Wax module for organizing chip array

A tissue chip and array technology is applied in the field of tissue chip array wax block molds, which can solve problems such as lack of performance molds, achieve the effects of high production speed, improved production efficiency and quality, and easy slicing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

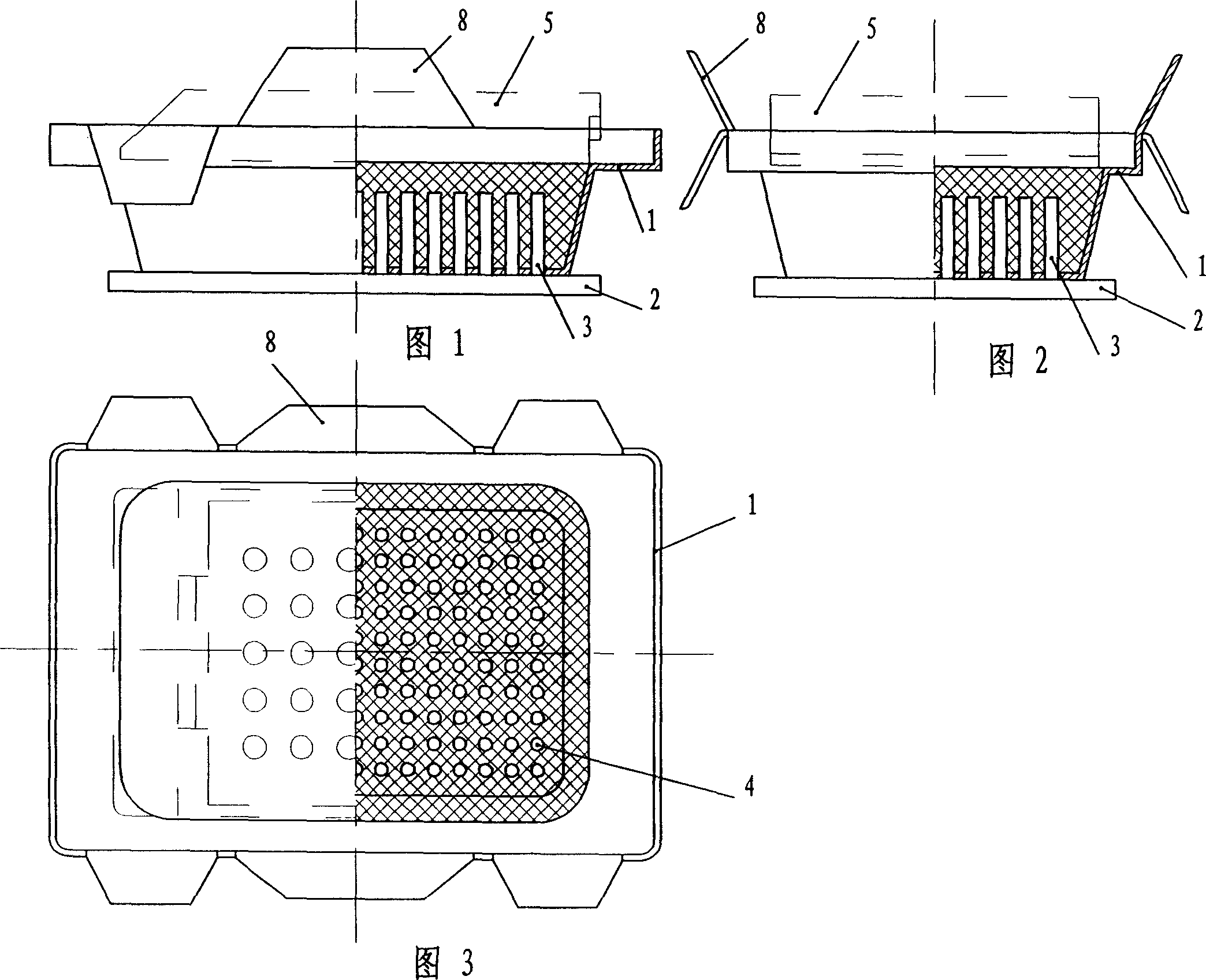

[0032] 1-3, in the first embodiment of the tissue chip array wax block mold of the present invention, the tissue chip array wax block mold includes a groove-shaped mold body 1 and an array grid plate 2 made of stainless steel, and the mold body 1 Fins 8 are provided, and a number of evenly arranged columnar grids 3 are arranged on the array grid plate 2. The diameter of the columnar grids 3 is 0.6-2.0mm and the height is 3mm, forming a 25*20-10*8 dot matrix, and the array distance 0.4mm. The bottom surface of the mold body 1 is provided with array holes 4 arranged correspondingly to the columnar grid 3. The columnar grid 3 passes through the array 4 holes from the bottom of the mold body 1 and enters the groove of the mold body 1. The array grid plate 2 is movably matched with the array hole 4. An embedding cassette 5 (drawn with a dotted line in the figure) is provided on the top of the body 1 for its movable cooperation. Referring to Figure 11 and Figure 12 for the structur...

Embodiment 2

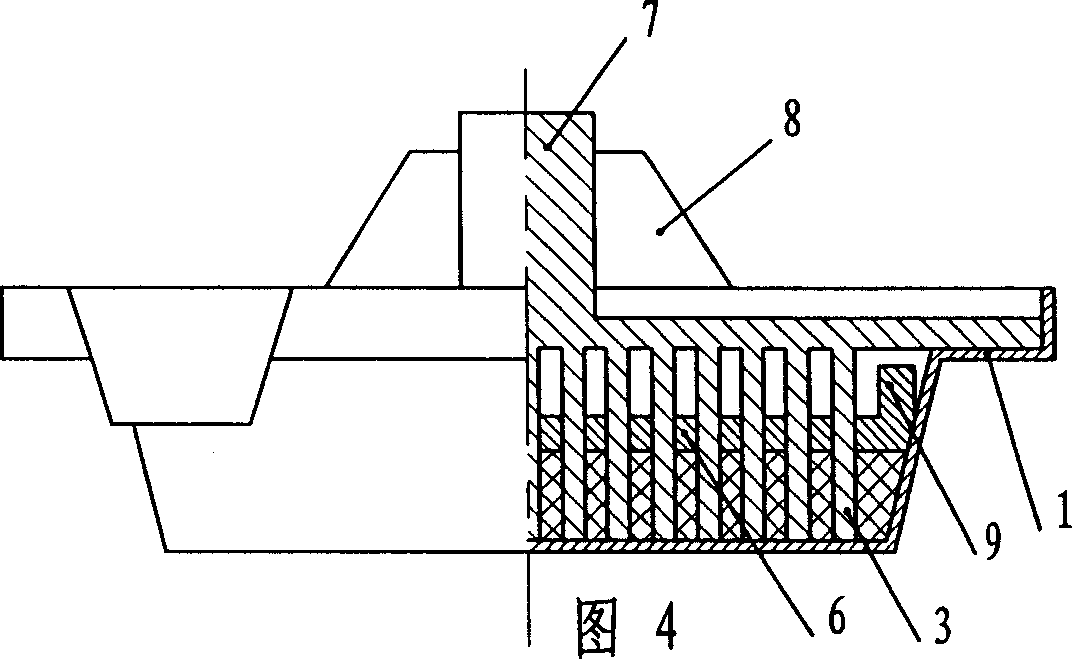

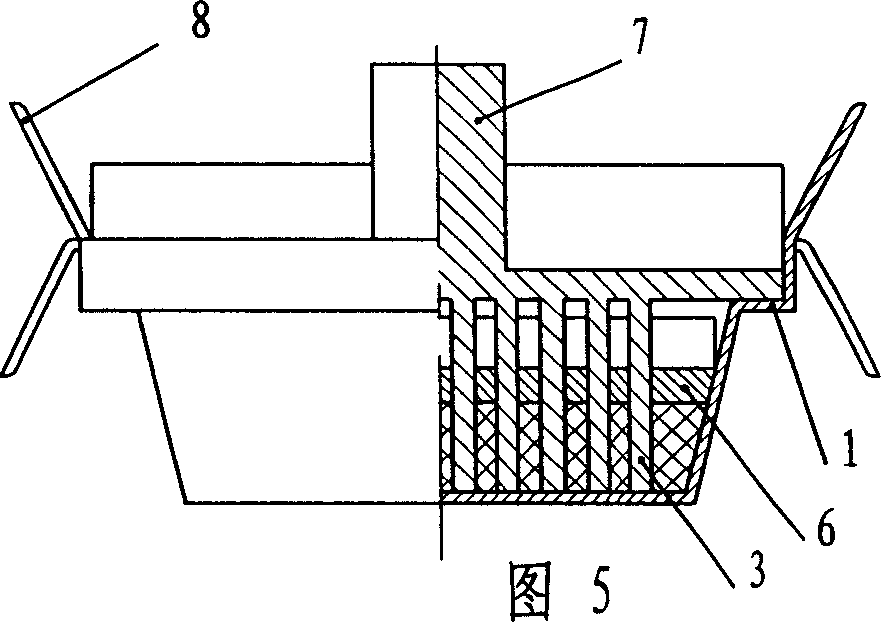

[0037] Referring to Figures 4-6, in the second embodiment of the tissue chip array wax block mold of the present invention, it also includes an array orifice plate 6 placed in the middle of the groove of the mold body 1 and a movable buckle through the array orifice plate 6. Array grid 2 in groove of mold body 1 . The array orifice plate 6 is provided with fins 9 and is made of stainless steel. The lower surface of the array grid plate 2 is provided with a number of evenly arranged columnar grids 3 , and the upper surface is provided with a handle 7 . The columnar grid 3 is movably matched with the array hole plate 6. Referring to FIG. 10 , an embedding cassette 5 (drawn by a dotted line in the figure) which is movably matched with it is arranged above the phantom body 1 .

[0038] In the second embodiment of the tissue chip array wax block mold of the present invention, referring to FIGS. At the 3mm mark on the wall, place the array orifice plate 6 in the groove of the mold...

Embodiment 3

[0040] Referring to Figures 7-9, in the third embodiment of the tissue chip array wax block mold of the present invention, the groove bottom of the mold body 1 is upwardly provided with a columnar grid 3 integrated with it, and the top of the mold body 1 is provided with a movable joint Embedding cassette 5 (drawn with dotted lines in the figure).

[0041] In the third embodiment of the tissue chip array wax block mold of the present invention, referring to FIGS. It condenses, and then hold the flap 8 to separate the phantom 1 from the plastic embedding box 5 .

[0042] In the above three embodiments, the mold body 1, the grid array 2 and the orifice array 6 can also be made of aluminum or hard plastic. The tissue chip array wax blocks formed by the mold of the present invention are shown in Fig. 13 and Fig. 14 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com