Patents

Literature

52results about How to "Overcoming technical hurdles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

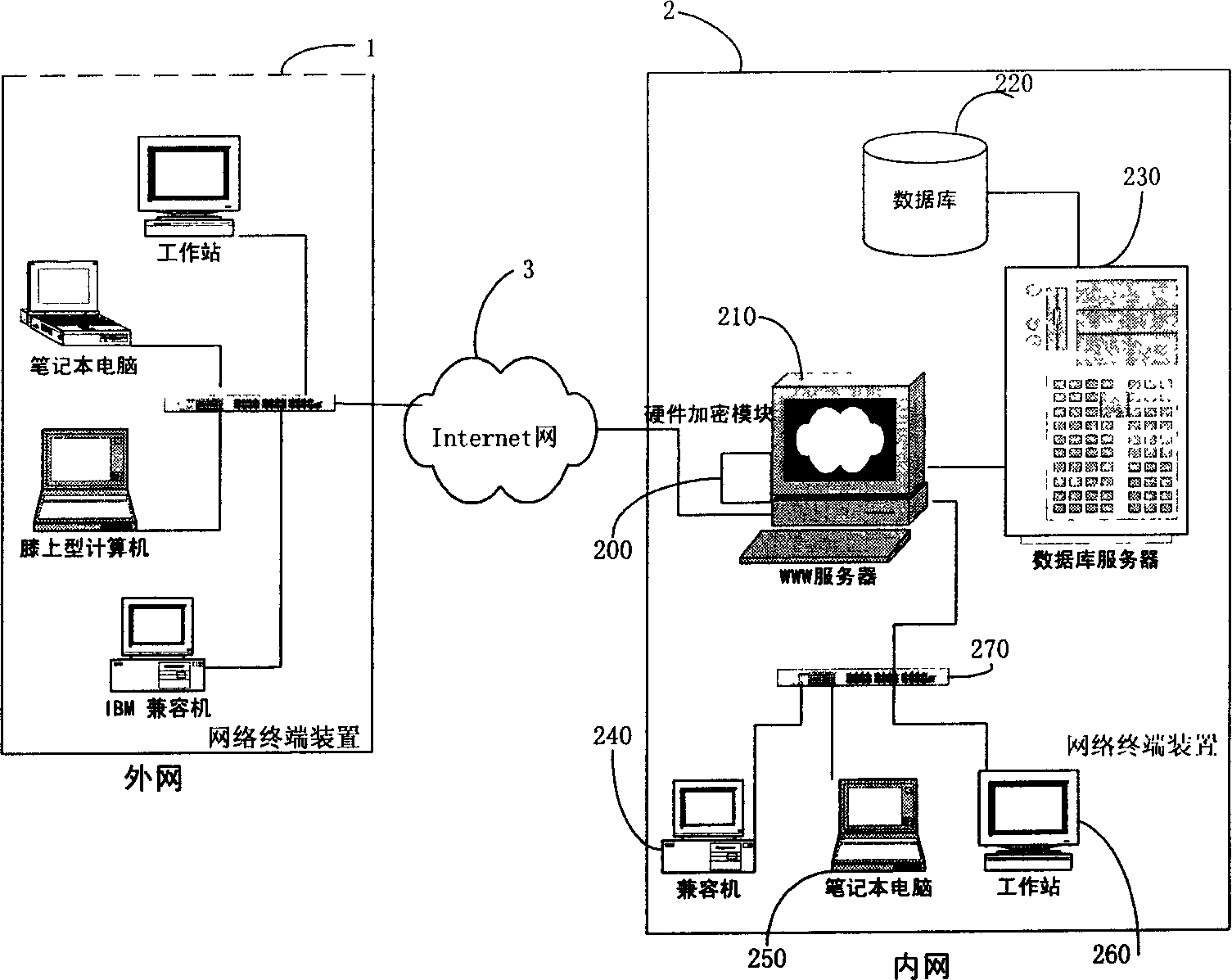

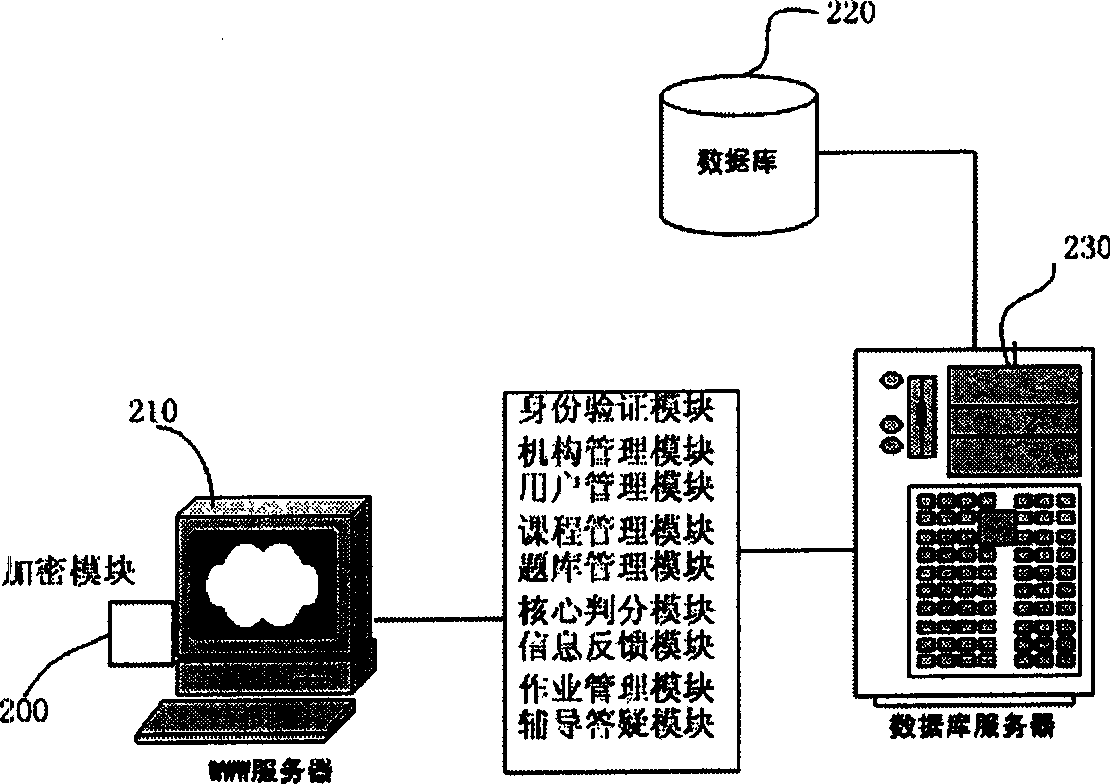

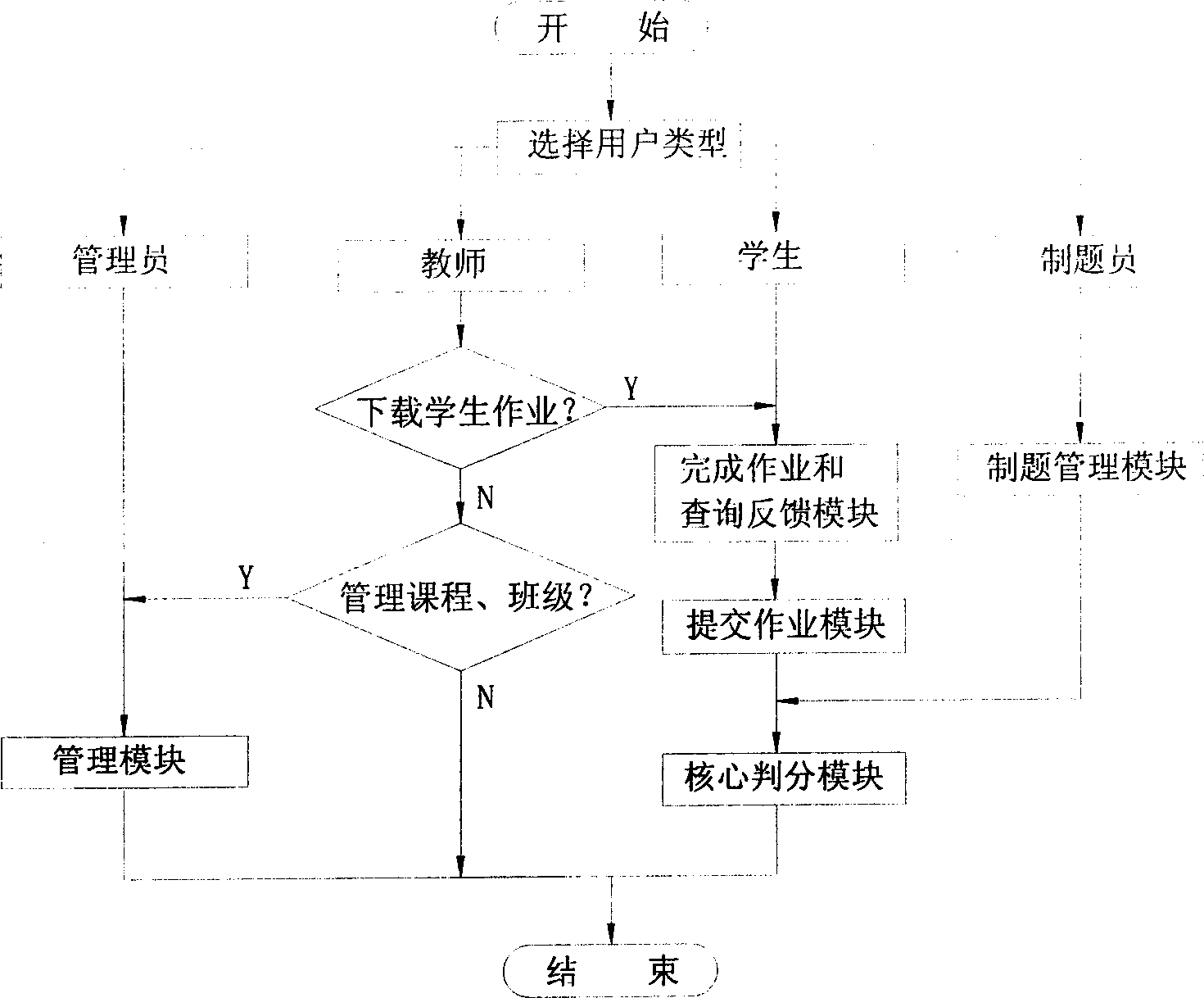

Network-based engineering drawing automatic judging method

InactiveCN1776724ADetailed Scoring DetailsSolve the problem of automatic scoringElectrical appliancesSpecial data processing applicationsGraphicsComputer aided instruction

The invention is applicable to computer aided instruction for engineering drawing. According to different users, the method decomposes relevant functions into different module units including management module based on network, kernel module for judging credit based on detailed analyzing knowledge points, module for students to submit homework, module for completing homework and querying feed back, and networked module for managing titles of engineering drawing. Under specific requirement, the system can implement specific rules for judging credits, possessing better flexibility. According to presetting rules, the method can mark highlighted tags on error positions in graph. Through colors, linewidth, line type, and text discrition, taking full advantage of graphical display, the invention realizes adding artificial comment automatically.

Owner:NANJING NORMAL UNIVERSITY

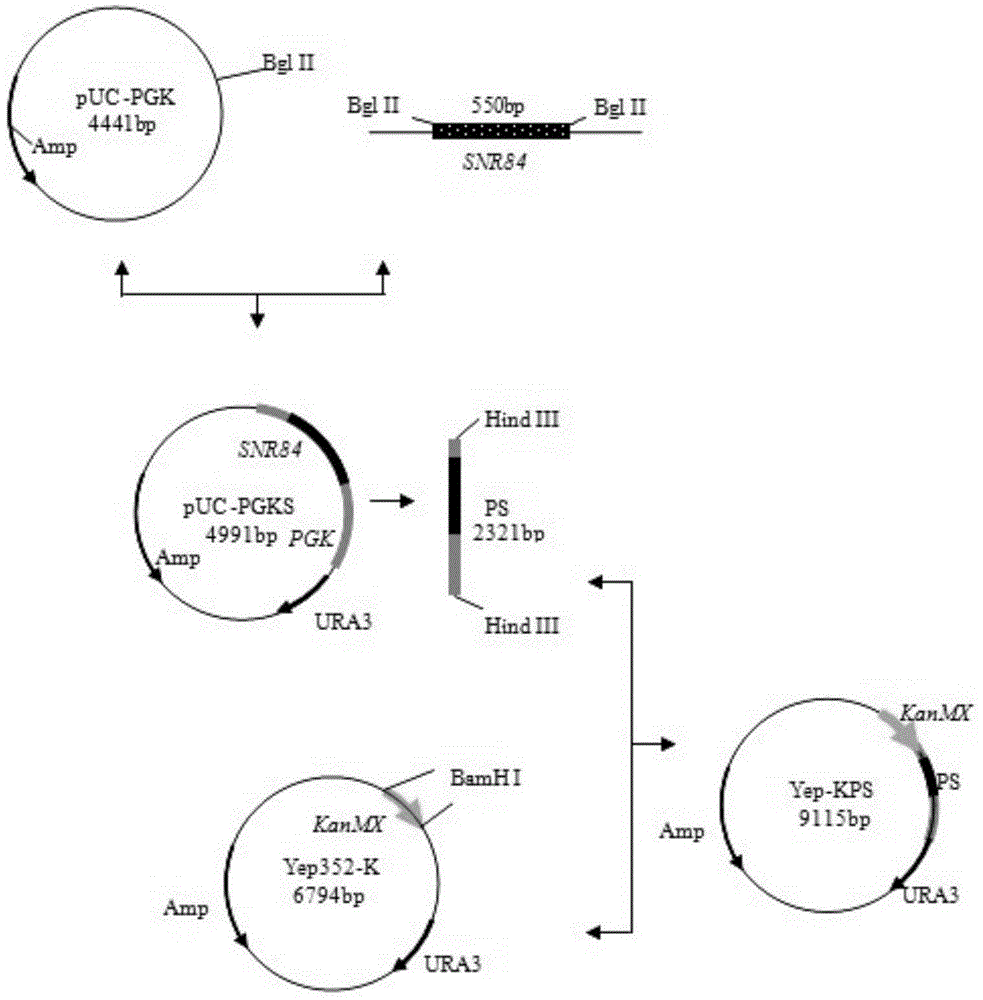

High-resistant yeast strain and preparation method thereof

ActiveCN104017742AOvercoming high temperature resistanceOvercome High Glucose ToleranceFungiPre-baking dough treatmentHeat shockBiotechnology

The invention discloses a high-temperature-resistant, high-sugar-resistant and freezing-resistant high-resistant yeast strain and a preparation method thereof. The preparation method comprises the following steps: over-expressing a complete sequence of H / ACA snoRNA (SNR84) by selecting and using a strong promoter PGK1 in a parent yeast strain to obtain the high-resistant yeast strain. The cell activity of the strain is remarkably improved in high-temperature, high-sugar and freezing environments in comparison with that of the parent strain. Saccharomyces cerevisiae are good in high-temperature resistance in heat shock treatment, high-sugar resistance in high-sugar dough and freezing resistance in frozen dough, the technical obstacle and the quality detect in a bread making process are overcome, and the application prospect is wide.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

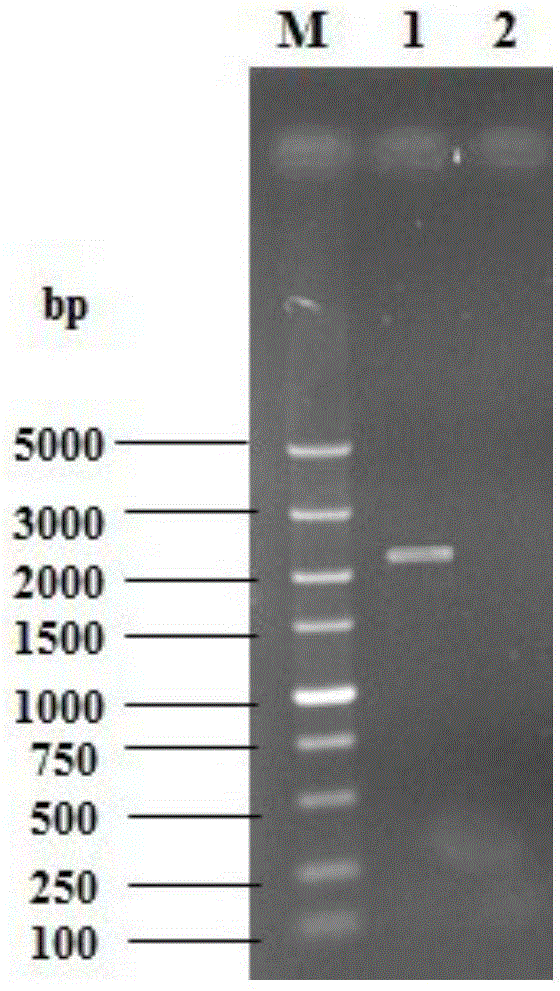

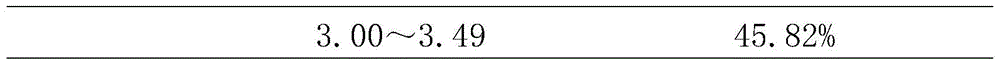

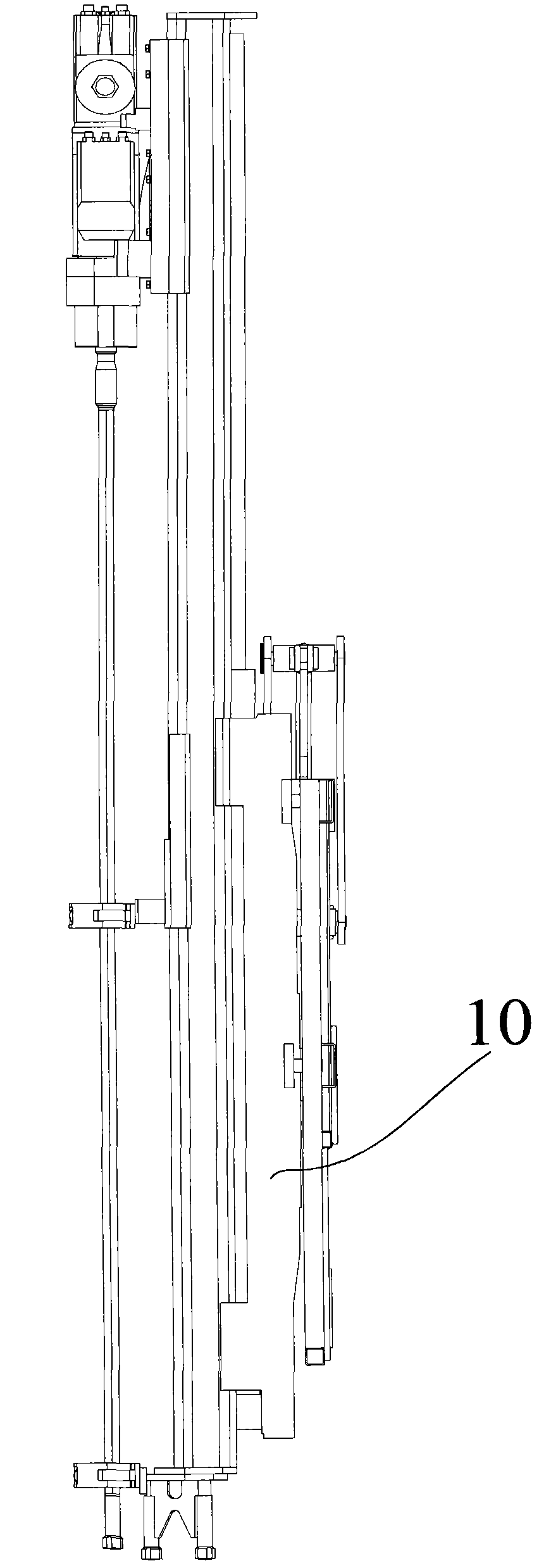

Culture medium and culture method for cultivating immature embryo of double-petal paeonia lactiflora

InactiveCN102428872AOvercoming technical hurdlesFast growthHorticulture methodsPlant tissue cultureBudGermination

The invention specifically relates to a culture medium prescription for cultivating immature embryo of double-petal paeonia lactiflora and a method for cultivating the seedlings of the paeonia lactiflora by using the culture medium. The culture medium comprises adventitious bud induction culture medium, adventitious bud strengthening culture medium and rooting culture medium; and the culture medium is formed by adding TDZ, cane sugar and agar based on improved MS or 1 / 2 improved MS. The culture method comprises the following steps: selecting the seedling embryo; preparing the culture medium; and inoculating to cultivate, wherein the step of inoculating to cultivate is the step of adopting the three culture mediums to induce the adventitious bud, strengthen the adventitious bud and root. Because of the invention, the seedling rate of the immature embryo reaches over 60%, and the technical obstacle that the double-petal paeonia lactiflora cannot establish the seedlings caused by the dysplasia of the seedling embryo. Each germination seedling embryo can establish 3-8 adventitious buds and 5-10 fleshy roots, so the effect that the seedlings of the normal seed differentiate the buds after three years is realized, the growth speed of the seedlings of the paeonia lactiflora is improved, the hybrid seedlings of the paeonia lactiflora flowers at early stage, and the breeding period of the paeonia lactiflora is shortened.

Owner:YANGZHOU UNIV

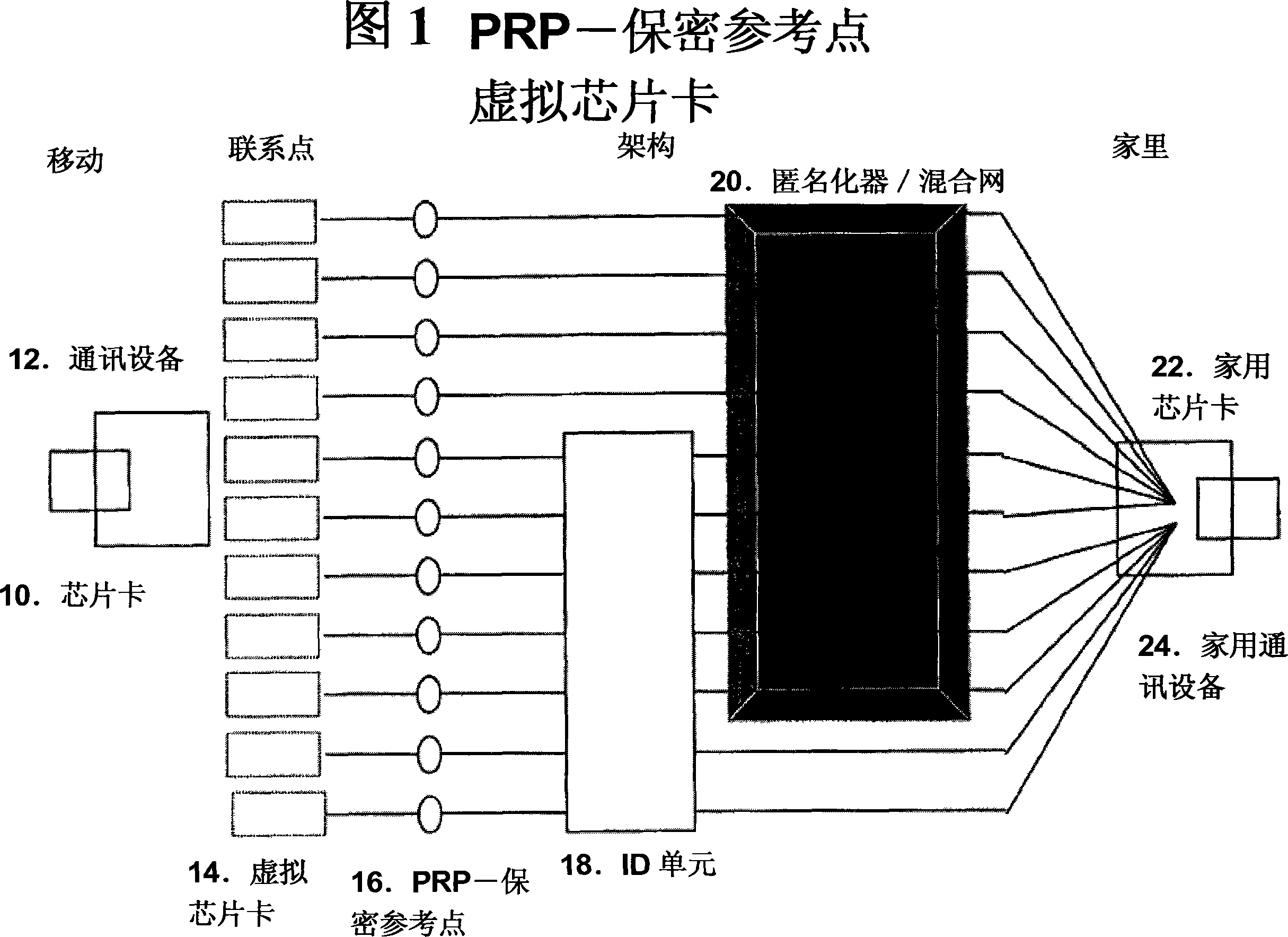

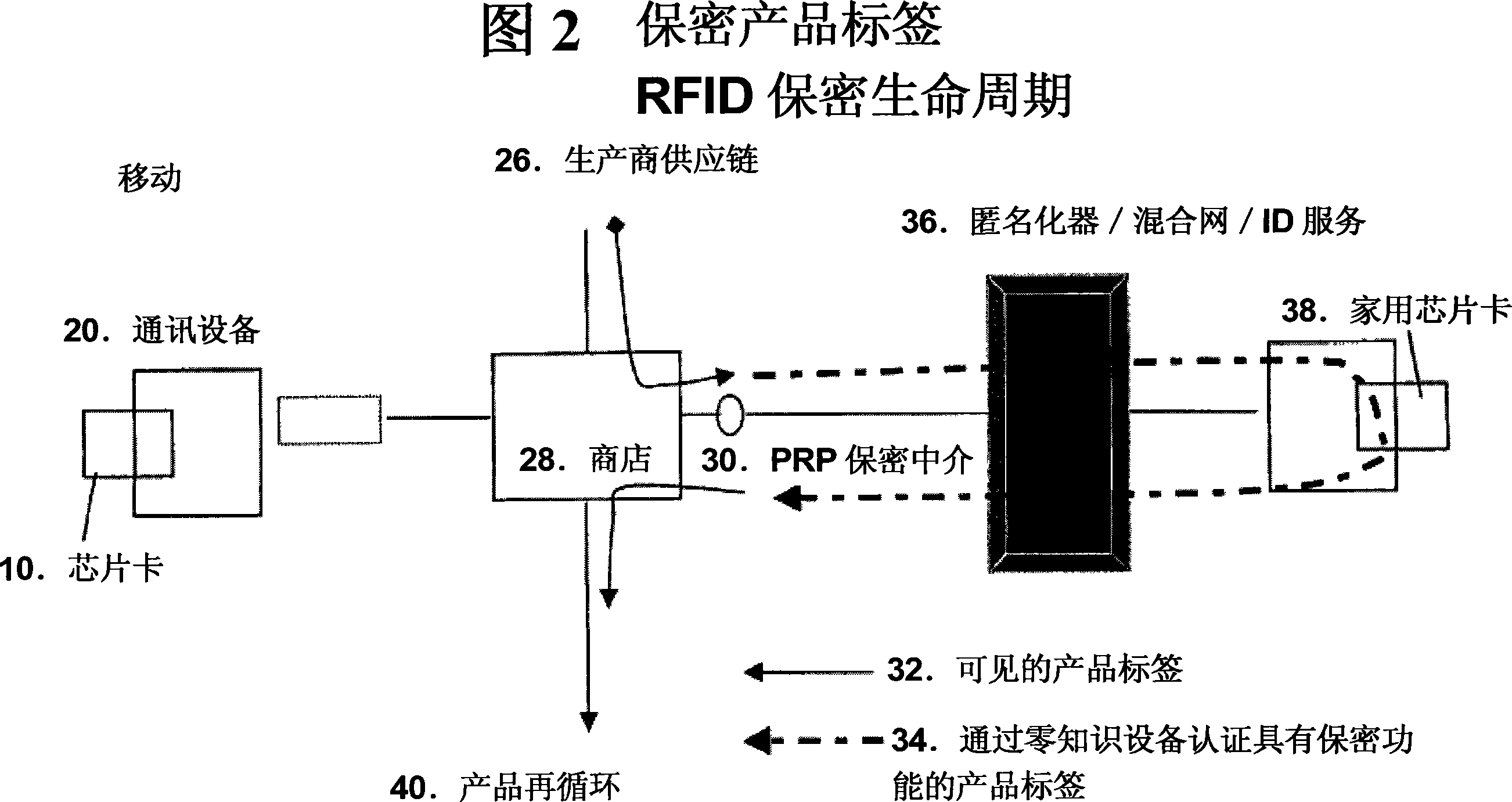

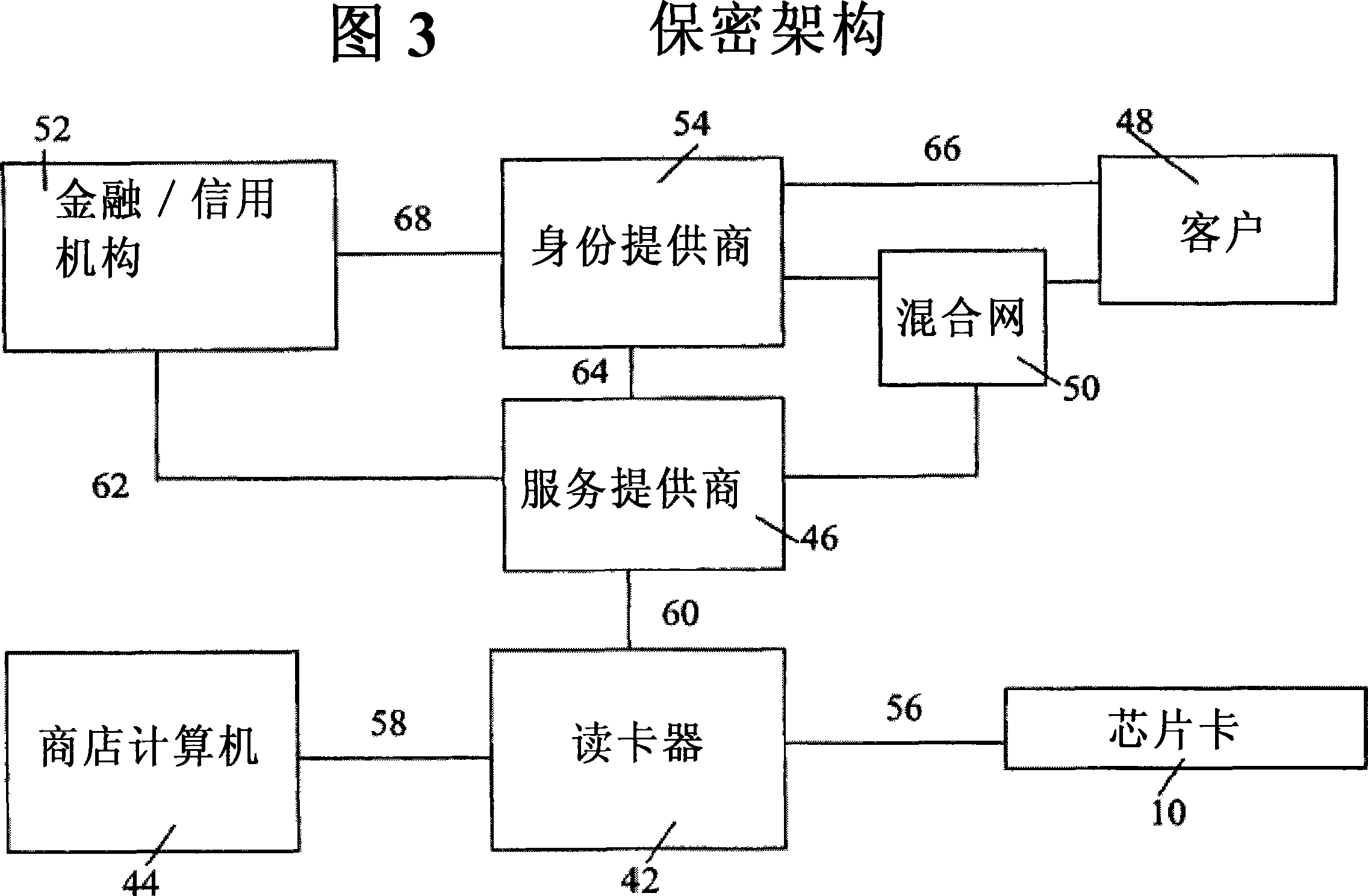

Method and system for establishing a communication using privacy enhancing techniques

InactiveCN1894923AOvercoming technical hurdlesSolve the problem of how to provide anonymous creditDigital data authenticationSecuring communicationInternet privacyAuthentication

A method of establishing a communication path from a first legal entity in a data communication network comprises the steps of providing at least one private reference point comprised in the data communication network and establishing a communication path from the first legal entity to the private reference point. The method further comprises verifying the authentication of the first legal entity relative to the private reference point from the first legal entity and still further a method of establishing communication from the private reference point to a second legal entity through the data communication network without disclosing the identity of the first legal entity without disclosing the identity of the first legal entity.

Owner:史蒂芬·J·英格博格

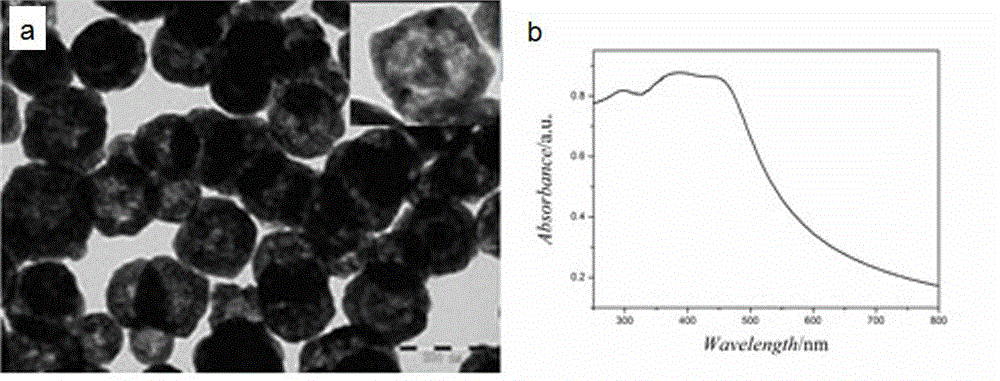

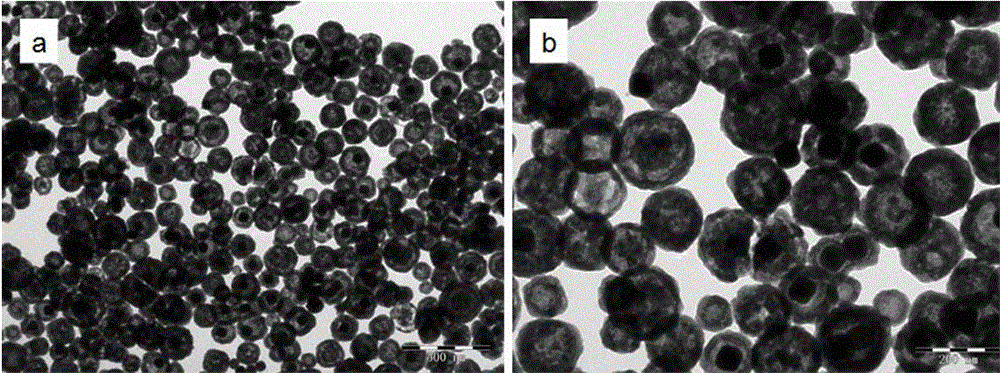

Rapid preparation method of AU@Cu2O nanocomposite in yolk-shell structure

The invention relates to a rapid preparation method of an AU@Cu2O nanocomposite in a yolk-shell structure. According to the nano material, the coverage degree of a shell layer can be controlled by regulating parameters of concentration, temperature and the like of CTAB. The preparation method comprises the following main steps: (1) adding a certain quantity of Vitamin C in mixed liquor of CuSO4.5H2O and cetyl trimethylammonium bromide (CTAB), stirring, and dissolving; (2) adding 3ml of aqueous solution of gold octahedron in the solution; (3) keeping the solution for 20min at the temperature of 60 DEG C, and then adding a certain quantity of NaOH solution dropwise; and (4) carrying out centrifugation on the obtained product, washing precipitates with deionized water and ethanol for many times, and finally dispersing in an ethanol solution. The AU@Cu2O nano material in the yolk-shell structure has very important application value in the aspects of catalysis, surface-enhanced raman scattering (SERS) and the like.

Owner:UNIV OF JINAN

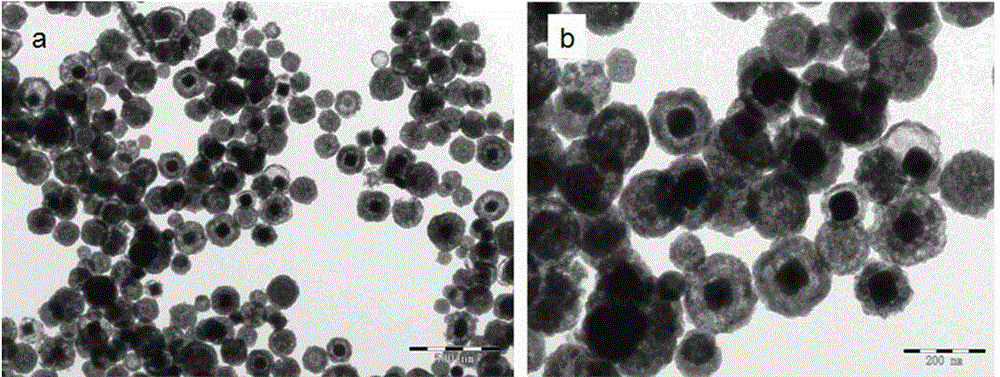

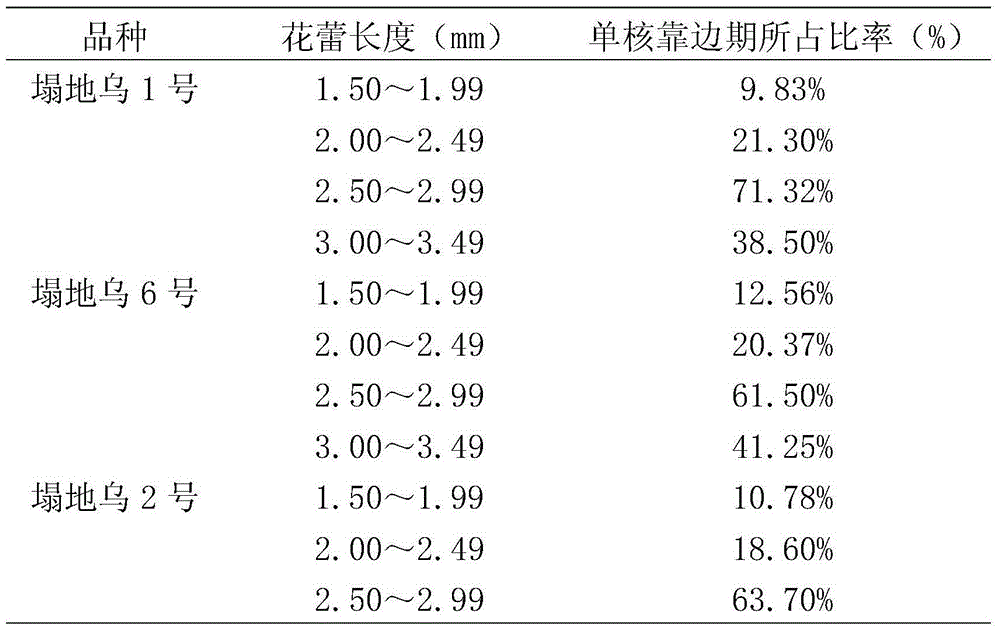

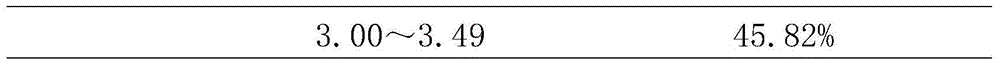

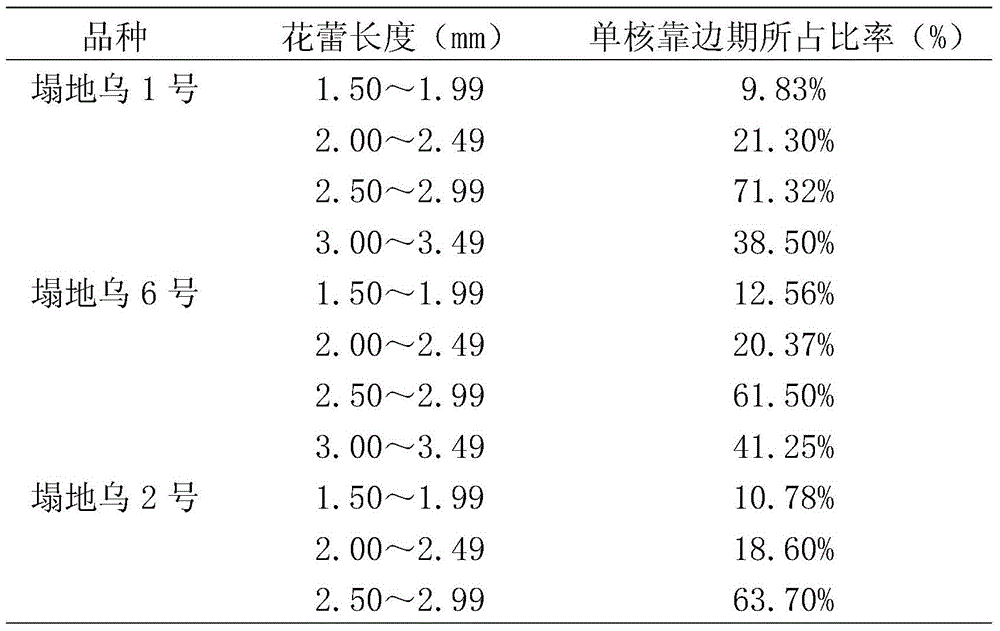

Method for improving microspore embryogenic rate of wuta-tsai

ActiveCN104429969AIncrease incidenceEffective induction of embryo production rateHorticulture methodsPlant tissue cultureSporeMixed culture

The invention discloses a method for improving microspore embryogenic rate of wuta-tsai. The method comprises the following steps: carrying out mixed culture to buds easy in embryogenesis and buds difficult or weak in embryogenesis, extracting by virtue of a B5 extracting solution, and inducing embryogenesis in a 1 / 2NLN-13 culture medium. Compared with the single culture of the prior art, the method disclosed by the invention can be used for effectively inducing the embryogenic rate of the variety difficult in embryogenesis and for improving the embryogenesis rate and the plant regeneration rate of the variety weak in embryogenesis, and the technical problem that the variety weak in embryogenesis is low in embryogenesis rate and embryogenesis genotypic ratio can be solved; meanwhile, the technical obstacle of generating plants from the variety difficult in embryogenesis by virtue of microspore culture is solved; and the method disclosed by the invention is significant in the microspore culture of the wuta-tsai.

Owner:ANHUI AGRICULTURAL UNIVERSITY

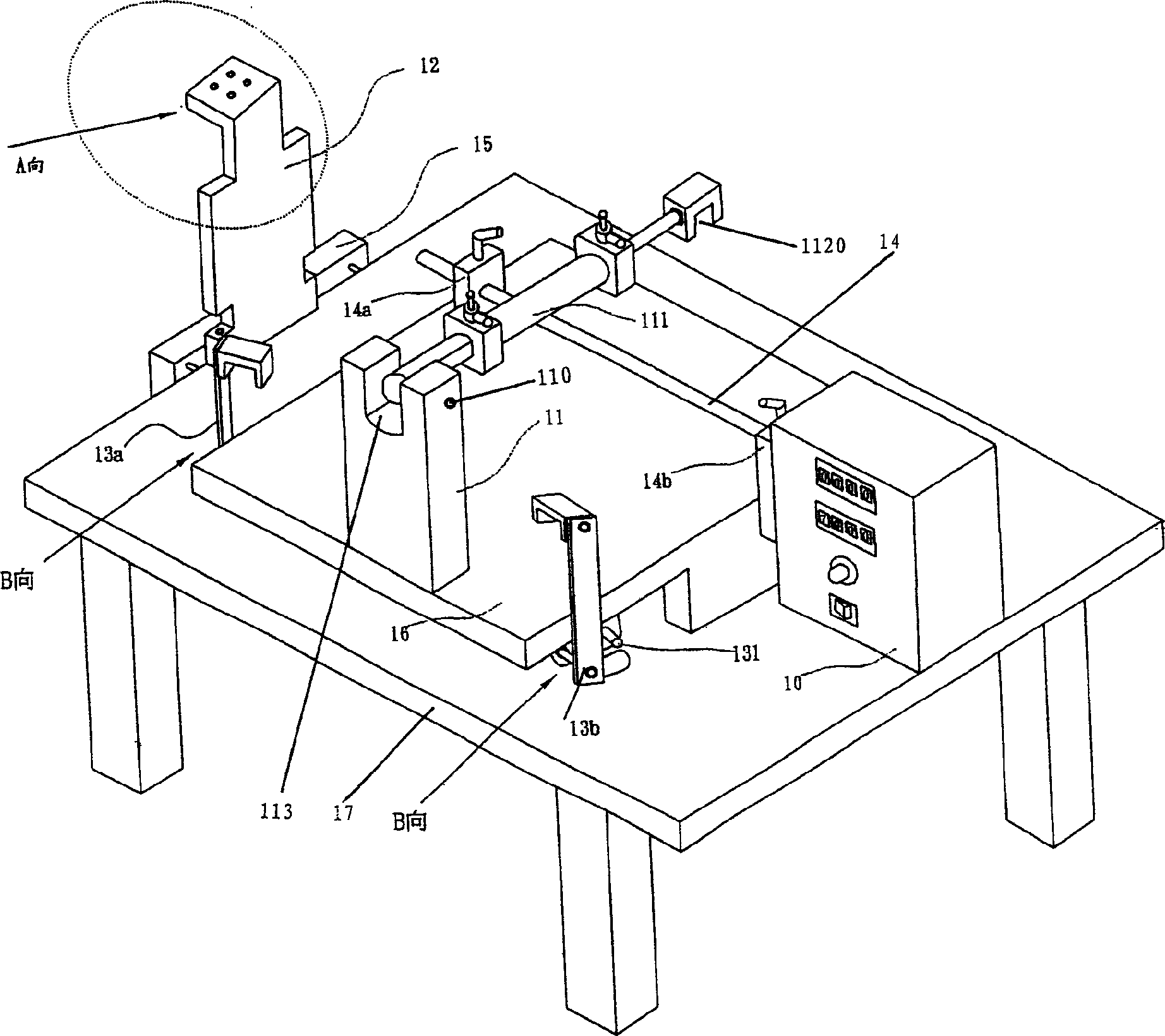

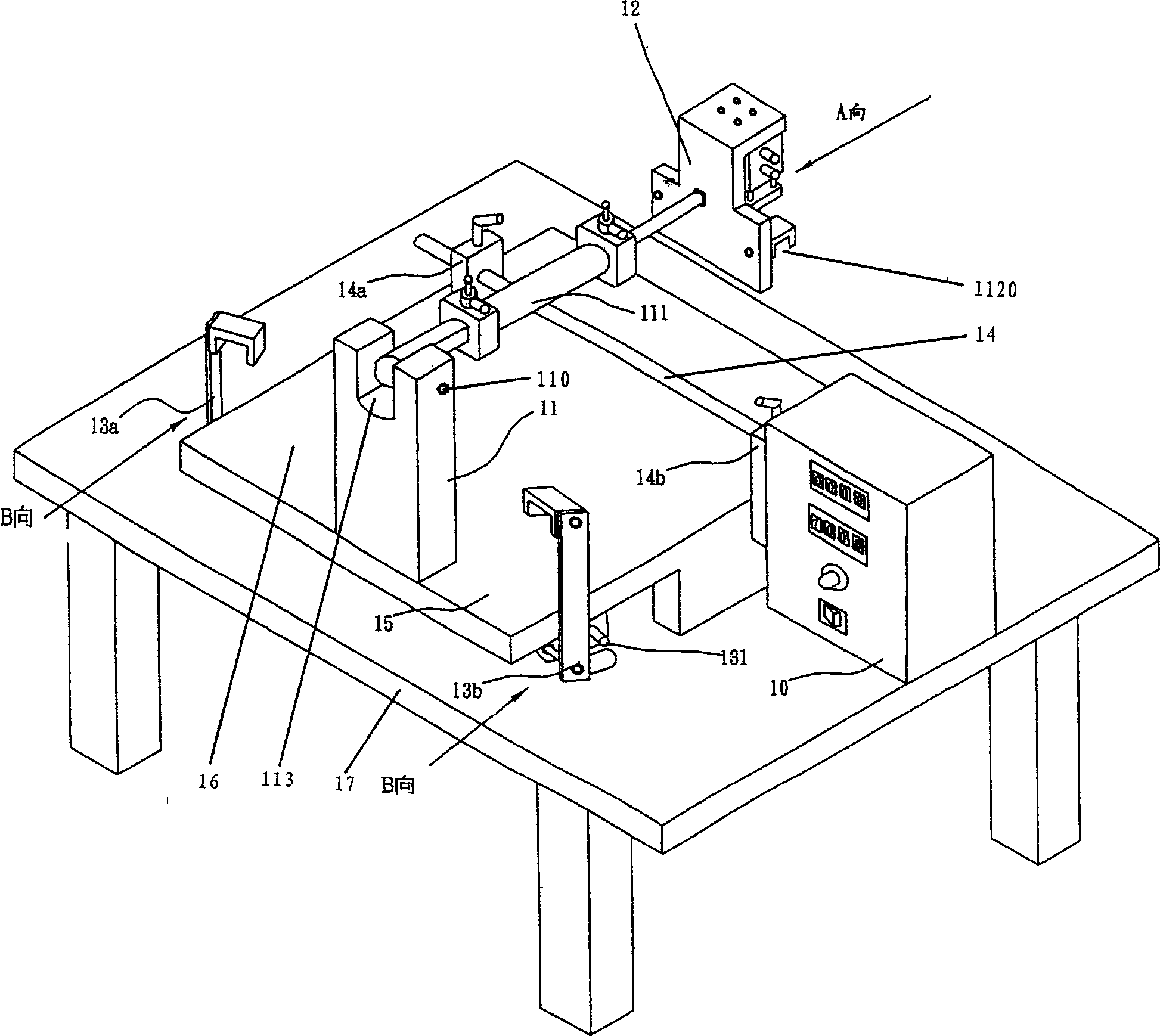

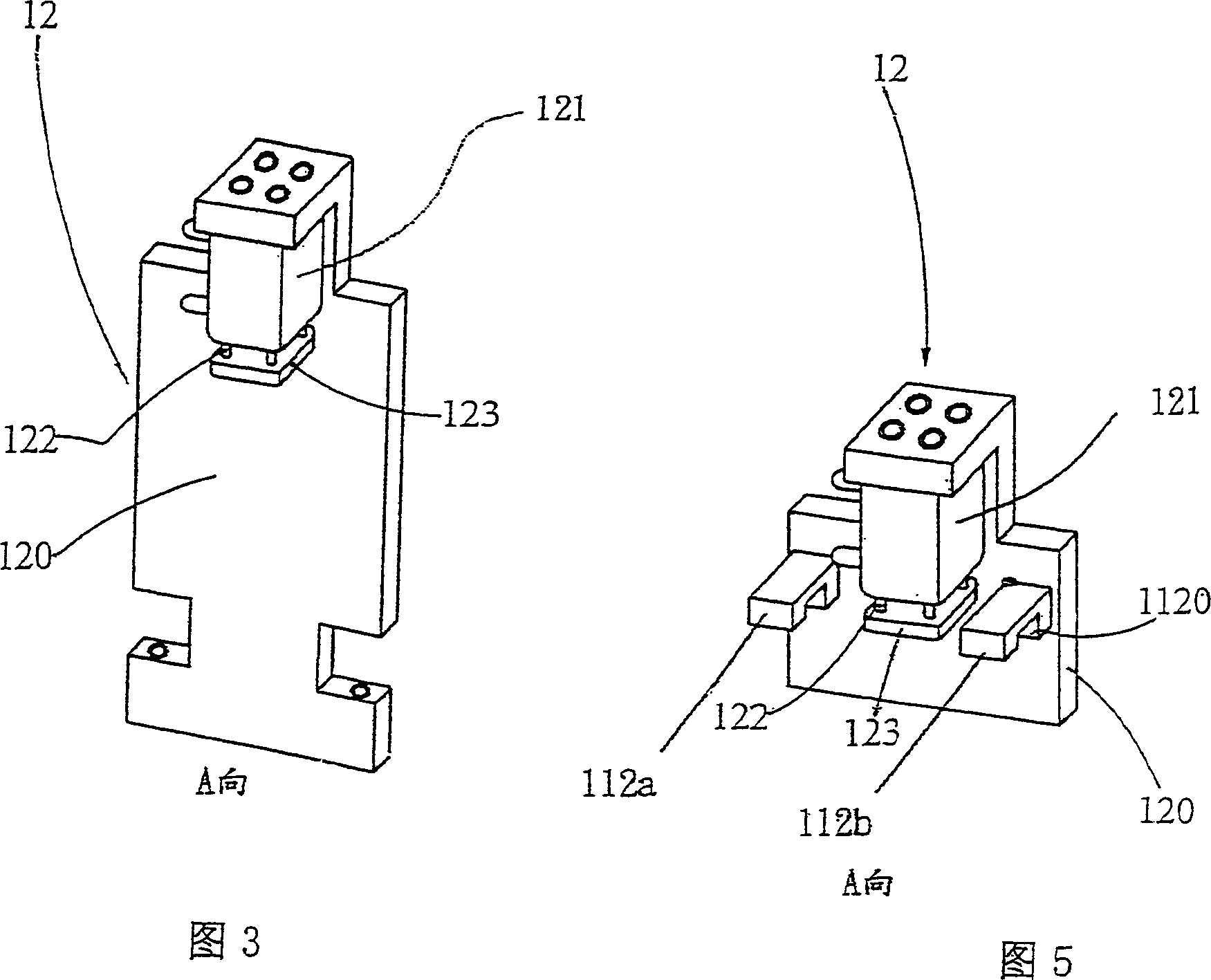

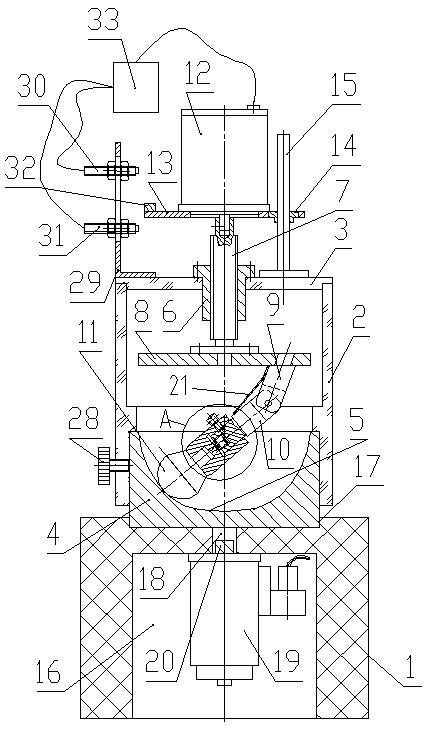

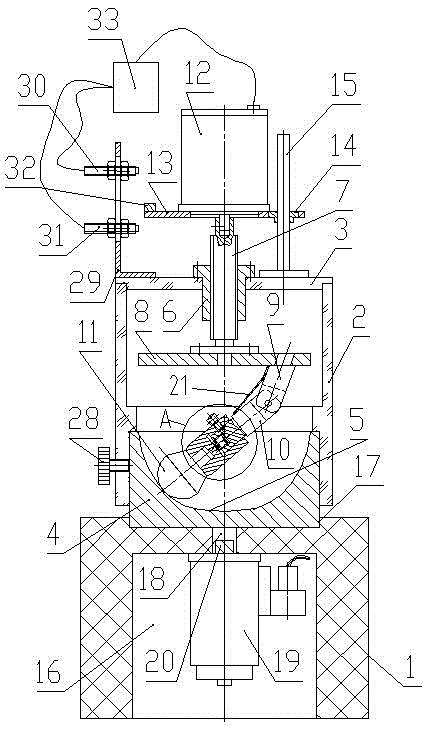

Comprehensive function test machine for children seat of car and test method thereof

The present invention relates to an integrated function testing method of child car chair and its testing machine. Said testing machine includes working table, on its intermediate table surface a supporting table is mounted, its front end is connected with supporting seat, the upper end of the supporting seat is connected with cylinder, and two sides of the supporting table of the testing machine are respectively equipped with symmetrically mounted fixing devices which are perpendicular to the cylinder for fixing bars, and in the interior of hollow cavities formed from two side supporting tables of front end of the supporting table and working table the table-cup function durability testing devices are respectively and symmetrically mounted, on the proper position of working table a head and back function durability testing device and electric control box and mounted.

Owner:WONDERLAND NURSERYGOODS CO LTD

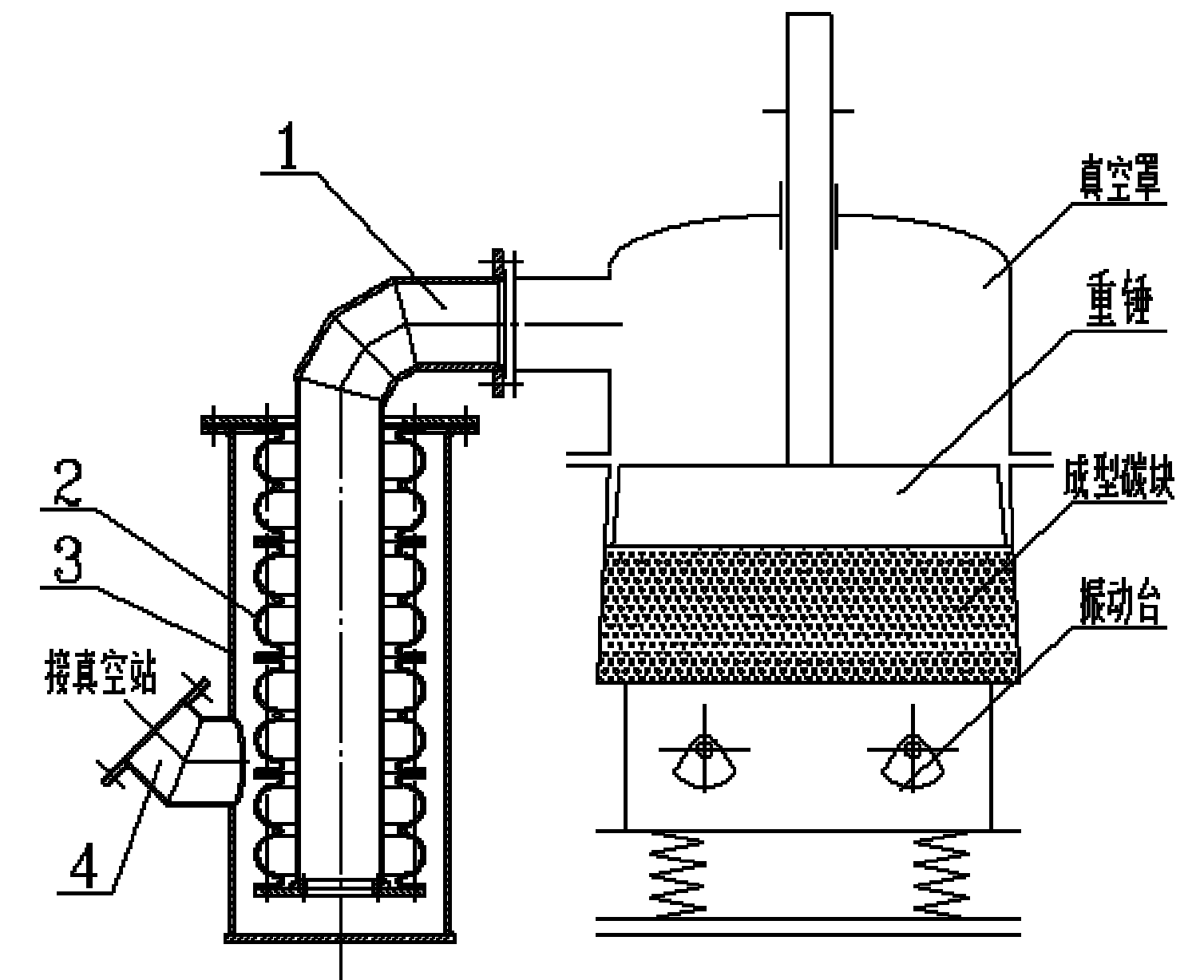

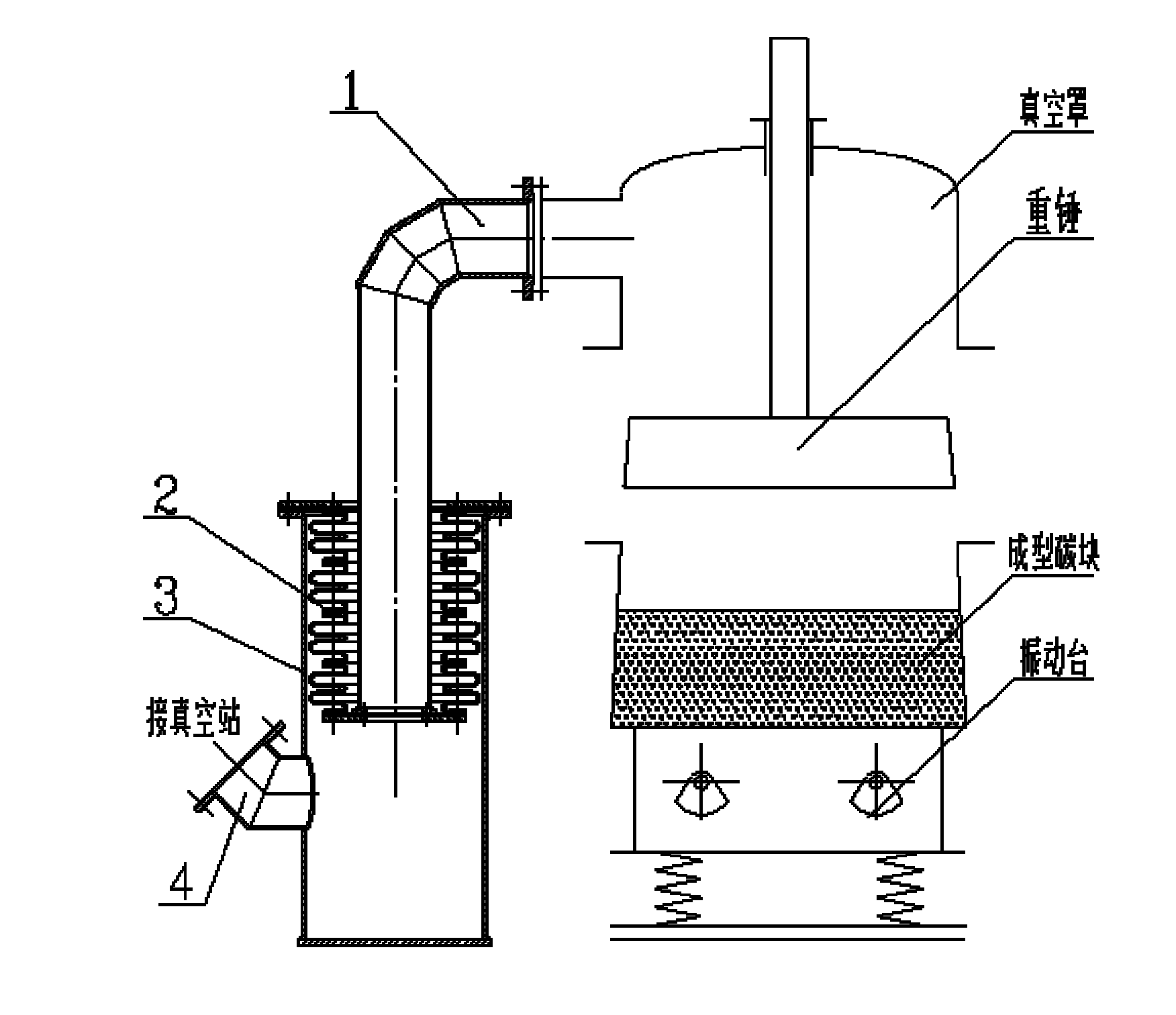

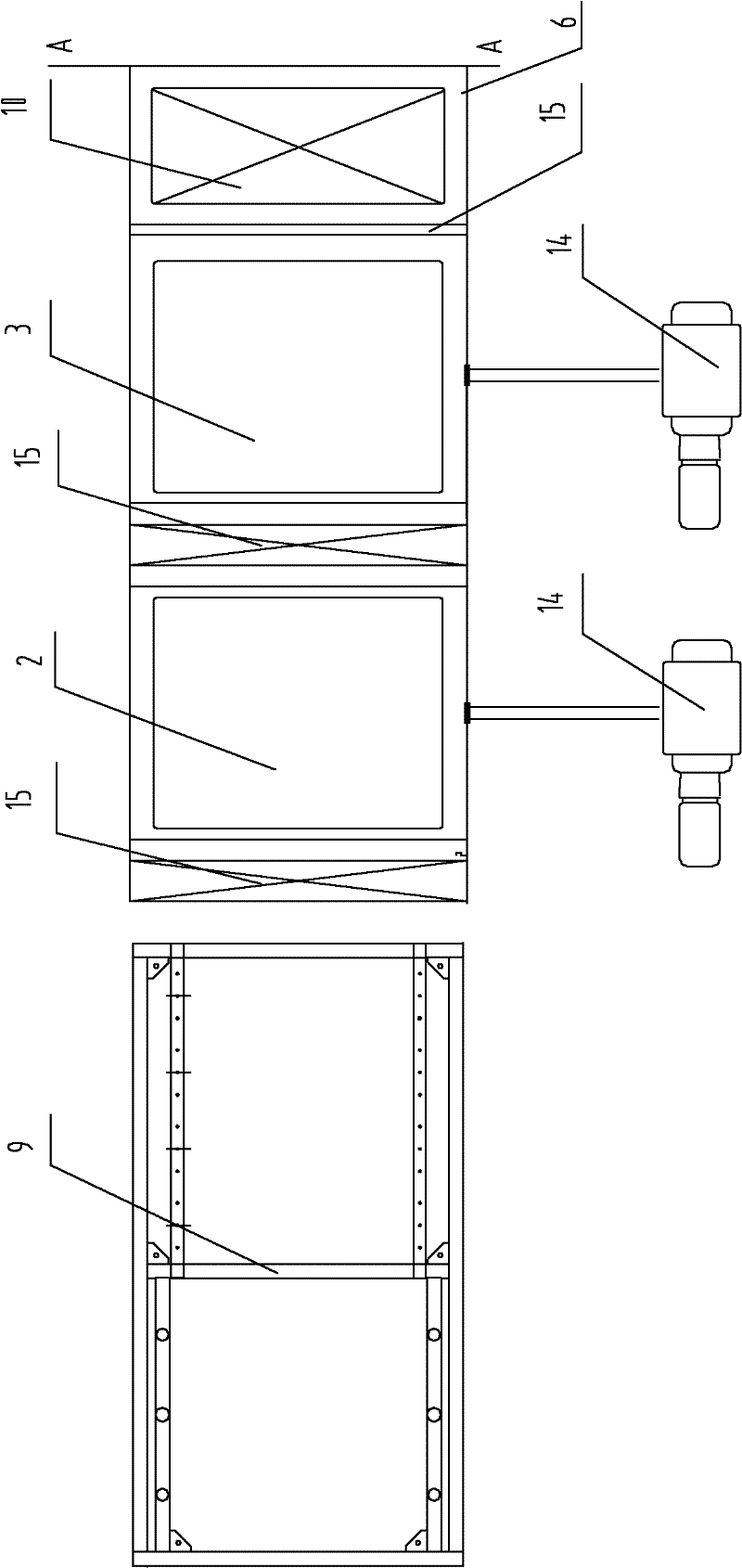

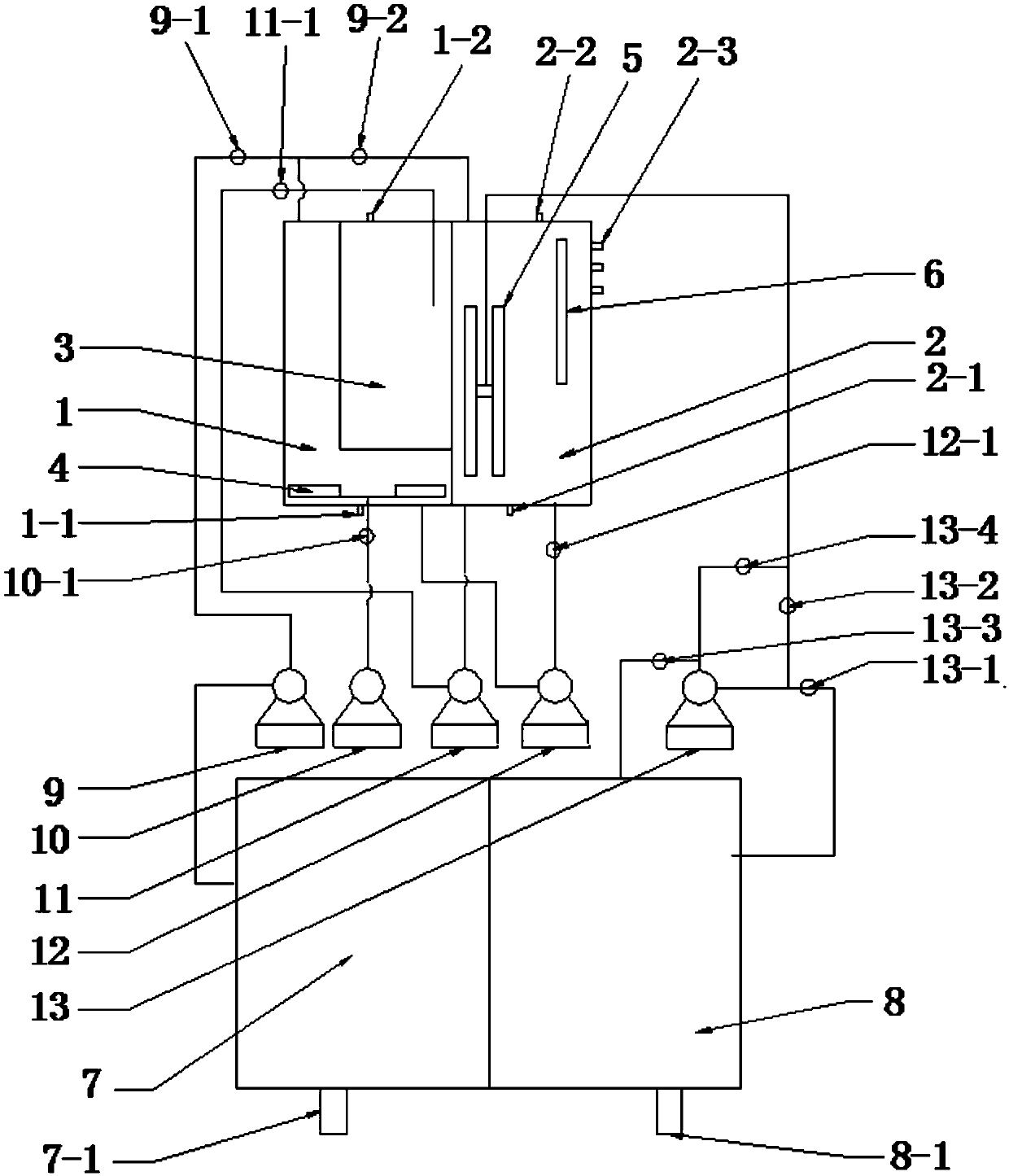

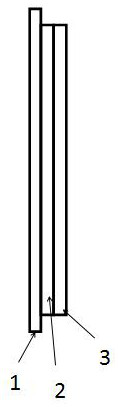

Flexible structure for vacuum-pumping system of vibratory forming machine

ActiveCN102059732AMeet working conditionsSimple structurePipe elementsCeramic shaping apparatusVacuum pumpingWhole body

The invention discloses a flexible structure for a vacuum-pumping system of a vibratory forming machine used in electrolytic aluminum production. The flexible structure is characterized in that one end of an inner pipe (1) is connected with a vacuum cover on a vibrating table; the other end of the inner pipe is connected with the bottom of a gasbag group (2) after passing through the inner cavityof the gasbag group (2); the whole body of the gasbag group (2) is arranged in an outer housing (3); the top of the gasbag group (2) is connected with the inner side of the top of the outer housing (3); a connecting pipe (4) is arranged on the outer housing (3); and the outer housing (3) is connected with the machine frame or base of the vibratory forming machine. The flexible structure is simple, has low manufacturing cost, and can satisfy the working condition requirement of the vacuum-pumping system of the vibratory forming machine, thereby solving the technical obstacle of retrofitting a vacuum-pumping system to a domestic vibratory forming machine and filling the gap of domestic technology in the link.

Owner:SUNSTONE DEV

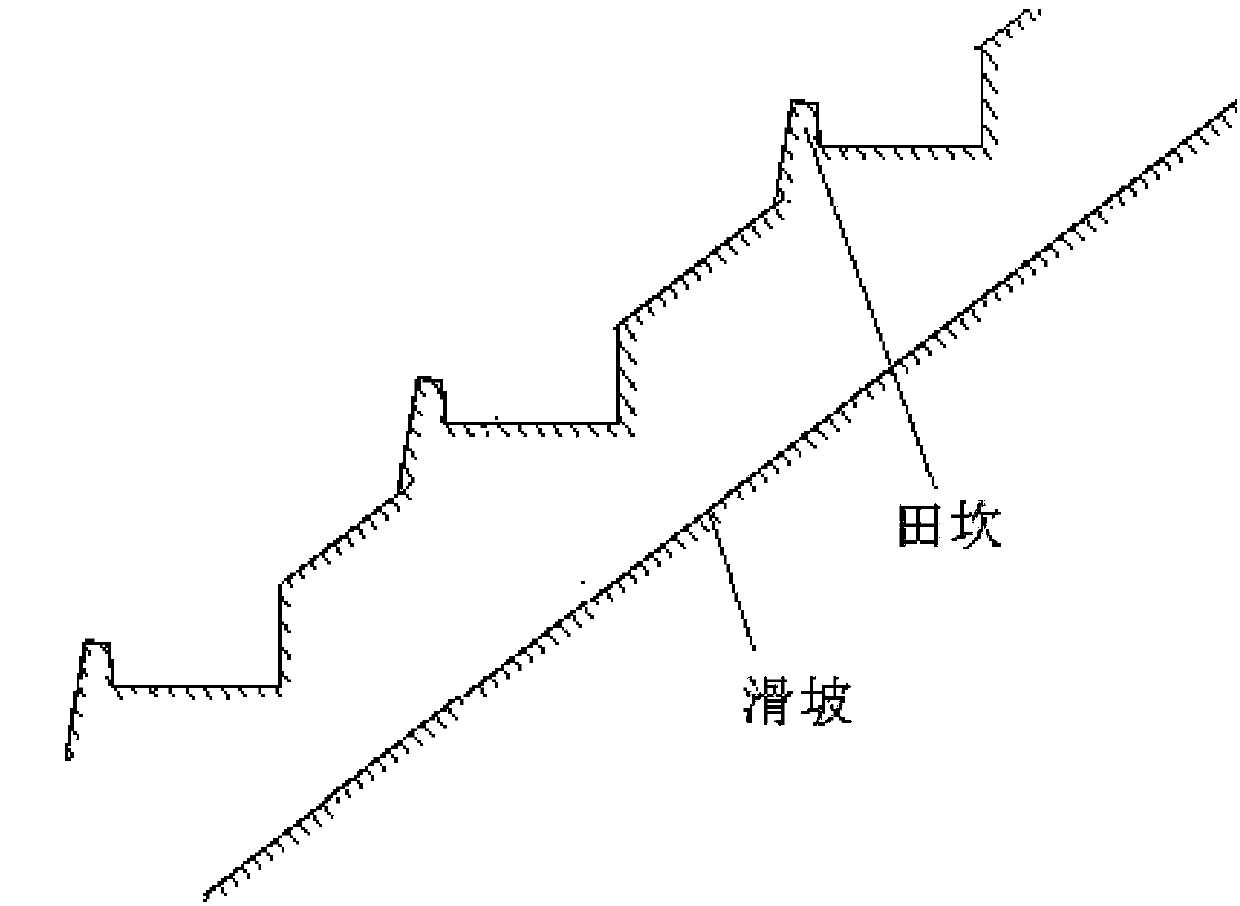

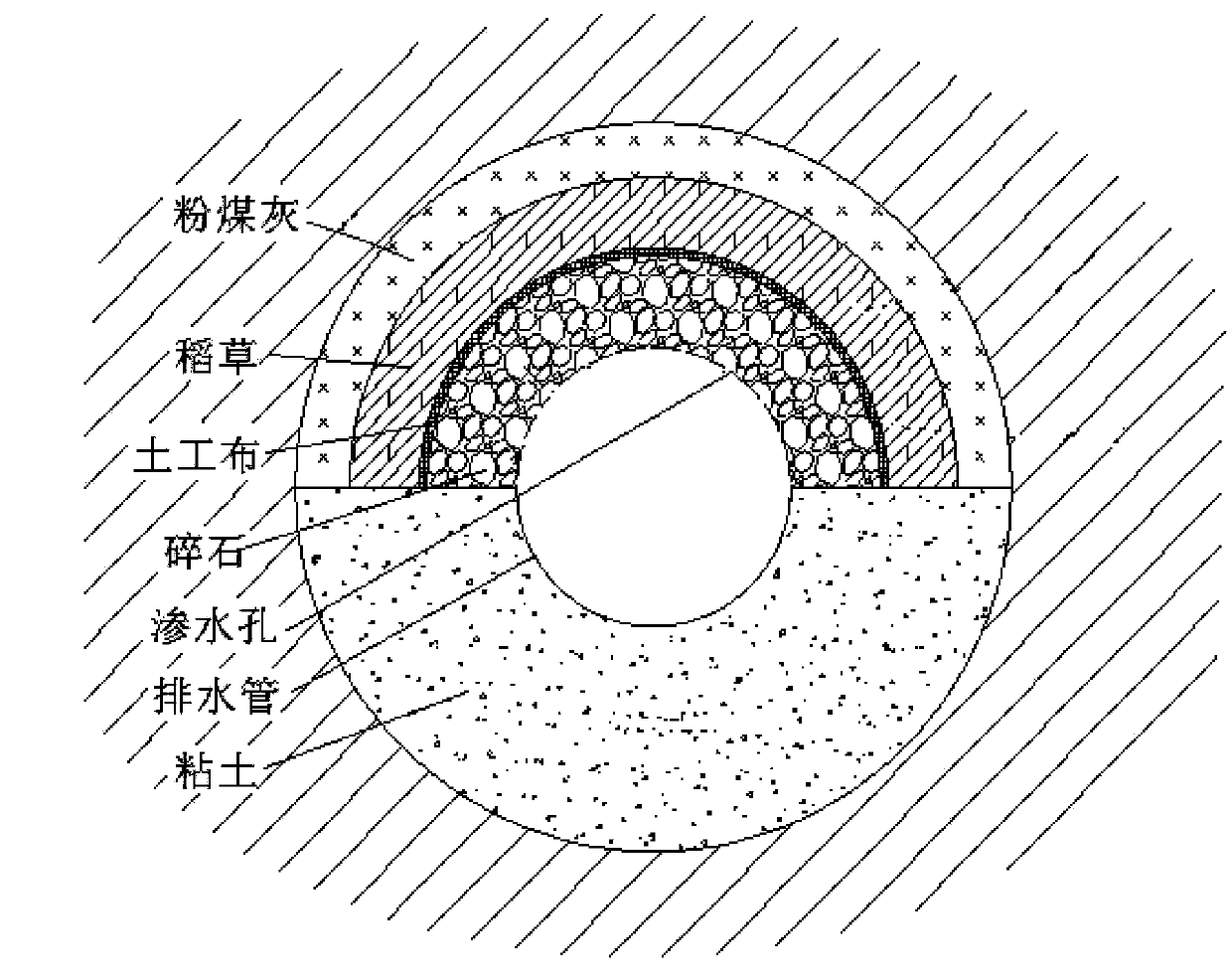

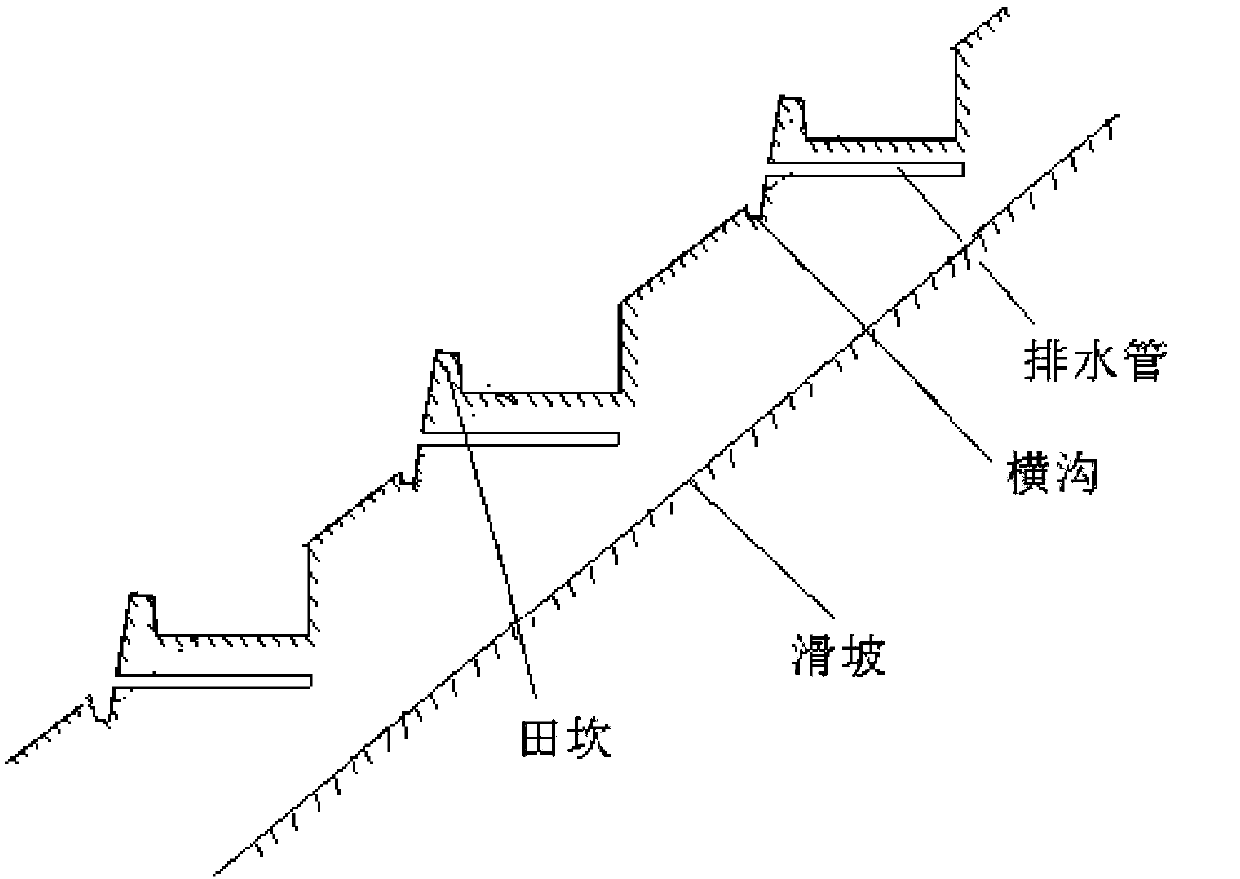

Method for eliminating landslide mass area terrace interflow

InactiveCN103898884AOvercoming technical hurdlesReduce churnConstructionsSoil drainageLandslideCrushed stone

The invention provides a method for eliminating landslide mass area terrace interflow. The method includes the following steps: a, excavating a drainage ditch on a terrace; b, laying a layer of clay in the drainage ditch; c, placing a drainage pipe with water seepage holes uniformly arranged on the peripheral wall by 180 degrees in the drainage pipe, enabling a face with the water seepage holes to be upward and a portion without the water seepage holes to be buried in the clay, and compacting the clay; d, laying a layer of gravel of 8-13cm in thickness on an upper half of the drainage pipe, and laying geotechnic cloth to wrap the gravel; e, laying a layer of straw and fly ash; f, backfilling soil and hierarchically compacting to be flat; arranging a transverse furrow along a ridge of a previous step of the terrace in each step of the terrace. By the method, surface water seeping in the landslide mass area terrace and interflow formed by the surface water can be effectively eliminated, so that technical obstacles when a landslide area is reclaimed to be a terrace are overcome. The method has the advantages of being low in cost, simple, convenient, high in efficiency, easy in operation and the like, and is convenient for large-scale popularization and use.

Owner:CHONGQING INST OF GEOLOGY & MINERAL RESOURCES

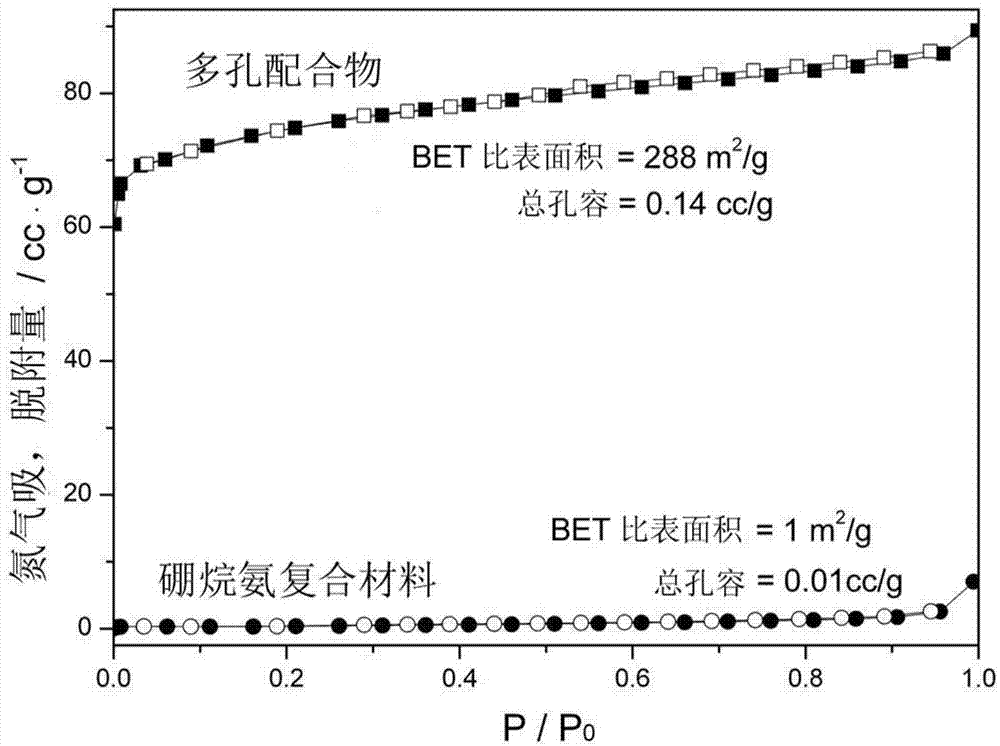

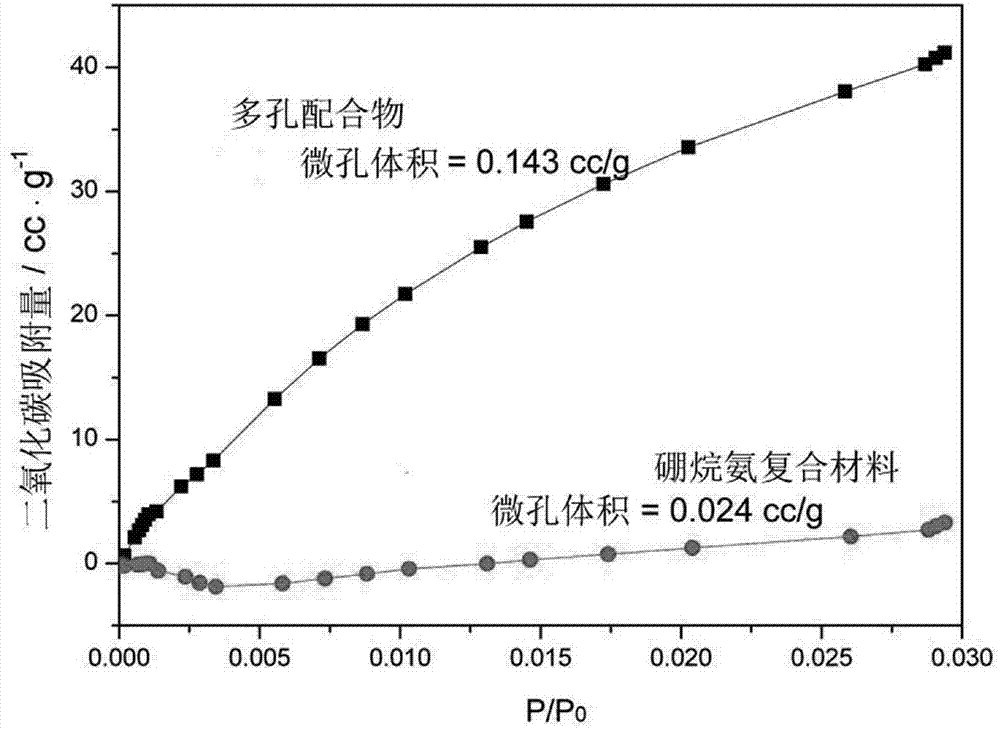

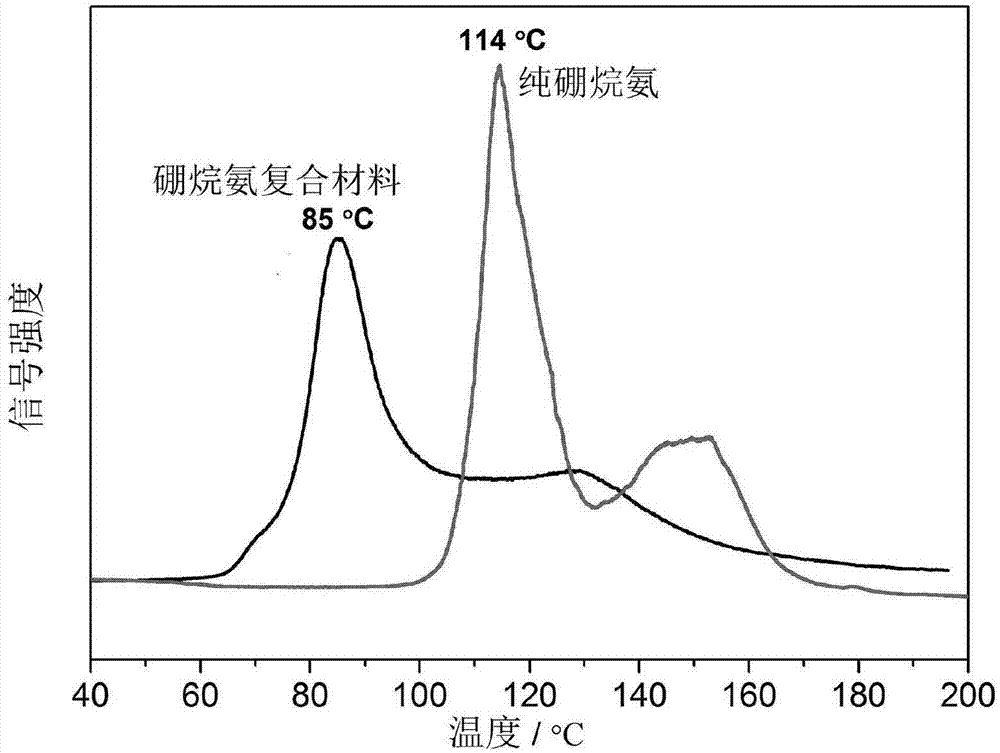

Ammonia borane composite hydrogen storage material and preparation method thereof

InactiveCN103613068AImprove thermal decomposition hydrogen release performancePerfect Applied ResearchHydrogen productionNew energySource material

The invention belongs to the technical field of storage and transportation of a new energy source namely hydrogen energy, and in particular relates to an ammonia borane composite hydrogen storage material and a preparation method thereof. The ammonia borane composite hydrogen storage material is prepared by loading ammonia borane into a porous coordination polymer by adopting an impregnation method. The composite material disclosed by the invention reduces the thermal decomposition hydrogen release temperature of ammonia borane, accelerates hydrogen release kinetics, avoids generation of volatile byproducts, solves technical obstacles for taking ammonia borane as a hydrogen source material, and provides probability of applying a hydrogen energy source to vehicles and industries. Meanwhile, the preparation method is simple and feasible, low in cost and good in effect.

Owner:HENAN POLYTECHNIC UNIV

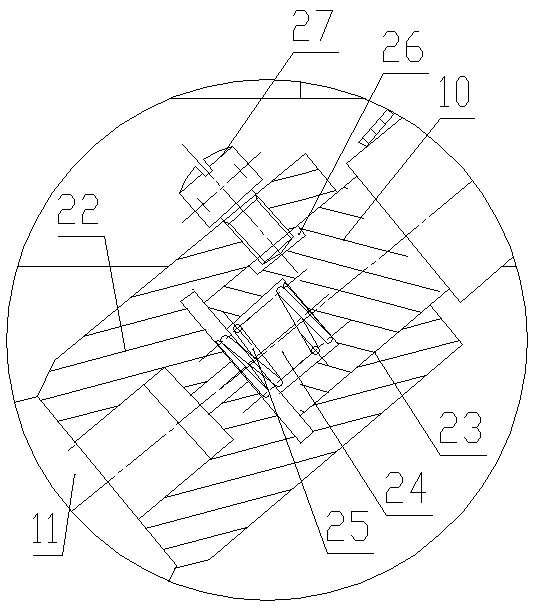

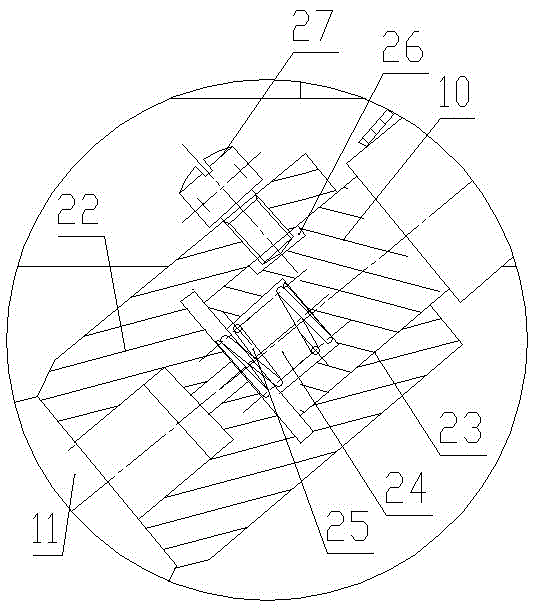

Automatic grinding and mixing device for ultrahard material

ActiveCN103301918ASimple structureSimple and efficient operationGrain treatmentsEngineeringBoron nitride

The invention discloses an automatic grinding and mixing device for an ultrahard material. The automatic grinding and mixing device comprises a base and a supporting barrel, wherein a cover plate is arranged at the top of the supporting barrel; a hard alloy mortar is arranged at the bottom of an inner cavity of the supporting barrel; a nut is arranged in the center of the cover plate; a screw rod is screwed in the nut; the bottom end of the screw rod extends into the supporting barrel and is connected with a rotary supporting plate; the rotary supporting plate is downwardly and fixedly connected with an upper hinge; the upper hinge is downwardly hinged with a lower hinge; the lower hinge is connected with a hard alloy grinding head; the top end of the screw rod extends out of the nut and is connected with a positive and negative rotation motor; the bottom of the positive and negative rotation motor is fixedly connected with a motor supporting plate; one side of the motor supporting plate is connected with a guide sleeve; an anti-rotation guide rod glidingly penetrates through a through hole of the guide sleeve; the bottom end of the anti-rotation guide rod is fixedly connected to the top of the cover plate. In short, the labor intensity of an worker can be reduced, an actual state of a manual grinding and mixing process can be automatically simulated, the defect of high material uniformity difference caused by the manual grinding and mixing process can be avoided, and the technical obstacle in producing high-quality diamond and cubic boron nitride polycrystalline composite sheets can be overcome.

Owner:ZHONGNAN DIAMOND CO LTD

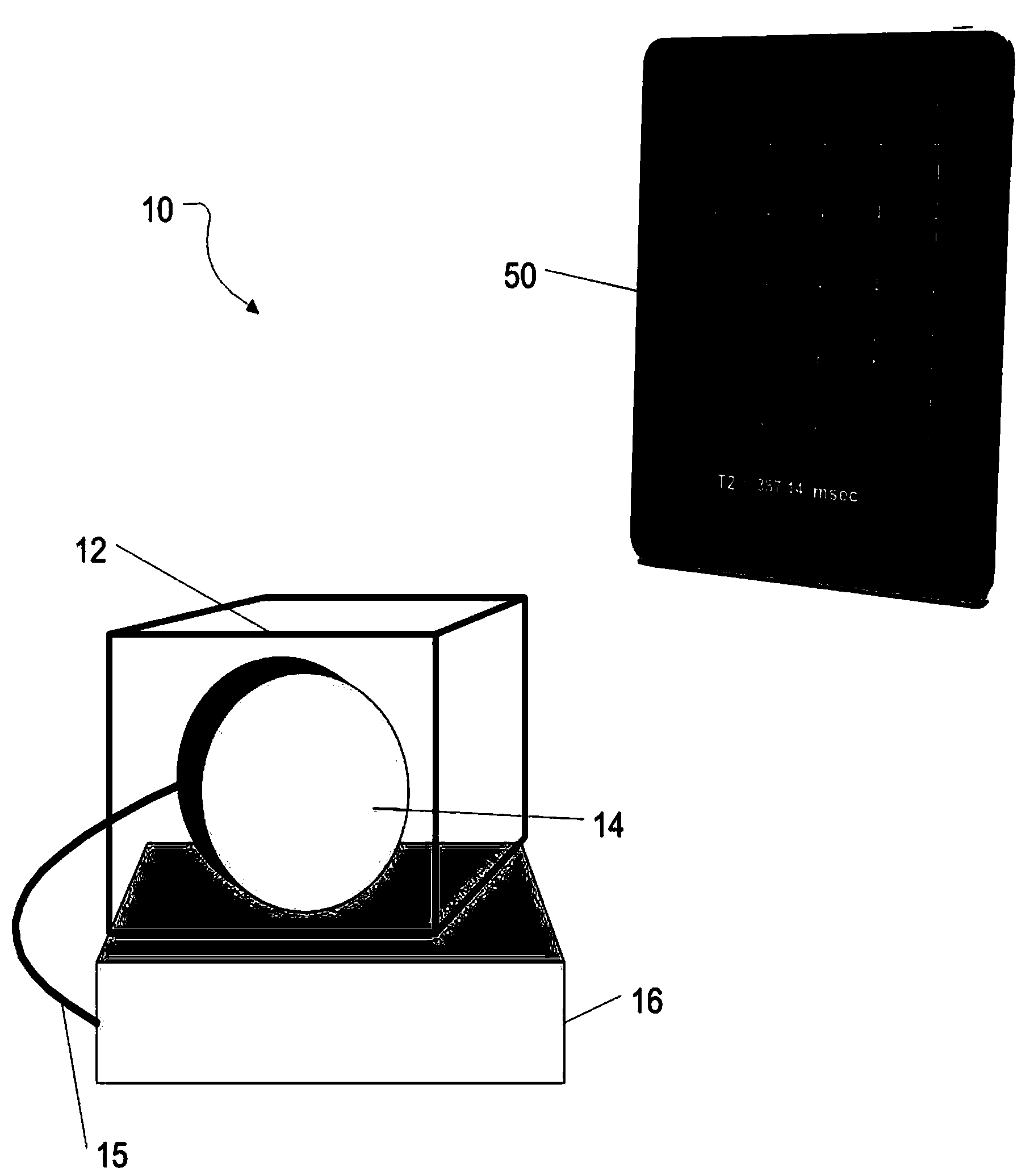

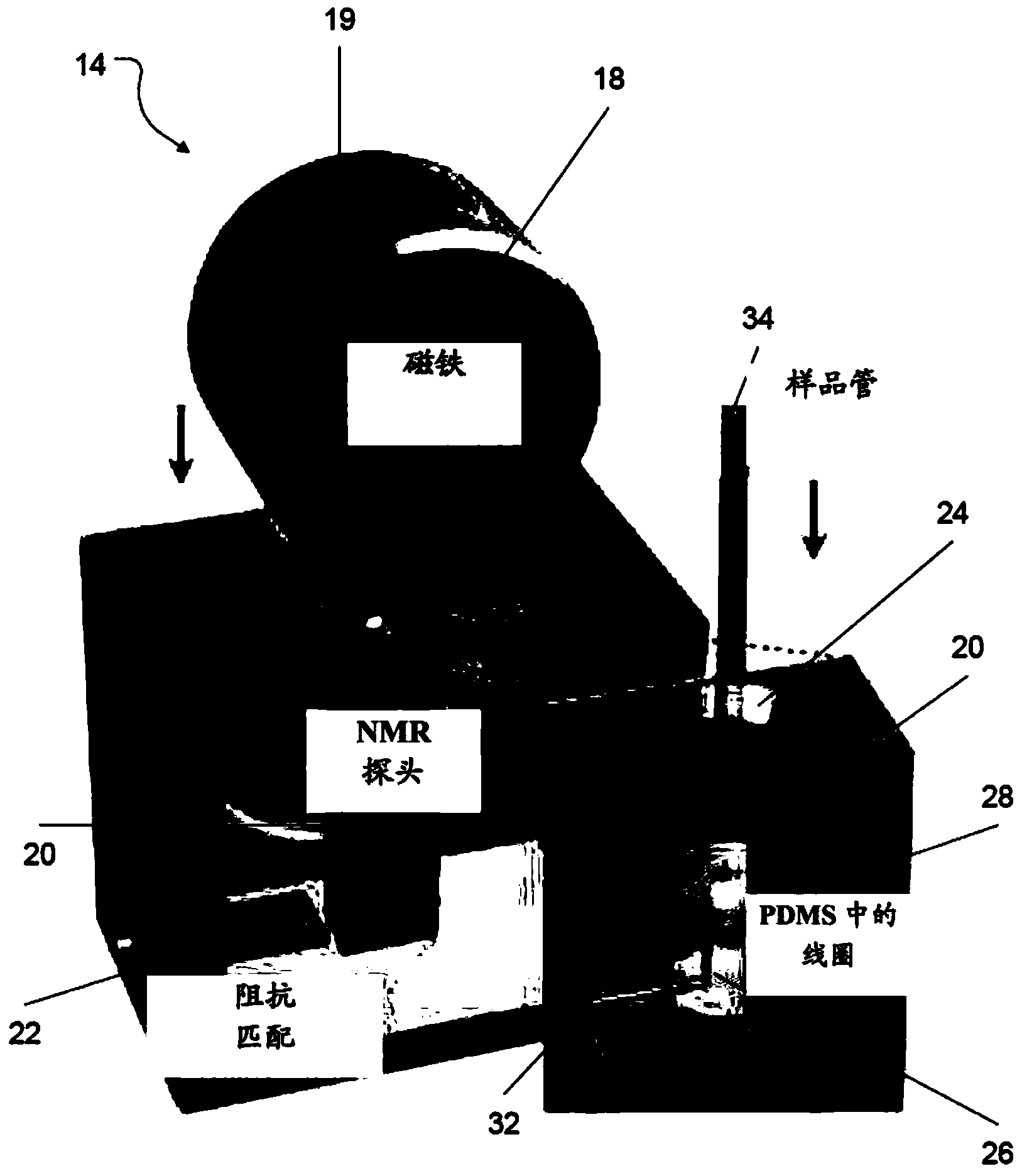

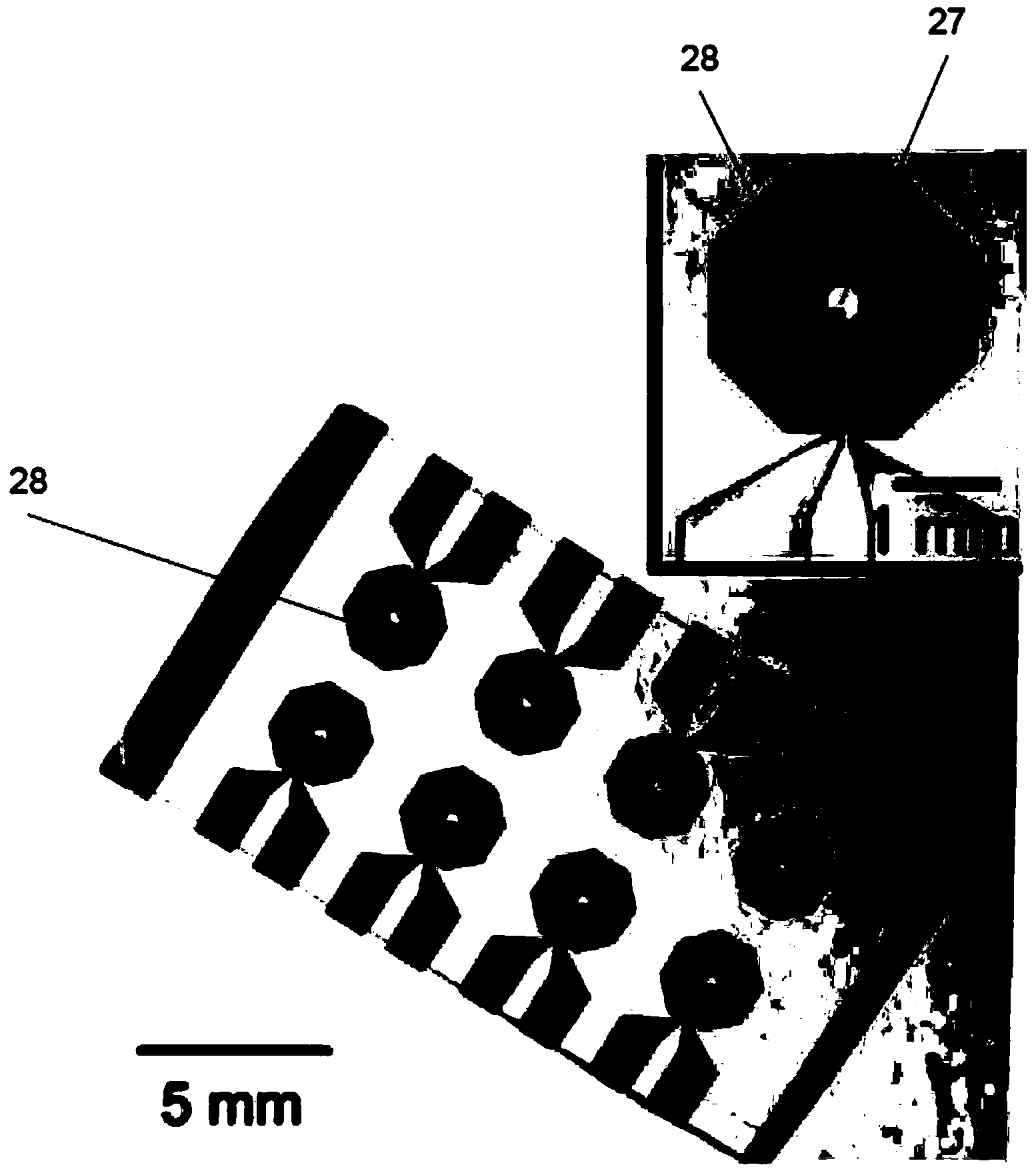

Detection of targets using magnetic resonance

InactiveCN103732136ANo input requiredReliable determinationMaterial analysis by optical meansDisease diagnosisResonance measurementNMR - Nuclear magnetic resonance

A portable magnetic resonance system includes a permanent magnet, a nuclear magnetic resonance probe, and control electronics. The control electronics are configured to transmit to the probe a magnetic resonance excitation signal having an excitation frequency f, receive from the probe a magnetic resonance measurement signal, detect in the magnetic resonance measurement signal a magnetic resonance frequency f0, and automatically adjust the excitation frequency f until the difference between the excitation frequency and the magnetic resonance frequency is approximately equal to a target offset.

Owner:THE GENERAL HOSPITAL CORP

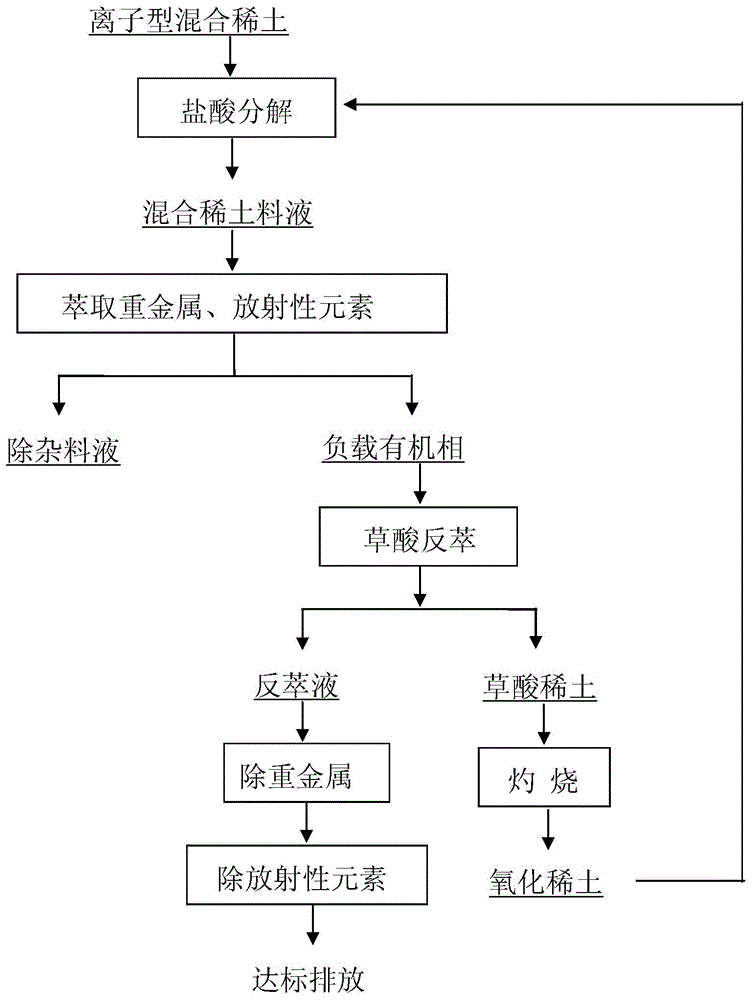

Method for removing heavy metals and radioactive elements in ionic type mixed rare earth material liquid

The invention relates to a method for removing heavy metals and radioactive elements in ionic type mixed rare earth material liquid. The method is characterized by comprising the following steps: performing acid decomposition on ionic mixed rare earth to form the ionic mixed rare earth material liquid; performing extraction and separation by using an ammonia-free saponified organic extracting agent and the ionic mixed rare earth material liquid, wherein the heavy metals and the radioactive elements are extracted into an organic phase, and the rare earth material liquid after impurity removal is in a water phase; performing back extraction on a loaded organic phase, so that the heavy metals, the radioactive element and other impurities in the loaded organic phase and a small quantity of extracted rare earth are all subjected to back extraction; removing the heavy metals and the radioactive elements in back extraction liquid by adding a heavy metal, uranium and thorium removing agent, so that wastewater after impurity removal reaches the standard to be discharged. According to the method provided by the invention, the contents of the heavy metals and the radioactive elements are reduced from a source, so that the follow-up sewage heavy metal and radioactive element treatment procedures are omitted, the sewage treatment cost is reduced, and meanwhile, sewage is discharged after reaching the standard.

Owner:GANZHOU NONFERROUS METALLURGICAL RES INST

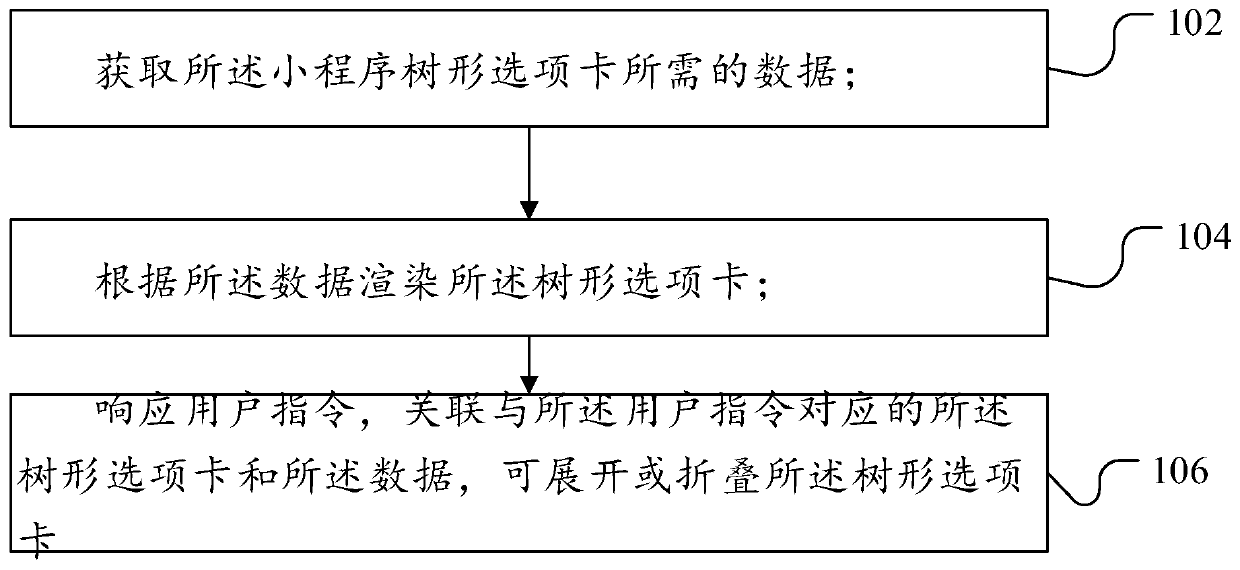

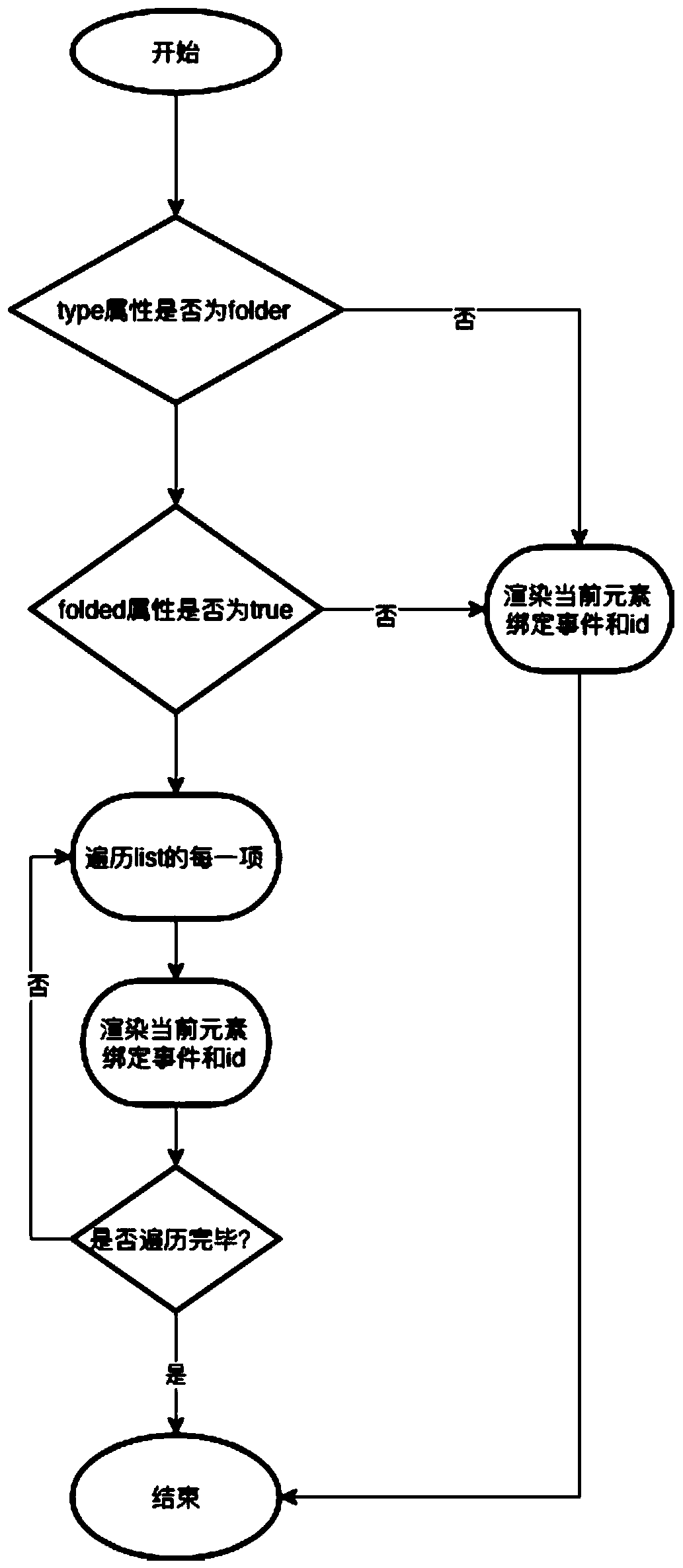

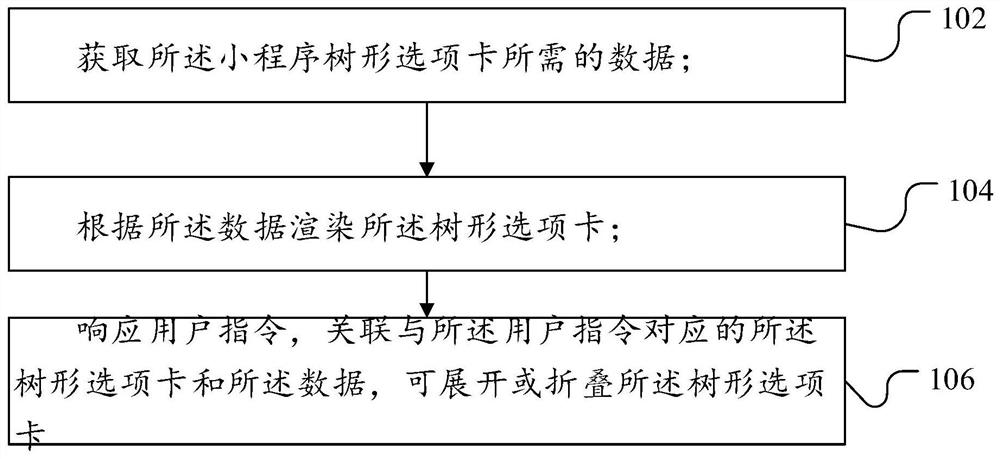

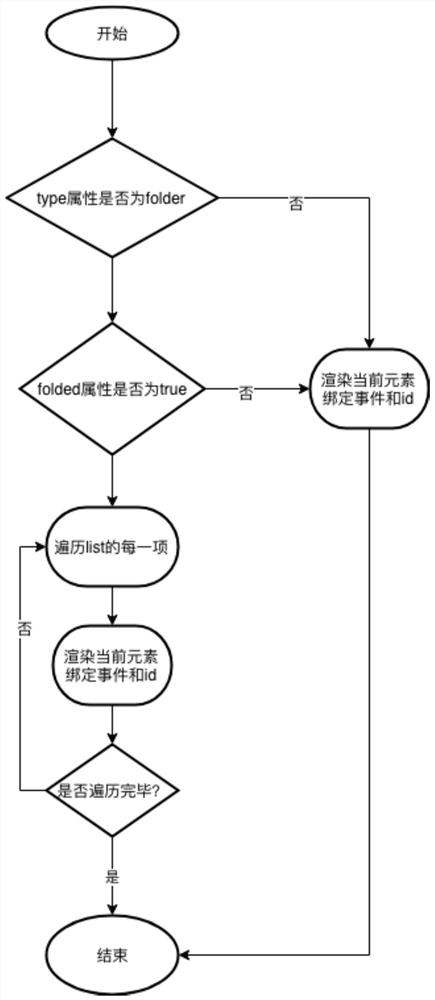

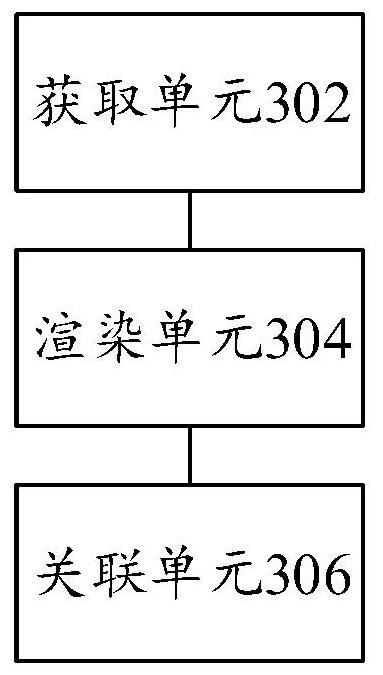

Implementation method and device of mini-program tab, electronic equipment and medium

ActiveCN109814778AImprove experienceMeet needsExecution for user interfacesInput/output processes for data processingUser needsTree shaped

The invention provides a method for realizing a mini-program tab. The method comprises the following steps: acquiring data of a tree-shaped tab of a mini-program; rendering the tree-shaped tab according to the data; responding to a user instruction, associating the tree-shaped tab corresponding to the user instruction with the data, and unfolding or folding the tree-shaped tab. According to the embodiment of the invention, the technical index for managing the applet by adopting the tree-shaped tab is improved; According to the technical scheme, the small program can be managed in a tree tab mode, the technical obstacle of an original assembly is overcome, the user experience is enhanced, and therefore the small program not only meets the user requirement in the using function, but also ismore user-friendly in application management and convenient to operate, and the application value of the small program is improved.

Owner:SHANGHAI SUIXUNTONG ELECTRONICS TECH CO LTD

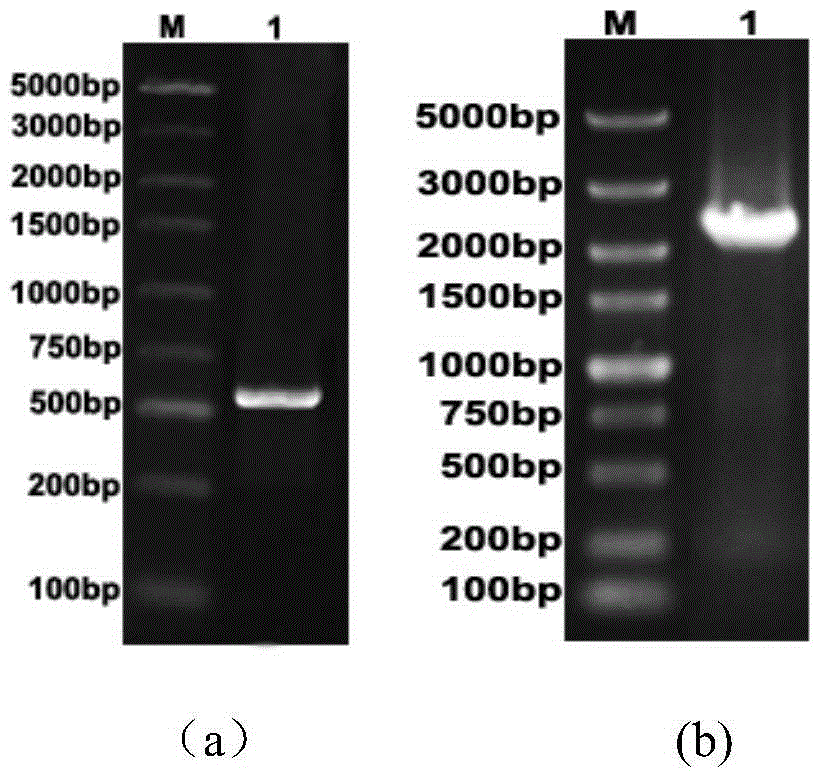

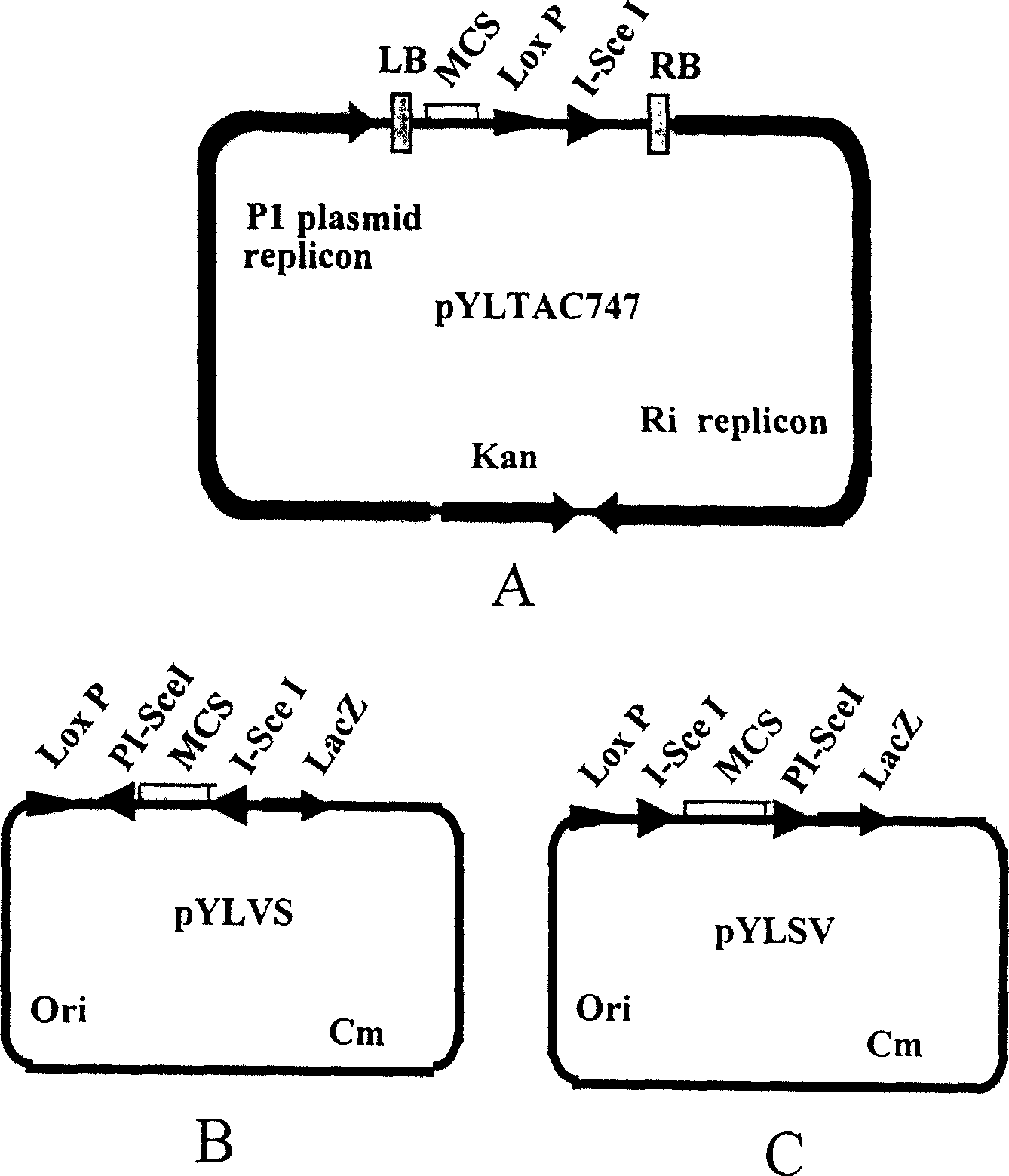

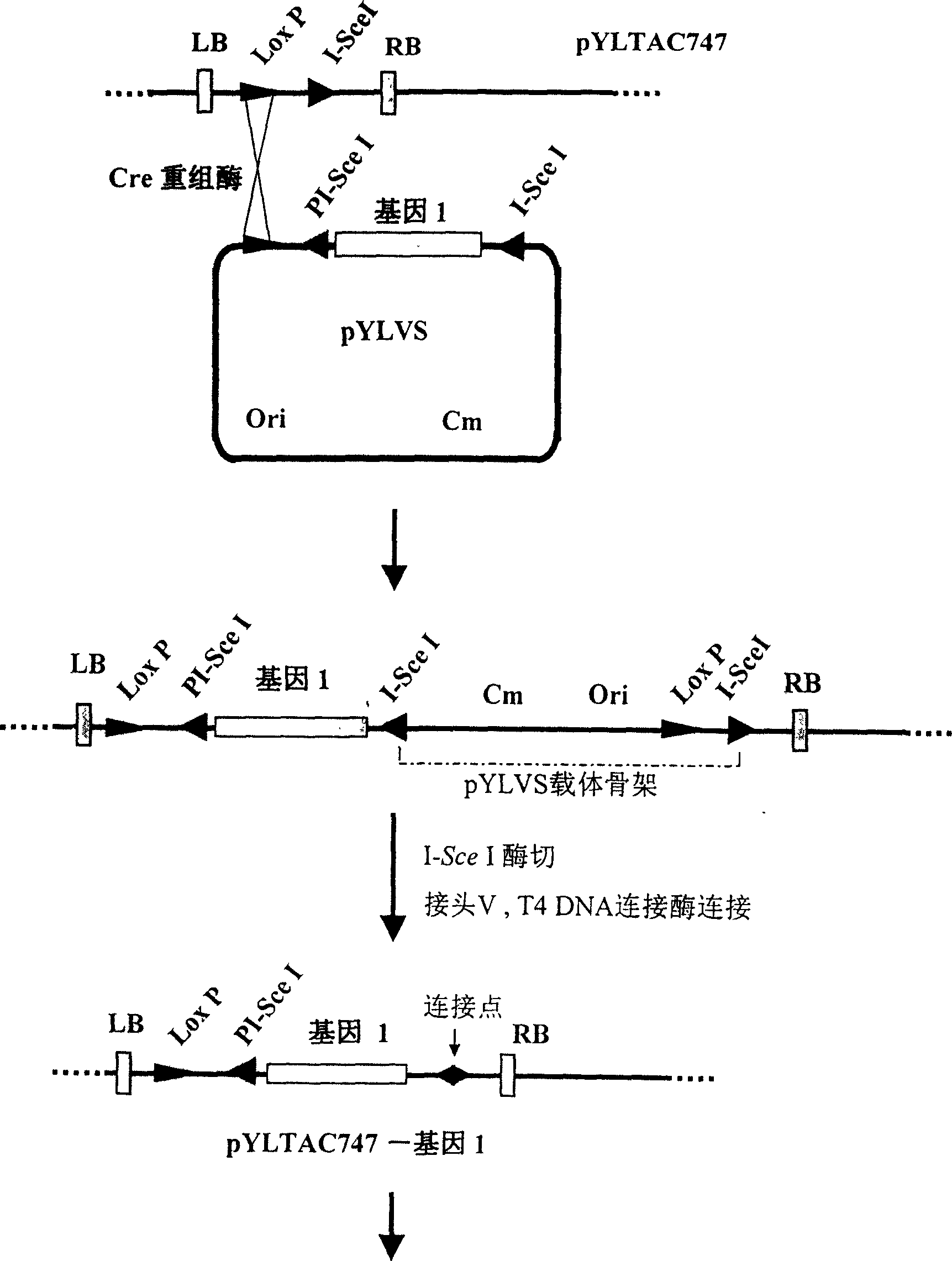

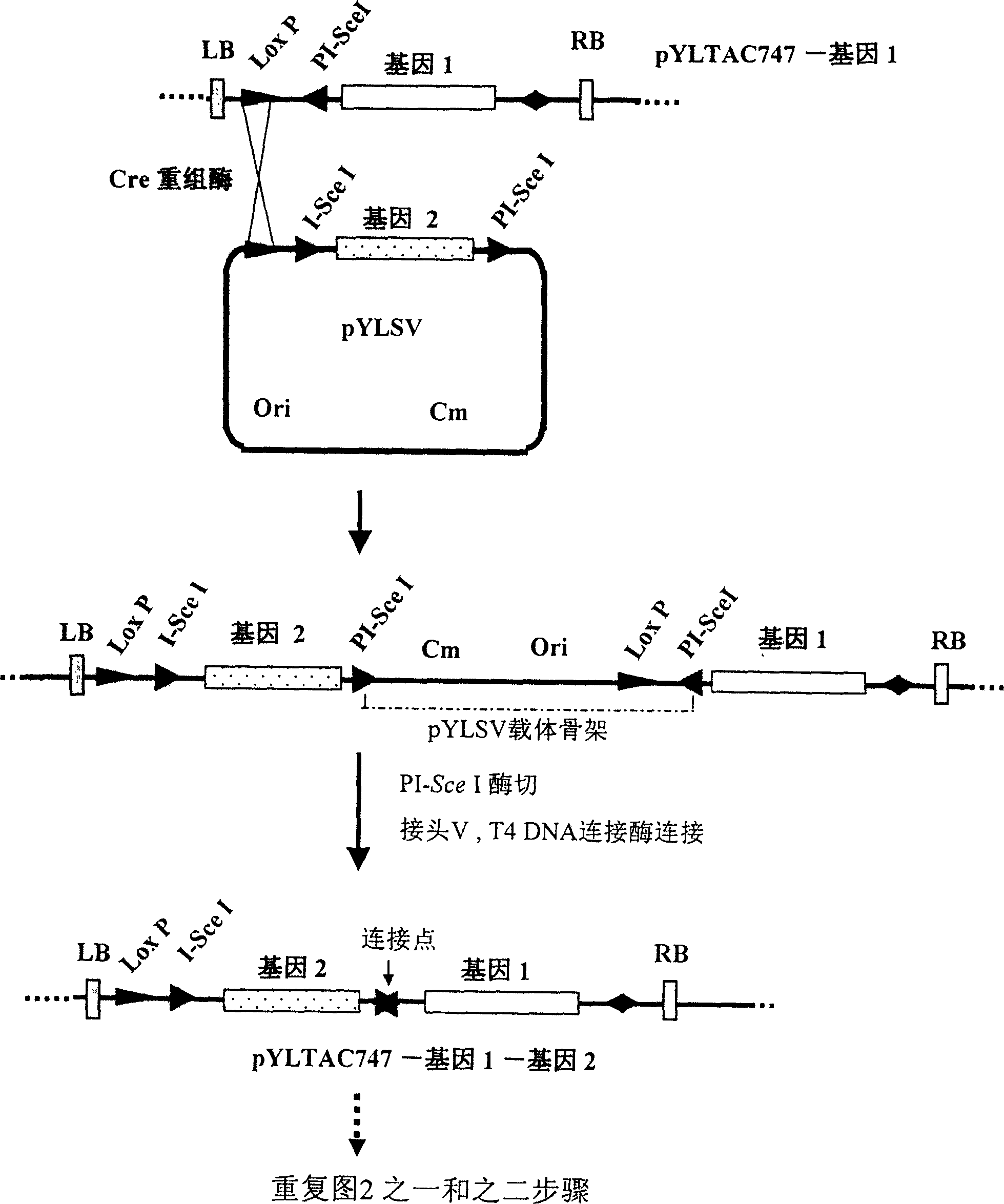

Construction method of multigene carrier and its application

InactiveCN1263860CEfficient assemblyOvercoming technical hurdlesVector-based foreign material introductionDNA preparationMultigene expressionGene assembly

A multi-gene carrier system is composed of a receptor carrier and at least two donor carriers, and is prepared by altermative gene assemblings with the said carriers. It can be used for conversion of multiple genes to obtain different genetically engineered products and multi-gene expression characteristics.

Owner:SOUTH CHINA AGRI UNIV

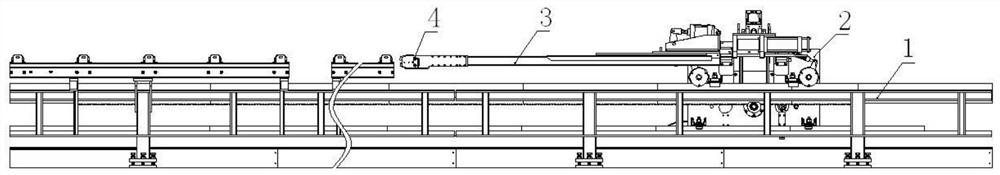

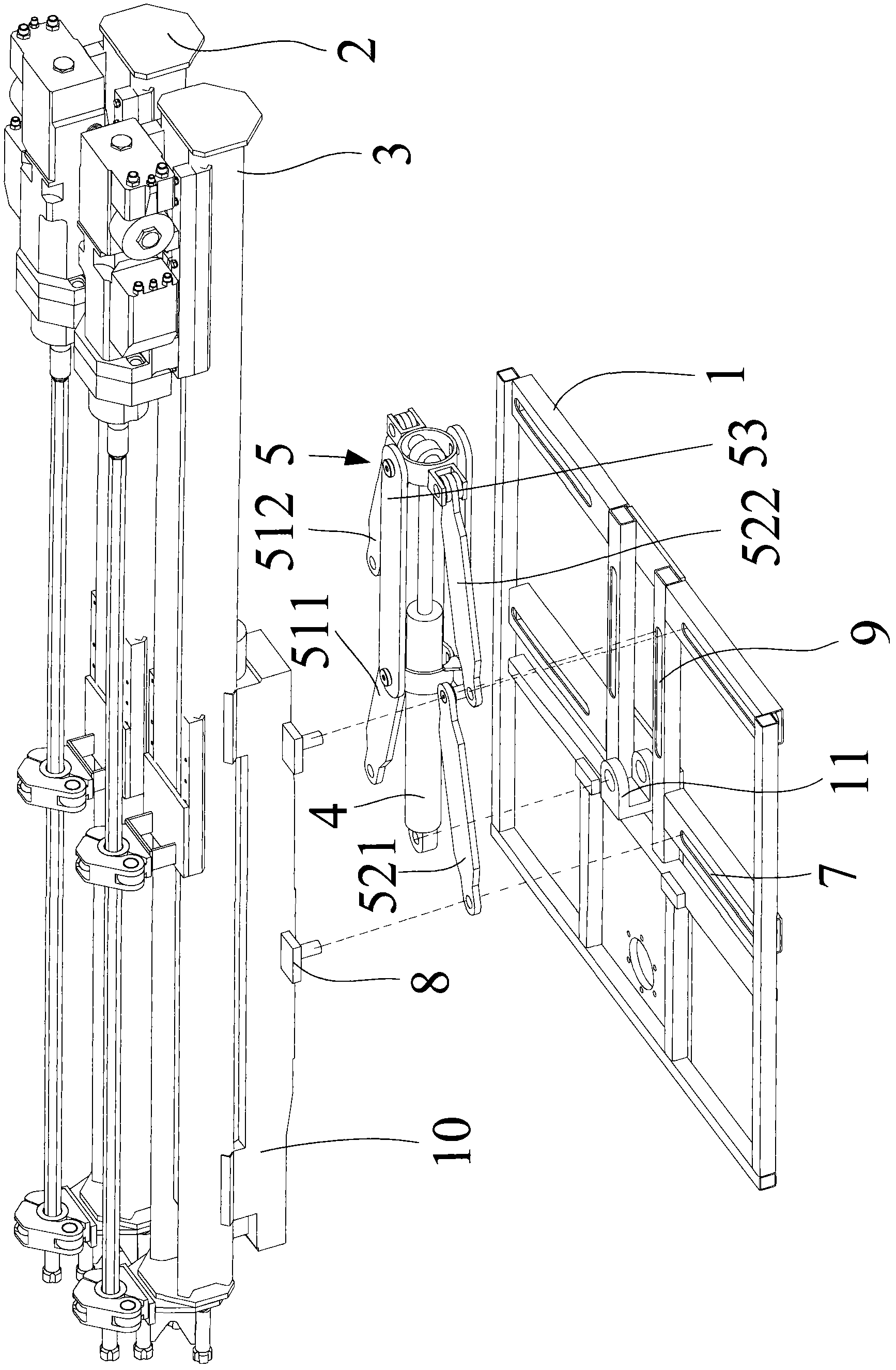

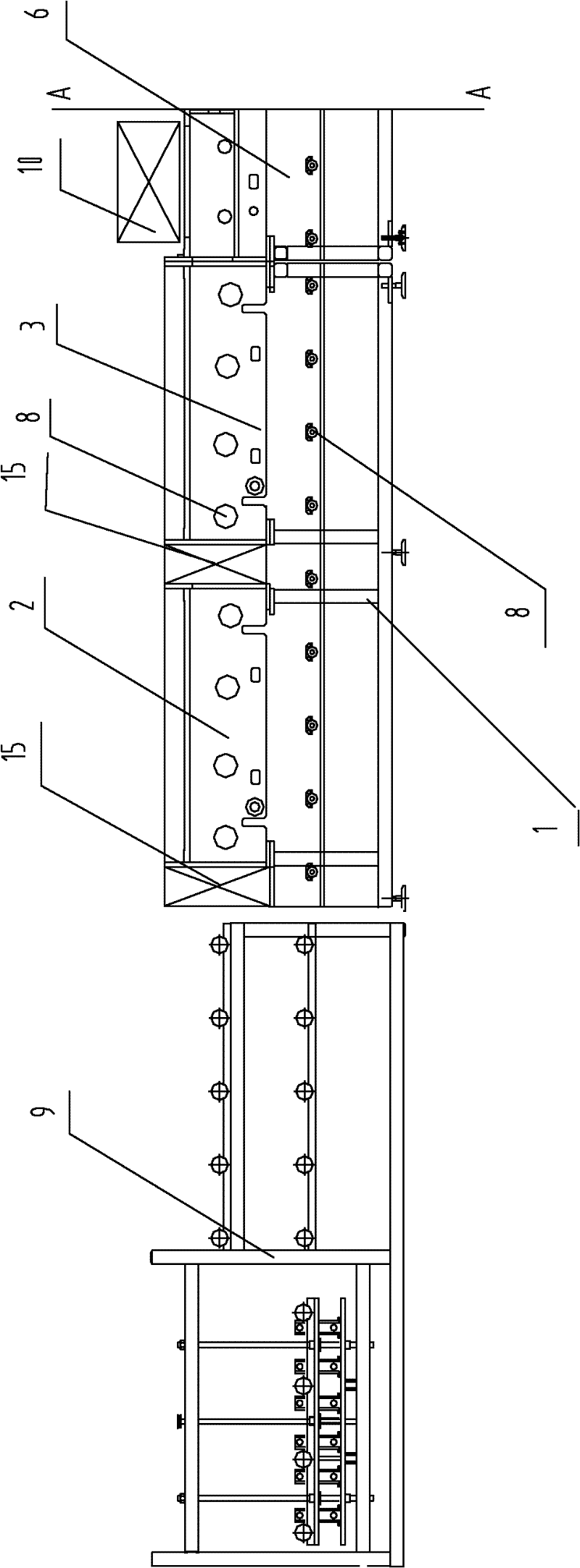

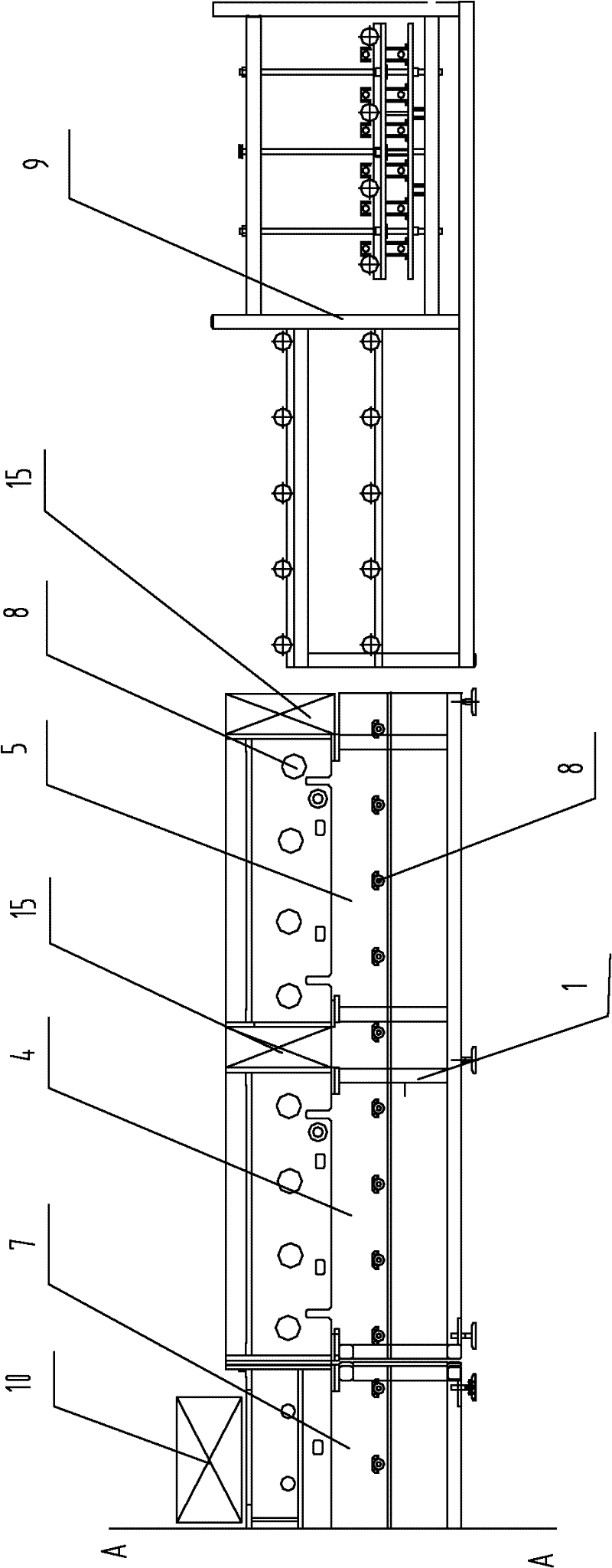

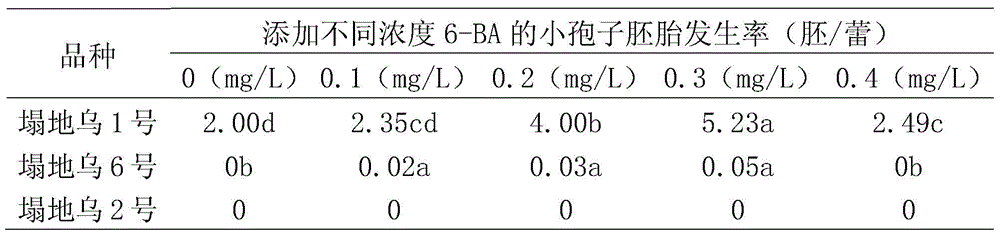

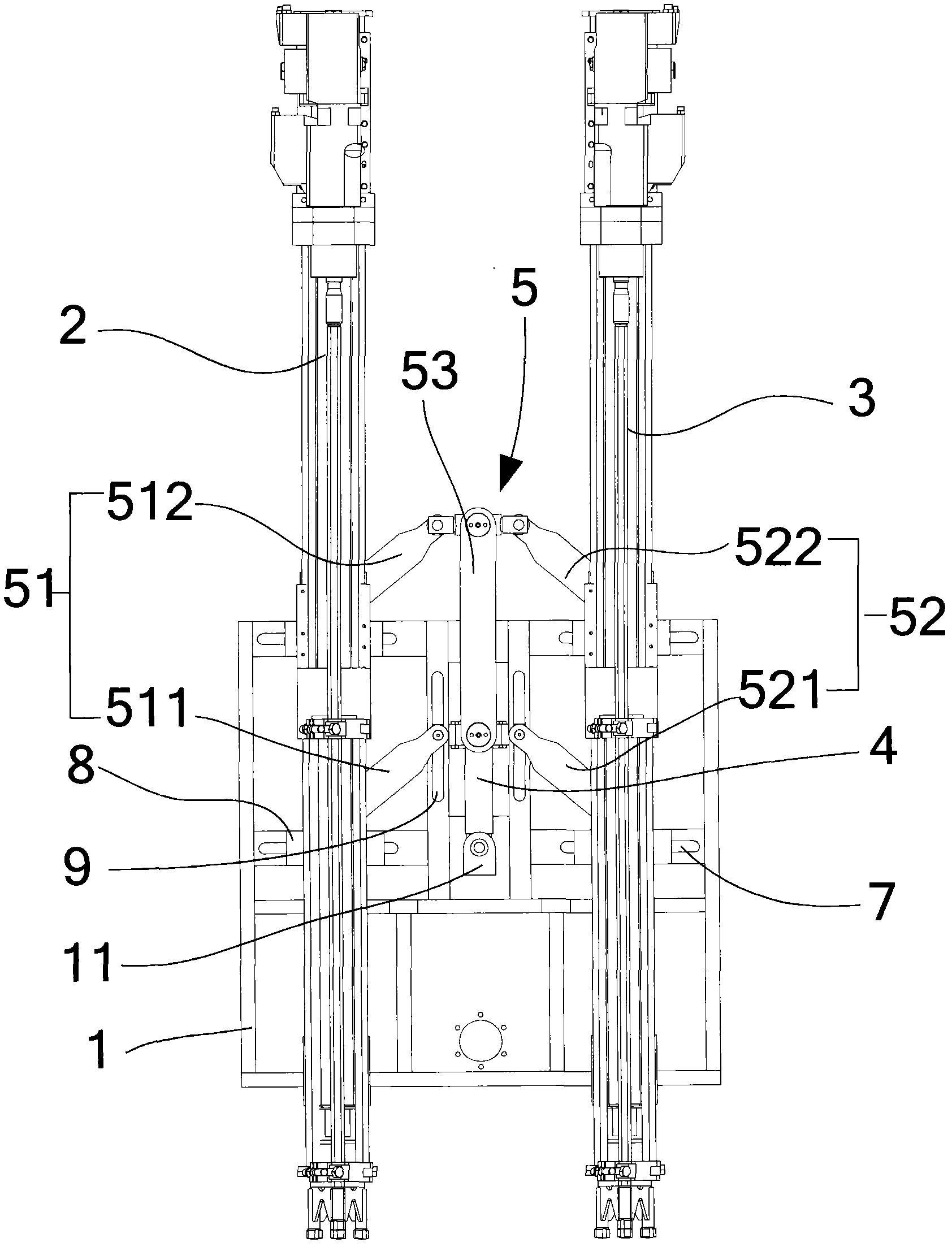

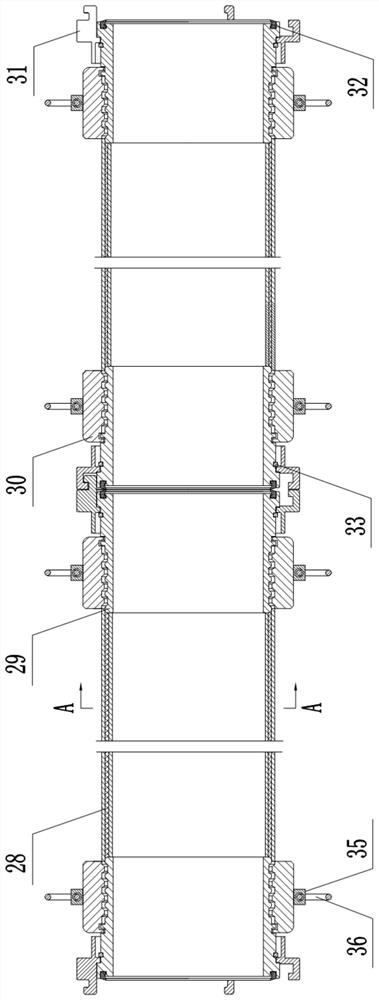

Profile steel numerical control feeding and automatic clamping device for profile steel machining production line

PendingCN114368594AGuaranteed automatic clampingGuaranteed stabilityConveyor partsMechanical conveyorsNumerical controlProduction line

The invention discloses a profile steel numerical control feeding and automatic clamping device for a profile steel machining production line, and belongs to the technical field of profile steel machining production equipment. The numerical control feeding device comprises a feeding channel and a numerical control feeding trolley which is installed on the feeding channel and can move along the feeding channel, a clamp rod and a clamp head are arranged on the numerical control feeding trolley, and the numerical control feeding device is characterized in that a clamp lifting mechanism is arranged on the numerical control feeding trolley, and the clamp rod is horizontally and movably connected with the clamp lifting mechanism through a supporting sliding block mechanism; a clamp rod resistance meeting signal distinguishing mechanism is arranged between the clamp rod and the supporting sliding block mechanism. A profile steel fixing mechanism is arranged on the front portion of the profile steel trough at the tail end of the feeding channel, and a clamp rod guide mechanism is arranged in the profile steel trough at the tail end of the feeding channel. The automatic clamping device can guarantee automatic clamping in the profile steel numerical control feeding process in a profile steel machining production line, full automation of profile steel machining can be achieved, and the production efficiency can be greatly improved.

Owner:山东山新信息技术有限公司

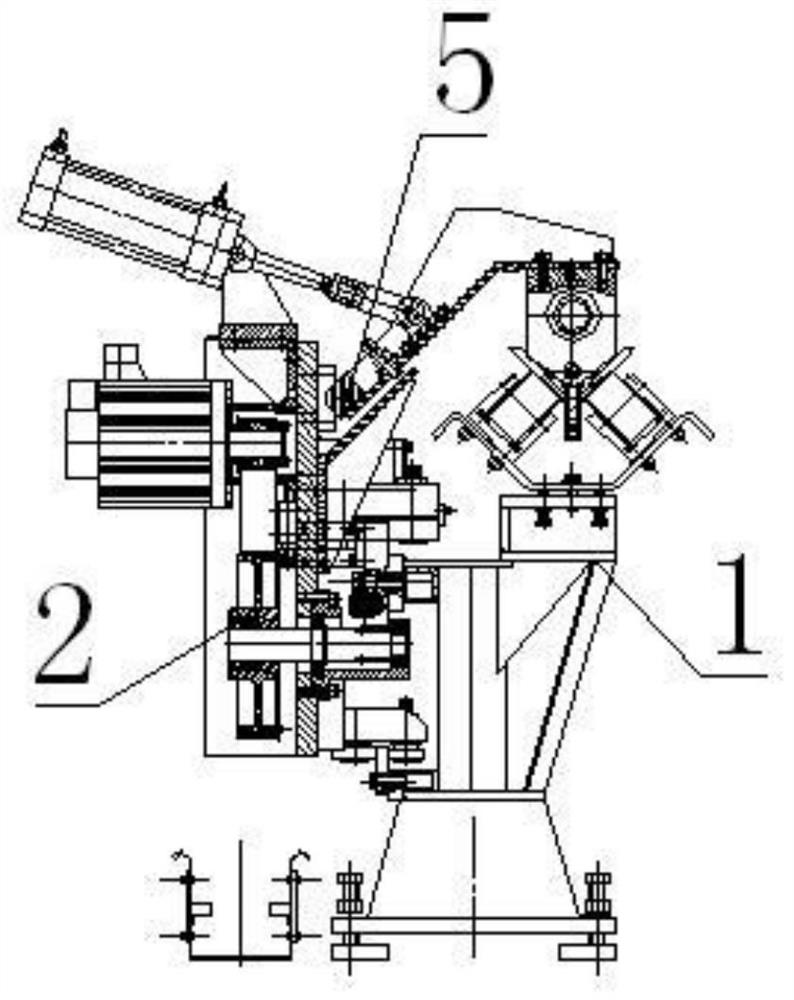

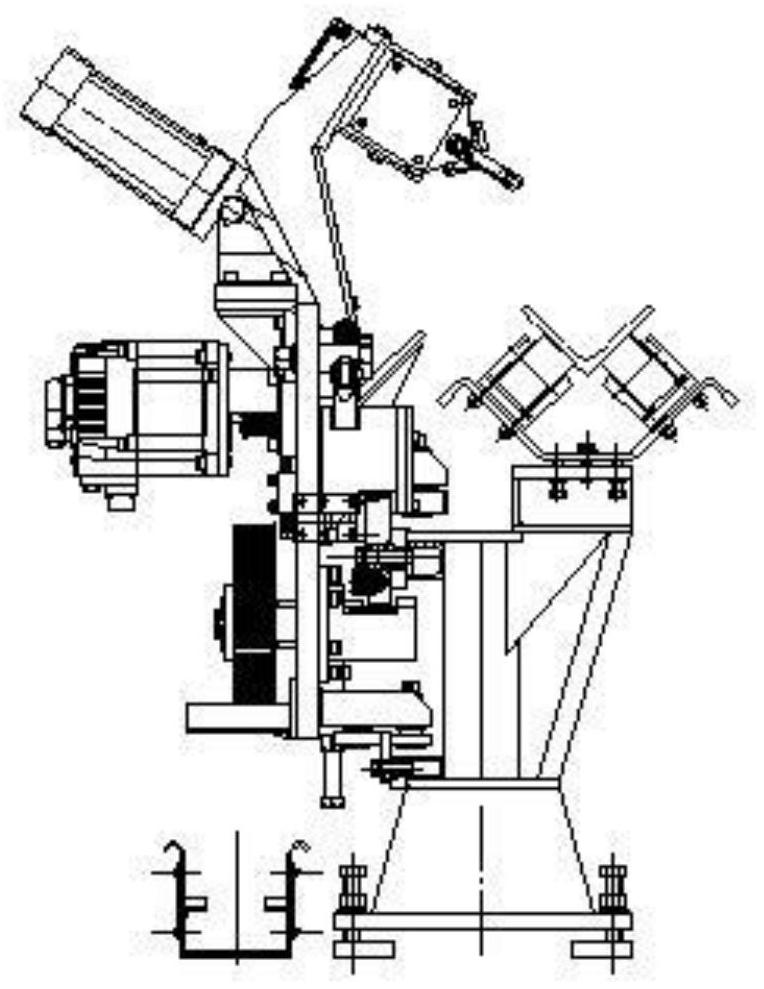

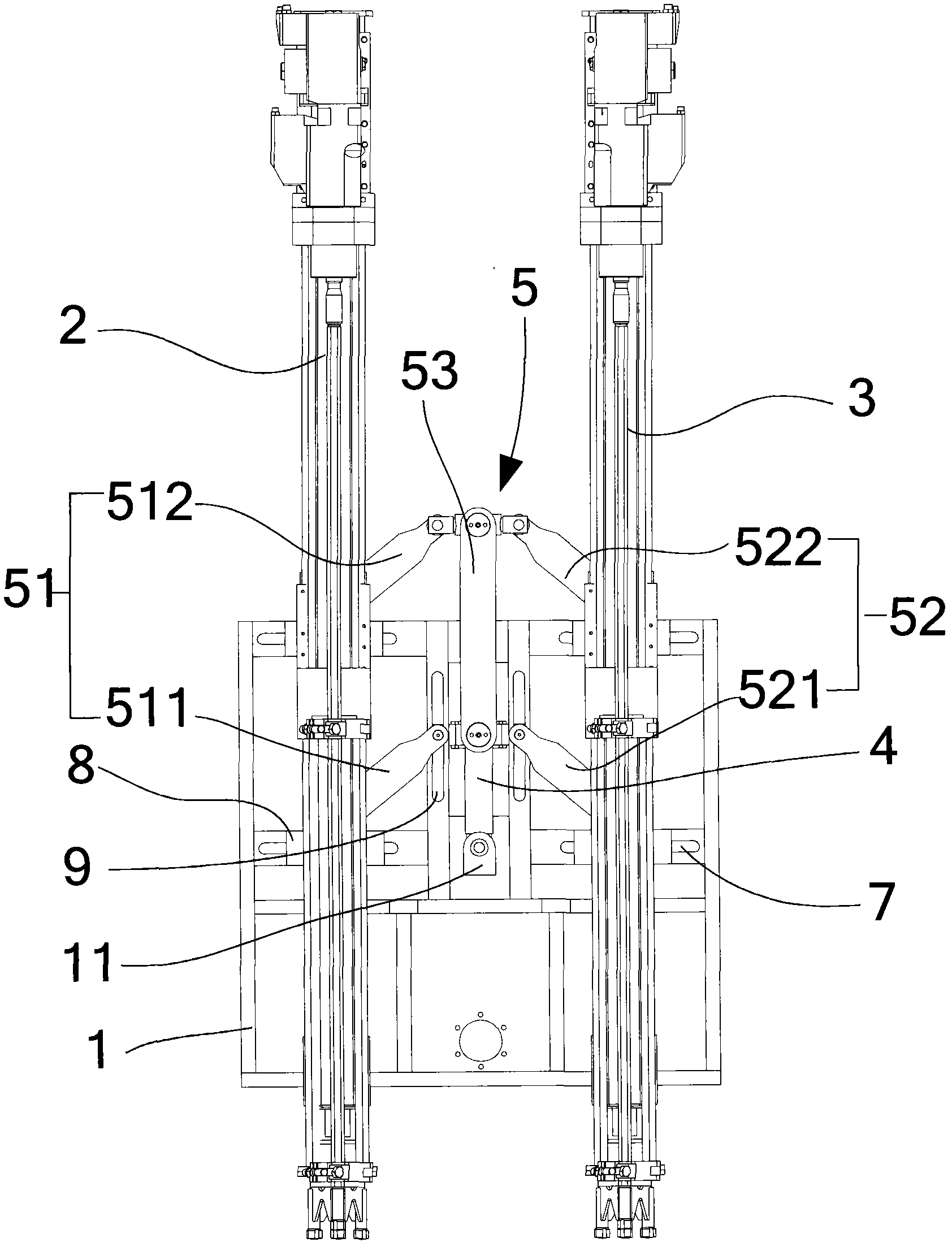

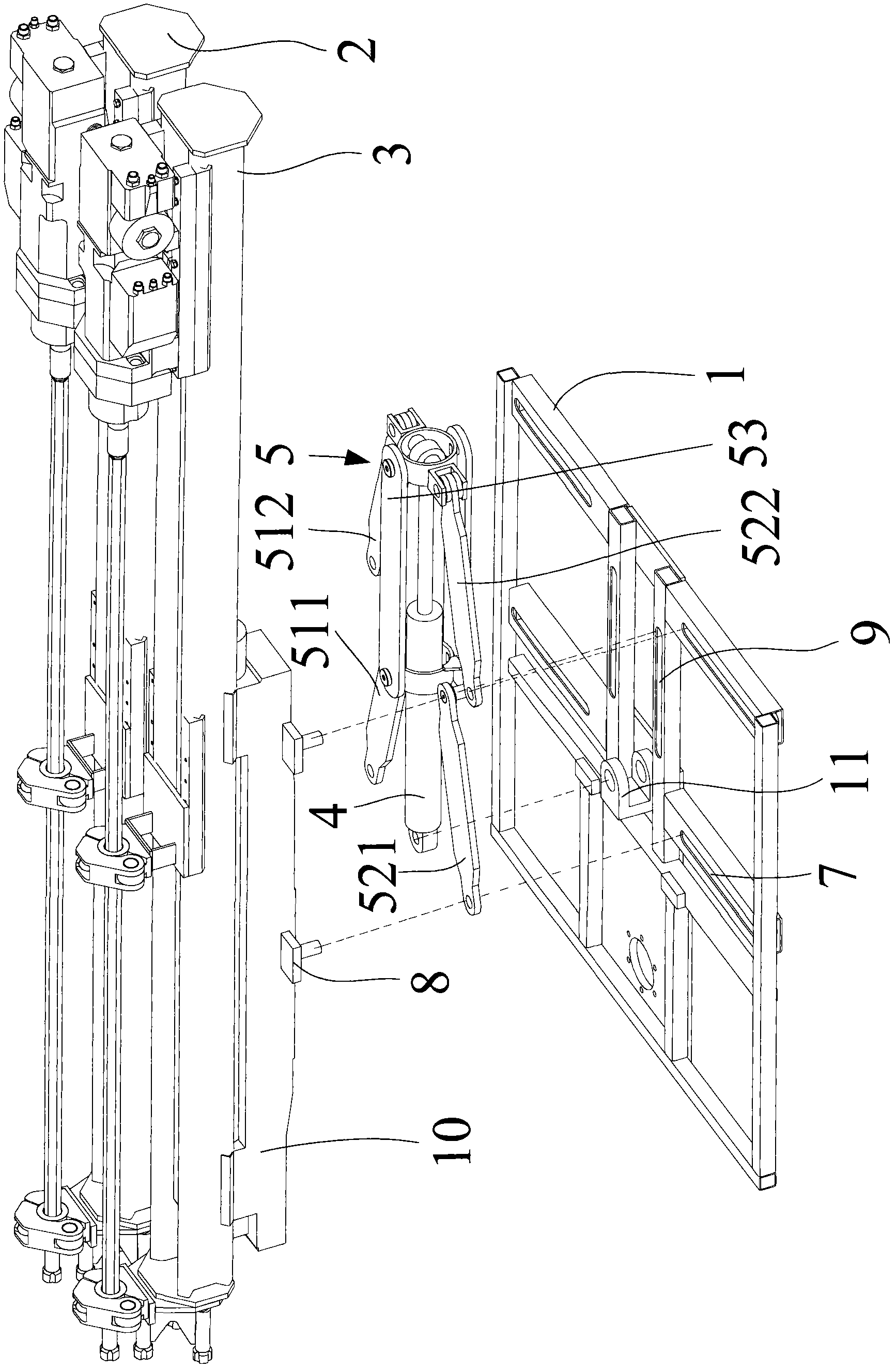

Hole-pitch-adjustable drilling device

InactiveCN102359348AAvoid mutual interferenceImprove work efficiencyDerricks/mastsPunchingPetroleum engineering

The invention provides a hole-pitch-adjustable drilling device. The device comprises a supporting frame, a first drilling mechanism, a second drilling mechanism, an oil cylinder and a linkage mechanism, wherein the first drilling mechanism and the second drilling mechanism are arranged on the supporting frame in a sliding way; and the oil cylinder is arranged on the supporting frame, is positioned between the first drilling mechanism and the second drilling mechanism and is used for driving the first drilling mechanism and the second drilling mechanism to slide close to each other or far away from each other on the supporting frame by using the linkage mechanism. In the hole-pitch-adjustable drilling device provided by the invention, the two drilling mechanisms are integrated on the supporting frame, hole pitch can be adjusted through the linkage mechanism, and the operation of two holes can be finished at a time, so that the working efficiency of punching is improved; and the operation can be finished by operating the device only by one operator, so that the device is conveniently and reliably operated, and the problems of mutual interference and avoidance of the two drilling mechanisms are solved.

Owner:JIKAI HEBEI MECHATRONICS TECH CO LTD

Horizontal high-temperature vacuum coating production line

ActiveCN101838799BAvoid secondary pollutionRealize fully automatic connectionVacuum evaporation coatingSputtering coatingProduction lineBuffer tank

Owner:XIANGTAN HONGDA VACUUM TECH CO LTD

Method and device for manufacturing one-time molded tissue chip receptor wax piece

PendingCN108801749ASolve the shortcomings of crackingEliminate the disadvantages of crackingPreparing sample for investigationWaxCofferdam

The invention discloses a device for manufacturing a one-time molded tissue chip receptor wax piece. The device comprises a rectangular recess cofferdam, an array grid guide hole structure and a columnar array grid, wherein a recess hole is formed in the rectangular recess cofferdam; the array grid guide hole structure is matched with the columnar array grid; the array grid guide hole structure ismoved in an up and down straight line manner on a columnar matrix of the columnar array grid through a lifting device; the array grid guide hole structure, the column matrix of the columnar array grid and the recess hole above form a cofferdam type wax holding mold cavity with the array grid guide hole structure as a bottom. By adopting the device, an axial position of the columnar array grid canbe effectively confirmed, on the basis of one-time molding, a hole drilling depth can be strictly controlled, strict control on precision can be achieved, and problems that in the prior art, breakage, burring, cracking and large batch differences in a receptor wax piece manufacturing process can be solved.

Owner:THE FIRST AFFILIATED HOSPITAL OF ZHENGZHOU UNIV

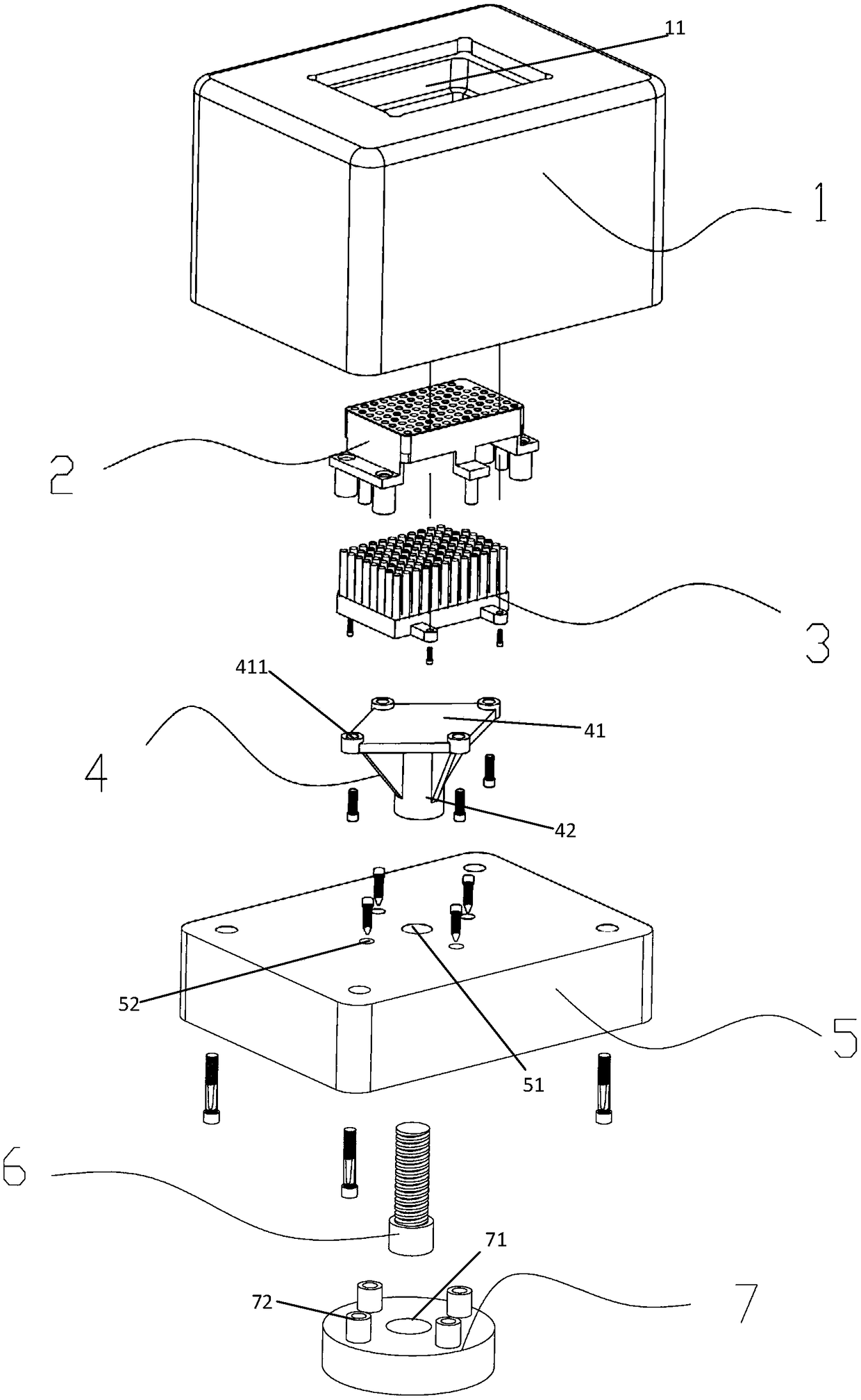

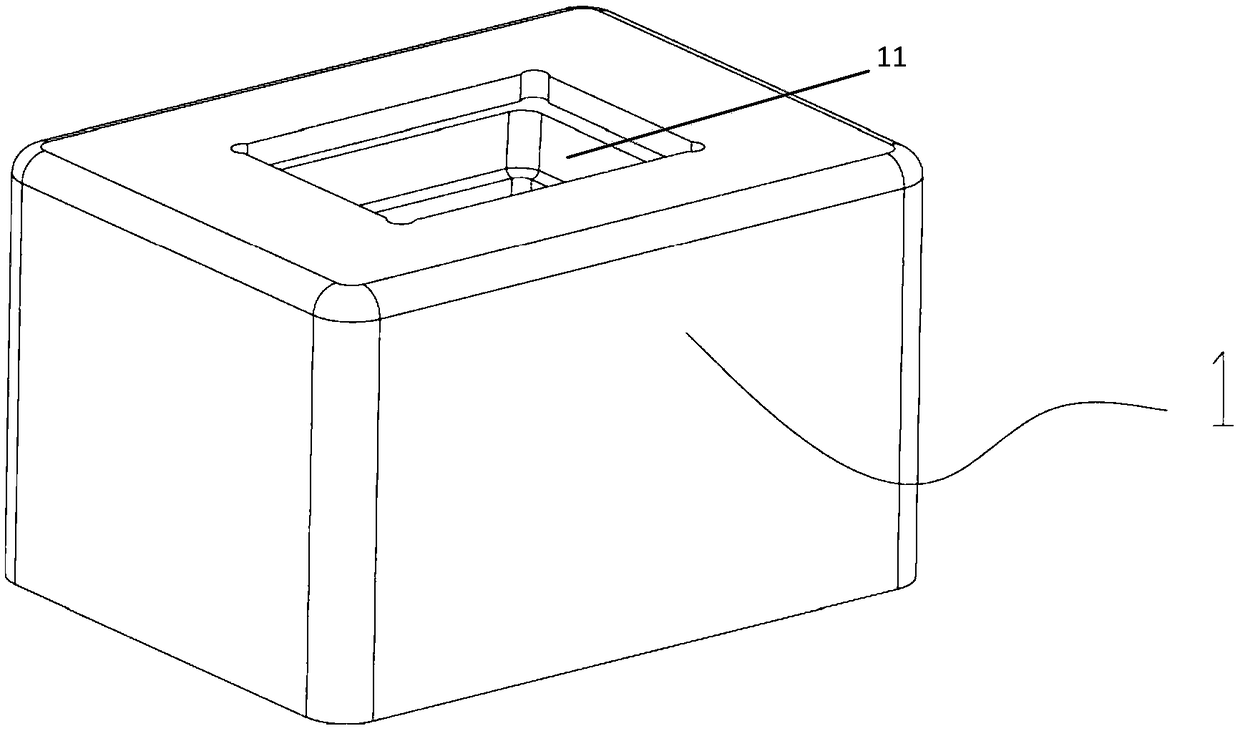

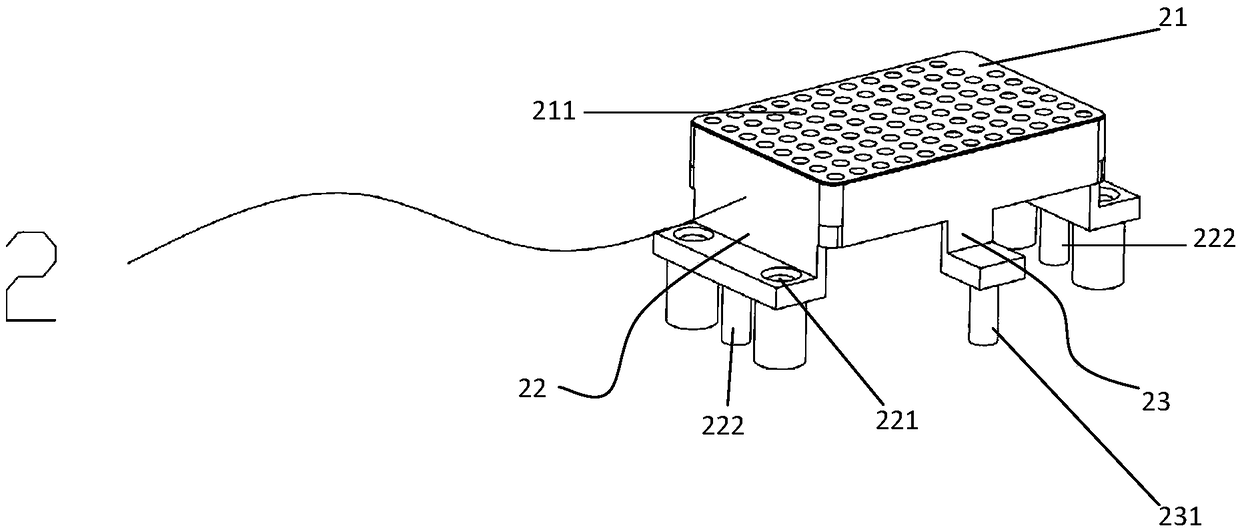

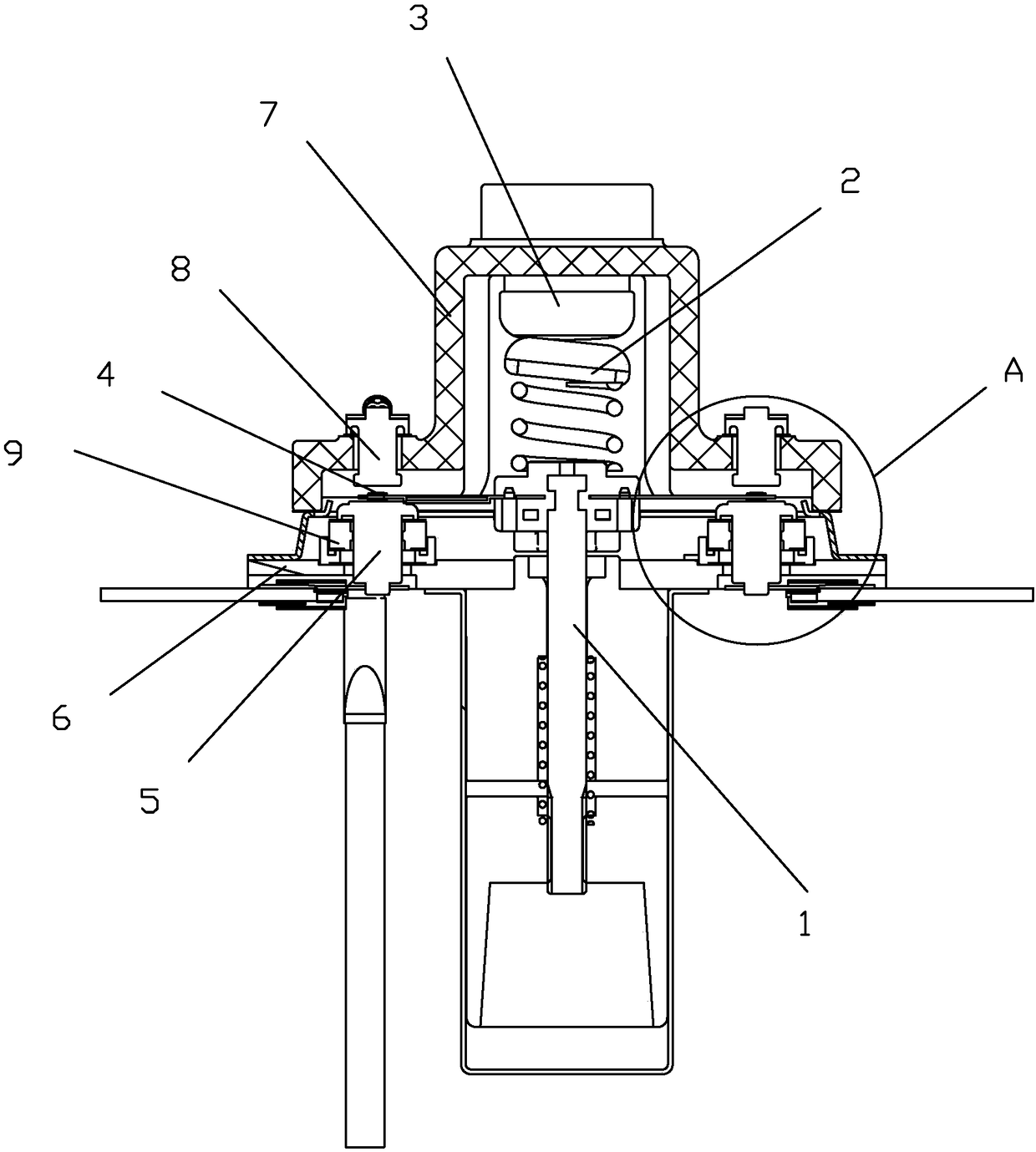

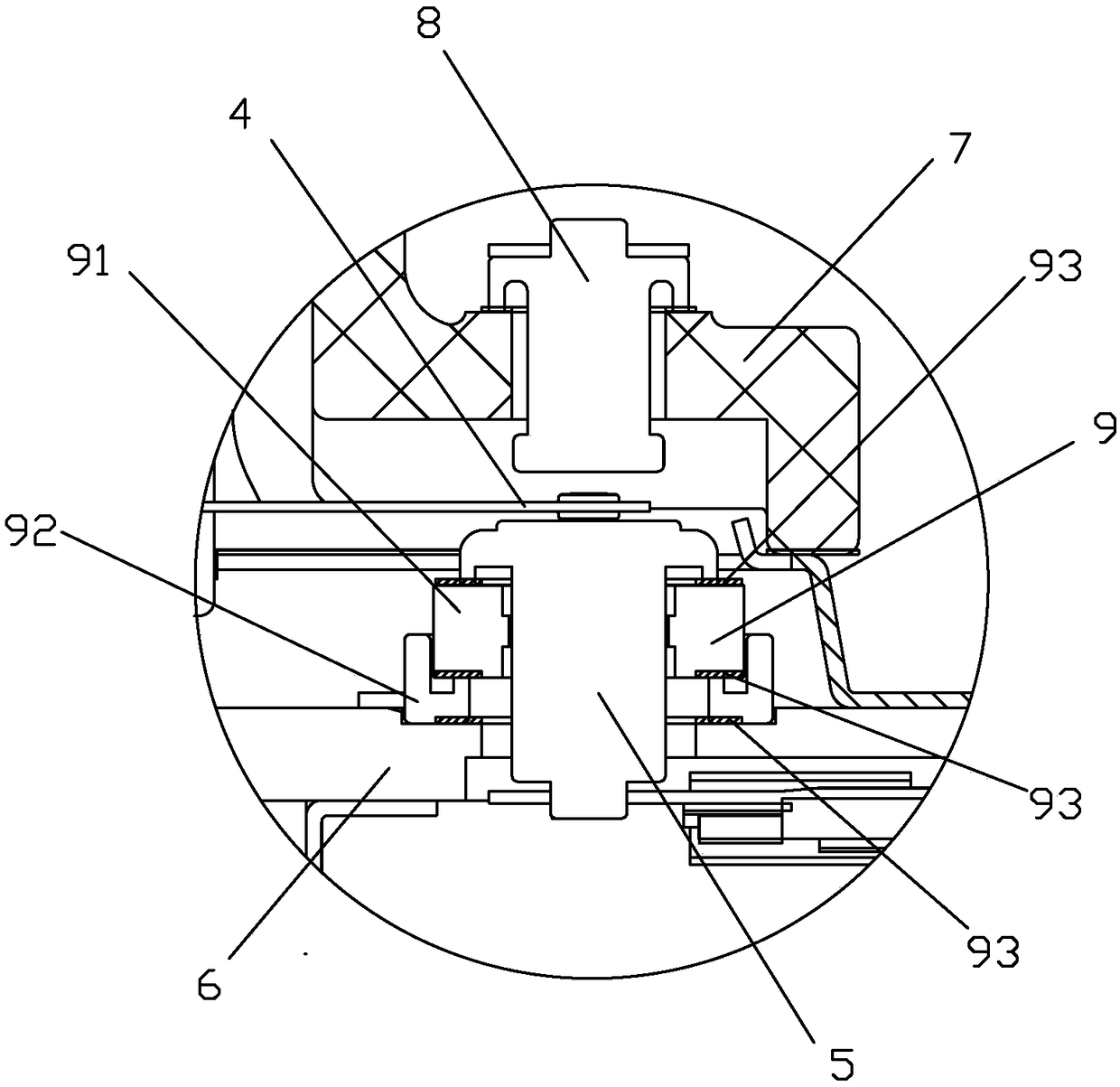

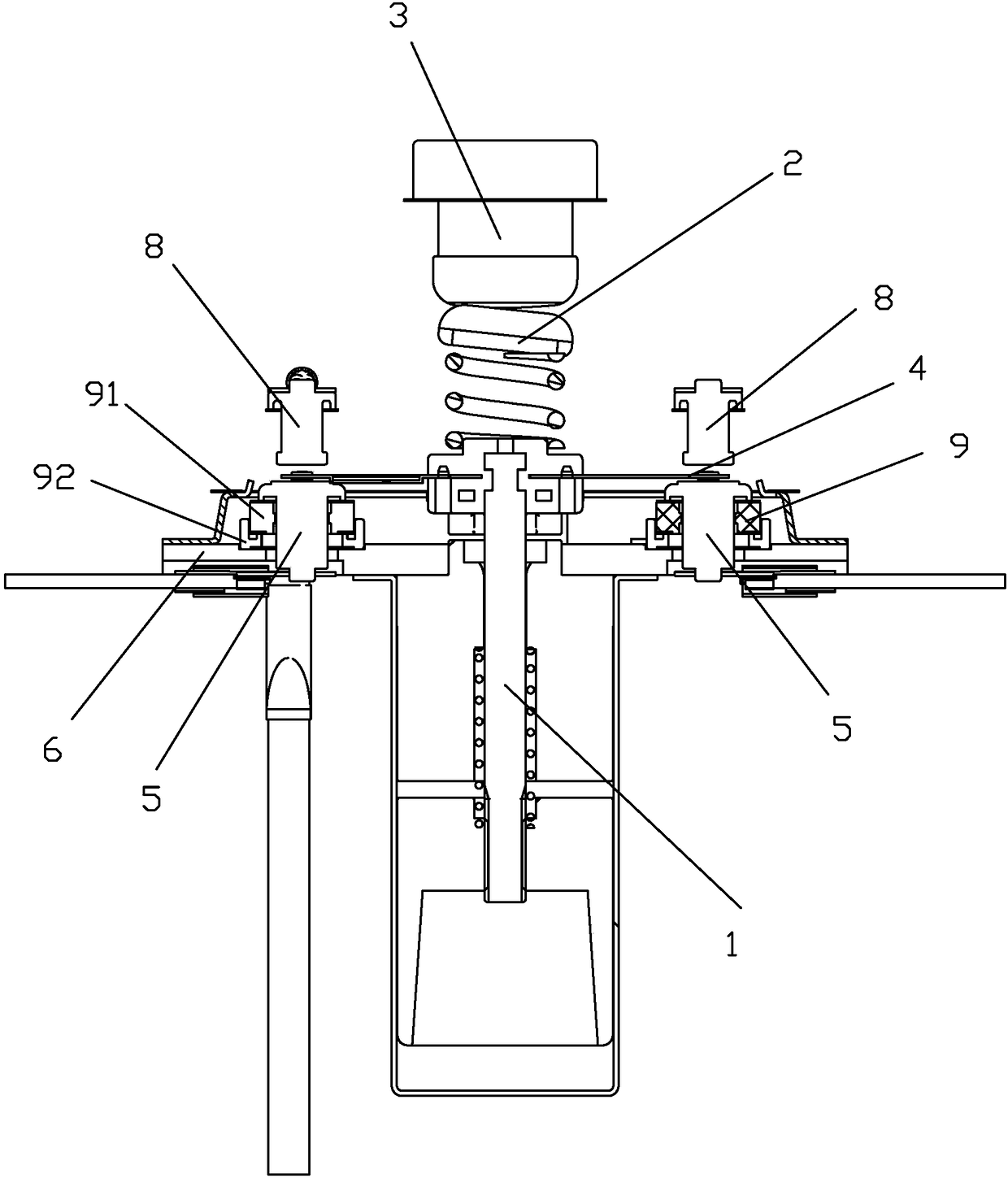

High-voltage direct-current relay with auxiliary contacts

PendingCN108597955AImprove reliabilityOvercoming technical hurdlesElectromagnetic relay detailsHigh-voltage direct currentEngineering

The invention discloses a high-voltage direct-current relay with auxiliary contacts. The high-voltage direct-current relay is composed of a pushing mechanism, a main moving spring with double main moving contacts, two main leading-out terminals respectively provided with main fixed contacts, an auxiliary moving spring with dual auxiliary moving contacts, two first auxiliary leading-out terminals respectively provided with first auxiliary fixed contacts, and a yoke plate. The pushing mechanism penetrates and sleeves the yoke plate. The main moving spring is installed at the upper end of the pushing mechanism; the auxiliary moving spring is installed on the pushing mechanism between the main moving sprng and the yoke plate; the two first auxiliary leading-out terminals are fixed on the yokeplate by adaptive members with insulation structures to realize mutual insulation with the yoke plate; and the auxiliary moving contacts at the two ends of the auxiliary moving spring correspond to the first auxiliary fixed contacts of the two first auxiliary leading-out terminals on the yoke plate. According to the high-voltage direct-current relay disclosed by the invention, one group of converted auxiliary contact structures is realized, so that the reliability of the high-voltage direct-current relay is improved substantially.

Owner:XIAMEN HONGFA ELECTRIC POWER CONTROLS

A method for improving the microspore embryogenesis rate of Utah

ActiveCN104429969BIncrease incidenceEffective induction of embryo production rateHorticulture methodsPlant tissue cultureMixed cultureBud

The invention discloses a method for improving microspore embryogenic rate of wuta-tsai. The method comprises the following steps: carrying out mixed culture to buds easy in embryogenesis and buds difficult or weak in embryogenesis, extracting by virtue of a B5 extracting solution, and inducing embryogenesis in a 1 / 2NLN-13 culture medium. Compared with the single culture of the prior art, the method disclosed by the invention can be used for effectively inducing the embryogenic rate of the variety difficult in embryogenesis and for improving the embryogenesis rate and the plant regeneration rate of the variety weak in embryogenesis, and the technical problem that the variety weak in embryogenesis is low in embryogenesis rate and embryogenesis genotypic ratio can be solved; meanwhile, the technical obstacle of generating plants from the variety difficult in embryogenesis by virtue of microspore culture is solved; and the method disclosed by the invention is significant in the microspore culture of the wuta-tsai.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Hole-pitch-adjustable drilling device

InactiveCN102359348BPunching distance can be adjustedOvercoming technical hurdlesDerricks/mastsPunchingPetroleum engineering

The invention provides a hole-pitch-adjustable drilling device. The device comprises a supporting frame, a first drilling mechanism, a second drilling mechanism, an oil cylinder and a linkage mechanism, wherein the first drilling mechanism and the second drilling mechanism are arranged on the supporting frame in a sliding way; and the oil cylinder is arranged on the supporting frame, is positioned between the first drilling mechanism and the second drilling mechanism and is used for driving the first drilling mechanism and the second drilling mechanism to slide close to each other or far away from each other on the supporting frame by using the linkage mechanism. In the hole-pitch-adjustable drilling device provided by the invention, the two drilling mechanisms are integrated on the supporting frame, hole pitch can be adjusted through the linkage mechanism, and the operation of two holes can be finished at a time, so that the working efficiency of punching is improved; and the operation can be finished by operating the device only by one operator, so that the device is conveniently and reliably operated, and the problems of mutual interference and avoidance of the two drilling mechanisms are solved.

Owner:JIKAI HEBEI MECHATRONICS TECH CO LTD

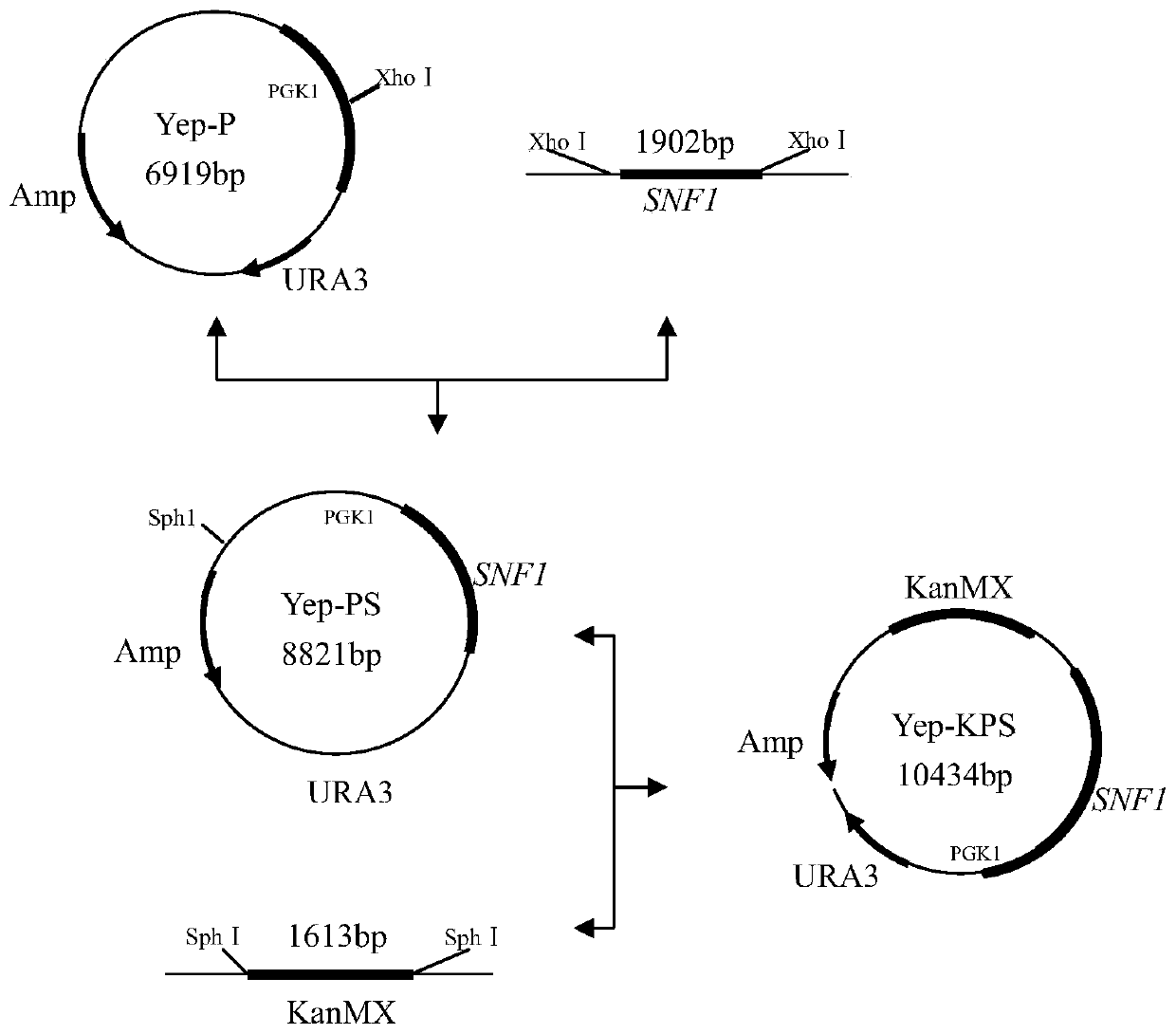

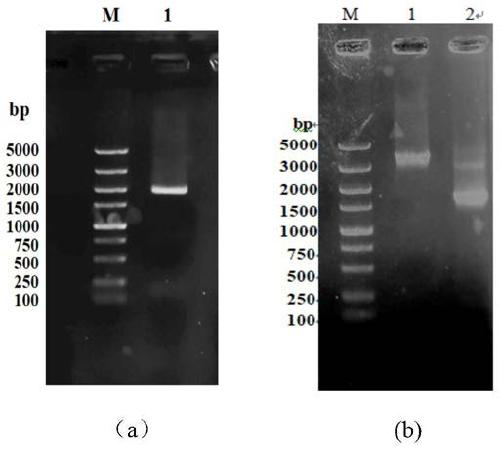

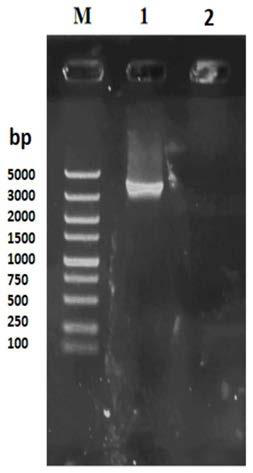

High-tolerance yeast strain suitable for fermentation of frozen dough and application of high-tolerance yeast strain

ActiveCN110358693AMeeting the Requirements of Resistant YeastOvercoming technical hurdlesFungiPre-baking dough treatmentBiotechnologyComplete sequence

The invention belongs to the technical field of bioengineering, and relates to breeding of industrial microorganisms, in particular to a high-freezing-tolerance accharomyces cerevisiae strain and a construction method thereof. The freezing-tolerance yeast strain is obtained in the mode that in a parent yeast strain, a strong promoter PGK1 is selected for overexpressing a complete sequence of an encoding gene SNF1 of Snf1 protein kinase alpha subunit. Compared with the parent strain, according to the freezing-tolerance accharomyces cerevisiae strain, in a freezing environment, the cell survivalrate and the fermentation capacity of frozen dough are significantly improved, technical obstacles and quality defects in the bread making process are overcome, and the high-freezing-tolerance accharomyces cerevisiae strain has a wide application prospect.

Owner:HAINAN UNIVERSITY

Implementation method, device, electronic equipment and medium of applet tab

ActiveCN109814778BImprove experienceMeet needsExecution for user interfacesInput/output processes for data processingUser needsTechnical specifications

The invention provides a method for realizing a mini-program tab. The method comprises the following steps: acquiring data of a tree-shaped tab of a mini-program; rendering the tree-shaped tab according to the data; responding to a user instruction, associating the tree-shaped tab corresponding to the user instruction with the data, and unfolding or folding the tree-shaped tab. According to the embodiment of the invention, the technical index for managing the applet by adopting the tree-shaped tab is improved; According to the technical scheme, the small program can be managed in a tree tab mode, the technical obstacle of an original assembly is overcome, the user experience is enhanced, and therefore the small program not only meets the user requirement in the using function, but also ismore user-friendly in application management and convenient to operate, and the application value of the small program is improved.

Owner:SHANGHAI SUIXUNTONG ELECTRONICS TECH CO LTD

Automatic grinding and mixing device for ultrahard material

ActiveCN103301918BAvoid instabilitySimple structureGrain treatmentsSuperhard materialElectric machinery

Owner:ZHONGNAN DIAMOND CO LTD

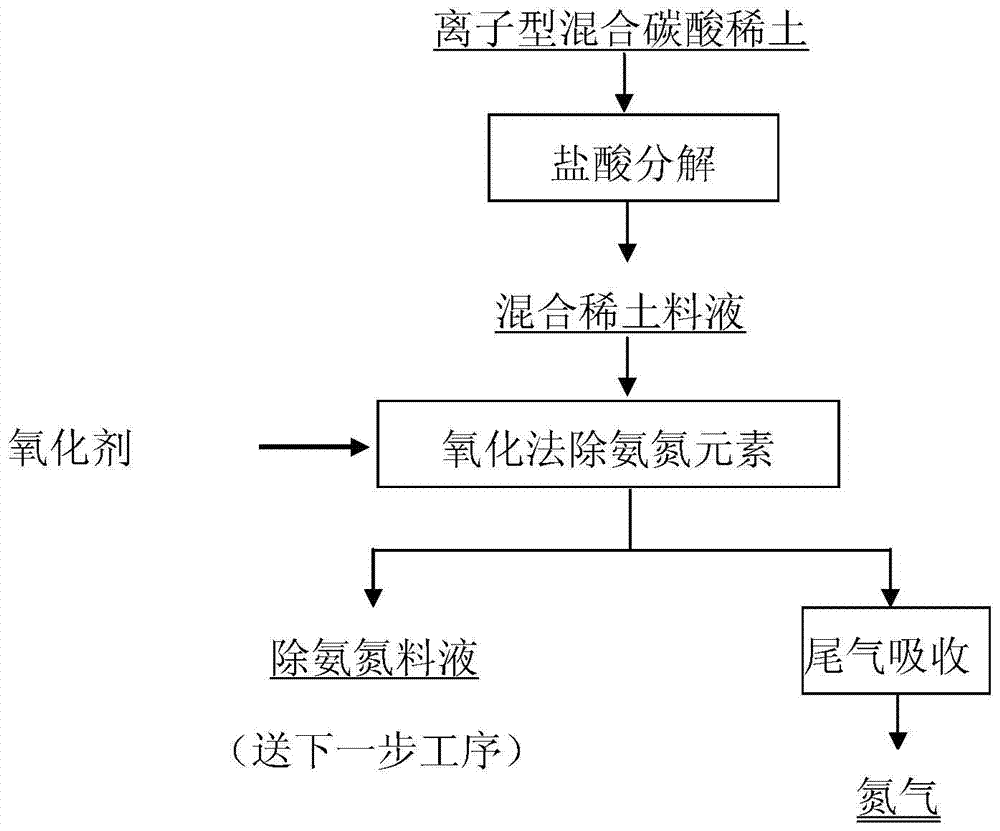

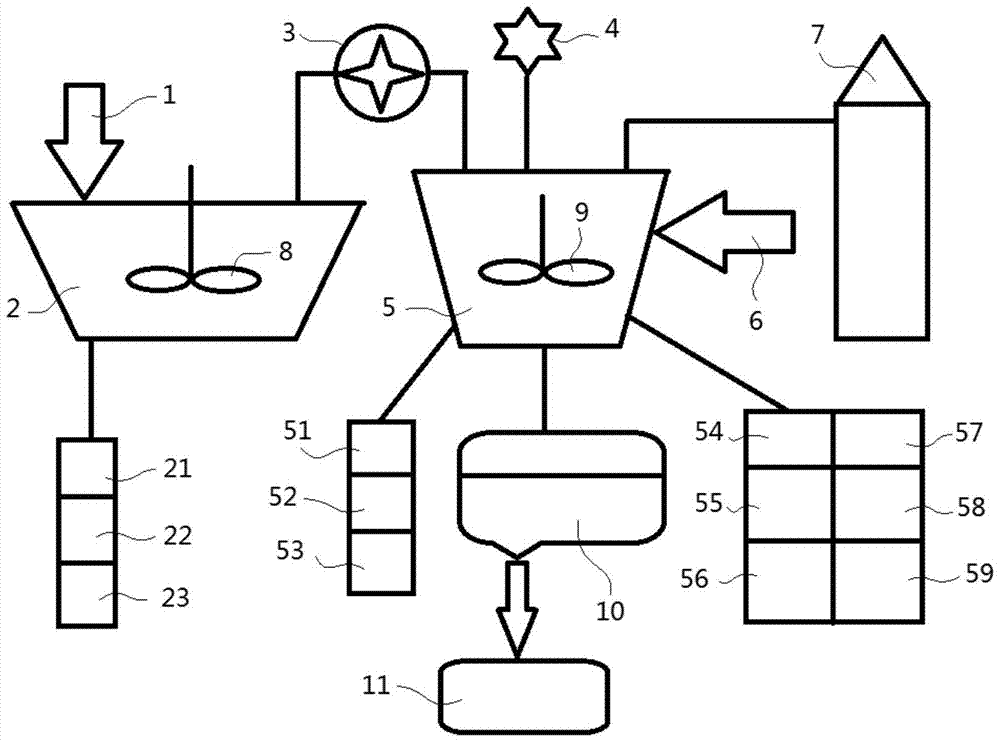

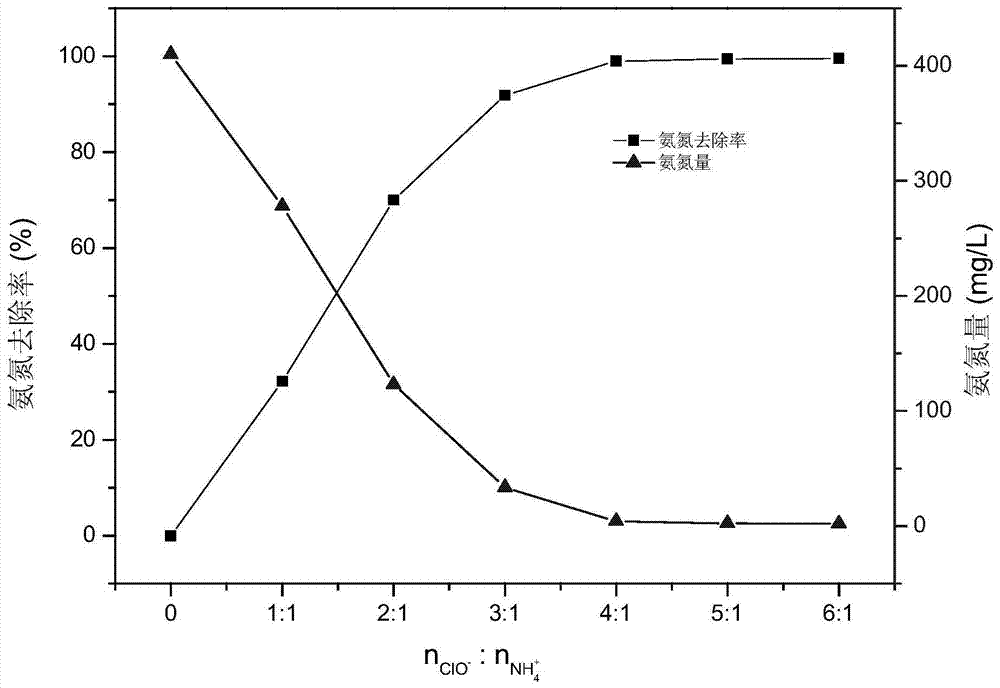

A method and system for removing ammonia nitrogen from ionic mixed rare earth feed liquid

ActiveCN104862507BHigh removal efficiency of ammonia nitrogenReduce processing costsProcess efficiency improvementRare earthSewage

The invention discloses a method for removing ammonia nitrogen from ionic mixed rare earth feed liquid. The method is characterized by comprising the following steps: decomposing ionic mixed rare earth to obtain mixed rare earth feed liquid; adding complex oxidants into the mixed rare earth feed liquid in batches according to the mass ratio of N oxidizing agent to N<NH4+> being equal to (2-30):1, and performing tail gas treatment on produced gas; filtering the feed liquid subjected to ammonia nitrogen removal, so as to obtain the clear rare earth feed liquid. The method has the advantage that the content of ammonia nitrogen is reduced from the source, so that a subsequent sewage ammonia nitrogen treatment process is avoided, the sewage treatment cost is reduced, and treatment up-to-standard release is achieved.

Owner:GANZHOU NONFERROUS METALLURGICAL RES INST +1

An o/a integrated membrane biological treatment device based on the amount of micro-anaerobic sludge and a method for treating sewage using the device

ActiveCN106277569BEasy to handleEfficient degradationWater treatment parameter controlWater/sewage treatment bu osmosis/dialysisActivated sludgeParticulates

Owner:施悦

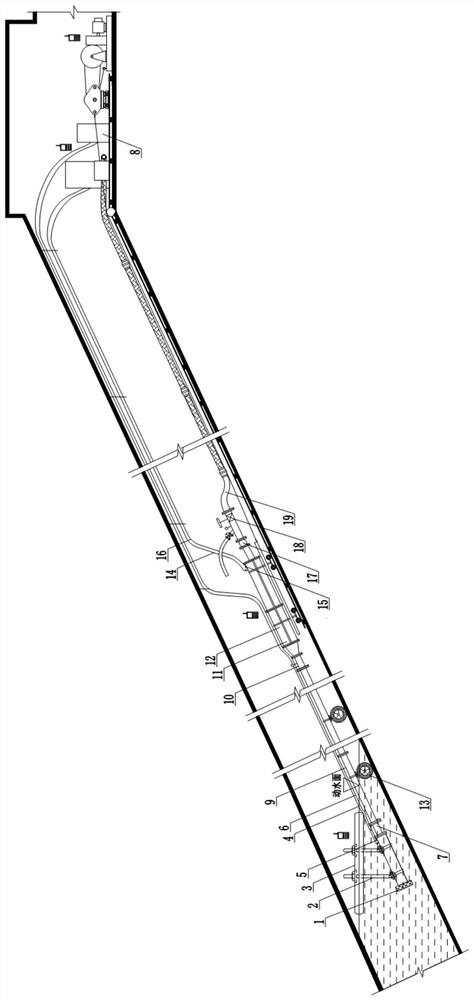

Mine trackless inclined shaft floating pump type emergency drainage system and mounting method

PendingCN113969803AHigh feasibilityPrevent tamperingMining devicesPortable liftingWater sourceVoice communication

The invention relates to the technical field of mine flood accident emergency rescue, in particular to a mine trackless inclined shaft floating pump type emergency drainage system and a mounting method. A floating pump is suspended in water through a support and a floating boat, is pushed by a hard metal pipeline, a main pump and a matched pipe valve which are sequentially connected behind a water outlet of a floating pump along the gravity component of a slope;, a condition of rolling along the slope is created by a pipe supporting rubber wheel pair, a pump supporting truck and an emergency light rail, traction tension and rope outlet speed are controlled by a mining double-speed winch, a movable pulley block and a steel wire rope, so that the floating pump synchronously descends along with the water level at a low speed, a soft pipeline and a slow closing valve are connected behind a water outlet of the main pump in a matched mode, and a water source is safely conveyed at a long distance. Operation and monitoring of the floating pump and the main pump are guaranteed through power supply and distribution equipment, and voice communication devices are arranged at key points in a serialized mode to assist efficient linkage operation. According to the mine trackless inclined shaft floating pump type emergency drainage system, an integrated matching process technology solution and an optimally matched equipment system for lightweight and rapid construction of the trackless inclined shaft emergency drainage system are formed.

Owner:重庆科华安全设备有限责任公司 +1

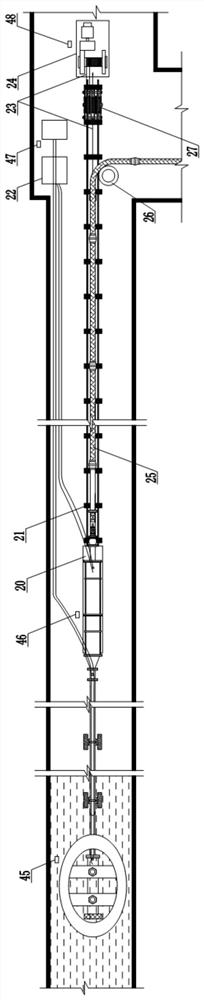

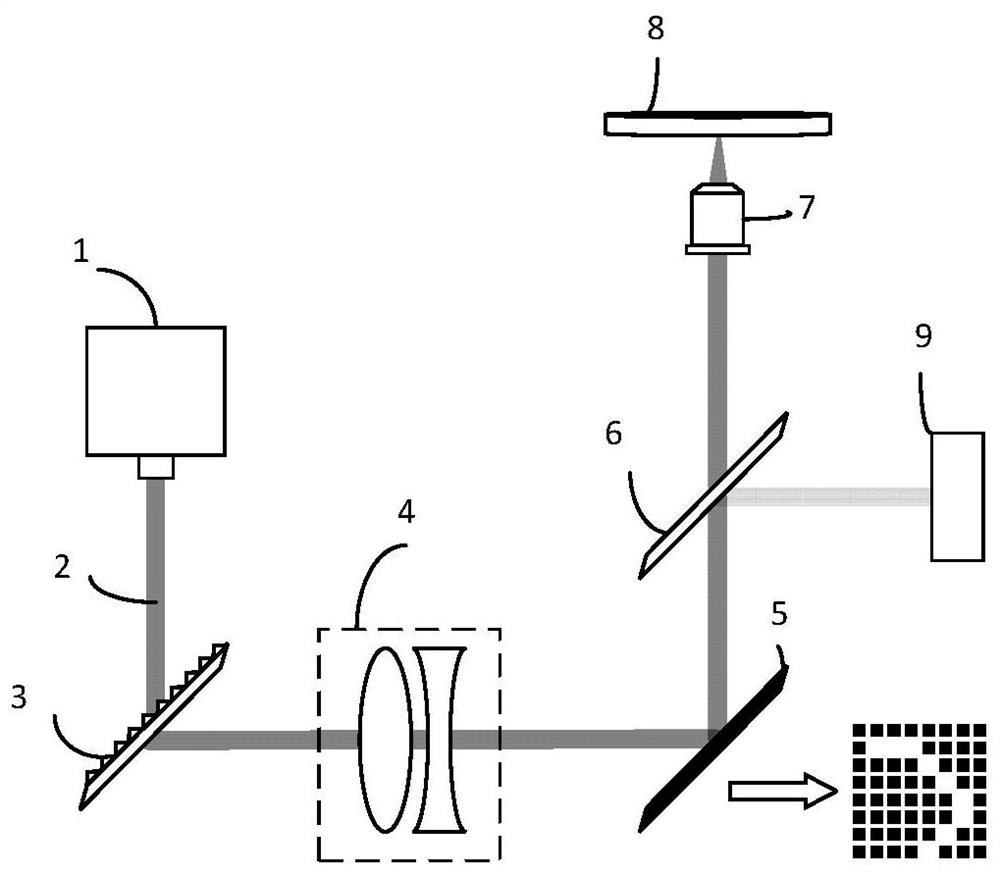

Laser microdissection apparatus and method

ActiveCN111283335BOvercoming technical hurdlesReduce volumeLaser beam welding apparatusControl cellErbium lasers

The invention provides a laser microdissection device and method, the laser microdissection device includes a laser and an objective lens; the micromirror array group includes a plurality of microreflectors arranged in an array; the output light of the laser passes through the The reflection of the micromirror array group is directed to the objective lens; the drawing unit is suitable for the operator to draw a cutting curve; the calculation unit obtains each of the micromirror array groups corresponding to any point in the cutting curve according to the drawn cutting curve The inclination angles of the micro-mirrors relative to the output light are transmitted to the control unit; the control unit adjusts each micro-mirror according to the received inclination angles. The invention has the advantages of simple structure, accurate cutting and the like.

Owner:NINGBO UNIV +1

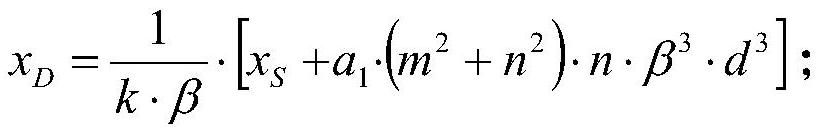

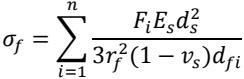

Calculation method and control method for coating film strain of ultra-thin lens, and ultra-thin lens

ActiveCN114019590ARealize computingAchieve forecastDesign optimisation/simulationSpecial data processing applicationsThin lensFilm-coated tablet

The invention discloses a calculation method and a control method for the coating film strain of an ultra-thin lens, and the ultra-thin lens. The coating film strain calculation method comprises the following steps of: obtaining a relation model between coating film stress and thickness of a film layer material required by an ultra-thin lens, calculating the corresponding coating film stress according to the thickness required by each film layer, and calculating the stress of the coating layer of the ultra-thin lens according to an improved stoneley formula so as to obtain the strain of the coating layer on a substrate. The coating film strain control method comprises the steps of: designing a metal oxide film layer based on the coating film layer stress of an ultra-thin lens, and adding the designed metal oxide film layer into the coating film layer of the ultra-thin lens to control the coating film stress, the vector sum of the coating film stress and the coating film layer stress being smaller than a preset stress threshold. According to the invention, the strain of the ultra-thin lens in the film coating process can be predicted and controlled, and the ultra-thin lens without strain after film coating is obtained.

Owner:HUNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com