Low-density zeolite biological aerated filter filling and preparation method thereof

An aerated biological filter, low-density technology, applied in the field of microbial carrier and its preparation, can solve the problems of high effluent quality, waste of water resources, less than 5% sewage reuse rate, etc., and achieves low treatment cost, energy saving, High efficiency in removing ammonia nitrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

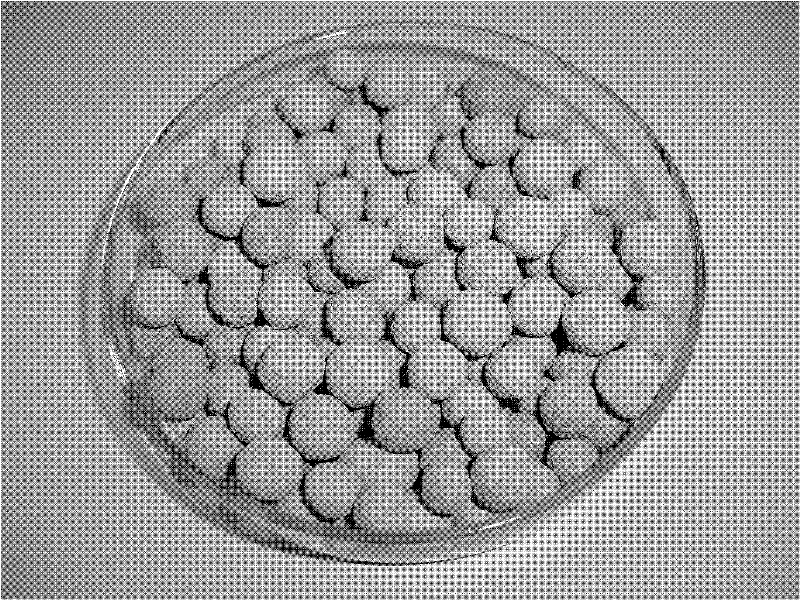

Image

Examples

Embodiment 1

[0027] In this embodiment, the low-density zeolite biological aerated filter filler is composed of zeolite ore 750g, No. 425 cement 250g, the diameter of foamed plastic particles is 2-4mm, and the volume of zeolite ore and cement is combined with foaming. The volume ratio of the plastic particles is 2:1.

[0028] The preparation method of the low-density zeolite biological aerated filter filler in this embodiment is as follows:

[0029] a. Crush the zeolite ore to obtain 40-100 mesh zeolite powder, add the zeolite powder and No. 425 cement to the mixer and mix for 30 minutes to mix the two raw materials uniformly to obtain a mixture;

[0030] b. Sprinkle foamed plastic particles into the ball-forming plate, spray water evenly on the surface of the foamed plastic particles to wet the surface, and then sprinkle the mixture obtained in step a at a constant speed and spray water on the surface of the particles. The mass ratio of the amount to the mixture is 1:2-2:1, and the ball-forming...

Embodiment 2

[0033] In this embodiment, the low-density zeolite biological aerated filter packing material is composed of 1200g of zeolite ore, 200g of cement 425, and foamed plastic particles with a diameter of 2-4mm. The volume of the zeolite ore and the cement The volume ratio of the foam particles is 1:2.

[0034] The preparation method of the low-density zeolite biological aerated filter filler in this embodiment is as follows:

[0035] a. Crush the zeolite ore to obtain 40-100 mesh zeolite powder, add the zeolite powder and No. 425 cement to the mixer and mix for 30 minutes to mix the two raw materials uniformly to obtain a mixture;

[0036] b. Sprinkle foamed plastic particles into the ball-forming plate, spray water evenly on the surface of the foamed plastic particles to wet the surface, and then sprinkle the mixture obtained in step a at a constant speed and spray water on the surface of the particles. The mass ratio of the amount to the mixture is 1:2-2:1, and the ball-forming disc ro...

Embodiment 3

[0039] In this embodiment, the low-density zeolite biological aerated filter filler is composed of: 800g of zeolite ore, 200g of cement 425, foamed plastic particles, diameter of 2-4mm, and the volume of zeolite ore and cement. The volume ratio of the foam particles is 1:1.

[0040] The preparation method of the low-density zeolite biological aerated filter filler in this embodiment is as follows:

[0041] a. Crush the zeolite ore to obtain 40-100 mesh zeolite powder, add the zeolite powder and No. 425 cement to the mixer and mix for 30 minutes to mix the two raw materials uniformly to obtain a mixture;

[0042] b. Sprinkle foamed plastic particles into the ball-forming plate, spray water evenly on the surface of the foamed plastic particles to wet the surface, and then sprinkle the mixture obtained in step a at a constant speed and spray water on the surface of the particles. The mass ratio of the amount to the mixture is 1:2-2:1, and the ball-forming disk rotates at a constant spe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com