Patents

Literature

242results about How to "Not easy to absorb water" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ternary positive electrode material with special single-crystal structure, and preparation method thereof

The invention relates to a preparation method for a ternary positive electrode material with a special single-crystal structure. A general formula of the positive electrode material is LiNixCoyMnzMvO2, wherein a sum of x, y and z is 1, x is equal to or larger than 0.2 but smaller than or equal to 0.6; y is equal to or larger than 0.1 but smaller than or equal to 0.4; z is equal to or larger than 0.2 but smaller than or equal to 0.5; v is equal to or larger than 0.01 but smaller than or equal to 0.03; and M is one of Ti, Zn, Cr and F. The preparation method for the ternary positive electrode material with the special single-crystal structure comprises two steps of 1. preparing a precursor-cobalt nickel manganese oxide with the single-crystal structure; and 2. preparing a cobalt nickel manganese ternary material with the single-crystal structure.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

Concrete cement foaming insulation brick and manufacturing method thereof

The present invention discloses a concrete cement foaming insulation brick, taking a concrete perforated brick as a main body. The concrete perforated brick is injected with a cement foam material, so that the cement foam material and the concrete perforated brick are fully combined. By adjusting the formulation and improving the process, the present invention makes full use of industrial wastes such as fly ash and coal gangue, does not need autoclaved curing, and is small in investment and simple in process. The foaming brick produced by the present invention has excellent heat insulation and sound insulation properties, and is high in strength, good in impact resistance, low in moisture absorption, light in weight, compression resistant, good in weather resistance, environmental-friendly and energy-saving, and non-toxic. The brick has great market space and development prospects in the application field of building energy efficiency.

Owner:嵊州市万顺新型墙体材料有限公司

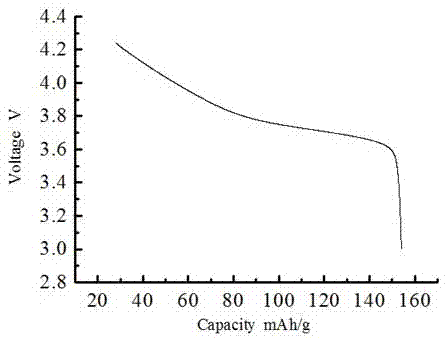

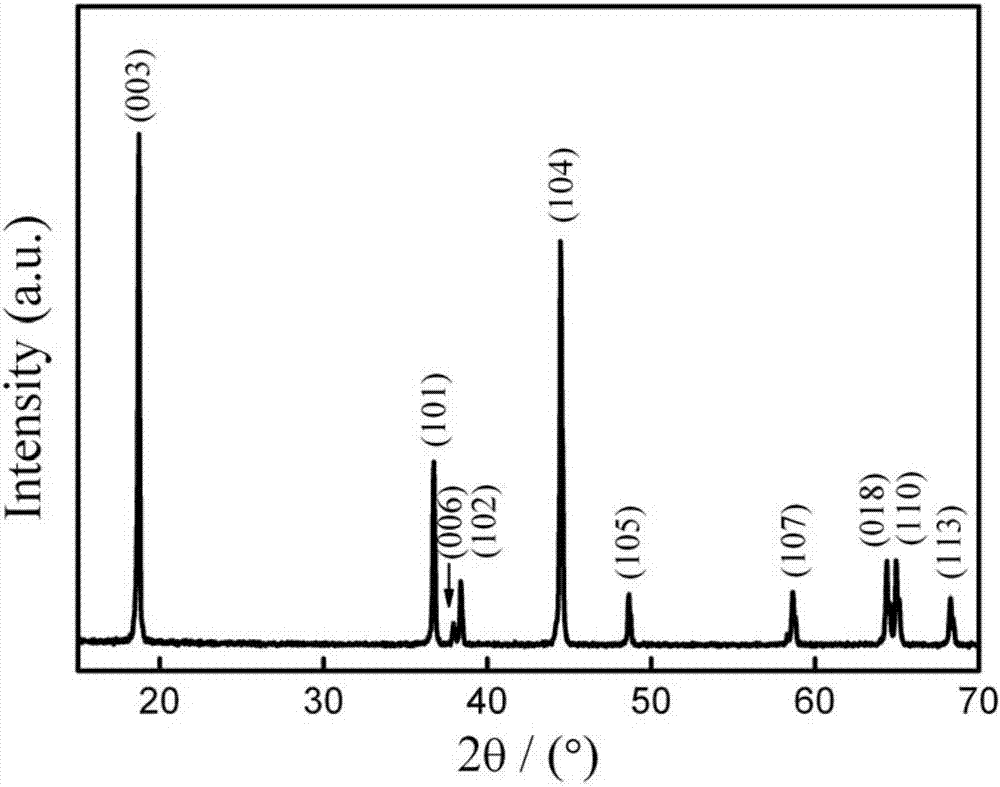

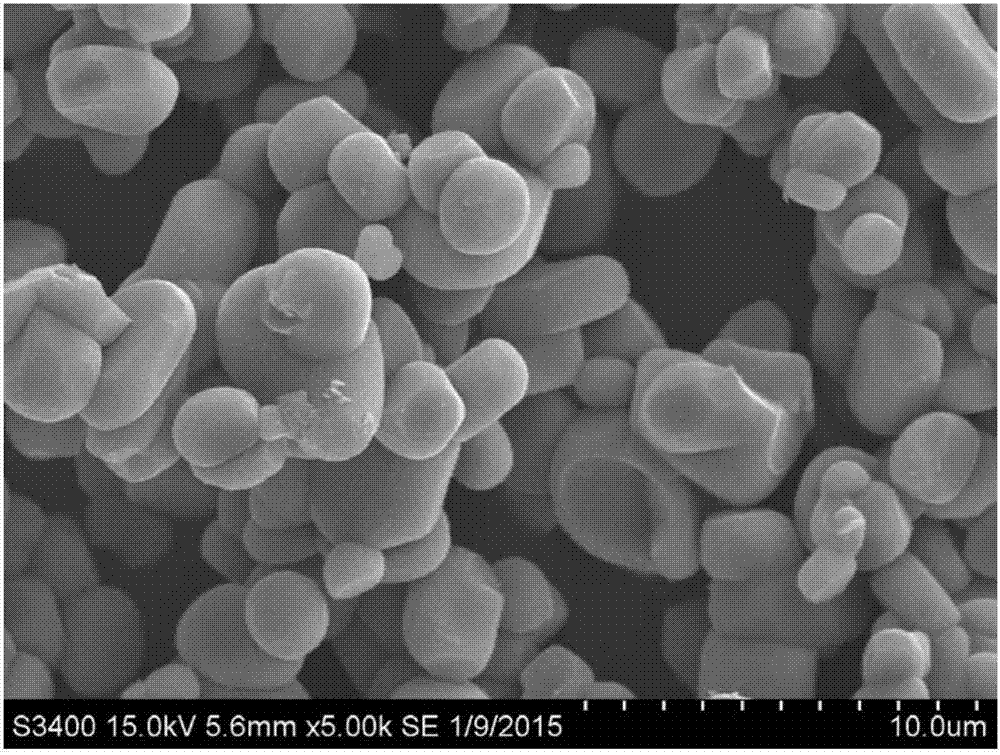

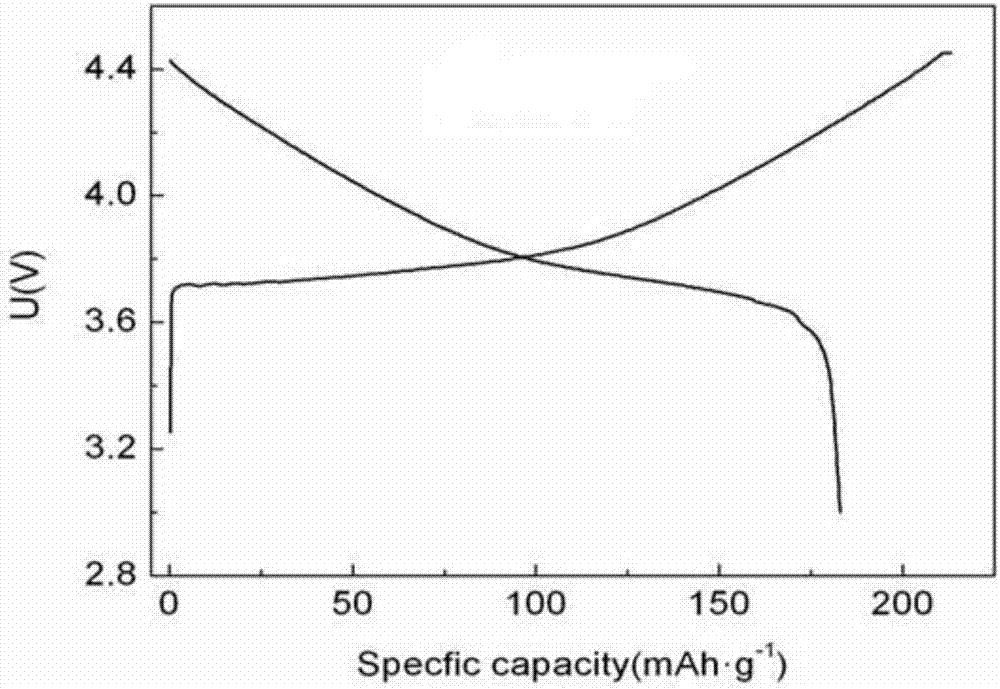

High-voltage and single-crystal ternary positive electrode material and preparation method thereof

InactiveCN107293744AEasy transferImprove cycle lifeCell electrodesHigh temperature storageChemical synthesis

The invention discloses a high-voltage and single-crystal ternary positive electrode material and preparation method thereof. The general formula of the material can be expressed with Li<x>Ni<1-m-n>Co<m>Mn<n>O2, wherein x is more than 0.96 but less than 1.12, m is more than 0 but less than 1, n is more than 0 but less than 1, and (m+n) is less than 1. The preparation method comprises the steps of preparing a precursor by taking a nickel salt, a cobalt salt and a manganese salt as raw materials and by employing a co-precipitation method or a chemical synthesis method, mixing the precursor with a lithium source, adding a modifying agent into the mixture after pre-processing, and performing sintering, smashing and sieving after uniform mixing to obtain the high-voltage and single-crystal ternary positive electrode material. The grain size of the prepared high-voltage and single-crystal ternary positive electrode material is 2-15 micrometers, and the compaction density reaches 3.8-3.9g / cm<3>; meanwhile, the surface of the ternary positive electrode material is modified by a wet process to package Al, the material structure is stabilized, and side reaction of the material and an electrolyte is prevented; and according to actual detection, the cycle property, the high-temperature storage performance and the safety performance of the lithium ion battery under high voltages of 4.4V and 4.5V are effectively improved.

Owner:HENAN KELONG NEW ENERGY CO LTD

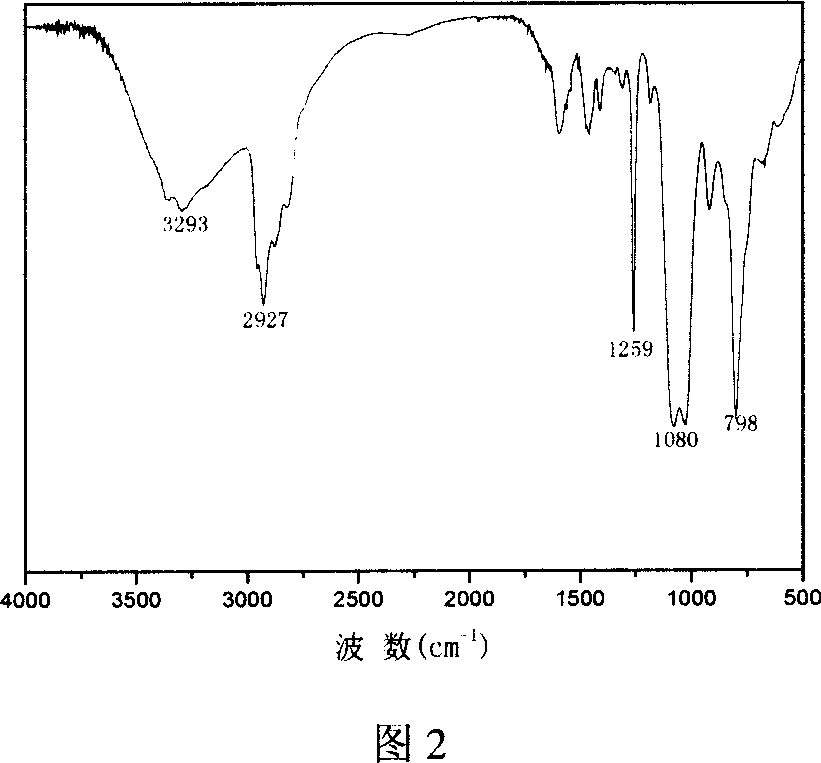

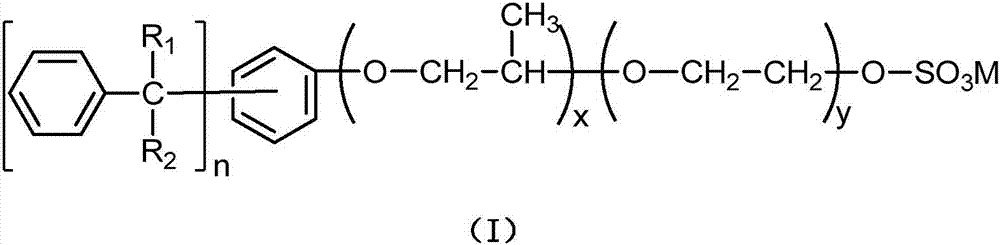

Silicious expanding fire retardant and its prepn process

InactiveCN1974721AImprove thermal stabilityImprove flame retardant performanceFireproof paintsHalogenPhosphate

The present invention discloses silicious expanding fire retardant in the structure as shown and its preparation process. Being superior to traditional fire retardant, which contains halogen and hydroscopic, the silicious expanding fire retardant has three essentials as expanding fire retardant, and 9, 10-dihydro-9-oxo-10-phospha phenanthryl-10-oxide without phosphate ester structure as acid source, and possesses excellent fire retarding performance.

Owner:凌庆平

Plastic-wooden composite tray and preparation method thereof

The invention discloses a plastic-wooden composite tray which is prepared from the raw materials in parts by weight: 50-60 parts of high density polyethylene, 20-30 parts of copolymerization polypropylene, 30-40 parts of modified wood meal, 40-50 parts of plastic renewable material, 20-30 parts of active calcium, 1-2 parts of zinc stearate, 1-2 parts of calcium stearate, 2-3 parts of n-butyl methacrylate, 0.3-0.5 part of polyethylene wax, 0.4-0.6 part of triethoxyvinylsilane, 0.3-0.4 part of antioxidant 1010, 0.4-0.6 part of anti-aging agent MB, 8-10 parts of foaming modifier, 4-8 parts of ACM, 4-8 parts of MBS, 25-30 parts of oxidized polyethlene wax, 0.2-0.3 part of foaming agent, 4-8 parts of TPE (Thermoplastic Polyurethane Elastomer), 8-12 parts of chlorinated polyvinyl chloride, 5-8 parts of glass fiber and 3-4 parts of semi-reinforced carbon black. The plastic-wooden composite tray produced by using the preparation method has the advantages of excellent mechanical property, capability of being sawed, planed and nailed, good durability, high repeated usage rate, capability of being recycled, resistance to insect biting, acid and alkaline resistance, aging resistance, and low water absorption and low deformation rate.

Owner:芜湖太平洋塑胶有限公司

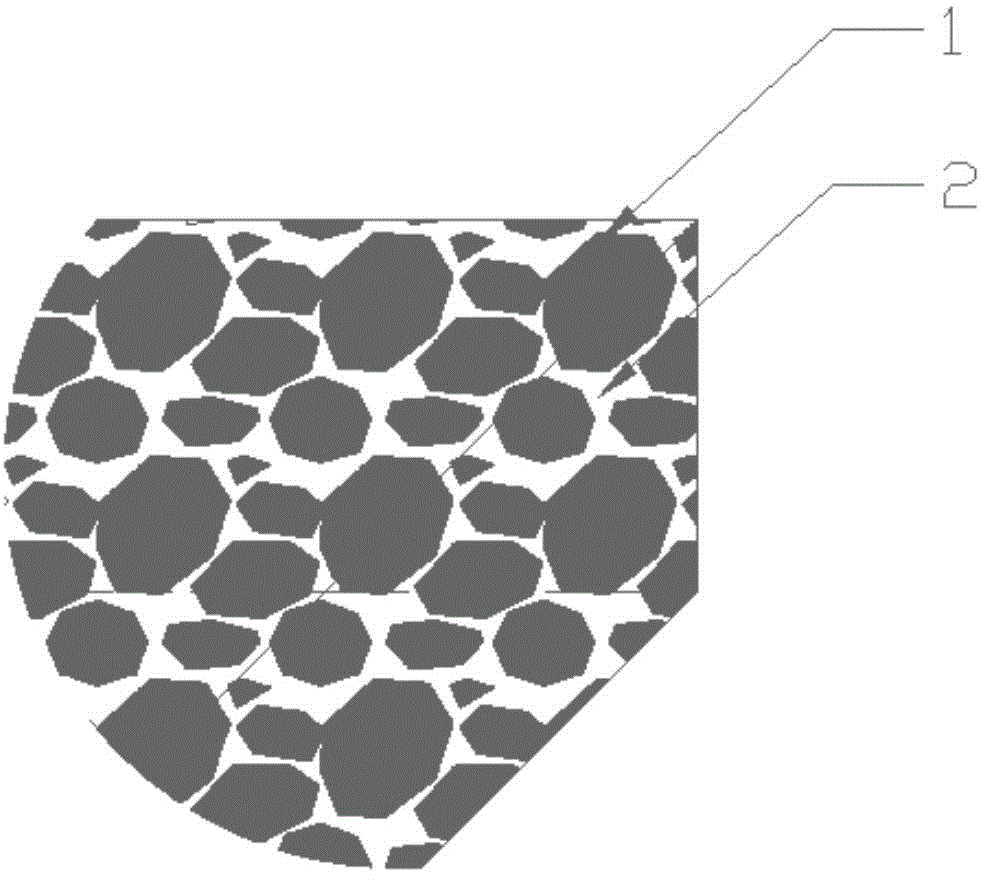

Novel heat insulating plate and manufacturing method thereof

ActiveCN104058630AImprove thermal insulationHigh mechanical strengthActive componentMembrane configuration

The invention provides a novel heat insulating plate. Active components of the novel heat insulating plate comprise 70-95 parts by weight of inorganic heat insulating particles and 5-30 parts by weight of an organic coating membrane material, wherein the outer surfaces of all inorganic heat insulating particles are coated with the organic coating membrane material to form 'capsule' type inorganic-organic composite heat insulating units, subsequently the 'capsule' type inorganic-organic composite heat insulating units are connected together by using a curing agent, and then a plate is formed in a mold, namely the novel heat insulating plate is obtained. The novel heat insulating plate disclosed by the invention can be used for improving the mechanical strength, also preventing exposure and water absorption of the inorganic heat insulating particles and limiting the air inside the 'capsule' type inorganic-organic composite heat insulating units as well so as to effectively reduce air motion inside the plate and reduce convective heat transfer, thus the heat conductivity coefficient is relatively as low as 0.032W / (m.K) to 0.040W / (m.K) and A-grade non-ignition can be truly realized, and therefore the novel heat insulating plate has both excellent fireproof performance and relatively-good heat insulation performance.

Owner:合肥候鸟新型材料有限公司

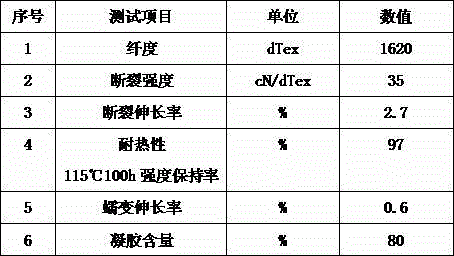

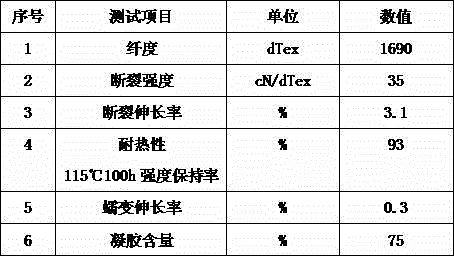

Heat-resisting creep-resisting ultra-high molecular weight polyethylene constant-strength fiber and preparation method thereof

InactiveCN104695038AHeat resistantHeat resistance and creep resistance haveMonocomponent polyolefin artificial filamentArtifical filament manufactureFiberCross-link

The invention discloses a heat-resisting creep-resisting ultra-high molecular weight polyethylene constant-strength fiber. The fiber comprises ultra-high molecular weight polyethylene powder, graphene, a cross-linking agent, a curing agent, an initiator and an anti-oxidant. The preparation method comprises the following steps: swelling the ultra-high molecular weight polyethylene powder by a solvent so as to form pores; then adding a composite modifying agent wetted by the cross-linking agent, the curing agent, the initiator, the anti-oxidant, the graphene and the solvent together; penetrating the composite modifying agent evenly into the ultra-high molecular weight polyethylene powder pores, and mixing evenly; and finally, carrying out irradiation crosslinking to obtain the heat-resisting creep-resisting ultra-high molecular weight polyethylene constant-strength fiber. The heat-resisting creep-resisting ultra-high molecular weight polyethylene constant-strength fiber has the comprehensive performances of heat resistance, creep resistance, abrasion resistance, impact resistance, self lubrication, corrosion resistance, low temperature resistance, hygiene, no toxicity, difficulty in adhesion and water absorption and relatively low density, is wide in applicability, and is long in service life.

Owner:JIANGSU SHENTAI SCI & TECH DEV

Fly ash/bentonite ceramsite concrete hollow insulation block and preparation method thereof

ActiveCN103253906ALightweight and low densityCorrosion resistantSolid waste managementCeramicwareSoluble glassNano al2o3

The invention discloses a fly ash / bentonite ceramsite concrete hollow insulation block and a preparation method thereof. The block is prepared from the following raw materials by weight: 100 to 150 parts of ordinary Portland cement grade 42.5, 500 to 600 parts of stone chippings, 30 to 40 parts of fly ash, 10 to 15 parts of bentonite, 5 to 10 parts of paper pulp waste liquid, 2 to 4 parts of nanometer alumina, 3 to 6 parts of light calcium carbonate, 20 to 30 parts of soluble glass, 10 to 15 parts of straw powder, 4 to 6 parts of a foaming agent, 1 to 2 parts of foots, 2 to 3 parts of a glass fiber, 0.5 to 1.5 parts of a redispersible latex powder and 150 to 210 parts of water. The boron fly ash / bentonite ceramsite concrete hollow insulation block produced in the invention has the advantages of high strength, low density, good heat insulation performance, good impact resistance, small possibility of water absorption, fire resistance, flame retardation, good weatherability, environment-friendliness, energy conservation and the like and has great market space and development prospects in the application field of building energy conservation in China.

Owner:池州市新蕾绿色建材有限公司

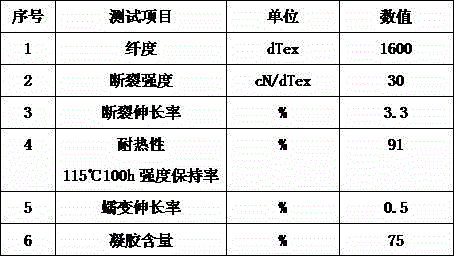

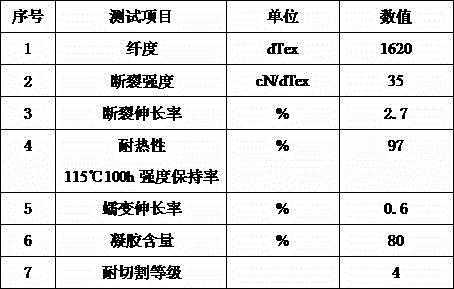

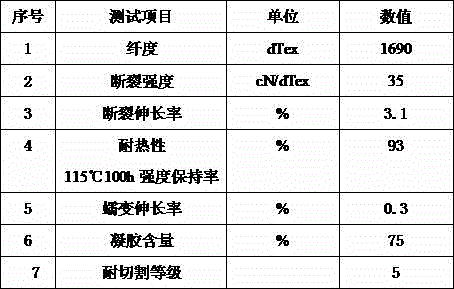

Thermal-resistant anti-cutting ultra-high molecular weight polyethylene fiber and preparation method thereof

InactiveCN104695039AHeat resistantHeat and cut resistant withPhysical treatmentMonocomponent polyolefin artificial filamentFiberCross-link

The invention discloses a thermal-resistant anti-cutting ultra-high molecular weight polyethylene fiber which comprises ultra-high molecular weight polyethylene powder, inorganic nanoparticles, a cross-linking agent, a curing agent, an initiator and an antioxidant. The preparation method of the thermal-resistant anti-cutting ultra-high molecular weight polyethylene fiber comprises the following steps: swelling the ultra-high molecular weight polyethylene powder by using a solvent to form pores, adding a composite modifier formed by common infiltration of the cross-linking agent, the curing agent, the initiator, the antioxidant, the inorganic nanoparticles and the solvent are moistened by one another, enabling the components to uniformly permeate into the pores of the ultra-high molecular weight polyethylene powder, uniformly mixing, extruding and spinning through a screw extruder, removing the solvent, drawing so as to obtain the ultra-high molecular weight polyethylene fiber, and finally performing irradiation crosslinking, thereby obtaining the thermal-resistant anti-cutting ultra-high molecular weight polyethylene fiber. The thermal-resistant anti-cutting ultra-high molecular weight polyethylene fiber is wide in application and long in service life.

Owner:JIANGSU SHENTAI SCI & TECH DEV

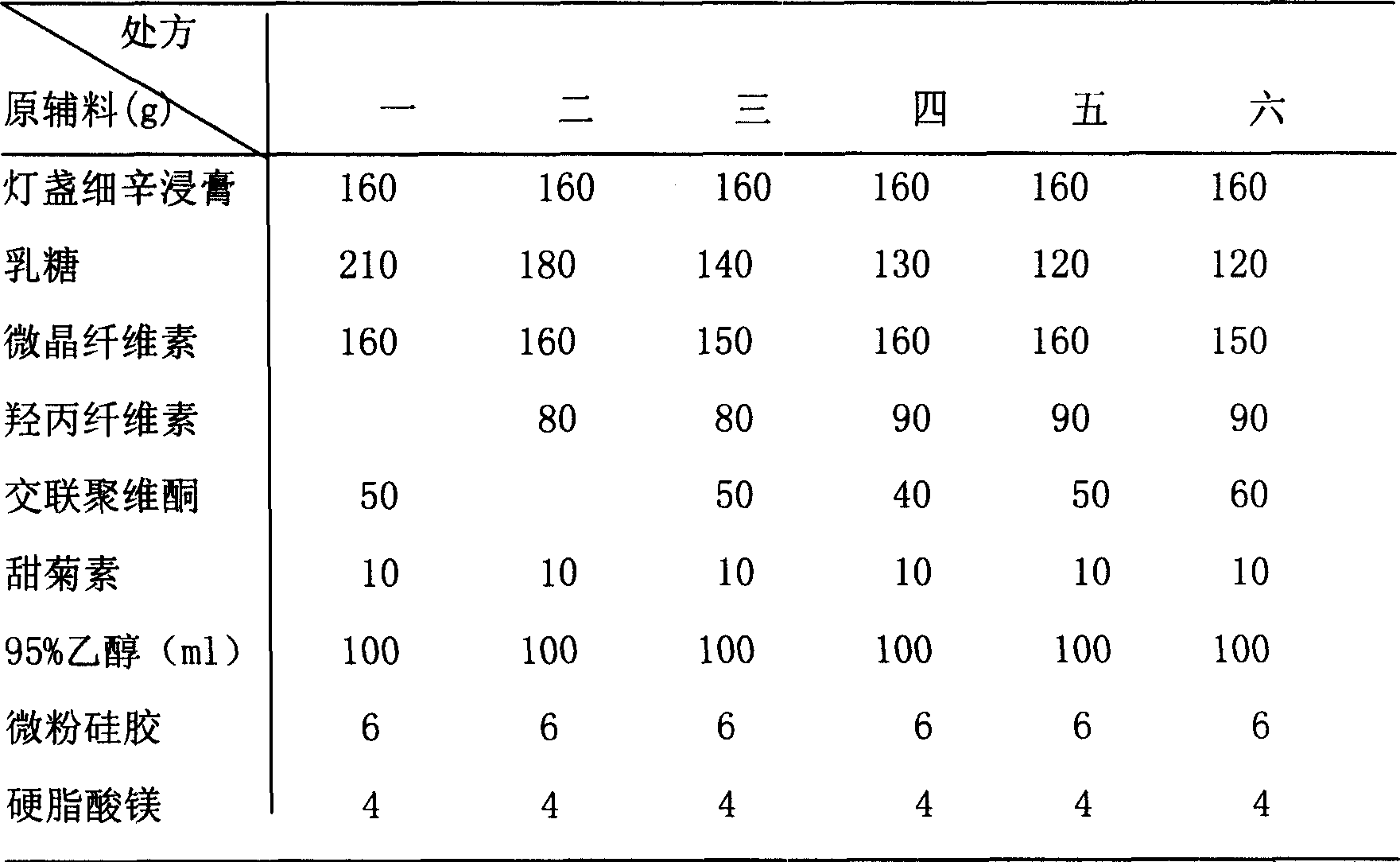

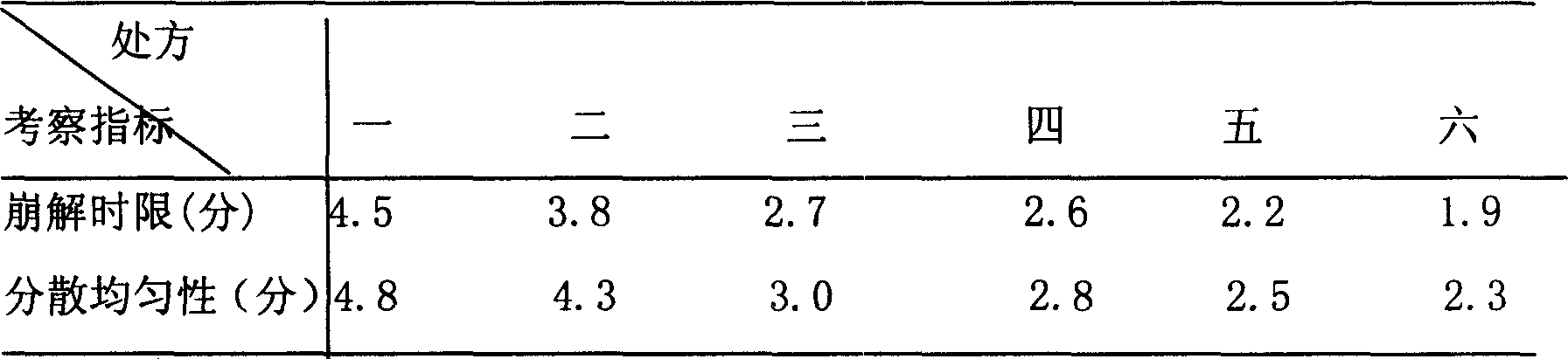

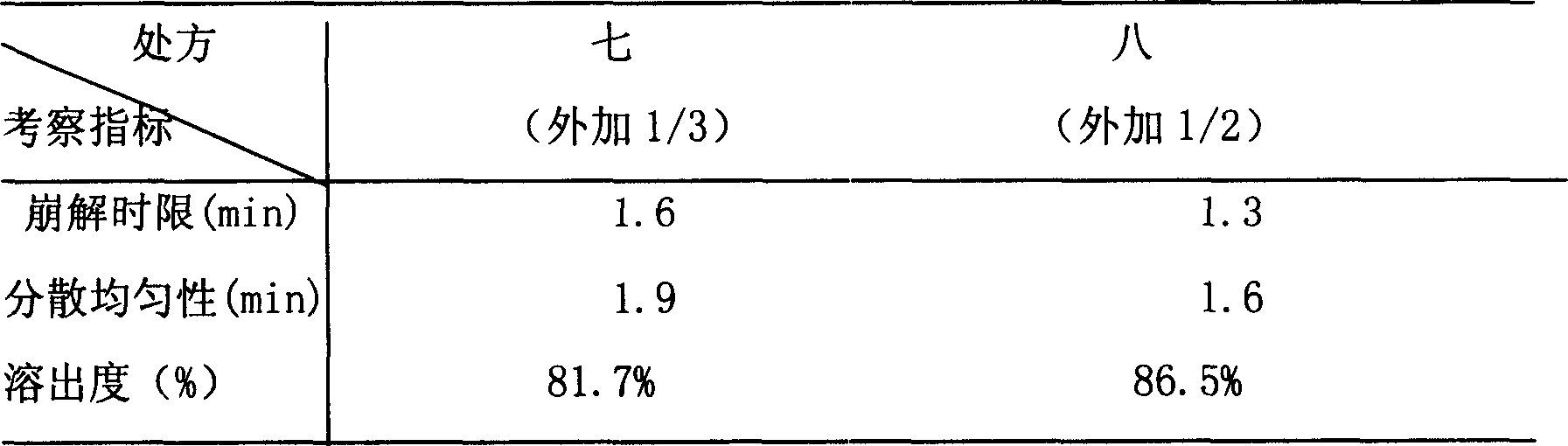

Yimaikang dispersion tablet and its preparing method

The Yimaikang dispersion tablet consists of fleabane extractum and medicine carrier. Its recipe includes fleabane extractum, lactose, microcrystalline cellulose, low-substituted hydroxypropyl cellulose, cross-linked polyvidon, steviosin, alcohol, fine silica gel powder and magnesium stearate. The dispersion tablet can disintegrate completely in 3 min to reach homogeneous dispersive state and its effective component andrographolide has dissolving rate reaching 60 % in 10 min. It is used in treating ischemic cerebral vascular diseases, cerebral hemorrhage sequela, vein obstruction, etc. and has fast acting, good taste and convenient taking.

Owner:云南白药集团大理药业有限责任公司

Method for synthesizing barium-manganese carbonate monocrystal under high temperature and high pressure

InactiveCN108642565AHigh purityHigh crystallinityPolycrystalline material growthFrom solid stateManganeseSingle crystal

The invention discloses a method for synthesizing barium-manganese carbonate monocrystal under high temperature and high pressure. The method comprises the following steps of uniformly grinding and mixing analytically pure barium carbonate and analytically pure manganese carbonate according to a molar ratio of 1:1, so as to obtain an initial raw material; reacting for 12h at high temperature of 700 to 900 DEG C and high pressure of 1 to 3GPa, so as to obtain a sample of barium-manganese carbonate powder crystal; grinding and mixing the sample of the barium-manganese carbonate powder crystal and anhydrous oxalic acid according to a molar ratio of 1:0.1, so as to obtain a sample; reacting for 100h at high temperature of 700 to 900 DEG C and high pressure of 3GPa, so as to obtain the sample of the barium-manganese carbonate monocrystal. The high-temperature and high-pressure method has the advantages that the operation process is simple, the experiment conditions are easy to control, andthe like. The obtained barium-manganese carbonate sample has the characteristics that the purity is high, the crystallizing degree is high, the chemical stability is good, the easiness in water absorbing is avoided, and the like; the technical problem of lack of growth method in the existing artificially synthesized barium-manganese carbonate monocrystal is solved.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI

Flame-retardant glass fiber reinforced polypropylene composite material for manufacturing coil frame and preparation method thereof

The invention discloses a flame-retardant glass fiber reinforced polypropylene composite material for manufacturing a coil frame and a preparation method thereof. The composite material is mainly prepared from polypropylene, glass fiber, a fire retardant, a compatilizer, a nucleating agent, a dispersing agent and an antioxidant serving as raw materials. The preparation method comprises the following steps of: (1) uniformly mixing the polypropylene, the fire retardant, the compatilizer, the nucleating agent, the dispersing agent and the antioxidant; and (2) performing melt extrusion on the mixed raw materials obtained by the step (1) and the glass fiber in a melt extruder and pelleting to obtain a product. The invention provides the flame-retardant glass fiber reinforced polypropylene composite material for manufacturing the coil frame and the preparation method thereof.

Owner:ANHUI KEJU NEW MATERIALS

Method for manufacturing surface-carbonized furniture

InactiveCN104526829ANot easy to absorb waterReduce moisture contentWood charring/burningWater basedHazardous substance

The invention relates to the field of furniture manufacturing methods, in particular to a method for manufacturing surface-carbonized furniture. The method includes the following steps that a board is stewed by boiled water, degreased and decolored; the board is soaked and cleaned in circular flowing water; the board is dried under the conditions of shading, normal temperature and ventilation and then enters a hot air drying chamber for drying; the board is spliced and reinforced through water-based glue for the furniture; the furniture is manufactured; the furniture is assembled and then is ground with grinding paper; the furniture is subjected to pressurization and roasting of a blast burner at a uniform speed, and finally the surface is carbonized; floating ashes are brushed away; the furniture is washed by water; the furniture is waxed and polished, and finally the furniture is completed after hardware is installed. The surface-carbonized board is not prone to water absorption, low in water content, resistant to dampness, not prone to deformation, good in corrosion resistance and insect prevention and free of any harmful substance, prolongs the service life of the furniture and will not have any negative effects on human bodies or animals or the environment in the production and use process and the waste treatment process after use.

Owner:ZHENGZHOU RED SUN FURNITURE

Toughened plastic tray and preparation method thereof

InactiveCN102952318AWide variety of sourcesLow costRigid containersTG - TriglycerideMechanical property

The invention discloses a toughened plastic tray prepared from the following raw materials in parts by weight: 50-60 parts of high density polyethylene, 20-30 parts of polyvinyl chloride, 20-30 parts of wood flour, 10-15 parts of silicon carbide, 10-20 parts of modified kaolin, 40-50 parts of recycled plastic polymer, 20-30 parts of active calcium, 1-2 parts of zinc stearate, 1-2 parts of calcium stearate, 2-3 parts of glycerol triglyceride, 0.3-0.5 part of polyethylene wax, 0.4-0.6 part of anilmomethyl triethoxy silane, 0.3-0.4 part of antioxidant 1680, 0.4-0.6 part of anti-aging agent ODA, 8-10 parts of foaming regulator, 4-8 parts of ACM, 4-8 parts of MBS, 25-30 parts of oxidized polyethlene wax, 0.2-0.3 part of foaming agent, 4-8 parts of ACR, 8-12 parts of chlorinated polyvinyl chloride, 5-8 parts of high silica glass fiber, 4-6 parts of mineral fiber and 3-4 parts of semi-reinforced carbon black. The toughened plastic tray produced by the invention has good mechanical properties, good durability, high repeated utilization rate, ageing resistance and corrosion resistance, the tray can be sawed, planed and nailed while needing no steaming or high temperature sterilization treatment, the tray can be flushed and has less possibility of absorbing water and deforming, and no mildew is generated, so that the toughened plastic tray is especially suitable for application at plum rain seasons in the south of the lower reaches of the Yangtze river.

Owner:芜湖太平洋塑胶有限公司

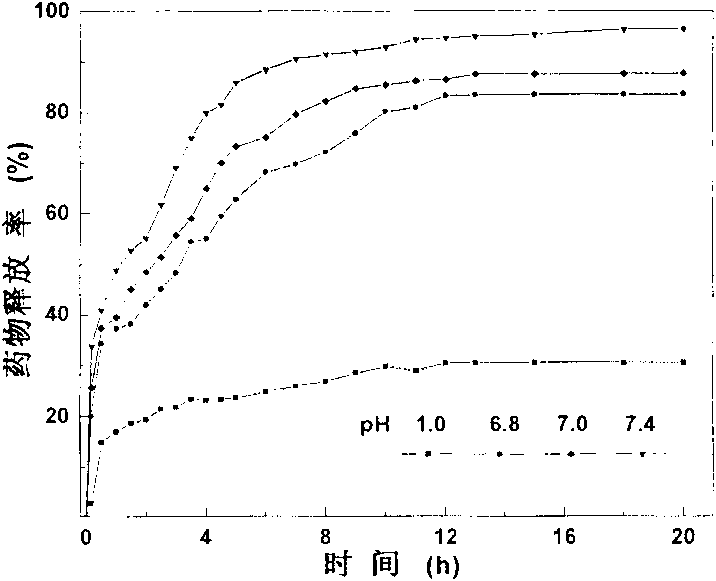

Alginic acid inorganic nanometer composite gel microspheres and preparation method

InactiveCN101612128APreparation process safetyIncrease sustained releasePharmaceutical non-active ingredientsGranular deliveryPolypropyleneCarbon nanotube

The invention relates alginic acid inorganic nanometer composite gel microspheres and a preparation method; the gel microspheres comprise the following components by weight percent: 1-7% of alginate, 0.5-10% of carbon nanotubes, 1-50% of triblock surfactant polyethylene oxide-polypropylene oxide-polyethylene oxide and the balance water. The production process of the gel microspheres is safe, simple and effective and accords with the requirements of environmental protection. The alginic acid carbon nanotubes composite gel microspheres which is prepared by the preparation method of the invention and is introduced with carbon nanotubes can relieve the swelling speed of the complexed alginic acid microspheres, can be used as a carrier to combine with drugs, proteins, enzymes and other biological products and can be used as a drug carrier owning to the pH sensitivity of the composite gel microspheres.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH +1

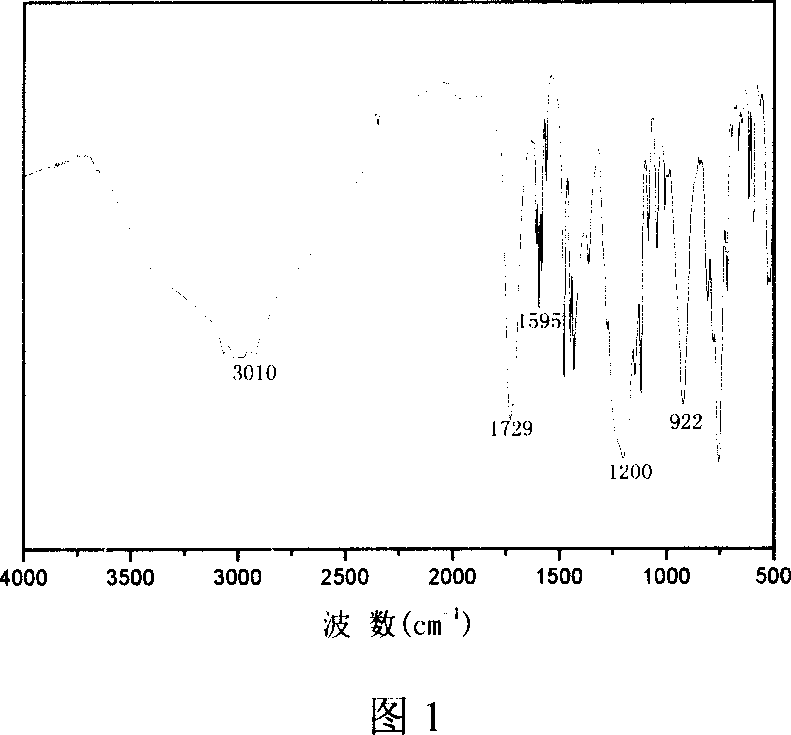

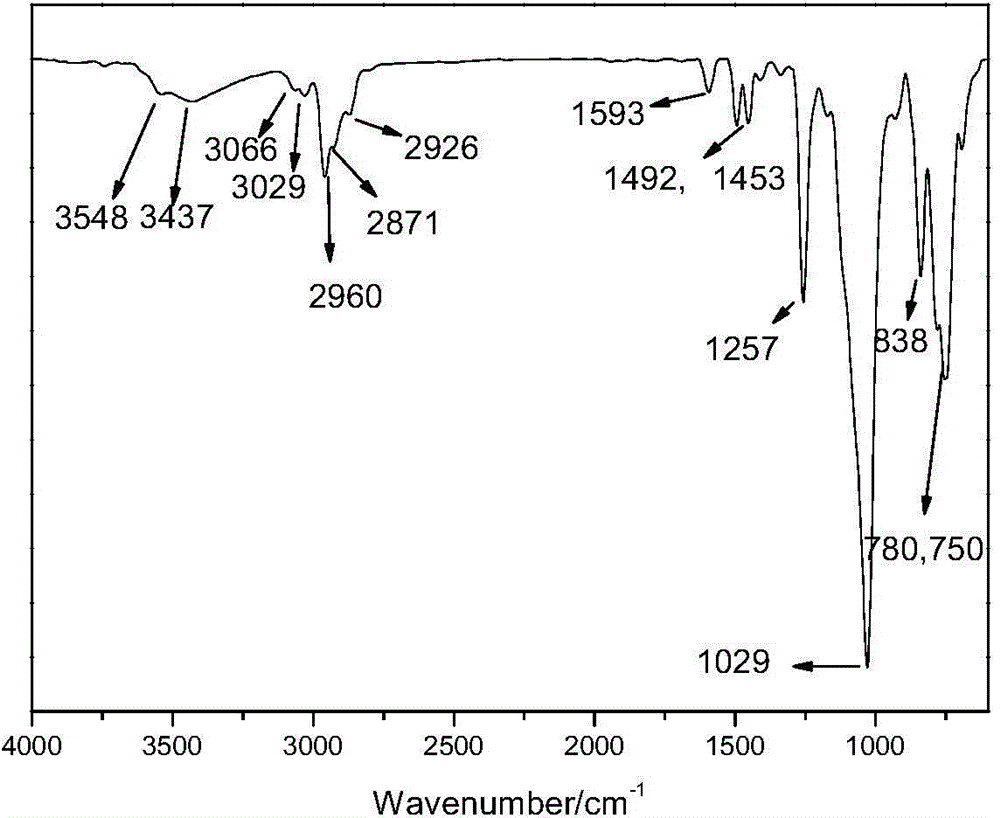

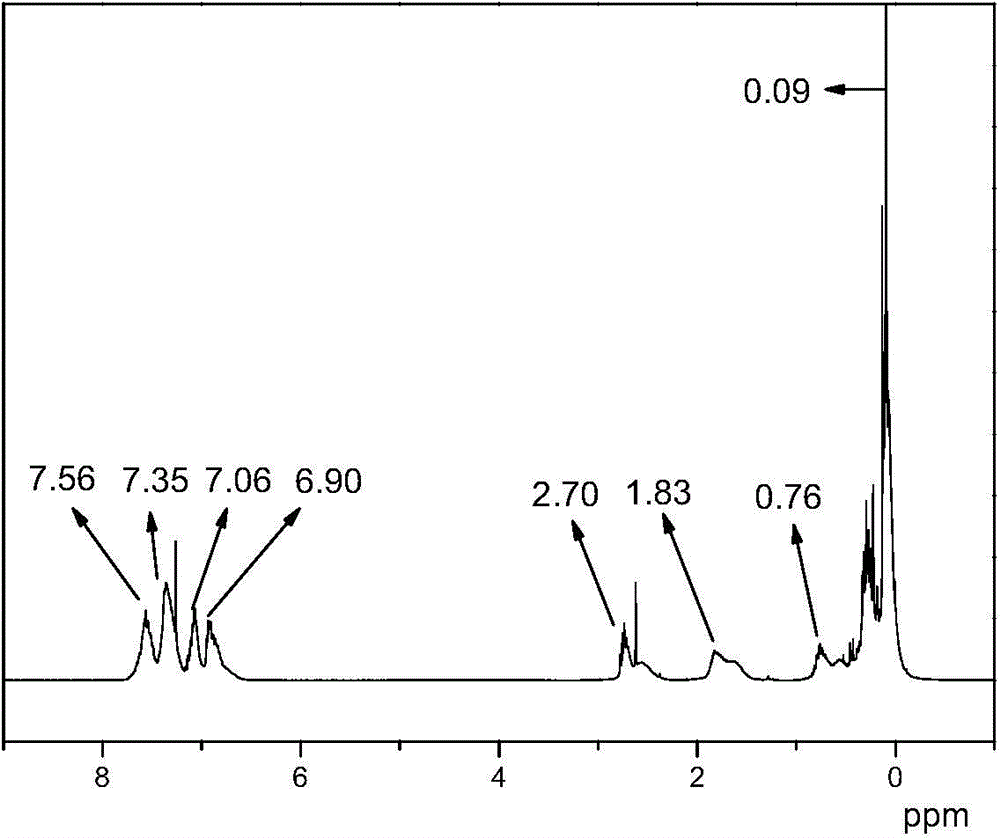

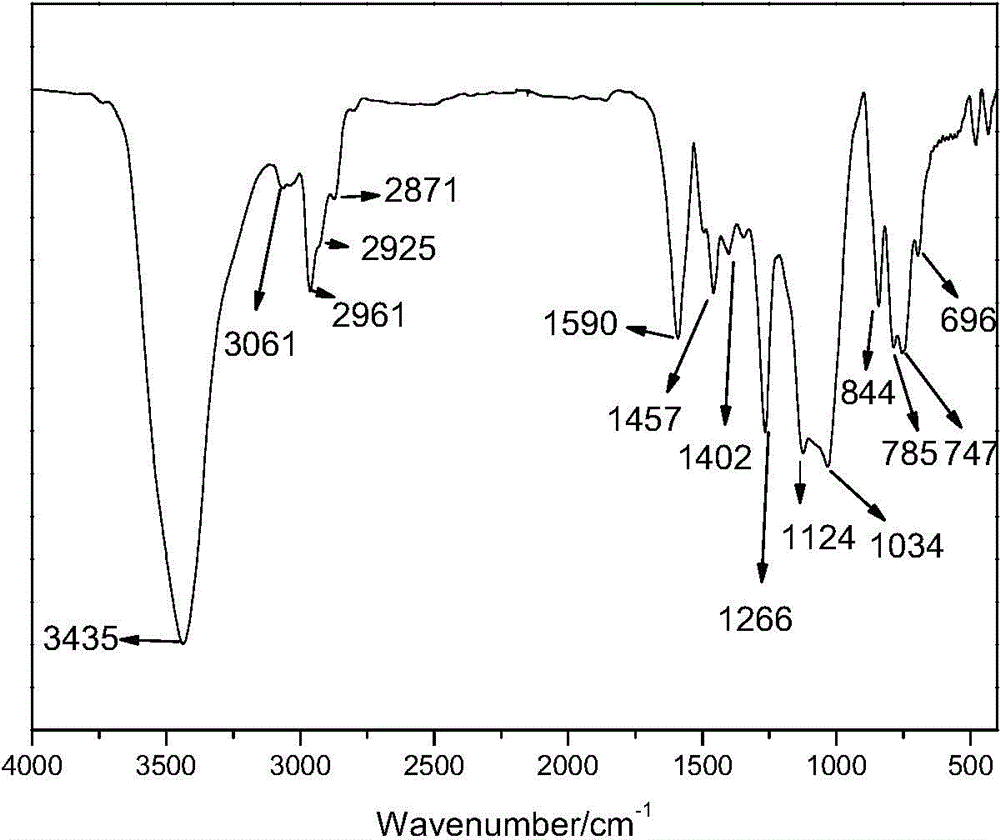

Organosilicon high-molecular material and preparation method thereof

The invention relates to an organosilicon high-molecular material in a phenolic resin structure and a preparation method thereof. The organosilicon high-molecular material is prepared by carrying out crosslinking reaction on polysiloxane, of which the side chain is modified by a phenolic group, under the catalytic action of an alkali by using aldehydes or derivatives thereof as a crosslinking agent. The organosilicon high-molecular material polymer uses Si-O-Si as the main chain of the molecule, the side chain contains the phenolic group, and the aldehydes or derivatives thereof are used for crosslinking to form the phenolic-resin-like crosslinking point, thereby enhancing the high temperature resistance. The organosilicon high-molecular material can be stored for a long time, can not easily absorb water, and has stable physicochemical properties. The invention also relates to a preparation method of the organosilicon high-molecular material.

Owner:SHANDONG UNIV

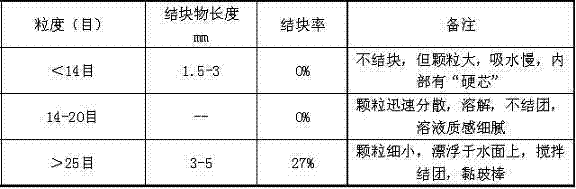

Mixed product comprising beta-glucan and preparation method of mixed product

ActiveCN102919964AUnited will notImprove function and effectFood preparationBiotechnologyButter cocoa

The invention relates to a mixed product comprising beta-glucan, which is prepared by the following raw materials in ratio by weight: 7.5-80% of beta-glucan, 6-20% of cocoa butter, 0-30% of supermicro carrot powder, 0-30% of supermicro highland barley, and 0-40% of erythritol. Meanwhile, the invention further discloses a preparation method of the product. In the mixed product, beta-glucan can be quickly dissolved in daily drinking water. The mixed product has a certain healthcare effect, is convenient to have and good in taste, and can meet the recommended dose of beta-glucan to reach the health keeping effect.

Owner:TIBET TIANMAILI HEALTH PROD CO LTD

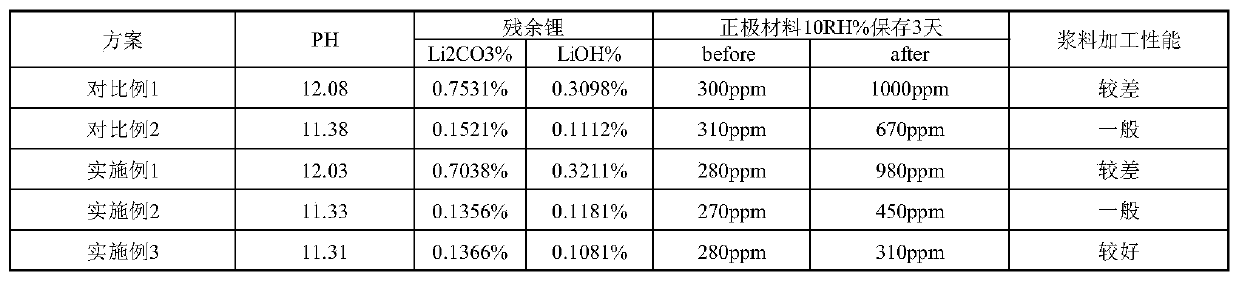

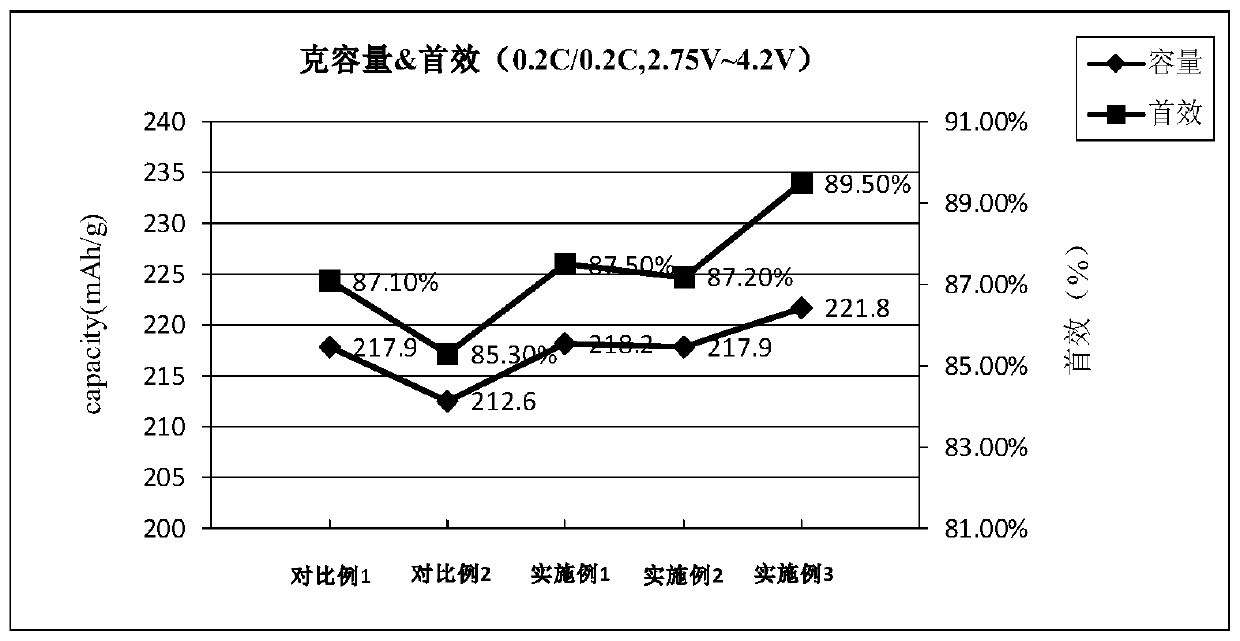

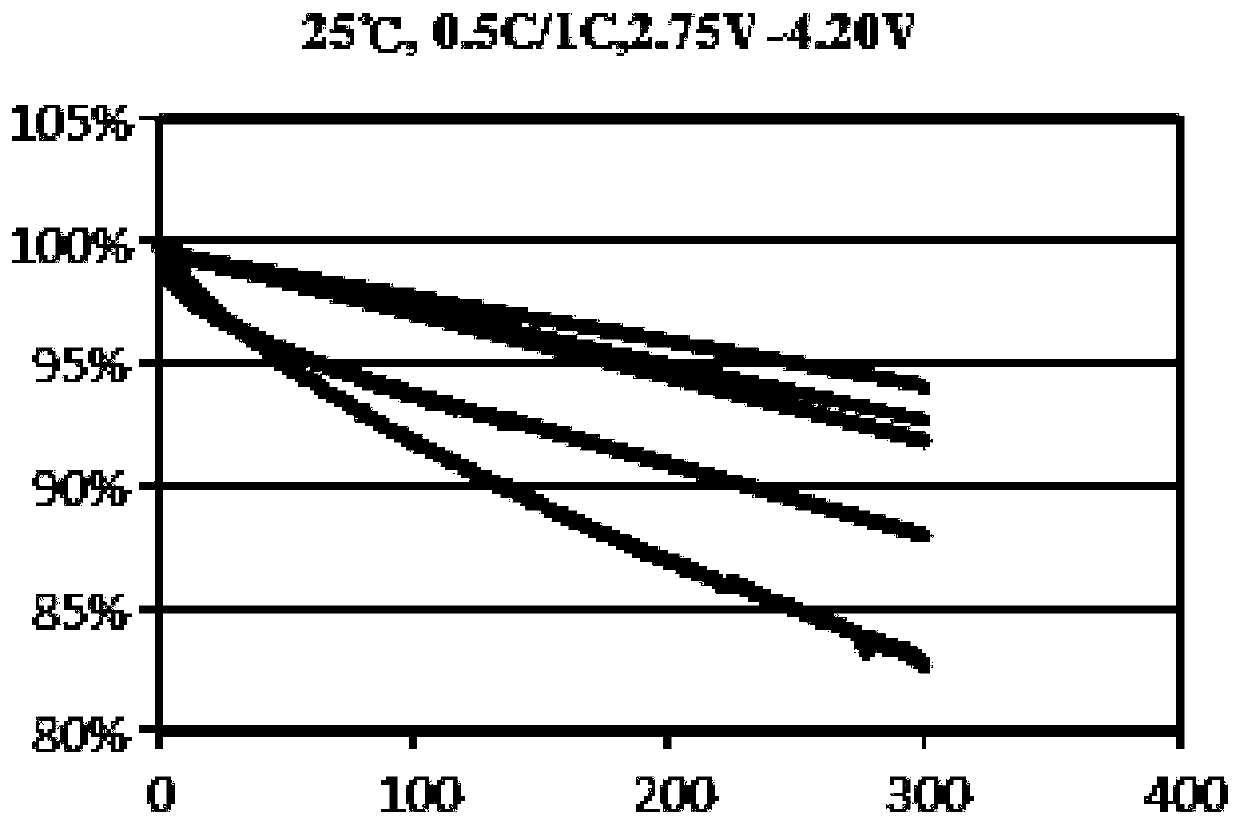

Preparation method of high-nickel positive electrode material

InactiveCN109802123AImprove high temperature stabilityImprove water absorptionCell electrodesSecondary cellsLithium hydroxideLithium carbonate

The invention discloses a preparation method of a high-nickel positive electrode material, which comprises the following steps: uniformly mixing up a Ni-containing hydroxide, a lithium-containing compound and a doping element, and calcining to obtain a base material A after the mixing operation; adding the base material A into a washing solution, controlling the temperature of the washing solution, washing away residual lithium carbonate and lithium hydroxide on the surface, adding a lithium-containing compound into the washing solution, and drying the washed base material to obtain a mixtureB; uniformly mixing the mixture B, a coating element and a lithium-containing compound, calcining, and crushing to obtain the finally modified high-nickel positive electrode material. The high-temperature stability of the nickel material is improved through doping. The residual lithium carbonate and lithium hydroxide on the surface are reduced through washing. The water absorption and processing performance of the material is improved. The damage to the surface of the material during washing can be repaired through coating. The direct contact between the positive electrode material and the electrolyte can be reduced, so that the high-temperature characteristic and long-cycle performance of the battery cell are improved.

Owner:浙江迈纳新材料有限公司

Sympodial bamboo integration profile manufacturing method

ActiveCN103737692AHigh densityImprove the bactericidal effectPressure wood treatmentWood treatment detailsCarbonizationHigh pressure

The invention discloses a sympodial bamboo integration profile manufacturing method. The method is characterized by including the following steps: S1, soaking bamboo filaments of sympodial bamboo which are subjected to green planing and yellow removing in water for high-temperature stewing at temperature of 100-120 DEG C for at leat four hours, wherein the water contains, by mass, 5-10% of hydrogen peroxide and 0.5-1% of sodium hydroxide; S2, disposing wet bamboo filaments in a carbonization furnace for carbonizing at temperature of 130-15o DEG C and at pressure of 3-4 MPa for 4-6 hours; S3, drying for the first time, dipping in glue, and drying for the second time after glue dipping; S4, performing high-pressure forming at pressure of being not less than 1.2 t / cm2; S5, performing thermosetting for more than 10 hours at temperature of 80-150 DEG C under the condition that the pressure of being not less than 1.2 t / cm2 is maintained. By the sympodial bamboo integration profile manufacturing method, sympodial bamboo integration profiles meeting structural profile requirements can be manufactured.

Owner:SHENZHEN KANGER BAMBOO & WOOD

Preparation method of sterilized high-strength crack prevention wood

InactiveCN106182249AGood mechanical propertiesGood dimensional stabilityPressure wood treatmentWood treatment detailsChemistryDiethylene glycol

The invention discloses a method for preparing sterilized and anti-cracking high-strength wood, which belongs to the field of wood. In the present invention, the wood is boiled in water and placed in a pressure tank for blasting treatment. After the treatment, the water content is controlled by drying, and the wood is soaked in the wood modification liquid. The wood modification liquid is concentrated and extracted from lily leaves and tea seed dregs. Allyl glycidyl ether, dimethylacetamide, diethylene glycol, sodium hydroxide, diammonium hydrogen phosphate, cyproconazole and other substances. Take out the soaked wood and dry it, and spray ten times on the wood surface evenly The nano-silica sol modified by hexaalkyltrimethoxysilane can be dried after spraying. The wood prepared by the invention has good mechanical properties and dimensional stability, has excellent sterilization and anti-mold properties, and has a high anti-swelling coefficient. , long-term use will not cause cracking and warping, and the prepared wood modification solution is safe and environmentally friendly, and has no formaldehyde release.

Owner:张静

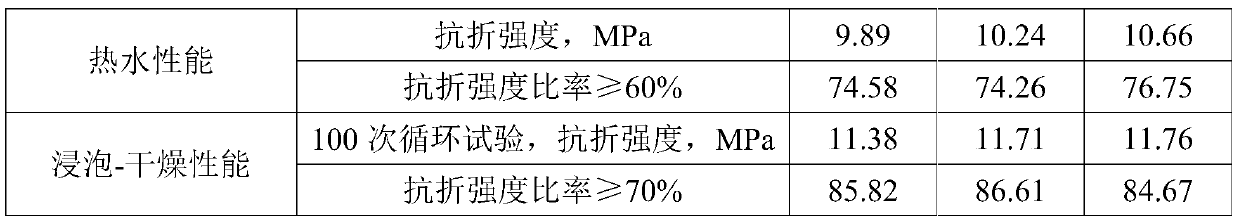

Asbestos-free straw fiber reinforced cement board and preparation method thereof

InactiveCN111217560ALittle loss of strengthGood moisture and heat stabilityCeramic shaping apparatusTriethoxysilaneCement board

The invention relates to an asbestos-free straw fiber reinforced cement board and a preparation method thereof. The straw fiber reinforced cement board is mainly prepared from, by weight, 6-8 parts ofmodified wheat straw fibers, 5-6 parts of silica fume, 48-52 parts of cement, 10-12 parts of metakaolin, 20-22 parts of quartz sands and 5-6 parts of fly ash. A preparation technology of the modifiedwheat straw fibers comprises the following steps: 1) cutting dry wheat straws into a short material, and soaking and softening with water to obtain a prepared material; 2) performing steam explosionon the prepared material to obtain an exploded material; 3) sequentially carrying out alkaline leaching and water washing on the exploded material to obtain a fiber material; and 4) modifying the fiber material with gamma-aminopropyltriethoxysilane to obtain the asbestos-free straw fiber reinforced cement board. The asbestos-free straw fiber reinforced cement board is good in appearance quality, low in water absorption and wet expansion rate, good in water resistance and moisture resistance, high in mechanical properties, resistant to freeze thawing and hot water, good in dry-wet cycle performance, stable in properties, green and environmentally friendly, and can replace a wood pulp fiber reinforced cement board.

Owner:郑州知淘信息科技有限责任公司

Polyurethane board and preparation method thereof

The invention discloses a polyurethane board and a preparation method thereof. The manufacturing method comprises the following steps of uniformly mixing a component A, a component B and compound filler to prepare a foaming material, injecting the foaming material into a die for compression molding, and finally demoulding to form a polyurethane board product, wherein the component A comprises a polyether polyol auxiliary a and a polyester polyol auxiliary b; the component B is isocyanate; the filler is prepared from an inorganic powder material, a plant powder material and a fiber material. According to the manufacturing method, the polyurethane board product is manufactured by uniformly mixing the compound polyester polyol, the isocyanate and the compound filler, injecting the mixture into the die and carrying out heat-preservation pressing. The obtained product is high in mechanical performance strength, low in linear shrinkage rate during storage and use, is not easy to warp after long-term storage and high in production and secondary processing precision, does not easily absorb water and can be applied to the field having high requirement on size precision.

Owner:昆山市柳鑫电子有限公司

Heat-resisting antistatic UHMWPE (ultra high molecular weight polyethylene) fiber and preparation method thereof

InactiveCN104711696AHeat resistantHeat-resistant and anti-staticElectroconductive/antistatic filament manufactureMonocomponent polyolefin artificial filamentCross-linkFiber

The invention provides a heat-resisting antistatic UHMWPE (ultra high molecular weight polyethylene) fiber and a preparation method thereof. The fiber includes UHMWPE powder, nano conductive particles, a cross-linking agent, a curing agent, an initiator and an antioxygen. The preparation method includes the following steps: the UHMWPE powder swells through a solvent and holes are formed; then a composite modifying agent formed through jointly soaking the cross-linking agent, the curing agent, the initiator, the antioxygen, the nano conductive particles and the solvent is added, and uniformly permeates the holes in the UHMWPE powder; after uniform mixing, spun silks are extruded out through a screw extruder; and the UHMWPE fiber is obtained through drafting after the solvent is removed; the heat-resisting antistatic UHMWPE fiber is obtained through irradiation crosslinking. The heat-resisting antistatic UHMWPE fiber has the comprehensive performance of wear resistance, heat resistance, static resistance, shock resistance, self-lubrication, corrosion resistance, low temperature resistance, sanitary and non-poisonous performance, less possibilities of adhesion and water absorption, small density and the like, is wide in application range and long in service life.

Owner:JIANGSU SHENTAI SCI & TECH DEV

Method of making pottery tea set

InactiveCN101306940ASuitable for preservationSuitable for long term storageClaywaresPositive pressureFree cooling

The invention discloses a method for making an earthtype tea set. The method comprises the following steps that: mottled earth, loess, blue earth and purple soil are respectively mixed according to the weight percent of 56 to 64 percent, 17 to 23 percent, 4 to 6 percent and 13 to 17 percent, and then are ground; water is added in to carry out stirring; slurry is calmed and filtered; sunshine is carried out; water is filtered out to form mud; billet drawing and finishing are finished; natural drying is carried out; oxidizing flame negative pressure baking is finished at 1,100 DEG C; equal to or higher than 1,110 DEG C and lower than or equal to 1,180 DEG C reducing flame positive pressure baking is carried out to generate kiln transformation; and finally, natural cooling, grinding and polishing are carried out. The earthtype tea set made by the method is firm and durable and has high drying degree, infrequent water absorption and better gas permeability after grinding and polishing; therefore, the earthtype tea set is suitable for containing tea and Pu'er tea particularly for a long time, and can prevent the tea from easy deterioration; moreover, the tea set has smooth and rounded surface, excellent hand feeling and both practicality and ornamental property.

Owner:田波

Method for synthesizing barium carbonate iron monocrystal at high temperature and under high pressure

InactiveCN108588835AHigh purityHigh crystallinityPolycrystalline material growthFrom solid stateIron powderSingle crystal

The invention discloses a method for synthesizing barium carbonate iron monocrystal at high temperature and under high pressure. The method comprises the following steps: grinding and uniformly mixingthe analytic pure barium carbonate and the synthetic ferrous carbonate according to the molar ratio of 1:1 to serve as a starting raw material, performing high-temperature and high-pressure reactionfor 12 hours at 500 to 800 DEG C and under the pressure of 1 to 3 GPa to obtain a barium carbonate iron powder crystal sample, grinding and mixing the barium carbonate iron powder crystal sample and anhydrous oxalic acid according to the molar ratio of 1:0.1 to prepare a sample, and performing high-temperature and high-pressure reaction for 100 hours at 700 to 900 DEG C and under the pressure of 3GPa to prepare a barium carbonate iron monocrystal sample. The high-temperature and high-pressure method has the advantages that the operation process is simple and the experimental condition is easyto control; the obtained barium carbonate iron sample has the characteristics of high purity, high crystallinity degree, chemical stability, insusceptibility to water absorption and the like; and thetechnical problem that the existing method for artificially synthesizing the barium carbonate iron and growing the monocrystal has defectiveness is solved.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI

Multifunctional polyethylene and stainless steel composite pipe

InactiveCN102964659ALow densityImprove mechanical propertiesCorrosion preventionPipe protection against corrosion/incrustationCalcium bicarbonateShock resistance

The invention relates to an UHMW-PE (ultrahigh molecular weight polyethylene) pipe, in particular to a multifunctional polyethylene and stainless steel composite pipe formed by compositing the UHMW-PE pipe and stainless steel, and a preparation method of the composite pipe. The UHMW-PE pipe comprises the following components in parts by weight: 100 parts of UHMW-PE, 10-15 parts of diatomite, 8-10 parts of short glass fiber, 7-10 parts of calcium bicarbonate, 7-10 parts of organic tin, 1-5 parts of nano aluminum nitride, 1-2 parts of graphite, 0.1-1.5 parts of PE wax, 2-5 parts of acrylic ester, 3-5 parts of silicone polymer, 3-6 parts of titanium dioxide, 6-10 parts of shock-resistance MBS (methyl methacrylate-butadiene-styrene copolymer) resin, 0.5-1.0 parts of antioxygen 1010, and 3-5 parts of light absorption agent FeMnOx composite oxide. The composite pipe comprises an UHMW-PE inner pipe and a stainless steel outer pipe between which hot glue adhesion layer is adhered, wherein a SiO2 composite coating is coated on the outer surface of the stainless steel pipe. The multifunctional polyethylene and stainless steel composite pipe disclosed by the invention has the advantages of convenience in installation, good performance and wide application.

Owner:SHANXI JINLONG MASTERY PIPE IND CO LTD

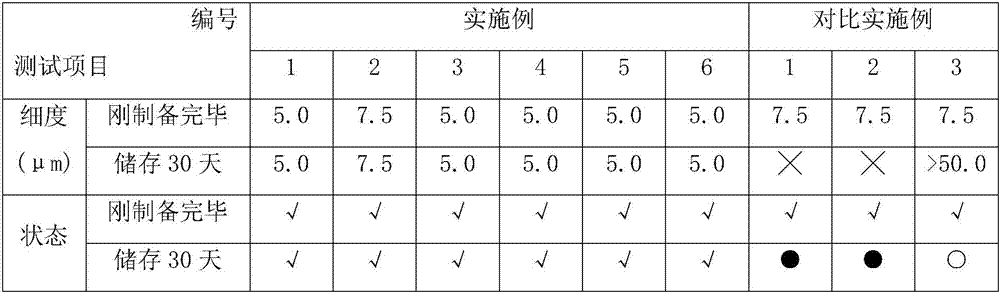

Liquid colorant for coloring polyester fiber stock solution and preparation method thereof

ActiveCN106978639AReduce pollutionBroaden your optionsPigment addition to spinning solutionMonocomponent polyesters artificial filamentPolyesterFiber

The invention discloses a liquid colorant for coloring polyester fiber stock solution. The liquid colorant comprises the following components by weight percent: 65 to 95% of liquid dispersion medium, 3 to 30% of colorant, 2 to 5% of dispersing agent and the like. According to the liquid colorant disclosed by the invention, a pigment or a dye and a liquid carrier are processed by dispersion equipment, such as grinding by a grinding machine and the like; a dispersion degree and a pigment utilization rate are high; the liquid colorant has the advantages of high storage stability, good coloring effect and the like.

Owner:SUZHOU SUNMUN TECH CO LTD

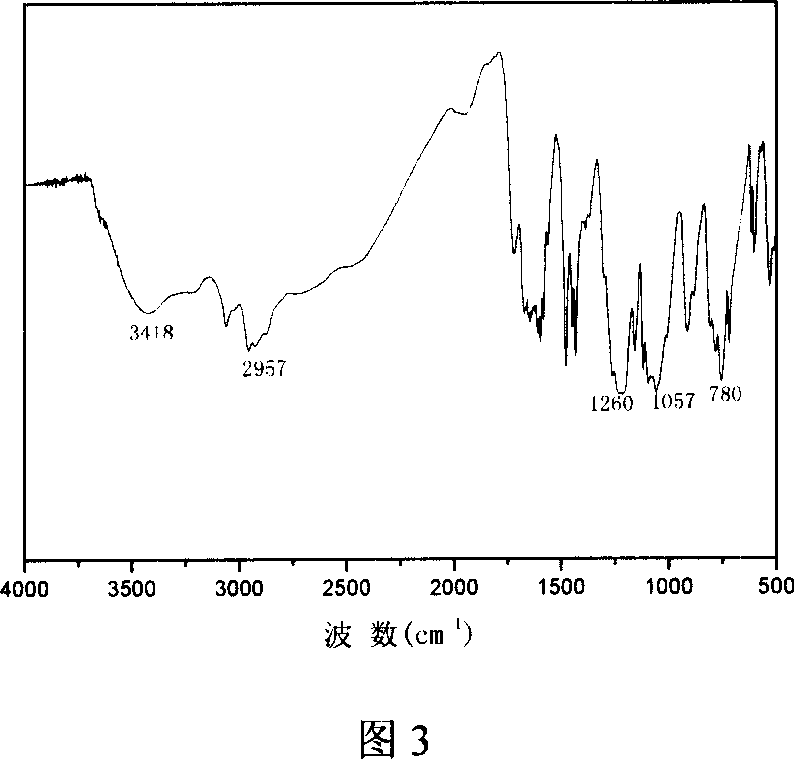

Method for preparing kutnohorite at high temperature under high pressure

ActiveCN107640787ASolve the technical problems of difficult preparationExtended reaction timeManganese compoundsStoichiometryKutnohorite

The invention discloses a method for preparing kutnohorite at a high temperature under high pressure. The method includes evenly grinding and mixing analytically-pure calcium carbonate, magnesium oxalate (MgC2O4.2H2O), manganese carbonate powder and anhydrous oxalic acid according to stoichiometry, pressing a mixture into a cylinder by a tablet machine, inserting a cylindrical sample into a platinum tube, sealing two ends of the platinum tube by a welding gun, putting the sample sealed by platinum in an h-BN tube by taking h-BN as a pressure transfer medium, assembling the sample in the h-BN tube in a high-pressure combined assembly block, putting the high-pressure combined assembly block in a cubic press for high-temperature high-pressure reaction, taking out the reacted sample, opening the platinum tube by a diamond cutter, and naturally air-drying the sample to obtain the kutnohorite. By the method, the technical problems such as operation process complexity, long reaction time, andlow purity, low chemical stability and proneness to water absorption of obtained samples in existing kutnohorite preparation methods are solved.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI

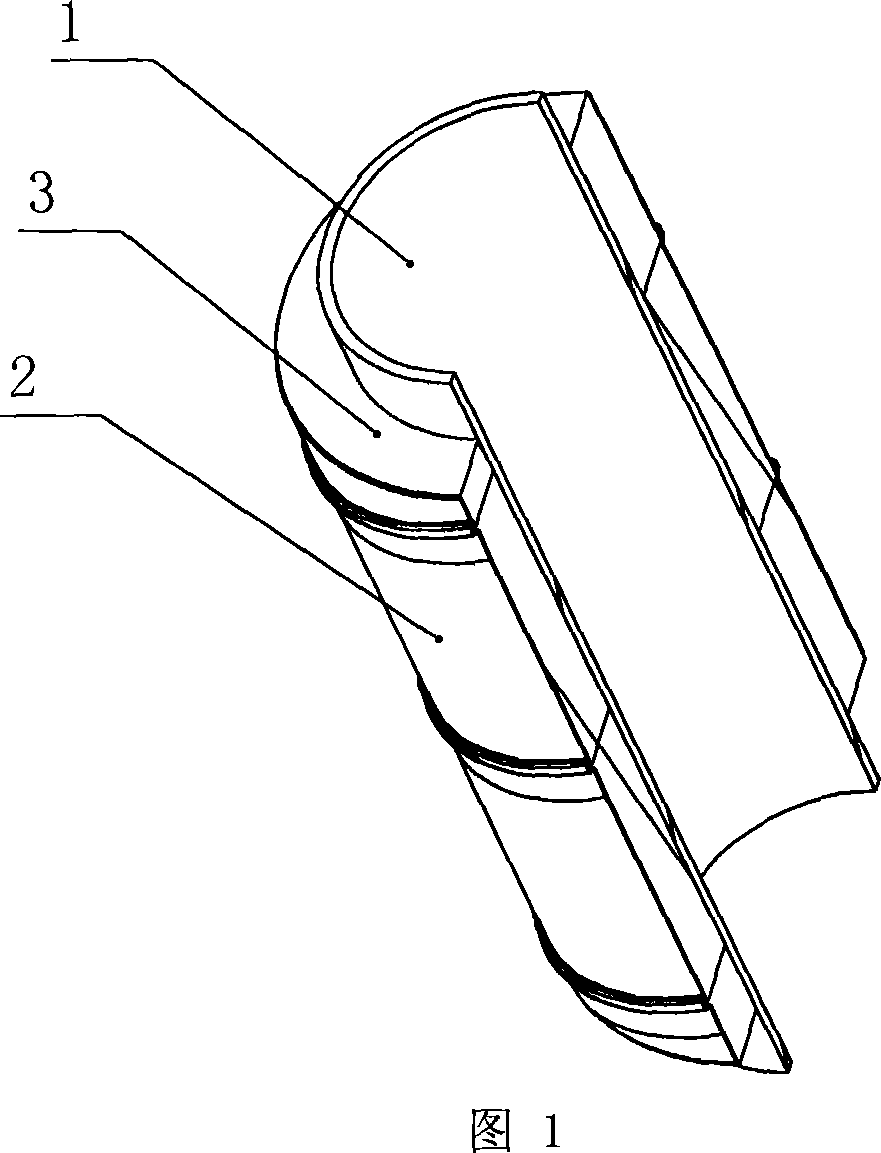

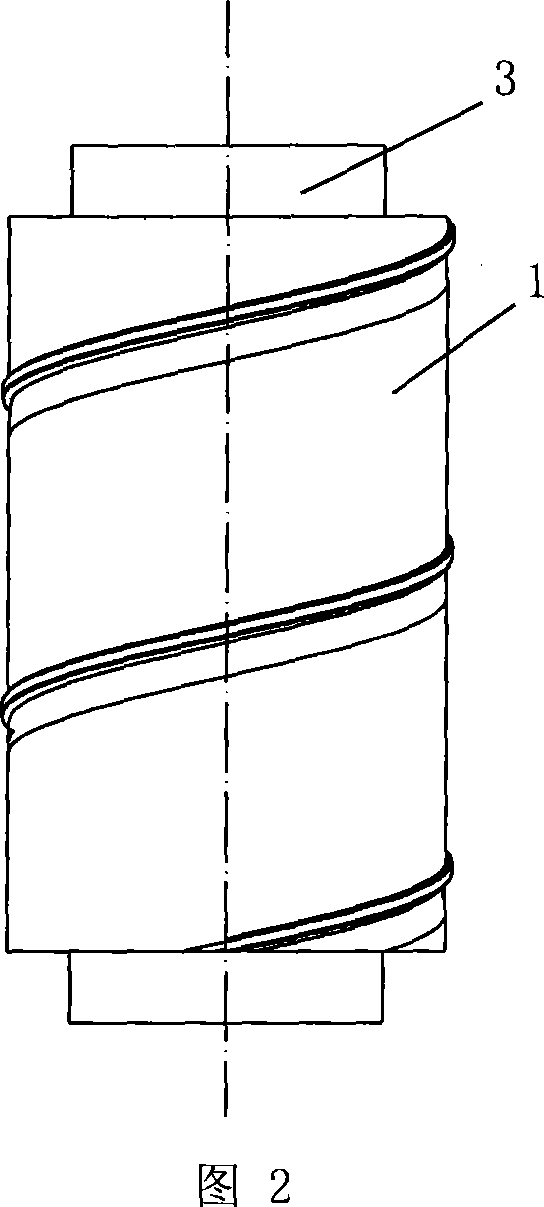

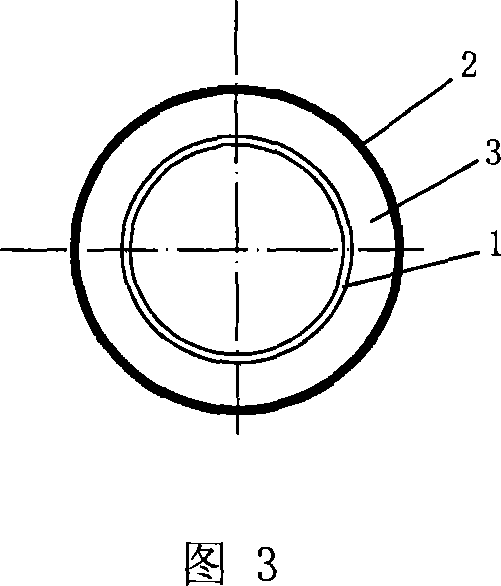

Prefabricated spiral phenolic aldehyde insulation tube and its production method

InactiveCN101055049AImprove insulation effectImprove insulation performanceLayered productsRigid pipesIsolation effectThermal insulation

A prefabricated spiral pnenolic aldehyde thermal insulation pipe and a manufacturing method thereof, a thermal insulation pipe is related. A prefabricated spiral pnenolic aldehyde thermal insulation pipe which has good heat preservation, insulation and sound isolation effect, is difficult in burning, no smoke in open flame, nontoxic, difficult in water absorption, not constringency, not deformation, good in machinery intensity, low in heat conductivity coefficient, no harm for human body, and broad in application and a method which is simple in technics, forming in one time, low in cost and can continuously or intermittently produce the prefabricated spiral pnenolic aldehyde thermal insulation pipe are provided. The thermal insulation pipe is a three layer composite pipe and is disposed with an inner pipe, an outer pipe and an intermediate pipe. The step is that: mixing formaldehyde-phenol resin, combustion inhibitor, modifying agent, and surfactants with proportion as A material; mixing firming agent and aerating powder as B material, opening a drying tunnel and heating it to predetermined temperature, starting a tube machine and a high-pressure foam maker, pouring A material and B material into the spiral pipe after mixing them with high pressure, pouring the material while making pipe, the pipe after being poured with foaming materials will be heated in the drying tunnel to foam, the one time form can be achieved, cutting after the foam body solidified and piling code by an automatic code putting machine.

Owner:厦门高特高新材料有限公司

Drying method for rosewood

ActiveCN105666618ANot easy to absorb waterNot easy to expand and deformWood treatment detailsWood dampingVegetable oilProcess engineering

The invention discloses a drying method for rosewood. The drying method comprises the following steps that 1, the rosewood is sawed into a finished material which is dried through a steam drying box; 2, the finished rosewood material is put into a pot to be boiled with boiling water and is subjected to degreasing for 110-130 min; 3, then the boiled finished rosewood material is subjected to drying and dewatering treatment; 4, the dewatered finished rosewood material is put into an oil tank to be soaked for six to eight days with vegetable oil and alums and is heated to 72 DEG C-78 DEG C; and 5, the soaked finished rosewood material is placed in a ventilated place so that the oil can be dried through blowing. The rosewood material obtained through the method is environmentally friendly, colorless and tasteless, and a human body is not injured through close contact. A rosewood plate processed through the method is not prone to absorbing water and being swelled and deformed as well as shrunk and torn through high-temperature baking and is especially suitable for production of seamless furniture.

Owner:南通美霆紫檀艺术品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com