Automatic grinding and mixing device for ultrahard material

A technology of superhard materials and mixing devices, which is applied in grain processing and other fields, can solve the problem of research on high-grade diamond and cubic boron nitride polycrystalline composite sheets, and the quality difference between diamond and cubic boron nitride polycrystalline composite sheets Larger, lack of automatic grinding and mixing devices for superhard materials, etc., to achieve the effect of easy automatic control, simple structure and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

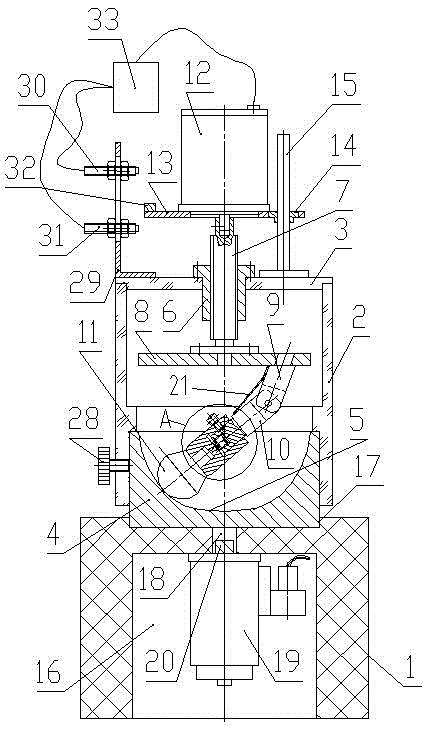

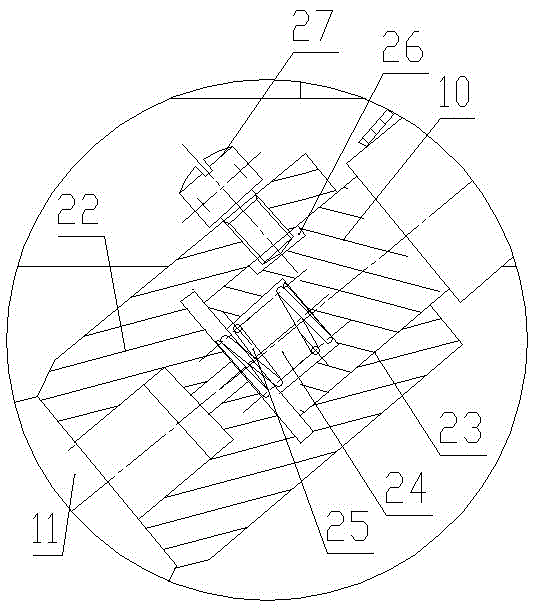

[0022] like figure 1 and figure 2 As shown, the superhard material automatic grinding and mixing device of this embodiment includes a base 1 and a support tube 2, a cover plate 3 is provided on the top of the support tube 2, a cemented carbide mortar is provided at the bottom of the inner cavity of the support tube 2, and a cemented carbide mortar is provided. The mortar comprises the mortar body 4 and the mortar groove 5 offered on the mortar body 4, and the mortar groove 5 top exposure The groove wall of the mortar tank 5 is provided with a bowl-shaped arc surface, and the mortar body 4 is supported and connected to the base 1 .

[0023] The center of the cover plate 3 is provided with a screw nut 6, the screw nut 6 is internally connected with a ball screw 7, the bottom end of the ball screw 7 extends in the support tube 2 and is connected with a rotating support plate 8, and the rotating support plate 8 is downward An upper hinge 9 is fixedly connected, and the upper h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com