A kind of non-melting pretreatment of polycarbosilane and its cracking conversion method for three-dimensional ceramics

A polycarbosilane and pretreatment technology, which is applied in the field of polycarbosilane non-melting pretreatment and its pyrolysis and transformation into three-dimensional ceramics, can solve problems such as difficulty in transforming three-dimensional ceramics, cracks, and difficulty in forming, and achieve industrialized production, simple process and high efficiency. Economical, the effect of improving the productivity of ceramics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

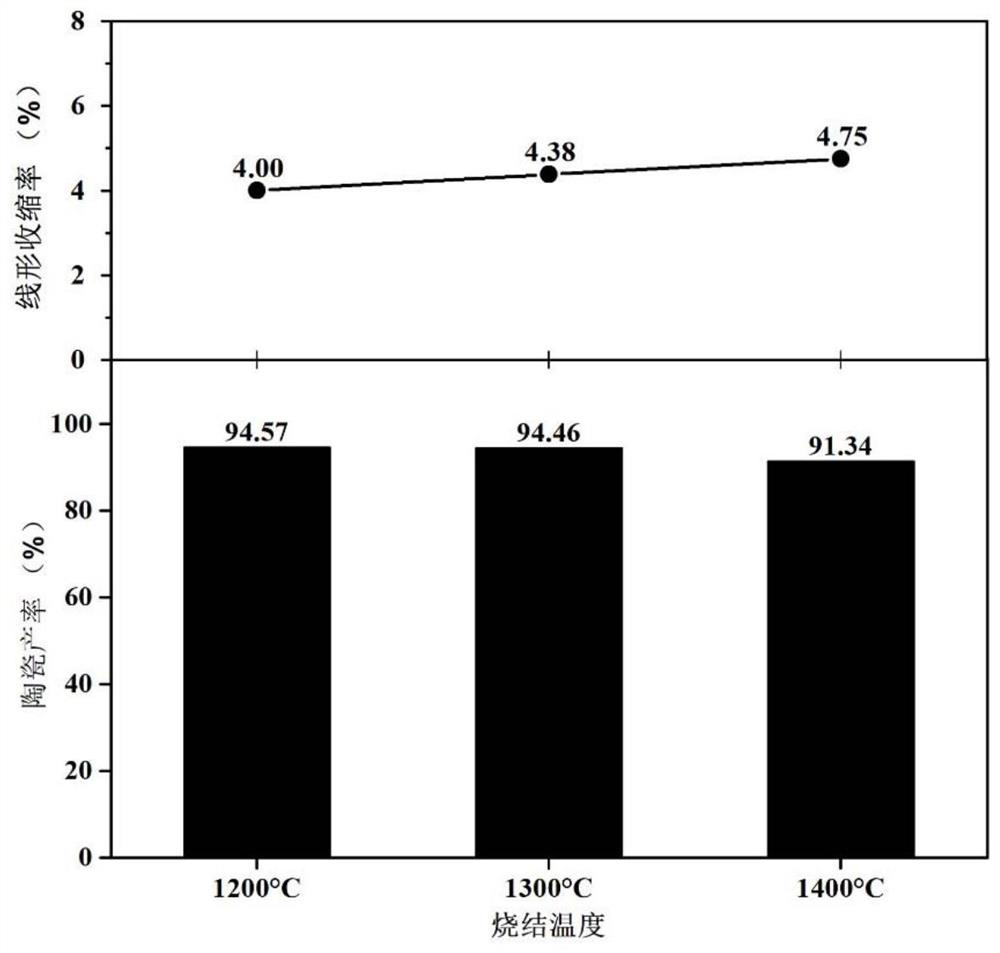

Embodiment 1

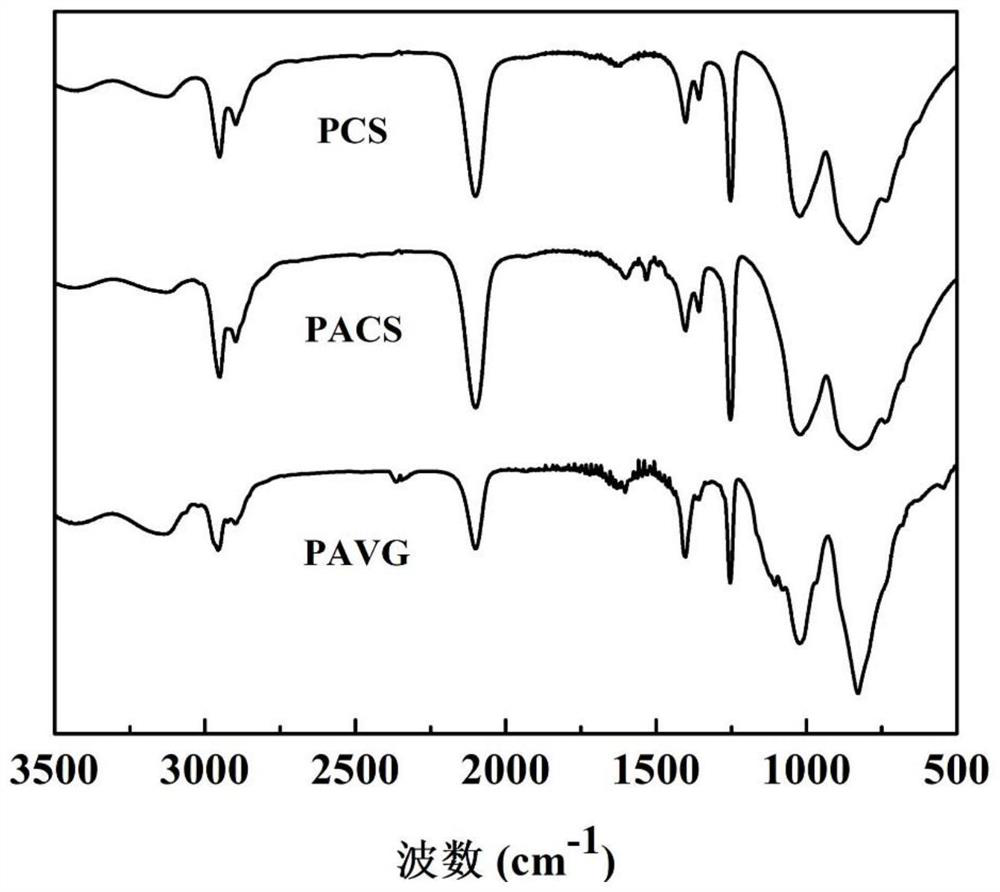

[0041] 1. Dissolve 2g of PCS powder and 0.12g of aluminum acetylacetonate powder in 40mL of xylene and pour it into a 150mL three-necked bottle to build a distillation device with argon protection at a flow rate of 35mL / min. Rapidly raise the temperature to 150°C at the speed of ℃ / min, evaporate the xylene to dryness, and keep the temperature for 1h;

[0042] 2. Raise the temperature of the electric heating mantle to 310° C. at a rate of 3° C. / min and keep it warm for 5 hours to obtain a highly cross-linked hyperbranched aluminum-containing polycarbosilane solid. After cooling, pour appropriate amount of xylene into the bottle to dissolve and filter to obtain 40mL golden yellow transparent solution;

[0043] 3. Disperse 0.02 g of graphene oxide powder in 40 mL of deionized water, and ultrasonically disperse the aqueous solution and the xylene solution obtained in step 2 for 30 min;

[0044] 4. Add 1mL of Custer Platinum Catalyst to the xylene solution, add 2mL of vinyltrietho...

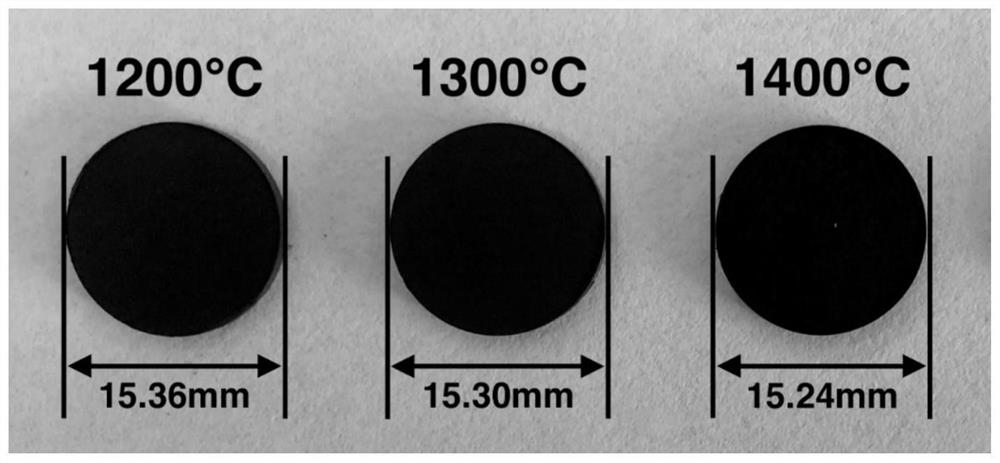

Embodiment 2

[0049] 1. Dissolve 2g of PCS powder and 0.12g of aluminum acetylacetonate powder in 40mL of xylene and pour it into a 150mL three-necked bottle to build a distillation device with argon protection at a flow rate of 35mL / min. Rapidly raise the temperature to 150°C at the speed of ℃ / min, evaporate the xylene to dryness, and keep the temperature for 1h;

[0050] 2. Raise the temperature of the electric heating mantle to 310° C. at a rate of 3° C. / min and keep it warm for 5 hours to obtain a highly cross-linked hyperbranched aluminum-containing polycarbosilane solid. After cooling, pour appropriate amount of xylene into the bottle to dissolve and filter to obtain 40mL golden yellow transparent solution;

[0051] 3. Disperse 0.02 g of graphene oxide powder in 40 mL of deionized water, and ultrasonically disperse the aqueous solution and the xylene solution obtained in step 2 for 30 min;

[0052] 4. Add 1mL of Custer Platinum Catalyst to the xylene solution, add 2mL of vinyltrietho...

Embodiment 3

[0058] 1. Dissolve 2g of PCS powder and 0.12g of aluminum acetylacetonate powder in 40mL of xylene and pour it into a 150mL three-necked bottle to build a distillation device with argon protection at a flow rate of 35mL / min. Rapidly raise the temperature to 150°C at the speed of ℃ / min, evaporate the xylene to dryness, and keep the temperature for 1h;

[0059] 2. Raise the temperature of the electric heating mantle to 310° C. at a rate of 3° C. / min and keep it warm for 5 hours to obtain a highly cross-linked hyperbranched aluminum-containing polycarbosilane solid. After cooling, pour appropriate amount of xylene into the bottle to dissolve and filter to obtain 40mL golden yellow transparent solution;

[0060] 3. Disperse 0.02 g of graphene oxide powder in 40 mL of deionized water, and ultrasonically disperse the aqueous solution and the xylene solution obtained in step 2 for 30 min;

[0061] 4. Add 1mL of Custer Platinum Catalyst to the xylene solution, add 2mL of vinyltrietho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com