Inorganic vitrified micro bubble external heat-insulating system for outer wall

A technology of inorganic vitrified microbeads and external thermal insulation of external walls, which is applied in thermal insulation, building thermal insulation materials, building components, etc. It does not meet the requirements of heat insulation in summer, and achieves the effect of solving heat preservation, strength optimization, and shrinkage rate optimization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A resettlement community in Xinyang City, with a construction area of about 300,000 square meters. In April 2010, in terms of external wall insulation, the following inorganic vitrified microbead external wall external thermal insulation system was partially used, and the thermal insulation and decoration area reached more than 20,000 square meters.

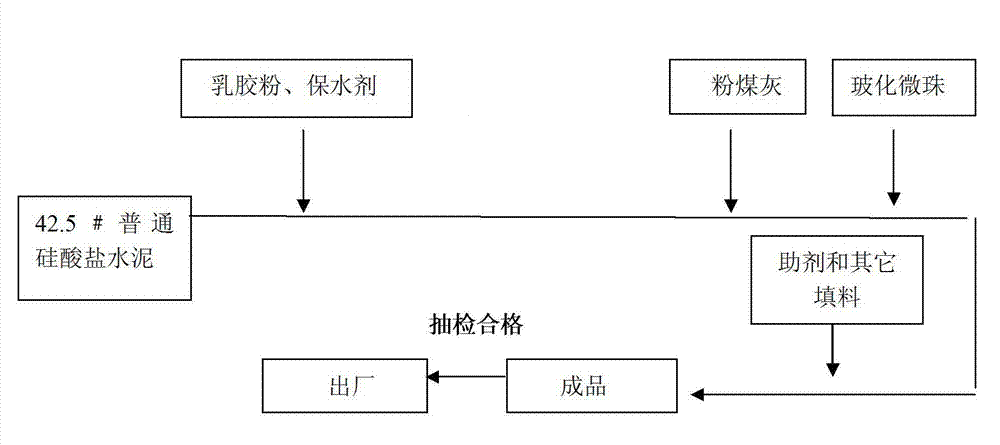

[0038] The above-mentioned inorganic vitrified microbead external wall thermal insulation system includes an interface layer, an inorganic vitrified microbead thermal insulation layer, an anti-crack mortar overlay and a finish layer, and the inorganic thermal insulation mortar for preparing the inorganic vitrified microbead thermal insulation layer is made of Vitrified beads and powder are composed at a weight ratio of 0.7:1, and the water-cement ratio during construction is 1:0.9. Described powder proportioning:

[0039] 280 parts of cement, 210 parts of fly ash, 8 parts of latex powder, 1 part of modified polypropylen...

Embodiment 2

[0047] In March 2010, in the exterior wall insulation decoration of Xinyang "Xianshan · Tianxiacheng" Phase I, the inorganic vitrified microbead exterior wall insulation system was used, and the insulation decoration area reached 22,000 square meters.

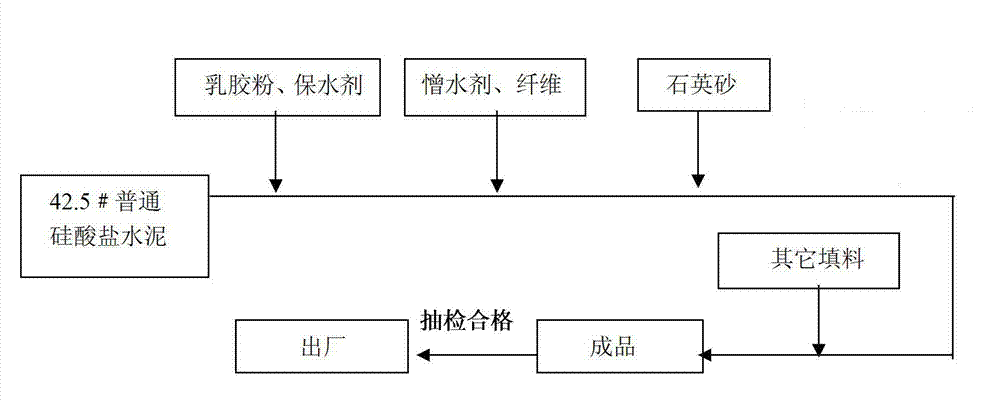

[0048] The above-mentioned inorganic vitrified microbead external wall thermal insulation system includes an interface layer, an inorganic vitrified microbead thermal insulation layer, an anti-crack mortar overlay and a finish layer, and the inorganic thermal insulation mortar for preparing the inorganic vitrified microbead thermal insulation layer is made of The vitrified microspheres and the powder are composed in a weight ratio of 0.7:1, and the powder ratio is:

[0049] 250 parts of cement, 240 parts of fly ash, 9 parts of latex powder, 1.5 parts of polypropylene fiber, 90 parts of calcium hydroxide, 4.5 parts of wood fiber, 3 parts of water repellent (B1490), 7 parts of HPMC, modified polyethylene oxide 4 parts, 0.4 parts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com