A kind of I-type inorganic building thermal insulation mortar with high fly ash content

A technology for building thermal insulation mortar and fly ash, applied in the field of building materials, can solve the problems of high dry density and thermal conductivity, reduce the energy-saving effect of inorganic thermal insulation mortar, limit the utilization rate of fly ash, etc., so as to reduce the dry density and thermal conductivity. , Improve workability, improve the effect of anti-cracking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] The high fly ash content type I inorganic building thermal insulation mortar of the present embodiment, its raw material composition is: 45 parts of P.0425 cement, 45 parts of secondary fly ash, 2.5 parts of sodium sulfate, 10 parts of ash calcium powder 85 parts of vitrified microbeads, 0.2 part of hydroxypropyl methylcellulose ether, 1 part of VAE redispersible latex powder, 0.1 part of polypropylene fiber, and 0.2 part of rosin air-entraining agent.

Embodiment 2

[0012] The high fly ash content type I inorganic building thermal insulation mortar of the present embodiment, its raw material composition is: P.0425 cement 50 parts, secondary fly ash 50 parts, sodium sulfate 3 parts, ash calcium powder 13 parts by mass ratio 90 parts of vitrified microbeads, 0.3 parts of hydroxypropyl methylcellulose ether, 2 parts of VAE redispersible latex powder, 0.2 parts of polypropylene fiber, and 0.3 parts of rosin air-entraining agent.

Embodiment 3

[0014] The high fly ash content type I inorganic building thermal insulation mortar of the present embodiment, its raw material composition is by mass ratio: P.O425 cement 55 parts, secondary fly ash 55 parts, sodium sulfate 3.5 parts, ash calcium powder 15 parts 95 parts of vitrified microbeads, 0.4 parts of hydroxypropyl methylcellulose ether, 3 parts of VAE redispersible latex powder, 0.3 parts of polypropylene fiber, and 0.4 parts of rosin air-entraining agent.

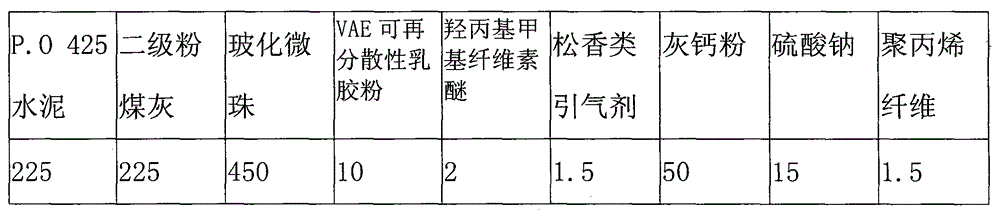

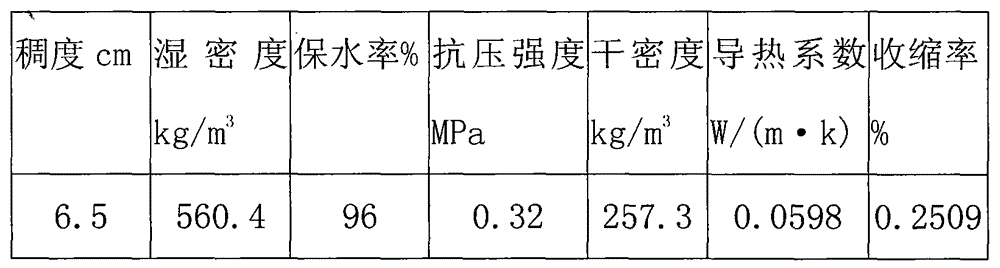

[0015] Randomly select the raw material composition mass ratio of the high fly ash content type I inorganic building thermal insulation mortar obtained in the above-mentioned embodiment to carry out the orthogonal test performance test, and the specific test results are shown in the following tables 1 and 2:

[0016] Table 1:

[0017]

[0018]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com