A method and system for removing ammonia nitrogen from ionic mixed rare earth feed liquid

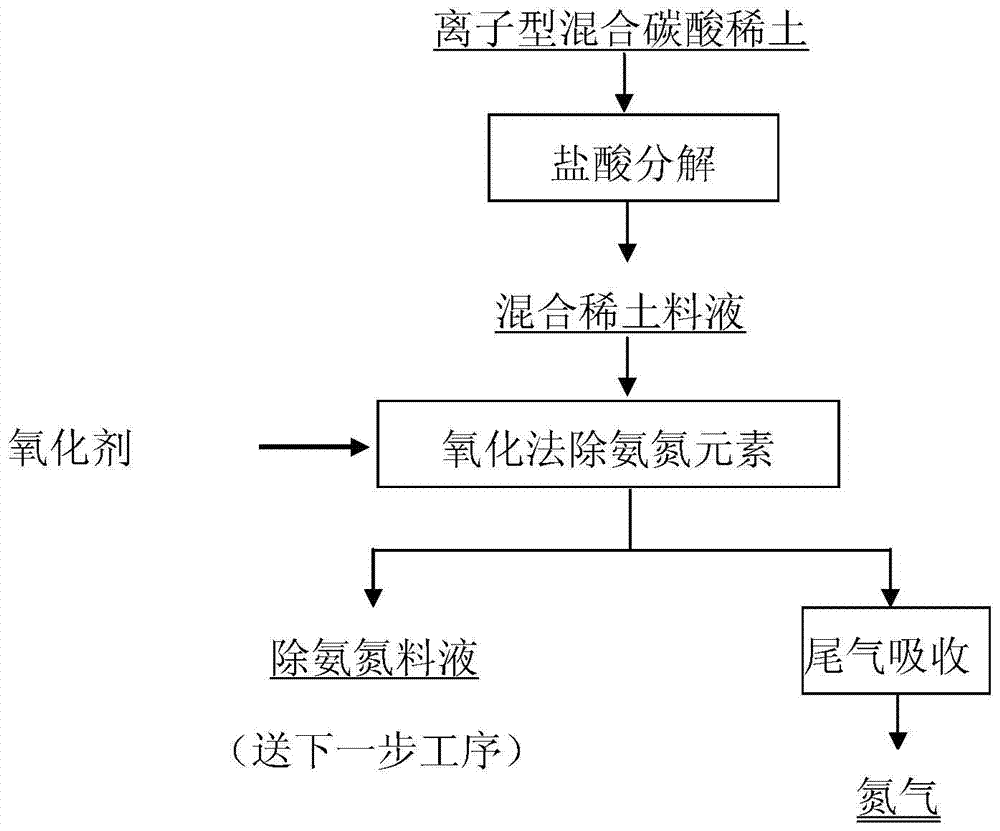

A technology for mixing rare earth and rare earth material liquid, applied in the process of removing ammonia nitrogen and the field of ammonia nitrogen removal, can solve the problems of excessive concentration of unorganized concentration at the factory boundary, ammonia odor pollution, and high pollution control cost, so as to avoid the loss of rare earth elements and eliminate the Odor pollution, high removal rate of ammonia nitrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

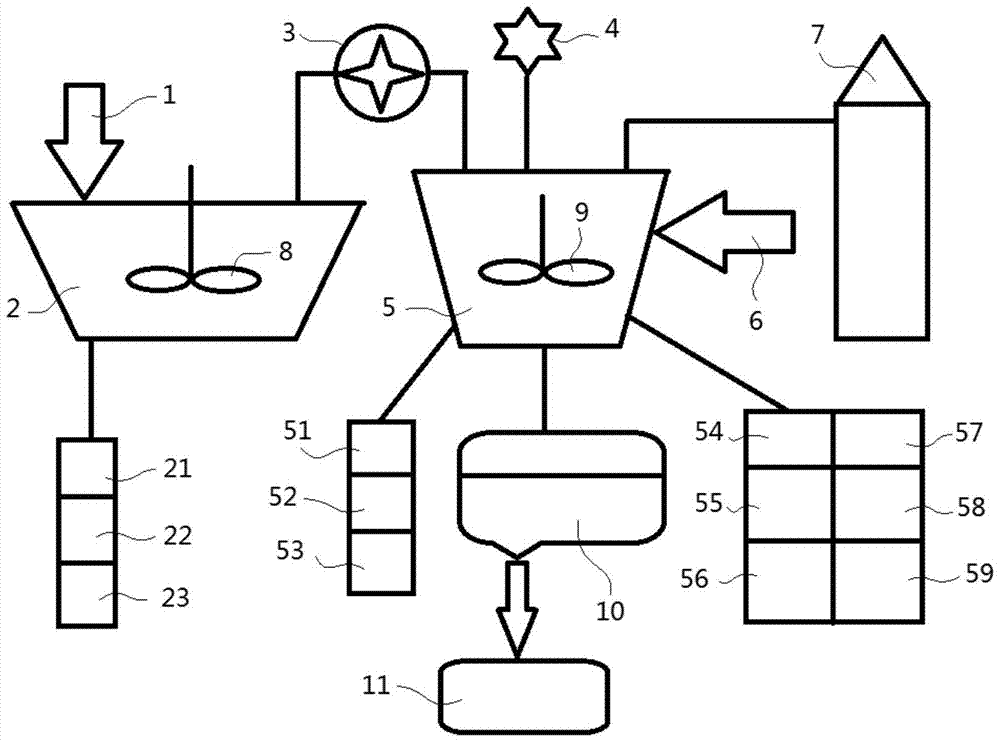

Method used

Image

Examples

Embodiment 1

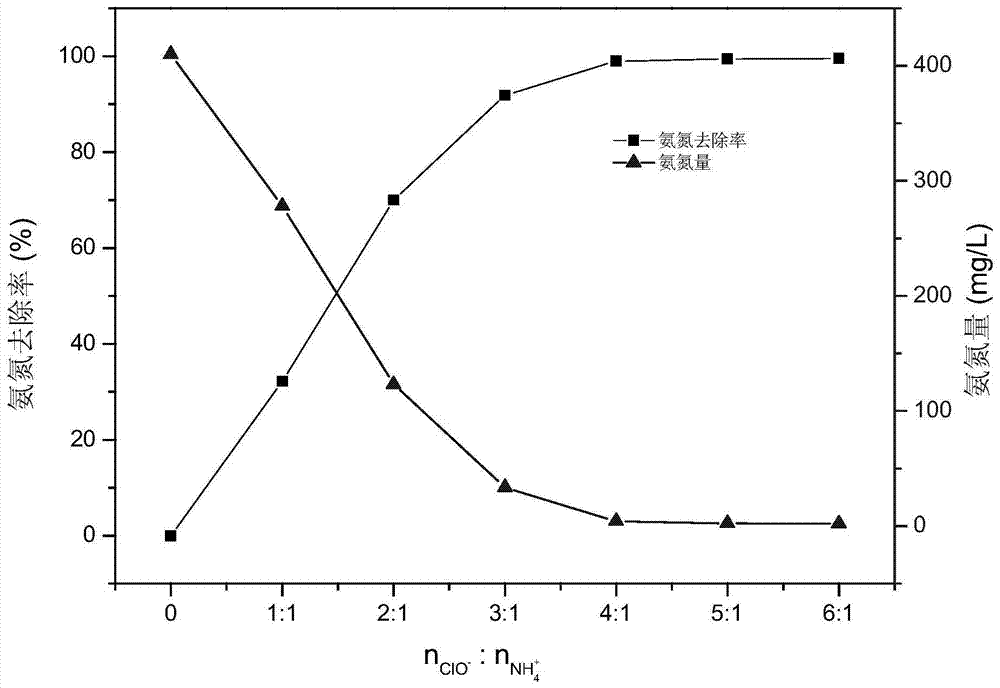

[0044] Example 1: Take 10Kg of mixed rare earth carbonate, control the amount of industrial hydrochloric acid, and obtain a rare earth feed solution with a rare earth concentration of 0.95 mol / L and a pH value of 4.5, and the measured amount of ammonia nitrogen in the rare earth feed liquid is 410 mg / L. Take 500mL of the rare earth material liquid for testing, according to the ratio of the amount of substances n ClO- :n NH4+ The amount of sodium hypochlorite was added at one time in different proportions, and stirred for 30 minutes. The results are shown in Table 1, and the data plotted as image 3 shown. From Table 1 and image 3 It can be seen that with the increase of sodium hypochlorite addition, the ammonia nitrogen content in the feed liquid gradually decreases, when n ClO- :n NH4+ When the ratio is greater than 3:1, the removal rate of ammonia nitrogen can reach more than 90%. Therefore, considering the removal rate and cost of ammonia nitrogen comprehensively, th...

Embodiment 2

[0050] Example 2: Take 10Kg of mixed rare earth carbonate, control the amount of industrial hydrochloric acid, and obtain a rare earth feed liquid with a rare earth concentration of 1.45 mol / L and a pH value of 1.5, and the ammonia nitrogen content of the rare earth feed liquid is 315 mg / L. According to the ratio of the amount of substance n ClO- :n NH4+ =3:1 Add the amount of sodium hypochlorite in 4 times, and the reaction is stirred for 1 hour in total. After the reaction, the concentration of ammonia nitrogen in the feed liquid is 2.5 mg / L, and the removal rate of ammonia nitrogen reaches 99.21%. Before and after the ammonia nitrogen removal reaction, the color of the feed liquid changes, and after the breakpoint chlorination removes ammonia nitrogen, the feed liquid becomes more transparent and clear.

Embodiment 3

[0051] Embodiment 3: take by weighing the rare earth carbonate of 0.6kg (water content is 76%), add 480ml pure water, then slowly add 250ml industrial hydrochloric acid (concentration is 30%), stir until rare earth carbonate is all dissolved, record the ratio of rare earth feed liquid The pH is 0.95, the concentration of ammonia nitrogen is 212mg / L, and the total amount of rare earth is 0.51mol / L. Get rare earth material liquid 500ml, add 25ml proportioning compound oxidant (hypochlorous acid and compound 50g, ozone feed rate are 5m 3 / h), aerated and stirred for 60min, centrifuged, and measured the data of the supernatant, the pH was 3.74, the ammonia nitrogen concentration was 14mg / L, the ammonia nitrogen removal rate reached 93.4%, and the total amount of rare earth was 0.51mol / L.

[0052] Embodiment 4: take by weighing the rare earth carbonate of 1kg (water content is 76%), slowly add 600ml industrial hydrochloric acid (concentration is 30%), stir until rare earth carbonat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com