Patents

Literature

59results about How to "Improve high temperature characteristics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

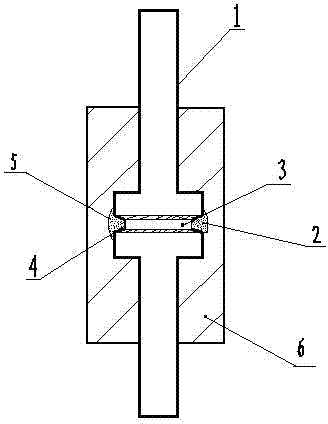

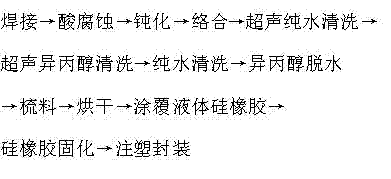

A plastic-encapsulated power diode and its manufacturing process

InactiveCN102263140AAvoid shockRelieve heat stressSemiconductor/solid-state device manufacturingSemiconductor devicesEpoxyManufacturing technology

The invention discloses a plastic-encapsulated power diode and a manufacturing process thereof, and relates to the technical field of semiconductor discrete devices. Its manufacturing process does not adopt the cleaning and dehydration process of organic solvents such as isopropanol and absolute ethanol in the prior art, and the water washing and dehydration process after cleaning with organic solvents is omitted; the chip connected with the wire is put into a heated oven Baking in medium temperature for 4-10 hours, the oven temperature is 200-250°C, and the hydrogen-nitrogen mixed gas or clean air is passed through the oven; put the chip coated with liquid epoxy resin or liquid silicone rubber into the oven at 150±10°C to cure the glue for 10 -60 minutes. Compared with the prior art, the product of the invention has excellent high-temperature characteristics, consistency and reliability.

Owner:SHANDONG YIGUANG ELECTRONICS

Preparation of polymer composite gelling agent for grouting and application method thereof

The invention belongs to the technical field of a gelling agent for geologic hazard control as well as filling control of goaf and waste laneway or collapse craters after exploitation of other mines, and provides a formula and a method of a novel polymer composite gelling agent for grouting. The gelling agent comprises the following components in percentage by weight: 10-25% of bentonite, 5-20% of cellulose, 5-20% of vegetable gum, 10-15% of calcium hydroxide, 10-25% of inorganic hygroscopic agent, 0.5-1.5% of inorganic dispersant, 0.5-2% of inorganic flocculent, 6-18% of organic flocculent, and 5-15% of alkali metal carbonate. The gelling agent is used for processing and crushing, mixing with water, and injecting to slurry for gelling. According to the invention, the characteristics of high-hydroscopicity mineral matters and hydroscopic synthetic resin are sufficiently absorbed and utilized, and various ion groups are introduced and adjusted to obtain specific performance, so that the gelling agent has strong water solubility, can form hydrophile and water-insoluble gel in the slurry, and has excellent adhesion force to solids and dissolved matters in the slurry, good gelling property, strong water control function, high and adjustable jelling speed, low cost and no pollution.

Owner:JICHANG XIANDAO ENG MATERIAL

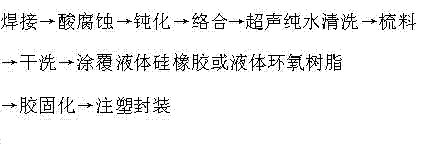

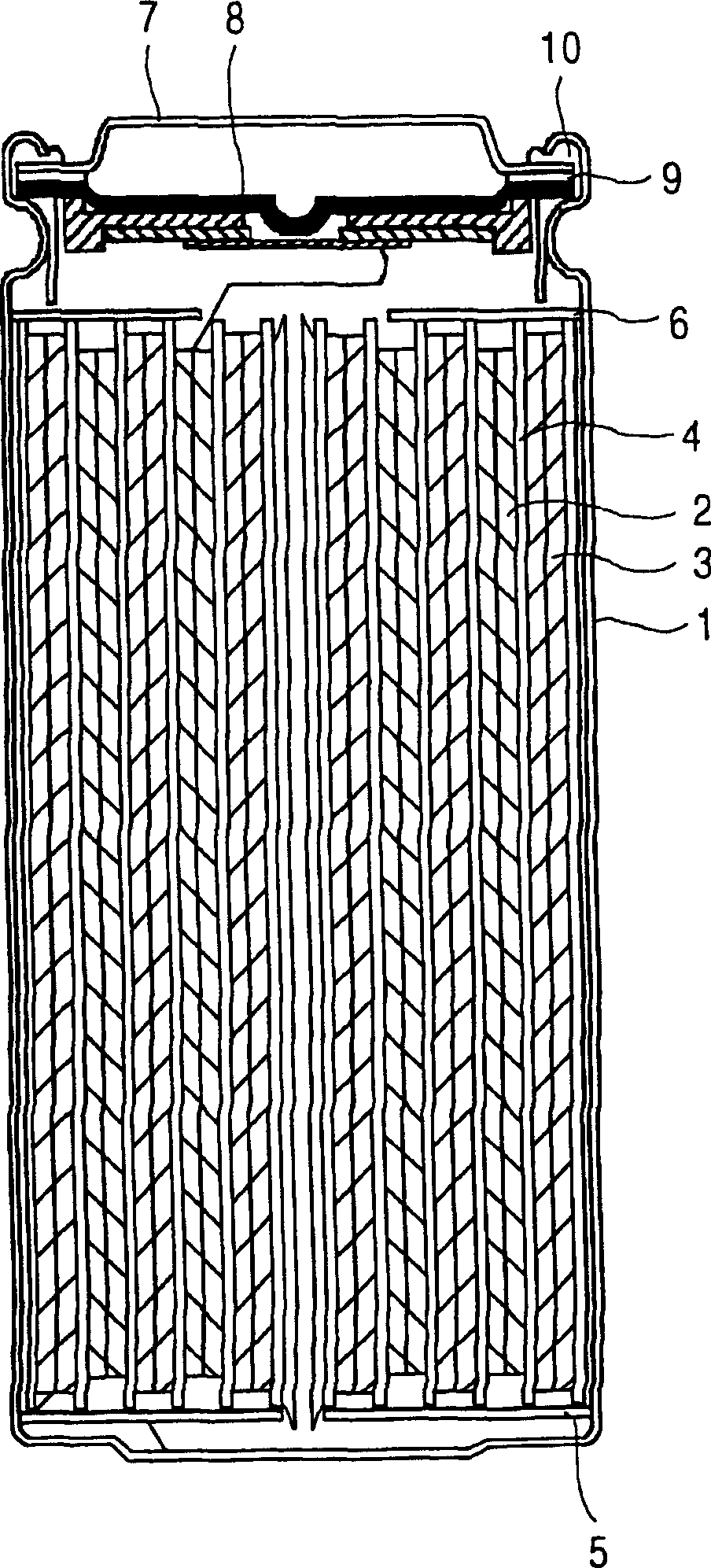

Long-life aluminum electrolytic capacitor and manufacturing method thereof

ActiveCN102222569AImprove high voltage resistanceImprove impact performanceCapacitor terminalsCapacitor electrodesElectrolysisPower flow

The invention belongs to the technical field of electrolytic capacitors, and in particular discloses a long-life aluminum electrolytic capacitor and a manufacturing method thereof. The aluminum electrolytic capacitor comprises an aluminum shell, a positive guide pin, an anode foil, a negative guide pin, a cathode foil and an electrolytic paper, wherein the electrolytic paper is arranged between the anode foil and the cathode foil, and with the electrolytic paper, the anode foil and the cathode foil are wound together to form a core bag; a cover body is sleeved on the core bag and the core bagis arranged in an aluminum shell; the nail connecting part of the negative guide pin and the cathode foil is provided with a foliation; the foliation covers a nail connecting hole of the cathode foiland the negative guide pin; the anode foil has high withstand voltage and low specific volume; the cathode foil is a formation cathode foil; and the electrolytic paper has low tightness and high thickness. The aluminum electrolytic capacitor has high temperature resistances and high-ripple current impact resistance, the high-temperature load service life reaches 20000 hours or longer at 105 DEG Cfor, and problems of short service life, low stability and poor capability of stable ripple current resistance of the aluminum electrolytic capacitor in the prior art are solved effectively.

Owner:江华绿宝石新能源储能科技有限公司

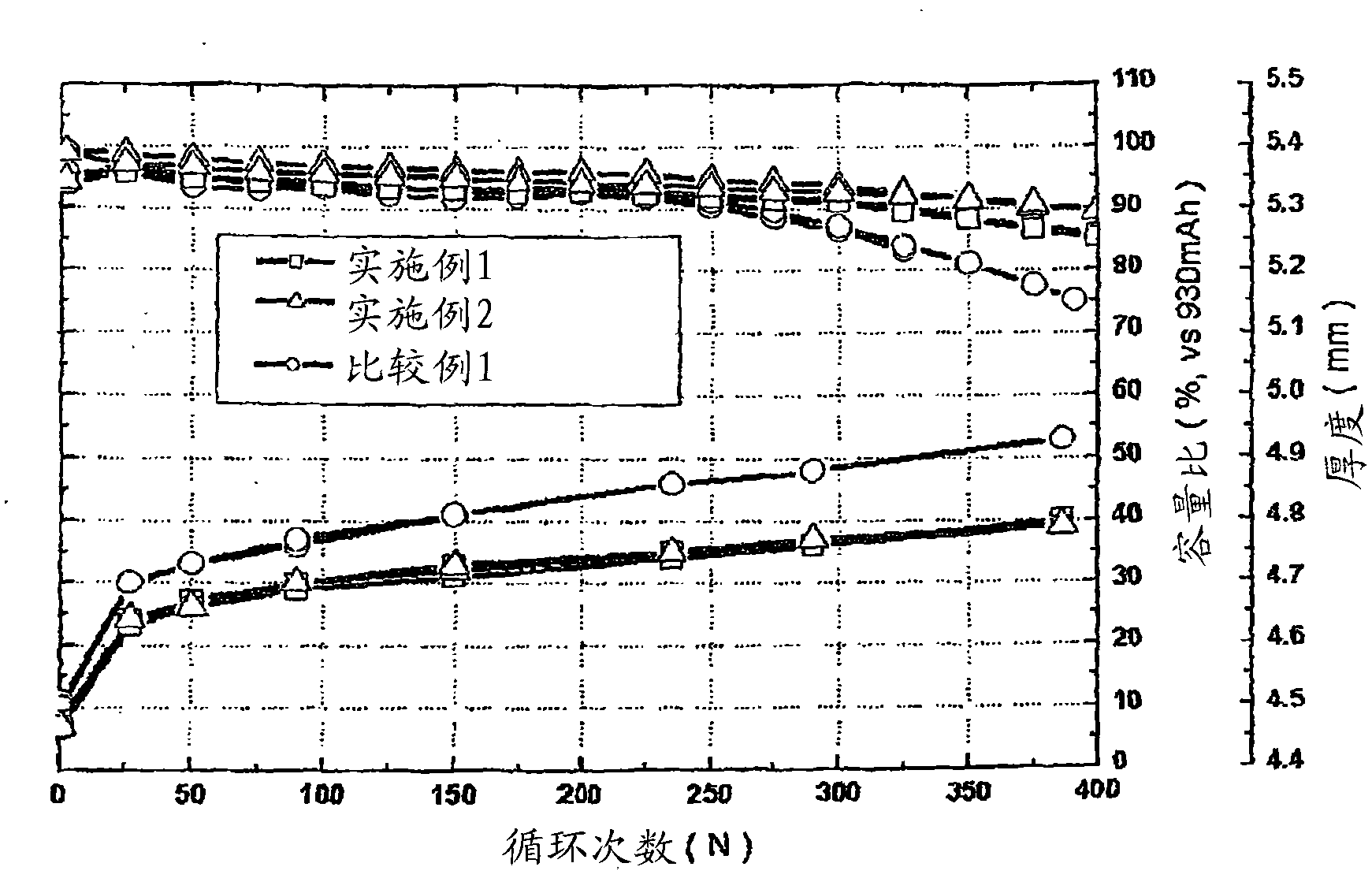

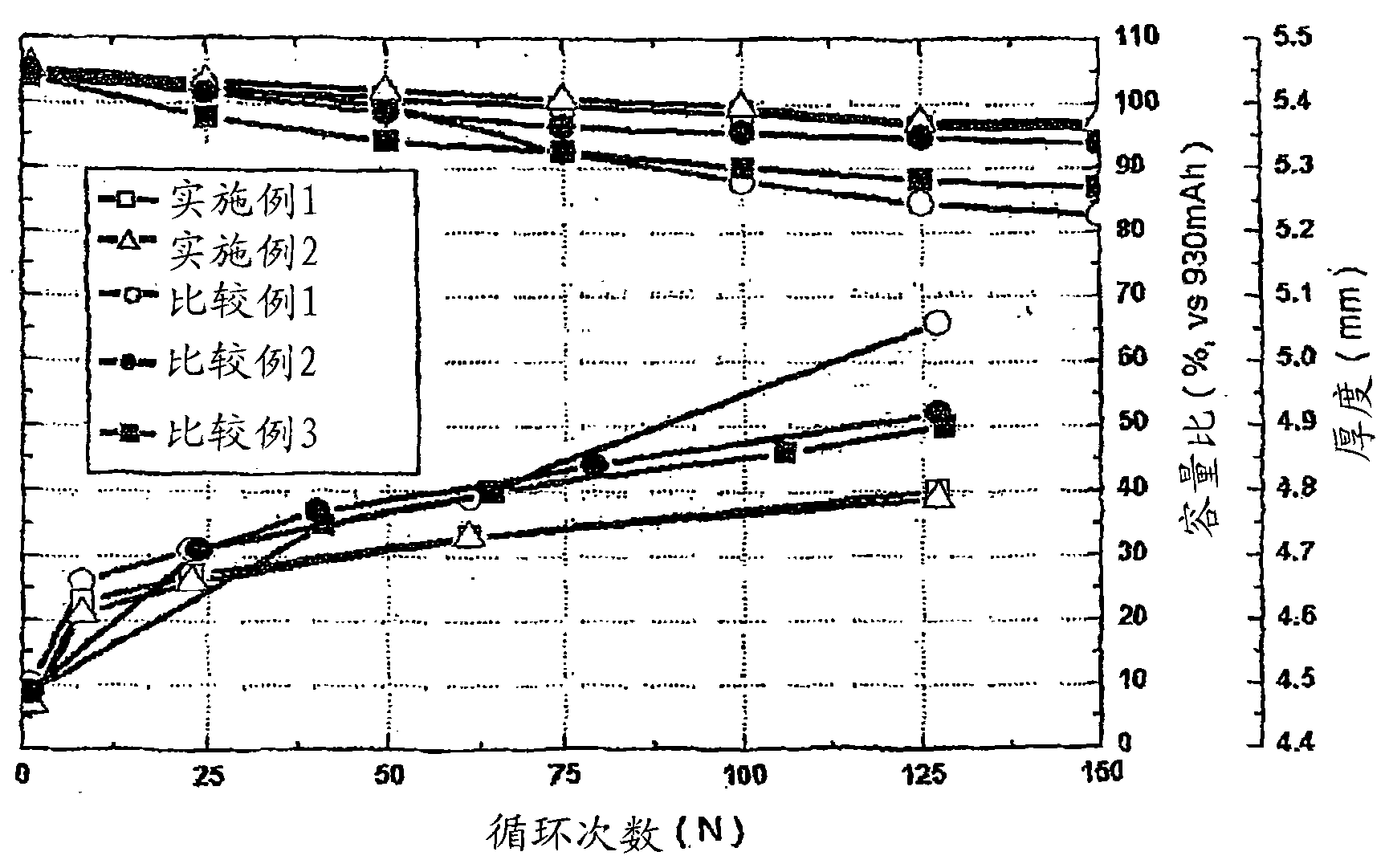

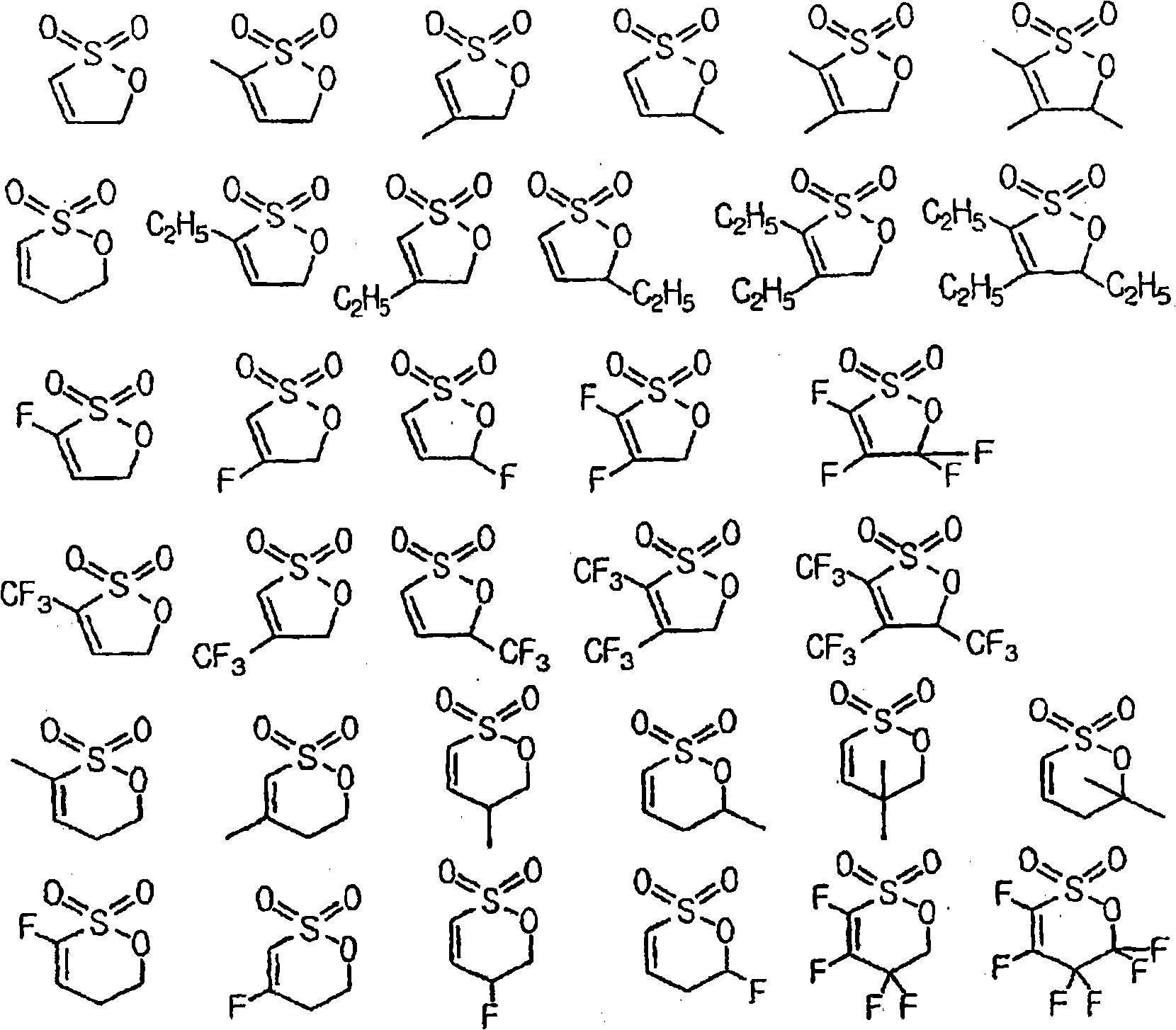

Non-aqueous electrolyte solution for lithium secondary battery and lithium secondary battery having the same

ActiveCN102017270AExtend your lifeReduce capacityCell electrodesLi-accumulatorsOrganic solventHalogen

A non-aqueous electrolyte solution for a lithium secondary battery includes a lithium salt and an organic solvent. Based on 100 parts by weight of the non-aqueous electrolyte solution, the non-aqueous electrolyte solution includes 1 to 5 parts by weight of sultone-based compound having a carbon-carbon unsaturated bond in a cyclic structure; 1 to 5 parts by weight of cyclic carbonate compound with a vinyl group; 5 to 10 parts by weight of cyclic carbonate compound that is substituted with halogen; and 1 to 5 parts by weight of dinitrile-based compound. This non-aqueous electrolyte solution improves stability of a SEI film formed on a surface of an anode of a lithium secondary battery and thus improves normal temperature cycle performance and high temperature cycle performance.

Owner:LG ENERGY SOLUTION LTD

Low-activation martensitic heat-resistant steel with oxidation resistance and liquid lead-bismuth corrosion resistance

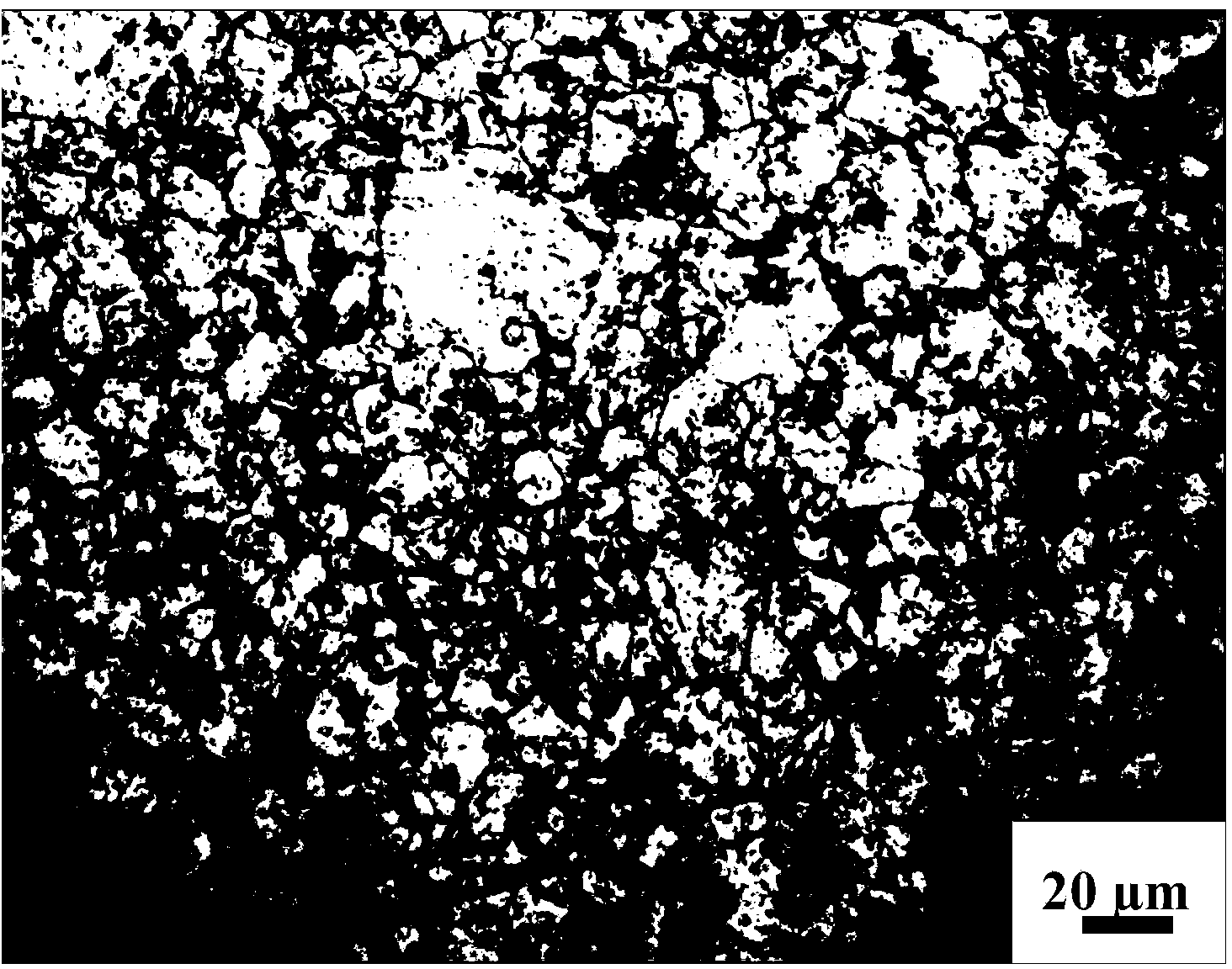

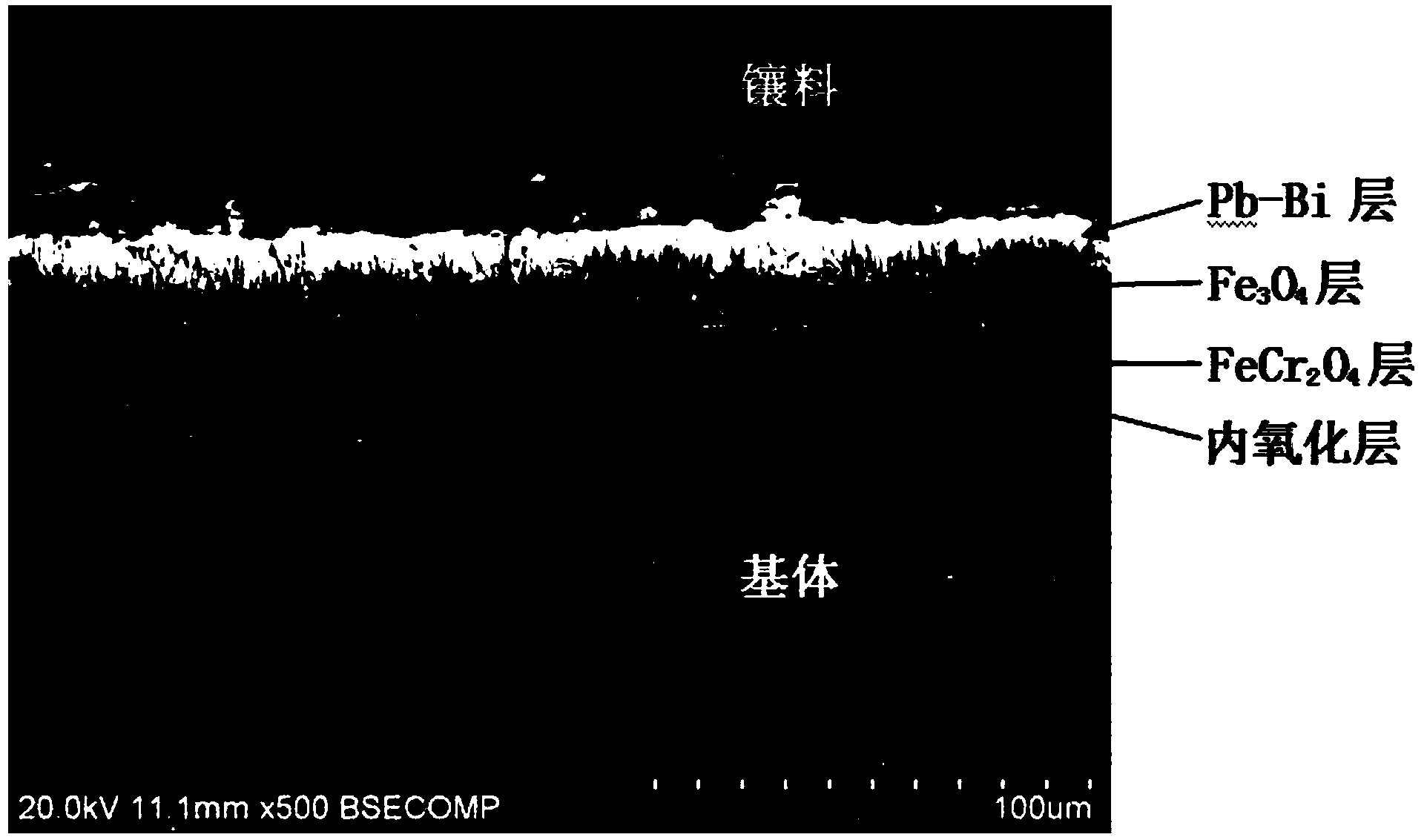

ActiveCN104032232AImprove toughnessImprove high temperature characteristicsAlloy elementOxidation resistant

The invention aims to provide a low-activation martensitic heat-resistant steel with oxidation resistance and liquid lead-bismuth corrosion resistance. The heat-resistant steel comprises the following alloy elements in percentage by mass: C not less than 0.09% and not more than 0.12%, Cr not less than 8.8% and not more than 9.2%, W not less than 1.48% and not more than 1.54%, V not less than 0.17% and not more than 0.23%, Ta not less than 0.12% and not more than 0.16%, Mn not less than 0.48% and not more than 0.50%, Si not less than 0.40% and not more than 0.80%, N less than 0.010%, Al less than 0.010%, Ni less than 0.005%, Mo less than 0.005%, Nb less than 0.010%, Co less than 0.005%, Ti less than 0.010%, Cu less than 0.010%, O less than 0.005%, P less than 0.005%, S less than 0.005%, and a matrix being Fe. The heat-resistant steel has excellent mechanical performance, high-temperature characteristic, oxidation resistance and liquid metal corrosion resistance.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

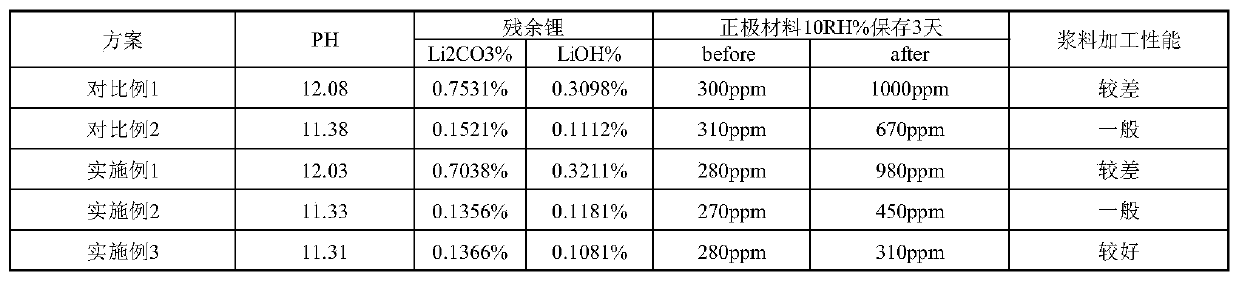

Preparation method of high-nickel positive electrode material

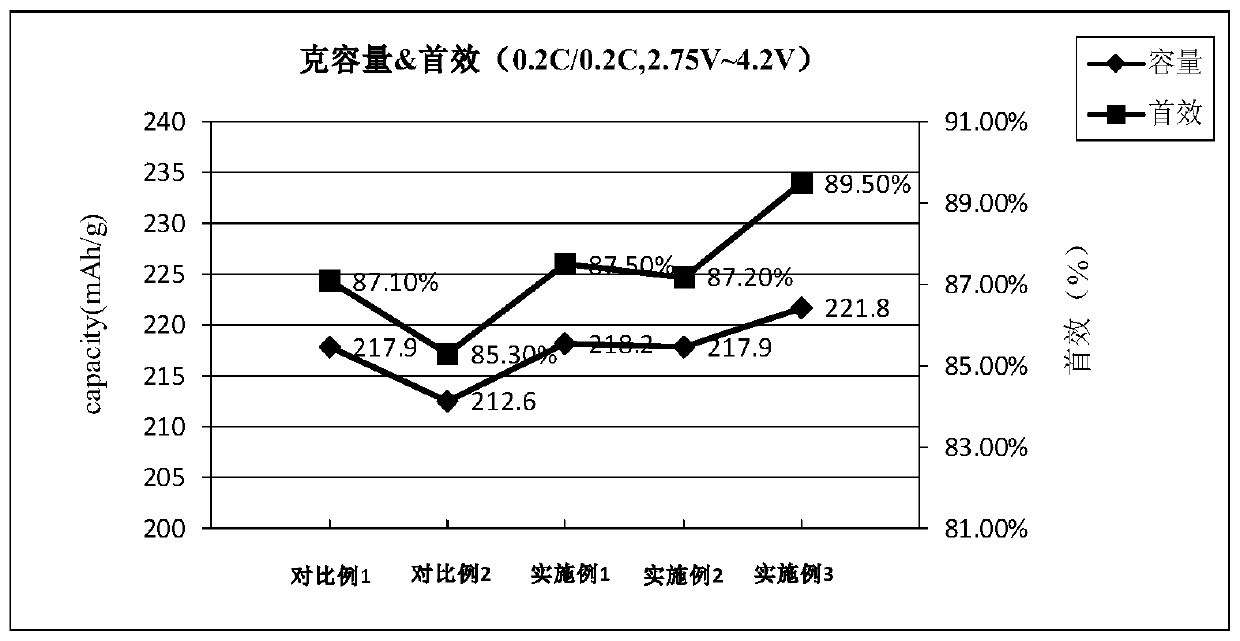

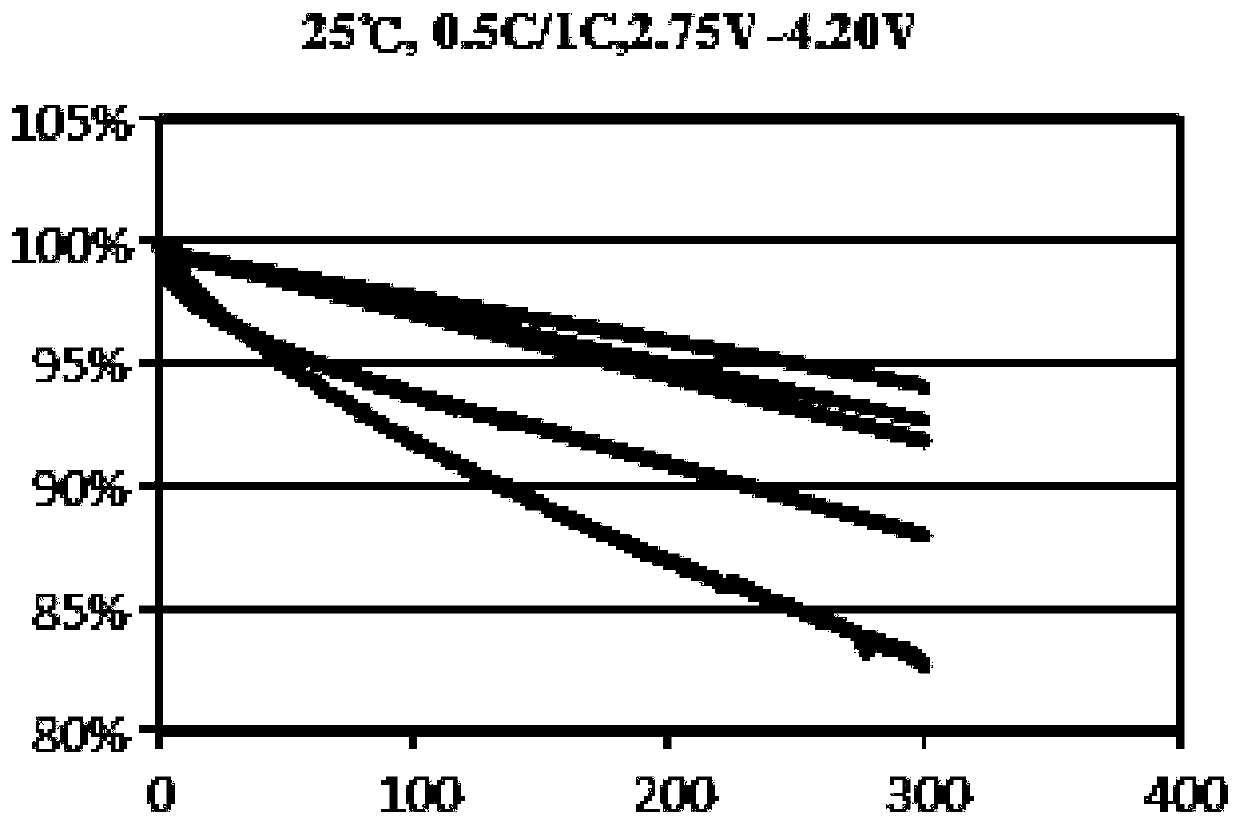

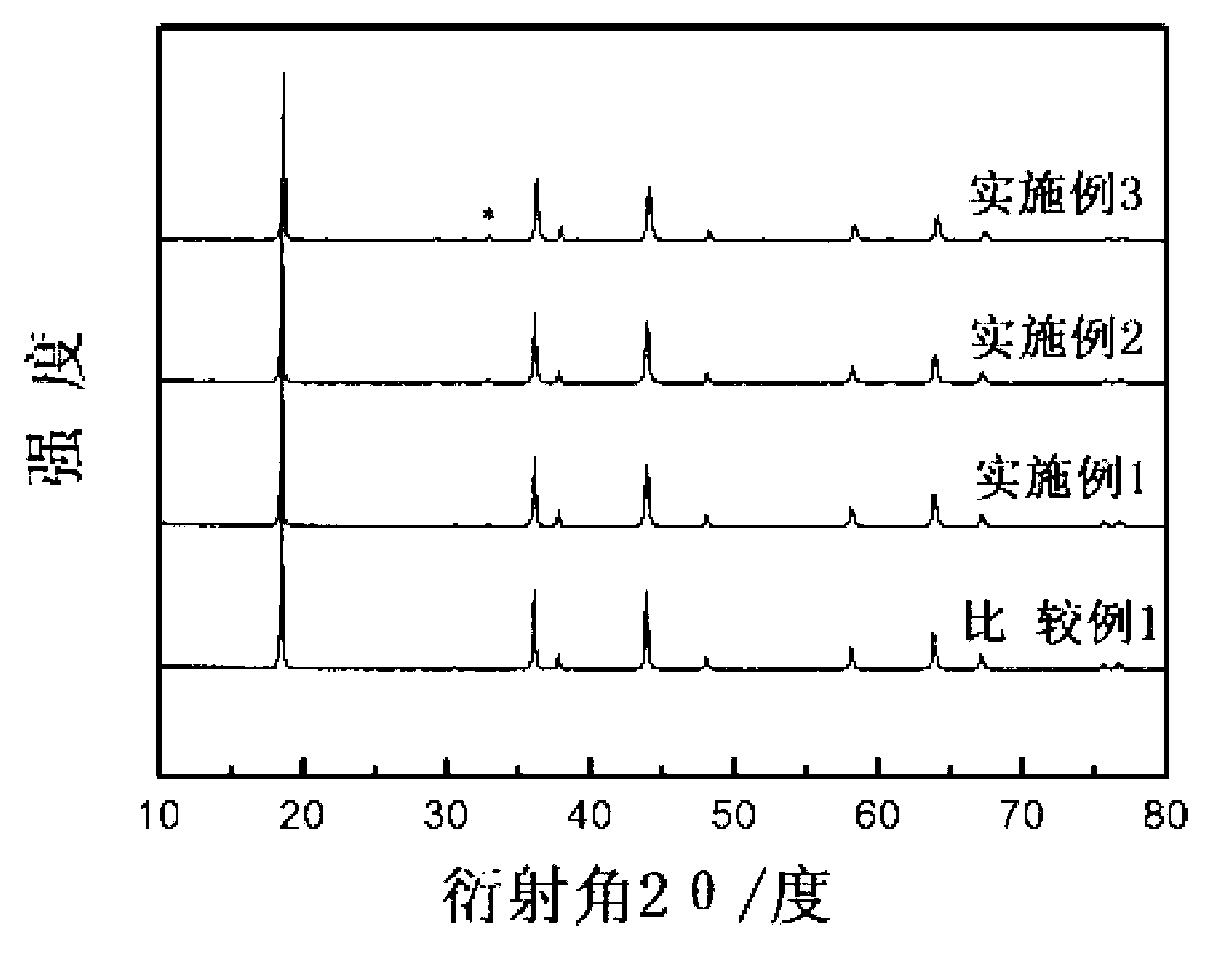

InactiveCN109802123AImprove high temperature stabilityImprove water absorptionCell electrodesSecondary cellsLithium hydroxideLithium carbonate

The invention discloses a preparation method of a high-nickel positive electrode material, which comprises the following steps: uniformly mixing up a Ni-containing hydroxide, a lithium-containing compound and a doping element, and calcining to obtain a base material A after the mixing operation; adding the base material A into a washing solution, controlling the temperature of the washing solution, washing away residual lithium carbonate and lithium hydroxide on the surface, adding a lithium-containing compound into the washing solution, and drying the washed base material to obtain a mixtureB; uniformly mixing the mixture B, a coating element and a lithium-containing compound, calcining, and crushing to obtain the finally modified high-nickel positive electrode material. The high-temperature stability of the nickel material is improved through doping. The residual lithium carbonate and lithium hydroxide on the surface are reduced through washing. The water absorption and processing performance of the material is improved. The damage to the surface of the material during washing can be repaired through coating. The direct contact between the positive electrode material and the electrolyte can be reduced, so that the high-temperature characteristic and long-cycle performance of the battery cell are improved.

Owner:浙江迈纳新材料有限公司

Low-voltage formation aluminum foil manufacturing method suitable for high-frequency low-impedance electrolytic condenser aqueous electrolyte

ActiveCN103366964AReduce lossReduce the impedance valueElectrolytic capacitorsElectrolysisMetallurgy

The invention aims to provide a low-voltage formation aluminum foil manufacturing method suitable for high-frequency low-impedance electrolytic condenser aqueous electrolyte. The low-pressure formation aluminum foil is long in service life, good in high-frequency property and small in impedance value. The aluminum electrolytic condenser is strong in high-temperature resistance, and has a high-temperature (105 DEG C) load service life of 6000 hours or more, thus effectively solving the difficult problems of short service life, low stability and poor ripple current resisting capacity of the aluminum electrolytic condenser in the prior art.

Owner:广西梧州华锋电子铝箔有限公司

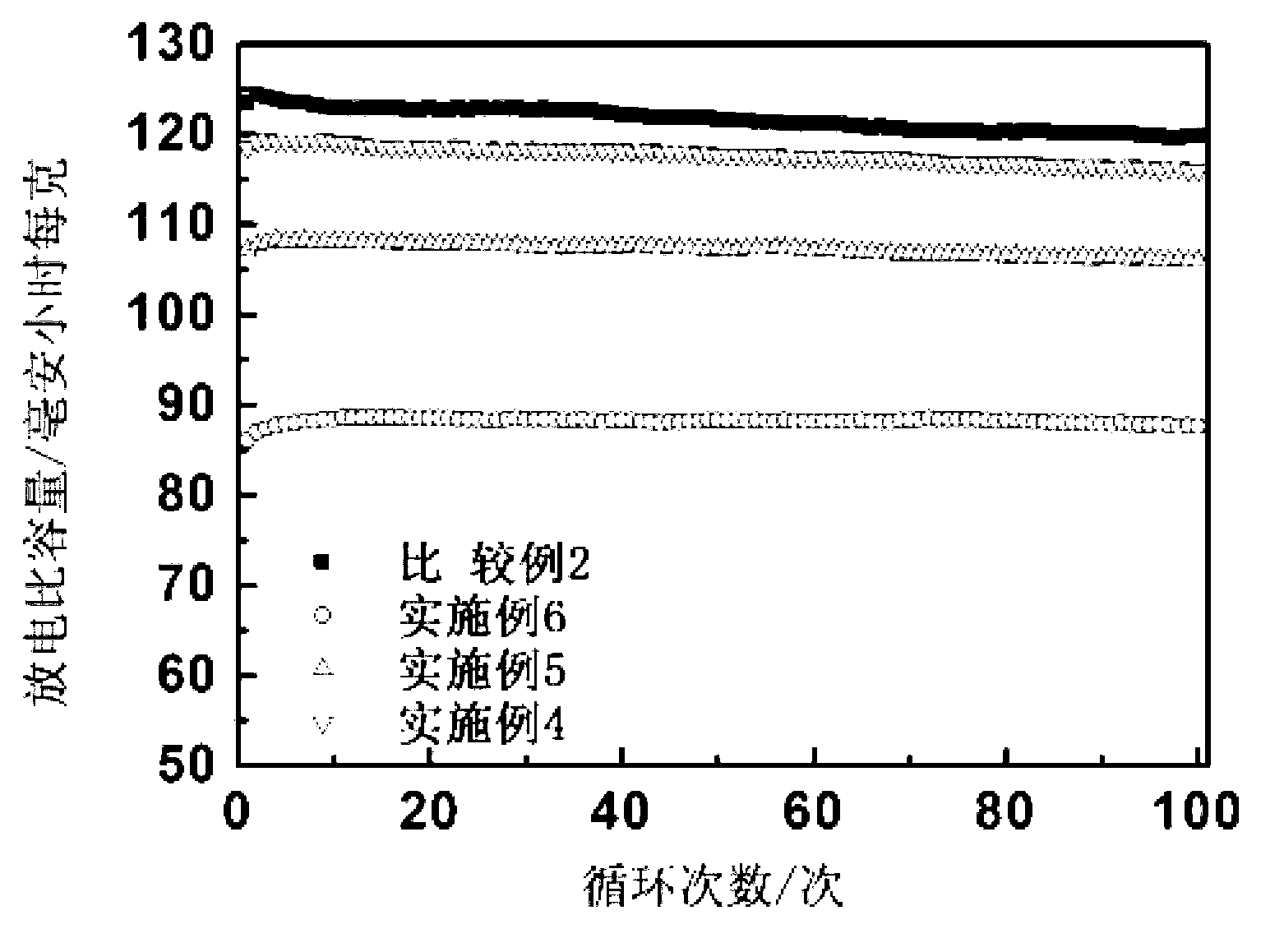

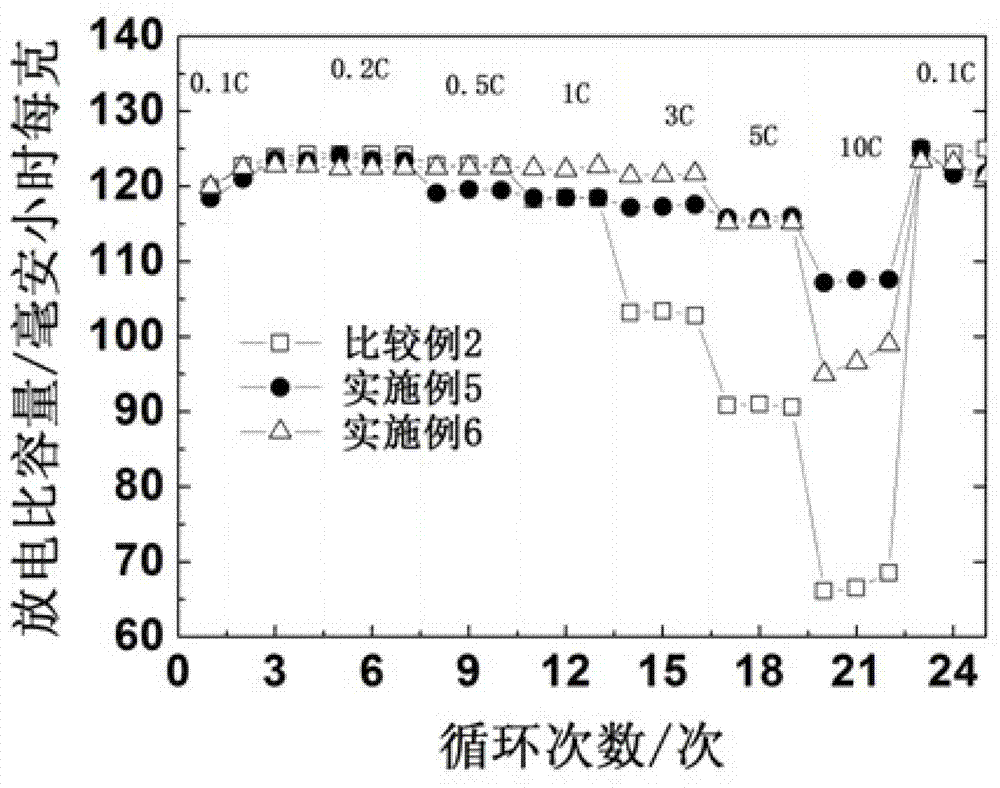

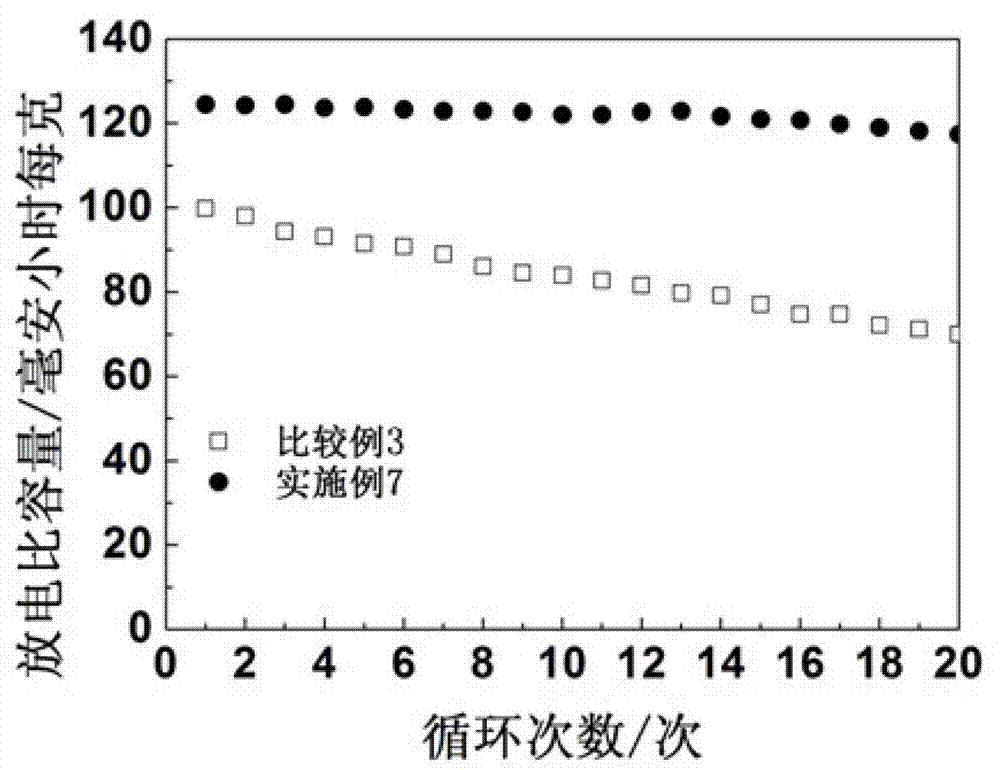

AZO-coated lithium manganate cathode material for secondary lithium battery and preparation method of same

ActiveCN103022470AImproved high-current discharge characteristicsAvoid decompositionCell electrodesPower flowDecomposition

The invention provides a cathode material for a lithium ion secondary battery, which is represented by a general formula of x (AlyZn1-yO) / (1-x)LiMn2O4. LiMn2O4 is coated with an AlyZn1-yO thin film, wherein x is more than or equal to 0 and less than or equal to 0.5; and y is more than or equal to 0 and less than or equal to 0.2. The invention further provides a preparation method of the cathode material, a lithium ion secondary battery anode adopting the cathode material and a lithium ion secondary battery adopting the cathode material. The cheap and environmental-friendly Al-doped ZnO thin film is adopted to carry out surface decoration on a LiMn2O4 material. On one hand, the large-current discharge characteristic of the material is improved by improving electronic conductivity; and on the other hand, the existence of the thin film can also prevent decomposition of an electrolyte on the surface of an active material so as to improve the high temperature characteristic of the electrolyte.

Owner:安徽博石高科新材料股份有限公司

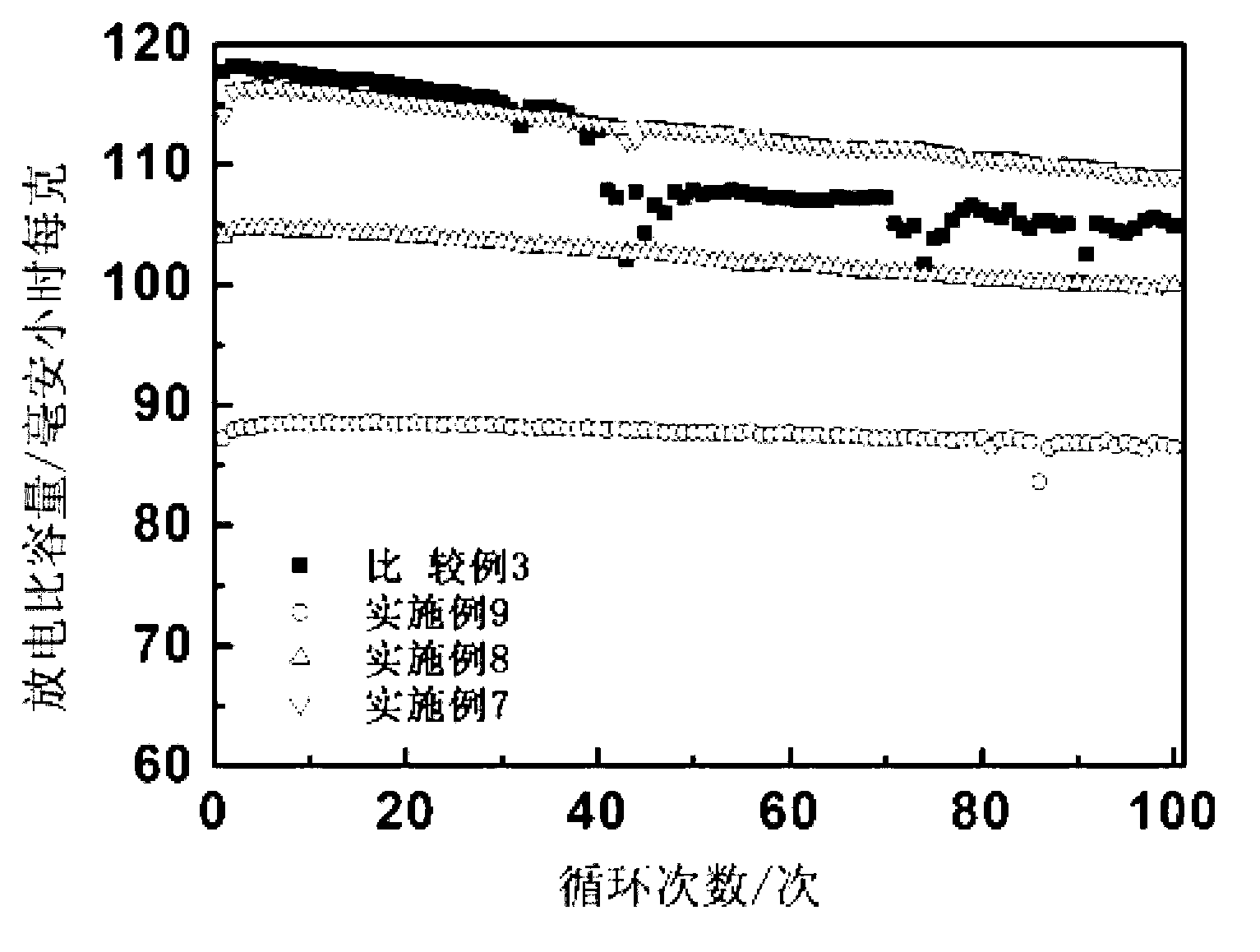

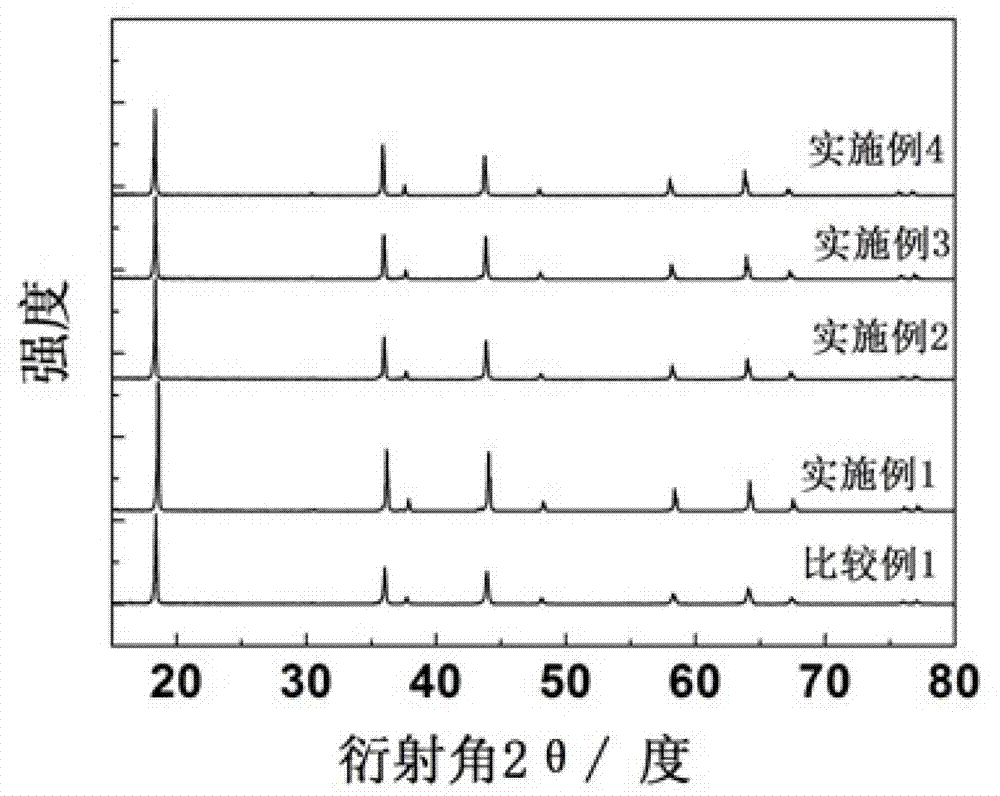

Positive active material and nonaqueous electrolyte secondary battery produced using the same

ActiveCN1571197ADoes not reduce electronic conductivityImprove high temperature characteristicsNon-aqueous electrolyte accumulatorsActive material electrodesInorganic compoundLithium compound

A positive active material is composed of particles of a compound oxide of lithium and a transition metal. This compound oxide has a layered structure. A coating layer of an inorganic compound and a carbonaceous material is formed on at least part of each surface of the particles. The inorganic compound is a lithium compound. The weight ratio of the inorganic compound to the carbonaceous material ranges between 99:1 and 60:40. The weight ratio of the particles to the coating layers ranges between 98:2 and 70:30.

Owner:MURATA MFG CO LTD

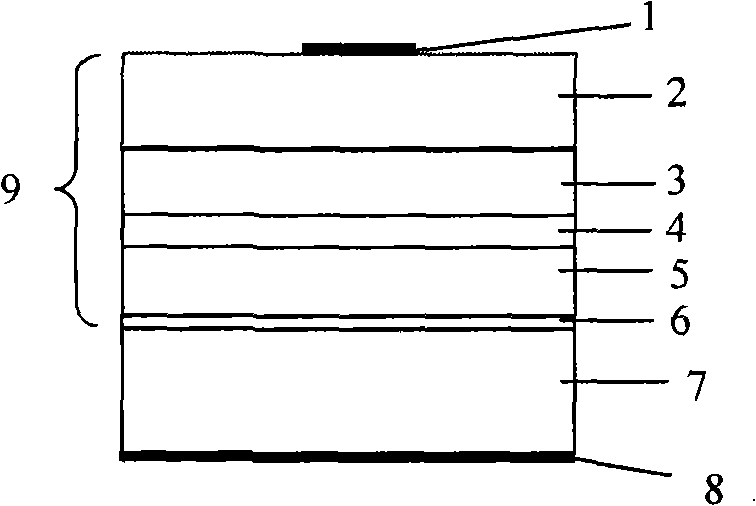

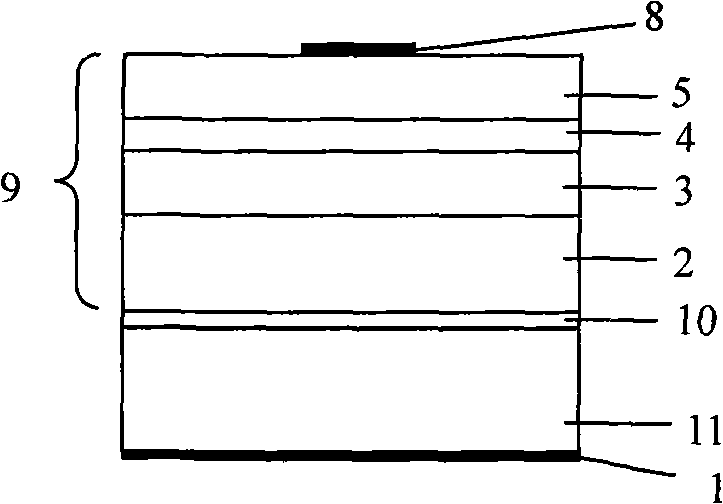

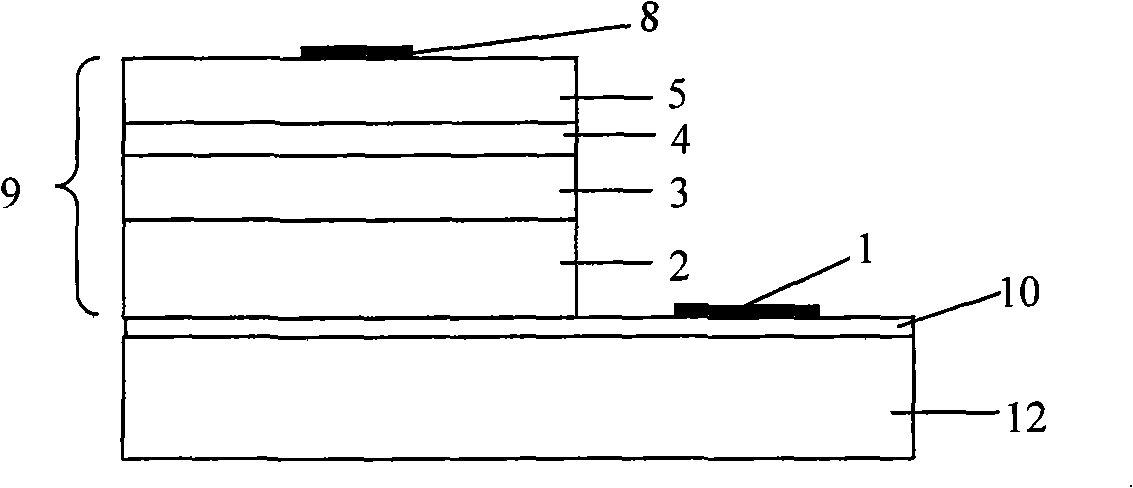

6H-SiC substrate reversed polarity AlGaInP LED chip

InactiveCN101540360AIncrease output powerHigh thermal conductivitySemiconductor devicesOptoelectronicsSic substrate

The invention discloses a 6H-SiC substrate reversed polarity AlGaInP LED chip and a manufacturing process thereof. The reversed polarity AlGaInP LED chip comprises a substrate and an epitaxial layer on the substrate, wherein a 6H-SiC material is used as the substrate; and the epitaxial layer sequentially comprises an N-type AlGaInP layer, a light emitting layer, a P-type AlGaInP layer, a P-type GaP layer and a metal reflecting and bonding layer from top to bottom; the N-type AlGaInP layer is provided with an N-type electrode; and the bottom surface of the 6H-SiC substrate or the metal reflecting and bonding layer is provided with a P-type electrode. The manufacturing process comprises the steps that the surface of the 6H-SiC substrate is provided with the metal reflecting and bonding layer in a vapor deposition mode; the epitaxial layer and the substrate are bonded together; then a selective corrosion method is used for corroding and peeling off an original CaAs underlay; and the electrode formed by the processes of vapor deposition, corrosion, and the like is manufactured into a pipe core. The 6H-SiC substrate reversed polarity AlGaInP LED chip uses the 6H-SiC substrate material with high heat conductivity as the substrate and transfers an LED light emitting layer onto the 6H-SiC substrate so as to improve the high-temperature characteristics of products and improve the reliability of the products.

Owner:Shandong Huaguang Optoelectronics Co. Ltd.

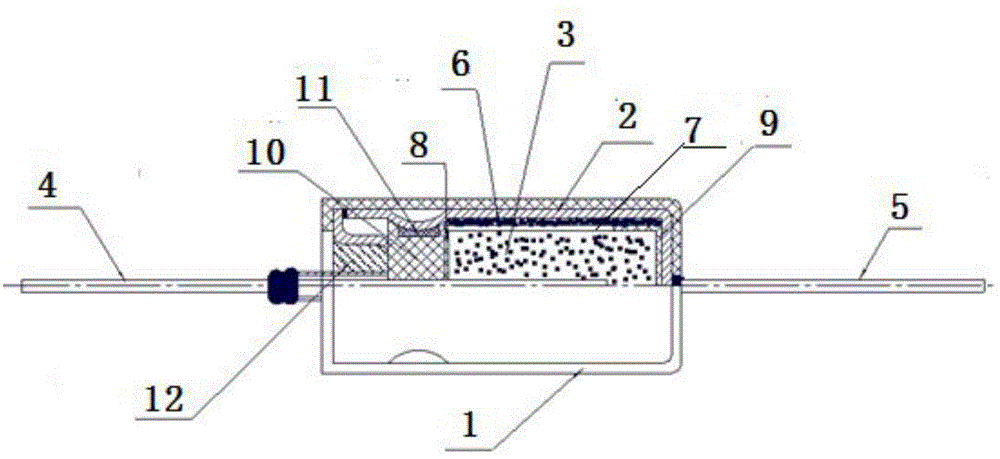

Method for manufacturing high-temperature-resistant high-reliability electrolytic capacitor

ActiveCN104465097AImprove high temperature characteristicsIncrease energy densityCapacitor electrolytes/absorbentsDielectricElectrolysis

The invention provides a method for manufacturing a high-temperature-resistant high-reliability electrolytic capacitor. The method includes the steps that an anode core block is manufactured in a pressed mode and sintered, a dielectric oxide film is manufactured on the surface of the anode core block, an electrolyte is prepared, a gel electrolyte is prepared, capacitor assembly is performed, and the electrical performance of the capacitor is tested under a high-temperature environmental condition. A low-temperature step change potentiostatic method dielectric oxide film forming process technology is adopted, a heat treatment crystalline phase adjustment process is further added under a vacuum or inert gas or hydrogen environment, high-boiling-point organic modified solvents and depolarizers are added in the working electrolyte of the capacitor so that the high-temperature characteristic of the capacitor can be improved, and the capacitor can still have excellent electrical performance even when capacitor elements are exposed in a high temperature (higher than 200 DEG C) environment.

Owner:GUIZHOU AVIC JODO TECH

Heat resistant steel for exhaust valve

InactiveCN102199739AImprove high temperature characteristicsFurnace typesMachines/enginesExhaust valveMaterials science

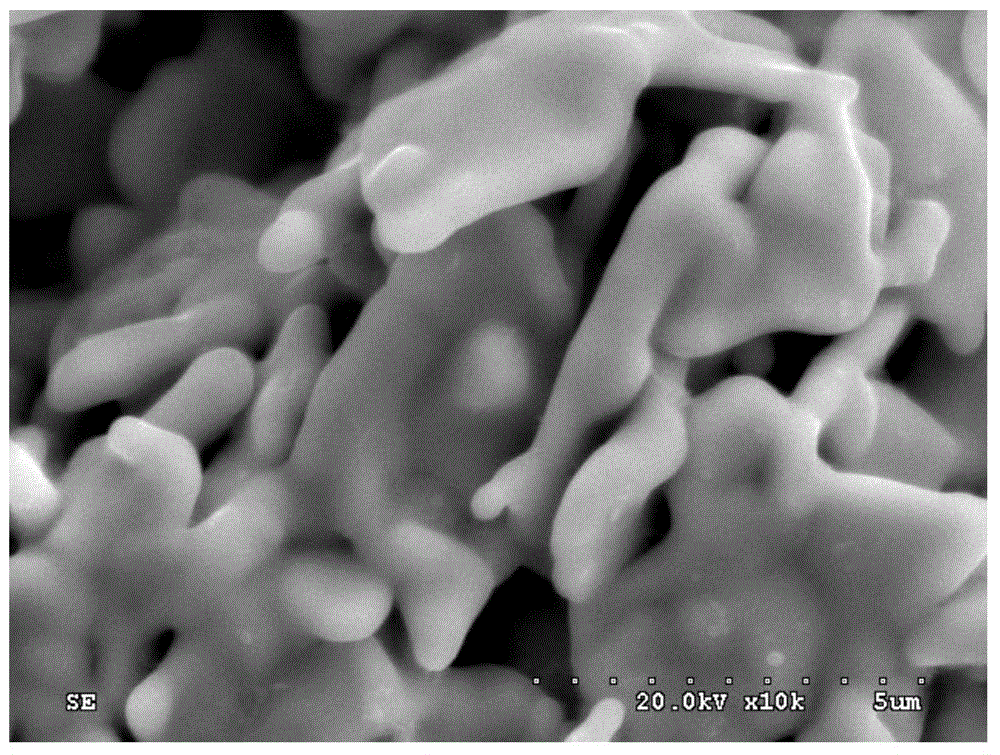

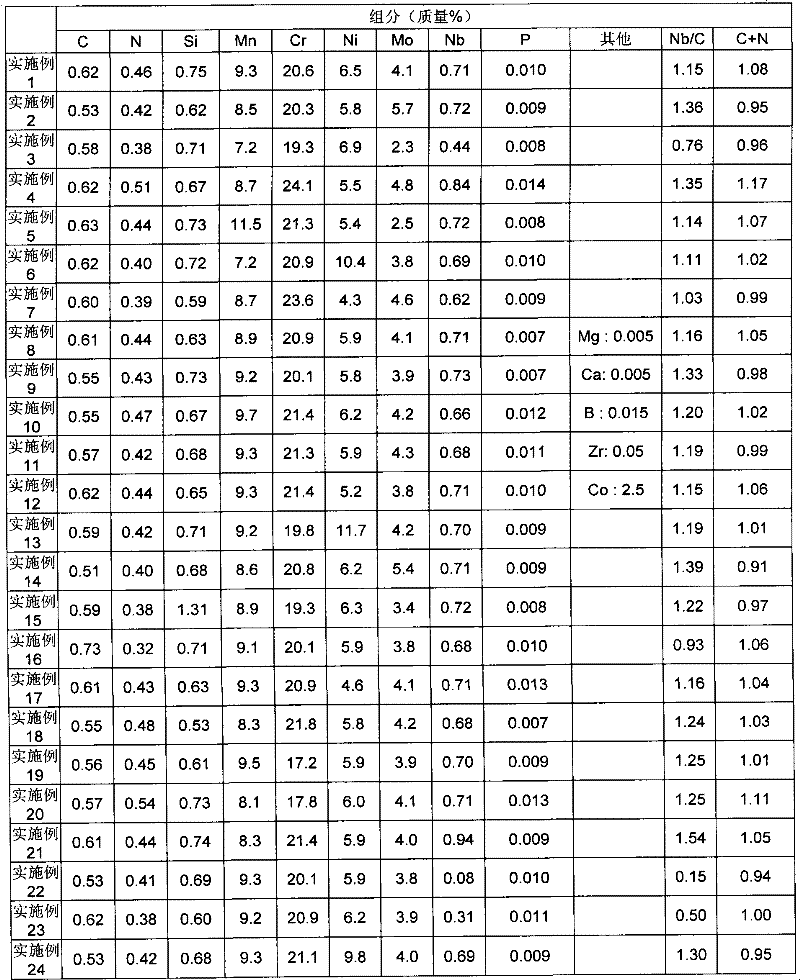

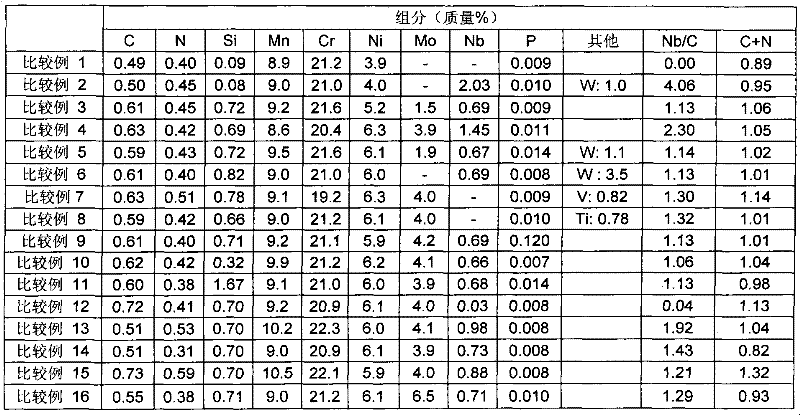

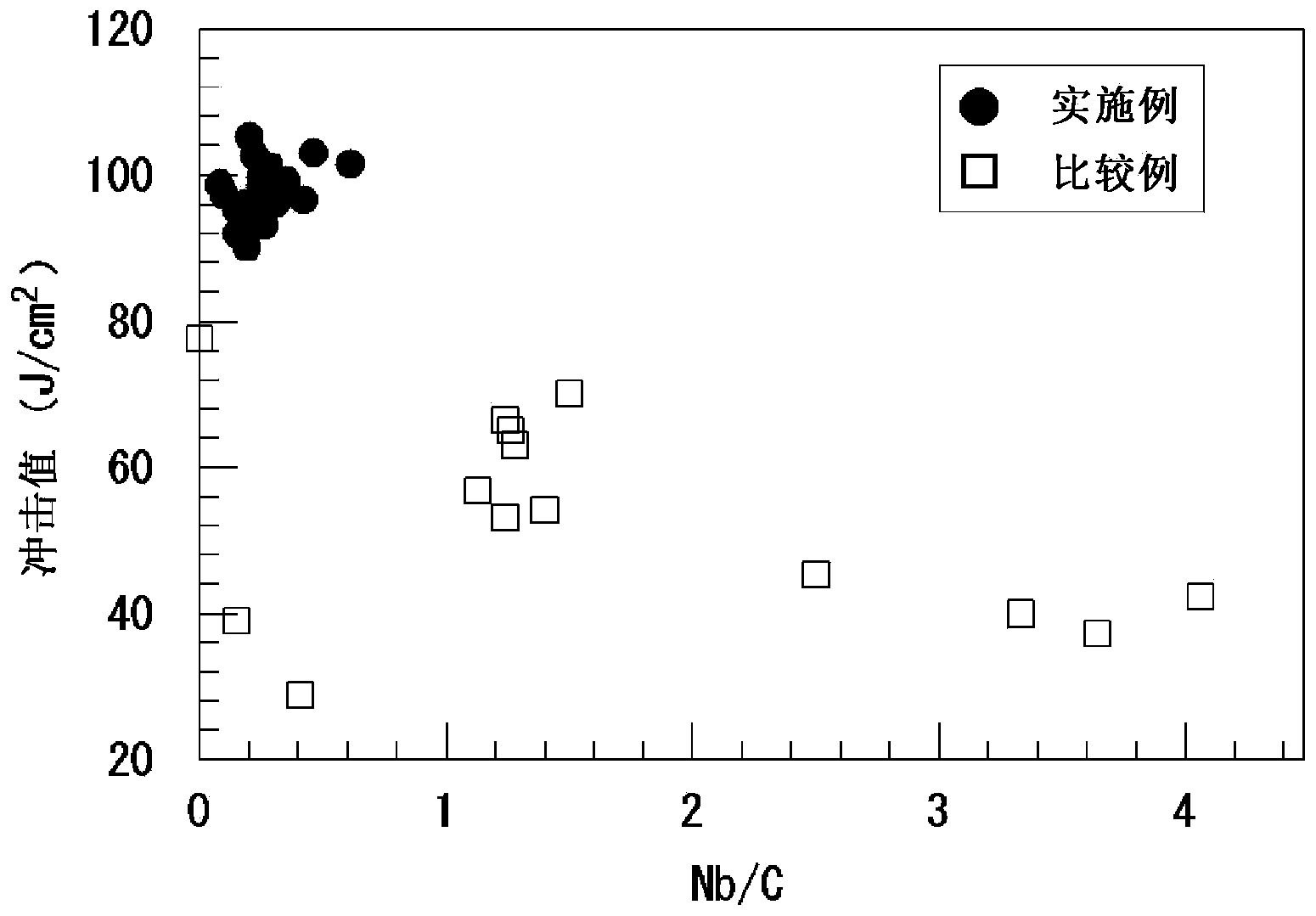

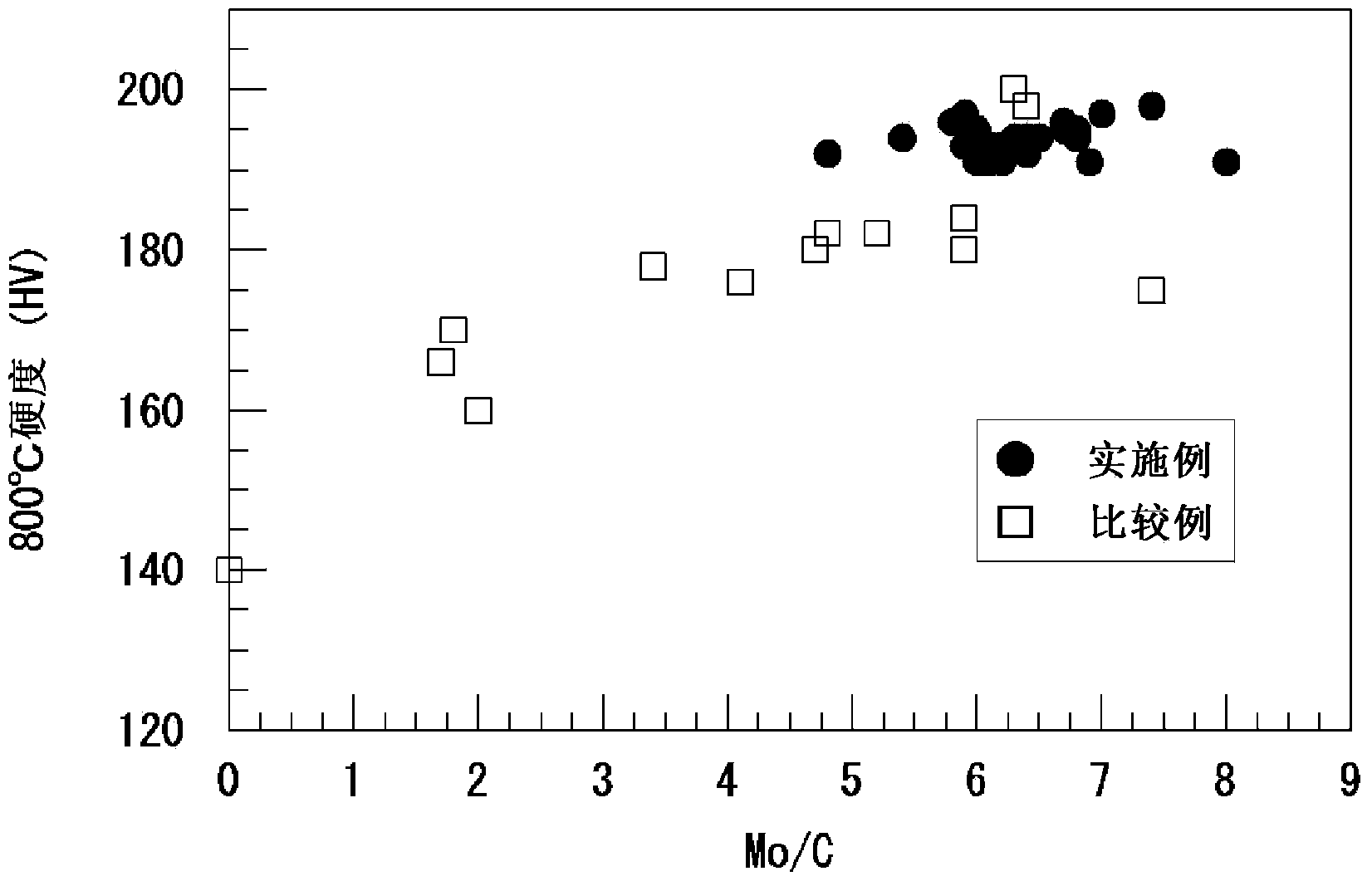

The present invention provides a heat resistant steel for an exhaust valve, containing: more than 0.50% by mass but less than 0.80% by mass of C, more than 0.30% by mass but less than 0.60% by mass of N, 17.0% by mass or more but less than 25.0% by mass of Cr, 4.0% by mass or more but less than 12.0% by mass of Ni, 7.0% by mass or more but less than 14.0% by mass of Mn, 2.0% by mass or more but less than 6.0% by mass of Mo, more than 0.5% by mass but less than 1.5% by mass of Si, and 0.025% by mass or more but less than 1.0% by mass of Nb, with the balance consisting of Fe and unavoidable impurities, in which a content of P contained in the unavoidable impurities is regulated to less than 0.03% by mass, a total content of C and N is from 0.85% by mass to 1.3% by mass, and a ratio of the content of Nb to the content of C is 0.05 or more but less than 1.8.

Owner:DAIDO STEEL CO LTD +1

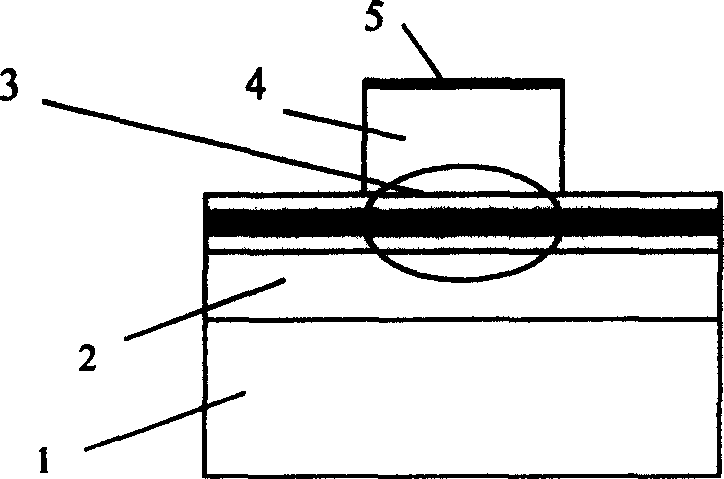

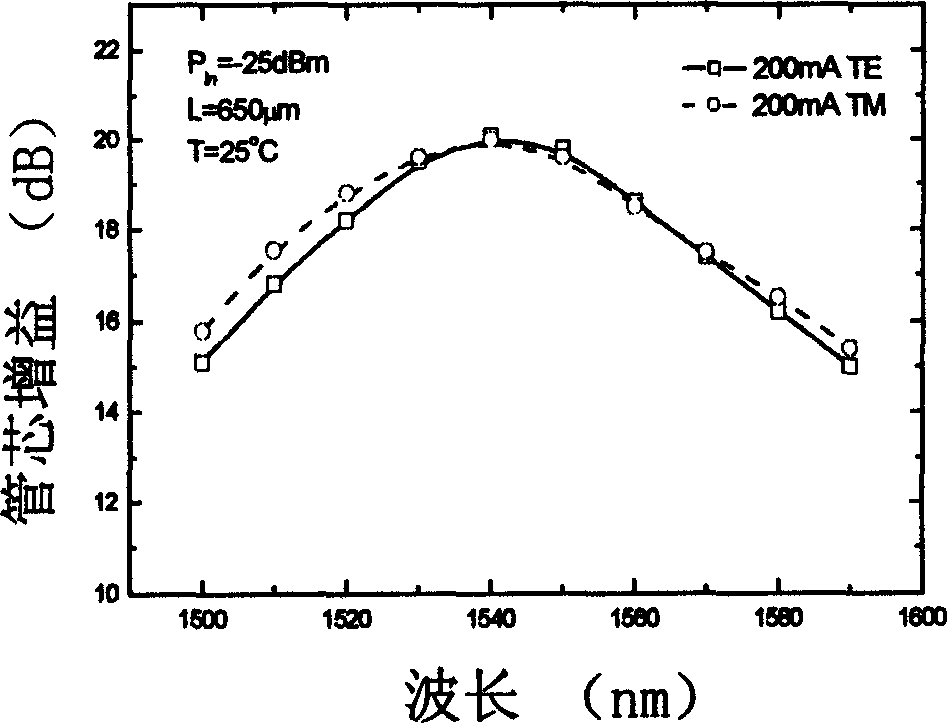

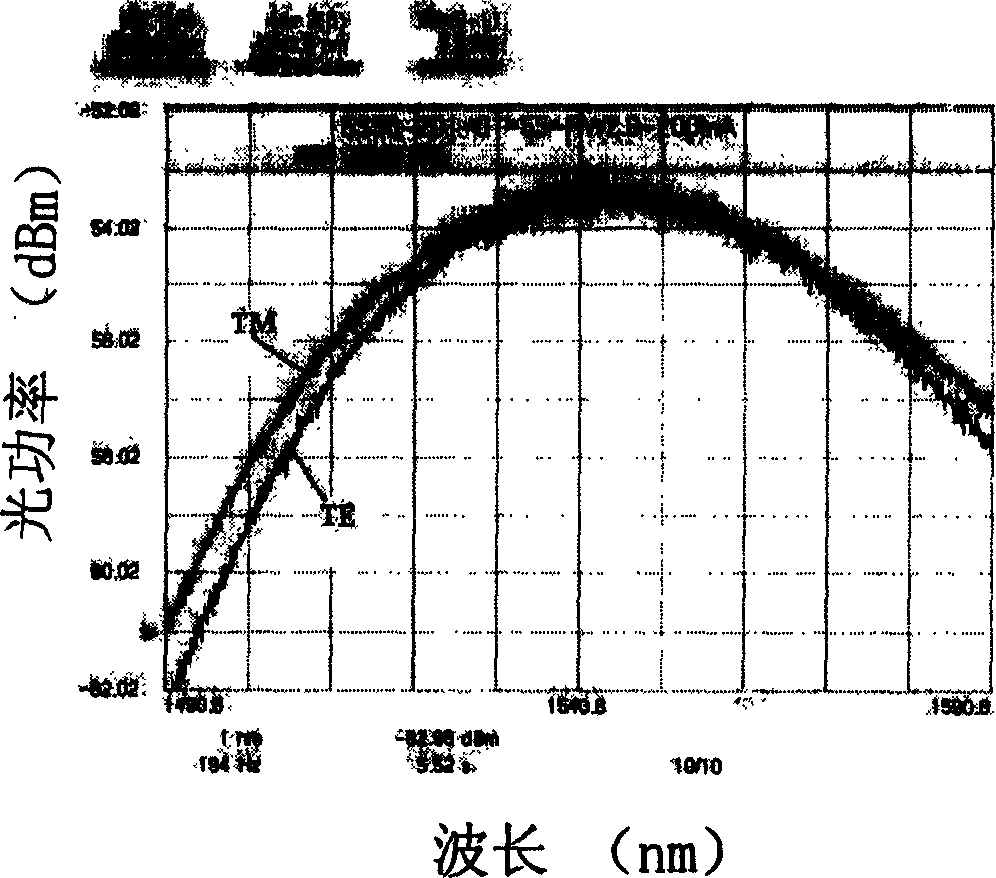

Polarized don't-care semiconductor optical enlarger

InactiveCN1564407AStop the leakImprove high temperature characteristicsLaser detailsSemiconductor lasersTensile strainOptical integration

The light amplifier includes InP substrate, n type InP buffer layer, active region in tensile strain structure of quanta trap, O type InP cladding layer, P type InGaAs contact layer, and electrodes in top and bottom layers. Characters are that AlGalnAs is adopted in active region so as to prevent electrons to pass through barrier layer causing leak, and improve high temperature characteristics. The invention is low sensitive to polarization, and provides good temp characteristic, applicable to optical network, optical integration and photoelectron integration.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for designing and extending 808nm laser material by adopting (In)GaAs/GaAs straining isolated layer

InactiveCN101572387AImprove performanceImprove quantum efficiencyOptical wave guidanceLaser detailsHeterojunctionQuantum efficiency

High power 808nm semiconductor laser is widely applied to pumping Nd:YAG solid laser, laser processing, laser medical treatment and other fields, due to the fact that the semi-conductor laser has the advantages of high efficiency, compact structure, convenient modulation and the like. Meanwhile, people always concern the problems of the semi-conductor laser on efficiency, temperature property and the like. The invention provides design and extension growth of a 808nm laser material by adopting (In)GaAs / GaAs straining isolated layer. Adopting insertion of strained quantum barrier into a wave guide layer and an active layer as a method for improving the physical distance between a quantum well and a growth interface of an initial barrier layer and the electron reflecting layer, and reducing accumulation of heterojunction interface oxygen of an active region and a wave guide region; multiple effective methods and special wave guide structure designs are utilized in the extension growth to improve conduction band edge potential energy, enhance capability of preventing current carrier leakage, restrict current density of threshold, and improve temperature property and quantum efficiency of the laser.

Owner:CHANGCHUN UNIV OF SCI & TECH

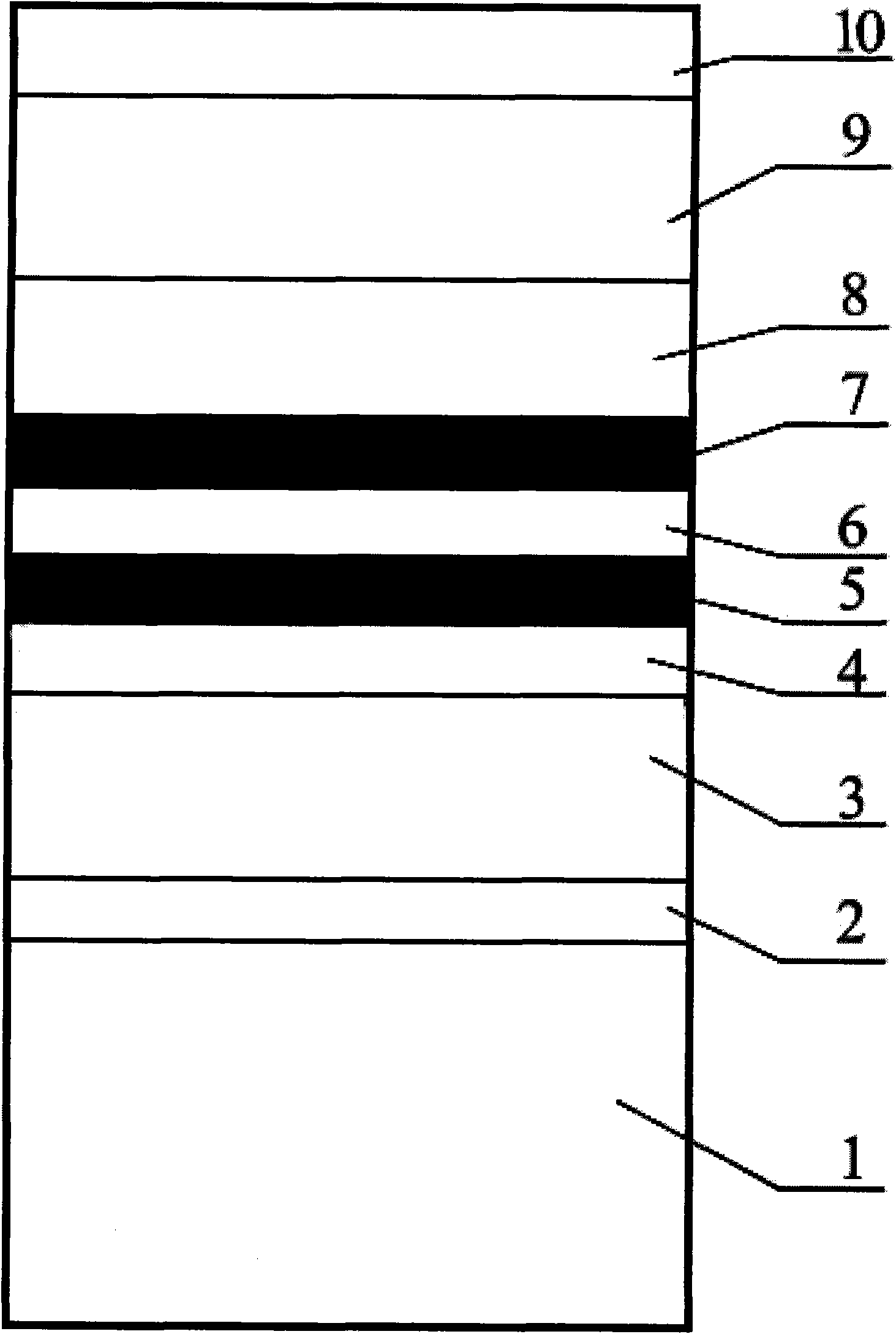

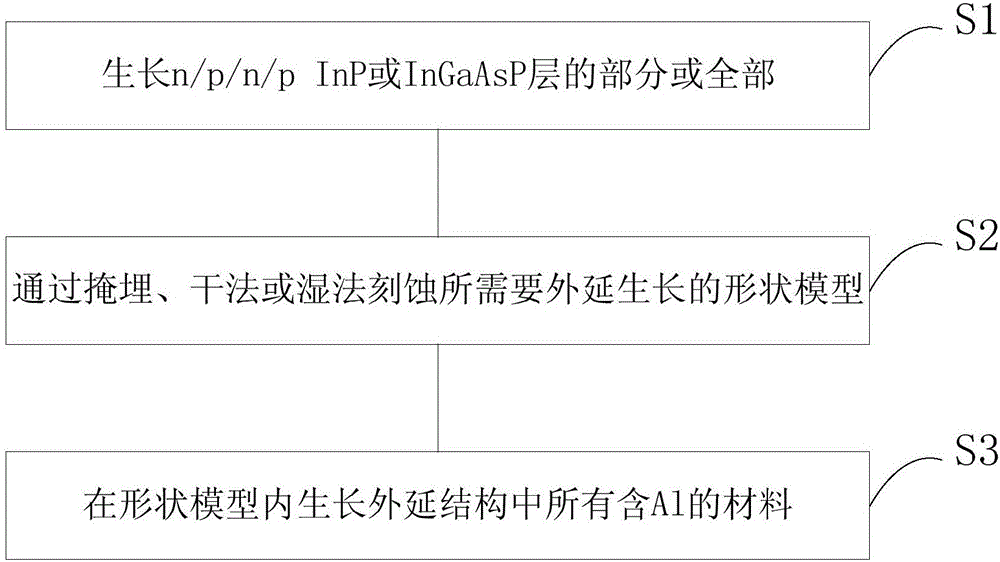

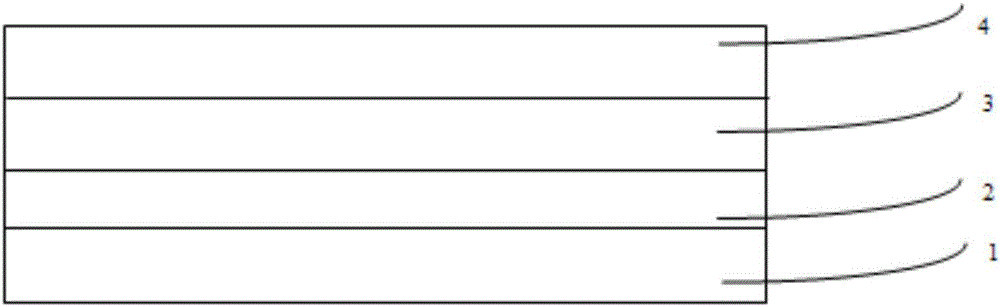

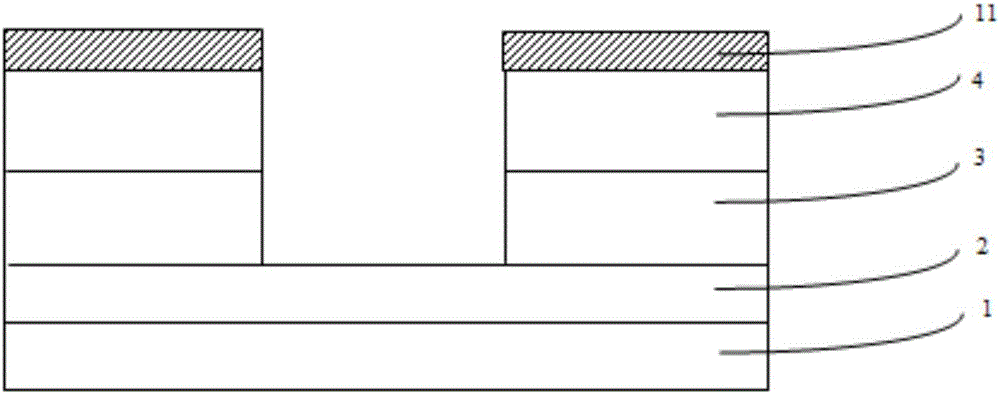

Epitaxial growth method and epitaxial layer with heterostructure buried

ActiveCN106300013ALower threshold current densityImprove high temperature characteristicsLaser detailsSemiconductor/solid-state device manufacturingQuantum efficiencyQuantum well

The invention relates to an epitaxial growth method and an epitaxial layer with a heterostructure buried. The epitaxial growth method includes following steps: S1, growing part of or all of an n / p / n / p InP or InGaAsP layer; S2, etching a shape model needing epitaxial growth through burying, a dry method or a wet method; S3, growing all material containing Al in an epitaxial structure in the shape model. Part of or all of an n / p / n / p structure is formed, the shape of the epitaxial layer needing growth is etched, and the epitaxial layer is grown in the shape. By utilizing the method, the advantages of AlGaInAs / InP materials and BH technology can be combined effectively to grow an efficient laser device epitaxial structure, effects of avoiding Al oxidation, lowering auger recombination and interband adsorption and improving high-temperature characteristics of devices are realized, threshold current density of a laser device is reduced, and feature temperature of an active layer material and external quantum efficiency, internal quantum efficiency and conversion efficiency of an active area quantum well are increased.

Owner:WUHAN HUAGONG GENUINE OPTICS TECH

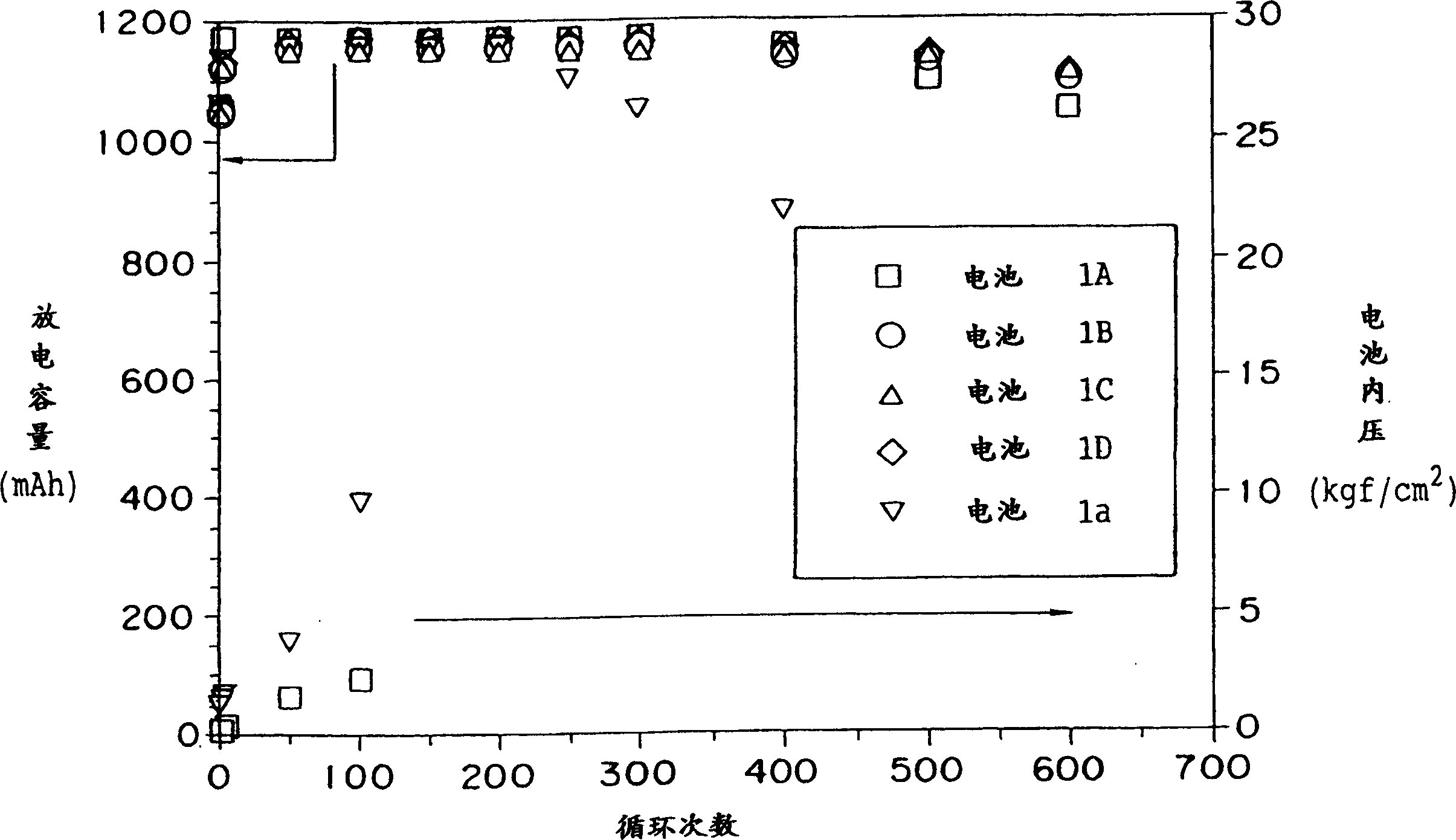

Hydrogen storage electrode, nickel electrode and alkaline storage battery

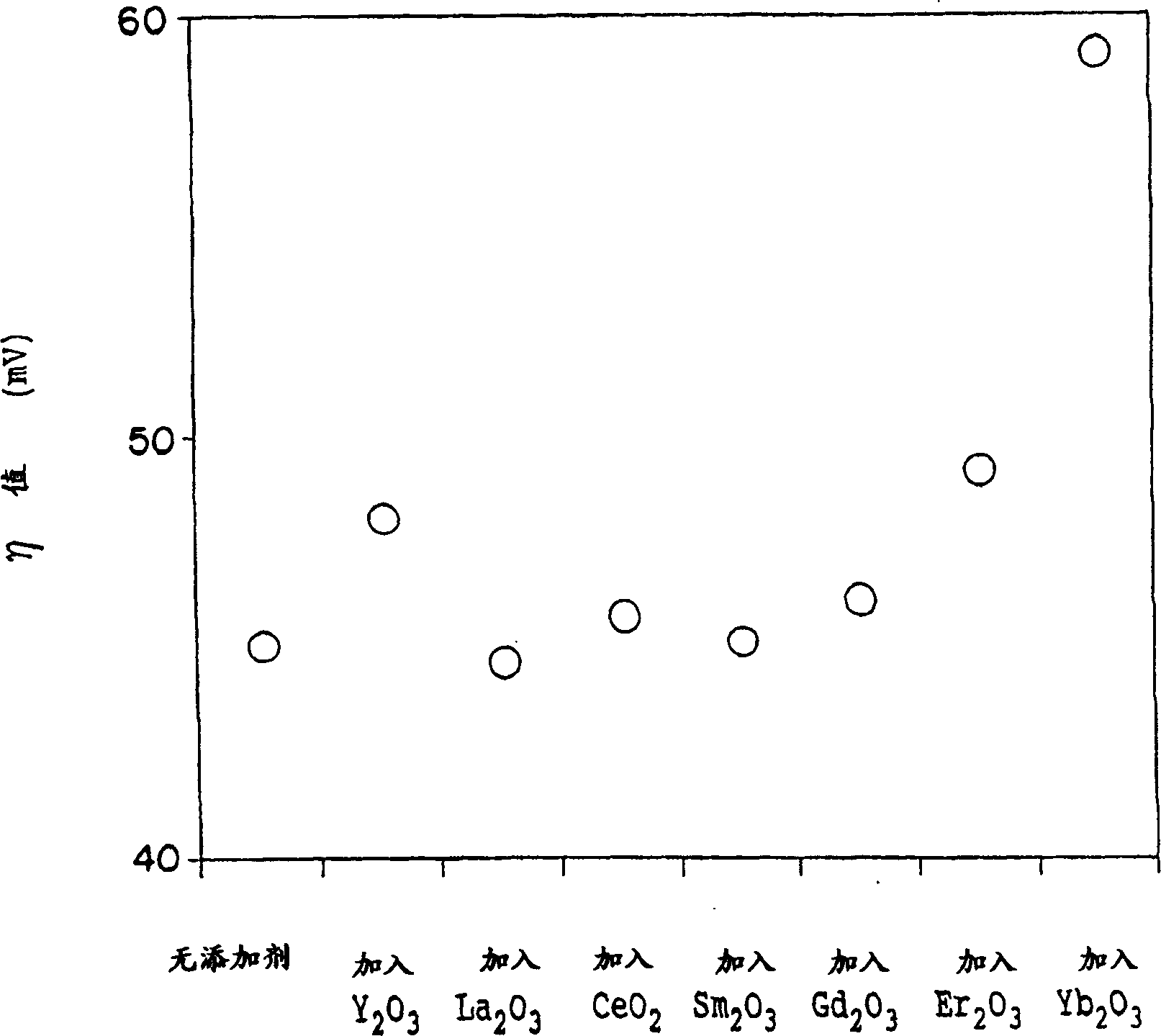

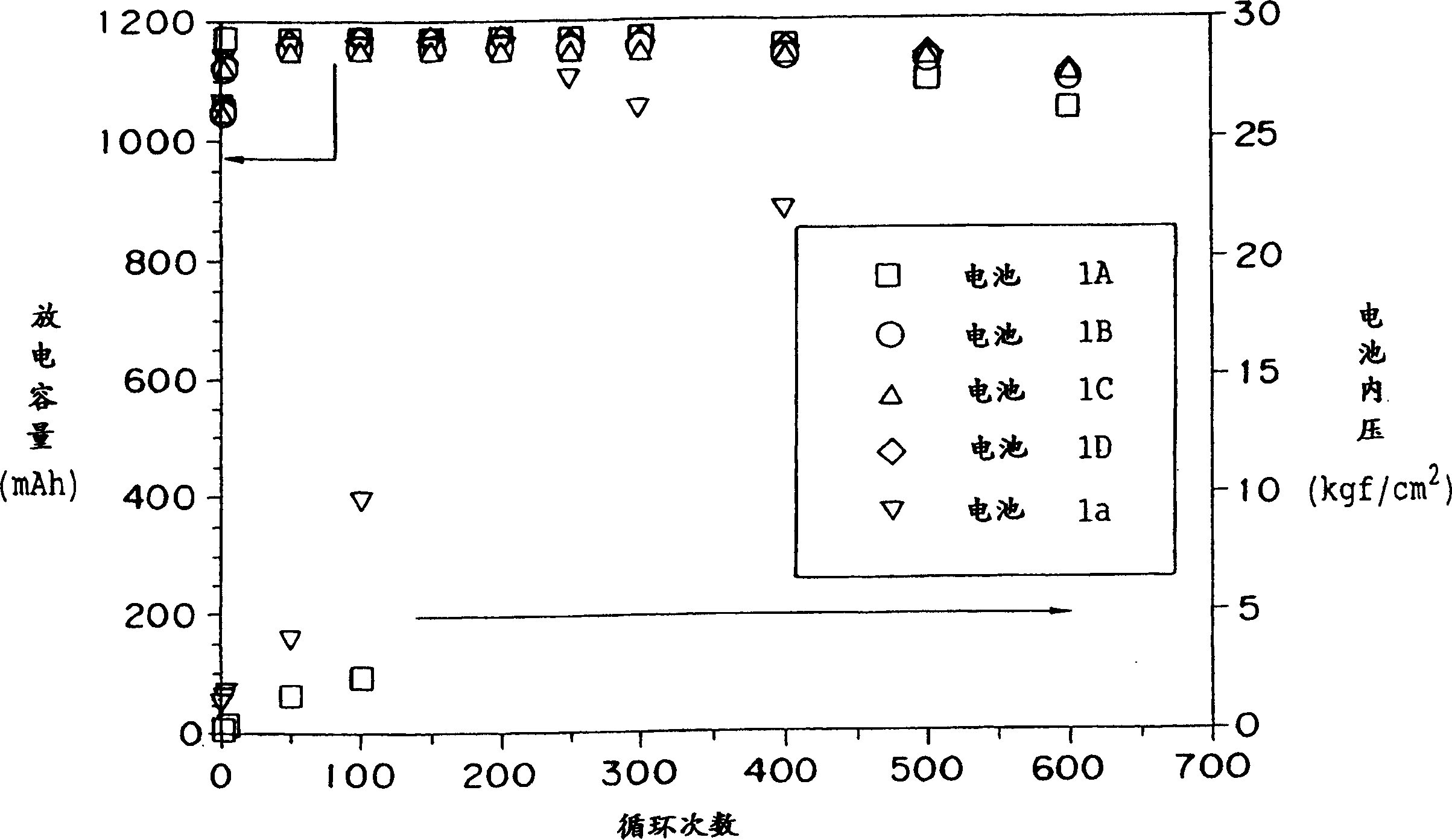

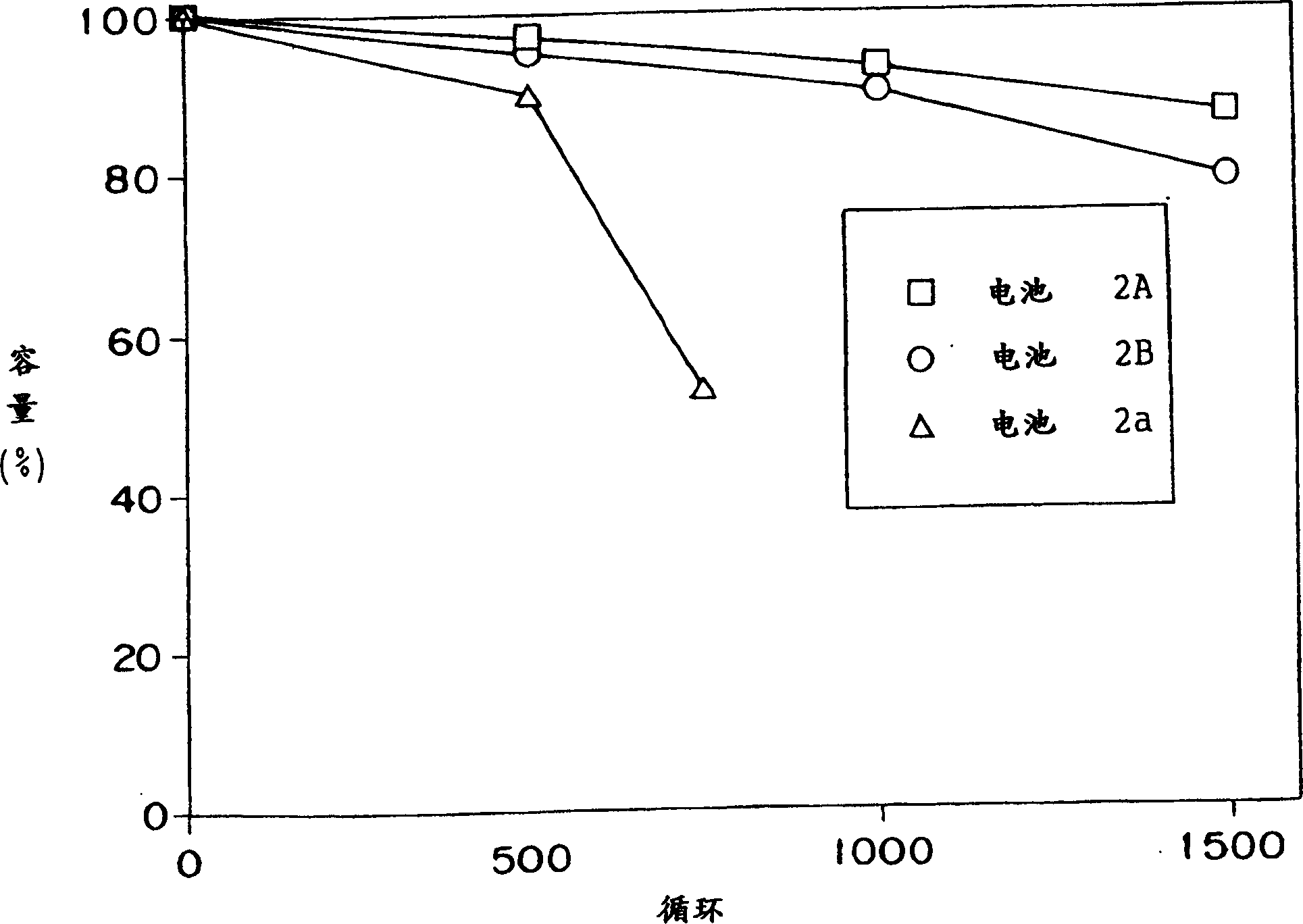

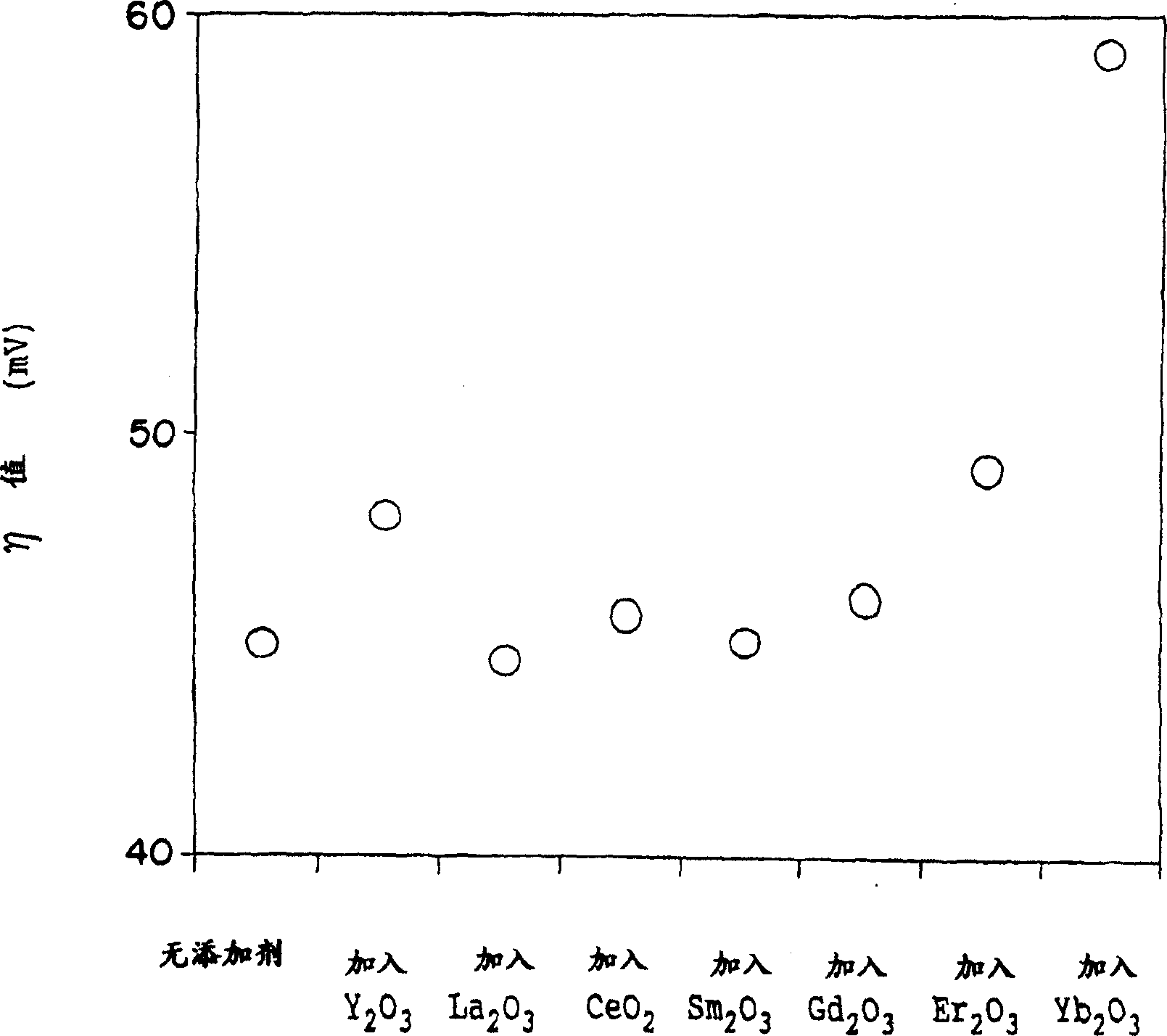

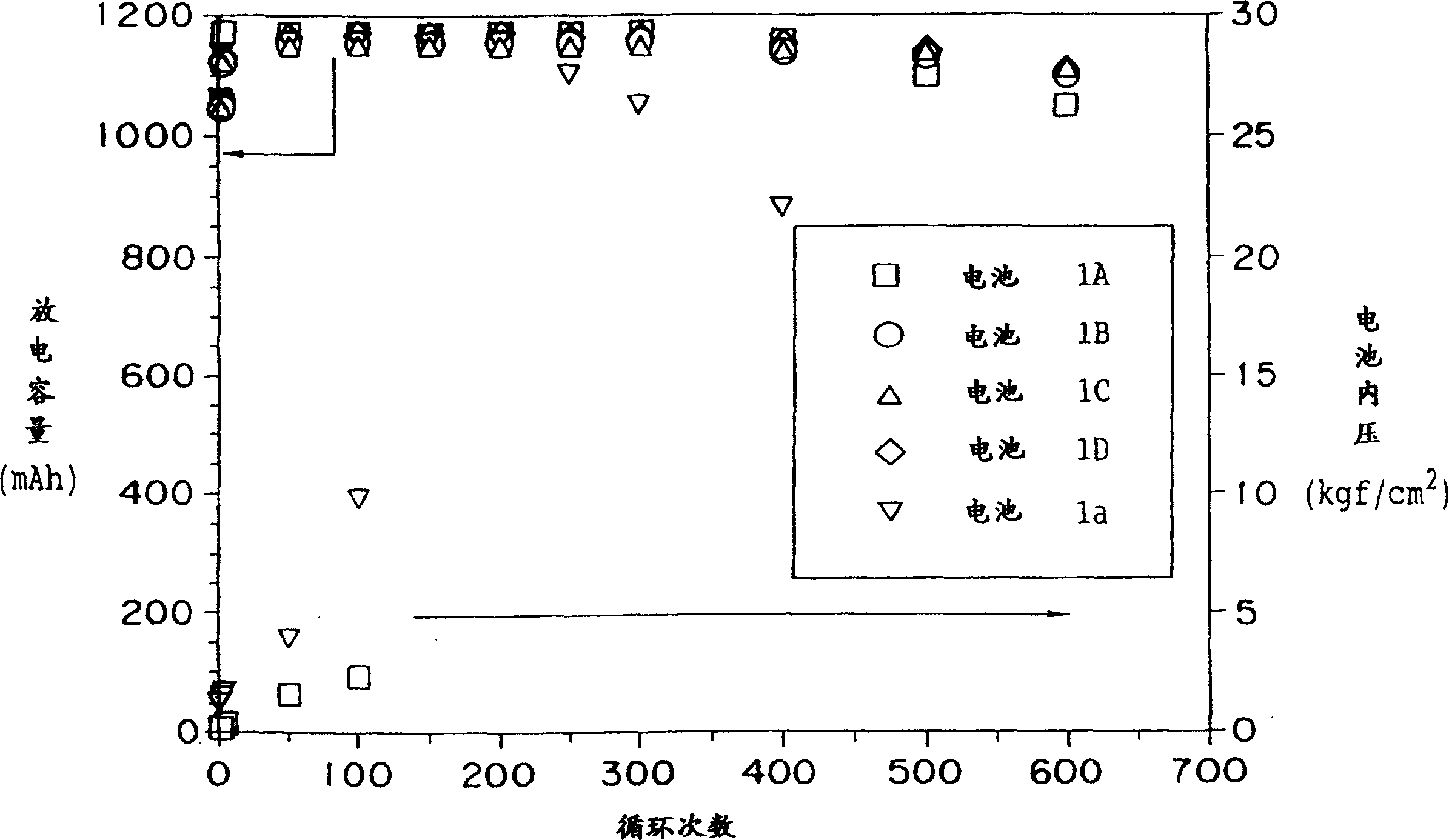

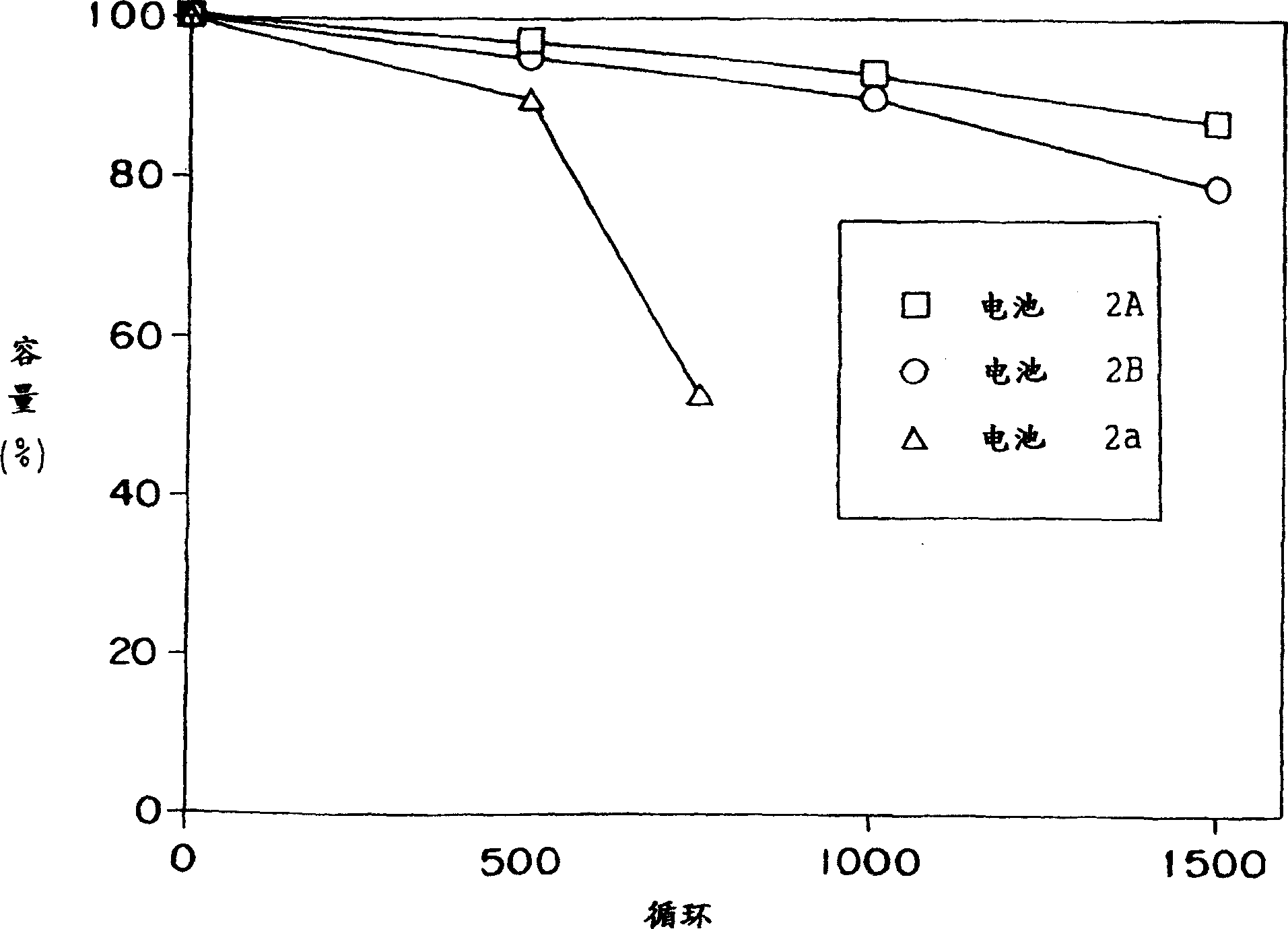

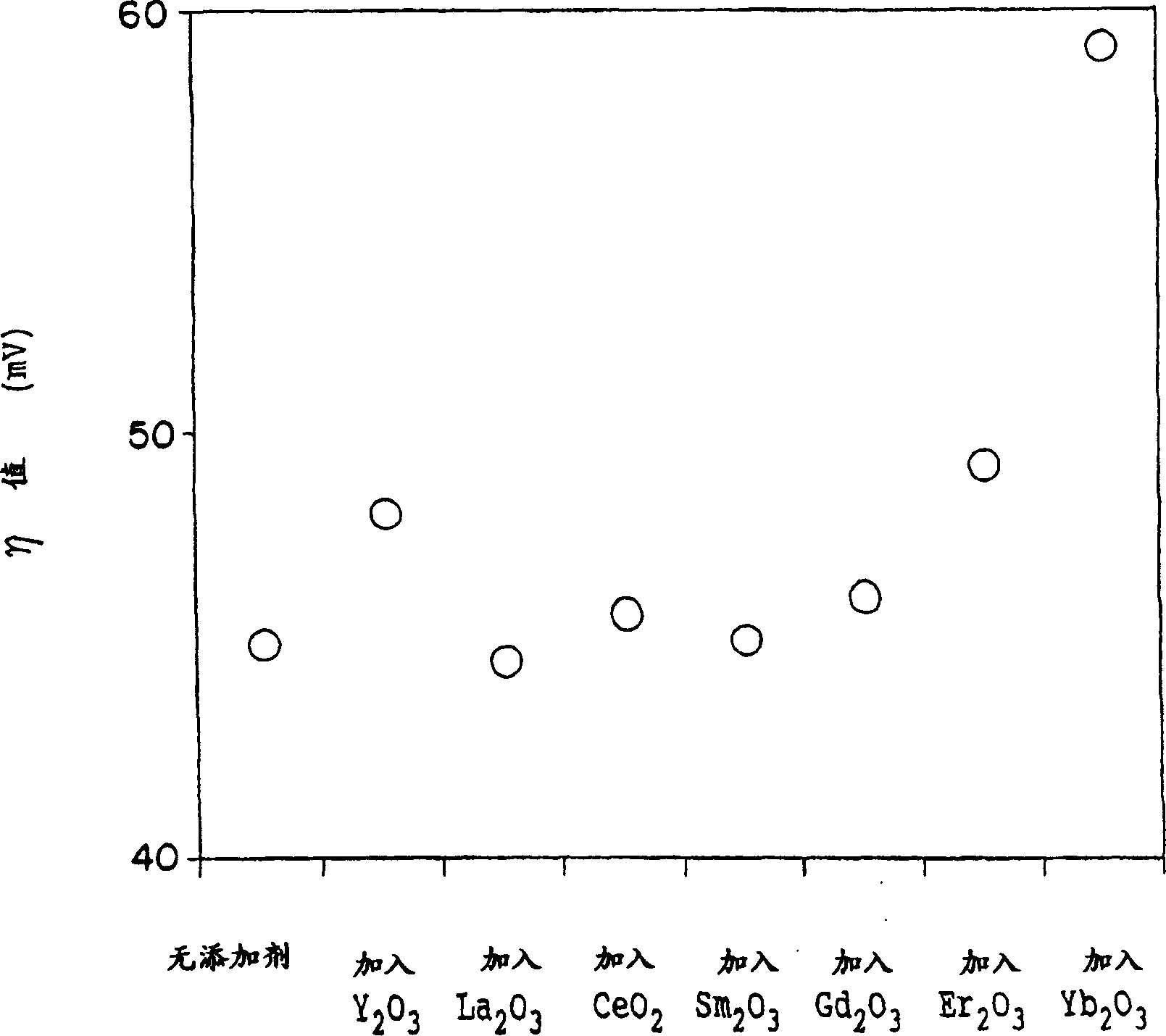

InactiveCN1536690AControl escapeImprove corrosion resistanceAlkaline accumulatorsCell seperators/membranes/diaphragms/spacersRare-earth elementNickel oxide hydroxide

This invention relates to a hydrogen absorbing electrode, in which a rare earth element having a basicity weaker than that of La is mixed to a hydrogen absorbing alloy or contained in it for serving as a component element. The invention relates to a nickel electrode, in which a rare earth element is mixed to a nickel hydroxide or contained in it as a solid solution. The invention further relates to an alkaline storage battery, in which a rare earth element is coated on a surface of a nickel electrode or a surface of a separator.

Owner:GS YUASA INT LTD

Heat-resisting steel for exhaust valves

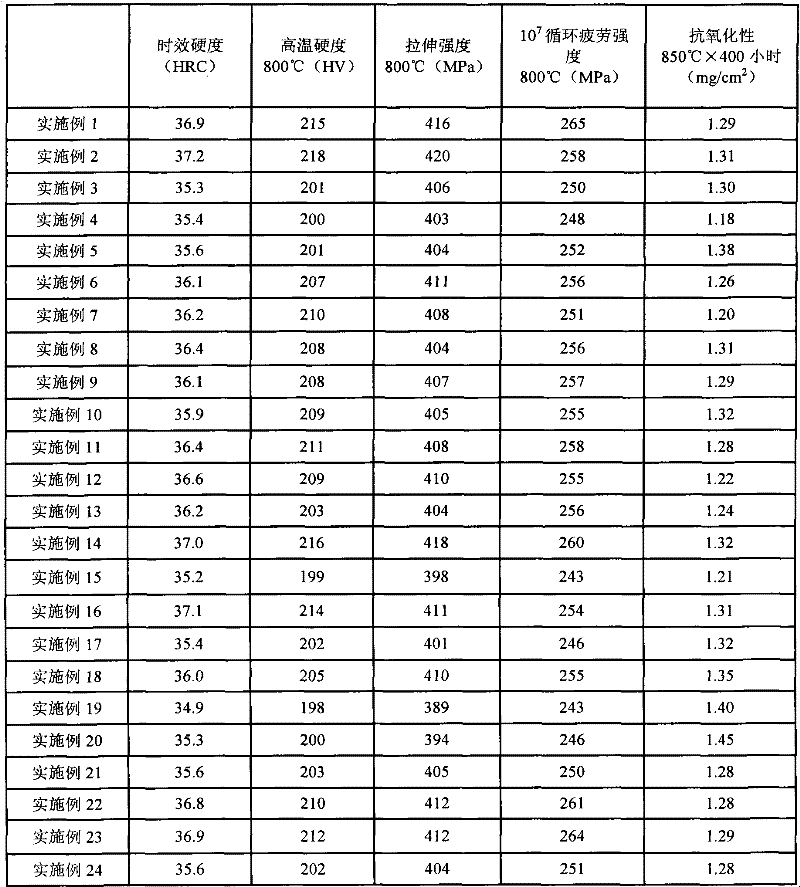

ActiveCN103764861AImprove high temperature characteristicsImprove hot workabilityFurnace typesMachines/enginesExhaust valveHardness

The purpose of the present invention is to provide a heat-resisting steel for exhaust valves, which contains a relatively small amount of Ni and has excellent mechanical characteristics (such as tensile strength, fatigue strength, wear resistance and hardness) at high temperatures and excellent corrosion resistance. The present invention provides a heat-resisting steel for exhaust valves, which contains 0.45 mass% or more but less than 0.60 mass% of C, 0.30-0.50 mass% (exclusive) of N, 19.0 mass% or more but less than 23.0 mass% of Cr, 5.0 mass% or more but less than 9.0 mass% of Ni, 8.5 mass% or more but less than 10.0 mass% of Mn, 2.5 mass% or more but less than 4.0 mass% of Mo, 0.01 mass% or more but less than 0.50 mass% of Si and 0.01 mass% or more but less than 0.30 mass% of Nb, with the balance made up of Fe and unavoidable impurities. This heat-resisting steel for exhaust valves satisfies 0.02 <= Nb / C < 0.70 and 4.5 <= Mo / C < 8.9.

Owner:DAIDO STEEL CO LTD +1

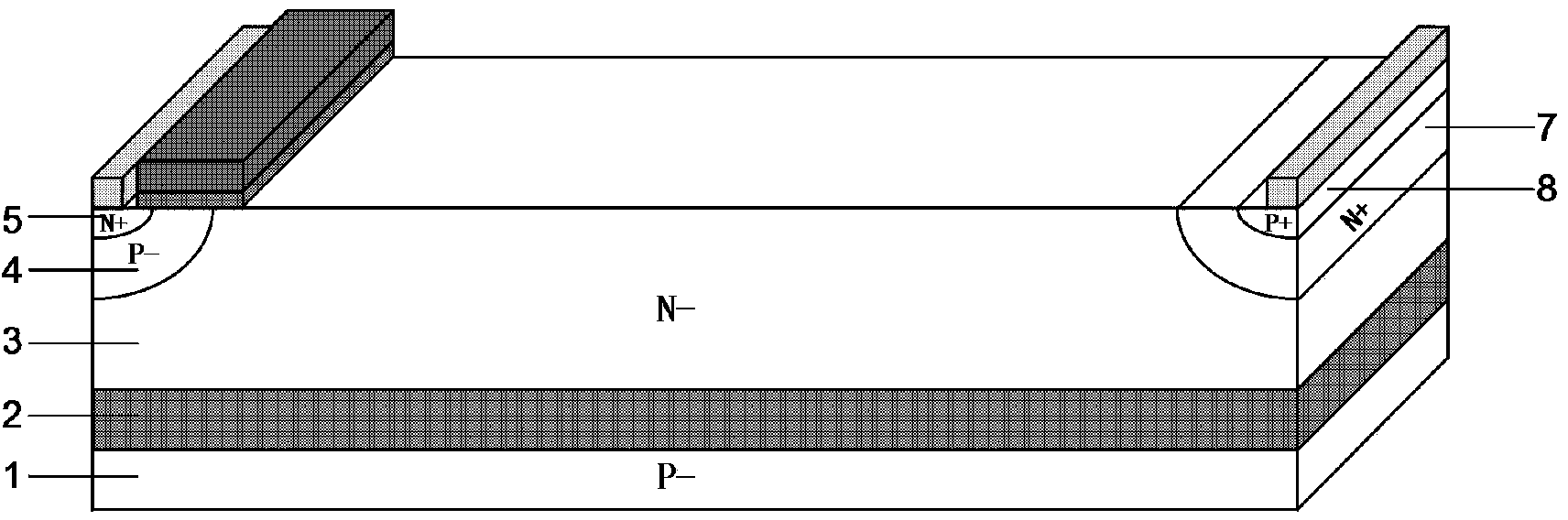

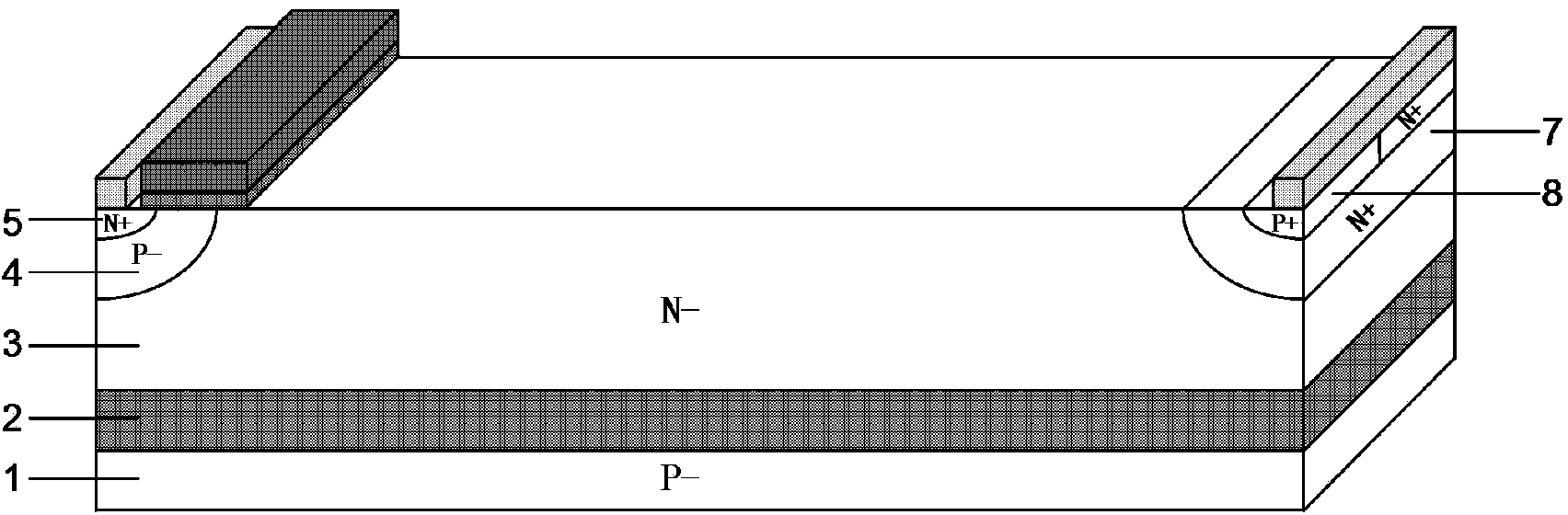

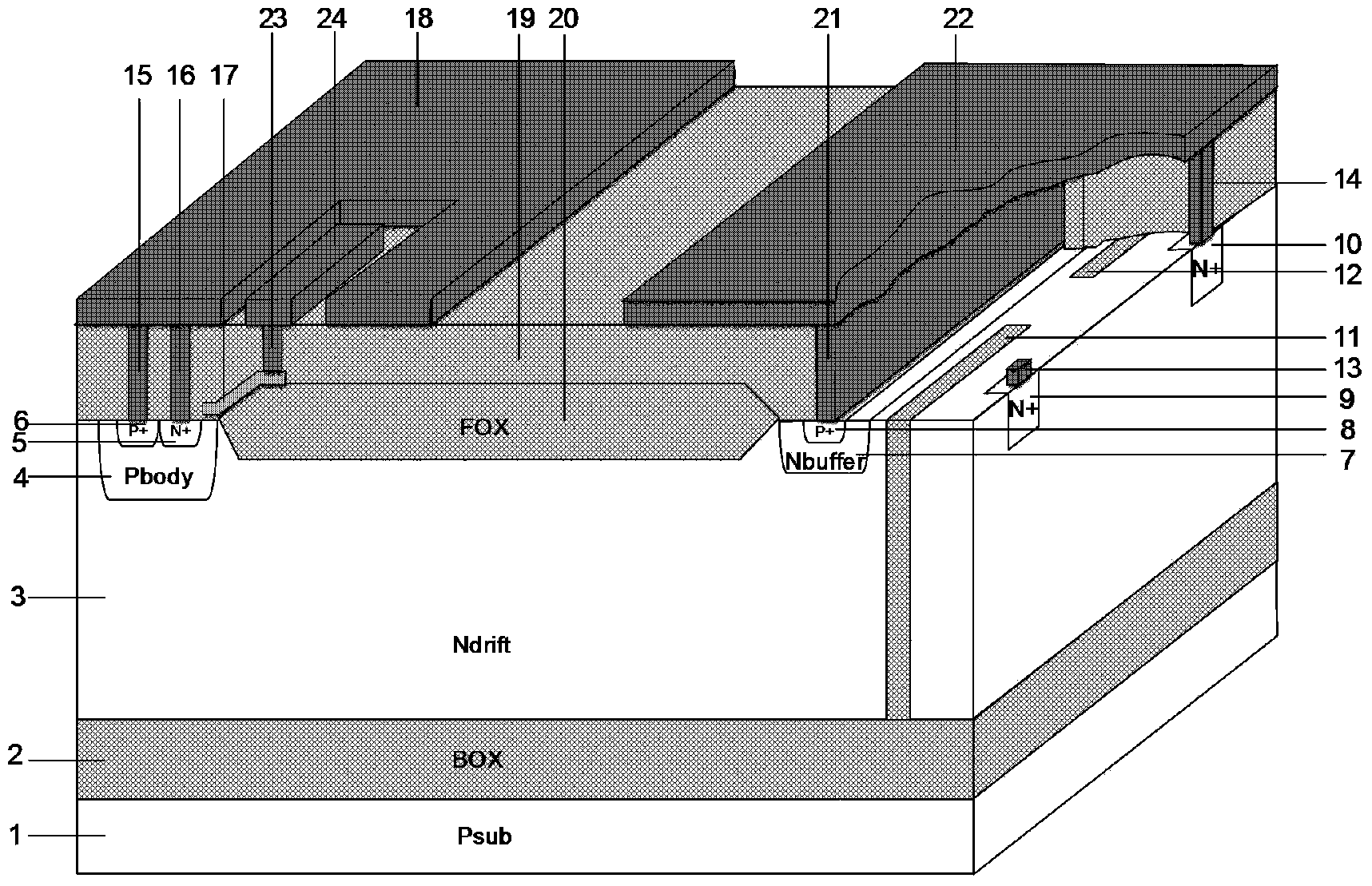

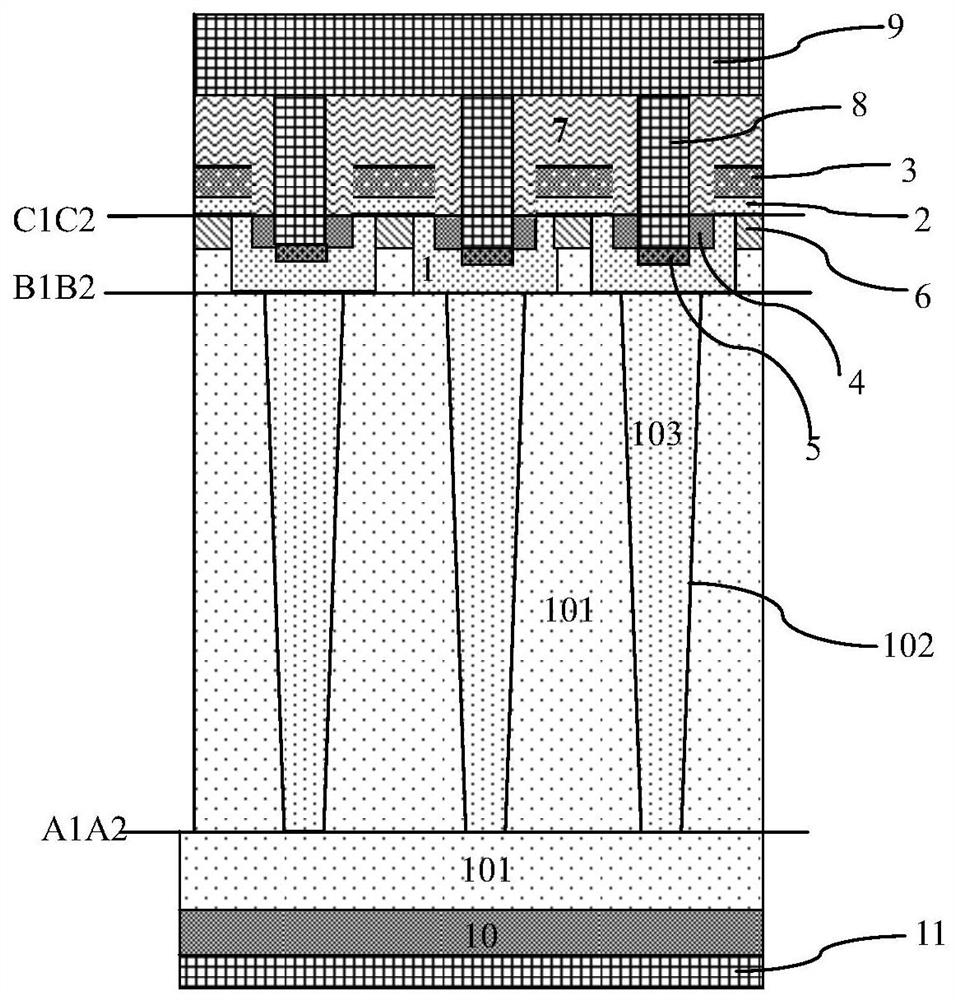

Trench isolation lateral insulated gate bipolar transistor

The invention provides a semiconductor device capable of improving the voltage endurance capability and the high temperature endurance of a common insulated gate bipolar transistor and avoiding the current rebounding phenomenon. According to the semiconductor device, a P type substrate is provided with a buried oxide layer, the buried oxide layer is provided with a drift region, a P type body region is arranged on one side of the drift region, and an N type buffer layer is arranged on the other side of the drift region. A P type emitter region and an N type emitter region connected with the P type emitter region are arranged in the P type body region, and the P type body region is provided with metal used for being connected with the P type emitter region and the N type emitter region and an emitter metal field plate. A P type collector region is arranged in the N type buffer layer, and the N type buffer layer is provided with metal used for connection and a collector metal field plate. A polysilicon gate is arranged above the portion, between the buried oxide layer and the N type emitter region, of the P type body region. Two trench isolation layers are arranged outside an N type body region, a gap for a carrier to flow is reserved between the two trench isolation layers, and two N type collector regions are arranged outside the trench isolation layers and connected with the P type collector region through the metal.

Owner:SOUTHEAST UNIV

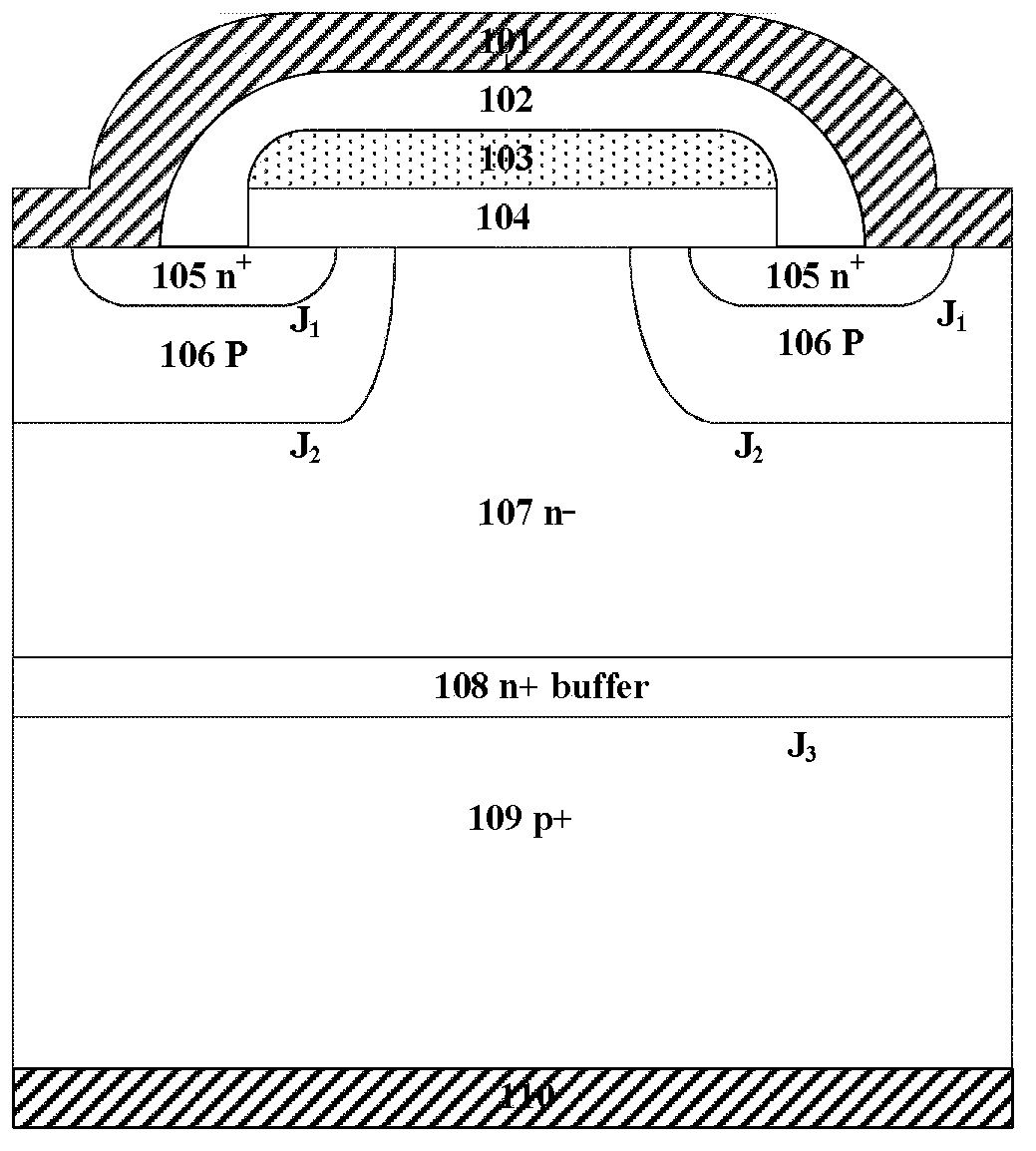

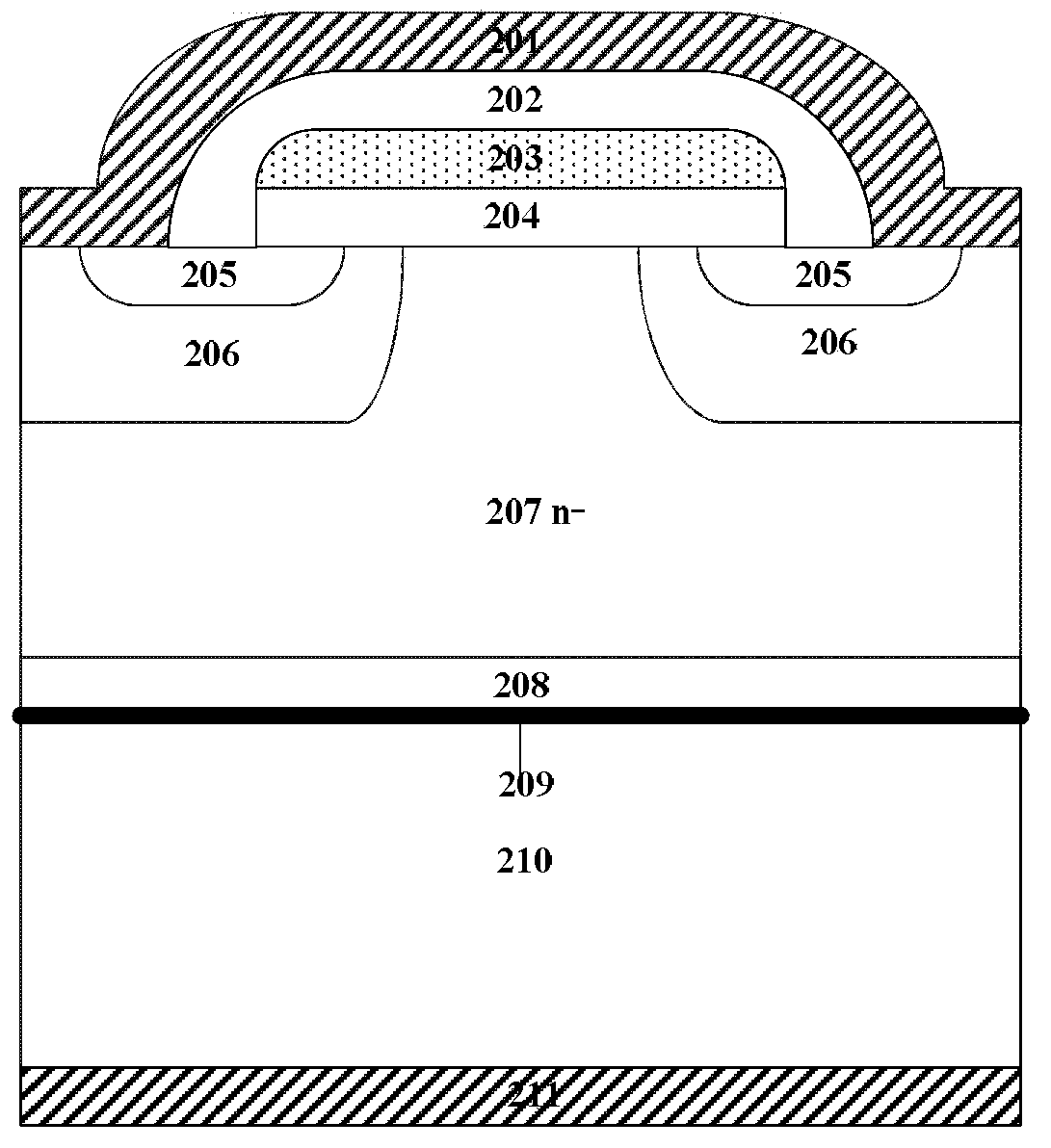

IGBT capable of realizing localized service lifetime controlling and manufacturing method thereof

ActiveCN103633129AShort lifeImprove high temperature characteristicsTransistorSemiconductor/solid-state device manufacturingRecombination currentGate dielectric

The invention brings forward an insulated gate bipolar transistor (IGBT) capable of realizing localized service lifetime controlling and a manufacturing method thereof. The IGBT comprises a current collection region; a buffer layer is formed on the current collection zone; and a drift region is formed on the buffer layer. At least one low-service life high recombination layer is formed between the current collection region and the drift region; and a recombination center is arranged in the low-service life high recombination layer, so that the service life of the carrier is reduced. Besides, well regions are formed in the drift region; emitter regions are formed in the well regions; a gate dielectric layer, a grid electrode and an emitter are successively formed on the drift region; and a collector is formed under the current collection region. According to the invention, because at least one low-service life high recombination layer is formed between the current collection region and the drift region, the low-service life high recombination layer can recombine lots of excess carriers that are generated in a device turn-on state, thereby improving recombination currents and reducing hole injection of the current collection region. Therefore, the turn-off trailing time is shortened; objectives of on-off time reduction and on-off loss reduction can be achieved; and the anti-latch capability of the device is improved.

Owner:BYD SEMICON CO LTD

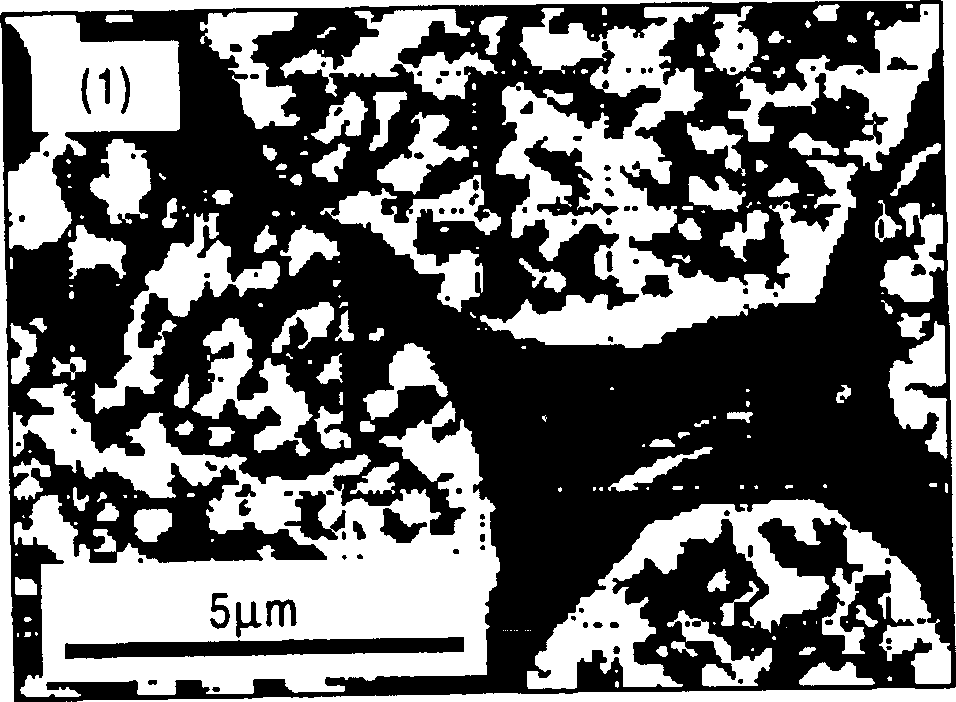

Neodymium-iron-boron permanent magnet and preparation method and application thereof

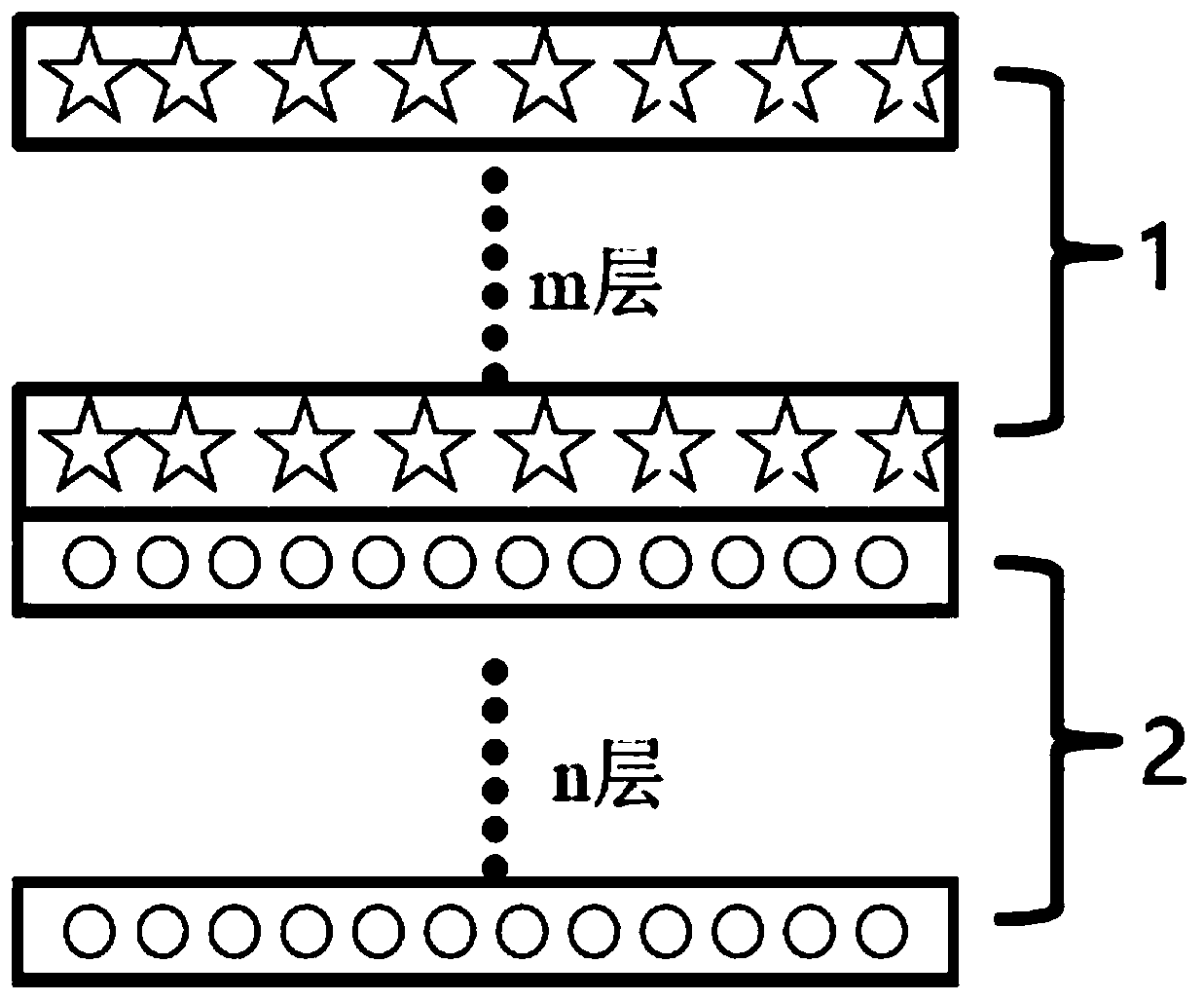

ActiveCN111968818AImprove high temperature characteristicsIncrease the proportionInductances/transformers/magnets manufactureMagnetic materialsCondensed matter physicsGrain boundary

The invention discloses a neodymium iron boron permanent magnet and a preparation method and application thereof. The grain boundary phase and the main phase of the neodymium iron boron permanent magnet have the following structure distribution: the total length of the grain boundary phase in the measurement range is recorded as Lm, the total length of the grain boundary phase with the grain boundary width of more than or equal to 1 [mu] m in the measurement range is recorded as Ln, and Lm and Ln satisfy the relationship of 0.40 < = Ln / Lm < = 1; in the measurement range, the total length of grain boundary phases with the width between adjacent grain boundaries being larger than or equal to 2 microns is recorded as Lx and Lm, and Lx meets the relation that Lx / Lm is larger than or equal to 0and smaller than or equal to 0.2; the total length of the grain boundary phase scanned by the EPMA line in the measurement range is recorded as Le, the total length of the grain boundary phase scanned by the EPMA line in the measurement range is recorded as LM, and Le and LM meet the relationship of 0.40 < = Le / LM < 1. The high-temperature demagnetization-resistant magnet with high Br, high Hcj,high square degree, specific grain boundary phase and main phase structure is prepared.

Owner:YANTAI ZHENGHAI MAGNETIC MATERIAL CO LTD

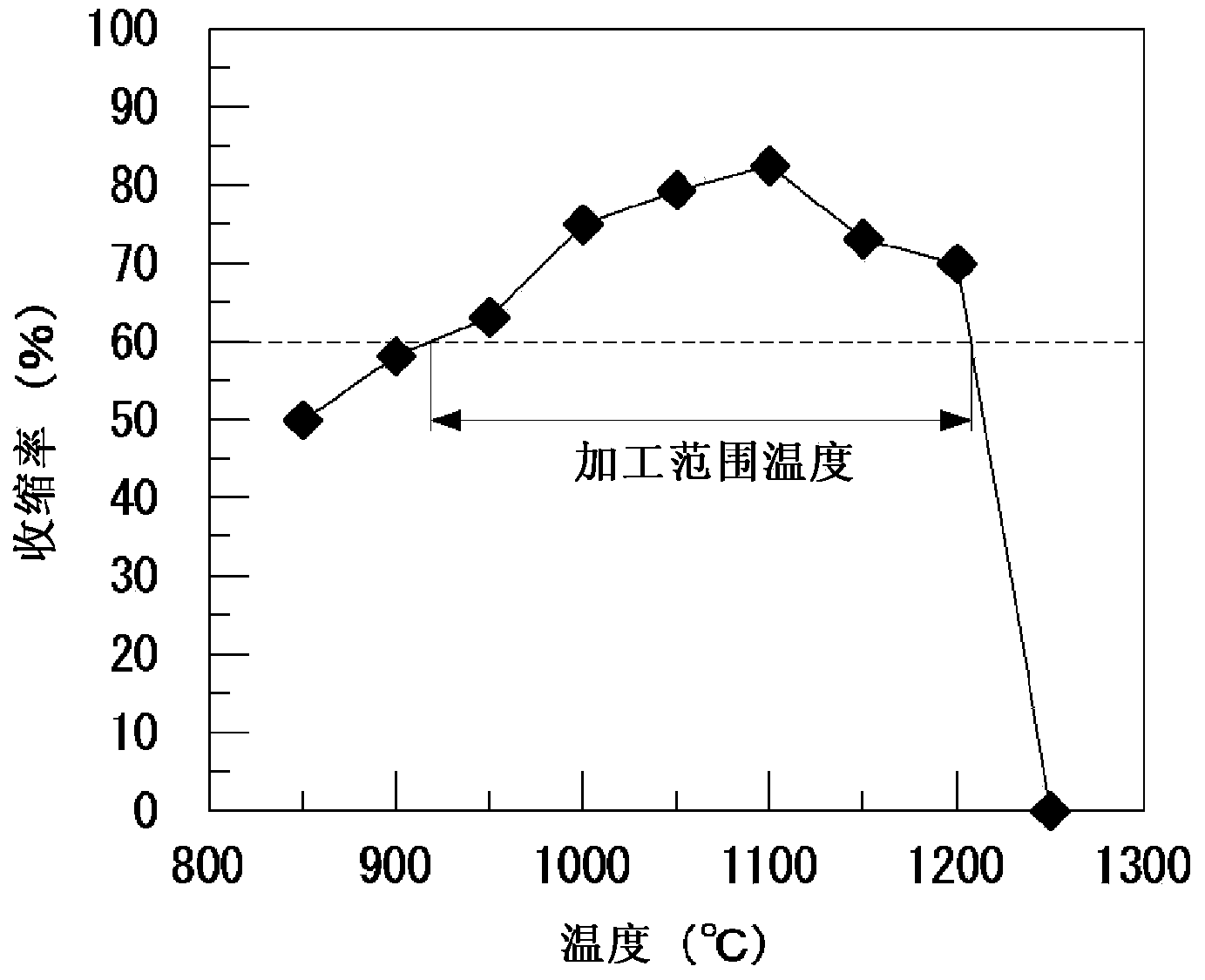

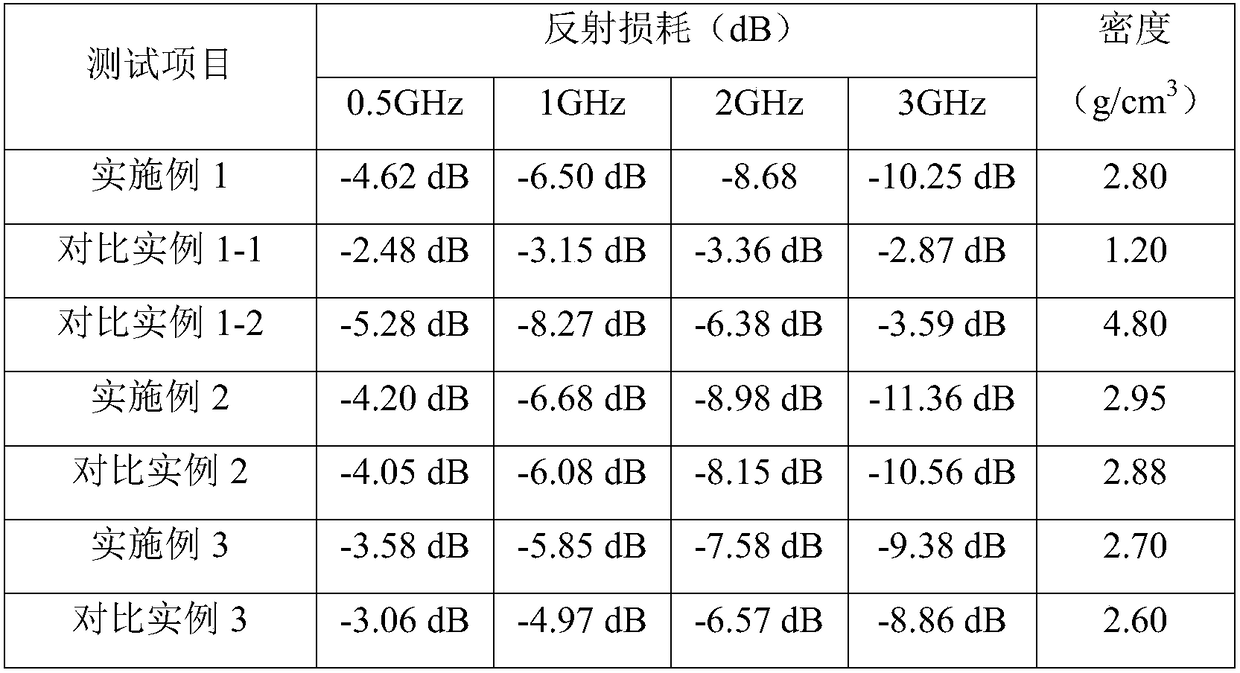

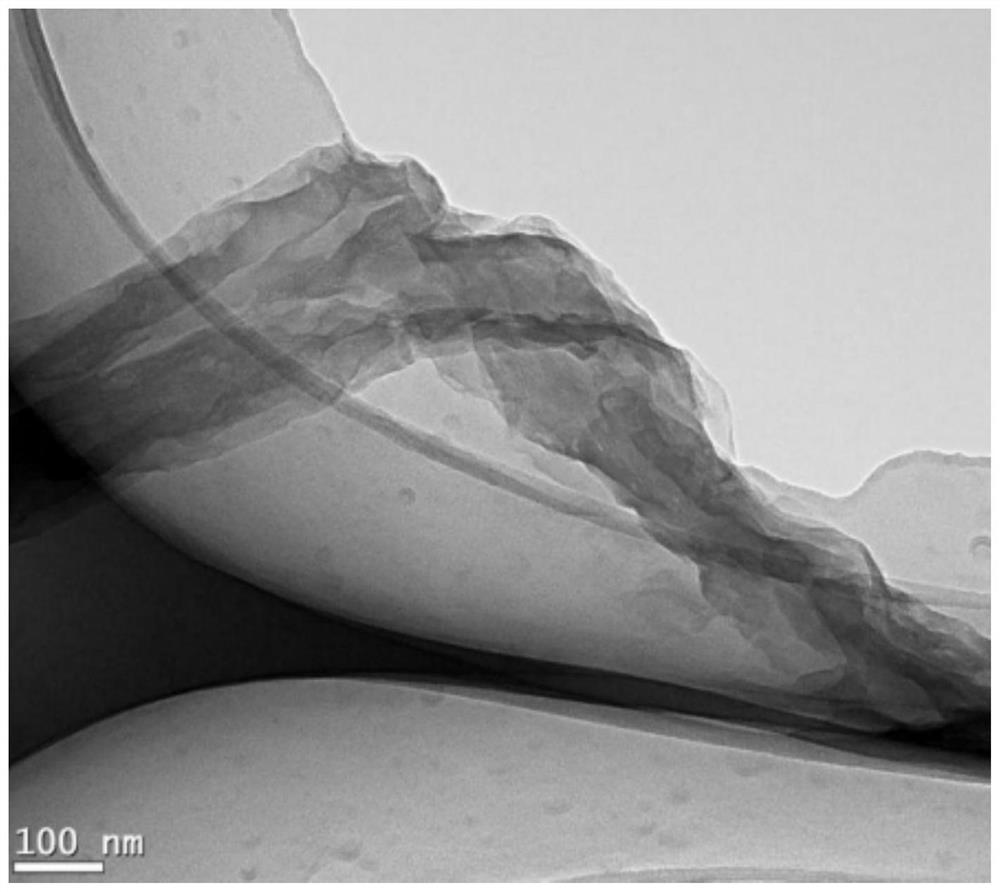

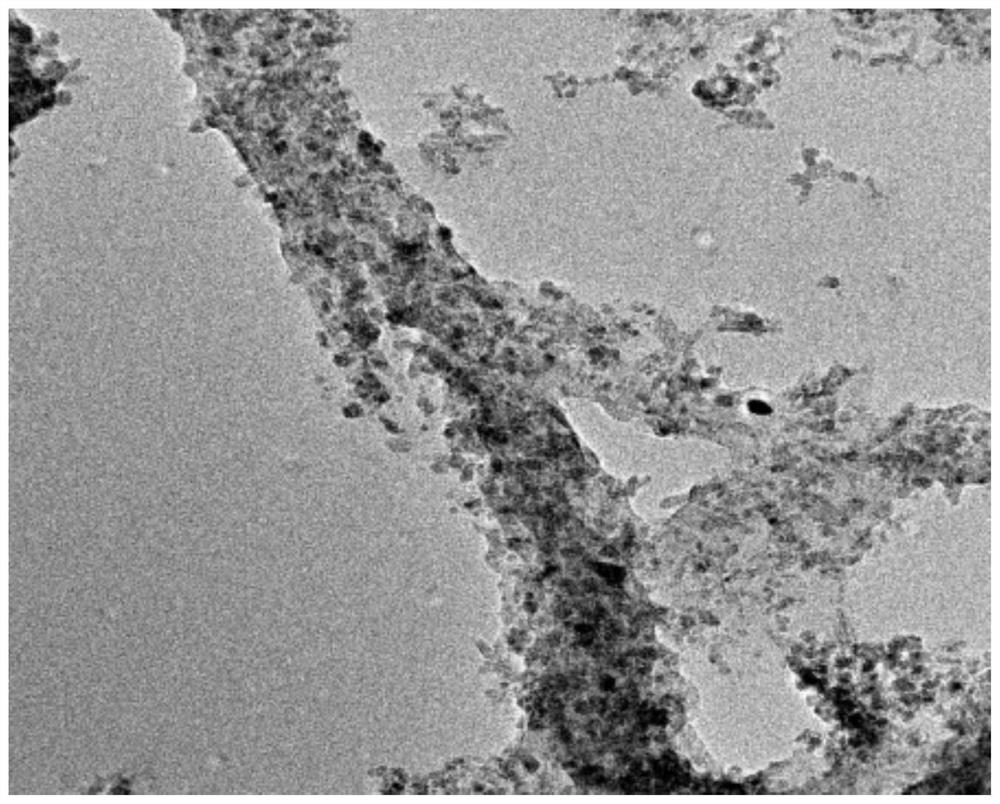

Ferrite-carbon nanotube composite wave absorption material and preparation method thereof

The invention discloses a ferrite-carbon nanotube composite wave absorption material and a preparation method thereof. The ferrite-carbon nanotube composite wave absorption material comprises a carbonnanotube and a ferrite layer, wherein the ferrite layer comprises 5-17% of macromolecule binding agent, 80-92% of ferrite and additive smaller than or equal to 3% by calculation according to percentby weight, and the carbon nanotube layer comprises 8-20% of macromolecule binding agent, 75-87% of carbon nanotube and an additive smaller than or equal to 5%. By combining a high-absorption magnetic-loss ferrite wave absorption material and light-weight dielectric loss-type carbon nanotube wave absorption material, the high-temperature property, the density, the stability, the processing performance and the application performance of the ferrite are improved; and by changing relative content of each constituent of the composite material, a formula and a preparation process, the electromagnetic parameter of the composite material is controlled, the wave absorption frequency band of a compound is expanded, and the absorption efficiency of the compound is improved.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

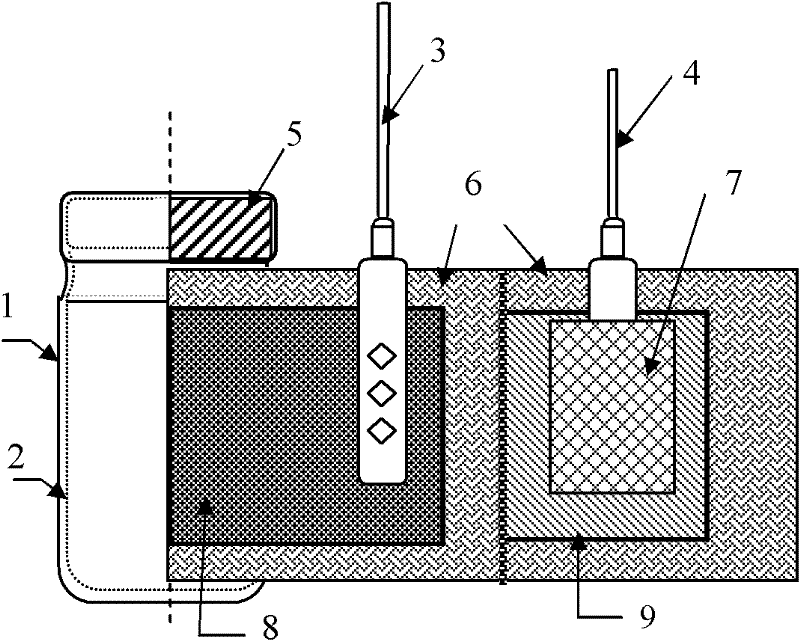

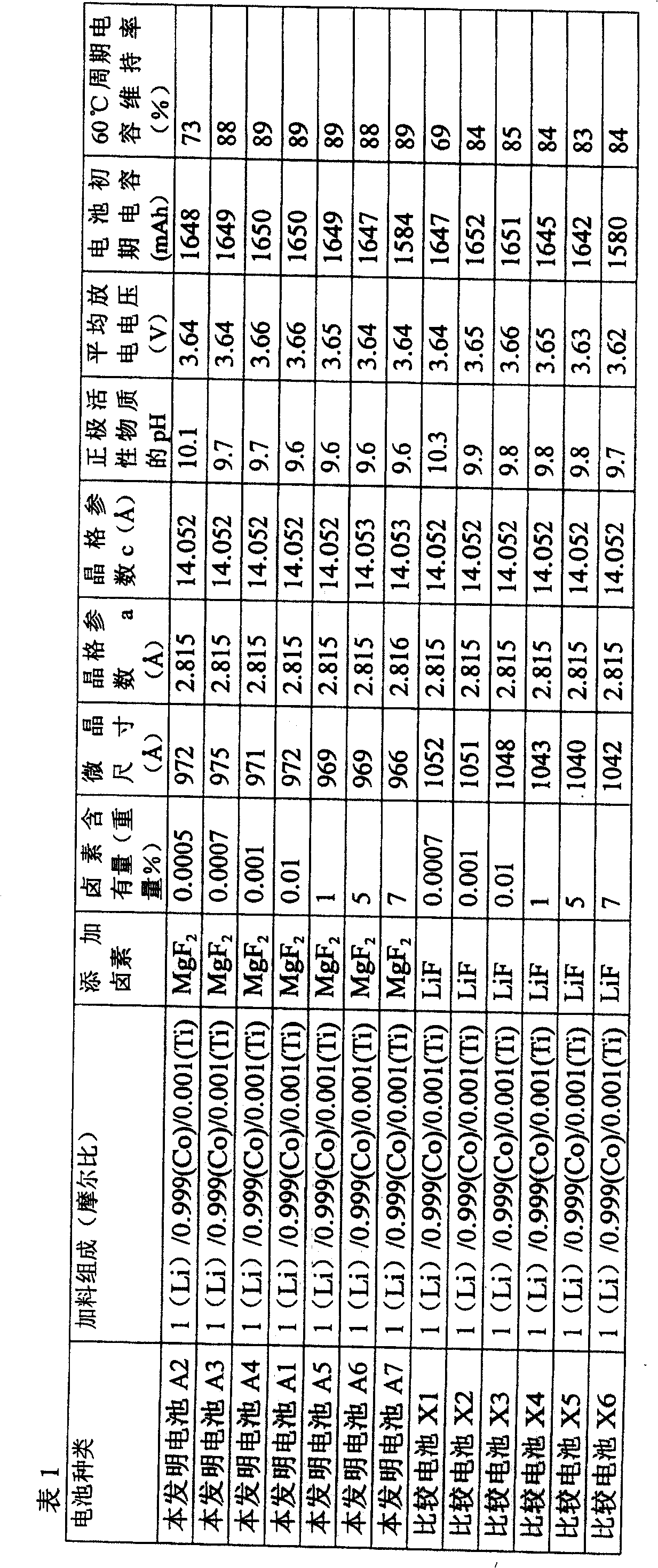

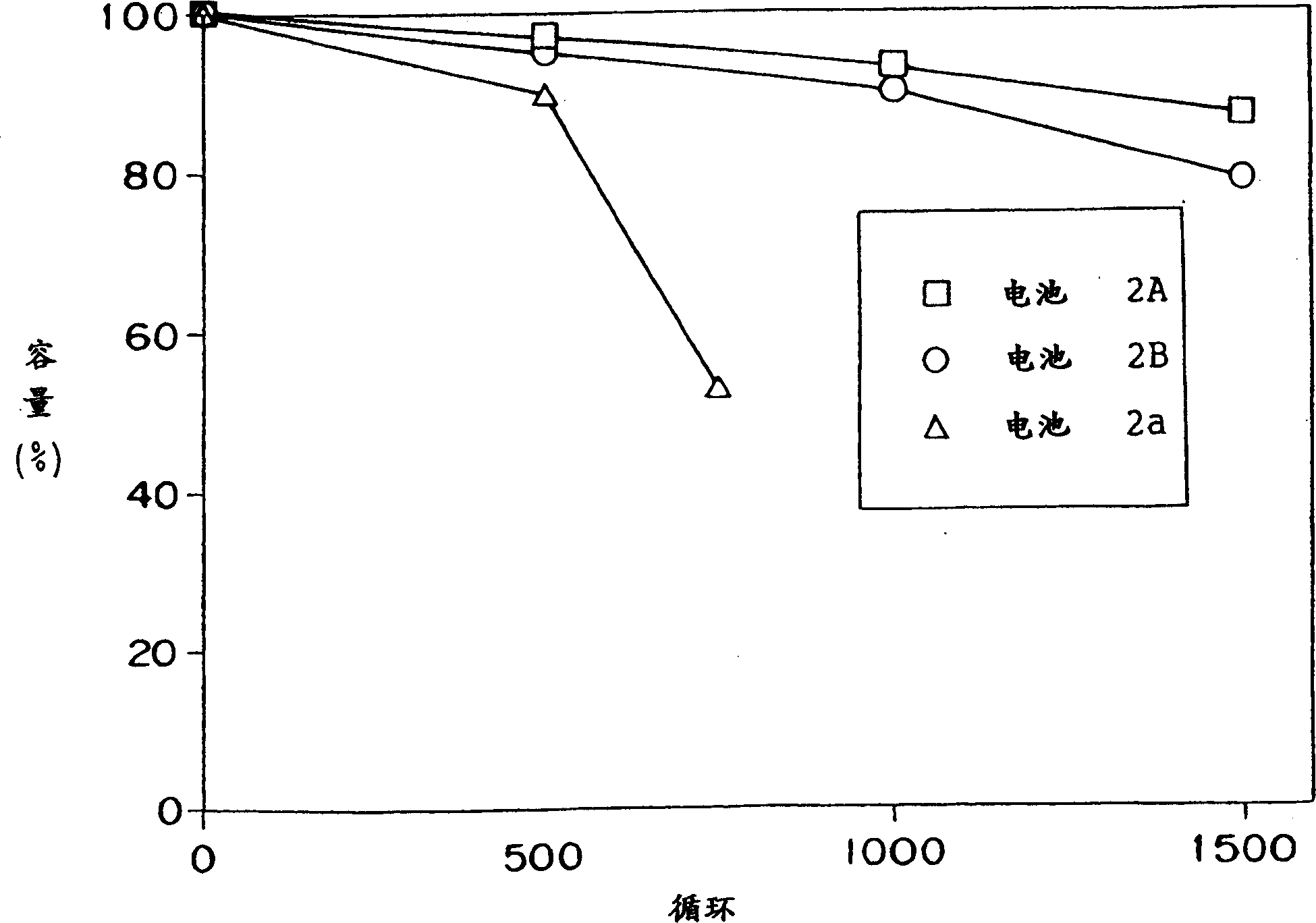

Nonaqueous electrolyte secondary battery and producing method thereof

InactiveCN100454652CImprove high temperature characteristicsFinal product manufacturePositive electrodesCapacitanceHexagonal crystal system

The present invention provides a nonaqueous electrolyte secondary cell having a positive electrode composed mainly of a positive electrode active material, a negative electrode, and a nonaqueous electrolyte. The positive electrode active material is a lithium-containing transition metal composite oxide of a hexagonal crystal system that includes a compound represented by the general formula LiCo1-xMxO2, where M is at least one species selected from the group consisting of V, Cr, Fe, Mn, Ni, Al, and Ti, magnesium, and halogen. In a nonaqueous electrolyte secondary cell having such a construction, the high-temperature characteristics are improved without reducing the cell capacity.

Owner:SANYO ELECTRIC CO LTD

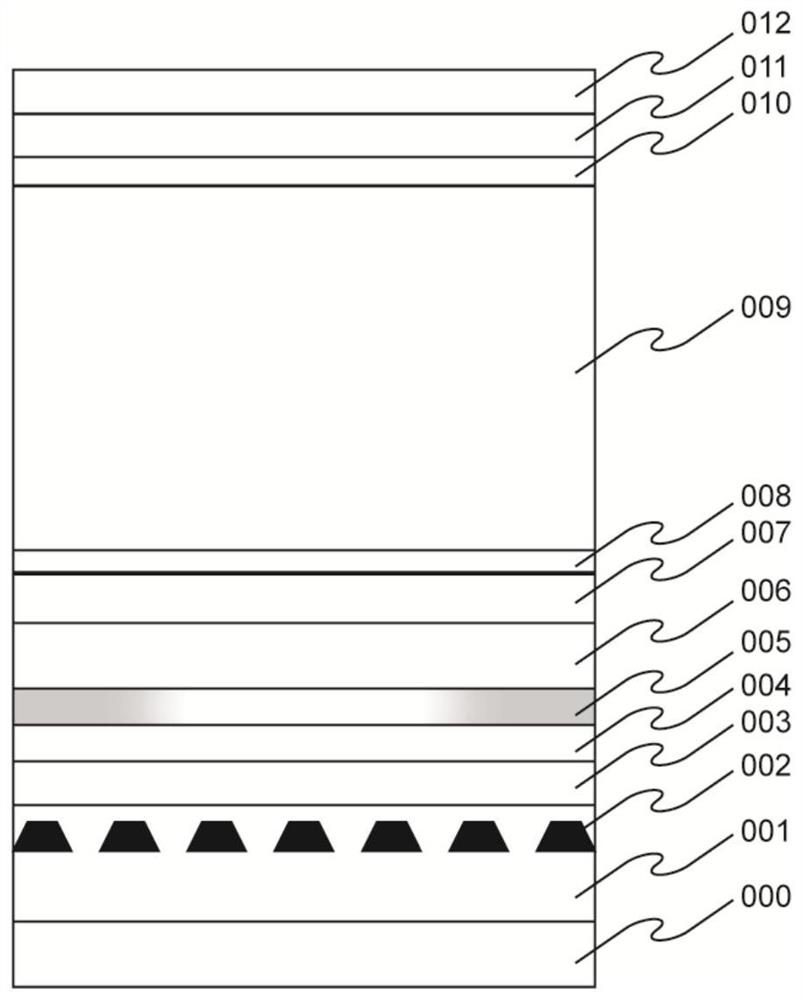

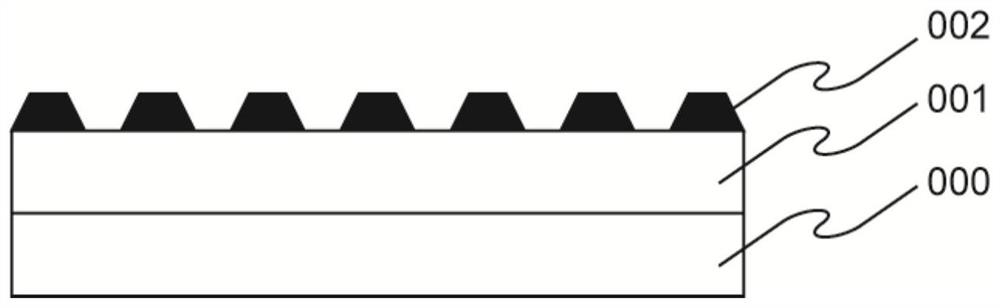

High-temperature working DFB laser and epitaxial structure growth method

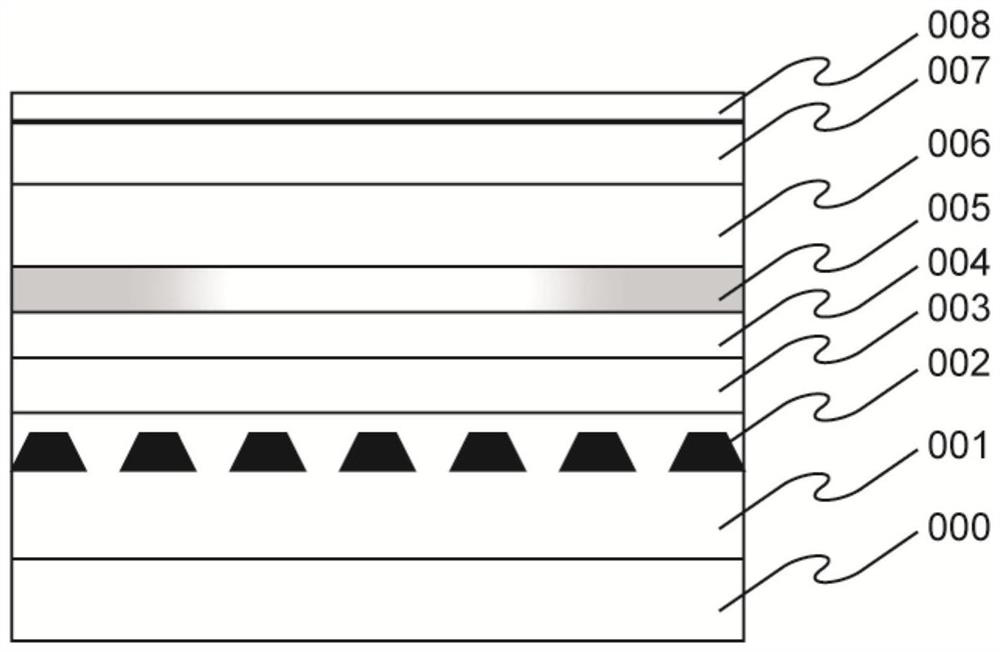

ActiveCN112531460AImprove high temperature characteristicsEasy injectionOptical wave guidanceLaser optical resonator constructionGratingWaveguide

The invention discloses a DFB laser for improving the high-temperature characteristics of a laser, and the epitaxial structure of the DFB laser comprises an InP substrate which is sequentially provided with a buffer layer, a grating layer, a lower limiting layer, a lower waveguide layer, a quantum well, an upper waveguide layer, an electron blocking layer, a corrosion blocking layer, a ridge waveguide layer, a potential barrier gradient layer and an ohmic contact layer from the bottom to the top; the electron blocking layer is a superlattice formed by AlAs0.56Sb0.44 with ternary components andAlxGa(1-x)AsySb(1-y) materials with quaternary components. According to the epitaxial structure of the DFB laser, a wide-bandgap superlattice electron blocking layer is designed through energy band engineering to limit carriers, on one hand, the probability that the carriers overflow out of a quantum well active region at high temperature is reduced through a high potential barrier, on the otherhand, the valence band potential barrier is reduced through superlattices, hole injection into the active region is facilitated, the high-temperature characteristic of the laser can be effectively improved, and the DFB laser can work normally within the temperature range of -40 DEG C to 115 DEG C.

Owner:全磊光电股份有限公司

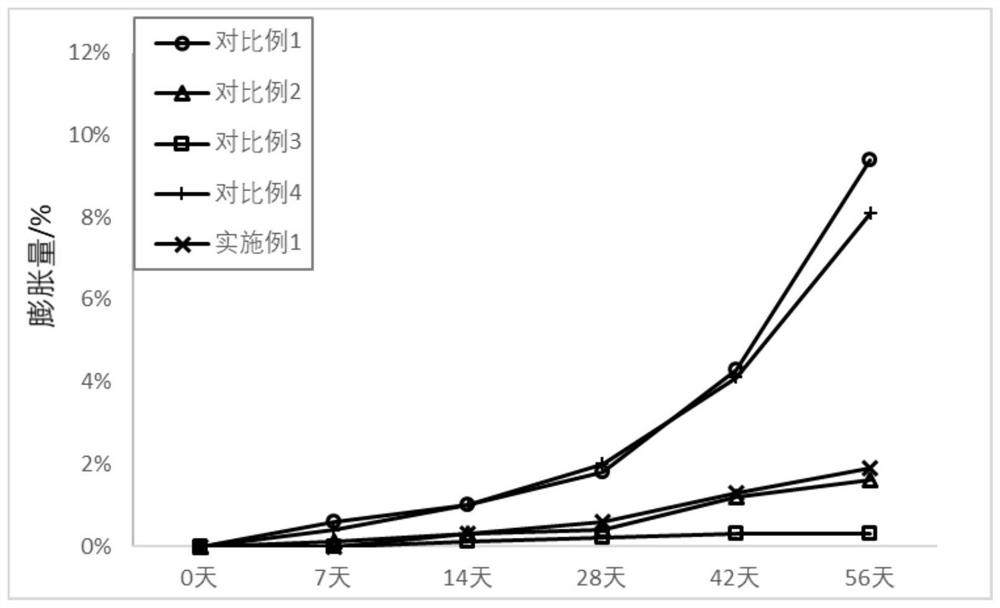

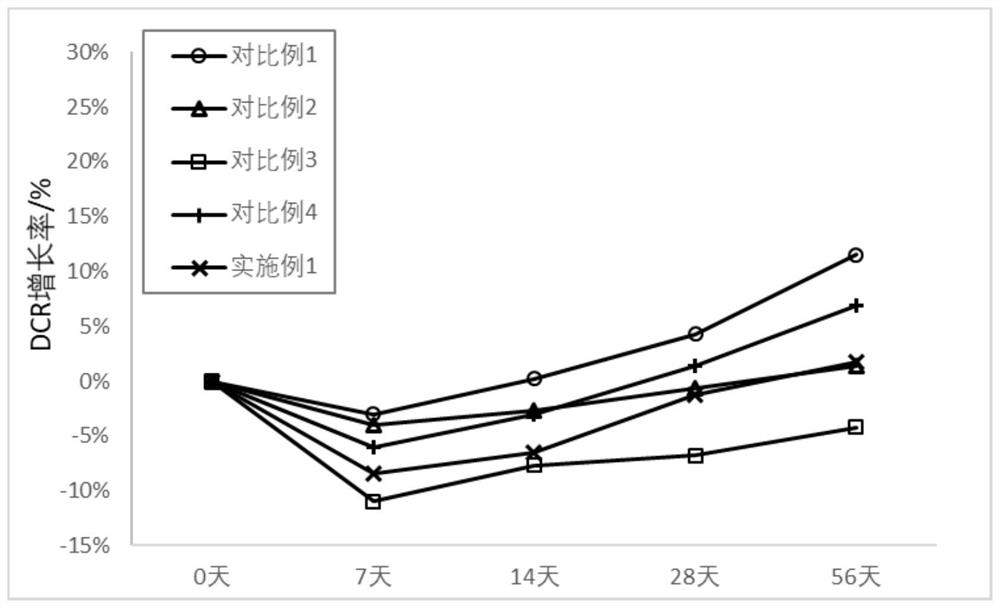

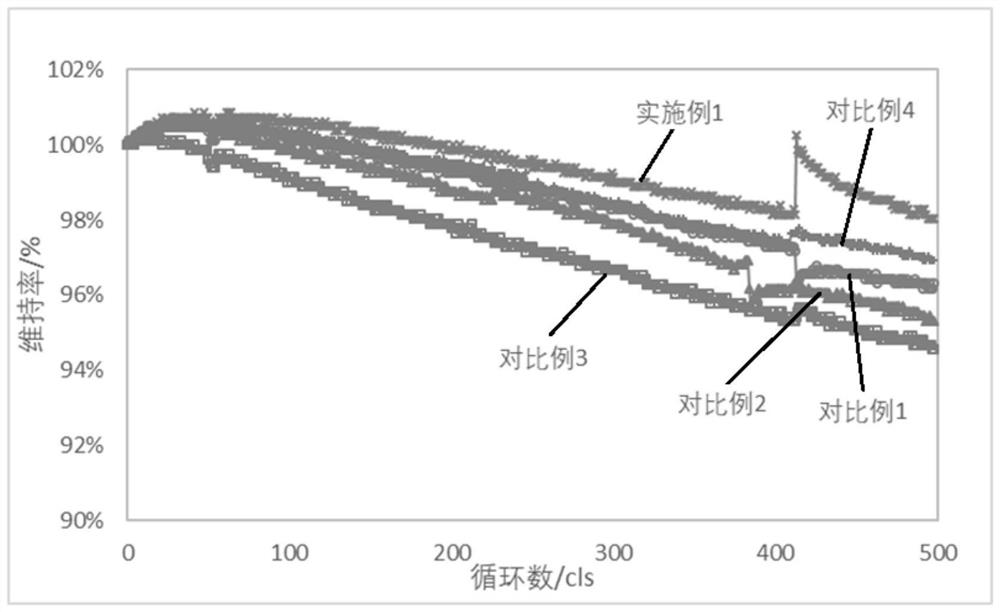

Non-aqueous electrolyte considering high-temperature characteristic and normal-temperature cycle, application thereof and lithium ion battery

InactiveCN112531213AExcellent lithium ion conductivityLow viscositySecondary cellsOrganic electrolytesElectrolytic agentOrganosolv

The invention relates to a non-aqueous electrolyte considering high-temperature characteristics and normal-temperature circulation, an application thereof and a lithium ion battery. Based on the totalweight, the non-aqueous electrolyte comprises the following components in percentage by mass: 70-90% of a non-aqueous organic solvent, 5-20% of electrolyte lithium salt and an additive, based on thetotal weight of the non-aqueous electrolyte, the additive comprises 0.1-2.5% of lithium difluorophosphate, 0.1-2.5% of propane sultone, 0.5-3% of lithium bis (fluorosulfonyl) imide, 0.1-1% of tetravinyl silane and 0.1-1.5% of lithium difluorobis (oxalato) phosphate. The non-aqueous electrolyte disclosed by the invention is good in stability under high voltage, relatively good in circularity, relatively small in gas production rate in the aspect of high-temperature storage and relatively small in DCR growth, and can improve the electrochemical characteristics of the lithium ion battery under high temperature and high pressure.

Owner:ENVISION DYNAMICS TECH (JIANGSU) CO LTD +1

Hydrogen storage electrode, nickel electrode and alkaline storage battery

InactiveCN1244964CIncreasing the thicknessImprove conductivityAlkaline accumulatorsCell seperators/membranes/diaphragms/spacersRare-earth elementNickel oxide hydroxide

Owner:GS YUASA INT LTD

Hydrogen storage electrode, nickel electrode and alkaline storage battery

InactiveCN1536691AControl escapeImprove corrosion resistanceAlkaline accumulatorsCell seperators/membranes/diaphragms/spacersRare-earth elementNickel oxide hydroxide

This invention relates to a hydrogen absorbing electrode, in which a rare earth element having a basicity weaker than that of La is mixed to a hydrogen absorbing alloy or contained in it for serving as a component element. The invention relates to a nickel electrode, in which a rare earth element is mixed to a nickel hydroxide or contained in it as a solid solution. The invention further relates to an alkaline storage battery, in which a rare earth element is coated on a surface of a nickel electrode or a surface of a separator.

Owner:株式会社杰士汤浅工业

Positive material of AZO-coated lithium nickel manganese oxide secondary lithium battery and preparation method of positive pole material

ActiveCN102983324BImproved high-current discharge characteristicsAvoid decompositionCell electrodesSecondary cellsDecompositionManganese oxide

Owner:新乡市中天新能源科技股份有限公司

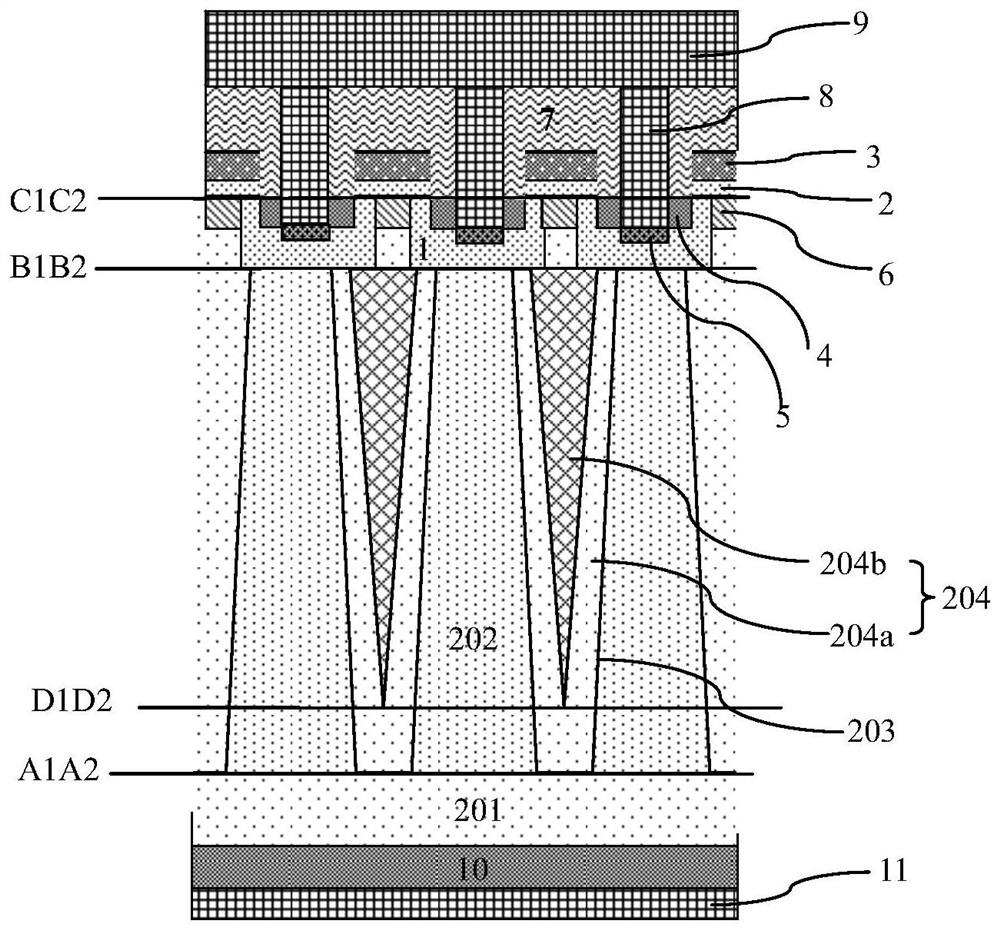

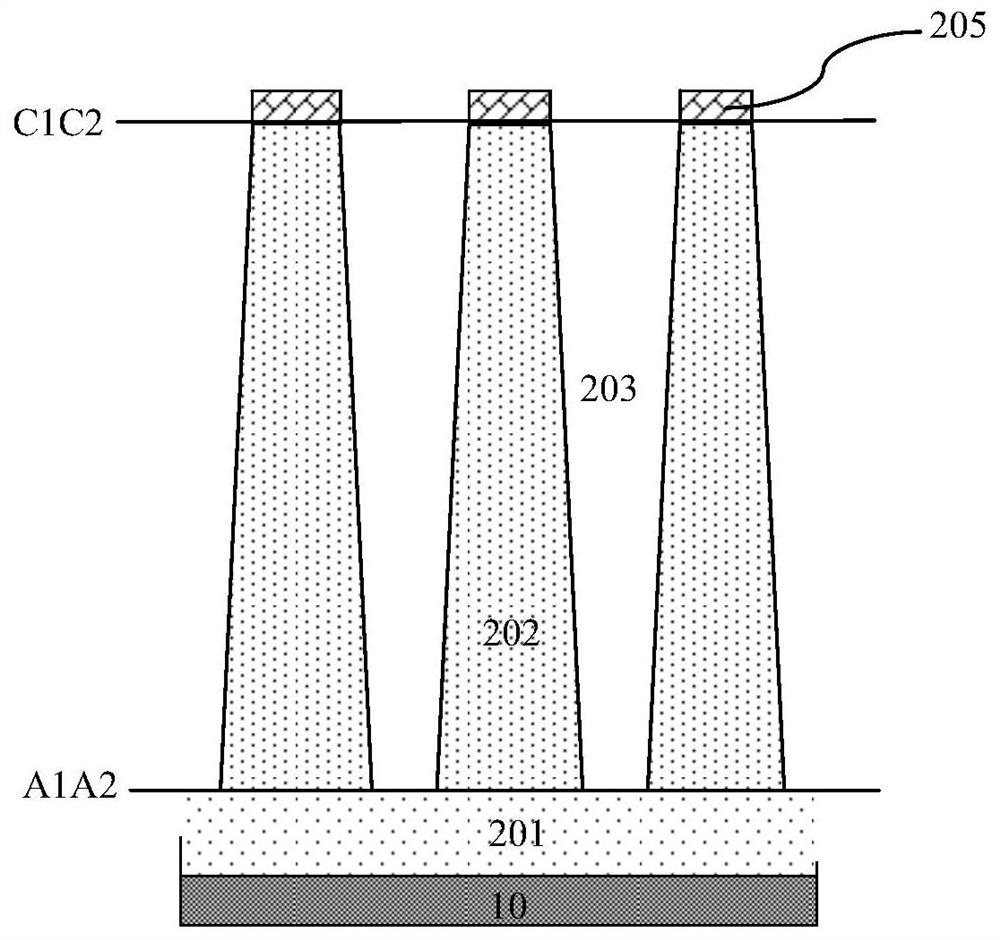

Super junction device and manufacturing method thereof

PendingCN112786677ASame ratio on-resistanceSame specific on-resistance (Rsp)Semiconductor/solid-state device manufacturingSemiconductor devicesReverse recoveryEngineering

The invention discloses a super junction structure, and the structure is formed above the surface of a first N-type epitaxial layer, wherein the width of a P-type column at the top position of a super junction unit is less than that of an N-type column and is unchanged in a step mode; the N-type column is composed of a second N-type epitaxial layer filling grooves, the P-type column is composed of a first P-type epitaxial layer between the grooves, and the first P-type epitaxial layer is formed on the first N-type epitaxial layer; the grooves penetrate through the first P-type epitaxial layer, and the bottoms of the grooves are in contact with the first N-type epitaxial layer; the total amount of P-type impurities of the P-type column in the super junction unit is matched with the total amount of N-type impurities of the N-type column, the second N-type epitaxial layer is formed by overlapping at least two N-type epitaxial sub-layers, and the doping concentration of the first N-type epitaxial sub-layer is higher than that of the P-type column. The invention further discloses a manufacturing method of the super junction device. According to the invention, the process control difficulty can be reduced, the charge balance of the super junction unit can be improved, the reverse recovery current of the body diode is reduced, and the high-temperature characteristic of the device is improved.

Owner:NANTONG SANRISE INTEGRATED CIRCUIT CO LTD

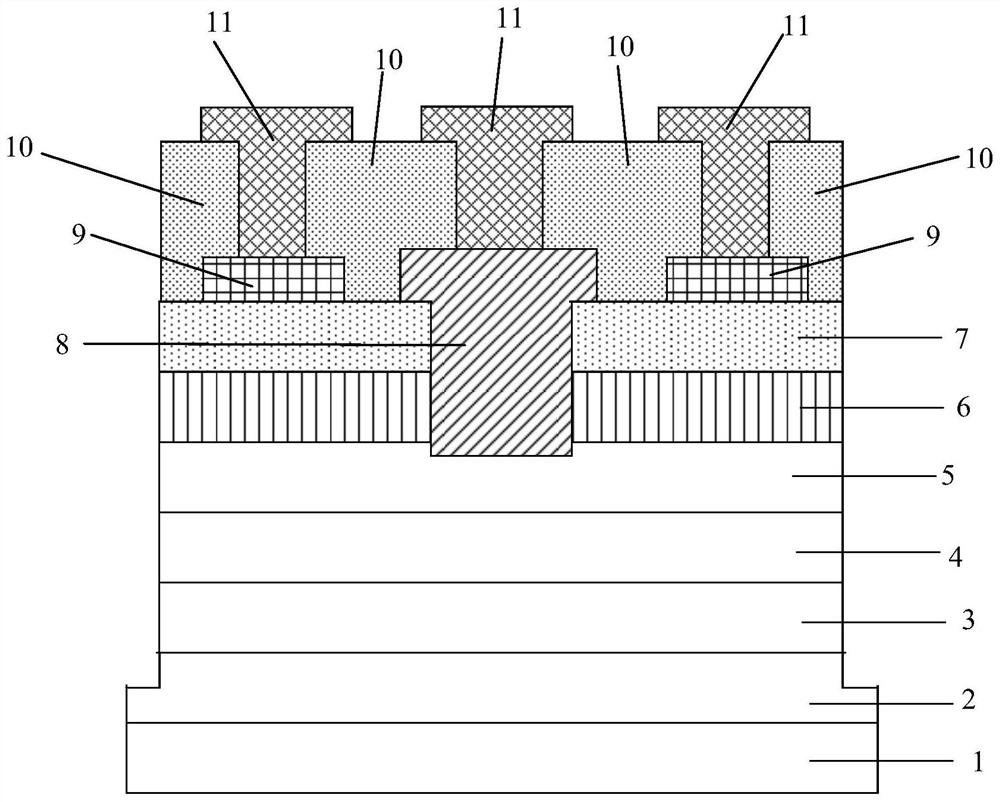

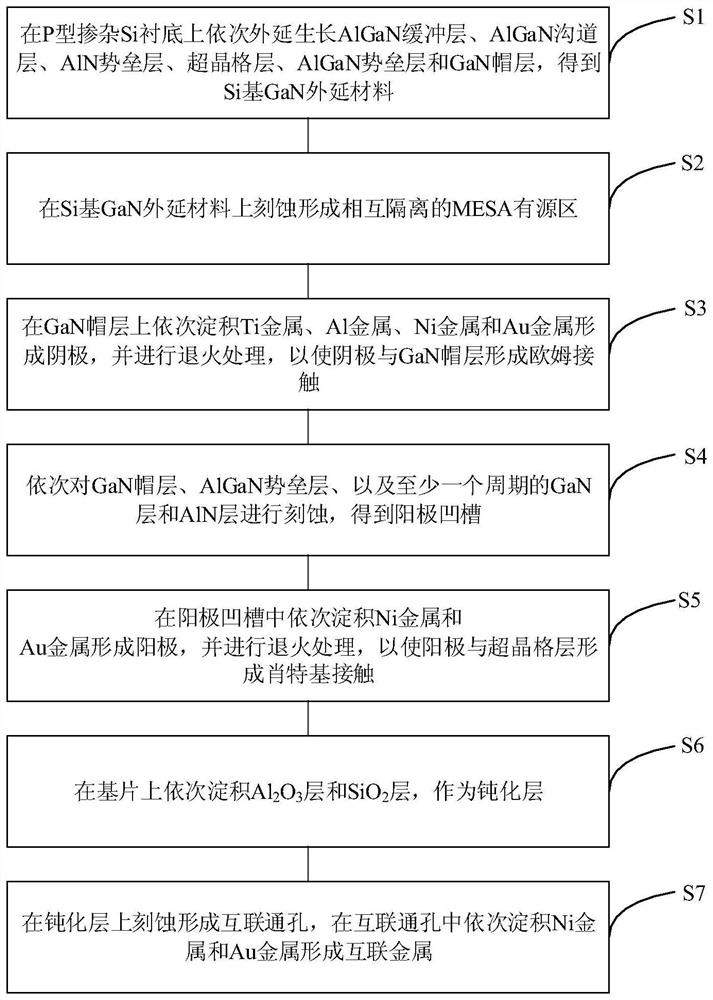

AlGaN-based double-channel Schottky diode based on groove anode structure and preparation method

PendingCN112768512AIncrease concentrationLower on-resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesPhysicsElectrically conductive

The invention relates to an AlGaN-based double-channel Schottky diode based on a groove anode structure and a preparation method. The diode comprises a substrate, a buffer layer, a channel layer, a first barrier layer, a superlattice layer, a second barrier layer and a GaN cap layer, an anode and a cathode; the substrate, the buffer layer, the channel layer, the first barrier layer, the superlattice layer, the second barrier layer and the GaN cap layer are sequentially stacked from bottom to top; a first conductive channel is formed between the channel layer and the first barrier layer; a second conductive channel is formed between the superlattice layer and the second barrier layer; the anode is arranged on the GaN cap layer; the bottom of the anode sequentially penetrates through the GaN cap layer and the second barrier layer; the anode is located in the superlattice layer; the anode and the superlattice layer form Schottky contact; the cathode is arranged on the GaN cap layer and surrounds the periphery of the anode; a distance exists between the cathode and the anode; and the cathode and the GaN cap layer form ohmic contact. According to the AlGaN-based double-channel Schottky diode based on the groove anode structure, the conductive channels are adopted, so that the electron concentration is improved, and the on-resistance is reduced.

Owner:XIDIAN UNIV

Preparation method of green electromagnetic shielding building material

InactiveCN111943274AImprove absorbing performanceWide absorbing performanceMaterial nanotechnologyMagnetic/electric field screeningGraphene nanoribbonsCarbon nanotube

The invention provides a preparation method of a green electromagnetic shielding building material, which comprises the following operation steps: selecting a proper amount of carbon nanotubes, and cutting the carbon nanotubes by a chemical longitudinal cutting method. Nano Fe3O4 particles and graphene oxide nanobelts are compounded to prepare a ferroferric oxide-graphene oxide nanobelt compositematerial, the ferroferric oxide-graphene oxide nanobelt composite material is reduced to obtain a Fe3O4-graphene nanobelt composite material; and the ferroferric oxide-graphene nanobelt composite material with different Fe3O4 loading capacities is prepared by adjusting the Fe3O4 loading capacity. The wave-absorbing performance of the material with the continuous thickness of 0.5 mm and 5 mm is calculated, the wave-absorbing performance of the material with the ratio of F to G being 1: 1 and the wave-absorbing performance of the material with the ratio of 2: 1 are the best, and the optimal loading capacity and the optimal thickness of Fe3O4 can be determined. The green electromagnetic shielding building material has the characteristics of light weight and wide wave absorption, and is convenient for industrial large-scale production. The material can be used in a multimedia indoor venue with a large number of electronic devices, not only can protect the health of visitors, but also can improve the visiting experience.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com