Method for removing heavy metals and radioactive elements in ionic type mixed rare earth material liquid

A radioactive element and mixed rare earth technology, applied in the field of hydrometallurgy, can solve the problems of large processing capacity and high pollution control cost, and achieve the effects of high removal rate, reduced impurity content, and reduced processing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

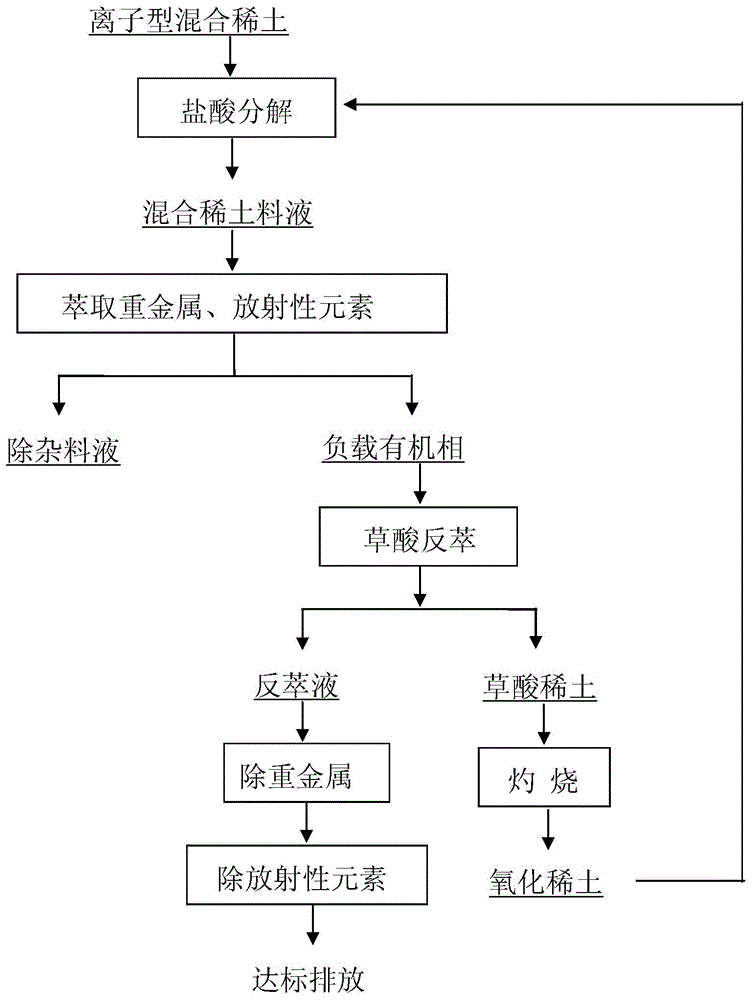

Method used

Image

Examples

Embodiment

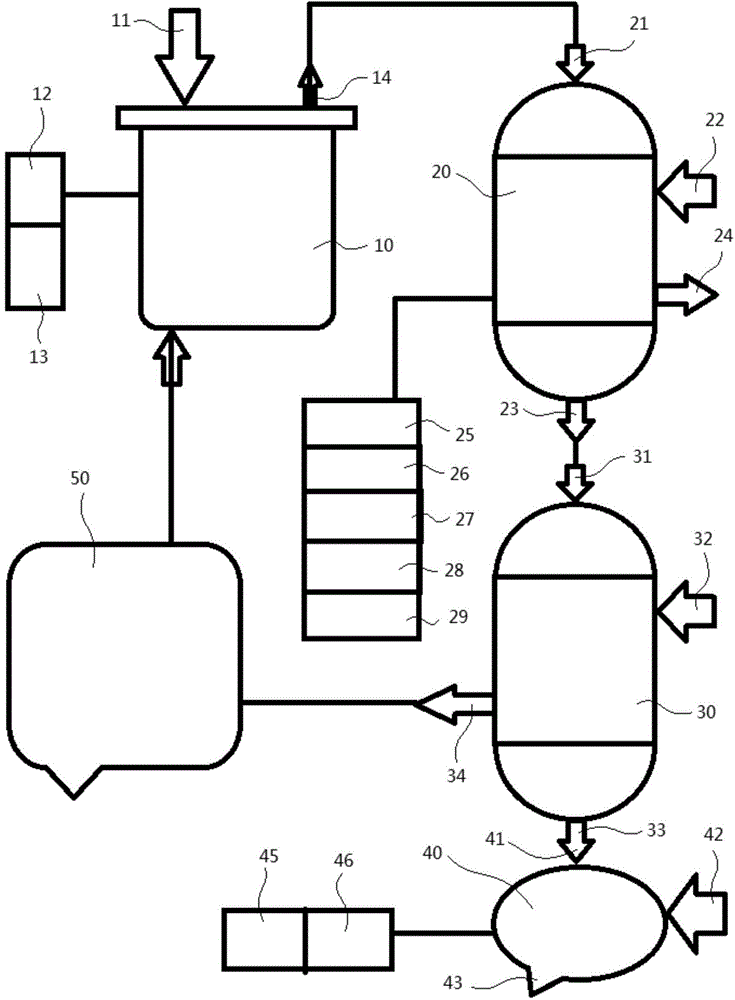

[0045] Embodiment: Hydrochloric acid decomposes ion-type mixed rare earth feed liquid acidity 0.05~0.5mol / L, rare earth feed liquid concentration 0.8~1.6mol / L; Organic extraction agent ammonia-free saponification degree 0.05~0.5mol / L; Compared to (1~ 4): 1. The mixing time is 10-20 minutes, and the clarification time is 10-15 minutes; the number of extraction tanks is 20-40, and the volume of the mixing chamber of the extraction tank is 5L; the processing capacity of feed liquid is 75-85kg / d.

[0046] After removal of impurities, the concentration REO of the ionic mixed rare earth feed solution is 0.8~1.6mol / L, the total amount of radioactive elements thorium and uranium<0.5mg / L; heavy metal elements: total cadmium<0.25mg / L, total lead<1.0mg / L , total arsenic <0.5mg / L, total chromium <4.0mg / L, hexavalent chromium <0.5mg / L.

[0047] The discharge outlet of the impurity removal wastewater workshop meets the "Rare Earth Industrial Pollutant Discharge Standard": the total amount o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com