Organosilicon material, preparation method thereof, and application method thereof in 3D printing

A 3D printing and silicone technology, applied in the field of silicone materials, can solve the problems of poor high and low temperature resistance, poor biocompatibility, and poor weather resistance, and achieve excellent weather resistance, small linear shrinkage, and excellent biocompatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

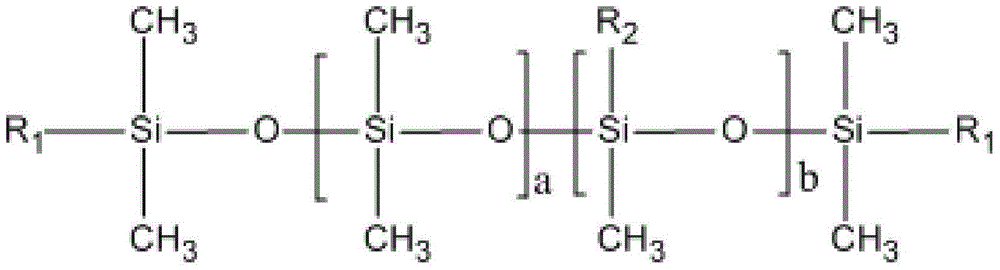

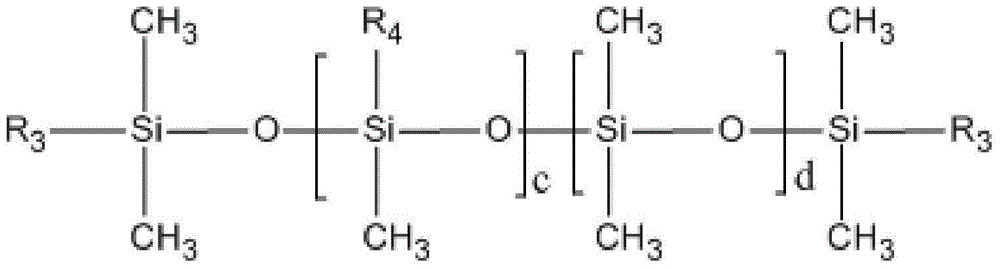

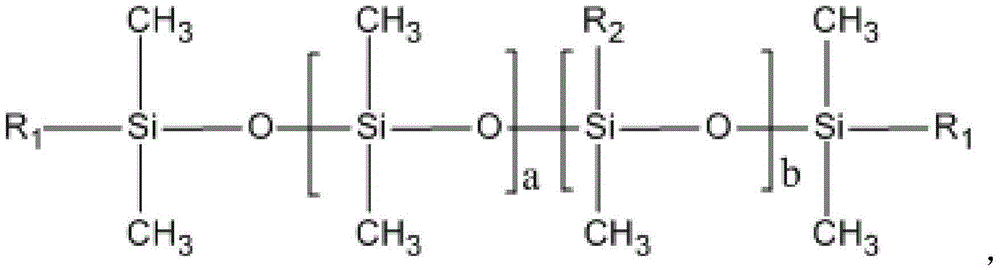

Method used

Image

Examples

Embodiment 1

[0058] In No. 1 vacuum planetary mixer, add 80 parts by weight of organopolysiloxane, 30 parts by weight of hydrophobized fumed silica (BET method specific surface area is 100m 2 / g, the bulk density is 80kg / m 3), 50 parts by weight of alumina, 2 parts by weight of hexamethyldisilazane, mixed at high speed for 1 hour; then heated to 120 °C for 1 hour in vacuum, and the vacuum degree was controlled in the range of -0.05MPa to -0.1MPa; The material was cooled to 25°C, 0.05 parts by weight of chloroplatinic acid solution was added, and mixed at high speed for 1 hour; after three-roll grinding, cooled to room temperature, component A was obtained.

[0059] In No. 2 vacuum planetary mixer, add 80 parts by weight of organopolysiloxane, 30 parts by weight of hydrophobized fumed silica (BET method specific surface area is 100m 2 / g, the bulk density is 80kg / m 3 ), 50 parts by weight of alumina, 2 parts by weight of hexamethyldisilazane, mixed at high speed for 1 hour; then heated to...

Embodiment 2

[0072] In No. 1 vacuum planetary mixer, add 100 parts by weight of organopolysiloxane, 20 parts by weight of fumed silica (BET method specific surface area is 300m 2 / g, the bulk density is 50kg / m 3 ), 10 parts by weight of silicone resin, 80 parts by weight of alumina, and 8 parts by weight of trimethylchlorosilane, mixed at high speed for 2 hours; then heated to 150°C for 2 hours in vacuum, and the vacuum degree was controlled at -0.05MPa~-0.1MPa Range: Cool the rubber material to 30°C, add 0.1 parts by weight of chloroplatinic acid solution, and mix at high speed for 2 hours; grind with three rollers and cool to room temperature to obtain Component A.

[0073] In No. 2 vacuum planetary mixer, add 100 parts by weight of organopolysiloxane, 20 parts by weight of fumed silica (BET method specific surface area is 300m 2 / g, the bulk density is 50kg / m 3 ), 10 parts by weight of silicone resin, 80 parts by weight of alumina, and 8 parts by weight of trimethylchlorosilane, mixed...

Embodiment 3

[0086] In No. 1 vacuum planetary mixer, add 150 parts by weight of organopolysiloxane, 60 parts by weight of precipitated silica (BET method specific surface area is 200m 2 / g, the bulk density is 200kg / m 3 ), 15 parts by weight of silicone resin, 60 parts by weight of zinc oxide, and 20 parts by weight of methyltrichlorosilane, mixed at high speed for 2.5 hours; then heated to 160°C for 3 hours in vacuum, and the vacuum degree was controlled at -0.05MPa~-0.1MPa Range: Cool the rubber material to 40°C, add 0.4 parts by weight of platinum diacetoacetate solution, and mix at high speed for 3 hours; grind with three rollers and cool to room temperature to obtain component A.

[0087] In No. 2 vacuum planetary mixer, add 150 parts by weight of organopolysiloxane, 60 parts by weight of precipitated silica (BET method specific surface area is 200m 2 / g, the bulk density is 200kg / m 3 ), 15 parts by weight of silicone resin, 60 parts by weight of zinc oxide, and 20 parts by weight o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com