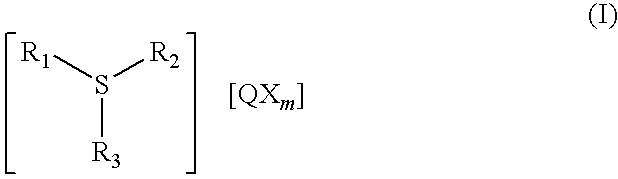

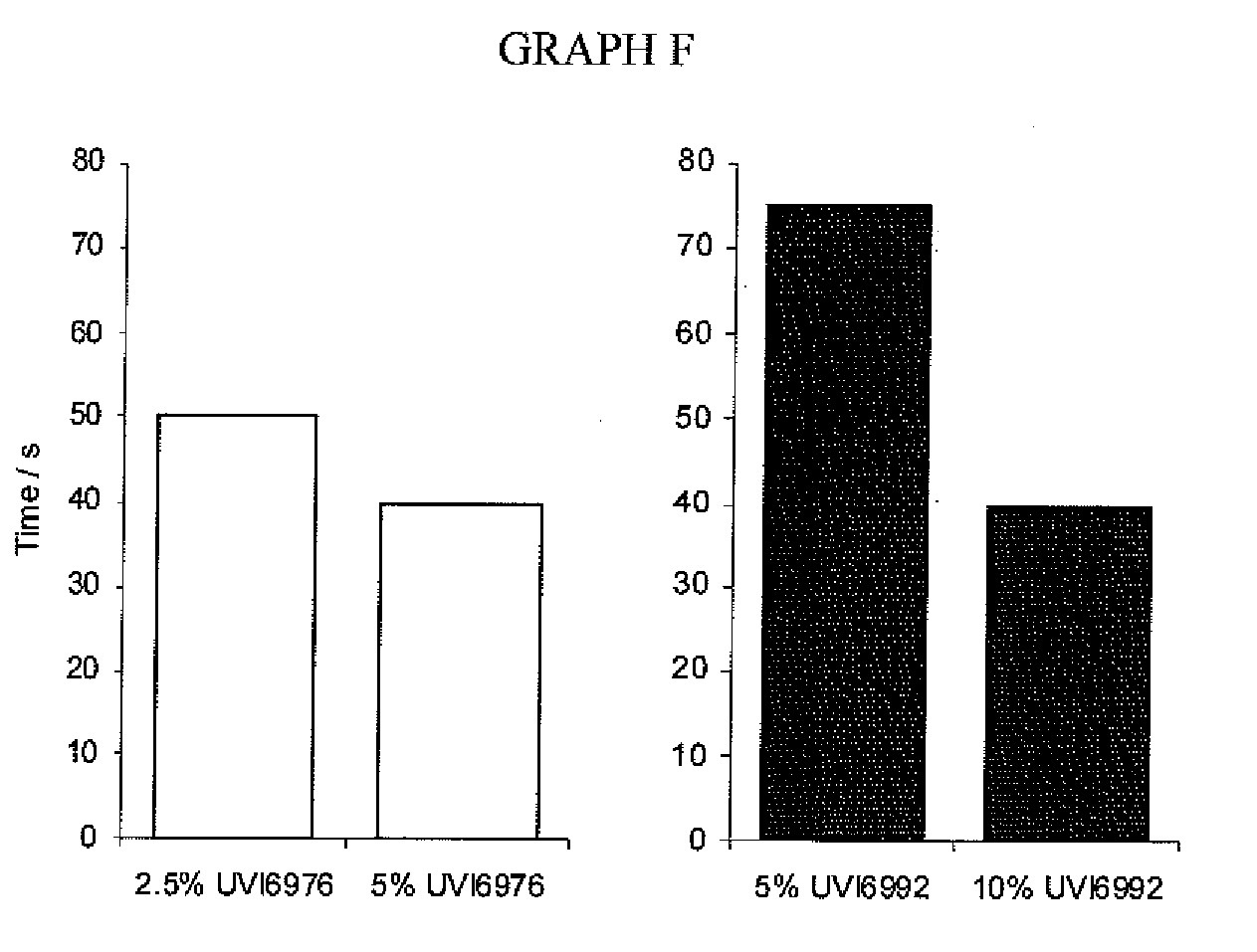

Antimony-free photocurable resin composition and three dimensional article

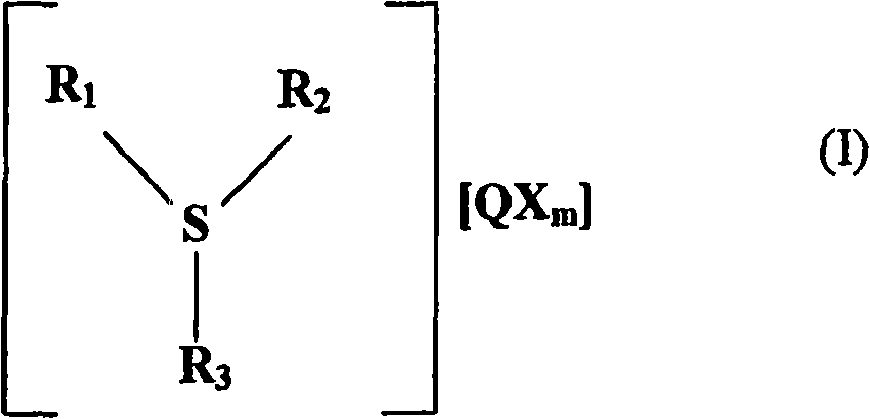

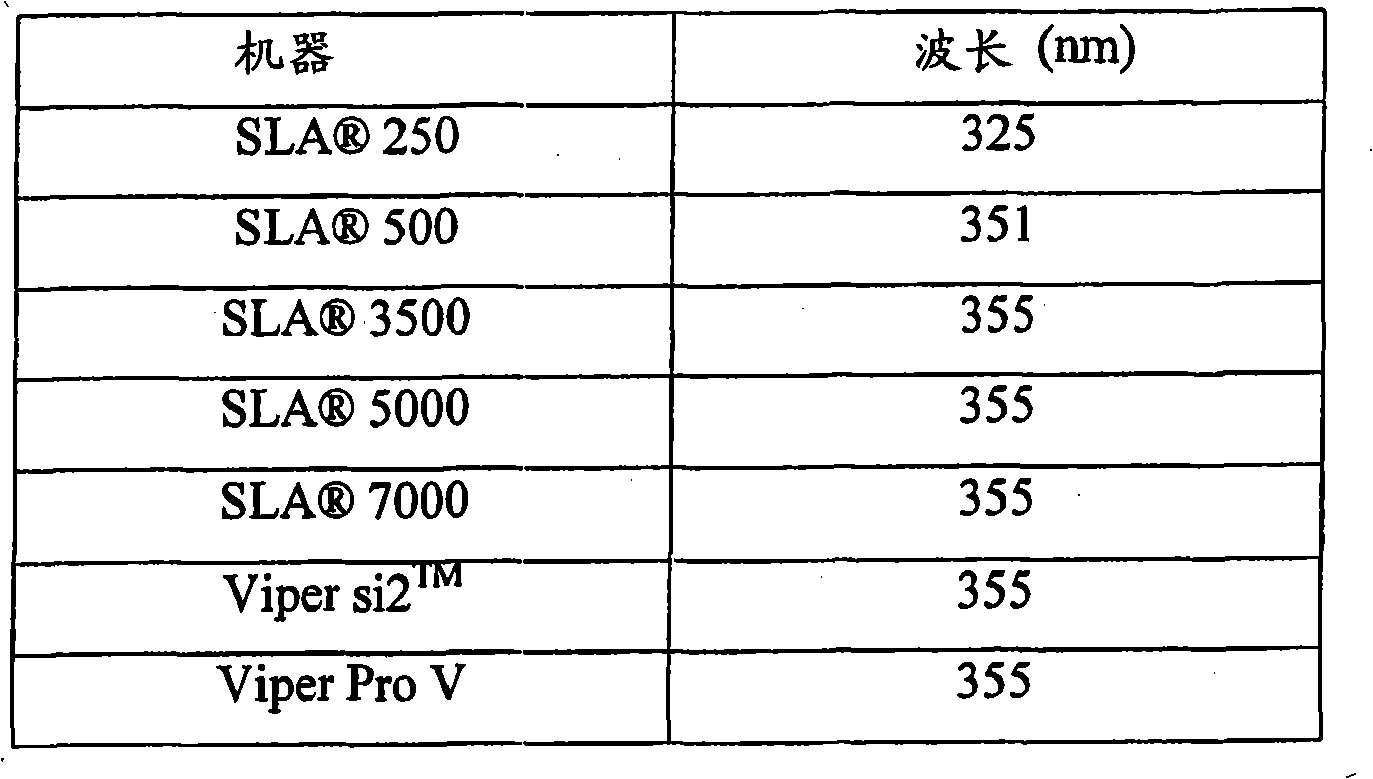

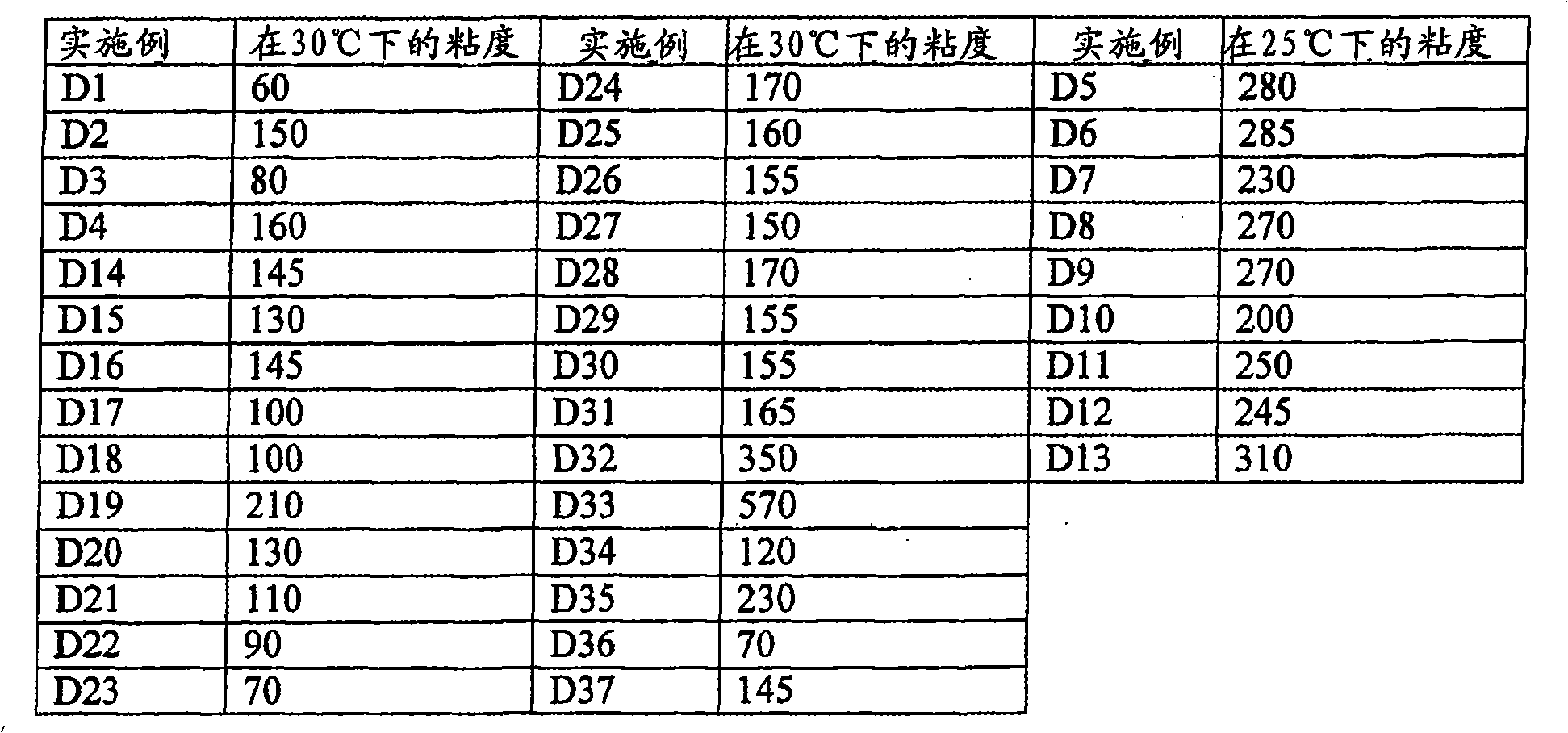

ActiveUS20100015408A1Fast curingLiquid surface applicatorsOrganic chemistryInvestment castingActive component

The present invention provides a low viscosity photocurable composition including (i) a cationically curable component (ii) a free radically active component (iii) an antimony-free cationic photoinitiator (v) a free radical photoinitiator, and (vi) a toughening agent. The photocurable composition can be cured using rapid prototyping techniques to form three-dimensional articles which can be used in various aerospace and investment casting applications.

Owner:3D SYST INC

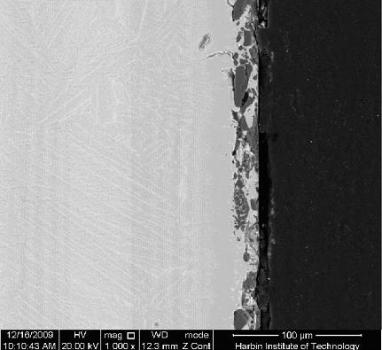

Grinder hammerhead with ceramic wearing coat and casting method thereof

InactiveCN101314145ANot easy to wearAvoid breakingFoundry moulding apparatusGrain treatmentsSurface layerHardness

The invention discloses a crusher hammer with a ceramic abrasion-resistant layer and a casting method thereof. The hammer adopts high boron cast steel as a parent body and a ceramic particle composite layer as a surface layer of the hammer, and is produced through a shape casting method that evaporated pattern casting is combined with casting by a cast-penetration process, and high temperature molten steel is taken as a parent body and is penetrated into the ceramic particle composite layer to form metallurgical bonding. The produced hammer has good strength and toughness as well as high hardness and wearing resistance.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Precisive ornament casting moulding material

ActiveCN101074320AHigh hardnessLow shrinkageFoundry moulding apparatusMINERAL WAXMicrocrystalline wax

A precision-casting mold material for ornament consists of hydrogenated microcrystalline wax, paraffin, petroleum resin, high-molecular polymer, mineral wax and animal and vegetable wax. It has better bending strength, surface hardness, thermal stability, fluidity, reutilization and less linear shrinkage rate. It can be used for gold and silver ornaments.

Owner:CHINA PETROLEUM & CHEM CORP +1

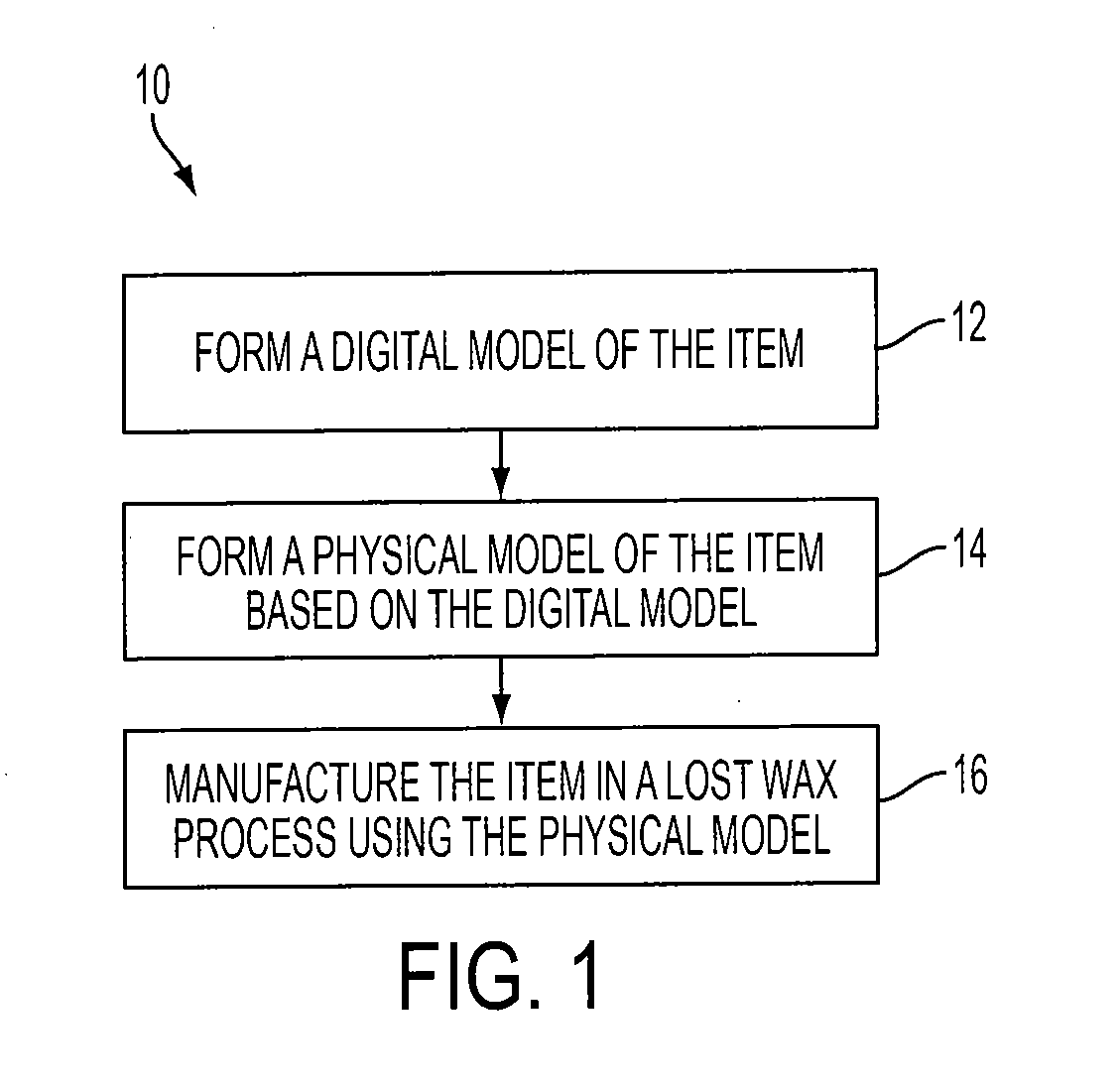

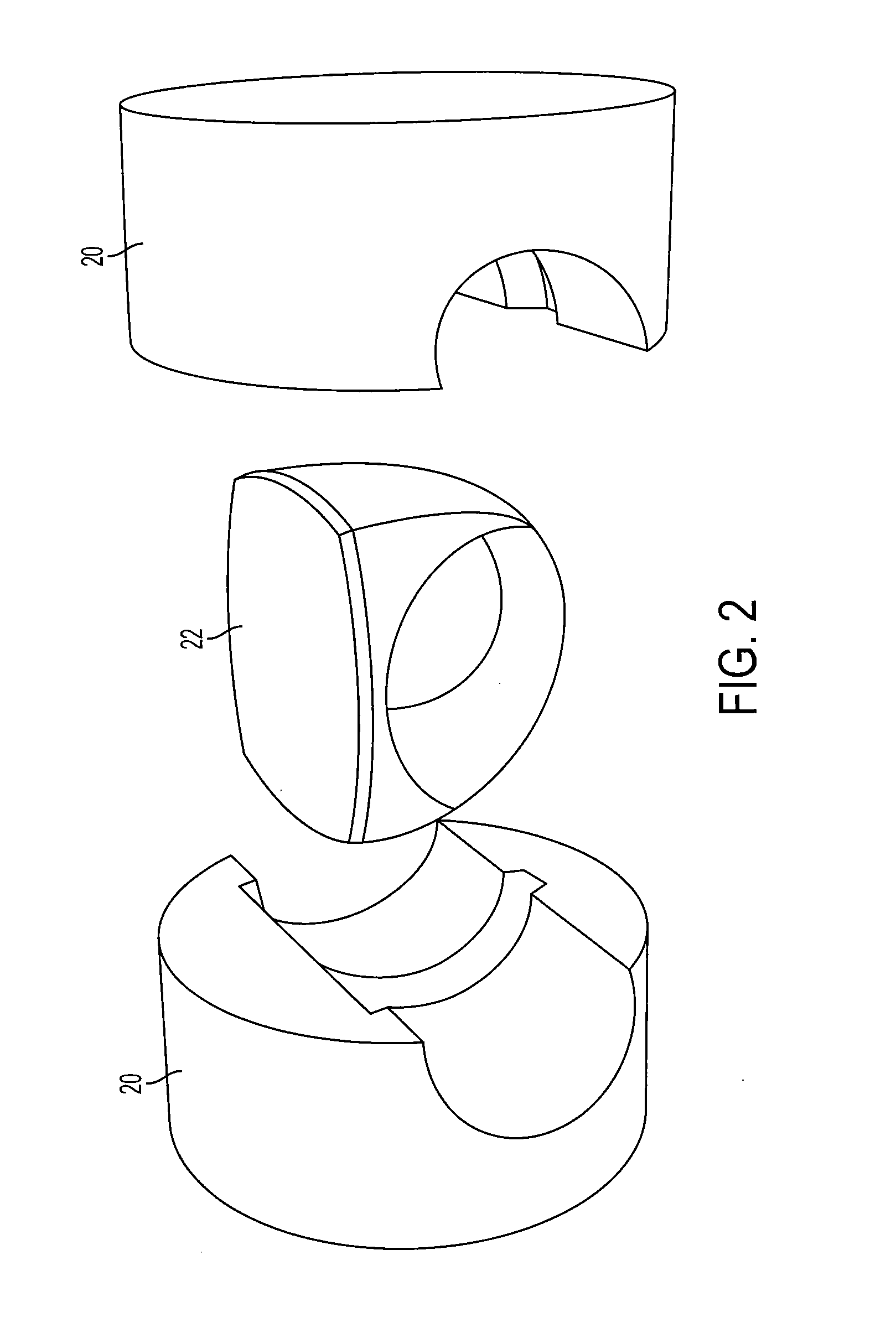

Method for digital manufacturing of jewelry items

In various embodiments, digital manufacturing of jewelry items is provided, including a physical process and software automation for implementing the physical process. Further, models formed during the process, as well as the resultant jewelry items, are provided. In some embodiments, the method comprises forming a digital model of the jewelry item, forming a physical model of the jewelry item based on the digital model, and manufacturing the jewelry item in a lost wax process using the physical model.

Owner:JOSTENS INC

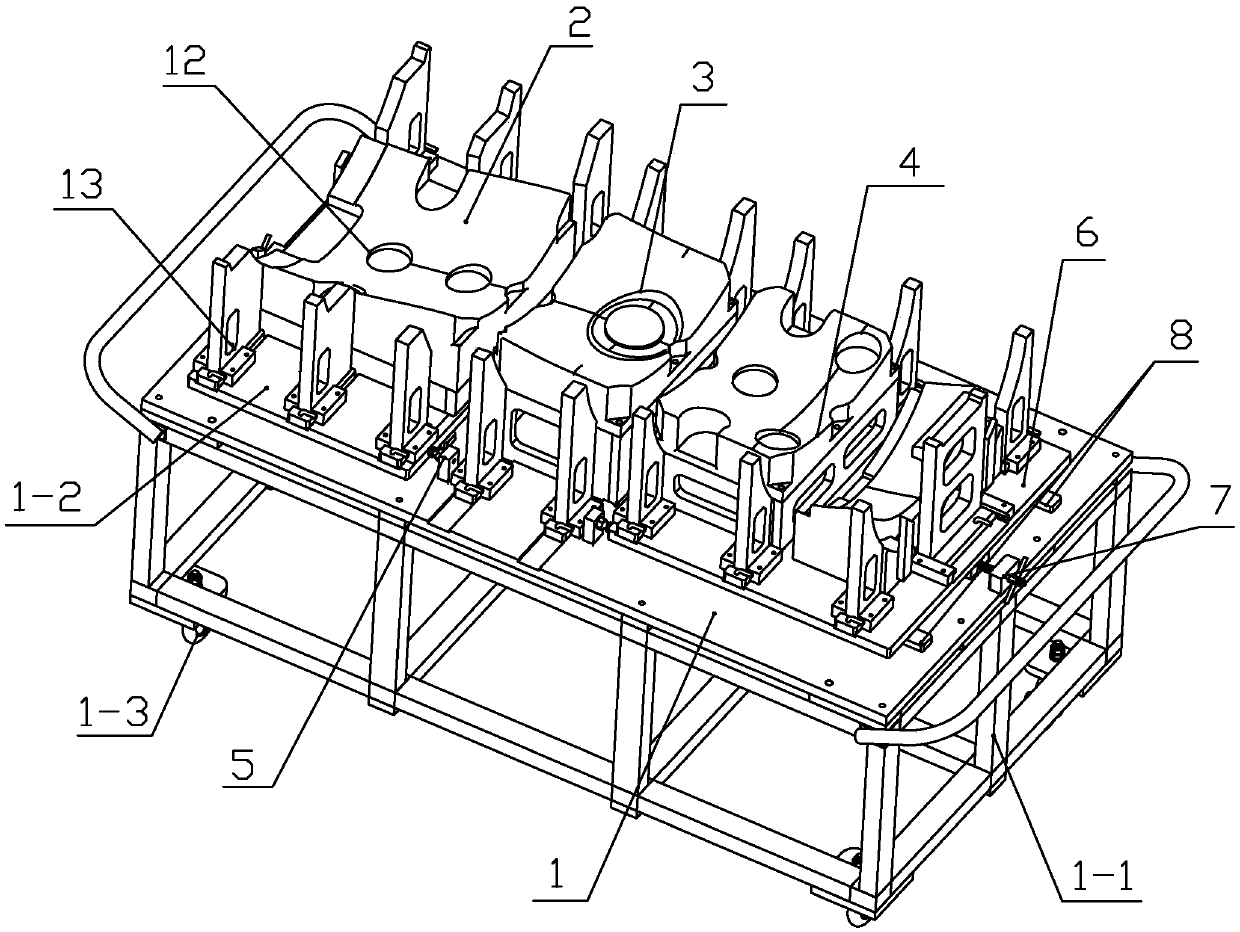

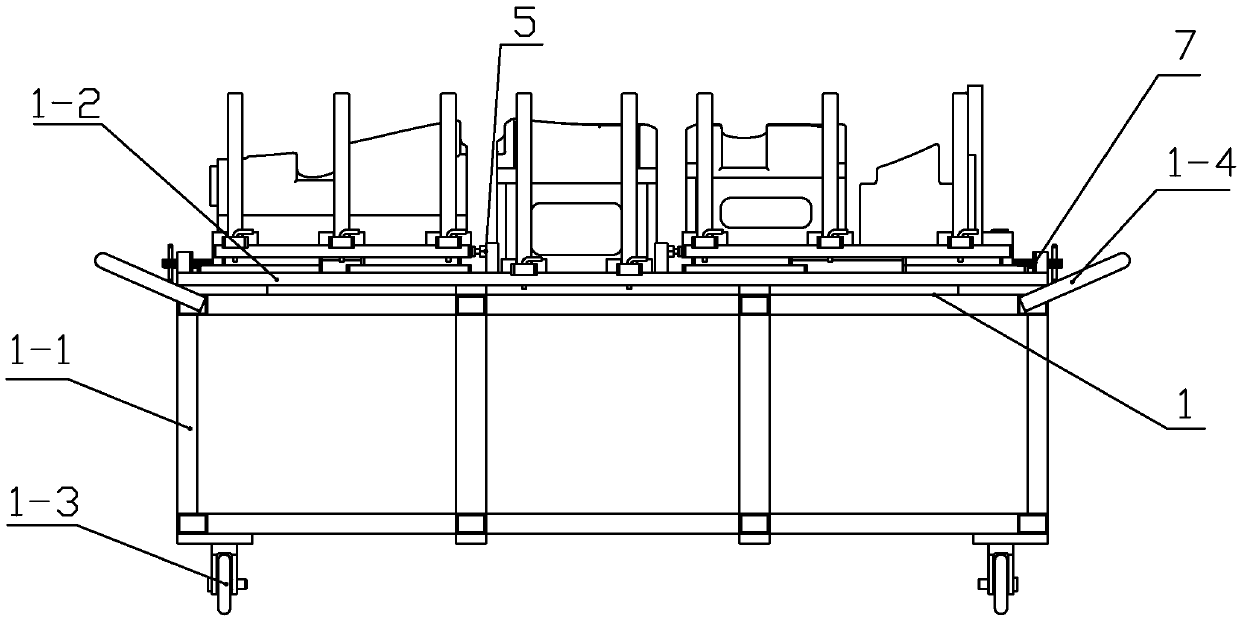

Manufacturing method and fixture of integral bladed-disk wax mold

ActiveCN102363199AImprove consistencyHigh dimensional accuracyFoundry moulding apparatusWaxPrimary standard

The invention discloses a manufacturing method and a fixture of an integral bladed-disk wax mold. According to the invention, an integral bladed-disk wax pattern is divided into single blades and a disk shaft. Processes of separated pressing, precise fixture positioning and wax mold welding assembling are adopted. The integral wax pattern is precisely cast. According to the invention, the disk shaft is fixed on an assembling fixture; the blades are sequentially positioned on positioning points on the fixture, and are welded onto the disk shaft. Blade bodies and channel inner walls with high precisions are adopted in the positioning of the blades, such that good consistency is provided for the blades. When the wax pattern is assembled, positioning points are positioned on the blade bodies;blade body positioning points are consistent with processing positioning points, primary standards of cold and hot processing are consistent, such that blade dimensional precision of the whole cast is optimally improved, throat areas between blades are ensured, and flow rate homogeneity is ensured. Positioning parts of the fixture can be adjusted according to measured dimensions of parts, such that the volume of flow rate can be changed according to directional positions of angles of the blades. Therefore, repairing or even rejecting risks caused by unqualified integral mold dimensions are avoided, production period is saved, and production cost is reduced. With the method provided by the invention, hard processes are turned easy, product precision is improved, and production efficiency is improved.

Owner:AECC AVIATION POWER CO LTD

Rigid foamed polyurethane-forming compositions, foamed polyurethane moldings and models made of the same

A rigid foamed polyurethane molding which reduce dust-scattering in cutting and is useful to a modeling stock. Said molding is produced by curing a composition by a mechanical frothing method, said composition comprising: a polyol with a filler (c); and a slight amount of dehydrating agent (d);wherein said composition further contains 3 to 30 percent, based on the total weight of the composition, of a (poly) oxyalkylene compound (e) expressed by the general formulain which "A" represents an alkylene group with two to four carbon atoms; "X" is a hydrocarbyl group or an acyl group; "m" is a value of one to one hundred; "n" is an integer of one to six; and "Z" is a residue produced by removing the active hydrogen atoms from a compound containing n active hydrogen atoms, in which at least one of Z and n X's has 5 to 20 carbon atoms.

Owner:SANYO CHEM IND LTD

Grinding material for precision casting

The invention relates to a precise casting mold material, which comprises: petroleum wax, petroleum resin, high polymer, mineral wax and animal-plant wax. This product has high bending strength, superficial hardness, small linear shrinkage and ash, and well other properties, overcomes opposite in prior art, and fits to manufacture large-scale thin-wall integral fine-casting structure part.

Owner:CHINA PETROLEUM & CHEM CORP +1

Packing mold material used in investment precision casting

InactiveCN102876054ALow linear shrinkageHigh strengthFoundry moulding apparatusWaxInvestment casting

The invention relates to a packing mold material used in investment precision casting, which comprises starch serving as a packing material, and further comprises petroleum wax, organic superpolymer, rosin and 5 to 20 percent by mass of tapioca. As tapioca is added in the packing mold material, the shrinkage ratio and the expansion ratio of the packing mold material can be controlled effectively, which is very important for controlling casting dimensional precision in investment precision casting. The tapioca is wide in source, and lower in cost than other packing mold materials, and does not react with an investment casting shell. The packing mold material has the advantages that the linear shrinkage ratio and the ash content are low and the strength, the smearing property and the flowability are better, thereby being suitable for manufacturing model wax of large thin-walled investment precision casting and ornamental article casting with higher surface quality requirements.

Owner:GUANGXI UNIV

Wax mold manufacturing method of melting mold precision-casting bridge shell

InactiveCN104439053ASolve underpaymentSolve the cold trapFoundry moulding apparatusCell separationMaterials science

The invention discloses a wax mold manufacturing method of a melting mold precision-casting bridge shell. The wax mold manufacturing method comprises the following process steps: preparing a wax material, manufacturing a wax mold, finishing the wax mold and checking. According to the wax mold manufacturing method of the melting mold precision-casting bridge shell, the process defects of under-injection, cold separation, bubbling and the like in the wax mold manufacturing method of the melting mold precision-casting bridge shell can be overcome; and the product quality of a casting can be improved, the production efficiency is improved and the production cost is reduced.

Owner:LIUZHOU JINTE NEW WEAR RESISTANT MATERIAL CO LTD

Antimony-free photocurable resin composition and three dimensional article

ActiveCN101300527AAdditive manufacturing apparatusFoundry moulding apparatusPolyesterActive component

The present invention provides a low viscosity photocurable composition including (i) a cationically curable component (ii) a free radically active component (iii) an antimony- free cat ionic photoinitiator and (v) a free radical photoinitiator. The photocurable composition can be cured using rapid prototyping techniques to form three-dimensional articles which can be used in various aerospace and investment casting applications.

Owner:HUNTSMAN ADVANCED MATERIALS (SWITZERLAND) GMBH

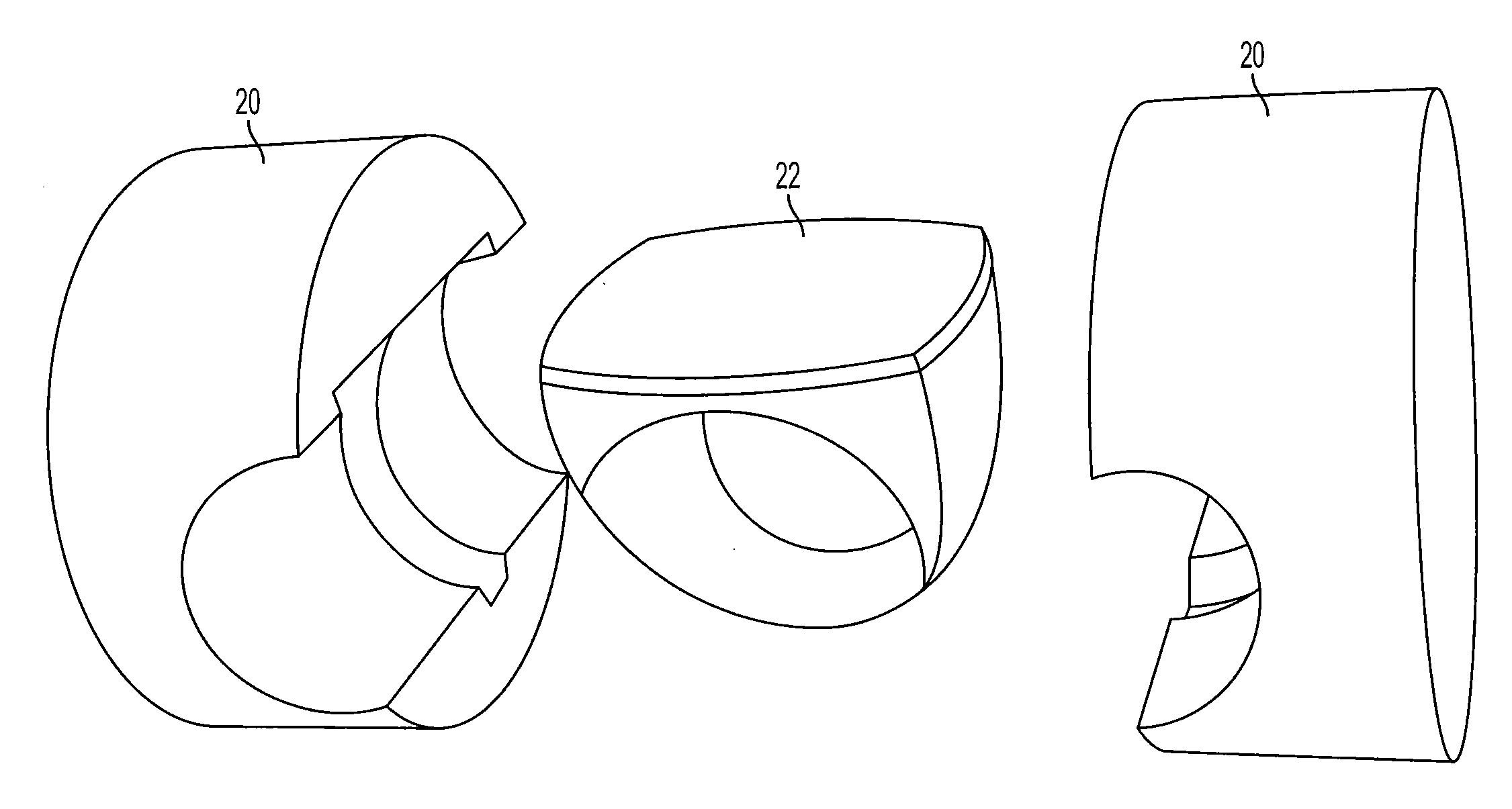

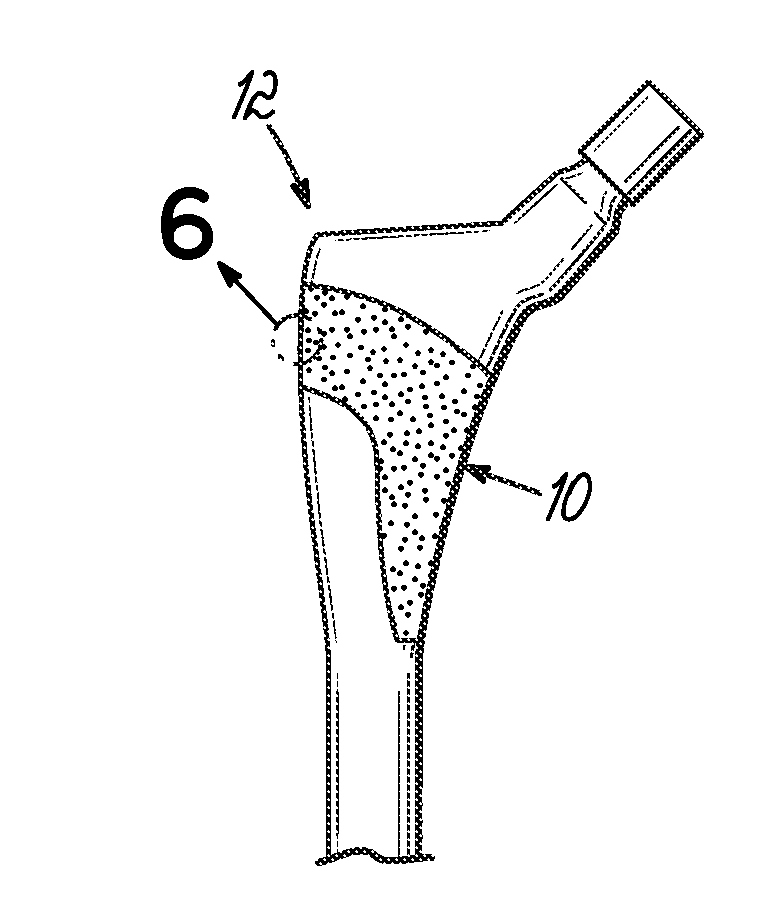

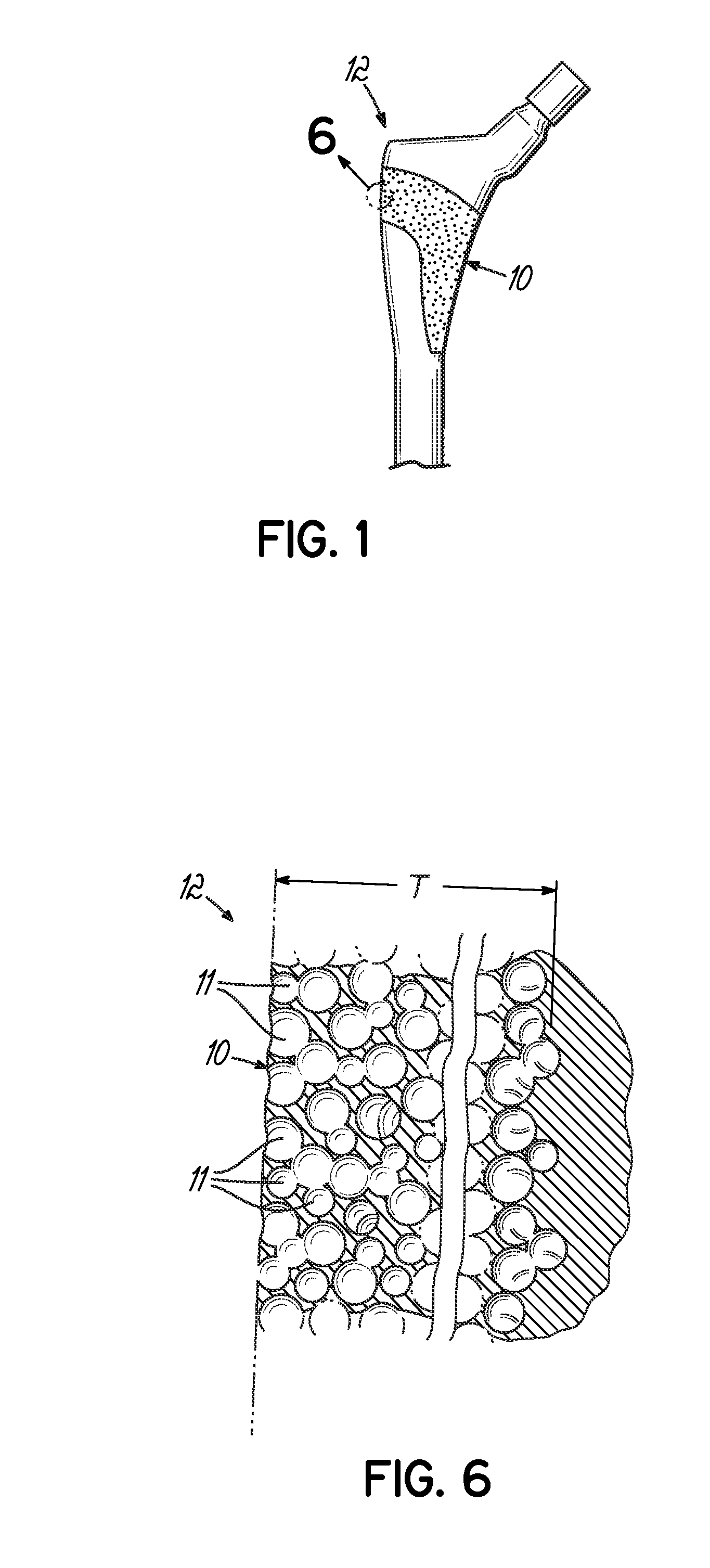

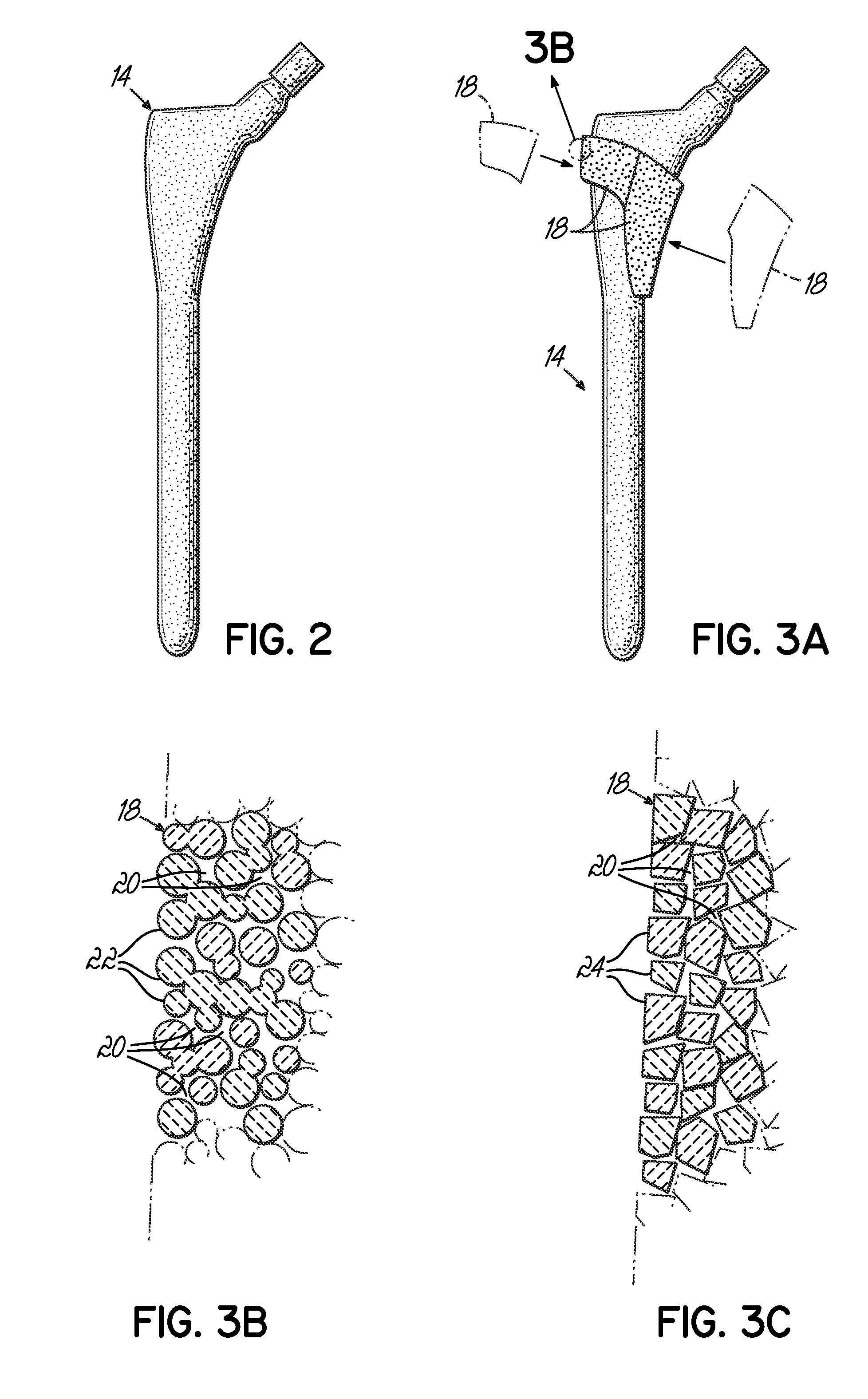

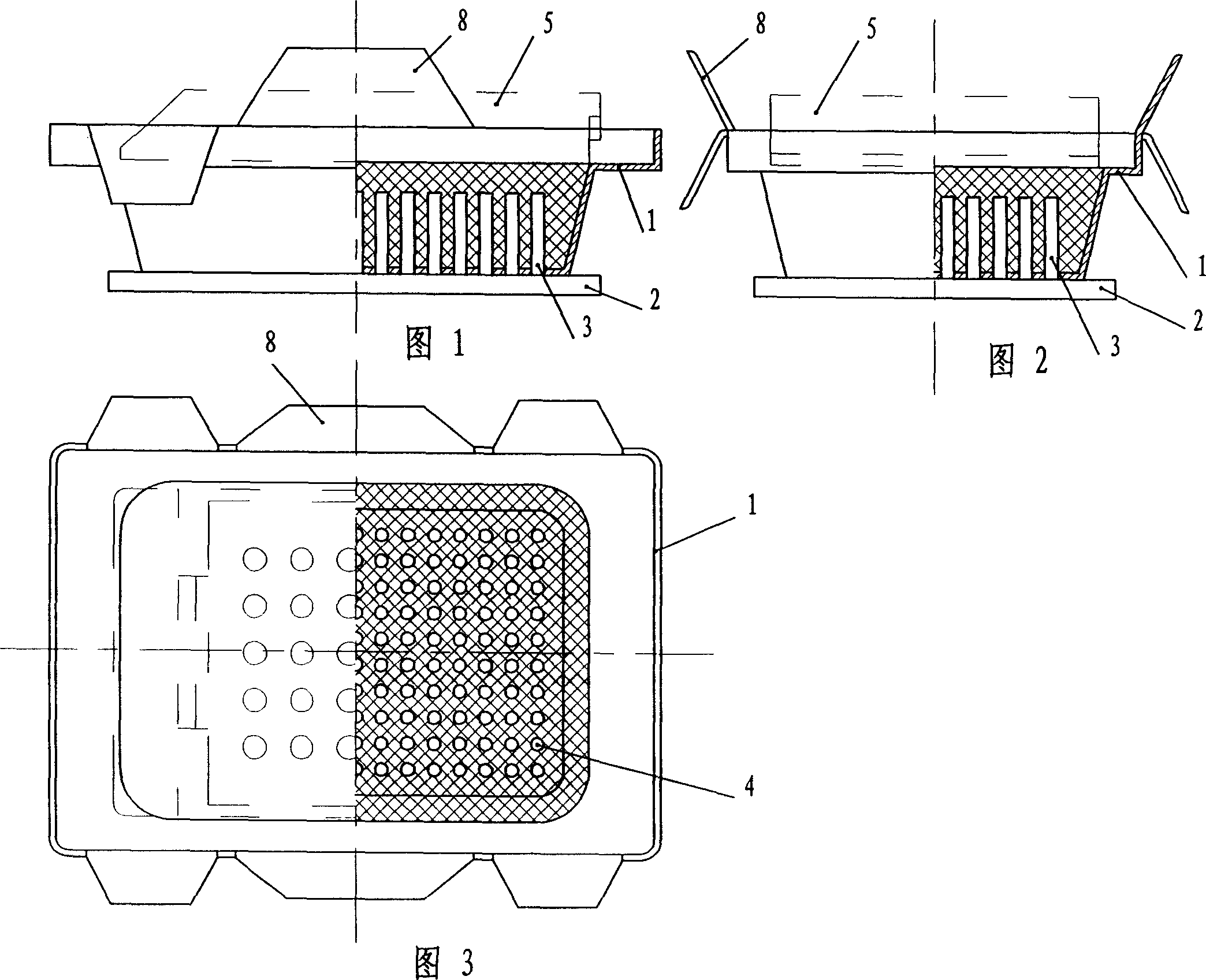

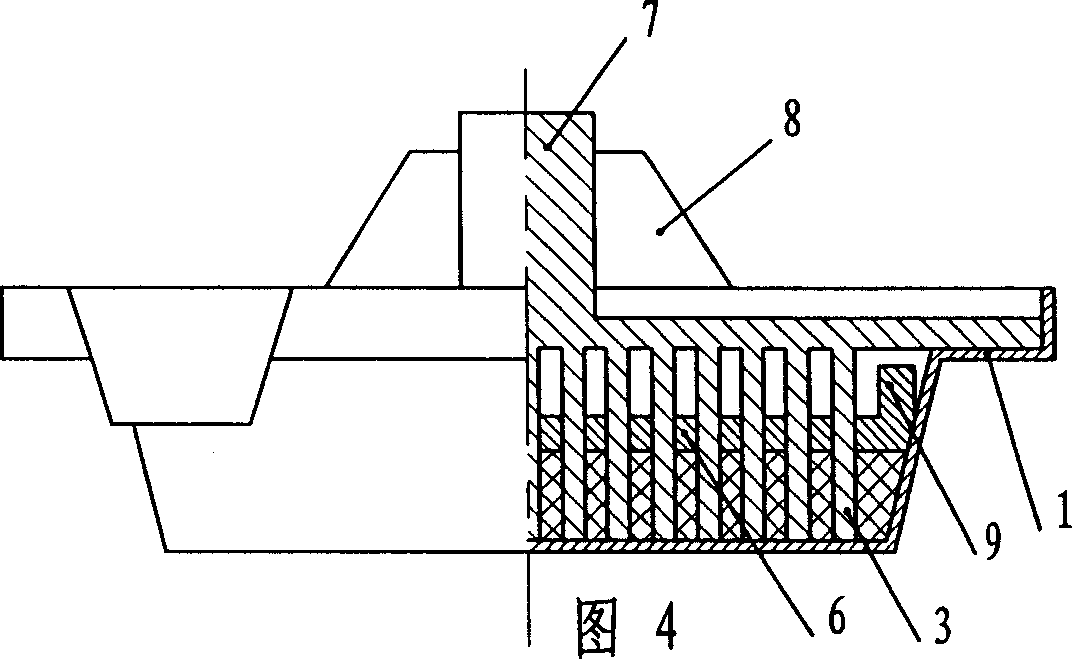

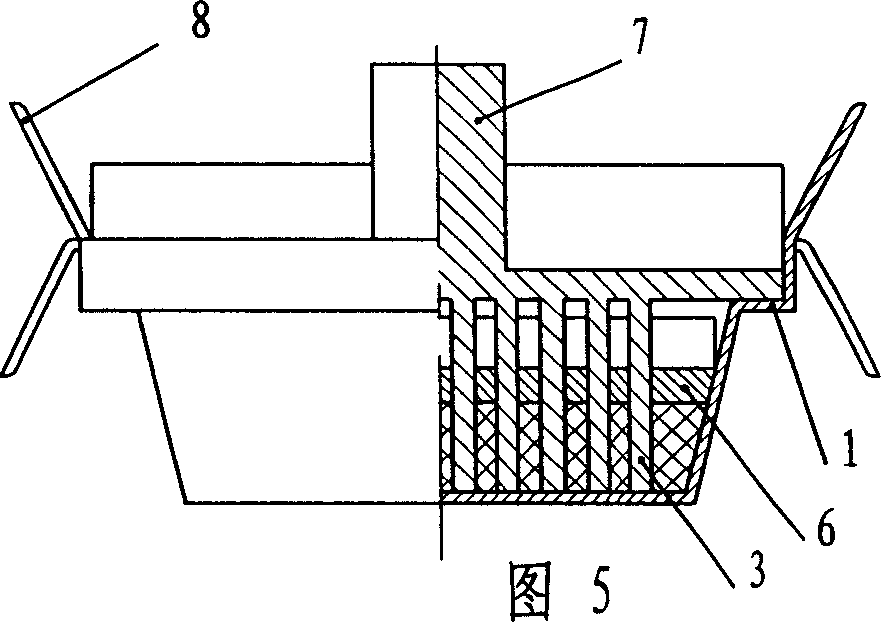

Method for forming an integral porous region in a cast implant

InactiveUS20090187256A1Promote growthBone implantFoundry moulding apparatusSurgical implantPlastic surgery

Methods for forming an integral porous region in an orthopedic implant are provided. The method uses an orthopedic implant pattern, together with a porous framework having a plurality of reticulated interstices in a molding technique. After filling the mold with a molten metal such that the molten metal enters at least a portion of the reticulated interstices, followed by cooling, an orthopedic implant is formed. The porous framework is then removed to expose an integral porous region of reticulated porosity in the implant. The orthopedic implant may comprise a monolithic metallic body having an integral porous metal region. Reticulated porosity extends into the monolithic metallic body and is adapted to allow living tissue growth therein.

Owner:ZIMMER INC

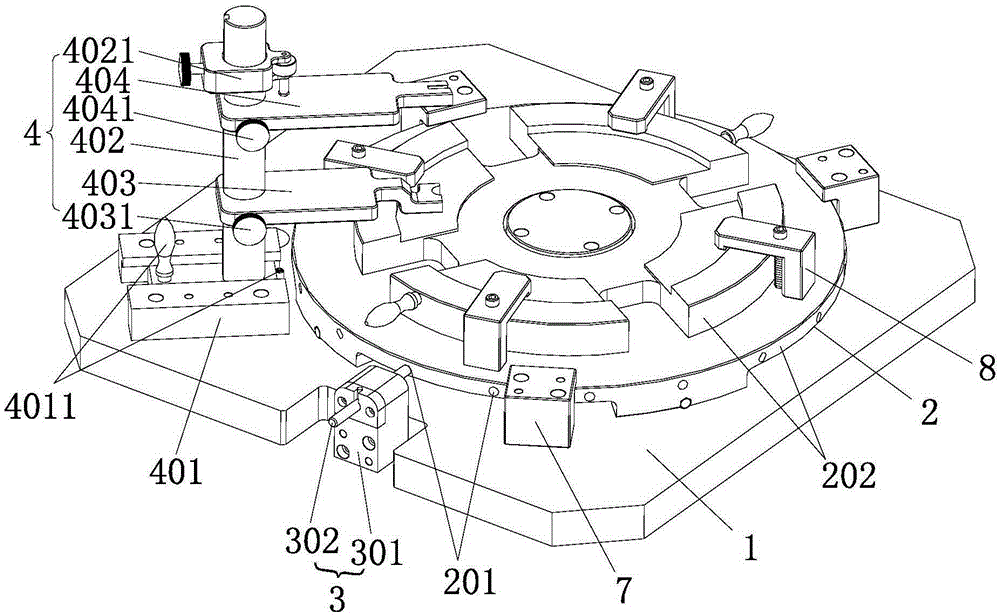

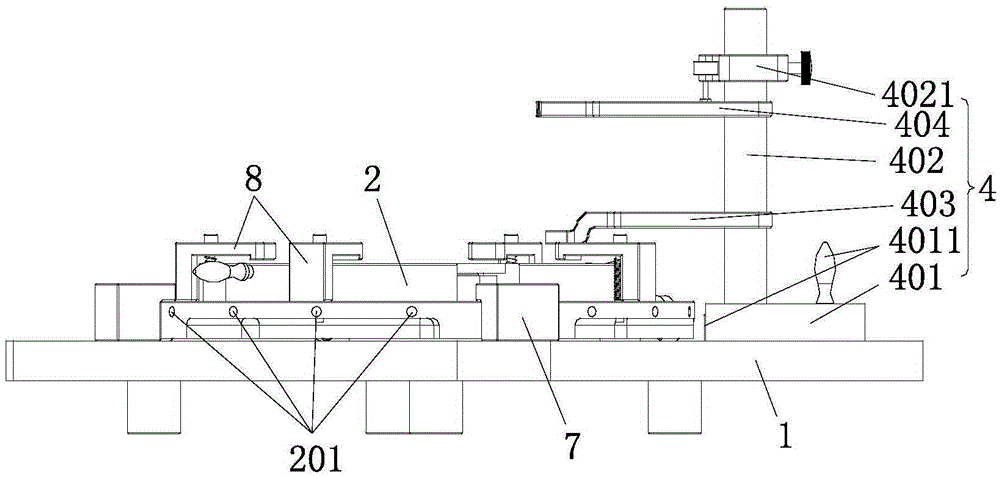

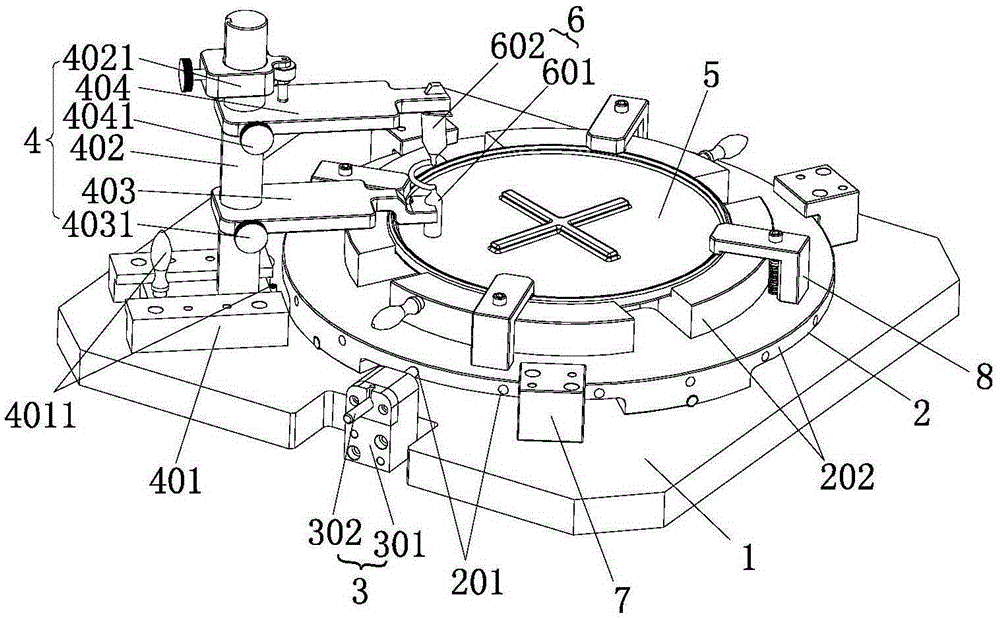

Single-crystal blade wax pattern combination assembly clamp and single-crystal blade wax pattern combination assembly method

The invention discloses a single-crystal blade wax pattern combination assembly clamp and a single-crystal blade wax pattern combination assembly method. The single-crystal blade wax pattern combination assembly clamp comprises a base, wherein a rotary chassis, a rotary locking mechanism and a wax pattern fixing mechanism are arranged on the base, the rotary chassis is rotationally connected to the base and used for bearing a wax pattern bottom plate and wax pattern assembly units on the wax pattern bottom plate, the rotary locking mechanism is used for locking the rotation position of the rotary chassis, and the wax pattern fixing mechanism is arranged outside the rotary chassis and used for clamping and fixing the wax pattern assembly units; and the wax pattern bottom plate and the wax pattern assembly units rotate with the rotary chassis along the peripheral direction of the rotary chassis. Each wax pattern assembly unit on the wax pattern bottom plate can be in one-to-one correspondence with a wax pattern assembly unit position, and the wax pattern assembly units are mutually fixedly connected, thus assembly for the whole single-crystal blade wax pattern combination is completed. The single-crystal blade wax pattern combination assembly clamp and the single-crystal blade wax pattern combination assembly method are applicable to investment casting for single-crystal directional blades of various aero-engines and industrial gas turbines.

Owner:株洲中航动力精密铸造有限公司

Resin casting mould rapid manufacturing method

InactiveCN101992264ASimple designEasy to modifyFoundry moulding apparatusComputer Aided DesignRoom temperature

The invention belongs to the technical field of material processing engineering, and in particular relates to a resin casting mould rapid manufacturing method. The resin casting mould rapid manufacturing method is characterized by comprising the following steps of: (1) drawing a three-dimensional CAD (Computer-Aided Design) model of a mould according to a casting process drawing of a casting, and preparing a resin prototype for manufacturing a resin casting mould by a rapid prototyping device; (2) rapidly obtaining a die cavity for manufacturing the resin casting mould through a rolling over of a room temperature vulcanized silicone rubber mould by utilizing the prepared resin prototype; (3) manufacturing the resin mould through a manual paste mode by utilizing the die cavity for manufacturing the resin casting mould; and (4) assembling the resin mould prepared by manual paste on a mouldboard to complete the manufacturing process of the mould. Compared with the prior art, the invention has the advantages of facilitating design and modification to the appearance of the casting, being capable of rapidly obtaining the die cavity for manufacturing the resin casting mould, manufacturing the mould with a few tenths of millimeter of dimensional accuracy and shortening the manufacturing cycle of the mould.

Owner:SHANDONG UNIV OF TECH

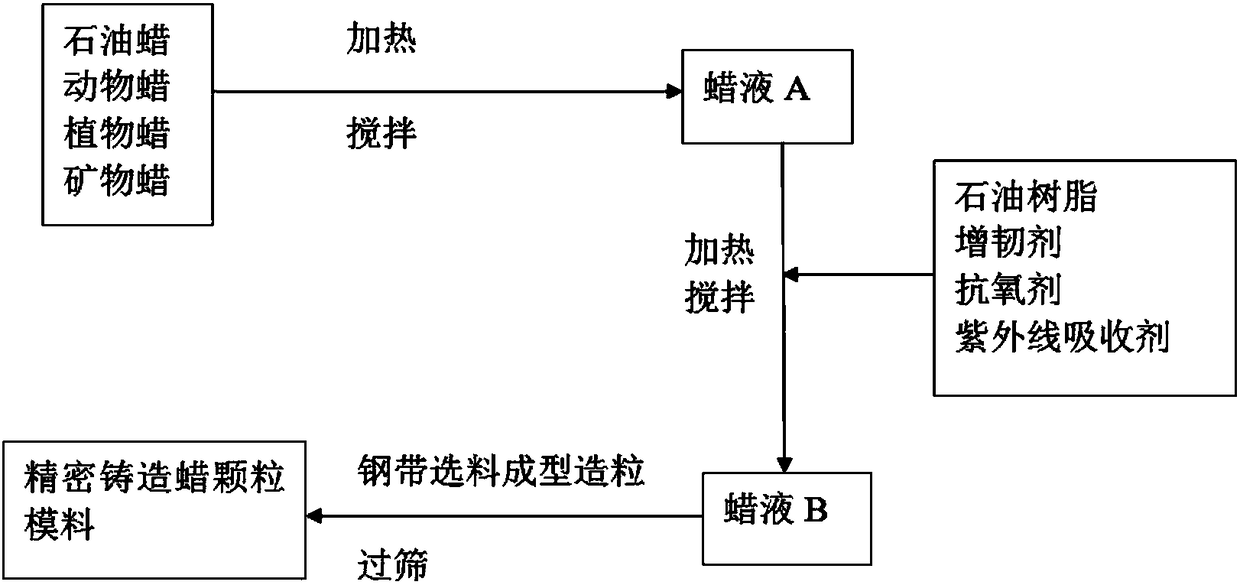

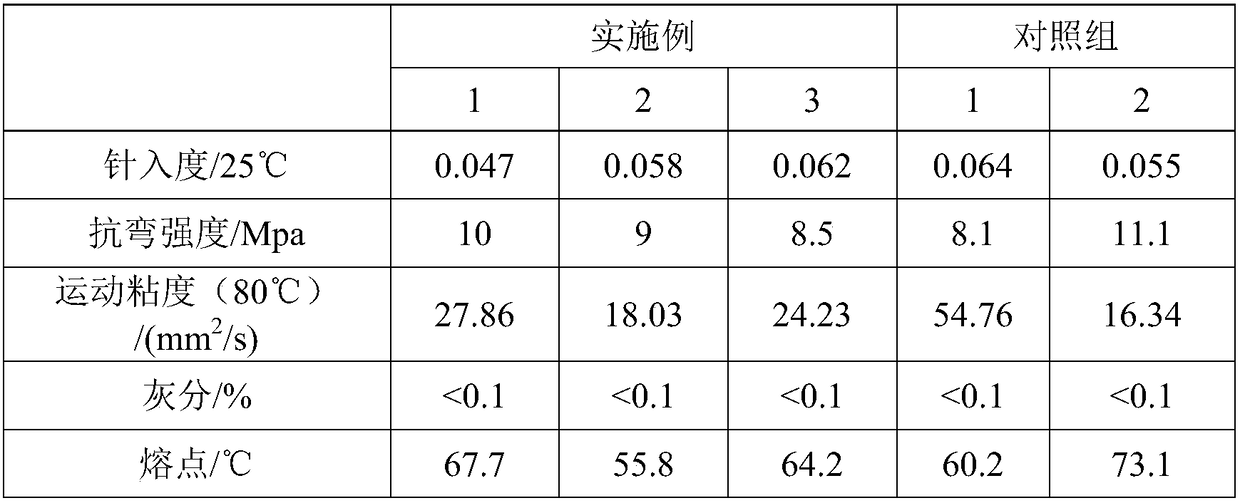

Precision casting wax granular molding material and preparation method and application of precision casting wax granular molding material

The invention belongs to the technical field of precision casting and discloses a precision casting wax granular molding material and a preparation method and application of the precision casting waxgranular molding material. The precision casting wax granular molding material comprises components including, by mass percent, 50%-70% of petroleum wax, 0%-10% of animal wax, 10%-15% of mineral wax,0%-15% of vegetable wax, 0%-15% of petroleum resin, 0%-10% of flexibilizer, 0.0%-0.5% of an ultraviolet light absorbent and 0.0%-1% of an antioxygen. The raw material of petroleum wax is stable and easy to obtain, the petroleum wax serves as a raw material, the cost of the printing wax powder material is greatly reduced, meanwhile, the animal wax, the mineral wax, the vegetable wax, the petroleumresin, the flexibilizer and the like are added to improve the tenacity, the strength and the hardness, the molding material is low in viscosity and melting point and good in flowability, and the granular material is convenient to transport and process. By means of a formula without rosin, it is guaranteed that the casting wax can be repeatedly used several times and is good in environment affinity, meanwhile, the process is simple, the working efficiency is improved, the cost is reduced, and wide market prospects and market competitiveness are achieved.

Owner:广州市德隆化工贸易有限公司

Method of preparing water-soluble mold core

InactiveCN101229574ANo pollution in the processGood water solubilityFoundry moulding apparatusSolubilityResin matrix

The invention pertains to a casting moulding technical field, which relates to improvement of a technical mold core for casting and molding resin matrix composites. The steps in the invention are the following: preparing aqueous solution of a bonder-adding aggregate-adding plaster powder-defoaming-casting moulding- drying- post-processing. Solidification has advantages of room temperature curing and good temperature endurance, good water solubility at room temperature and no environmental pollution.

Owner:BEIJING AVIATION MATERIAL INST NO 1 GRP CORP CHINA AVIATION IND

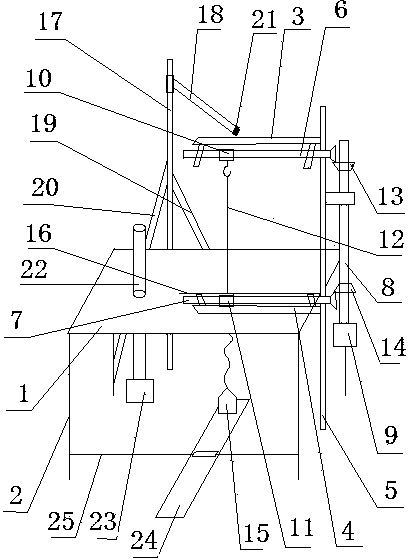

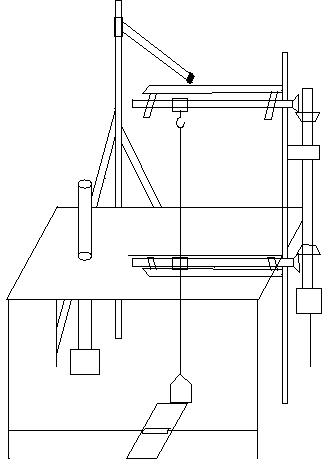

Material cutting machine

InactiveCN103350433AHigh precisionImprove cast iron qualityFoundry moulding apparatusMetal working apparatusRotational axisDrive shaft

The invention provides a material cutting machine. The material cutting machine comprises an operation table assembly, a support assembly, a supporting assembly, a rotating assembly and a cutting assembly, and further comprises a rectangular pedal, wherein a table leg transverse rod is arranged between two front operation table legs, the pedal is installed on the table leg transverse rod and can rotate with the table leg transverse rod as the axis, the front end of the pedal is located below a lead weight, and when the front end of the pedal is located at the highest point, the lead weight is supported by the pedal, and a cutting line is in a loosing state. A rotating shaft is adopted to drive materials to rotate, and regular circles can be cut out; the supporting assembly enables a support not to move easily when the machining is conducted; an upper screw rod and a lower screw rod rotate at the same time through a transmission shaft to regulate the position of the upper end and the lower end of the cutting line at the same time, and working efficiency is improved. The lower end of the cutting line is connected with the lead weight to tension the cutting line, and the appearance of a die which is cut out is much smoother. The pedal is further arranged, so that the cutting line is convenient to take down from or hang on an upper slide block, and the material cutting machine is convenient and rapid to use.

Owner:兴化市天和机械配件厂

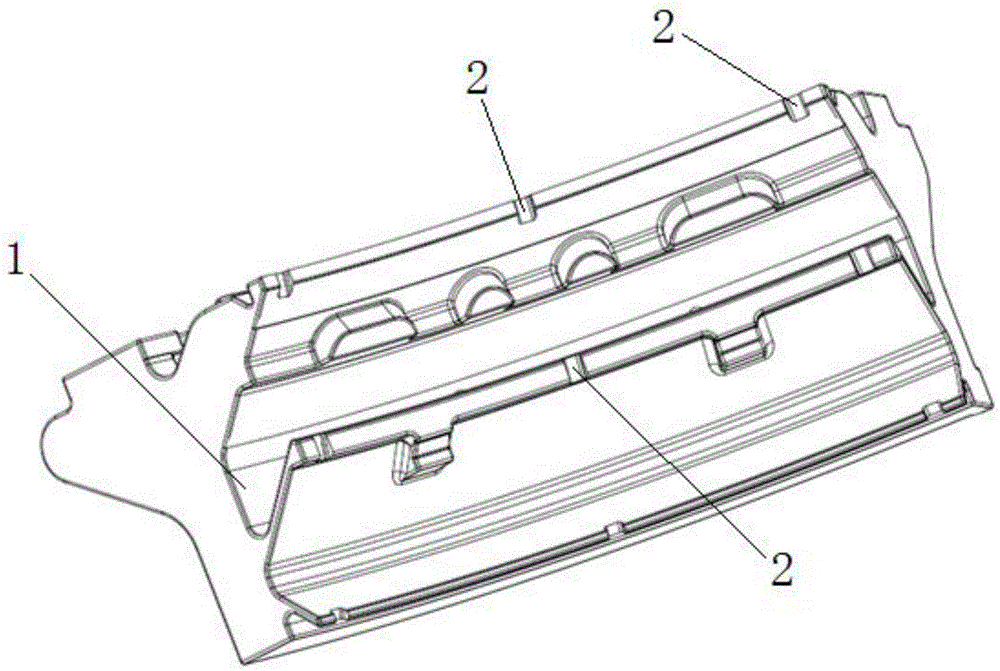

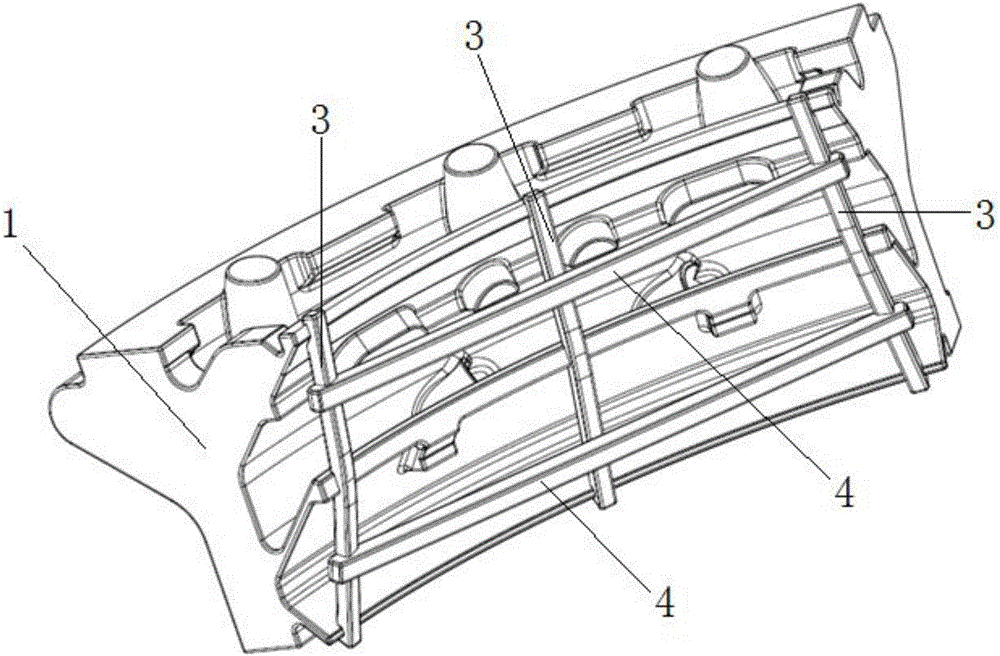

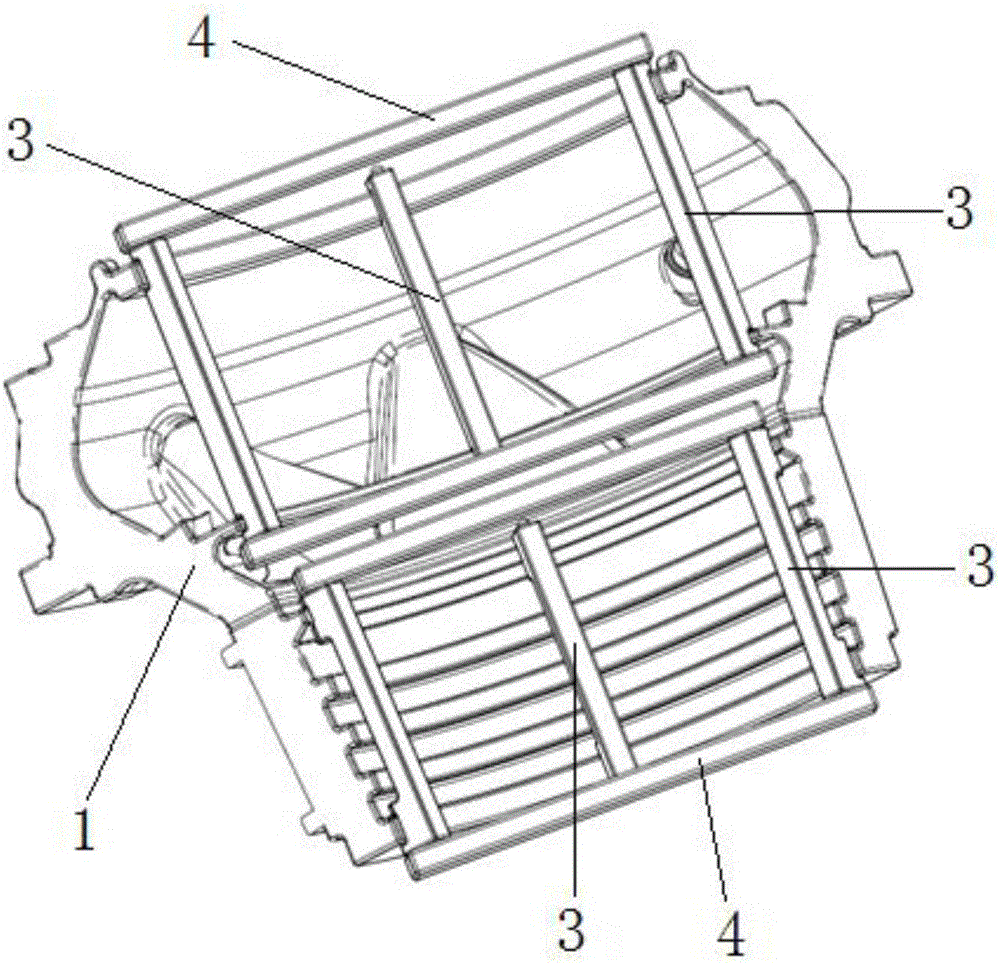

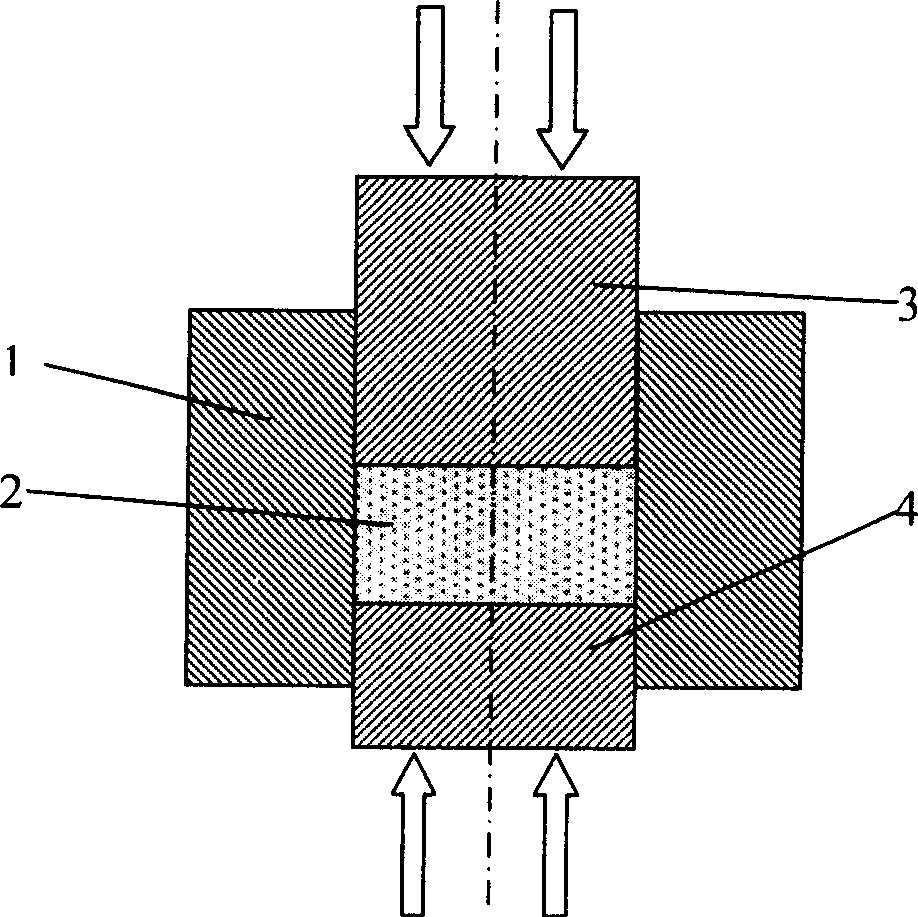

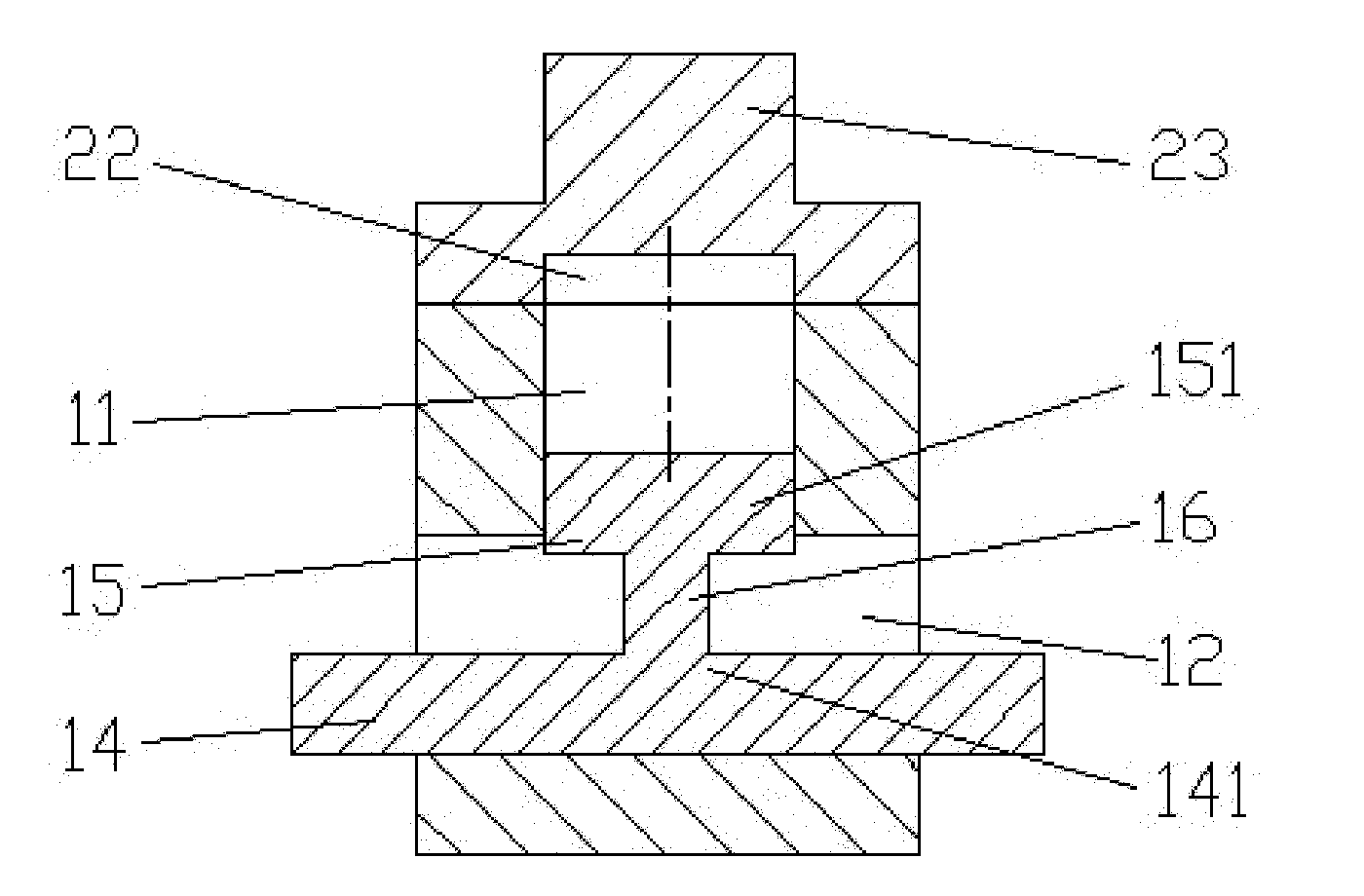

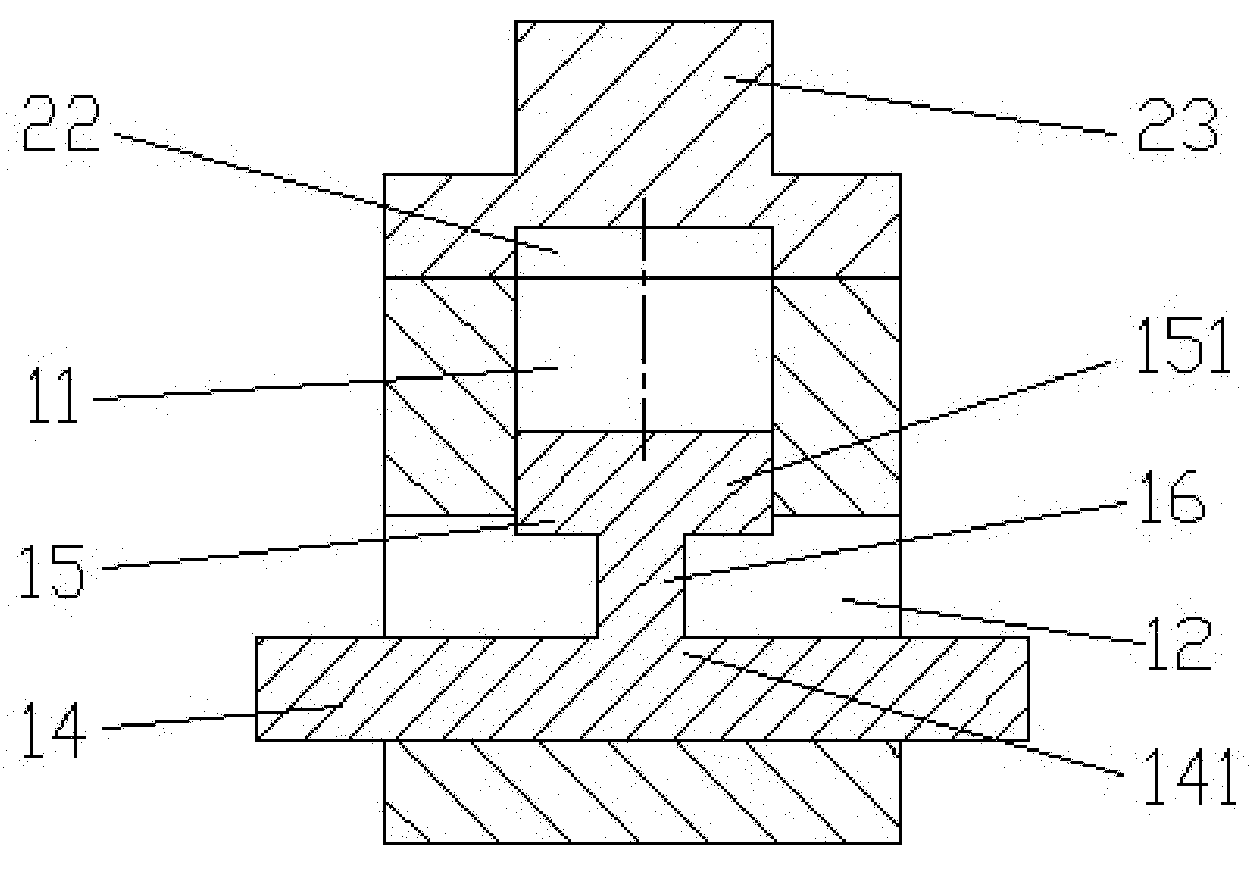

Wax pattern forming mould

ActiveCN106945205AReduce labor intensityImprove the efficiency of mold releaseFoundry moulding apparatusDomestic articlesWaxCam

The invention discloses a wax pattern forming mould comprising a locking upper seat; an inward-concave first mounting cavity is formed in the bottom end of the locking upper seat; a forming female mould is arranged below the locking upper seat; the forming female mould is partially inserted into the first mounting cavity through an opening end of the first mounting cavity; a forming cavity used for forming a wax pattern matrix of a wax pattern is formed in the forming female mould; and the top end of the forming cavity is opened. A rib plate forming member is mounted in the first mounting cavity. The rib plate forming member comprises a first cover plate used for sealing the opening end of the forming cavity; and a plurality of rib plate forming movable blocks inserted into the forming cavity to form a plurality of rib plates are arranged on the first cover plate. A deep groove forming member used for forming a plurality of deep grooves are arranged on the first cover plate. The deep groove forming member comprises a plurality of deep groove forming movable blocks penetrating through the first cover plate to stretch in the forming cavity to form the deep grooves. A cam pushing mechanism for pushing the wax pattern upward out of the forming cavity at the time of demoulding is connected to the lower portion of the forming female mould.

Owner:CHINA HANGFA SOUTH IND CO LTD

Method for preparing wax mold of monocrystal spiral crystal selector

The invention provides a method for preparing a wax mold of a monocrystal spiral crystal selector. The wax mold of the monocrystal spiral crystal selector comprises a seeding section wax mold, a spiral crystal selecting section wax mold and a transition section wax mold which are sequentially connected from bottom to top. The method comprises the following steps: firstly, manufacturing the seeding section wax mold and the transition section wax mold; winding on a screw corresponding to the size of the required spiral crystal selecting section by a plastic welding rod, sizing for a moment, immersing into 58# refined paraffin liquid at 68 DEG C, taking out after 4-7 seconds so as to obtain the spiral crystal selecting wax mold; connecting two ends of the spiral crystal selecting wax mold with the bottom of the transition section wax mold and the top of the seeding section wax mold respectively by utilizing bonding wax which is heated to be 130 DEG C. According to the invention, the crystal selector wax mold which meets the requirement can be prepared rapidly; compared with the traditional method using a wax injector and a wax mold, the method has the characteristics of no need of wax injector equipment, no need of machining the wax mold, low expense, simplicity in operation, short consumption time, high efficiency, high yield and the like.

Owner:DONGFANG TURBINE CO LTD

Precisely cast low-temperature modulated wax and preparation method thereof

InactiveCN104592765AReduced linear shrinkageReduce the probability of subsidenceFoundry moulding apparatusParaffin waxProduction rate

The invention discloses a precisely cast low-temperature modulated wax and a preparation method thereof. The precisely cast low-temperature modulated wax comprises the following raw materials in parts by weight: 44-46 parts of microcrystalline wax, 2.5-3.5 parts of lignite wax, 34-36 parts of rosin resin, 3.5-4.5 parts of an ethylene-vinyl acetate copolymer and 12-14 parts of pure monomer resin. The wax disclosed by the invention is applied to a precision casting industry, has stability, hardly deforms due to high strength and hardly pollutes the metal cast due to low gray scale, is easy to demold, can be melted together with a wax mold to flow out of a shell during demolding; and the production rate can be effectively improved in the precision casting process.

Owner:青岛新诺科铸造材料科技有限公司

Method for preparing surface molded shell cast by high-temperature titanium alloy melting mold

The invention discloses a method for preparing a surface molded shell cast by a high-temperature titanium alloy melting mold, and relates to a method for preparing a surface molded shell. The method solves the problems that the molded shell prepared by the conventional method has high cost during de-waxing and easily pollutes the environment. The method comprises the following steps: 1, preparing mixed adhesive; 2, preparing surface slurry; 3, coating and hanging, scattering sand and drying to obtain the surface molded shell. The molded shell prepared by the method can be used for steam de-waxing, has low de-waxing cost, and is environmentally-friendly and easy to operate.

Owner:HARBIN INST OF TECH

Method for preventing deformation of refined casting casing wax model

The invention discloses a method for preventing deformation of a refined casting casing wax model. The method comprises the steps that the shape of the wax model and the shape of a mould for the wax model are determined according to the structure of a casing, and positioning blocks are arranged on the mould; the mould is subjected to wax injection, the wax model is obtained, and reinforcing ribs are embedded between the positioning blocks of the wax model and connected for structural reinforcement; the wax model is taken out of the mould to be detected; then a gating system and risers are welded to the wax model; and finally, shell making, casting pouring and thermal treatment are conducted, and cleaning is conducted before the casing is obtained. According to the method for preventing deformation of the refined casting casing wax model, the deformation situation of the wax model is considered in the mould design stage, the reinforcing ribs are designed, the positioning blocks are reserved, the well prepared reinforcing ribs are assembled on the wax model which is then taken out of the mould, accordingly deformation of the wax model is controlled, the deformation quality problem of the wax model in the production process of the heavy duty gas turbine casing is finally solved, the operating process is simplified by adoption of the method, and risks caused by calibration for the wax model are lowered; and a calibration mould and tool do not need to be made independently, and the production cost is lowered.

Owner:CSIC NO 12 RES INST

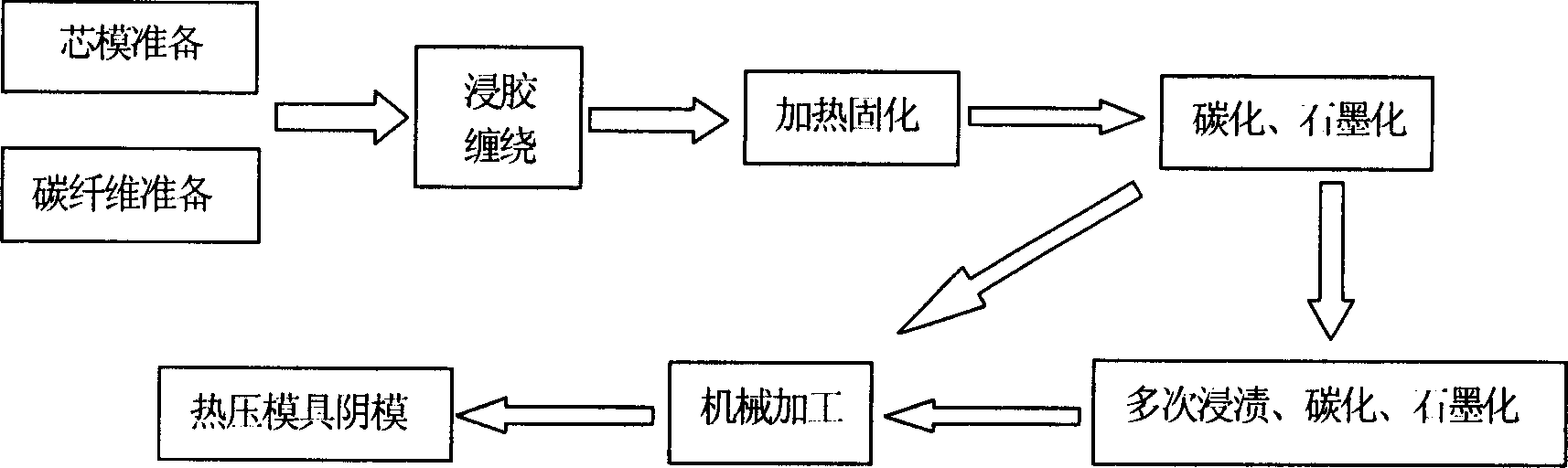

Bed die of large thermal-pressure mould and its production thereof

A female die of large hot pressing die set is prepared from the ordinary electrode graphite and carbon-carbon composition through dipping the high-strength carbon fiber yarn or unidirectional narrow carbon fiber cloth in thermosetting resin, winding them on the surface of an electrode graphite column, heating for solidifying, high-temp carburizing to obtain resin carbon, and removing part or all of said graphite column.

Owner:FUZHOU UNIV

Processing method of improved 6061 aluminum alloy refrigerator foaming die cast

InactiveCN103014448AHigh strengthImprove wear resistanceFoundry moulding apparatusRare-earth elementIcebox

The invention discloses a processing method of an improved 6061 aluminum alloy refrigerator foaming die cast. The processing method comprises the four steps of compounding, smelting, pouring, and carrying out thermal treatment. According to the invention, an appropriate amount of rare earth elements Nd, Ce and Sc are added to the improved 6061 aluminum alloy, so that the size of eutectic phase is significantly reduced, the as-cast structure of the alloy is uniformed and refined, and the strength as well as corrosion resistance and wear resistance of the alloy are improved. The processed aluminum alloy refrigerator foaming die cast has the advantages of good mechanical properties, high strength, good thermal resistance, good usability, good internal structure compactness, no pore and peeling defects, good wear resistance, good corrosion resistance and oxidation resistance, small expansion coefficient and the like.

Owner:滁州佳诚模具制造有限公司

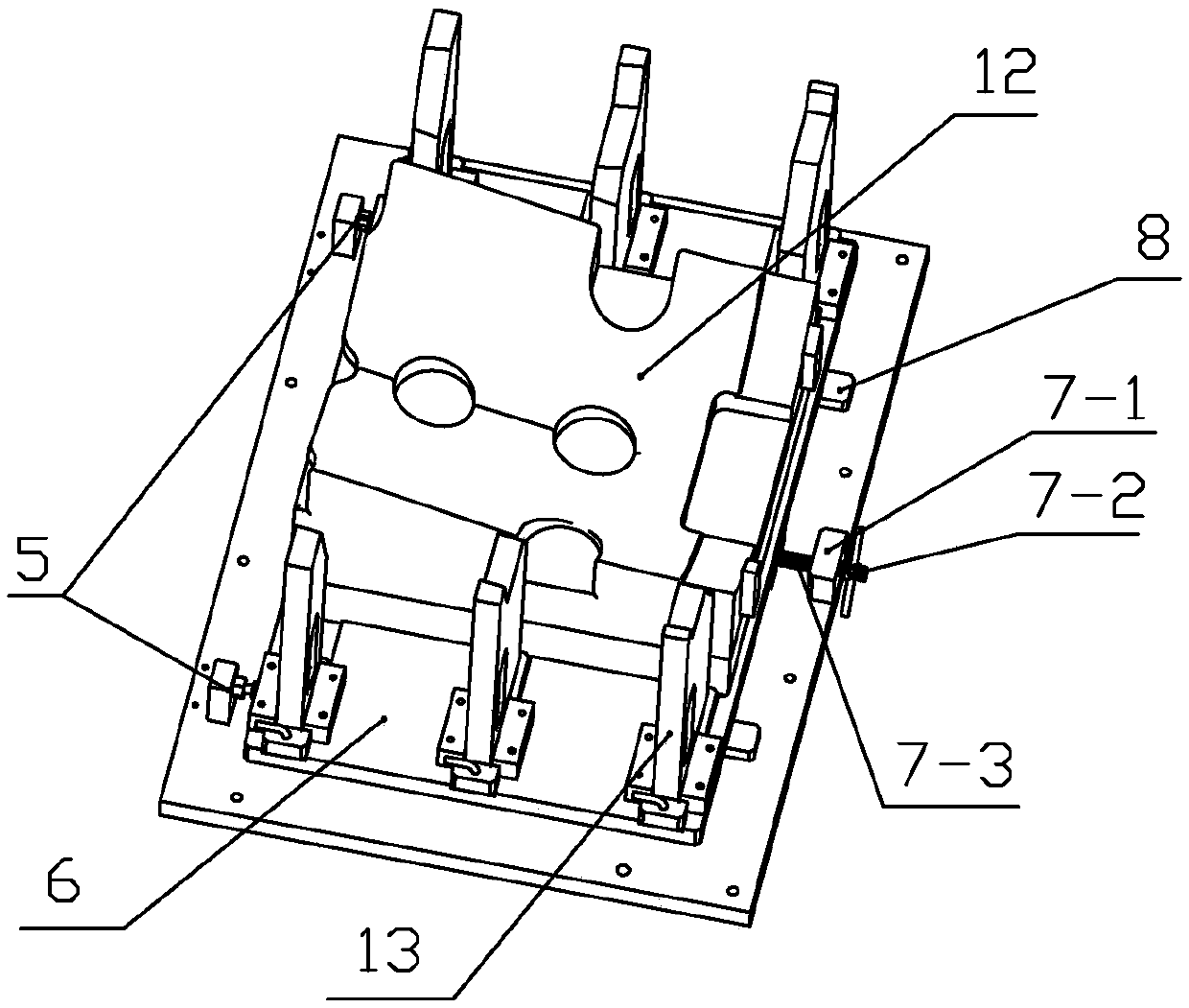

Wax pattern correcting tool

ActiveCN103273003AAvoid deformationHigh adjustment accuracyFoundry moulding apparatusWaxComputer science

The invention discloses a wax pattern correcting tool which comprises a bottom plate, wherein a first correcting device which is used for correcting a wax pattern crown and a second correcting device which is used for correcting wax pattern rabbet and body are at least fixedly arranged on the bottom plate; the first correcting device and the second correcting device have the same structure, and respectively comprise a correcting surface fixing plate installed on the bottom plate, as well as a correcting surface fixing bracket I and a correcting surface fixing bracket II; a cover plate is arranged on the correcting surface fixing plate; the correcting surface fixing bracket I and the correcting surface fixing bracket II are used for clamping the corresponding parts of the wax pattern; the correcting surface fixing bracket II is installed above the correcting surface fixing bracket I and is hinged with one end of the correcting surface fixing bracket I; the correcting surface fixing bracket I extends to the part above the cover plate from the interior of the cover plate; the other ends of the correcting surface fixing bracket I and the correcting surface fixing bracket II are clamped or released through a quick clamp; the height of the cover plate can be adjusted relative to the correcting surface fixing plate, and the cover plate is fixed through hexagon socket cap screws after the height is adjusted; and the inclination angle of the correcting surface fixing bracket I can be adjusted relative to the cover plate, and the correcting surface fixing bracket I is fixed by screws after the angle is adjusted.

Owner:XIANYANG BOLI MOLD MFG

Wax module for organizing chip array

ActiveCN1920558AQuality improvementImprove production efficiencyFoundry moulding apparatusBiological testingWaxEngineering

The invention relates to an organized chip array wax block module, wherein it comprises mould element and array grid plate; said array grid plate is arranged with several post grids uniformly; the bottom of mould has array holes relative to the post grids; the post grids are through the bottom of mould element to pass the array holes into mould element groove; the array grid plate is movably matched with array hole; and there is a packing box movably matched with mould. In addition, the moulds can be two types that the groove bottom of mould has one upwards integrated post grid; the middle ofgroove has array hole plate and the array grid plate through the array hole; the lower surface of array grid plate has post grid, and upper surface has handle; the post grid is movably matched with array hole plate. The invention has the advantages that: it has high producing speed, high quality, and one-time molding; and it can increase the points of micro array, to plant more organized chips into one array wax block, to improve the producing efficiency and quality.

Owner:胡苹

Titanium alloy investment cast precision part wax mold assembly tool

The invention provides a titanium alloy investment cast precision part wax mold assembly tool and belongs to the technical field of precision casting. Through the titanium alloy investment cast precision part wax mold assembly tool, the problems that an existing wax mold is poor in size accuracy and is likely to deform in the welding assembly process are solved. The titanium alloy investment castprecision part wax mold assembly tool comprises a working table, first, second and third position adjusting parts and a plurality of limiting assemblies, wherein the first, second and third position adjusting parts and the limiting assemblies are arranged on the working table; the second position adjusting part is fixedly connected with the working table; the first position adjusting part and thethird position adjusting part are located on the left and right sides of the second position adjusting part correspondingly; the first position adjusting part and the third position adjusting part both slide left and right to be arranged on the working table; three wax mold sections to be assembled are placed above the three position adjusting parts in a one-to-one correspondence mode; the shape of the top end face of each position adjusting part is identical to the molding surface of the wax mold on the position adjusting part; the top end face of each position adjusting part serves as the theoretical size of the molding surface of the wax mold. The multiple limiting assemblies are arranged between every two adjacent position adjusting assemblies.

Owner:AEROSPACE HIWING HARBIN TITANIUM IND

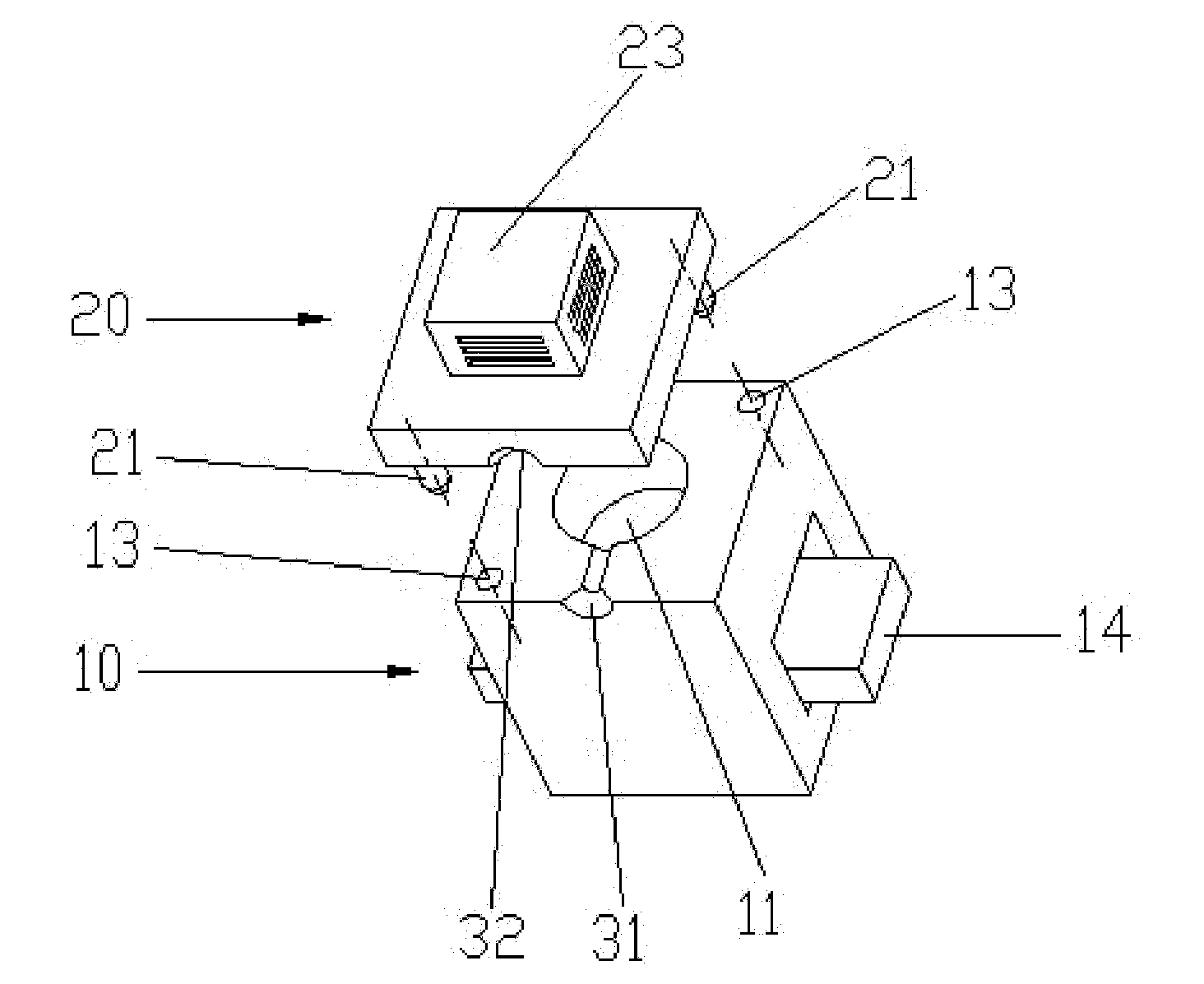

Evanescent mode production process of engine cylinder body

ActiveCN103372630APrevent water leakageImprove pass rateFoundry moulding apparatusWater leakageEvanescent mode

The invention discloses an evanescent mode production process of an engine cylinder body, belonging to the technical field of evanescent mode production processes. The evanescent mode production process comprises the steps of: S1, a bead pre-frothing process; S2, a white mode forming process; S3, a drying treating process for drying a white mode; S4, a mode sticking process; S5, a coating dip-coating process; S6, a drying process after dip-coating; and S7, a modeling and casting process. According to the evanescent mode production process, phenomena of sand burning and water leakage can be effectively prevented, and thus the qualified rate of produced engine cylinder bodies of automobiles is increased.

Owner:河北瑞丰科技有限公司

Casting die easy to strip

The invention discloses a casting die easy to strip, which comprises a lower die, an upper die, a lower die pouring opening and an upper die pouring opening. The casting die is characterized in that the lower die is provided with a vertical first through cavity and a horizontal second through cavity which is communicated with the first through cavity; a sliding block which is matched with the first through cavity is arranged in the first through cavity; a flat plate is arranged in the second through cavity; and both ends of the flat plate extend out of the second through cavity and are connected with the sliding block by a connecting piece. By adopting the technical scheme, when the casting die easy to strip is stripped, the flat plate drives the sliding block to move in the first through cavity up and down to achieve the aim of easy stripping; and the invention not only can omit the process that a wax die is taken directly with hands for stripping, but also ensures the stripping verticality.

Owner:WUJIANG SENTAI MACHINERY MFG

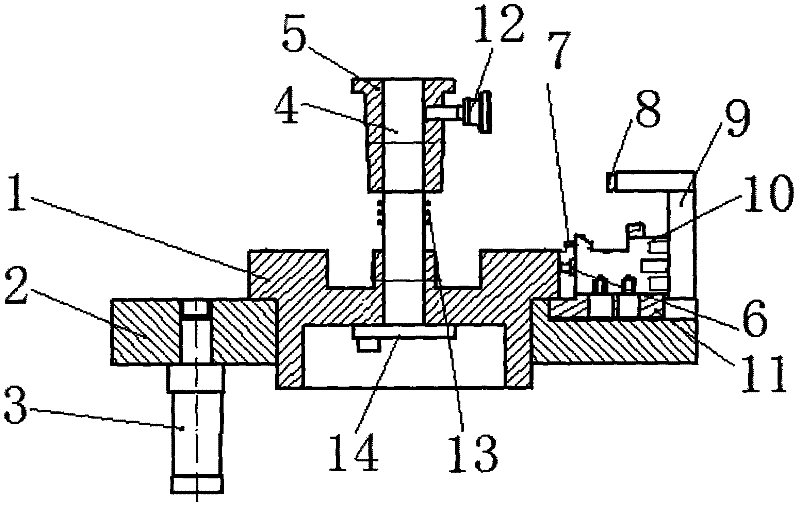

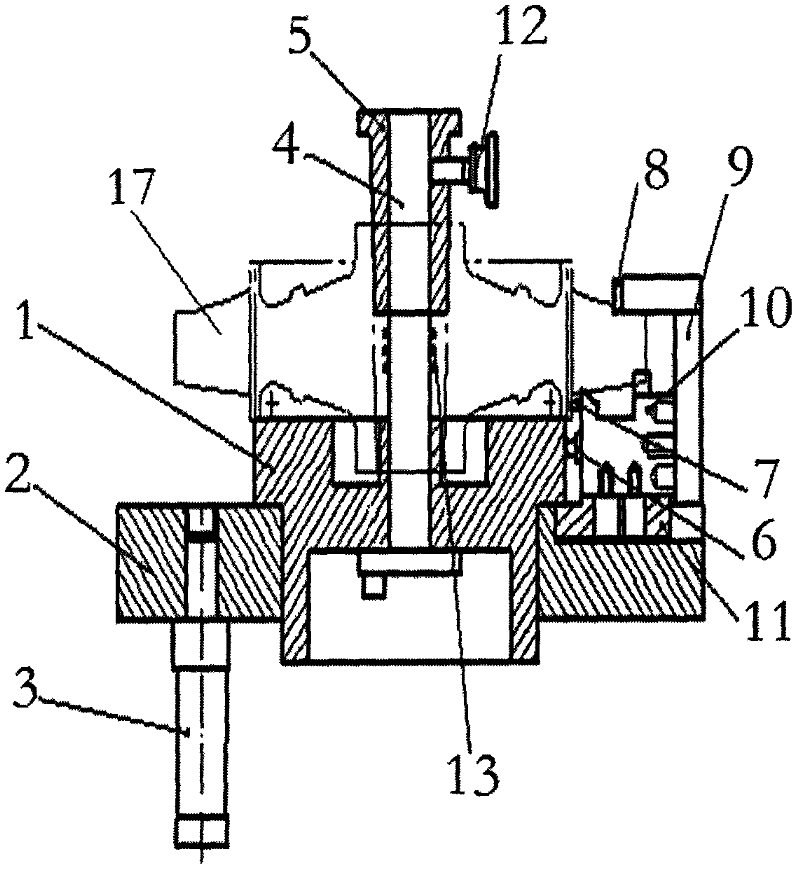

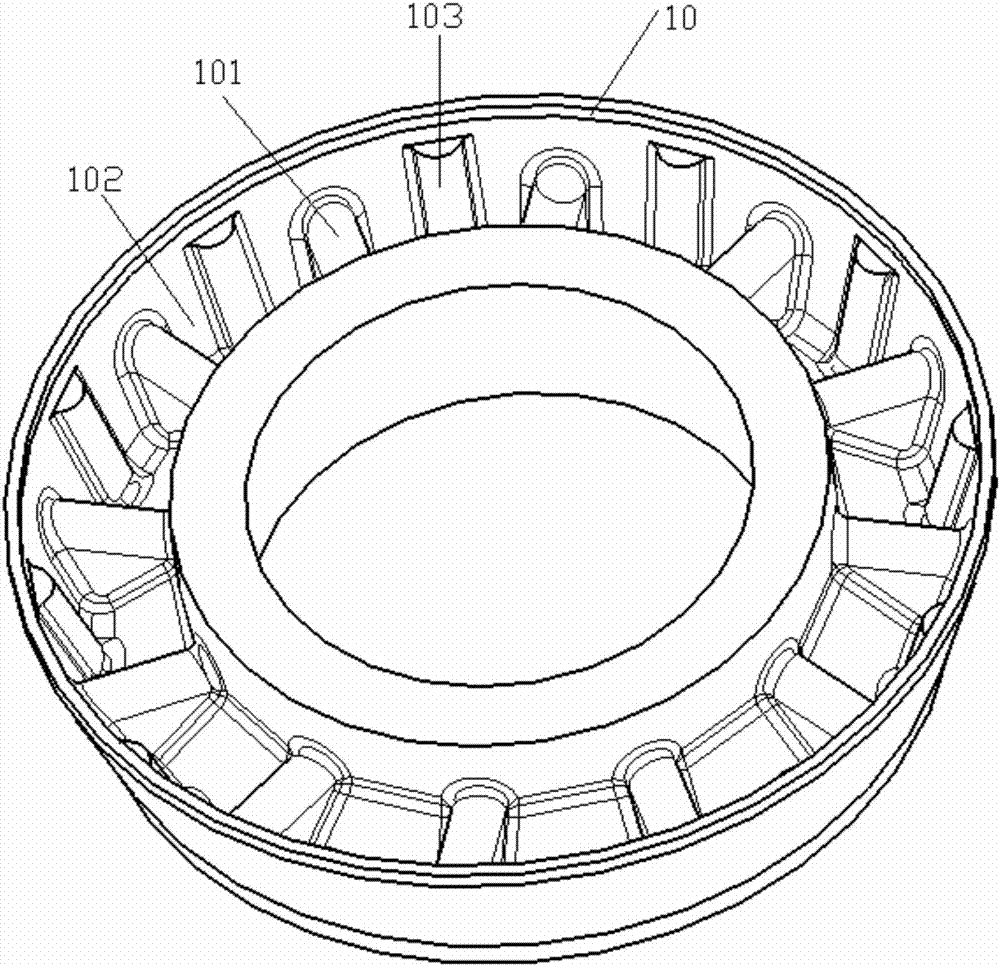

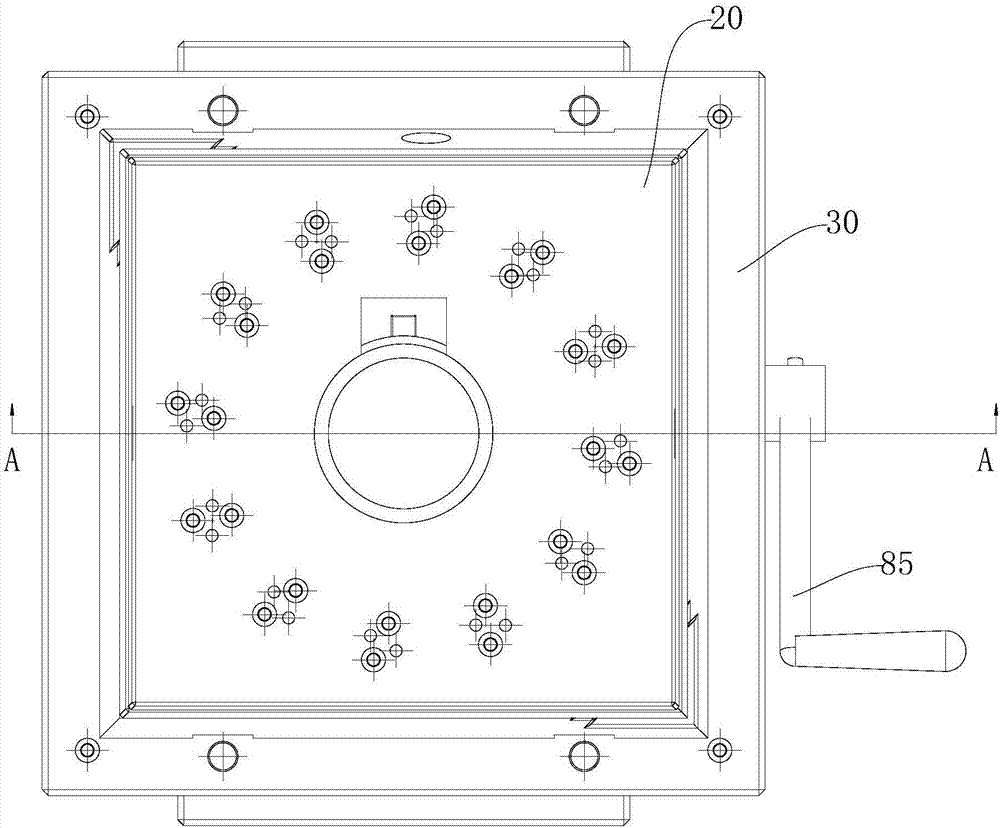

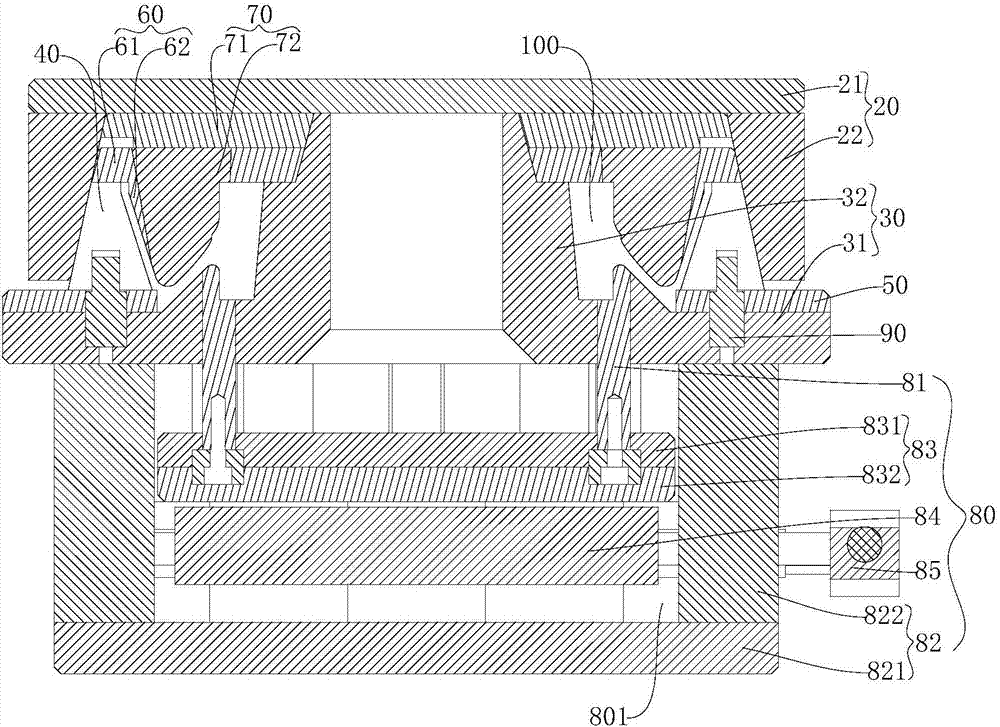

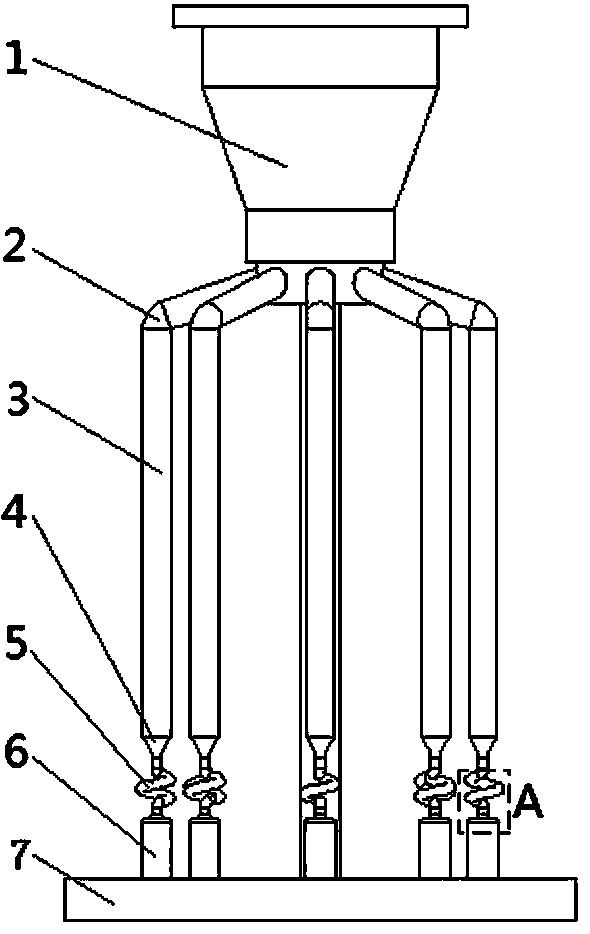

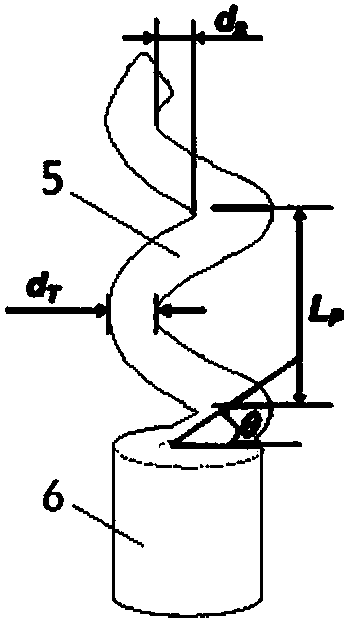

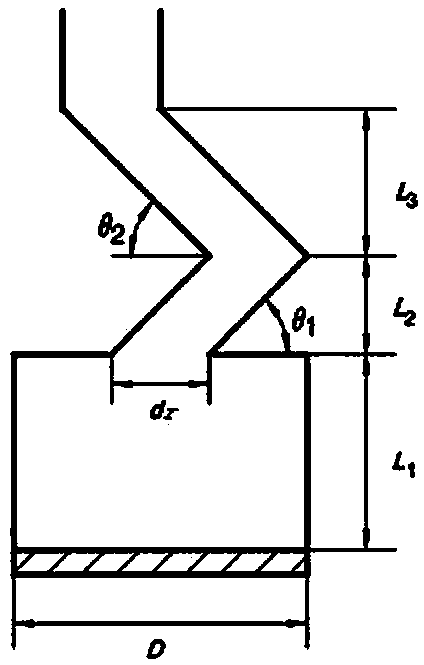

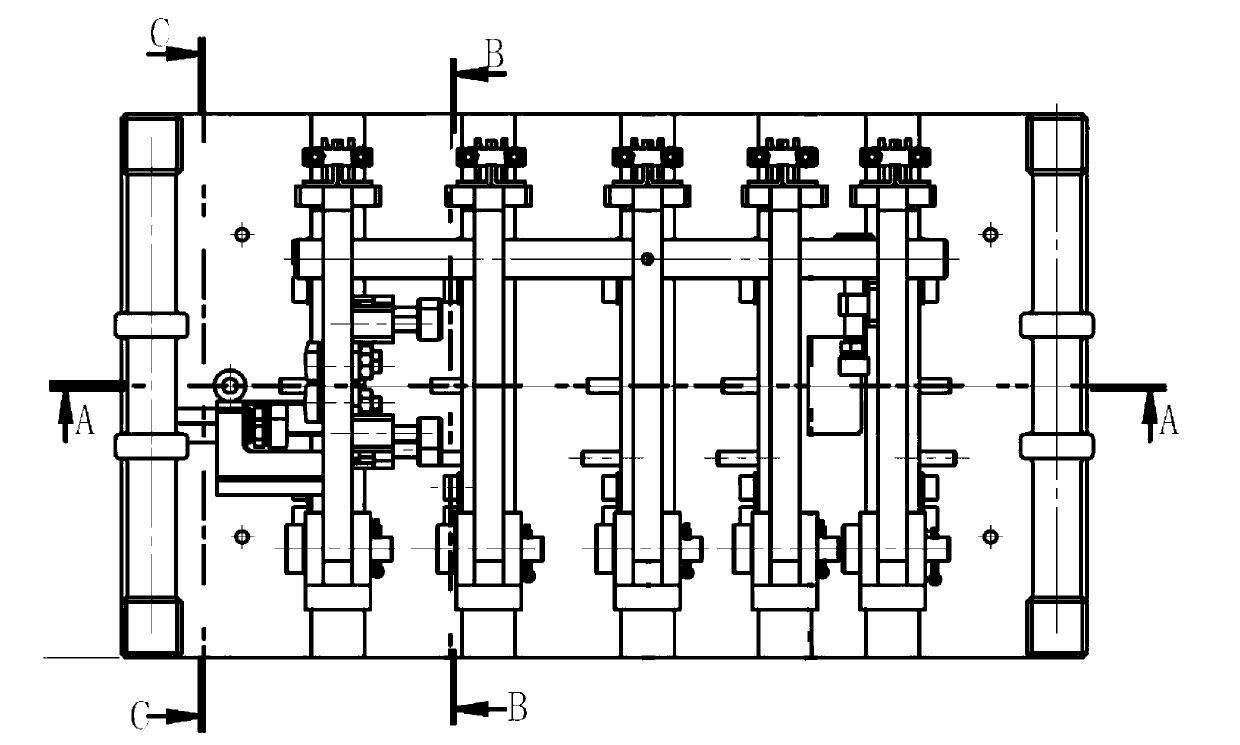

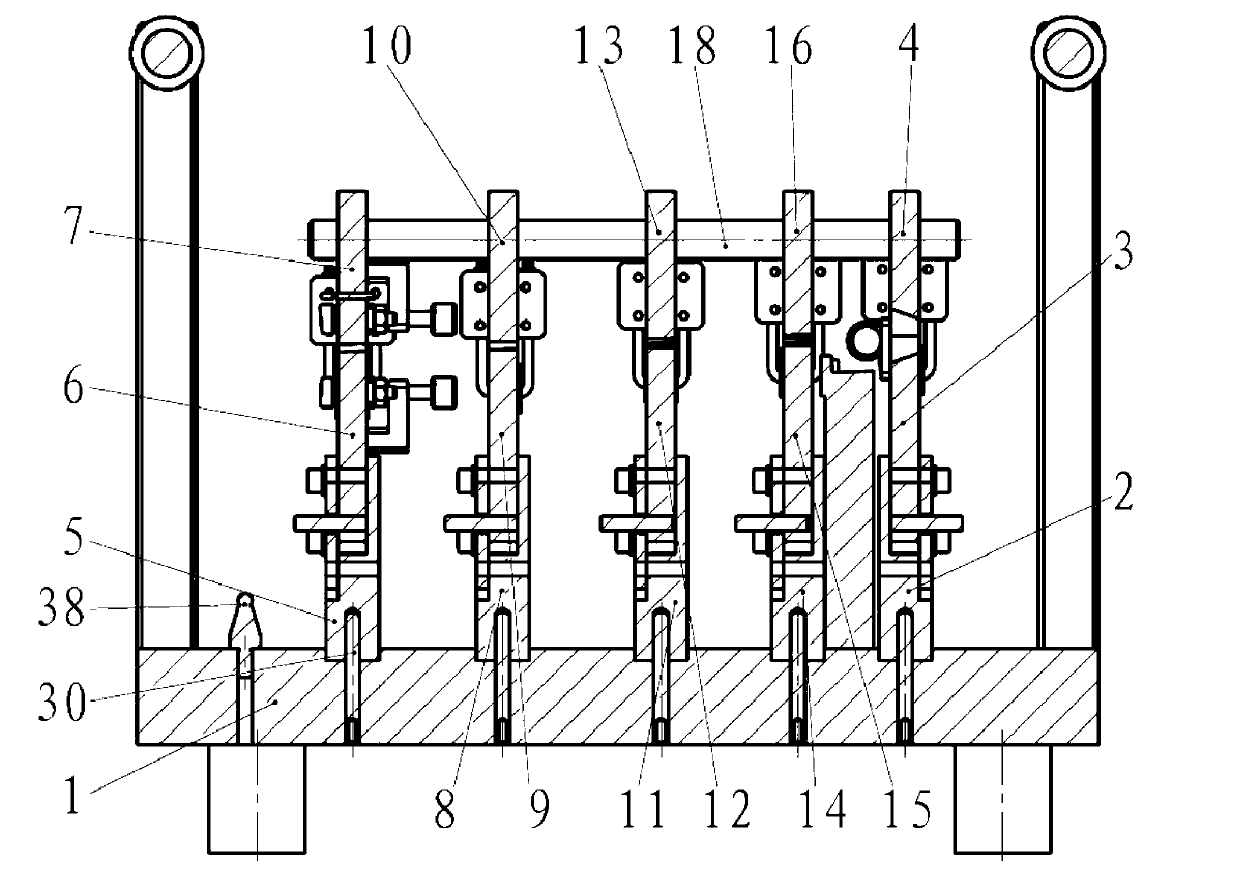

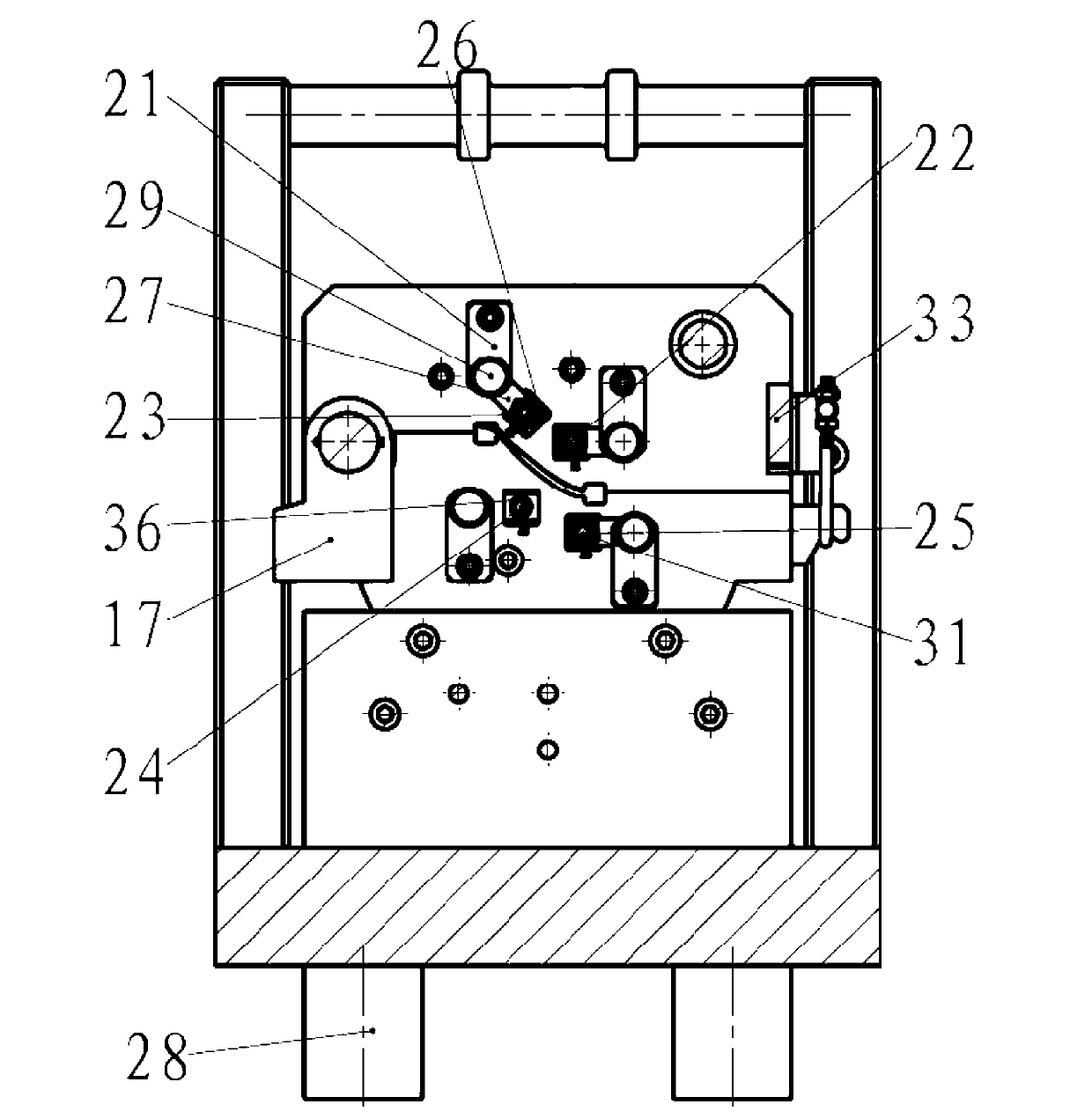

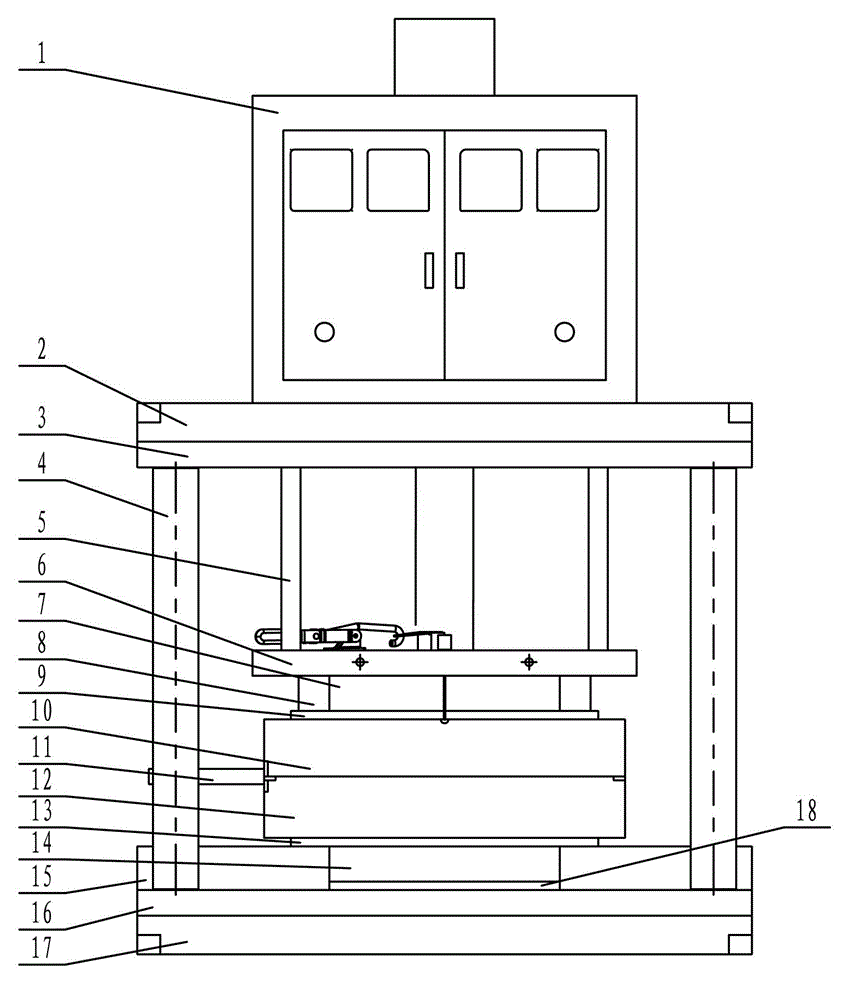

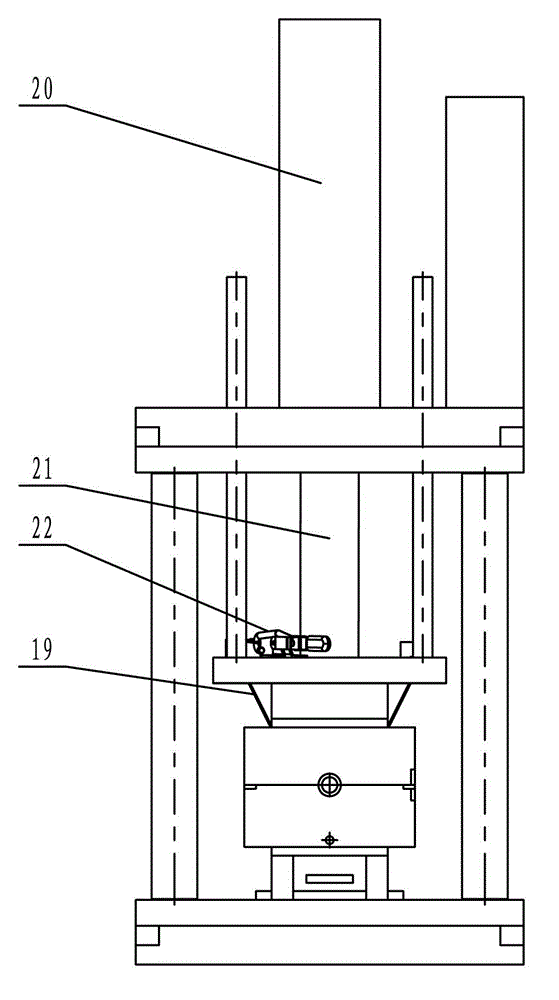

Automatic wax injection press

ActiveCN102717027AQuality improvementQuick die changeFoundry moulding apparatusWaxInvestment casting

The invention relates to an automatic wax injection press which is particularly used for automatic production of wax patterns, and belongs to the technical field of precision investment casting pattern making. The automatic wax injection press mainly comprises an electric cabinet, a reinforcing plate, a wax injection press cover plate, support pillars, an upper working table, a first magnetic sucking disc, an upper transitional plate, an upper die, a lower die, a lower transitional plate, a second magnetic sucking disc, a wax injection press seat, a magnetic sucking disc mounting board, an oil cylinder and a piston rod, wherein the lower transitional plate is magnetically adsorbed on the second magnetic sucking disc; the lower die is fixedly connected onto the lower transitional plate; the upper die is positioned on the lower die; a gate stick is connected to one side of the upper die and that of the lower die; the upper die is fixedly connected onto the upper transitional plate; and the upper transitional plate is magnetically adsorbed on the first magnetic sucking disc. The automatic wax injection press has the advantages as follows: the structure is simple, compact and reasonable; the automatic production of the wax patterns reduces the labor intensity of workers and improves work efficiency; the quality of the produced wax patterns is stable; and the die changing is fast, and the service lives of the dies are long.

Owner:鹰普(中国)有限公司

Method for manufacturing high temperature resistant casting resin-die

InactiveCN102658352AHigh precisionShorten the manufacturing cycleFoundry moulding apparatusNumerical controlWax

The invention provides a method for manufacturing a high temperature resistant casting resin-die, advantageous in comprising the following steps: 1. making a structural design for a die by drawing a three-dimensional modeling for the die through a three-dimensional software; 2. processing the three-dimensional modeling into a rapid prototype in an NC machine tool after conducting an NC programming; 3. manufacturing a silicone-rubber die for the high temperature resistant resin-die by using the rapid prototype and silicone rubber turnover-formwork technique; 4. first brushing a surface-layer resin material over the cavity of the silicone-rubber die, then after the solidification of the surface-layer resin material, brushing a back-layer resin material on the surface-layer resin material, pressing to make the two layers of resin material adhere to each other and the aggregate thickness thereof reaching 20mm+ / -5mm, and taking the two solidified layers of resin materials out of the silicone-rubber die after the back-layer resin material is solidified to obtain the high temperature resistance casting resin-die. The high temperature resistance casting resin-die of the invention, having high machining precision, short manufacturing cycle and low costs, can be applied to the manufacturing of foaming mould by lost foam or the precision casting of wax die through lost wax.

Owner:SHANDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com