Horizontal high-temperature vacuum coating production line

A coating production line, vacuum coating technology, applied in the fields of vacuum, electronic spraying, and machinery manufacturing, can solve the problems of restricting the development of solar photovoltaic industry, affecting the uniformity of the coating layer, and the poor high temperature resistance of rubber rollers, etc., to achieve an effective control box The body temperature, the smoothness of substrate transfer, and the effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

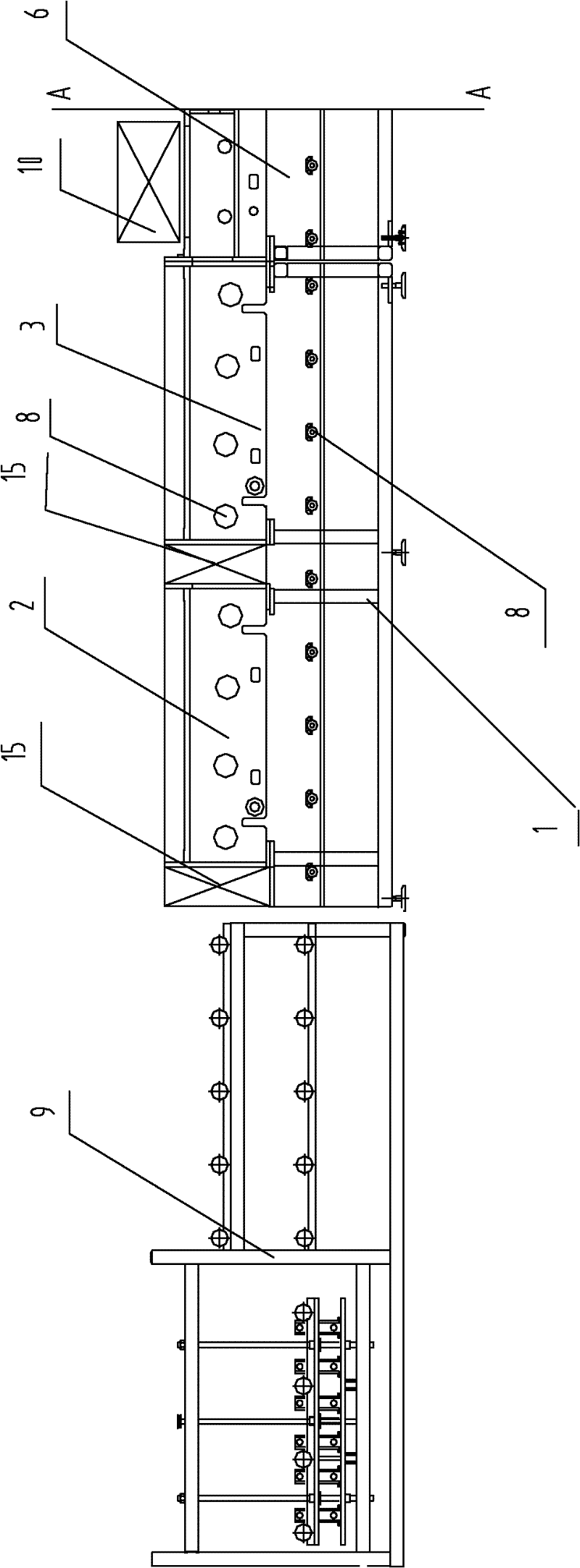

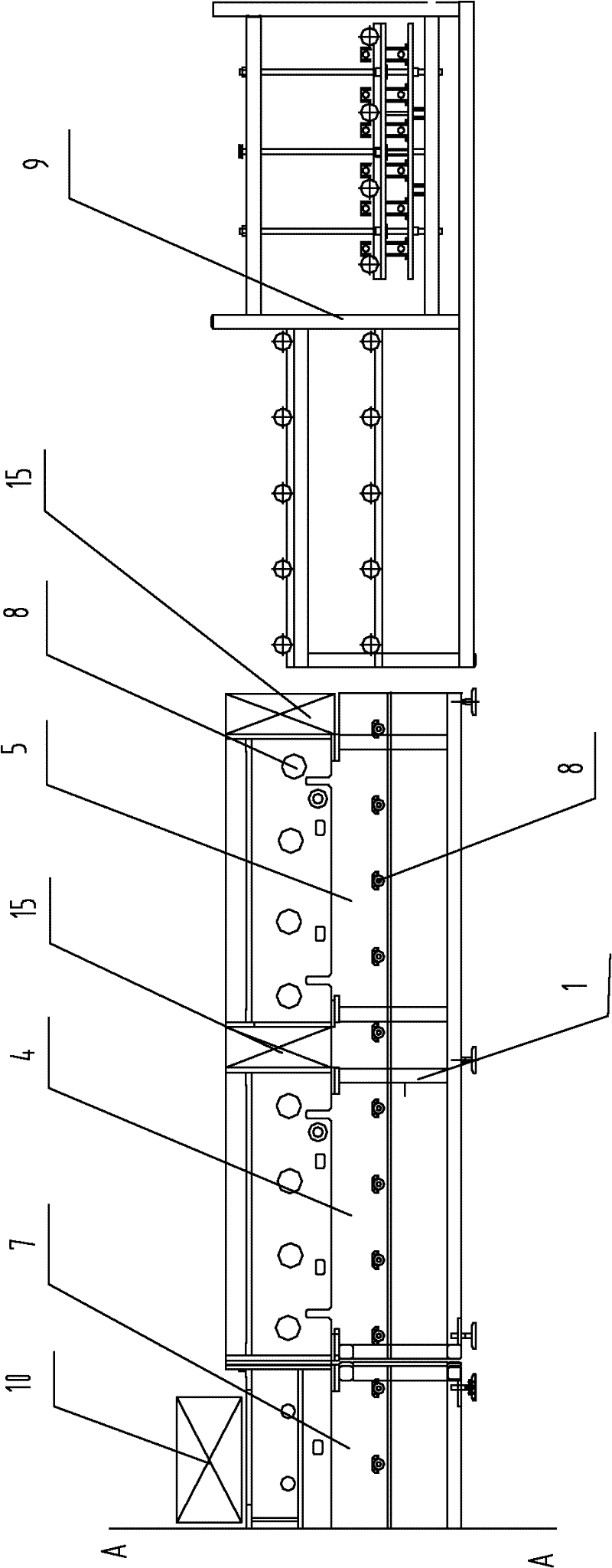

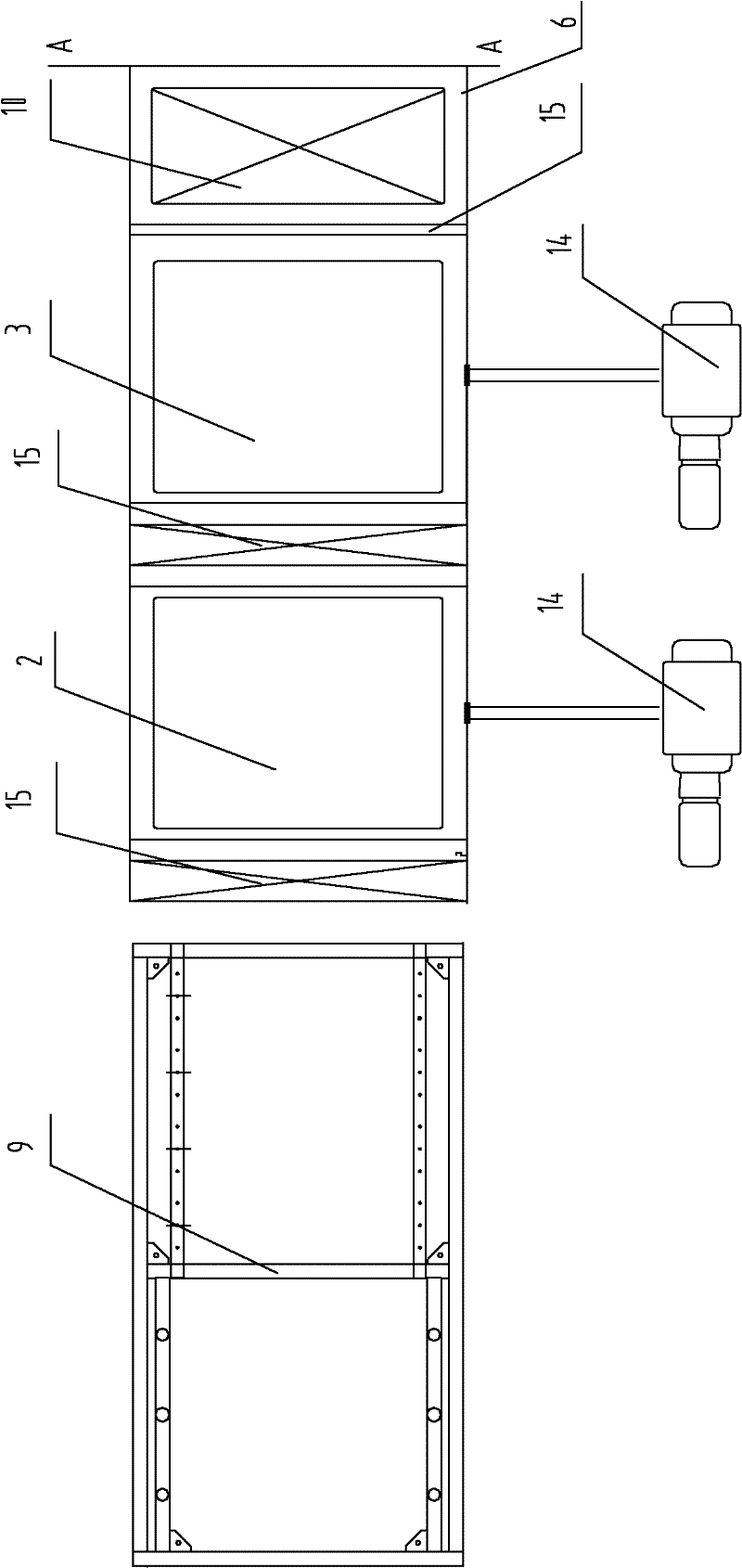

[0021] Referring to accompanying drawings 1, 2, 3, a horizontal high-temperature vacuum coating production line of the present invention includes a frame 1, four vacuum buffer boxes 2, 3, 4, 5, two vacuum coating boxes 6, 7, Substrate rack transfer mechanism 8, automatic loading and unloading sheet mechanism 9, the two vacuum coating boxes 6, 7 are arranged in the middle of the upper part of the frame 1, and the four vacuum buffer boxes 2, 3, 4, 5 Divided into two groups, respectively arranged on the frame 1 at the two ends of the vacuum coating box 6, 7, between the vacuum buffer box 2, 3, 4, 5 and between the vacuum buffer box 3, 4 and the vacuum coating box A pneumatic rotary plate valve 15 is arranged between the casings 6 and 7, and an automatic sheet loading and unloading mechanism 9 is respectively provided at both ends of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com