Self-flame-retardant organic silicon resin for PCB, preparation method of self-flame-retardant organic silicon resin and composition containing self-flame-retardant organic silicon resin

A PCB circuit board and resin composition technology, which is applied in the direction of circuit substrate materials, printed circuits, printed circuit components, etc., can solve problems such as environmental pollution and affecting the physical properties of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

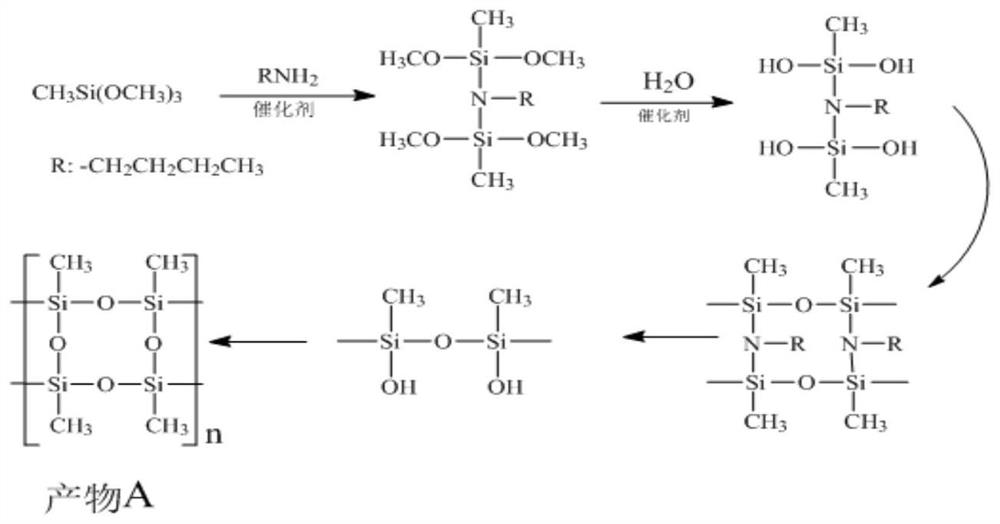

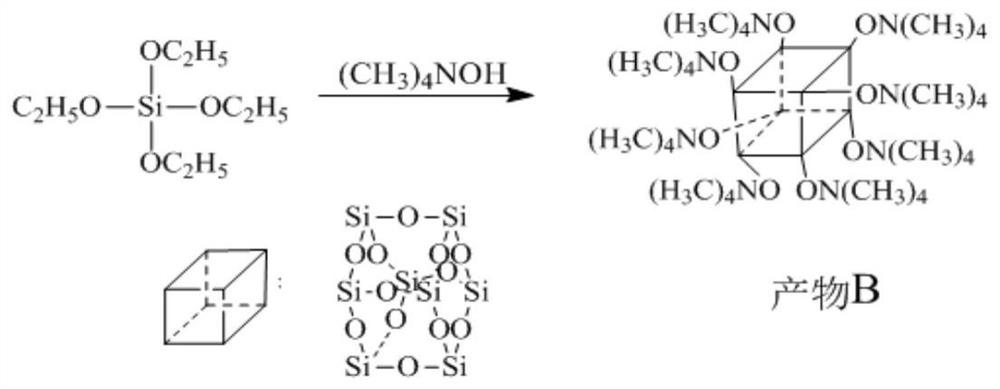

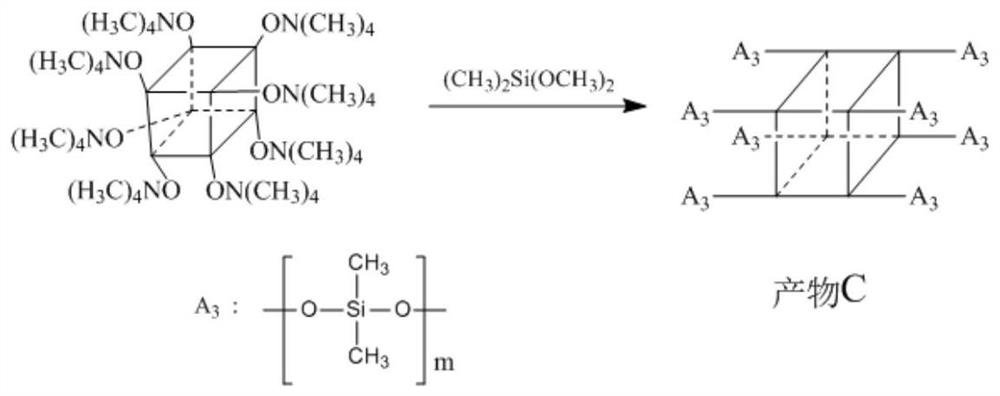

[0028] See Figure 1-Figure 7 , a self-flame-retardant silicone resin for PCB boards is prepared by steps from the following raw materials in parts by weight: 25 to 150 parts of methyltrimethoxysilane, 10 to 50 parts of tetraethoxysilane, tetramethylhydrogen 2-25 parts of ammonium oxide, 4-100 parts of dimethyldimethoxysilane, 5-30 parts of ethylenediamine, 20-60 parts of acetone, N, 30-80 parts of N-dimethylformamide, 50-100 parts of methyl isobutyl ketone, 2-10 parts of glacial acetic acid, and 10-60 parts of deionized water.

[0029] The above-mentioned circuit board uses self-flame-retardant silicone resin, which is synthesized by the following specific steps:

[0030] (1) Add methyl trimethoxysilane and methyl isobutyl ketone in sequence in the reactor, drop the mixture of acetone and ethylenediamine below 5°C, stir for 2h~4h, then add dropwise the mixture of glacial acetic acid and deionized water , and then heated to 50°C to 70°C for 6h to 9h, and the final reaction s...

Embodiment 2

[0040] On the basis of Embodiment 1, the scheme of the embodiment of the present invention is further described in detail by taking a specific manufactured product as an example.

[0041] Described a kind of flame retardant silicone resin for PCB circuit board is synthesized by following specific steps:

[0042] ⑴Add 65.4 parts of methyltrimethoxysilane and 50 parts of methyl isobutyl ketone in turn to the reactor, add dropwise a mixture of 20 parts of acetone and 14.5 parts of ethylenediamine at below 5°C, stir for 2 hours, and then add 1.4 parts dropwise A mixture of glacial acetic acid and 26 parts of deionized water was then heated to 60°C for 8 hours, and the final reaction solution was washed with water until neutral to obtain product A.

[0043] (2) Add 37.8 parts of a blend of tetraethoxysilane and ethanol dropwise to 16.6 parts of a stirring aqueous solution of tetramethylammonium hydroxide, react at room temperature for 25 hours, then heat to 55°C for 12 hours; the f...

Embodiment 3

[0047] Described a kind of flame retardant silicone resin for PCB circuit board is synthesized by following specific steps:

[0048] ⑴Add 109 parts of methyltrimethoxysilane and 50 parts of methyl isobutyl ketone in turn to the reactor, add dropwise a mixture of 30 parts of acetone and 24 parts of ethylenediamine at below 5°C, stir for 2 hours, then add 2.2 parts dropwise A mixture of glacial acetic acid and 43.2 parts of deionized water was then heated to 60°C for 8 hours, and the final reaction solution was washed with water until neutral to obtain product A.

[0049] (2) Add 16.6 parts of a blend of tetraethoxysilane and ethanol dropwise to 7.3 parts of a stirring aqueous solution of tetramethylammonium hydroxide, react at room temperature for 25 hours, then heat to 55°C for 12 hours; the final reaction solution Concentrate, cool, and filter to obtain product B.

[0050] (3) Add the product B obtained from (2) to the N,N-dimethylformamide solution of 28.4 parts of dimethyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com