Laser microdissection apparatus and method

A laser micro-cutting and cutting curve technology, applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problem that the corresponding relationship between the cutting curve and the action of the micro-mirror array group has not been established, and the aberration of the micro-mirror array group increases. , chromatic aberration, inability to achieve cutting and other problems, to achieve the effect of small error, reduced volume, and short time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

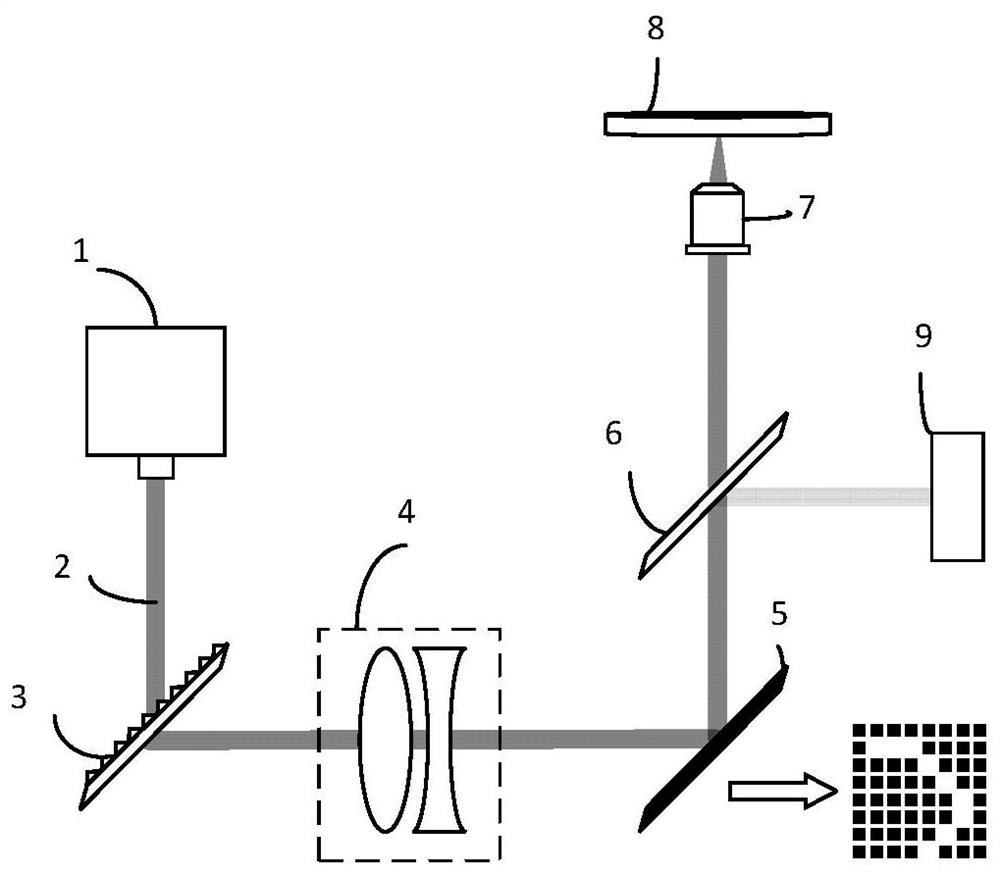

[0044] figure 1 Schematically provides a schematic structural diagram of the laser microdissection device in Example 1 of the present invention, as figure 1 As shown, the laser microdissection device includes:

[0045] Laser 1 and objective lens, these devices are the prior art in this field, and specific structure and mode of operation are not repeated here;

[0046] Micromirror array group 5, the micromirror array group includes a plurality of micromirrors arranged in an array; the output light of the laser is directed to the objective lens after being reflected by the micromirror array group;

[0047] A drawing unit, the drawing unit is suitable for operators to draw cutting curves, such as drawing cutting curves on computer screens and portable terminals;

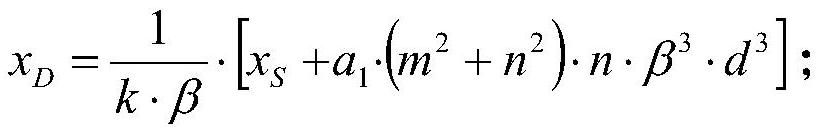

[0048] A calculation unit, the calculation unit obtains the inclination angle of each micromirror in the micromirror array group relative to the output light corresponding to any point in the cutting curve according t...

Embodiment 2

[0087] An application example of the laser microdissection device and method according to Embodiment 1 of the invention in embryo cutting.

[0088] In this application example, if figure 1 As shown, a laser 1, a transmission grating 3, an achromatic lens group 4, a micromirror array group 5, a dichromatic mirror 6, an objective lens 7, and a petri dish 8 are sequentially arranged on the optical path, and an eyepiece and a camera 9 are arranged on the side of the dichromatic mirror 6; The output light 2 of the laser 1 passes through the transmission grating 3 and the lens group 4, reflects on the micromirror array group 5, and passes through the dichromatic mirror 6 and the objective lens 7; the drawing unit and the calculation unit adopt a computer, which is suitable for the operator to operate on the computer Draw the cutting curve and display it on the computer screen;

[0089] In the laser microdissection method of the embodiment of the present invention, the laser microdi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com