Preparation method of high-nickel positive electrode material

A cathode material, high nickel technology, applied in the field of preparation of modified high nickel ternary cathode materials, can solve the problems of Li2CO3 flatulence, poor processing performance, affecting high temperature cycle and high temperature storage, etc., to reduce direct contact and processing. Good performance and the effect of improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A preparation method of high-nickel positive electrode material, comprising the following steps:

[0032] (1) Preparation of substrate: uniformly mix Ni-containing hydroxide, lithium-containing compound, and doping element in a molar ratio of 1:1-1.30:0-0.1, and then mix them at 650-900°C Calcining at high temperature to obtain the substrate A;

[0033] (2) Add substrate A to the washing solution, the solid-to-liquid weight ratio of the substrate A and the washing solution is 2 to 0.5, and control the temperature of the washing solution at 0 to 65°C to oxidize the residual lithium carbonate and hydroxide on the surface Lithium is washed away. In order to prevent the precipitation of excessive structural lithium, a lithium-containing compound is added to the washing solvent, and the washed substrate is dried at a temperature of 100-200 ° C to obtain a mixture B;

[0034] (3) Mix the mixture B, the coating element and the lithium-containing compound uniformly at a molar ...

Embodiment 1

[0054] (1) first Ni 0.94 co 0.045 Al 0.015 (OH) 2.015 , Lithium hydroxide and dopant strontium oxide are uniformly mixed, and the metal molar ratio is M(Ni+Co+Al):M(Li):M(Sr)=1:1.05:0.01.

[0055] (2) The mixture is calcined at 725° C. for 13 hours under oxygen-enriched conditions, and then the sintered product is crushed and sieved to obtain the positive electrode material.

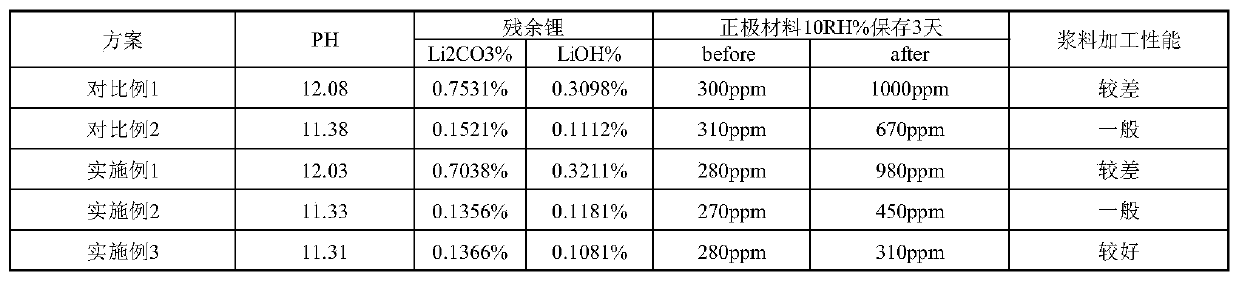

[0056] (3) Its pH is 12.03, and the residual lithium carbonate and lithium hydroxide on the surface account for 0.7038% and 0.3211% by weight of the positive electrode material respectively.

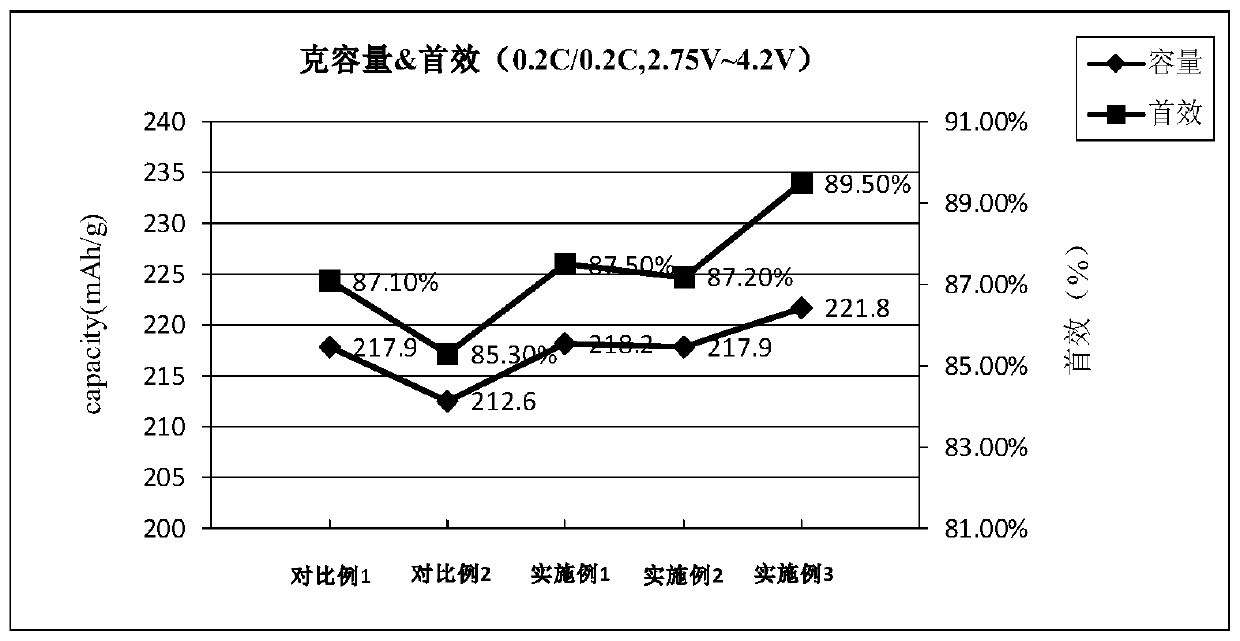

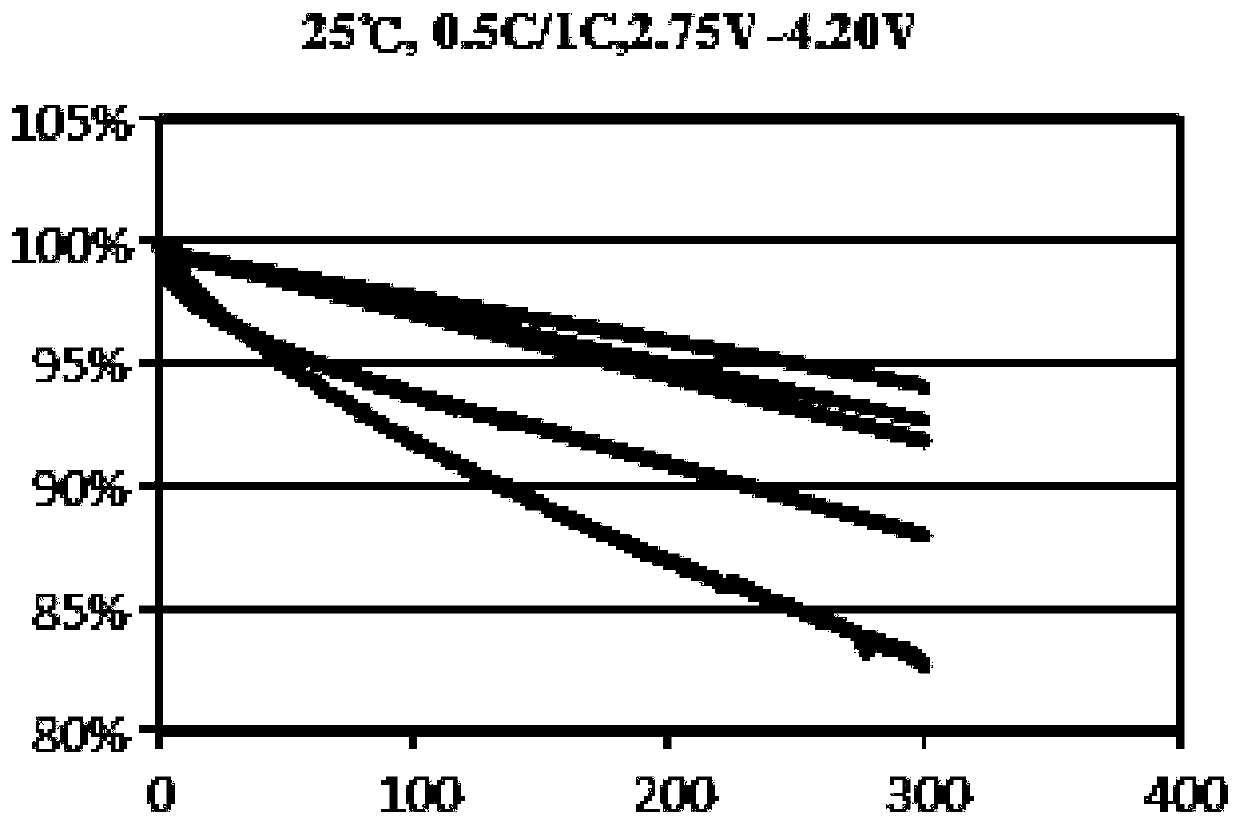

[0057] (4) Evaluation test of 18650 cylindrical batteries made of the obtained positive electrode material: the first effect and 0.2C gram capacity are 87.5% and 218.2mAh / g respectively; the capacity retention rate of 300 cycles at room temperature is 92.7% after cycling at 25°C ; High temperature cycle at 45°C, the capacity retention rate after 300 cycles is 94%; after high temperature storage at 60°C, the cap...

Embodiment 2

[0060] (1) first Ni 0.94 co 0.045 Al 0.015 (OH) 2.015 , Lithium hydroxide and dopant strontium oxide are uniformly mixed, and the metal molar ratio is M(Ni+Co+Al):M(Li):M(Sr)=1:1.05:0.01.

[0061] (2) The mixture is calcined at 725° C. for 13 hours under oxygen-enriched conditions, and then the sintered product is crushed and sieved.

[0062] (3) After mixing the crushed and sieved product obtained above with deionized water at a weight ratio of 1:1, the temperature of the deionized water is controlled to be 45° C. Lithium oxide, to prevent the transitional detachment of structural lithium), stirred and washed for 20 minutes, centrifuged to dry, and vacuum-dried at 150°C for 10 hours to obtain the positive electrode material.

[0063] (4) The test results showed that the pH was 11.33, and the residual lithium carbonate and lithium hydroxide on the surface accounted for 0.1356% and 0.1181% by weight of the positive electrode material, respectively.

[0064] (5) Evaluation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com