Patents

Literature

35results about How to "Reduced linear shrinkage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Two-component addition type room temperature vulcanized silicone rubber for manufacturing handprint mold and footprint mold

The invention discloses a two-component addition type room temperature vulcanized silicone rubber for manufacturing a handprint mold and a footprint mold, which comprises a basic component and a catalyst component, wherein the volume ratio of the basic component to the catalyst component is 1-3:1; the basic component comprises the following raw materials: 40-80% of vinyl silicone oil, 0.5-10% of methyl hydrogen silicone fluid of cross-linking agent, 0.01-0.5% of inhibitor, 3-15% of releasing agent, 1-10% of plasticizer and 10-60% packing; and the catalyst component comprises the following raw materials: 40-80% of vinyl silicone oil, 3-15% of methyl vinyl siloxane coordination platinum complex, 3-15% of releasing agent, 1-10% of plasticizer and 10-60% of packing. The invention has convenience and safety.

Owner:合肥凯蒙新材料有限公司

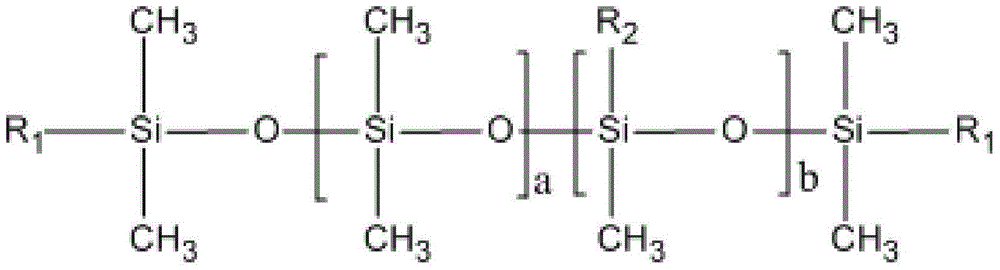

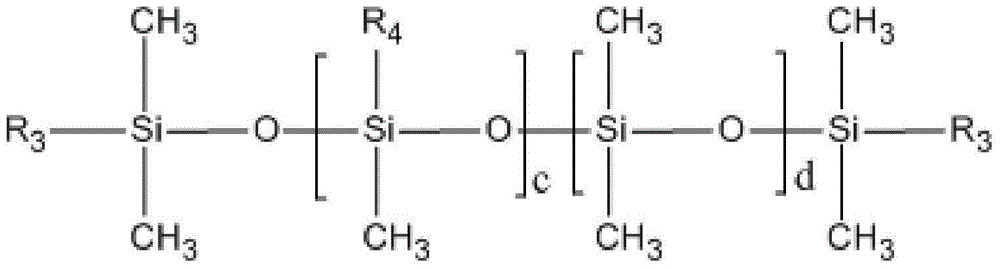

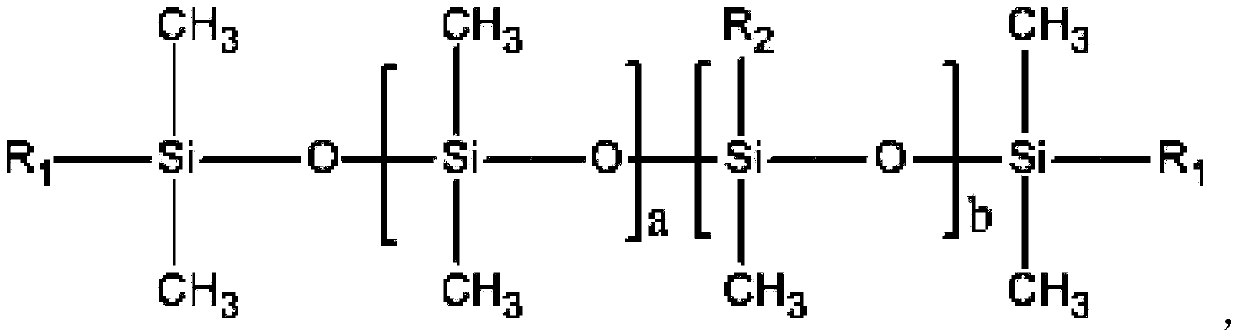

Organosilicon material, preparation method thereof, and application method thereof in 3D printing

The invention discloses an organosilicon material. The organosilicon material comprises: a component A comprising, by weight, 80-200 parts of organopolysiloxane, 20-60 parts of a reinforcing filler, 0-20 parts of silicon resin, 50-80 parts of a heat conduction filler, 2-20 parts of a structurized control agent, and 0.05-0.8 parts of a reaction catalyst; and a component B comprising, by weight, 80-200 parts of organopolysiloxane, 0.5-10 parts of organic hydrogen-containing polysiloxane, 20-60 parts of the reinforcing filler, 0-20 parts of silicon resin, 50-80 parts of the heat conduction filler, 2-20 parts of the structurized control agent, and 0.05-0.4 parts of a reaction inhibitor, wherein a weight ratio of the component A to the component B is 1:1. The invention also discloses a preparation method of the organosilicon material, and a method for applying the organosilicon material in 3D printing. The organosilicon material has the advantages of superior performances, safety and non-toxicity; the preparation method of the organosilicon material is simple and is easy to carry out; and application of the organosilicon material in 3D printing is maneuverable.

Owner:GUANGDONG BIOMAX SIANDF NEW MATERIAL CO LTD

Precisely cast low-temperature modulated wax and preparation method thereof

InactiveCN104592765AReduced linear shrinkageReduce the probability of subsidenceFoundry moulding apparatusParaffin waxProduction rate

The invention discloses a precisely cast low-temperature modulated wax and a preparation method thereof. The precisely cast low-temperature modulated wax comprises the following raw materials in parts by weight: 44-46 parts of microcrystalline wax, 2.5-3.5 parts of lignite wax, 34-36 parts of rosin resin, 3.5-4.5 parts of an ethylene-vinyl acetate copolymer and 12-14 parts of pure monomer resin. The wax disclosed by the invention is applied to a precision casting industry, has stability, hardly deforms due to high strength and hardly pollutes the metal cast due to low gray scale, is easy to demold, can be melted together with a wax mold to flow out of a shell during demolding; and the production rate can be effectively improved in the precision casting process.

Owner:青岛新诺科铸造材料科技有限公司

Polyurethane board and preparation method thereof

The invention discloses a polyurethane board and a preparation method thereof. The manufacturing method comprises the following steps of uniformly mixing a component A, a component B and compound filler to prepare a foaming material, injecting the foaming material into a die for compression molding, and finally demoulding to form a polyurethane board product, wherein the component A comprises a polyether polyol auxiliary a and a polyester polyol auxiliary b; the component B is isocyanate; the filler is prepared from an inorganic powder material, a plant powder material and a fiber material. According to the manufacturing method, the polyurethane board product is manufactured by uniformly mixing the compound polyester polyol, the isocyanate and the compound filler, injecting the mixture into the die and carrying out heat-preservation pressing. The obtained product is high in mechanical performance strength, low in linear shrinkage rate during storage and use, is not easy to warp after long-term storage and high in production and secondary processing precision, does not easily absorb water and can be applied to the field having high requirement on size precision.

Owner:昆山市柳鑫电子有限公司

Insulation mortar and preparation method thereof

InactiveCN107162634AImprove crack resistanceHigh bonding strengthCeramicwareFiberCarboxymethyl cellulose

The invention discloses an insulation mortar and a preparation method thereof, which belong to the technical field of the cement mortar. The insulation mortar comprises the following components: 100-150 parts of ordinary portland cement, 50-80 parts of vitreous bead, 50-70 parts of pregelatinized starch, 20-50 parts of coated expanded perlite, 20-30 parts of diatomite, 10-20 parts of modified attapulgite, 10-15 parts of rubber particles, 10-15 parts of plant composite fiber, 2-8 parts of soluble glass, 2-6 parts of carboxymethyl cellulose, 2-6 parts of fireproof particles, 1-6 parts of active admixture, 0.2-1.2 parts of a water repellent, 0.2-0.6 parts of a physical foaming agent, and 100-200 parts of water. The preparation method comprises the following steps: 1) preparing the coated expanded perlite; 2) preparing the straw-coated particles; 3) preparing a slurry; and 4) preparing the finished product. The insulation mortar has the advantages of excellent crack resistance, high bonding intensity and strong adhesive force.

Owner:合肥市晨雷思建筑材料科技有限公司

Preparation method of near net-shape of porous silicon nitride/silicon oxynitride ceramic composite material

InactiveCN101531538AReduced linear shrinkageIncreased three-point bending strengthCeramicwareCeramic compositeNear net shape

A preparation method of near net-shape of porous silicon nitride / silicon oxynitride ceramic composite material relates to a preparation method of near net-shape of composite material. The invention solves the problem that the shrinkage ratio of ceramic body of Si3N4 in sintering process is bigger. The method is as follows: porous silicon nitride green ware body is prepared; the green ware body is pre-sintered; dipping, gelation and drying are carried out; sintering is carried out so that the porous silicon nitride / silicon oxynitride ceramic composite material is prepared. The porous silicon nitride / silicon oxynitride ceramic composite material prepared by the method in the invention reduces the shrinkage ratio of the body when sintering while reaching the requirement of mechanical property. The method in the invention has simple technology, low cost and good repeatability.

Owner:HARBIN INST OF TECH

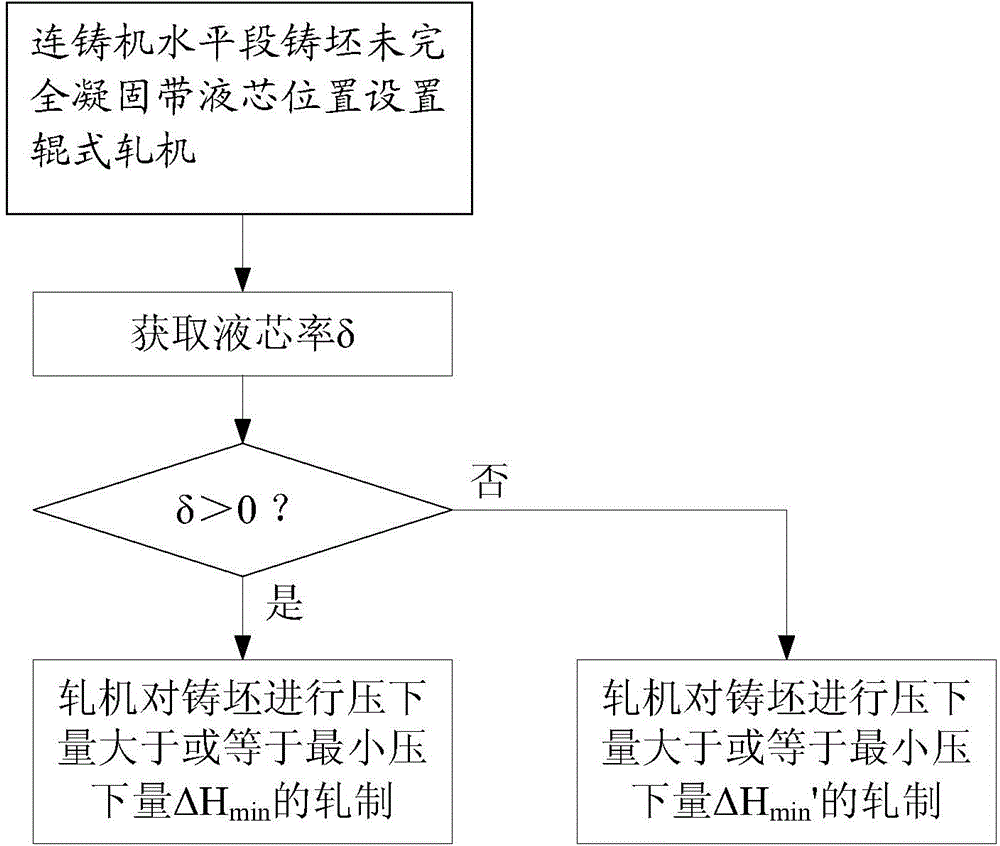

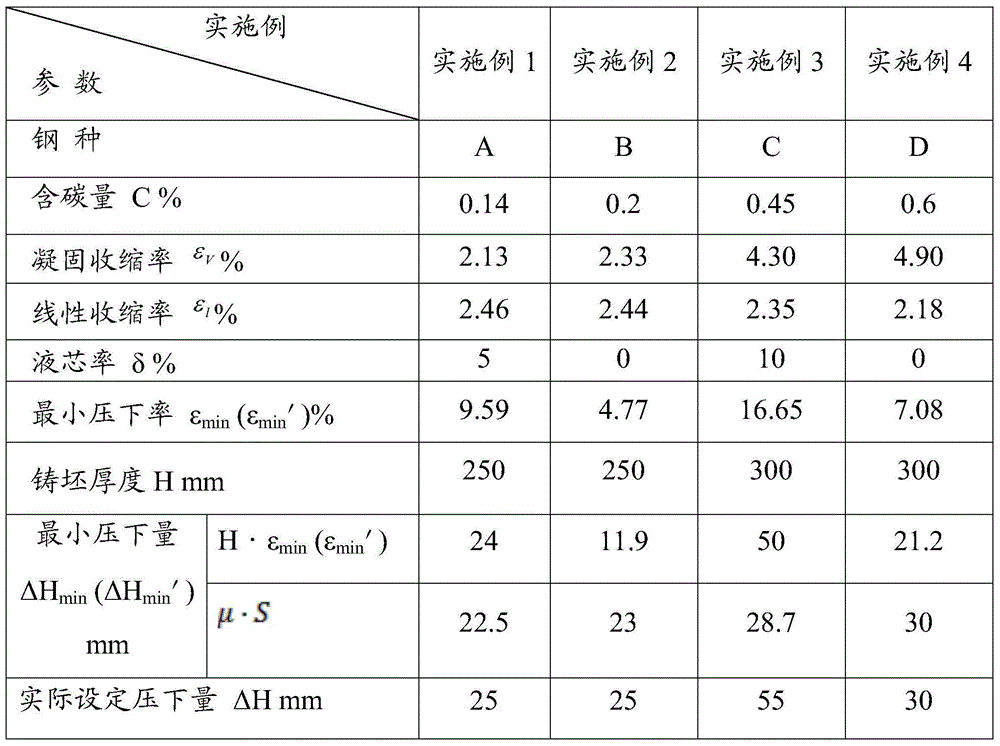

Rolling reduction control method under large liquid core pressure

ActiveCN104084429AImprove billet qualityRefine internal organizationRoll force/gap control devicePorosityModel control

The invention discloses a rolling reduction control method under large liquid core pressure. A roller-type rolling mill is arranged at the position, with a liquid core, of the horizontal segment of a continuous casting machine, wherein a casting blank is not completely solidified at the position. The liquid core rate delta is obtained at the position of the rolling mill, and whether the liquid core rate delta is larger than 0 or not is judged. If the liquid core rate delta is larger than 0, the rolling mill conducts rolling under the large liquid core pressure on the casting blank, wherein the rolling reduction of the rolling under the large liquid core pressure is larger than or equal to the minimum rolling reduction delta H min, and the minimum rolling reduction meets the equation that delta H min=max [H*(epsilon v + epsilon l + delta), mu*S]. According to the rolling reduction control method, center porosity, segregation, internal cracks and the like of the casting blank can be removed, the quality of the casting blank is improved, and internal organization is refined; the internal quality of the rolled casting blank is remarkably improved, the density of the casting blank is improved, the linear shrinkage percentage of cooling from high temperature to room temperature is at least reduced by 1.5%, the model control is easy, and the rolling reduction control method is easy to implement.

Owner:BERIS ENG & RES CORP

Heat insulation mortar and preparation method thereof

The invention discloses a heat insulation mortar and a preparation method thereof, and relates-the technical field of cement mortars. The heat insulation mortar comprises 100-150 parts of ordinary Portland cement, 50-80 parts of glazed hollow beads, 50-70 parts of pre-gelatinized starch, 20-50 parts of coated expanded perlite, 20-30 parts of diatomaceous earth, 10-20 parts of modified attapulgite,10-15 parts of rubber particles, 10-15 parts of plant composite fiber, 2-8 parts of water glass, 2-6 parts of carboxymethylcellulose, 2-6 parts of refractory particles, 1-6 parts of an active admixture, 0.2-1.2 parts of a water repellent, 0.2-0.6 part of a physical foaming agent and 100-200 parts of water. The preparation method comprises the following steps: (1) preparing the coated expanded perlite; (2) preparing straw coated particles; (3) preparing a slurry; and (4) preparing the finished product. The heat insulation mortar has the advantages of excellent crack resistance, high bonding strength and strong adhesion.

Owner:张建

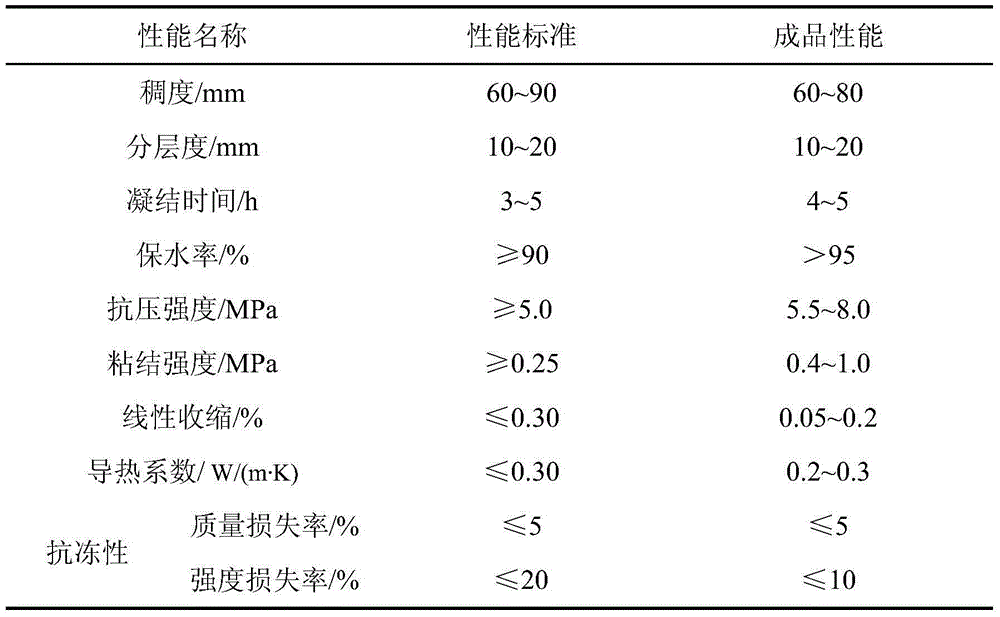

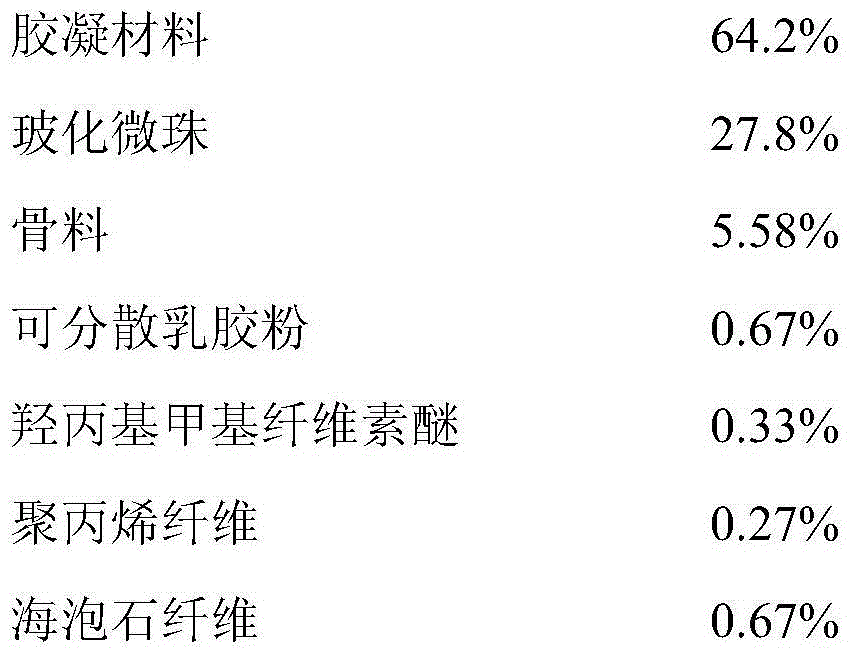

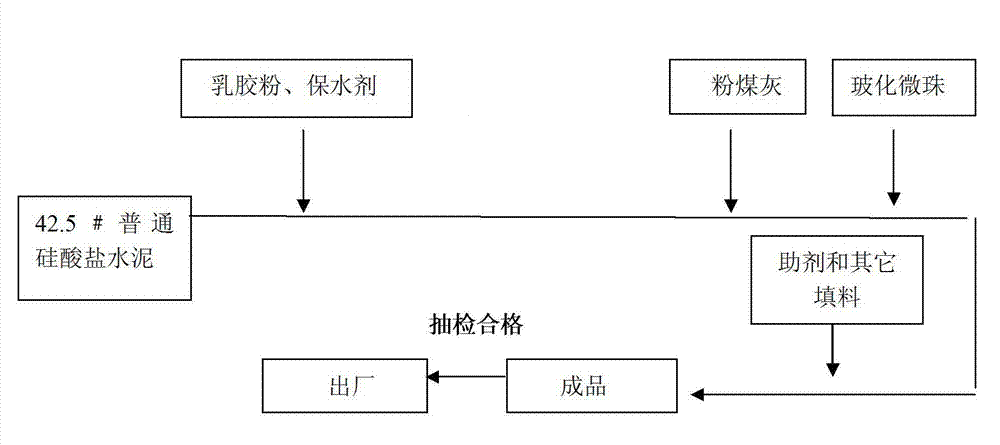

White vitrified bead modified insulation masonry mortar and using method thereof

ActiveCN104829179AReduce energy consumptionRemarkable effect of thermal insulation and energy savingEmulsionBuilding energy

The present invention belongs to the field of building energy-saving materials, and relates to white vitrified bead modified insulation masonry mortar and a using method thereof. The white vitrified bead modified insulation masonry mortar uses vitrified beads to partly replace aggregate, and comprises the fowling components by mass: 47.5-70.5% of a gelled material, 10%-35% of the vitrified beads, 3.6-20% of the aggregate, 0.3%-2% of dispersable emulsion powder, 0.1%-0.3% of hydroxypropyl methyl cellulose ether, 0.1%-1.2% of polypropylene fiber, 0.5%-1% of sepiolite fiber, 0.1%-0.5% of a waterproofing agent and 0.08%-0.3% of mortar king. The white vitrified bead modified insulation masonry mortar has excellent construction performance, good wall body bonding performance, and white color, and in the premise of meeting the basic mechanical properties and durability properties of the bonding mortar, effectively reduces the mortar thermal conductivity coefficient, saves building energy consumption, and is very broad in application development prospect.

Owner:SOUTHEAST UNIV

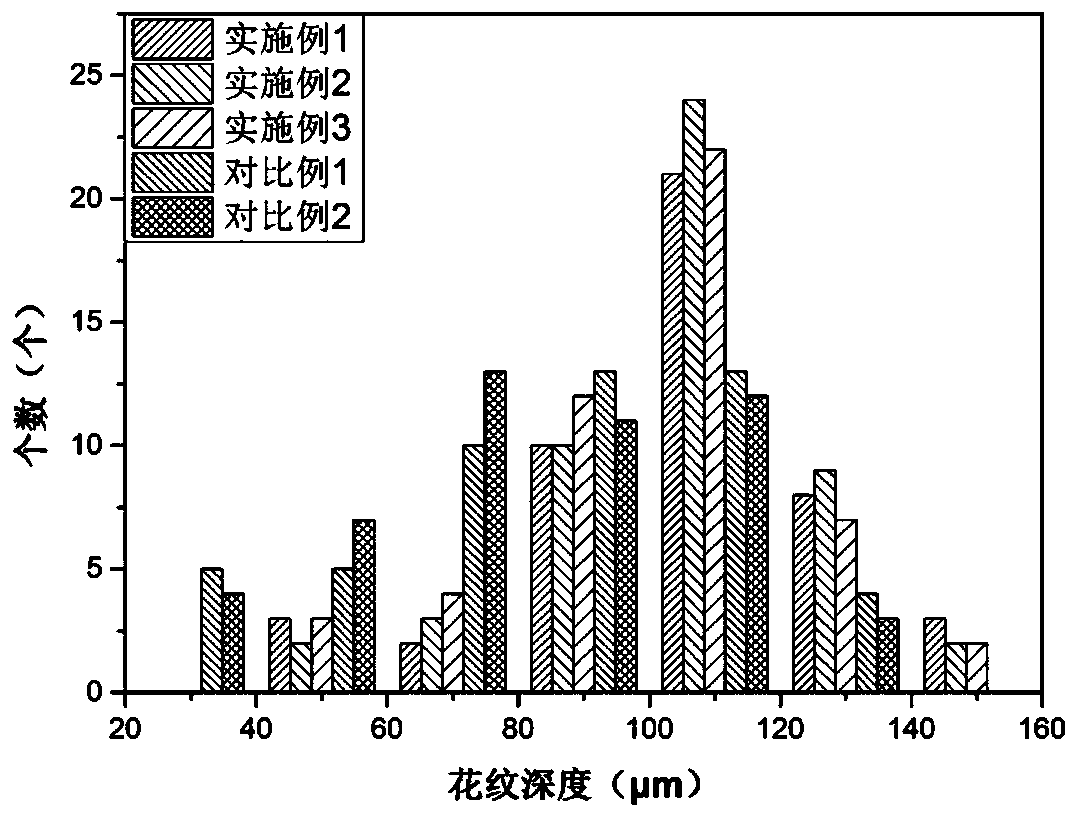

Addition type silica gel for remaking refined decorative pattern mold, preparation method and application thereof

The invention relates to an addition type silica gel for remaking a refined decorative pattern mold, a preparation method and application thereof and solves the problem that the simulation rate of a decorative pattern of an epoxy mold is low as epoxy resin and a double-component addition type silica gel are poor in wettability. The addition type silica gel is prepared from the following componentsin parts by weight: 50-70 parts of vinyl silicone oil, 25-35 parts of hydrogen containing silicone oil, 20-40 parts of vinyl MQ silicone resin, 10-12 parts of fumed silica, 1-2 parts of a platinum catalyst, 0.1-1.0 part of an inhibitor and 0.1-3 parts of a high molecular surfactant of polyether. The preparation method comprises the following steps: uniformly mixing the vinyl silicone oil, the hydrogen containing silicone oil, the high molecular surfactant of polyether and the inhibitor as a component A; uniformly mixing the vinyl silicone oil, the platinum catalyst, the high molecular surfactant of polyether and the inhibitor as a component B; and then separately blending the vinyl MQ silicone resin and the fumed silica into the components A and B to be stirred and vacuumizing and defoaming the mixture to obtain the addition type silica gel. The addition type silica gel is good in wettability to an epoxy resin mold and can copy the decorative pattern of the mold precisely, and the addition type silica gel is simple in method and low in cost.

Owner:JILIN UNIV +1

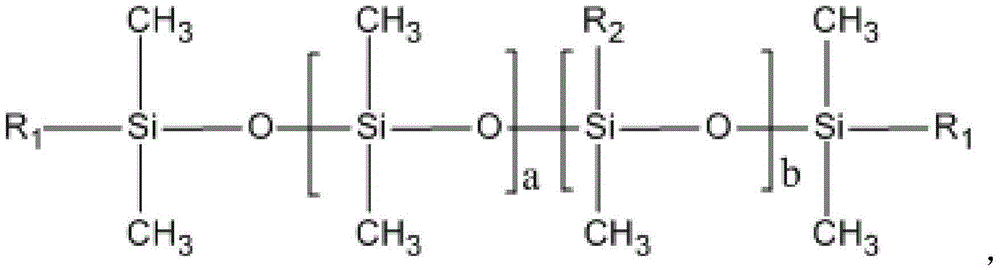

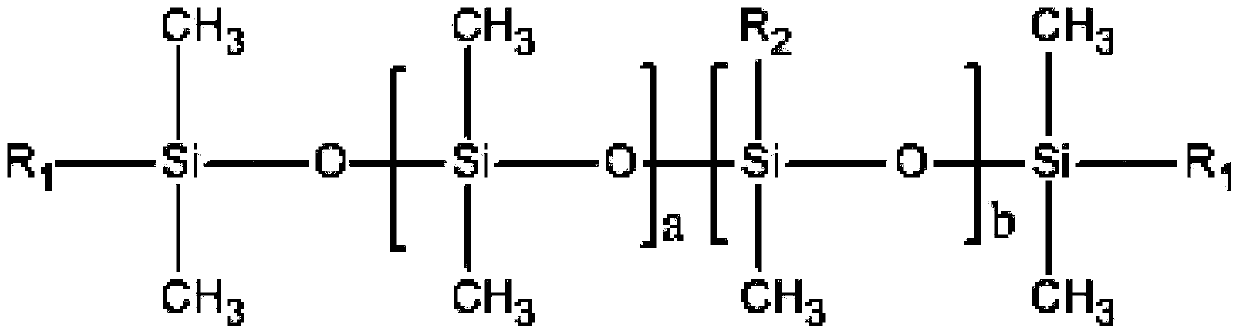

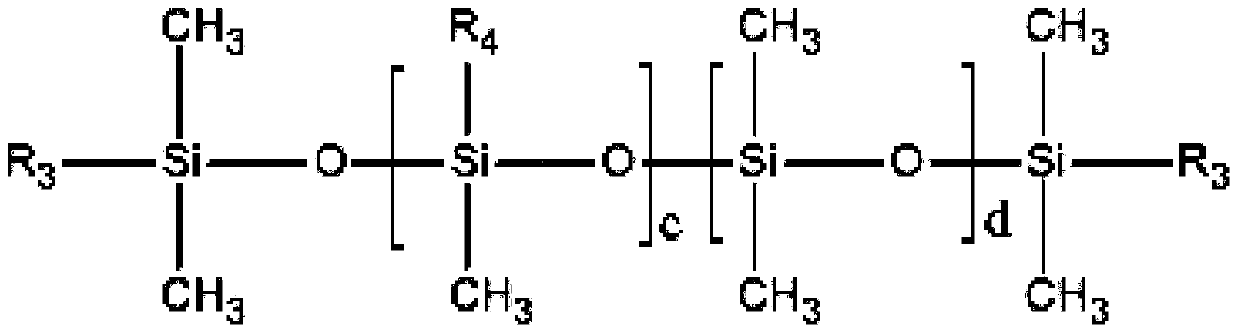

A kind of organosilicon material and its preparation method and its application method for 3D printing

ActiveCN105238064BReduced linear shrinkageGood flexibility3D object support structuresHydrogenNon toxicity

The invention discloses an organosilicon material. The organosilicon material comprises: a component A comprising, by weight, 80-200 parts of organopolysiloxane, 20-60 parts of a reinforcing filler, 0-20 parts of silicon resin, 50-80 parts of a heat conduction filler, 2-20 parts of a structurized control agent, and 0.05-0.8 parts of a reaction catalyst; and a component B comprising, by weight, 80-200 parts of organopolysiloxane, 0.5-10 parts of organic hydrogen-containing polysiloxane, 20-60 parts of the reinforcing filler, 0-20 parts of silicon resin, 50-80 parts of the heat conduction filler, 2-20 parts of the structurized control agent, and 0.05-0.4 parts of a reaction inhibitor, wherein a weight ratio of the component A to the component B is 1:1. The invention also discloses a preparation method of the organosilicon material, and a method for applying the organosilicon material in 3D printing. The organosilicon material has the advantages of superior performances, safety and non-toxicity; the preparation method of the organosilicon material is simple and is easy to carry out; and application of the organosilicon material in 3D printing is maneuverable.

Owner:GUANGDONG BIOMAX SIANDF NEW MATERIAL CO LTD

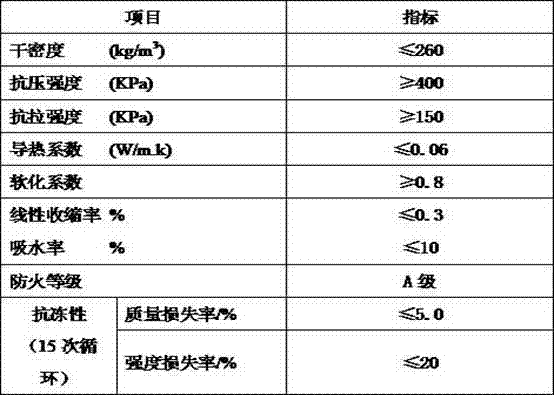

Inorganic vitrified micro bubble external heat-insulating system for outer wall

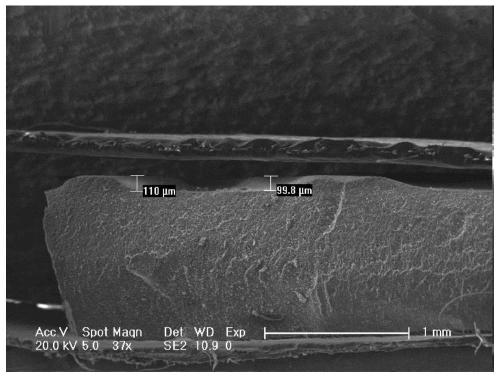

InactiveCN102359237BHigh densityImprove thermal conductivityCovering/liningsHeat proofingCalcium hydroxideInsulation layer

The invention relates to an inorganic vitrified micro bubble external heat-insulating system for an outer wall, which comprises an interface layer, an inorganic vitrified micro bubble heat-insulating layer, a crack-resisting mortar covering surface layer and a finishing coat. Inorganic heat-insulating mortar for preparing the inorganic vitrified micro bubble heat-insulating layer is formed by vitrified micro bubbles and powder according to the weight ratio of (0.6-0.8):1; the powder contains 200-300 parts of cement, 200-250 parts of fly ash, 8-10 parts of emulsion powder, 0.8-1.6 parts of polypropylene fiber, 60-100 parts of calcium hydroxide, 2-6 parts of wood fiber, 2-4 parts of water repellent, 6-8 parts of HPMC (Hydroxy-Propyl Methyl Cellulose), 2-5 parts of modified polyethylene glycol oxide and 0.4-0.6 part of bentonite. Various performance indexes of the heat-insulating mortar disclosed by the invention, such as material density, heat conductivity coefficient, heat storage coefficient, the shrinking percentage, the strength and the like, are superior to those of general vitrified micro bubble heat-insulating mortar; and the inorganic vitrified micro bubble external heat-insulating system has greater advantages in the heat storage coefficient, compressive strength and the like and can be used for well solving the problems of heat insulation, weather resistance and durability of the heat-insulating system.

Owner:信阳金固建筑节能保温工程有限公司

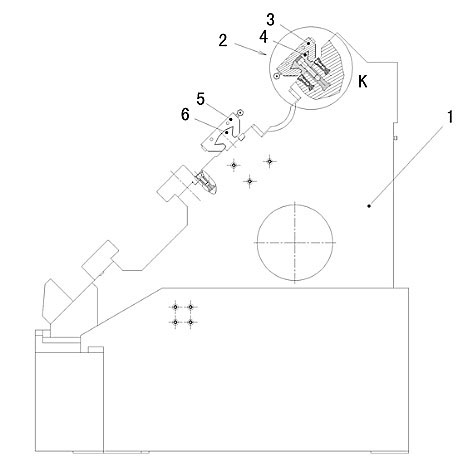

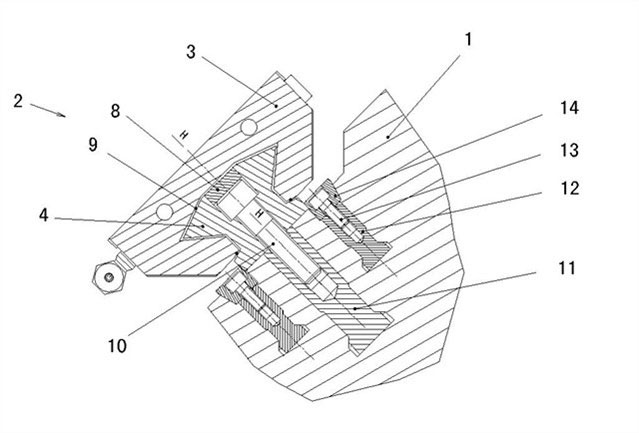

Numerical control turning center with hydrostatic guide rails and hydrostatic spindle system

InactiveCN102069198AIncrease oil film stiffnessImprove bearing capacityLarge fixed membersTurning machinesPhysicsEngineering

The invention relates to a numerical control turning center with hydrostatic guide rails and a hydrostatic spindle system. A slant bed body is provided with an upper guide rail and a lower guide rail which are parallel with each other, and each guide rail is provided with a slide block; a static pressure chamber is arranged between each guide rail and each slide block matched with the guide rail, the periphery of the static pressure chamber is provided with sealing element, the static pressure chamber is communicated with an oil inlet and outlet pipe joint, and the oil inlet and outlet pipe joint is in threaded connection with the slide block and is connected with an oil supply device through a pipeline; the slant bed body is fixedly provided with a spindle box bracket, and the upper part of the spindle box bracket is fixedly connected with the hydrostatic spindle system mechanism; and the slant bed body is made of artificial granite materials. An oil film is formed between the slide block and the guide rail in working, the oil film has high rigidity, large bearing capacity and a vibration absorbing function, a coupling surface of the guide rails is not rubbed or abraded, the rigidity of guide rail structures is enhanced with fewer overall parts, the vibration is reduced in operation, and the accuracy is high.

Owner:大连机床(数控)股份有限公司

Novel inorganic lightweight mortar and reinforcing agent product

The invention discloses a novel inorganic lightweight mortar and a reinforcing agent product. The novel inorganic lightweight mortar comprises the following components by mass: 75 to 85 parts of mineral fiber, 3.5 to 5.5 parts of magnesium carbonate (calcium carbonate), 2 to 4 parts of cellulose, 6 to 7.5 parts of water-proofing agent, 0.03 to 0.15 part of dispersing agent, and 4.5 to 6.5 parts of fiber. The novel inorganic lightweight mortar and the reinforcing agent product have the advantages that the operability of the inorganic lightweight mortar and the product can be obviously improved, the construction time is saved, the construction efficiency is improved, the construction cost is reduced, the tensile strength, the adhering strength and the softening coefficient of the inorganic lightweight mortar and the product are greatly improved; the linear shrinkage is reduced, the phenomena of hollowing, cracking and separating can be prevented, and the safety of the heat insulation material is improved; the inorganic lightweight mortar and the product with the reinforcing agent adopted are high in fireproofing grade, light in volume weight, low in coefficient of thermal conductivity, and excellent in heat insulation performance; and the reinforcing agent has no pollution in the production and application, and is environment-friendly and beneficial for recycling waste, so as to meet the requirement on energy conservation of a building.

Owner:江苏华伟佳建材科技有限公司

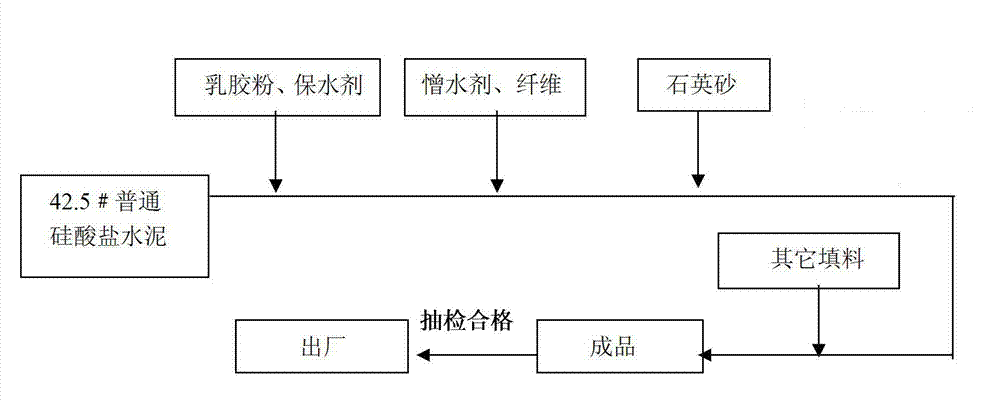

Lightweight plastering mortar and preparation method thereof

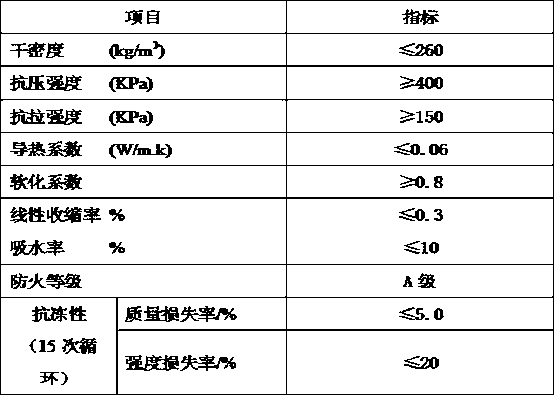

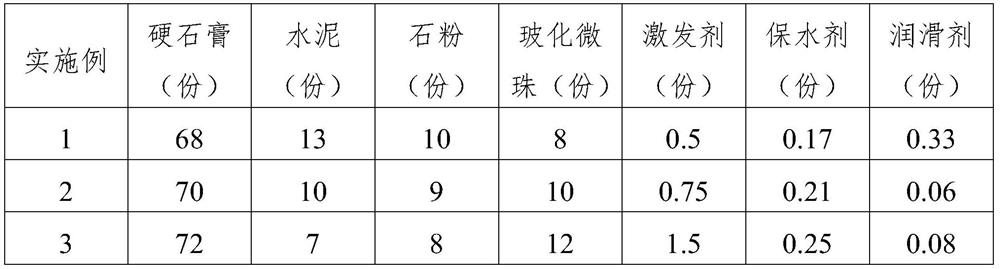

The invention discloses lightweight plastering mortar and a preparation method thereof. The lightweight plastering mortar is prepared from the following components in parts by mass: 68 to 72 parts of anhydrite, 10 to 15 parts of cement, 8 to 10 parts of stone powder, 8 to 12 parts of vitrified micro bubbles of 70 to 90 meshes, 0.5 to 1.5 parts of an accelerator, 0.17 to 0.25 part of a water-retaining agent and 0.03 to 0.08 part of a lubricant. The preparation method of the lightweight plastering mortar comprises the steps of S1, weighing the raw materials in parts by mass; and S2, sieving the anhydrite weighed in the step S1 with a 200-mesh sieve to obtain sieved anhydrite, crushing the stone powder, sieving with a 0.2 mm-sieve to obtain sieved stone powder, uniformly mixing the sieved anhydrite, the sieved stone powder and the other raw materials weighed in the step S1, stirring and mixing for 4-6 minutes, and then sub-packaging to obtain the lightweight plastering mortar. Compared with the traditional cement mortar, the lightweight plastering mortar disclosed by the invention has the advantages of higher strength, higher bonding strength, lower linear shrinkage rate, stronger water-retaining property and the like.

Owner:安徽亿捷环保科技有限公司

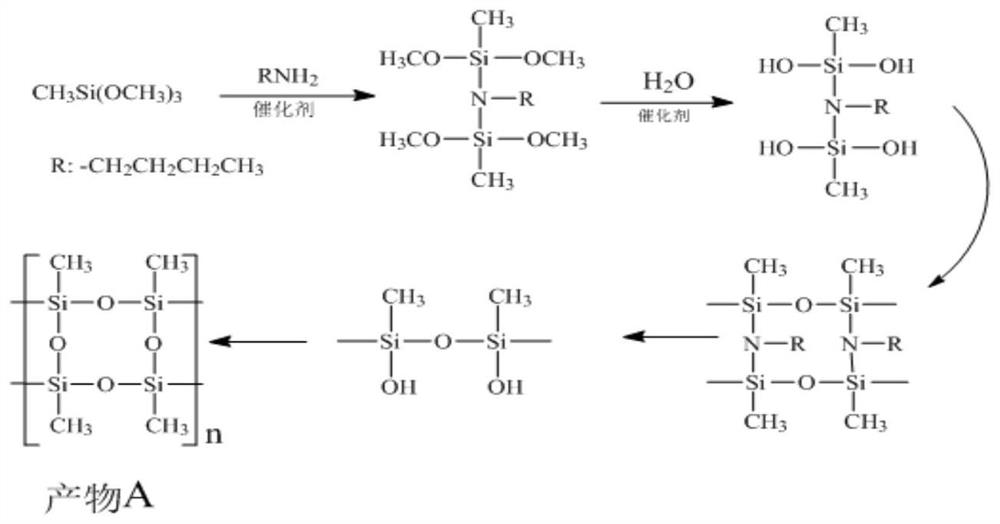

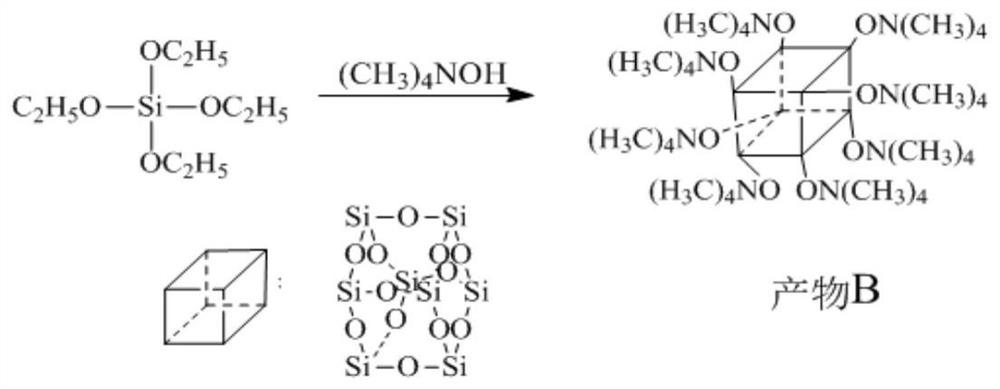

Self-flame-retardant organic silicon resin for PCB, preparation method of self-flame-retardant organic silicon resin and composition containing self-flame-retardant organic silicon resin

PendingCN112457496AImprove flame retardant performancePrevent overflowCircuit susbtrate materialsSilicone resinOrganosilicon

The invention provides a self-flame-retardant organic silicon resin for a PCB, a preparation method of the self-flame-retardant organic silicon resin and a composition containing the self-flame-retardant organic silicon resin, the resin structure takes a cage-shaped structure as a fulcrum, and an organic silicon main chain similar to a ladder-shaped structure is connected to a side chain of the fulcrum through a flexible chain segment, so that the product has high strength and certain toughness; the thermal stability of the cured organic silicon resin is superior to that of common bisphenol Aepoxy resin; by adjusting the numerical values of m and n in the molecular structure, the product has high carbon-forming property, and the synthesized organic silicon resin belongs to a flame-retardant material and has certain flame retardancy; and the synthesized organic silicon resin contains a vinyl group, has high stability, is easy to store for a long time, has a simple curing process, doesnot produce micromolecular byproducts in the curing process, and has low shrinkage rate, good dimensional stability, low product thermal expansion coefficient and good heat conduction property after curing.

Owner:西安安聚德纳米科技有限公司

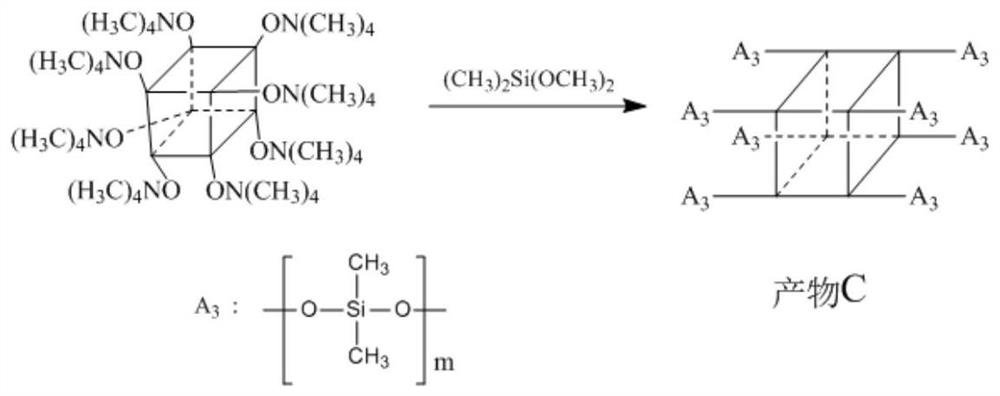

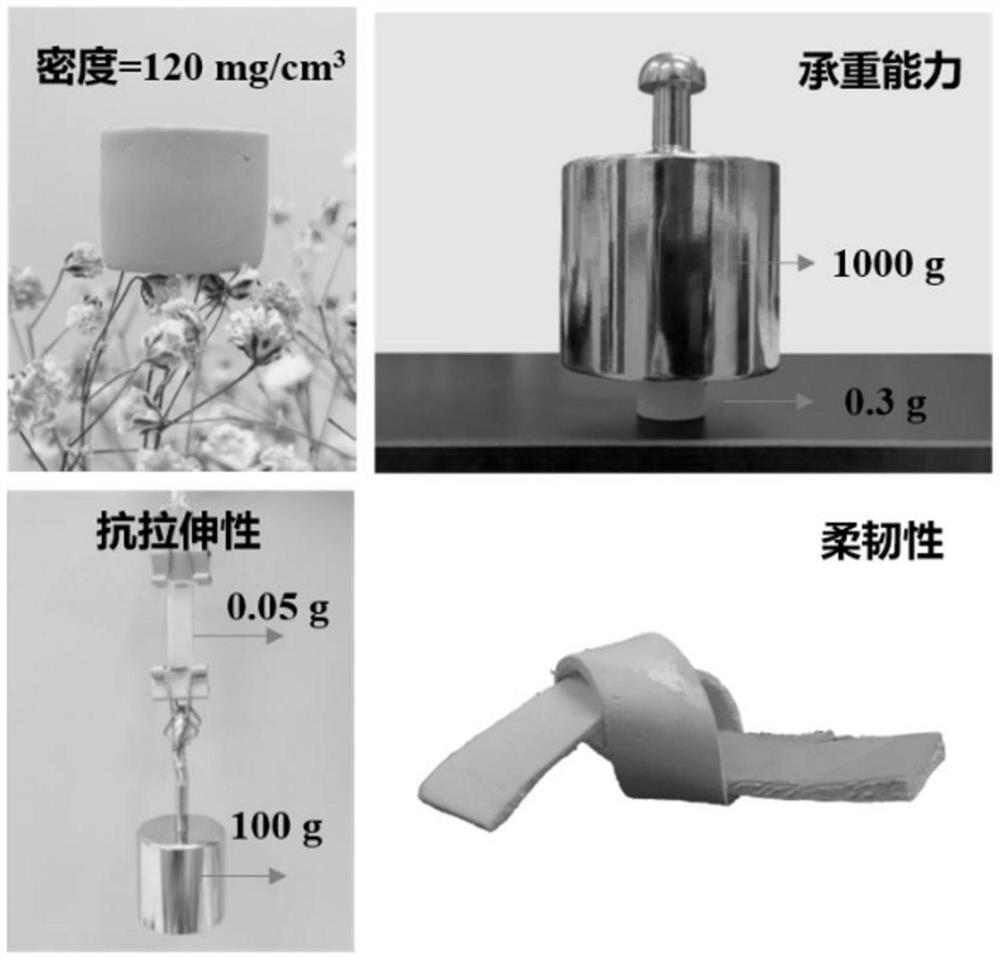

Recyclable multifunctional dynamic covalent polymer aerogel materials and their preparation methods and applications

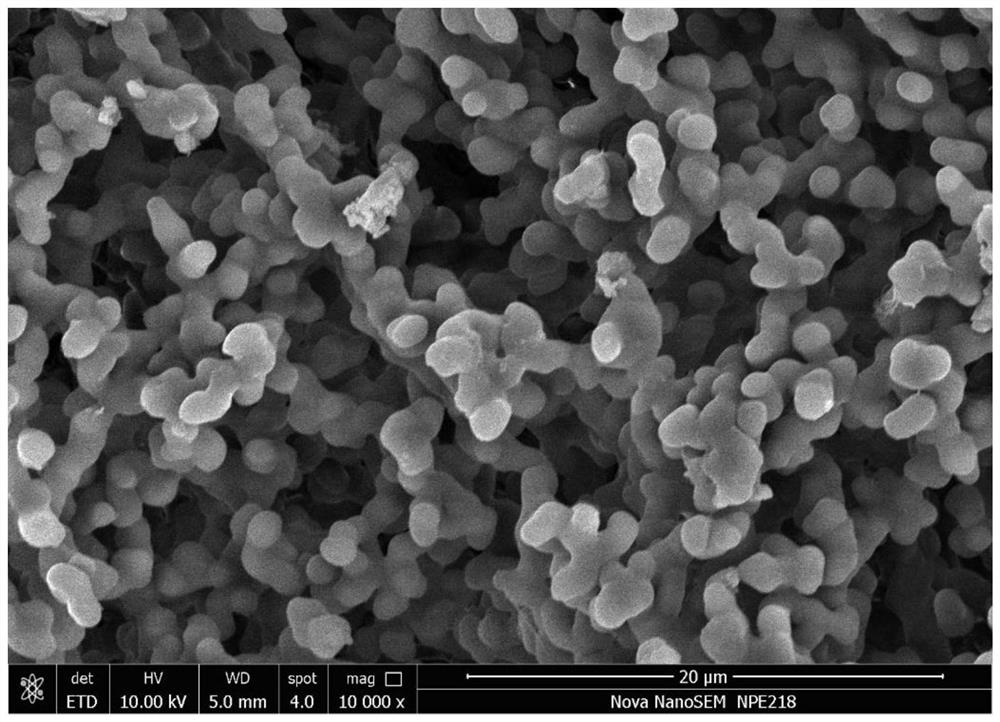

ActiveCN113402764BConductiveImprove mechanical propertiesCarbon preparation/purificationAerogel preparationPolymer scienceCross linker

The present invention provides a method for preparing a recyclable multifunctional dynamic covalent polymer aerogel material, which comprises the following steps: S1, mixing at least one difunctional reactive monomer A and at least one difunctional The reaction monomer B is dissolved in the solvent, and the prepolymer is obtained by stirring reaction; S2, adding a compound C containing at least three functional groups to the prepolymer obtained in step S1 as a crosslinking agent to obtain a dynamic covalent polymer wet coagulation glue; S3, subjecting the obtained dynamic covalent polymer wet gel to aging treatment and solvent exchange treatment, and then drying to obtain a recyclable multifunctional dynamic covalent polymer aerogel material; the recyclable multifunctional dynamic covalent polymer aerogel material; The dynamic covalent bond in the covalent polymer aerogel material is at least one of imine bond, disulfide bond and boron-oxygen bond. The method of the invention constructs a dynamic polymer gel network through dynamic covalent bonds, and realizes the recyclability of aerogel materials.

Owner:颜徐州

Near-net size preparation method of porous silicon nitride/silicon oxynitride ceramic composites

InactiveCN101531538BReduced linear shrinkageIncreased three-point bending strengthCeramicwareCeramic compositeShrinkage rate

Owner:HARBIN INST OF TECH

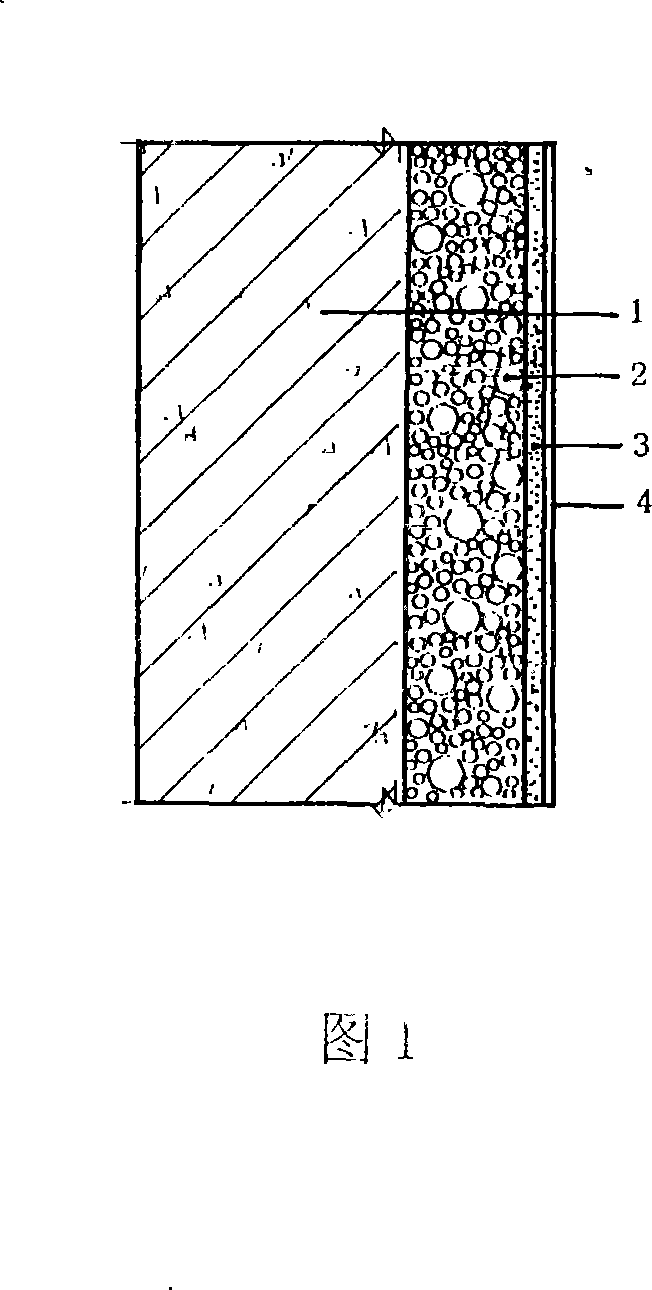

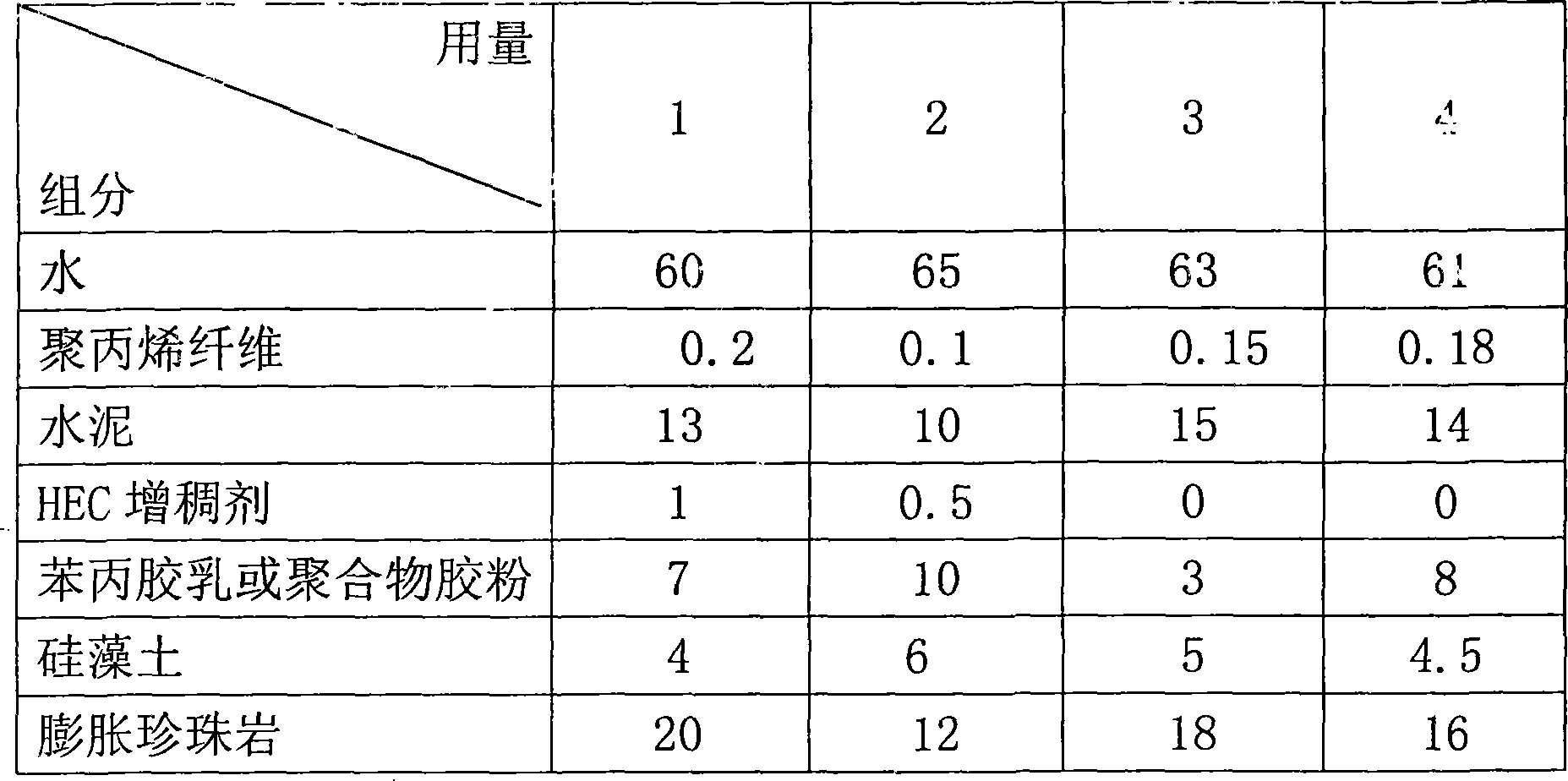

Construction thermal insulation decorative system

The invention relates to a building heat insulating finish system, which solves the problems existing in the current system of a plurality of levels, large thickness and weight, lots of construction procedures and high cost, and comprises a basal wall, a heat insulating paste layer and a flexible putty layer, wherein the basal wall (1) is connected with the heat insulating paste layer (2), the surface of the heat insulating paste layer is connected with the flexible putty layer (3) through self materials of the two layers, and the heat insulating paste layer is formed through directly smearing paste which is mixed by the constituents with the following parts by weight on the surface of the basal course wall (1), 60-65 water, 0.1-0.2 polypropylene fiber, 10-15 cement, 0-1 HFC thickening agent, 3-10 benzene propyl latex or polymer gelatin powder, 4-6 diatom earth and 12-20 expanded perlite.

Owner:干开鑫

Two-component addition type room temperature vulcanized silicone rubber for manufacturing handprint mold and footprint mold

The invention discloses a two-component addition type room temperature vulcanized silicone rubber for manufacturing a handprint mold and a footprint mold, which comprises a basic component and a catalyst component, wherein the volume ratio of the basic component to the catalyst component is 1-3:1; the basic component comprises the following raw materials: 40-80% of vinyl silicone oil, 0.5-10% of methyl hydrogen silicone fluid of cross-linking agent, 0.01-0.5% of inhibitor, 3-15% of releasing agent, 1-10% of plasticizer and 10-60% packing; and the catalyst component comprises the following rawmaterials: 40-80% of vinyl silicone oil, 3-15% of methyl vinyl siloxane coordination platinum complex, 3-15% of releasing agent, 1-10% of plasticizer and 10-60% of packing. The invention has convenience and safety.

Owner:合肥凯蒙新材料有限公司

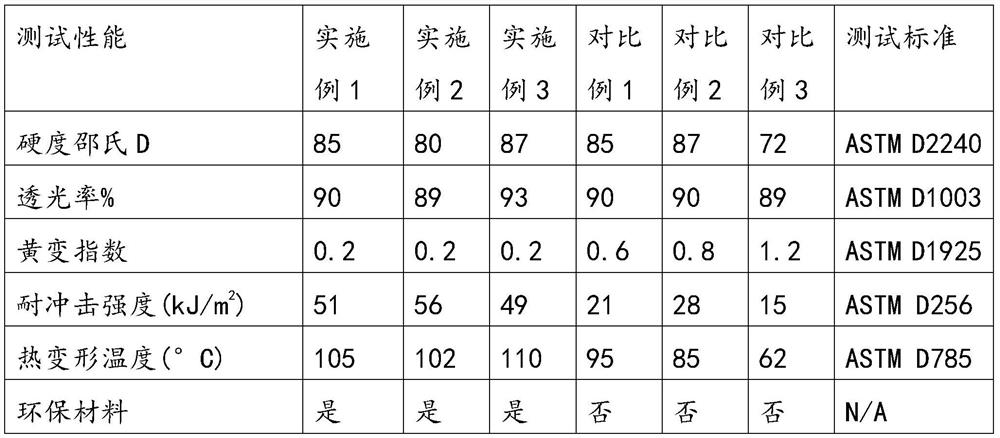

A kind of environment-friendly high-hardness and high-transparency polyurethane resin and preparation method thereof

The invention discloses an environment-friendly high-hardness and high-transparency polyurethane resin, which comprises the following raw materials in parts by weight: 65-100 parts by weight of a polymer and 100 parts by weight of a curing agent; the polymer is composed of the following parts by weight of raw materials: 96-98 parts by weight of grease polyol, 0.5-1 parts by weight of antioxidant, 0.5-1 parts by weight of ultraviolet absorber, 0.3-0.5 parts by weight of catalyst; the curing agent is composed of the following raw materials by weight: isocyanate 85-95 parts by weight, 5-15 parts by weight of organic amine; the beneficial effects of the present invention are: the environment-friendly high-hardness and high-transparency polyurethane resin of the present invention is made up of two parts, a polymer and a curing agent, and the raw materials used are environmentally friendly raw materials, which will not Harmful to the environment and the human body, without carcinogens; the environmentally friendly high-hardness and high-transparency polyurethane resin described in the present invention has high strength and toughness, and has the characteristics of high temperature resistance and low linear shrinkage rate. The products made of it Has excellent yellowing resistance and transparency.

Owner:北京小鸡磕技文化创意有限公司 +1

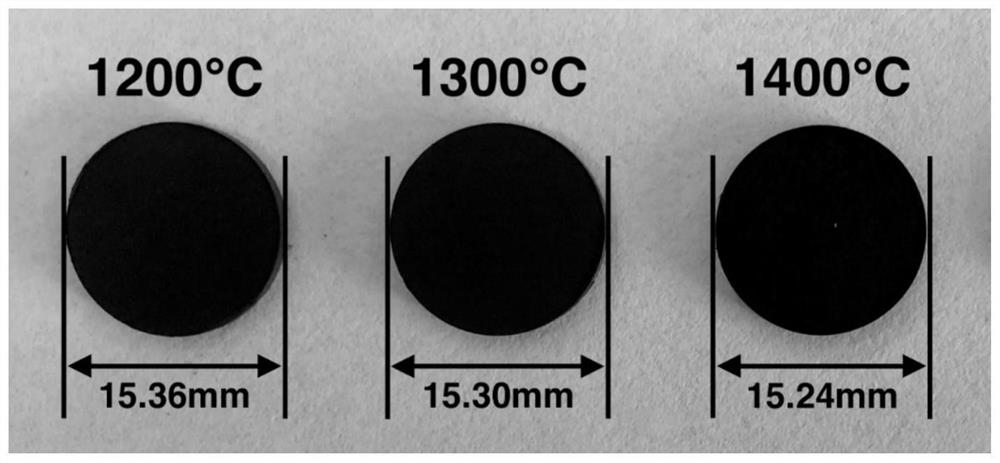

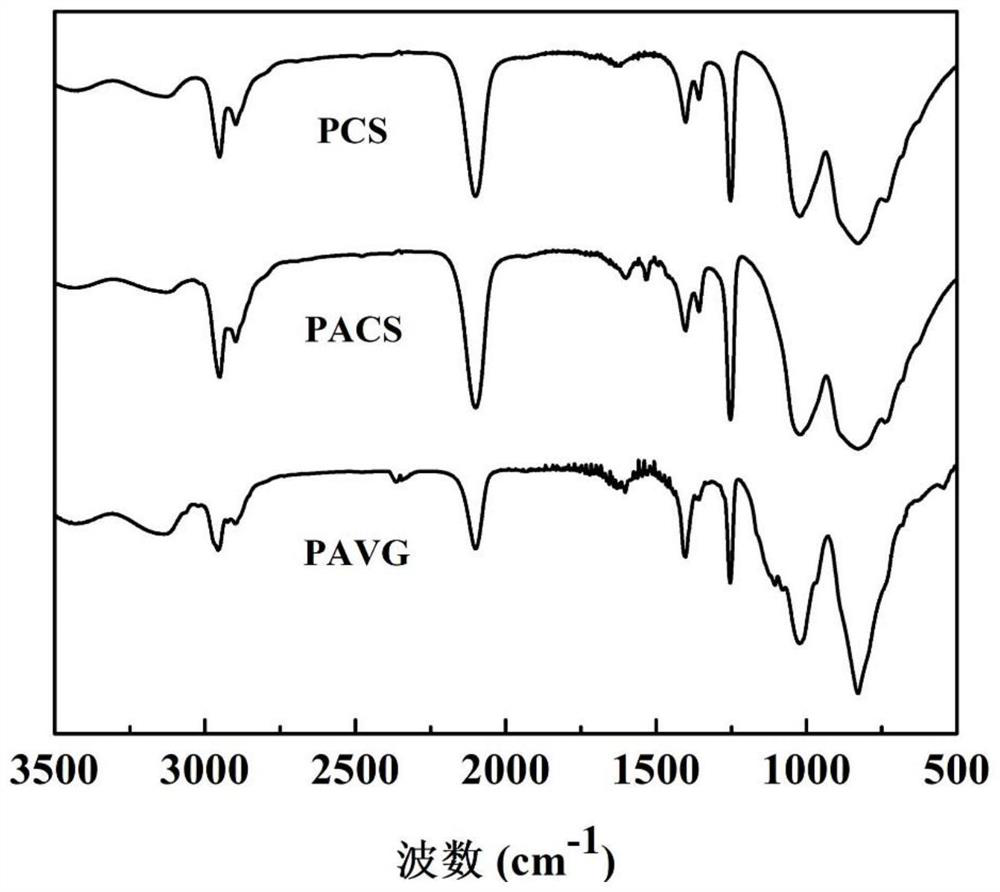

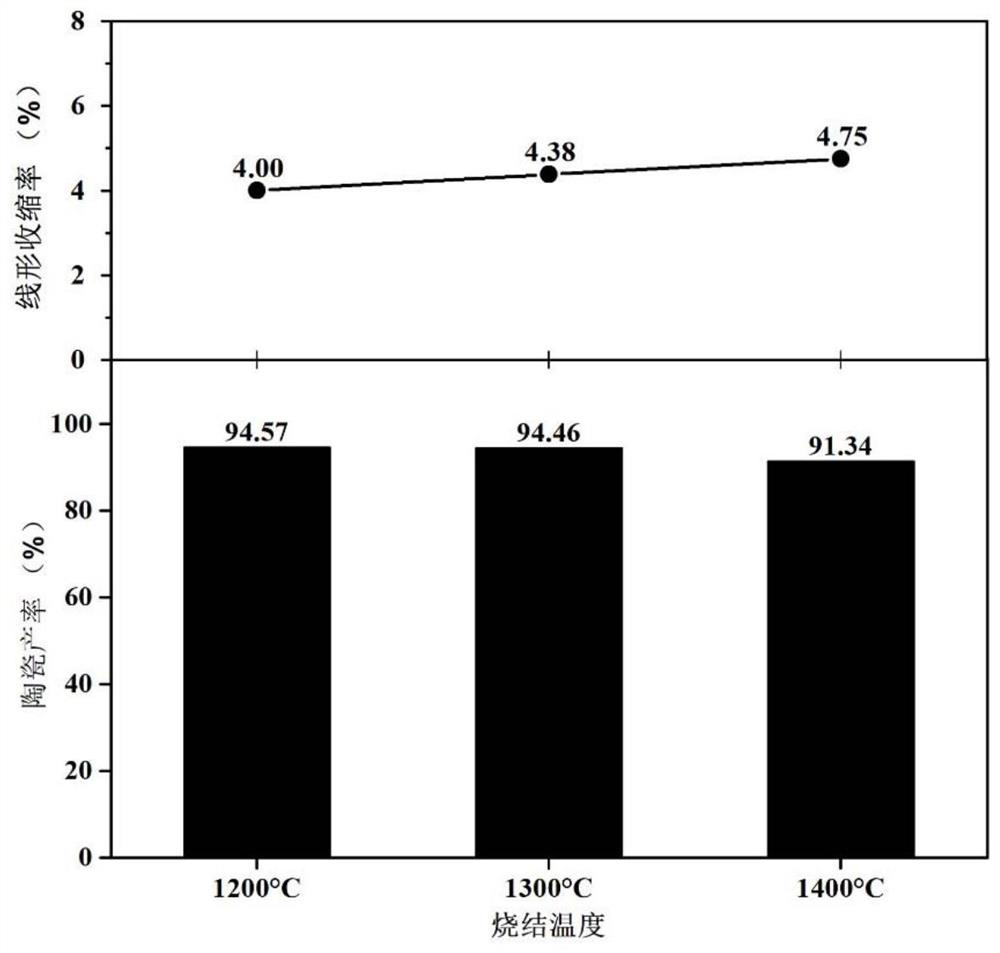

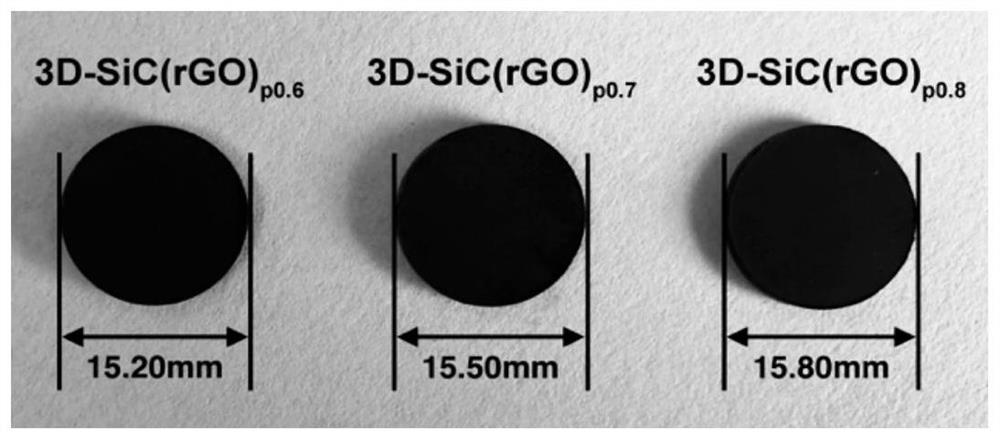

A kind of non-melting pretreatment of polycarbosilane and its cracking conversion method for three-dimensional ceramics

A polycarbosilane non-melting pretreatment and its cracking transformation method for three-dimensional ceramics relate to the preparation of ceramic materials. Synthesize the three-dimensional silicon carbide polymer precursor first, prepare SiC(Al,rGO)p ceramic particles by pyrolysis at high temperature under the protection of an inert atmosphere, mix with the precursor powder by ball milling, then dry, press into tablets and sinter at high temperature again to obtain 3D‑SiC (Al,rGO) ceramics, and finally modify the surface morphology of ceramics. The three-dimensional ceramic material contains four elements: Si, C, O, and Al, and Al is evenly distributed in SiO in an atomic state. x C y In the amorphous phase, β-SiC nanocrystals are embedded in SiO composited with rGO x C y / C free In the amorphous phase, there is SiO 2 Microcrystalline. Expand the crosslinking degree and molecular weight of the precursor to form a three-dimensional network structure, reduce the evaporation of small molecule gas during cracking, improve the fracture toughness and high temperature stability of ceramics, and meet the harsh environment applications such as high temperature.

Owner:中科德胜(常州)电子科技有限公司

Novel inorganic lightweight mortar and reinforcing agent product

The invention discloses a novel inorganic lightweight mortar and a reinforcing agent product. The novel inorganic lightweight mortar comprises the following components by mass: 75 to 85 parts of mineral fiber, 3.5 to 5.5 parts of magnesium carbonate (calcium carbonate), 2 to 4 parts of cellulose, 6 to 7.5 parts of water-proofing agent, 0.03 to 0.15 part of dispersing agent, and 4.5 to 6.5 parts of fiber. The novel inorganic lightweight mortar and the reinforcing agent product have the advantages that the operability of the inorganic lightweight mortar and the product can be obviously improved, the construction time is saved, the construction efficiency is improved, the construction cost is reduced, the tensile strength, the adhering strength and the softening coefficient of the inorganic lightweight mortar and the product are greatly improved; the linear shrinkage is reduced, the phenomena of hollowing, cracking and separating can be prevented, and the safety of the heat insulation material is improved; the inorganic lightweight mortar and the product with the reinforcing agent adopted are high in fireproofing grade, light in volume weight, low in coefficient of thermal conductivity, and excellent in heat insulation performance; and the reinforcing agent has no pollution in the production and application, and is environment-friendly and beneficial for recycling waste, so as to meet the requirement on energy conservation of a building.

Owner:江苏华伟佳建材科技有限公司

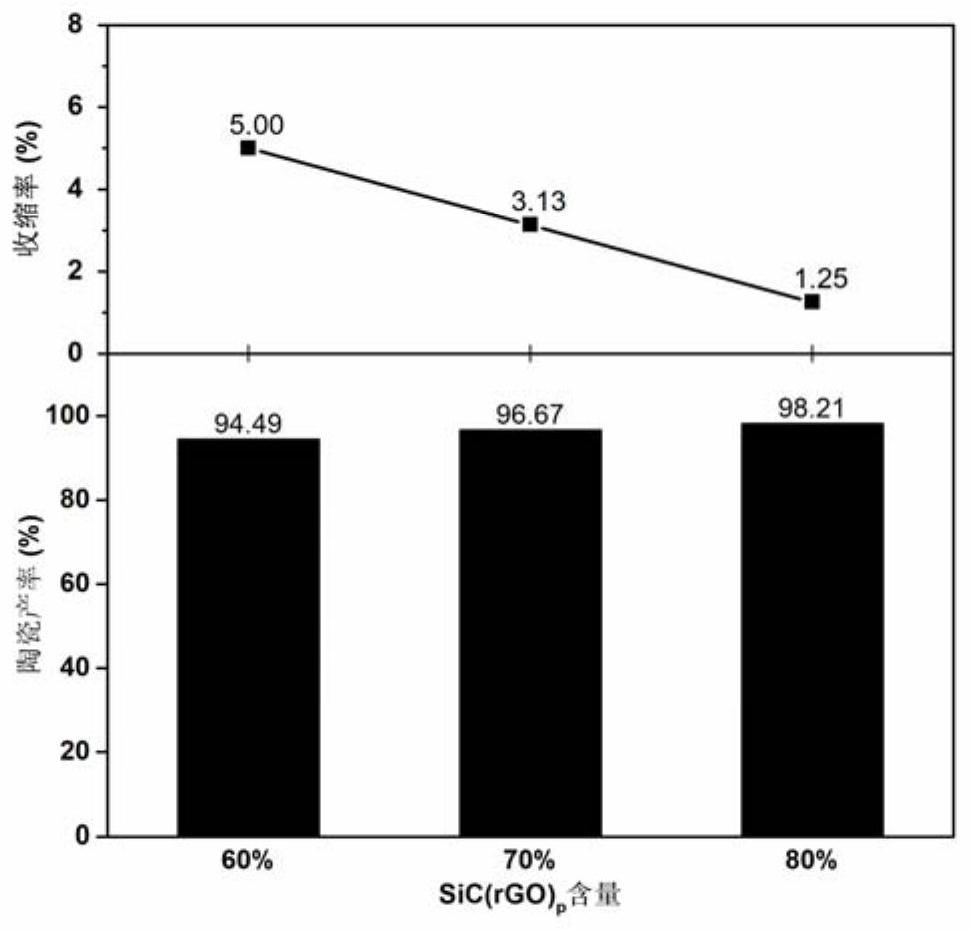

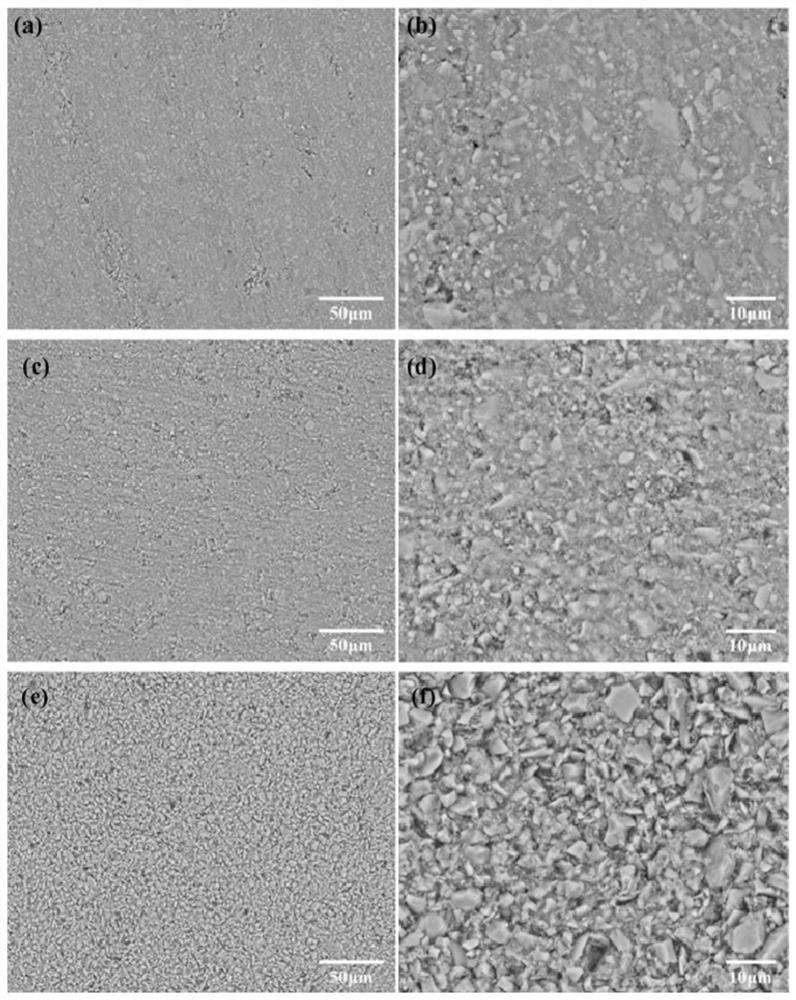

A kind of bulk silicon carbide polymer precursor ceramics and preparation method of blending and cracking

The invention provides a bulk silicon carbide polymer precursor ceramic and a blending-cracking preparation method thereof, belonging to the field of preparation of ceramic materials. The bulk siliconcarbide polymer precursor ceramic is named as 3D-SiC(rGO) ceramic and is composed of beta-SiC, SiO<x>C<y>, SiO<2>, rGO, and free carbon, wherein beta-SiC nanocrystals are dispersed in a SiO<x>C<y> / C<free> amorphous phase, and SiO2 grains are inlaid in a beta-SiC / SiO<x>C<y> / C<free> matrix. The homemade modified polymer precursor polycarbosilane-vinyltriethoxysilane-graphene oxide is used as a rawmaterial and is mixed with SiC(rGO) powder obtained after cracking the precursor in proportion, and then ball milling and re-cracking are carried out so as to prepare the ceramic. The ceramic has high ceramic yield, low linear shrinkage, good hardness and fracture toughness, uniform and dense microstructure, few pores, microcracks and interfaces, and good practicality and reliability.

Owner:中科德胜(常州)电子科技有限公司

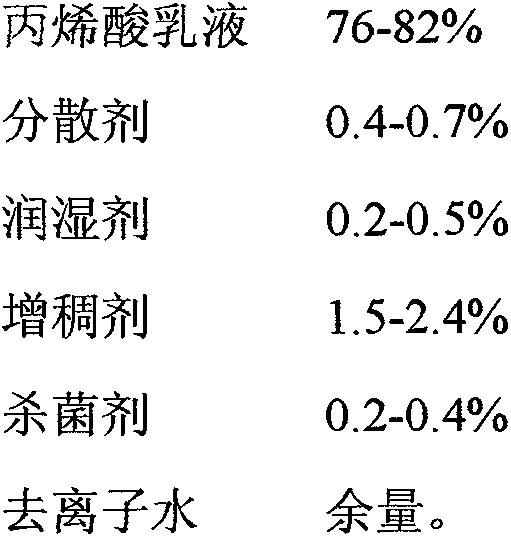

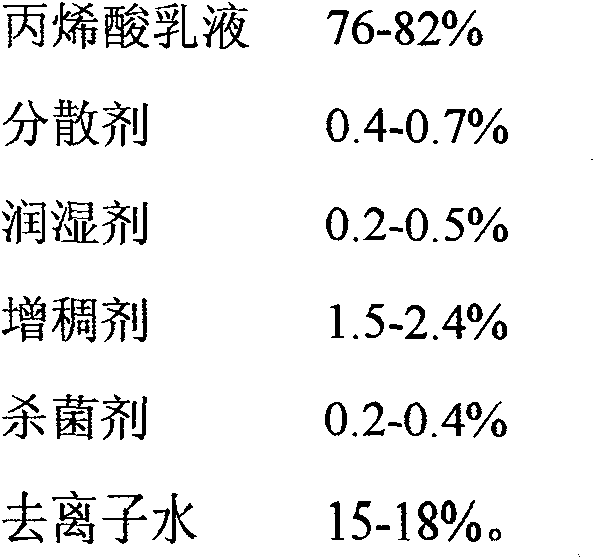

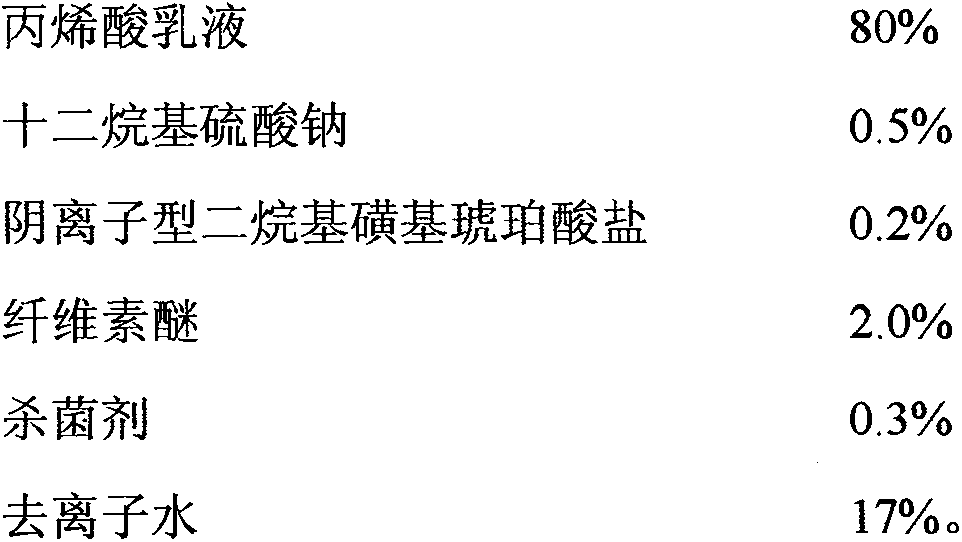

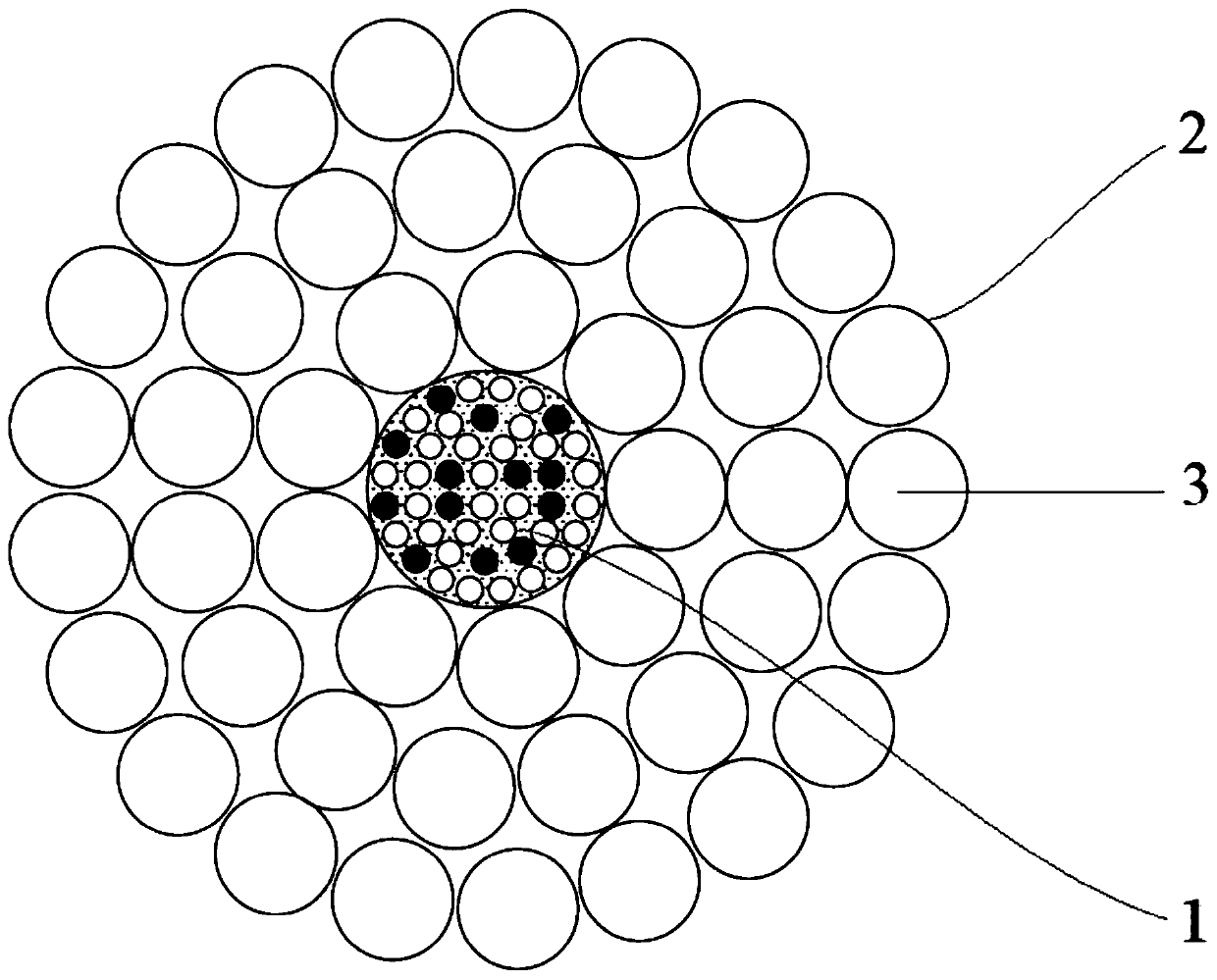

Cross linker of insulating anti-crack mortar

The invention relates to a cross linker of insulating anti-crack mortar, comprising the components with mass fraction as follows: 76-82% of acrylic emulsion, 0.4-0.7% of dispersant, 0.2-0.5% of wetting agent, 1.5-2.4% of thickener, 0.2-0.4% of fungicide and the balance of deionized water. The cross linker of the invention can improve the flexibility and waterproofness of the cement mortar, enhancethe alkaliproof breaking strength retention of fiberglass gridding cloth and prevent the cement mortar alkali from eroding the fiberglass gridding cloth by covering the fiberglass gridding cloth so as to improve the service life pf the gridding cloth and ensuring more compact connection between the gridding cloth and the anti-crack mortar; a flexible polymer film layer and a hardening cement bodyinterpenetrate each other and form a stable and flexible protective layer by firm bonding, thus solving the defect of overlarge elastic modulus and linear expansibility between an insulating layer and the protective layer and finish of the anti-crack mortar, achieving flexible release of stress and effectively reducing the linear shrinkage of the system.

Owner:浙江大森建筑节能科技有限公司

Casting wax and preparation method thereof

PendingCN114656794AGood bending strengthReduced linear shrinkageFoundry moulding apparatusHardnessHeat stability

The invention provides casting wax and a preparation method thereof, and the casting wax comprises the following raw materials in parts by weight: 70-80 parts of methylene polymer, 15-25 parts of microcrystalline wax, 1.5-5 parts of modified rosin and 1-5 parts of PE oligomer. Through specific compounding of all the raw materials, the prepared casting wax has excellent bending strength, surface hardness and viscosity, small linear shrinkage and ash content and excellent heat stability, the mechanical property, the processing property and the heat stability of the casting wax all meet the requirements, related indexes of the casting wax are close to those of foreign imported products, and the casting wax is suitable for medium-temperature precision casting products and has wide application prospects. In addition, the coating has better coating property, flowability and reusability, and the product competitiveness is strong.

Owner:SHANGHAI TONGS SCI & TECH

A kind of polyurethane board and preparation method thereof

Owner:昆山市柳鑫电子有限公司

Preparation method of high-conductivity heat-resistant aluminum alloy wire

ActiveCN109887681BHigh tensile strengthImprove structural stabilityPower cables for overhead applicationInsulated cablesYarnCarbon fibers

The invention discloses a method for preparing a high-conductivity and heat-resistant aluminum alloy wire, which comprises the following steps: S1. Place carbon fiber and basalt fiber on a yarn rack to divide the yarn, adjust the tension, perform dehydration treatment, and then pull and infiltrate through a constant temperature glue tank A thermosetting resin composition; S2. The carbon fiber and basalt fiber soaked in the thermosetting resin composition are cured and formed through a heating forming mold to obtain a composite fiber reinforced core; S3. Processing is made of an aluminum alloy rod with a diameter of 9.5mm, and then passed through an aluminum alloy Wire drawing machine draws aluminum alloy single wires; S4. Twisting several aluminum alloy single wires on the outer surface of the composite fiber reinforced core to form an aluminum alloy conductor layer to make a high-conductivity heat-resistant aluminum alloy wire product; The heat-resistant aluminum alloy wire has good heat resistance, and can still maintain stable performance when working at high temperature for a long time. It has a long service life and effectively reduces maintenance costs.

Owner:广西纵览线缆集团有限公司

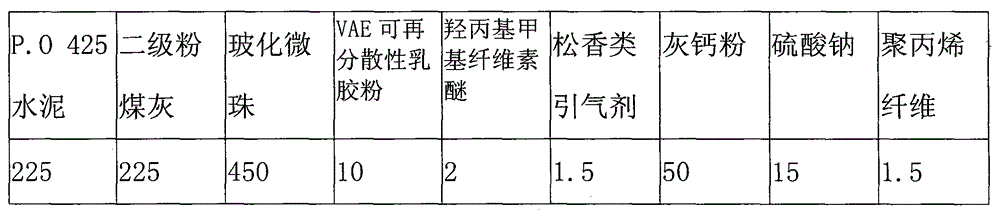

A kind of I-type inorganic building thermal insulation mortar with high fly ash content

ActiveCN104058688BImprove mechanical propertiesImprove crack resistanceSolid waste managementMechanical propertySodium sulfate

Owner:SHENZHEN GANGCHUANG BUILDING MATERIAL

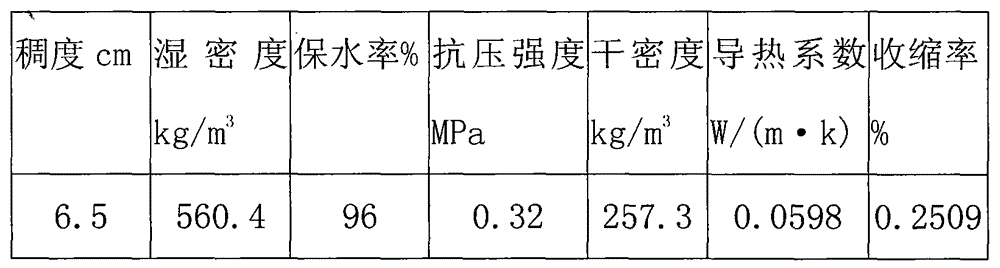

Fiber continuous forming process based on composite chain preparation

The invention discloses a fiber continuous forming process based on composite chain preparation, and relates to the field of fiber processing, the fiber continuous forming process comprises the following steps: S1, glass fiber, carbon fiber and polyurethane resin fiber are bundled and woven to prepare a pre-impregnated material; s2, carrying out melting treatment on the pre-impregnated material, and carrying out melt impregnation; uniformly mixing the dried components according to the proportion, and putting the mixture into a premixing device for high-temperature melting; s3, rolling the pre-impregnated material in the molten state to prepare a composite blank pre-impregnated belt; and S4, the composite blank prepreg tape sequentially passes through a forming mold, a heating mold and a cooling mold under the cooperation of a traction device, and finally continuous forming is conducted. Under the condition of room temperature, the continuously formed glass fiber has the characteristics of good strong acid resistance, strong alkali resistance and high-concentration salt resistance, the mechanical property loss is less in a damp-heat aging experiment, and the glass fiber has good aging resistance; the linear shrinkage rate is small, and the deviation from the design size is very small.

Owner:南通市真伟复合材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com