Patents

Literature

33results about How to "Lower threshold current density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

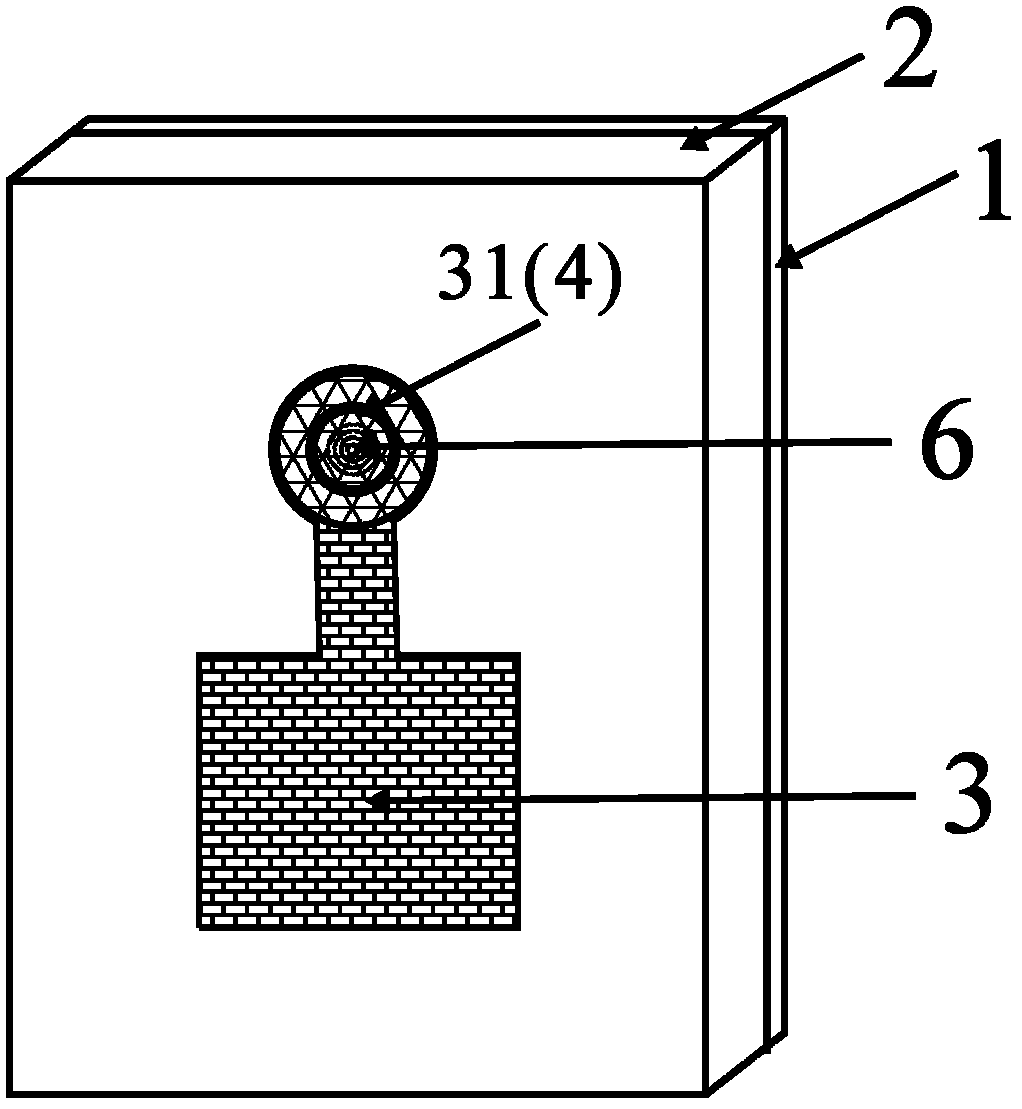

Semiconductor laser light source for emitting nanometer dimension vertical to cavity surface and method for making

InactiveCN101202419ASmall sizeAchieve integrationLaser detailsSemiconductor lasersVertical-cavity surface-emitting laserInsulation layer

The invention provides a method which manufactures a vertical-cavity surface-emitting nano-scale semiconductor laser source with surface plasma modulation effect. The method is prepared on the base of normal vertical cavity surface emitting laser. The detailed process comprises that an antireflection coating layer is grown on the output cavity surface of the normal vertical cavity surface emitting laser; a sub-wavelength periodic structure is prepared on the antireflection coating of the cavity surface in the range of an output optical hole by a method of focused ion beam etching; a layer of metal film is plated after an insulation layer on a P-surface electrode is removed; after that, a hole with sub-wavelength dimension and a sub-wavelength periodic structure are prepared on the metal film of the output optical cavity surface by the method of focused ion beam etching; the light is restricted in a low-loss micro-resonant cavity and emitted through a slight opening to generate a near field light with high efficiency and high directivity.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

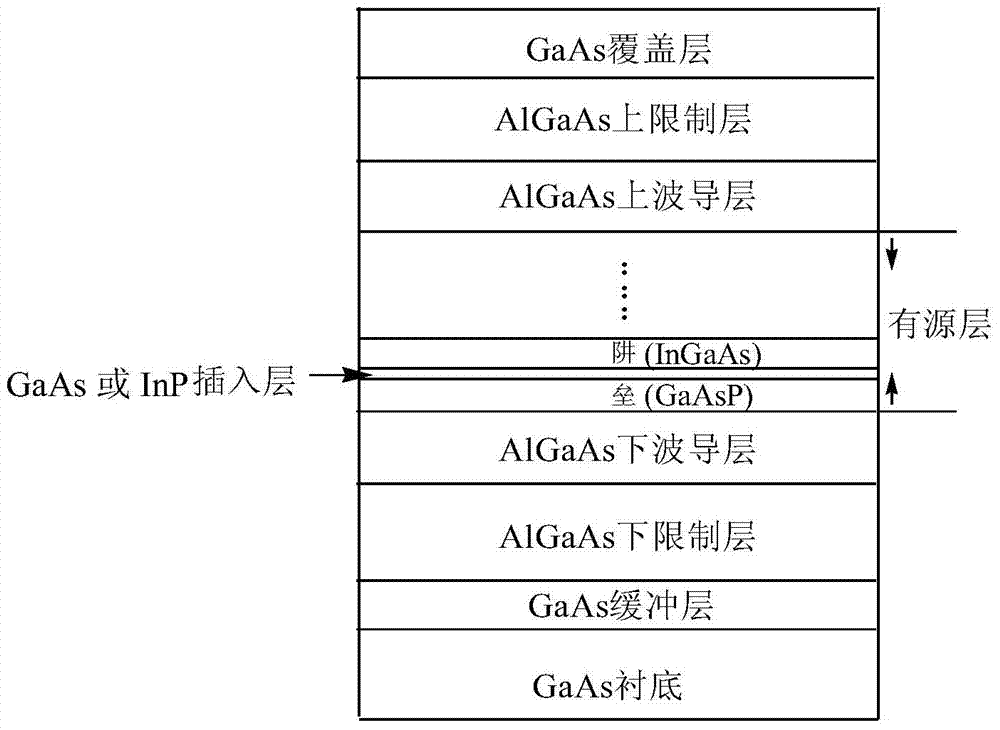

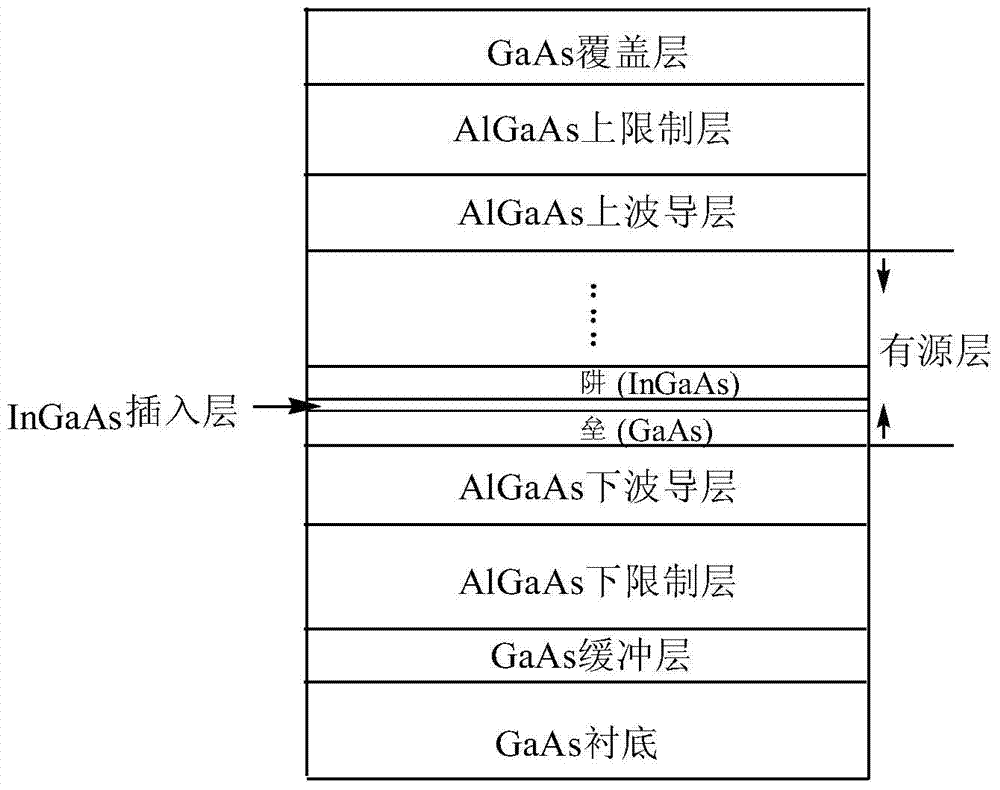

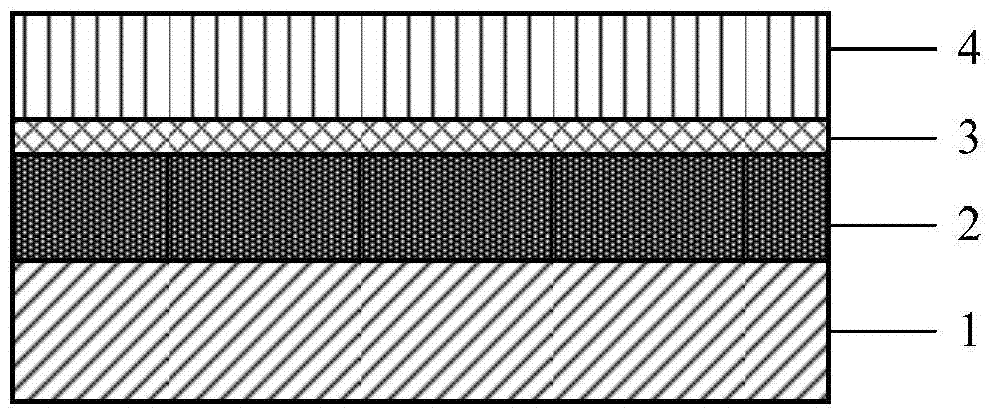

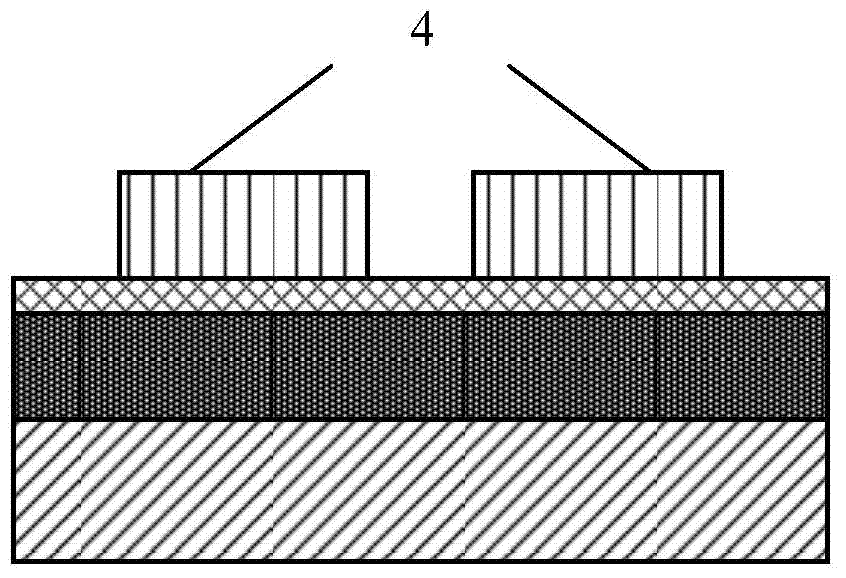

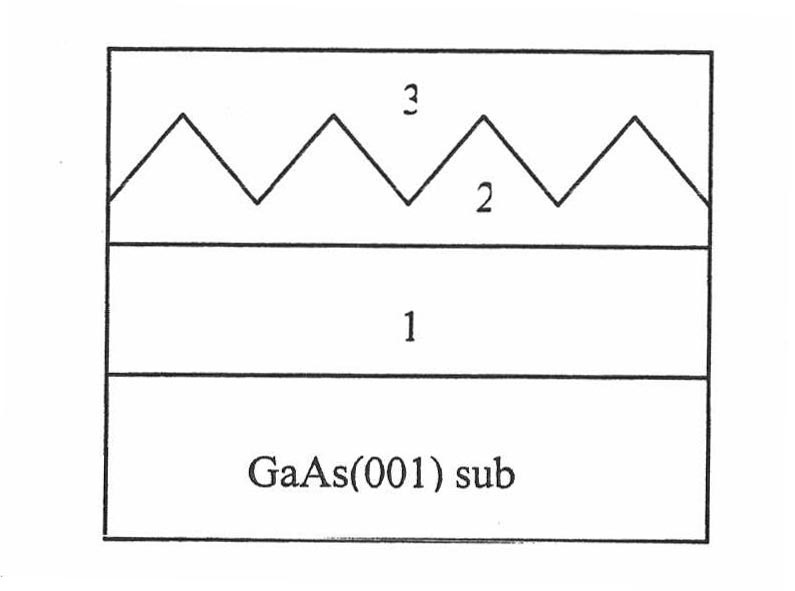

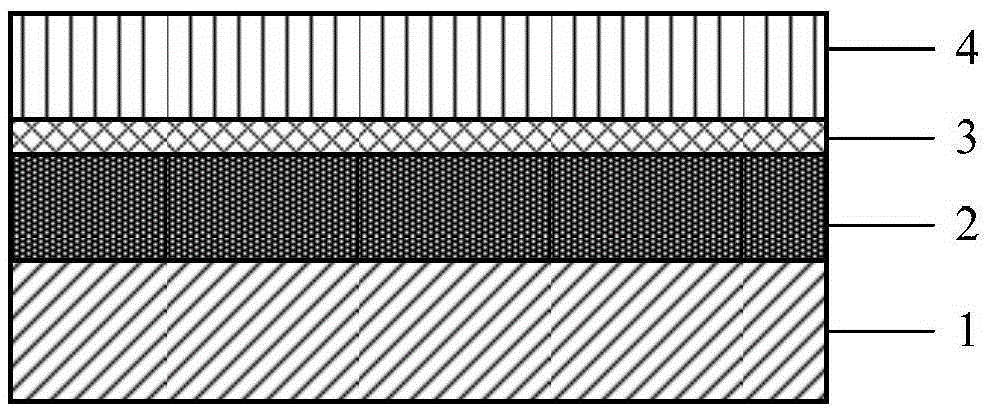

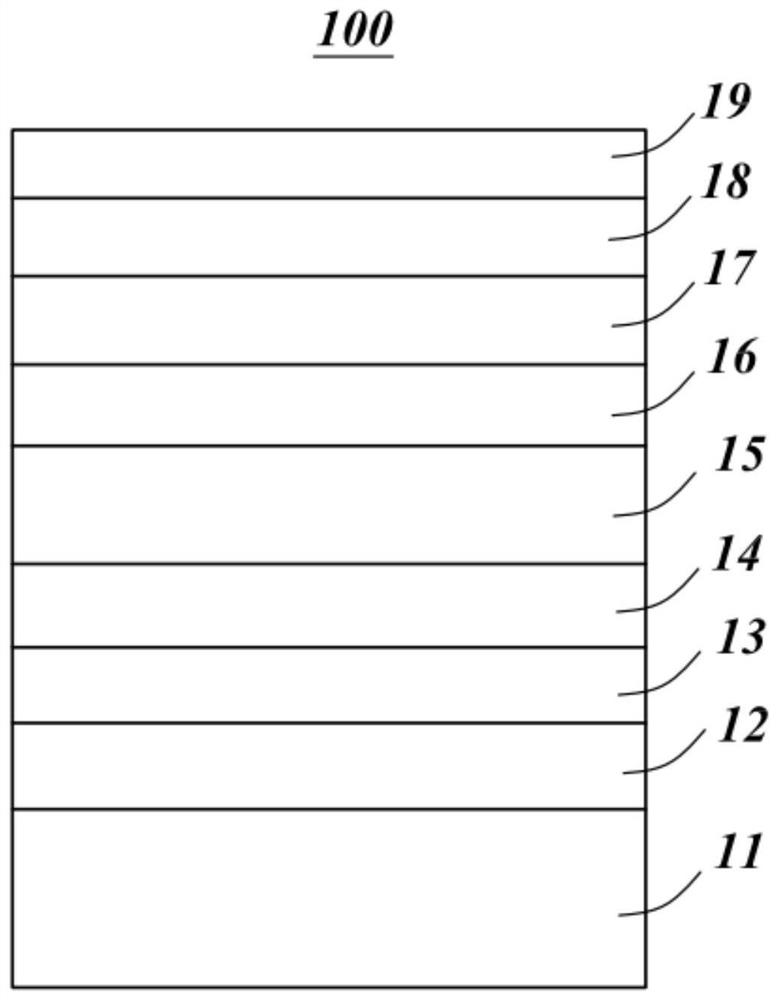

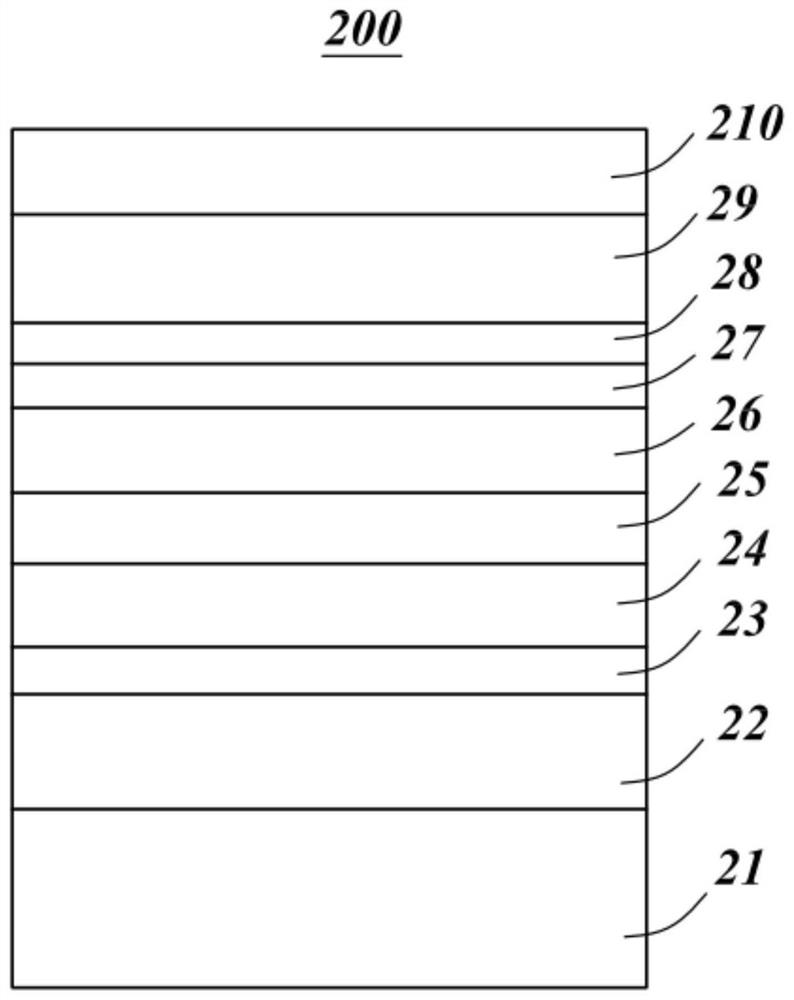

Epitaxial structure with interposed layer quantum well semiconductor laser

InactiveCN103779786AEase character fitImprove photoelectric performanceLaser detailsSemiconductor lasersQuantum wellWaveguide

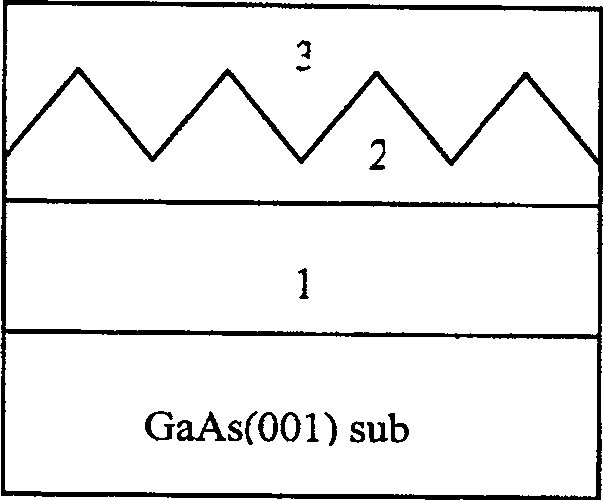

The invention relates to an epitaxial structure with an interposed layer quantum well semiconductor laser. The invention discloses a preparation method of a semiconductor laser with a special structure. The structure comprises from the top to the bottom a GaAs substrate, a GaAs buffer layer, an AIGaAs lower restriction layer, an AIGaAS lower waveguide layer, an active layer, an AIGaAs upper waveguide layer, an AIGaAs upper restriction layer and a GaAs cover layer. In the structure, a thin InGaAs layer whose GaAs or InP or In component content is quite low (compared to the In component in a quantum well) is inserted between the quantum well and the barrier of the active layer, so that the quality adaption between the quantum well and the barrier can be effectively relieved, the interface quality is improved, the stress is lowered, a quite low threshold current density is obtained, and the photoelectric performance of the semiconductor laser device is improved.

Owner:TAIYUAN UNIV OF TECH +1

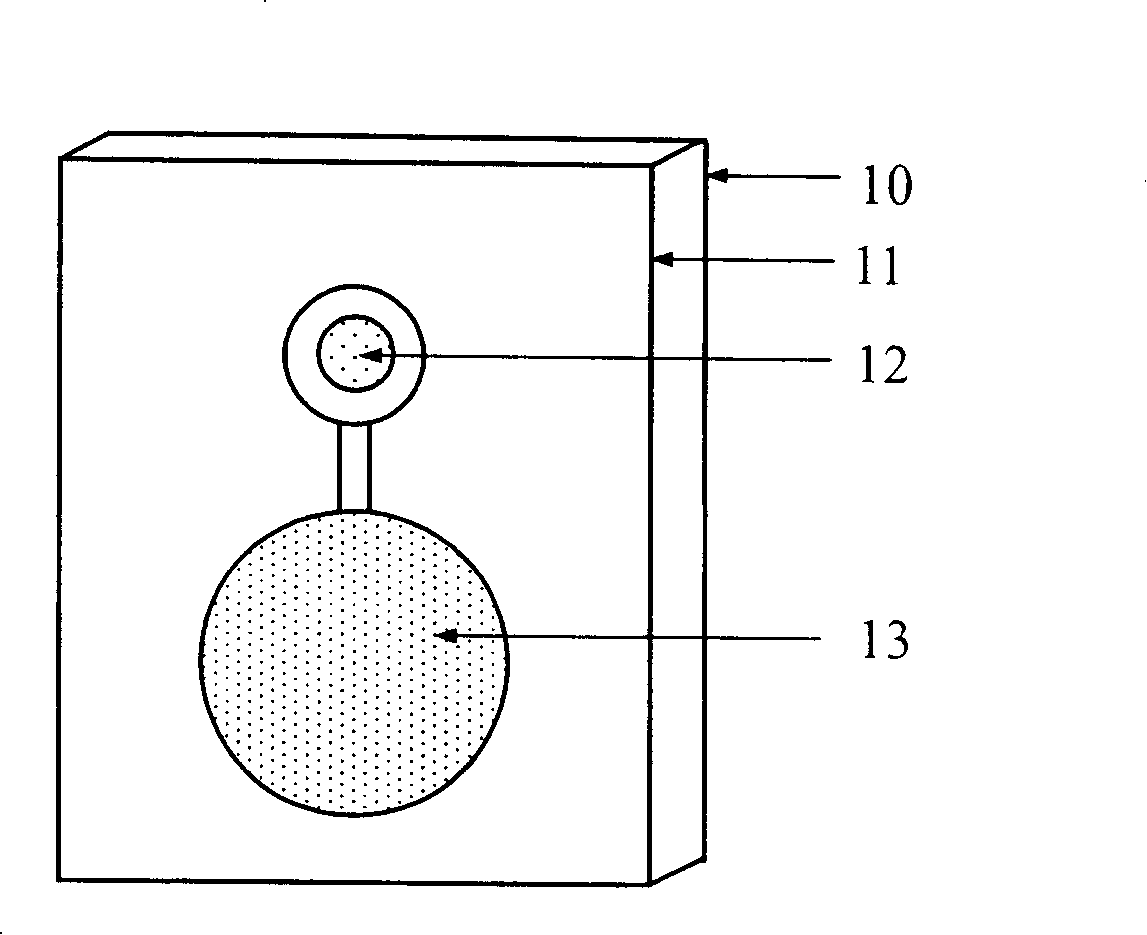

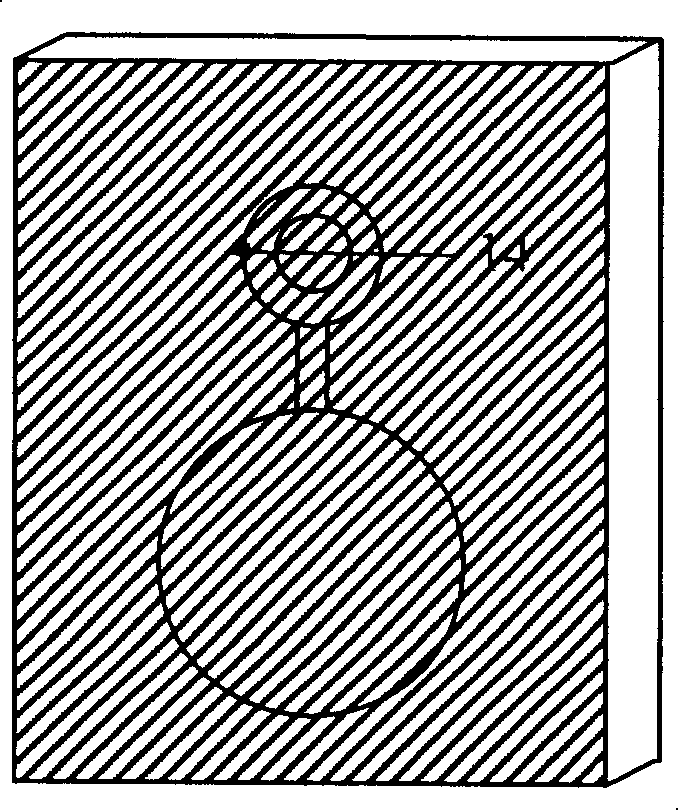

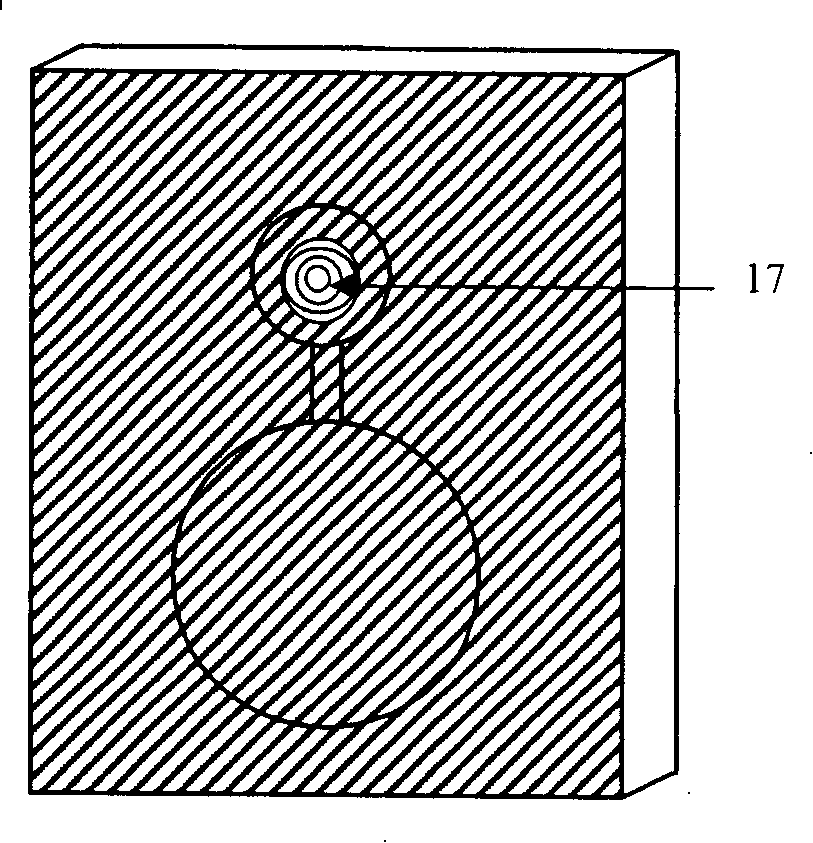

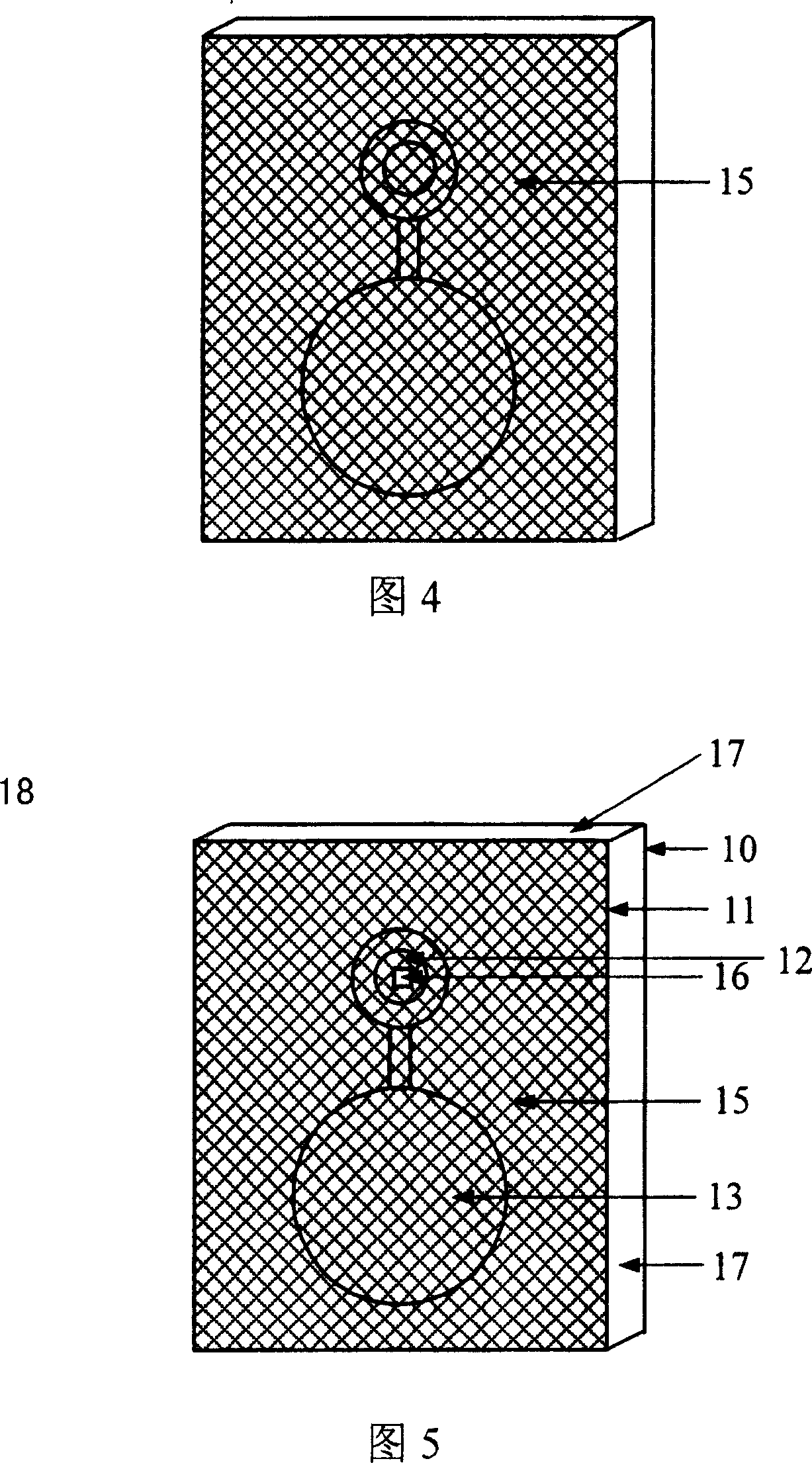

Making method for micro-hole vertical cavity radiation laser

InactiveCN101145672ASmall sizeAchieve integrationLaser detailsSemiconductor lasersVertical-cavity surface-emitting laserWavelength

A method for preparing microporous vertical cavity surface emitting laser comprise the following steps: (1) collecting a common vertical cavity surface emitting laser comprising a N-electrode, an emitting cavity surface, an emitting hole, and a P-electrode; (2) fabricating an anti-reflection film on the emitting cavity surface of the common vertical cavity surface emitting laser; (3) etching the anti-reflection film on the P-electrode by using the focused ion beam etching technique; (4) fabricating a metal film on the anti-reflection film of the emitting cavity surface and the P-electrode; and (5) etching the micropores with subwavelength on the emitting hole to finish the preparation of the microporous vertical cavity surface emitting laser.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

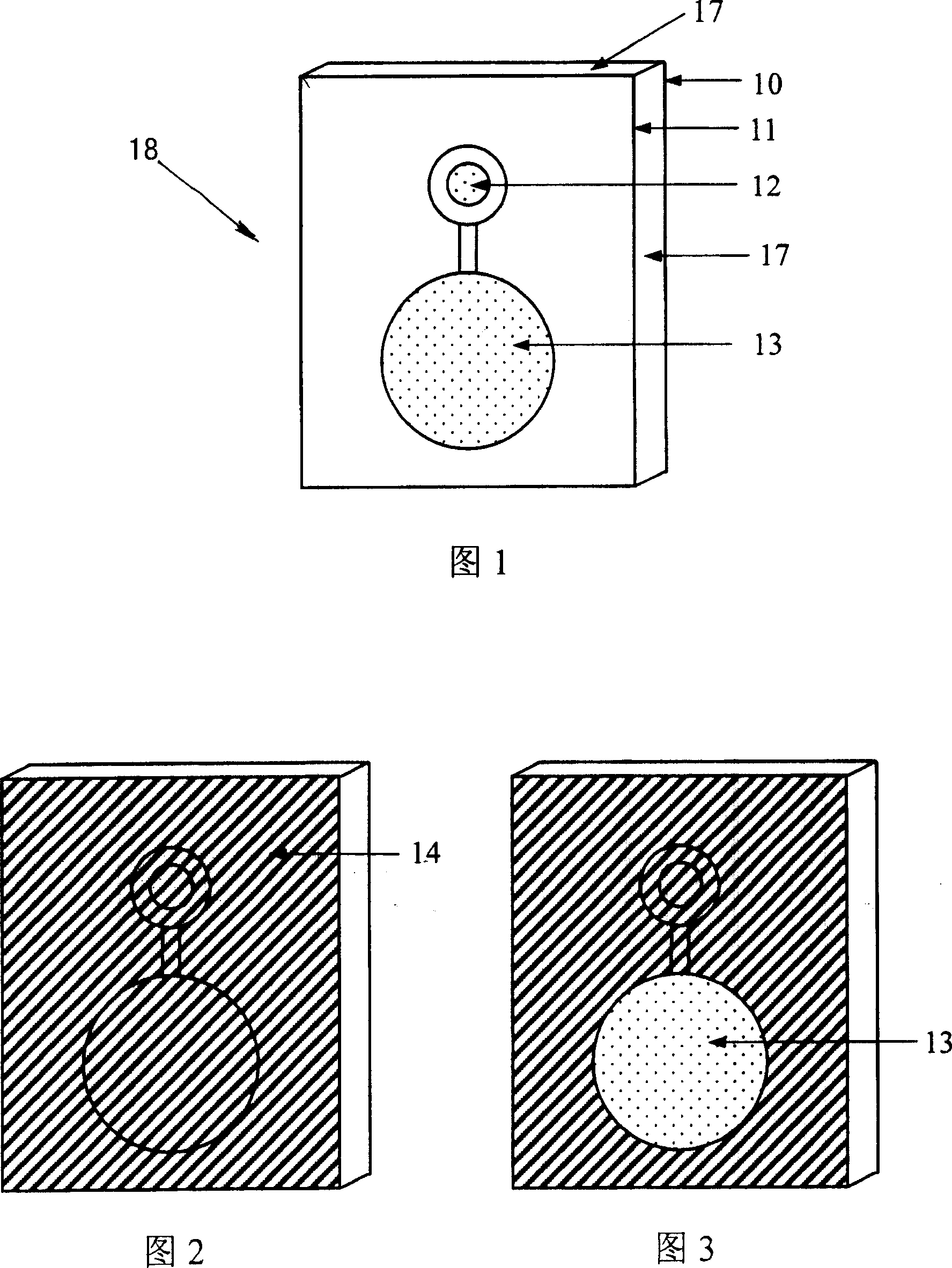

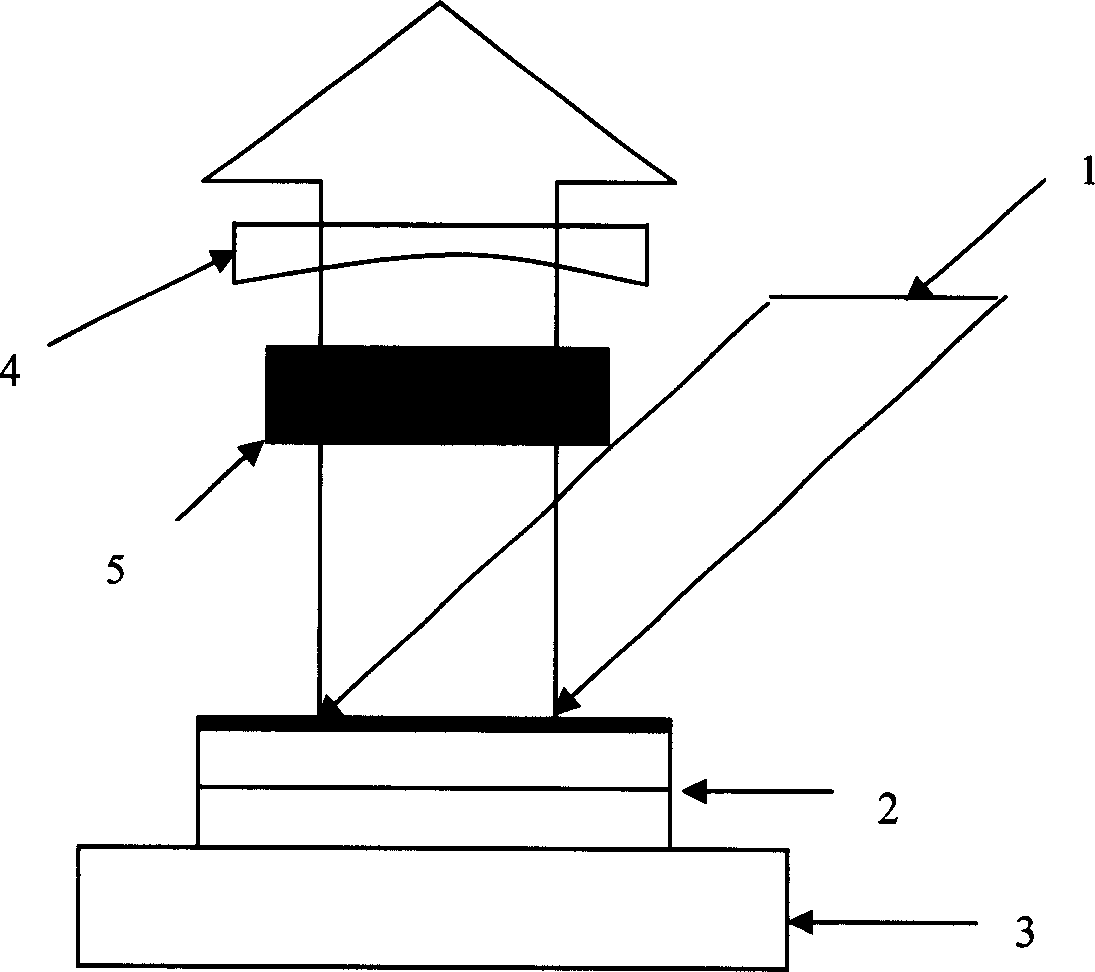

Optical pump high-power vertical external cavity emitting laser

InactiveCN1710763ASimple processReduce photolithography processLaser detailsSemiconductor lasersEtchingProtection layer

Structure of the disclosed laser includes pump light source, epitaxial wafer, heat sink, outer cavity mirror, and double frequency crystal. The epitaxial wafer includes window layer, protection layer, active area, multiple layered Bragg reflector, and substrate. The active area includes quanta trap layer, and absorbing layer. Characters are that quanta trap layer includes light pumped vertical outer cavity face emission in high power of 2-3 pieces of quanta traps so as to raise fill factor of laser, efficiency of outer quanta trap, output power of device, and lowers current density of threshold value. The invention obtains circular symmetrical, linear polarized laser output in high power near to diffraction limit. Using the light pump mode, the invention possesses features of simplifying technique, reducing procedures such as photo etching, preparing poles, hard coat etc, and cost, as well as raising yield.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Short wavelength AlGaInP red light semiconductor laser

ActiveCN105390937AImprove reliabilityLimit escapeLaser detailsSemiconductor lasersLower limitQuantum well

A short wavelength AlGaInP red light semiconductor laser structurally comprises a substrate, a lower buffer layer, a lower limiting layer, a lower waveguide layer, a quantum well layer, an upper waveguide layer, an upper limiting layer, an upper buffer layer and an ohmic contact layer in sequence from the bottom to the top; the lower buffer layer is an AlxIn1-xP component gradual change layer, and x linearly gradually changes to 0.6 from 0.5; the upper buffer layer is an AlyIn1-yP component gradual change layer, and y linearly gradually changes to 0.5 from 0.6; the upper waveguide layer and lower waveguide layer are both (AlzGa1-z)0.6In0.4P; the lower limiting layer and upper limiting layer are both Al0.6In0.4P. By the AlInP component gradual change buffer layer, an In component of the limiting layers and the waveguide layers is reduced to 0.4, the refraction index of a material of the limiting layers is reduced, a bandgap of a material of the waveguide layers is increased, photons and carriers are better limited, and meanwhile, the quantum well layer can obtain short wavelength light of 590-620nm under a lower strain condition.

Owner:Shandong Huaguang Optoelectronics Co. Ltd.

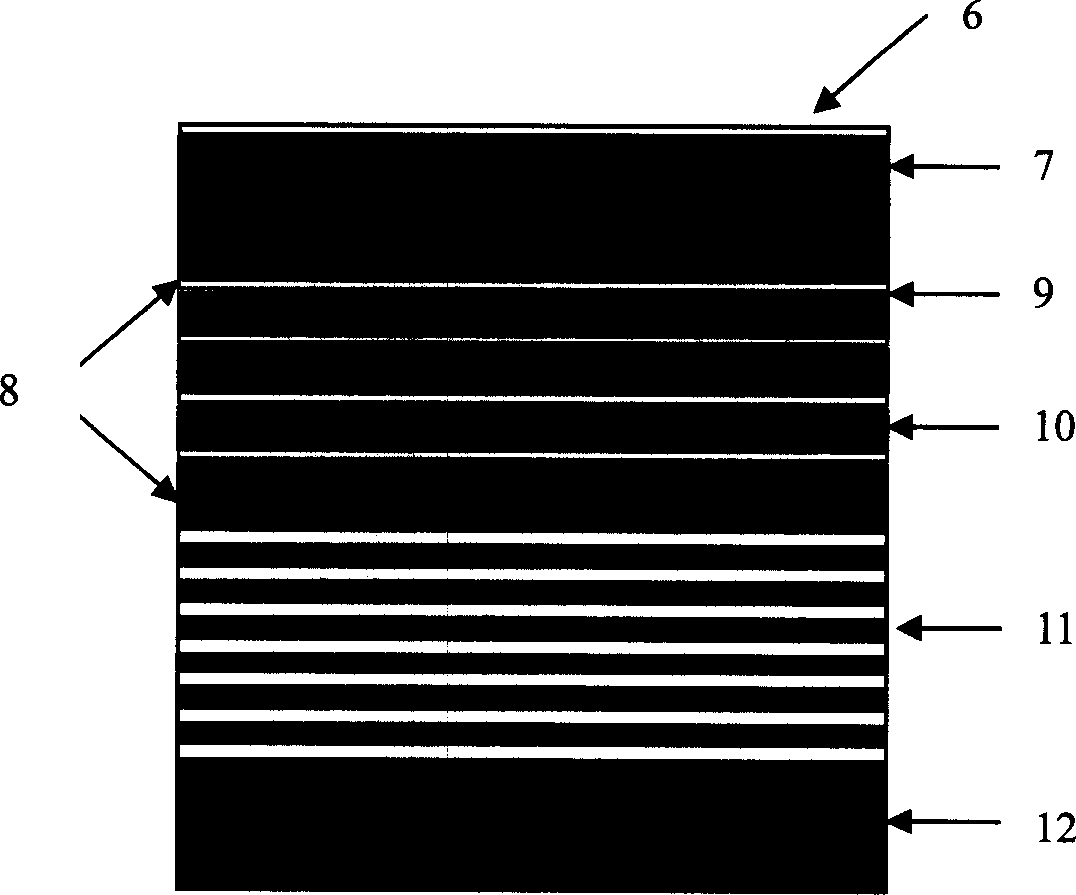

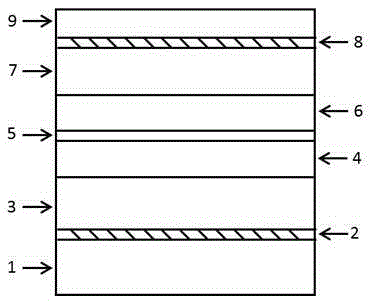

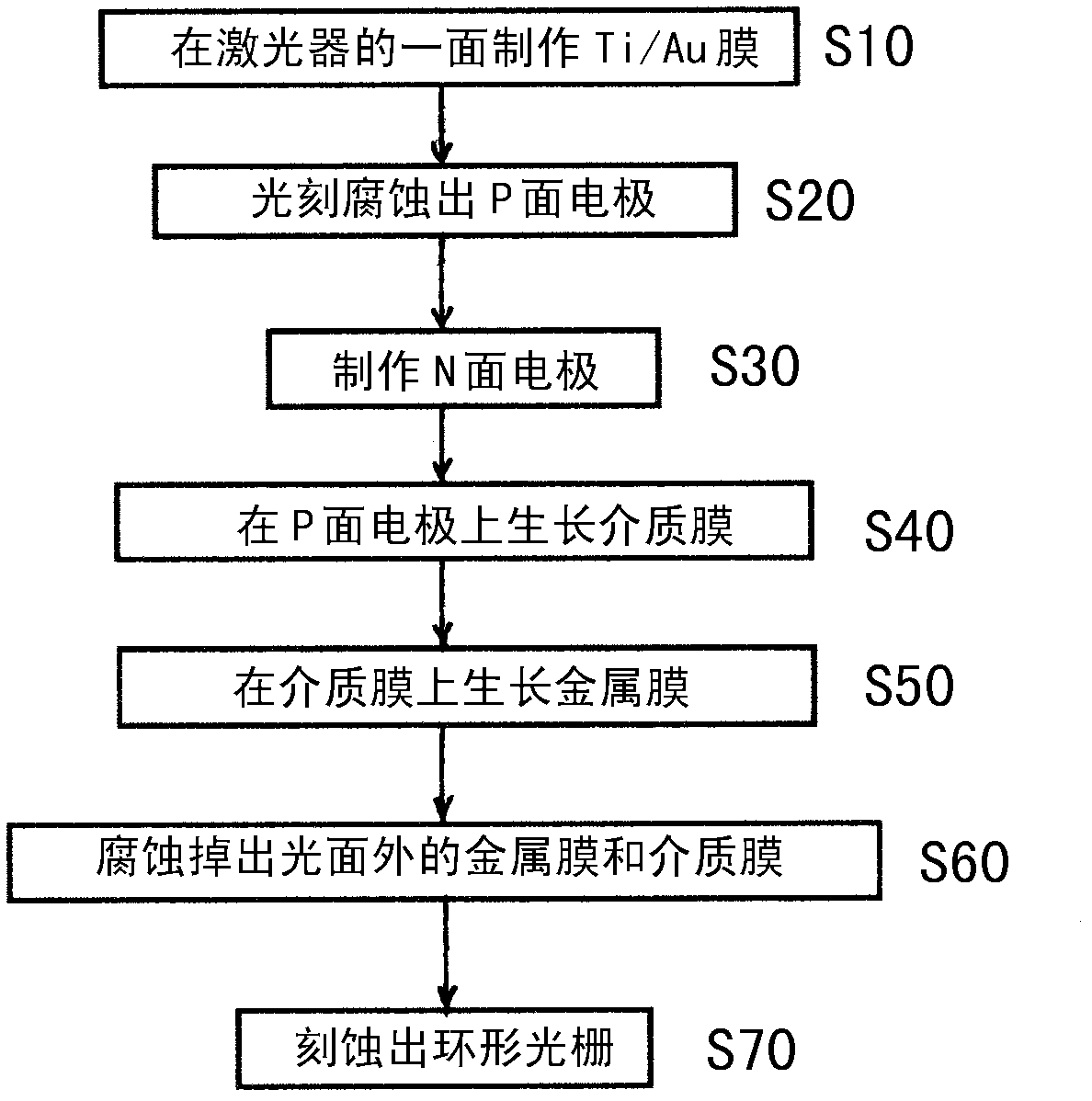

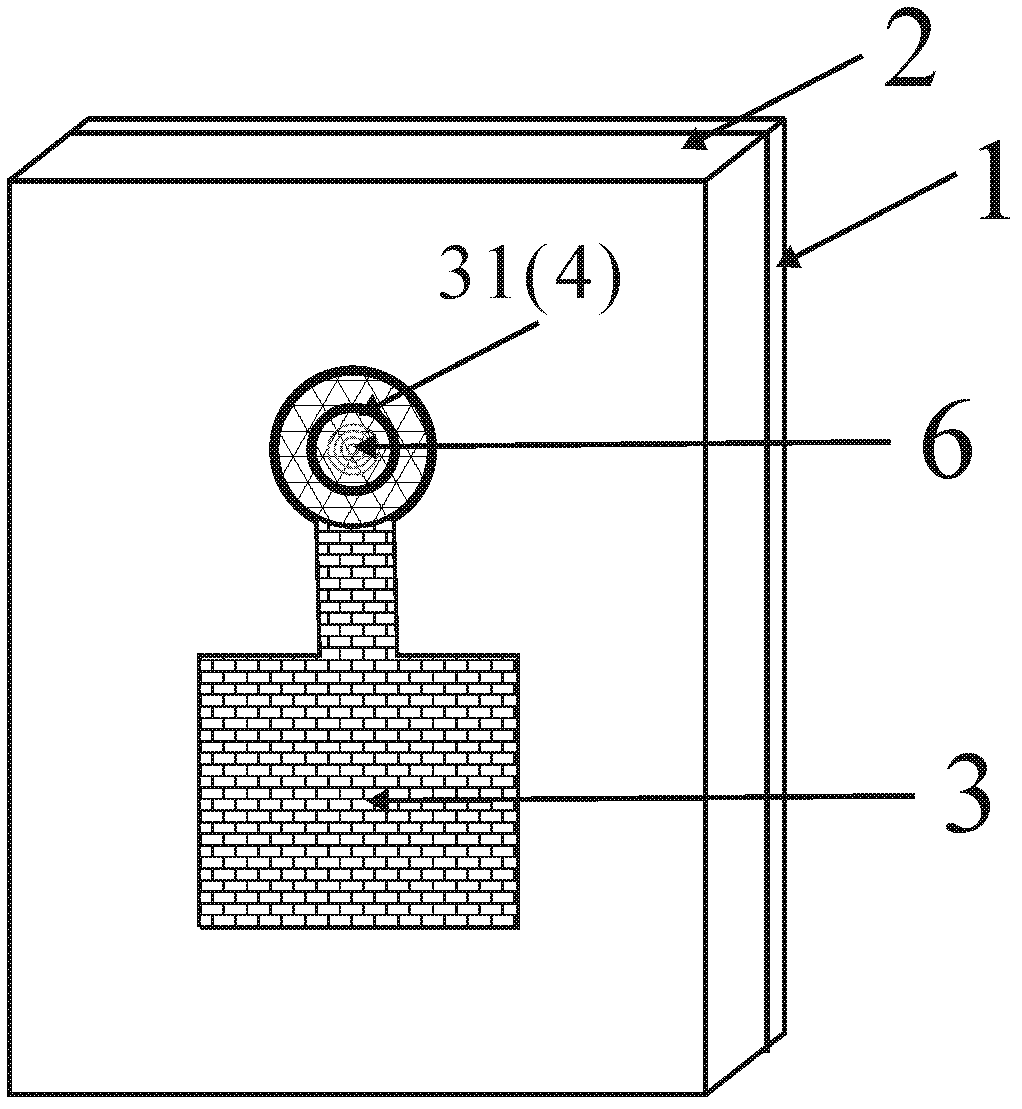

Sub-wavelength self-focusing radial polarization vertical-cavity surface-emitting laser and preparation method thereof

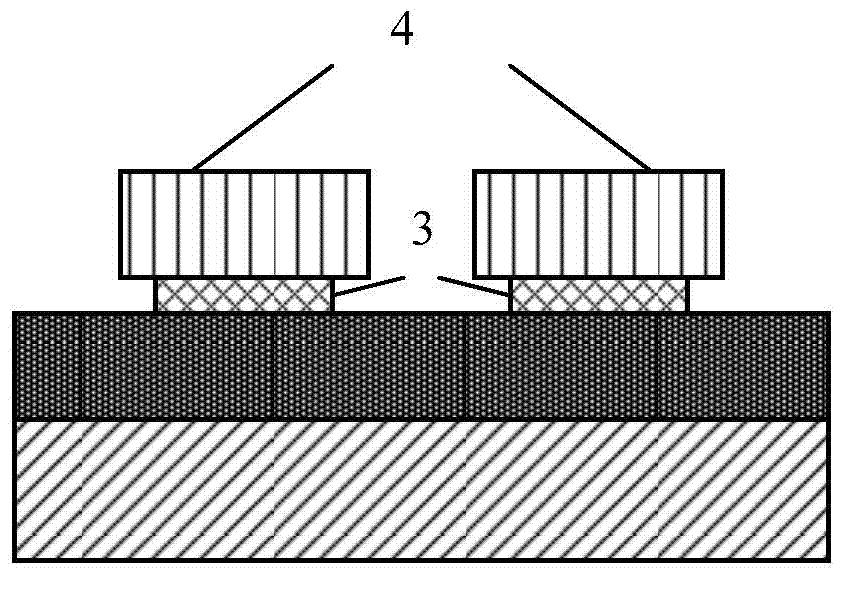

InactiveCN102637999ALower threshold current densityCompact structureLaser detailsSemiconductor lasersVertical-cavity surface-emitting laserLight spot

The invention discloses a sub-wavelength self-focusing radial polarization vertical-cavity surface-emitting laser which comprises a vertical-cavity surface-emitting laser, an N electrode, a dielectric film and an annular grating, wherein a P electrode is arranged on one surface of the vertical-cavity surface-emitting laser; the middle of the annular part of the P electrode is a light emitting surface; the N electrode is arranged on the other surface of the vertical-cavity surface-emitting laser; the dielectric film is arranged on the light emitting surface of the P electrode; and the annular grating is arranged on the dielectric film. According to the invention, the radial polarization output is obtained according to the polarization selection characteristic of the sub-wavelength annular metal grating, and the self-focusing sub-wavelength light spot is obtained through the coherence of each annular groove.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

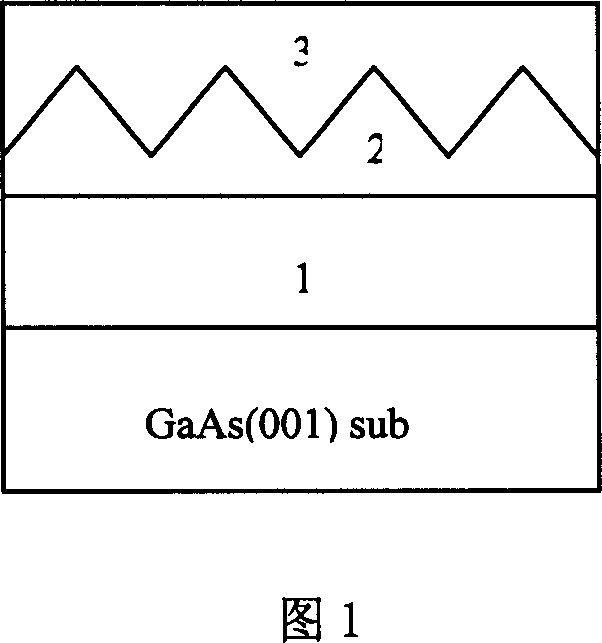

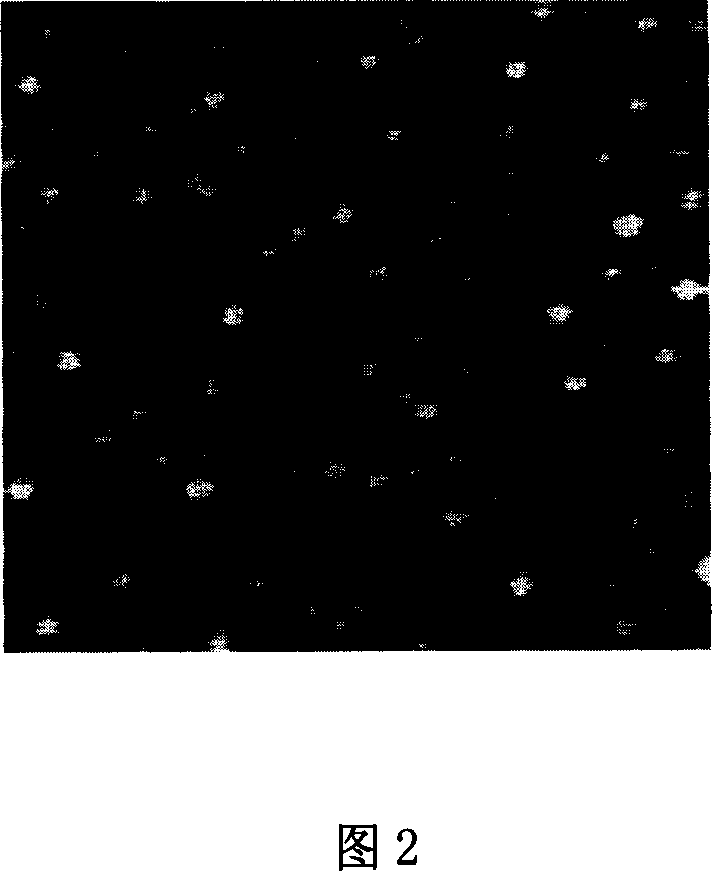

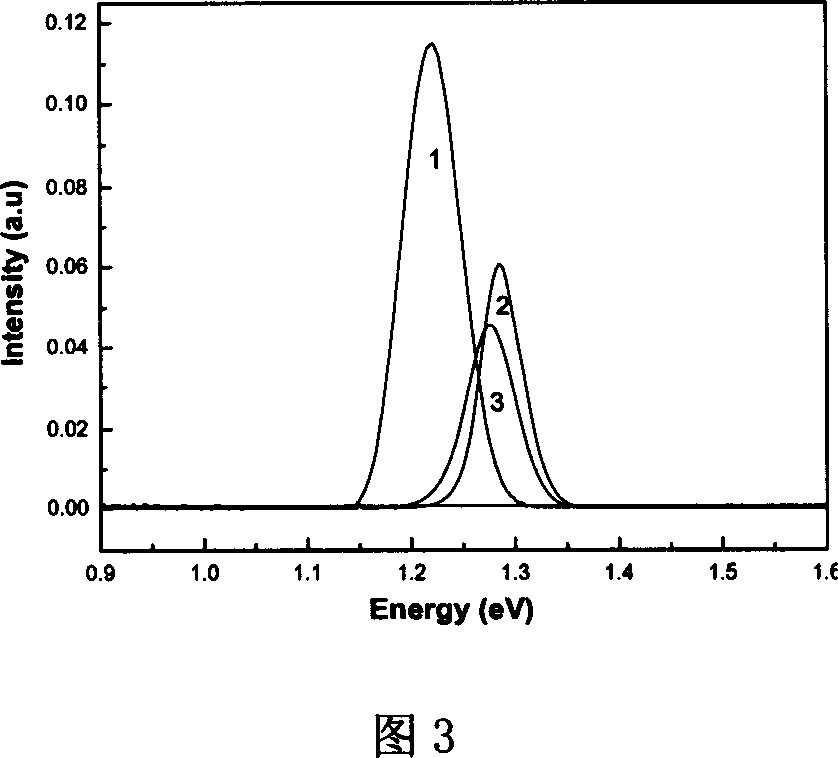

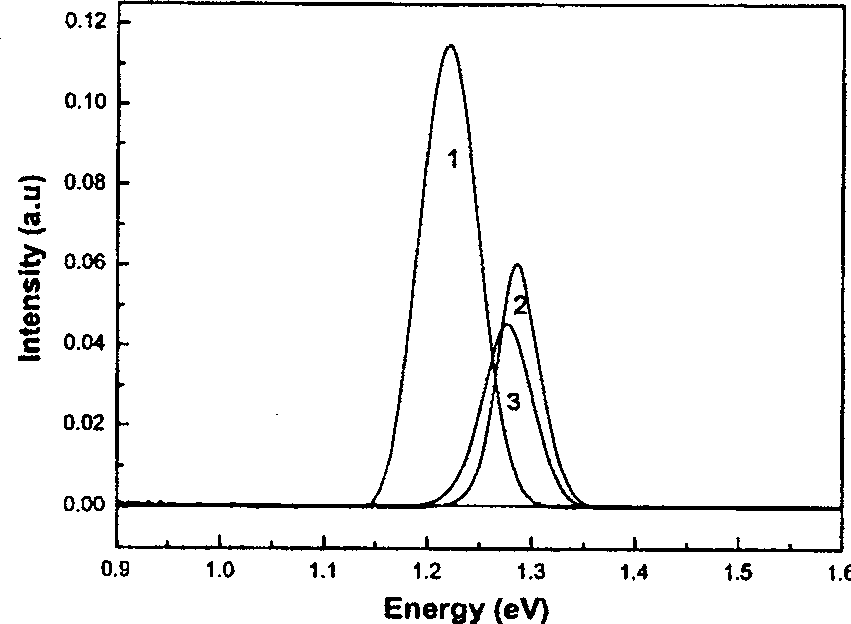

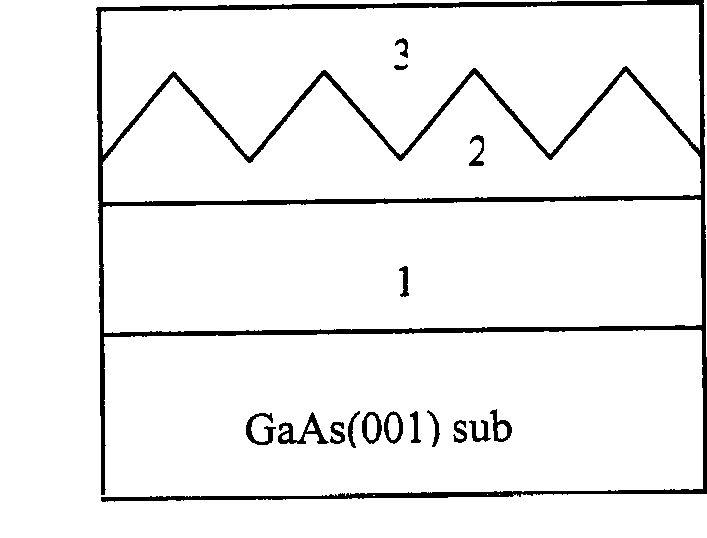

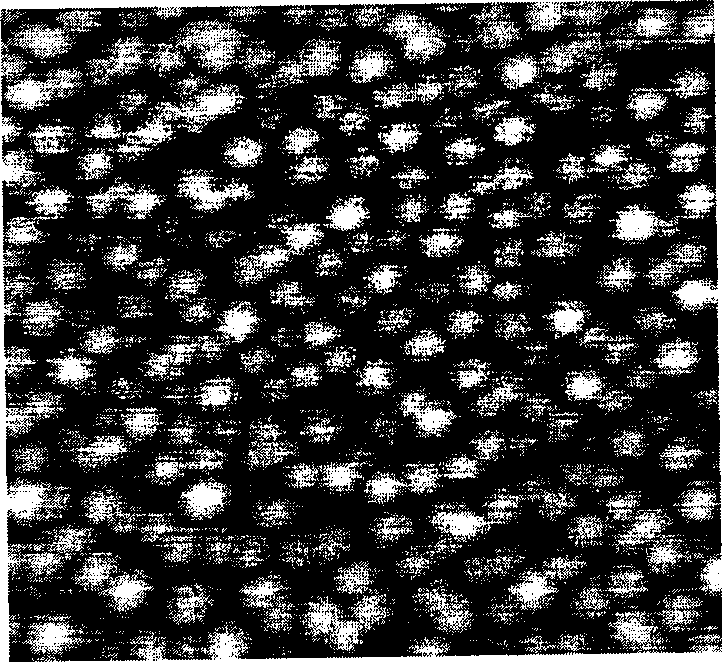

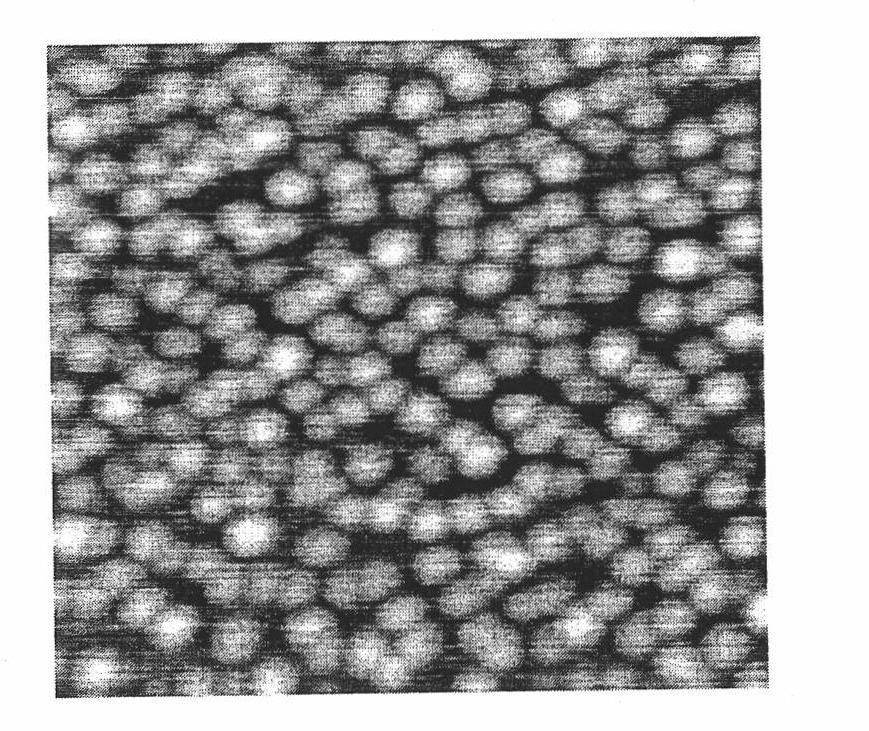

Extension developing method for high-power semiconductor quanta point laser material

InactiveCN1925175AHigh planar densityGood size uniformityLaser detailsSemiconductor lasersHigh intensityErbium lasers

This invention relates to semiconductor laser technique field and provides one InGaAs / GaAs SK growth high intensity quantum point extension layer structure to realize this extension molecule beam semiconductor quantum laser materials method. Through accurate control molecule beam extension growing condition and using submolecule single layer to control quantum points component, extensive thickness, shape structure to realize room temperature PL spectrum of 1.02-1.08 micrometer band.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

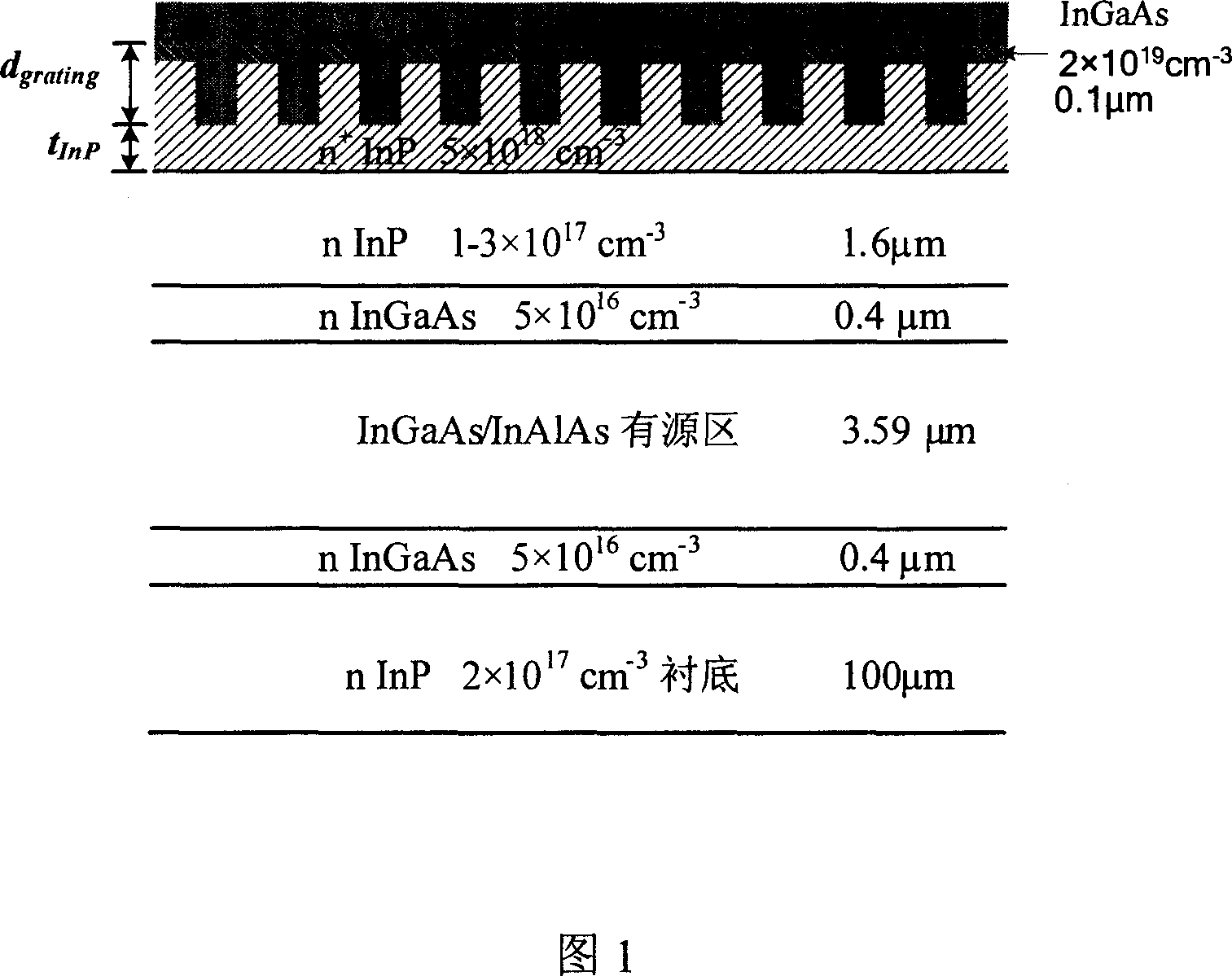

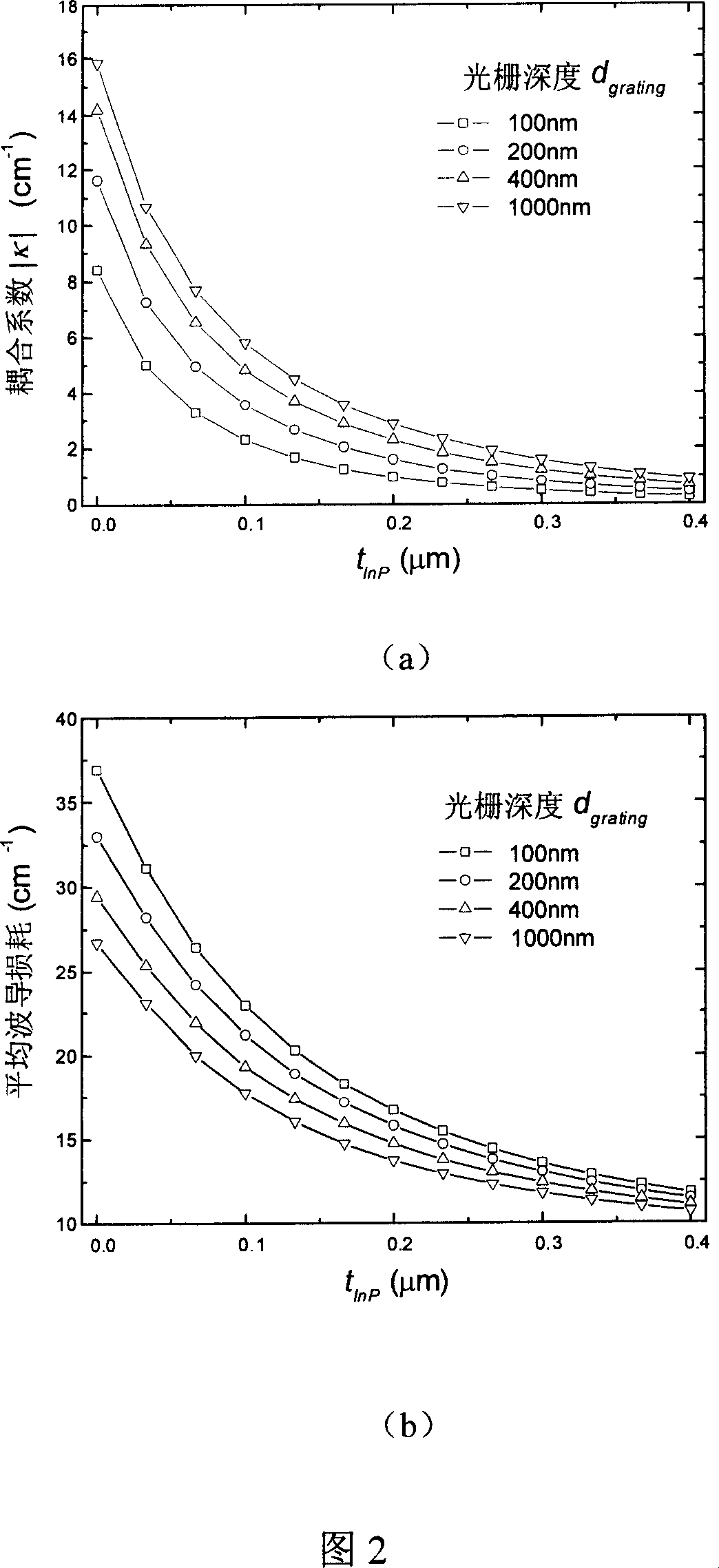

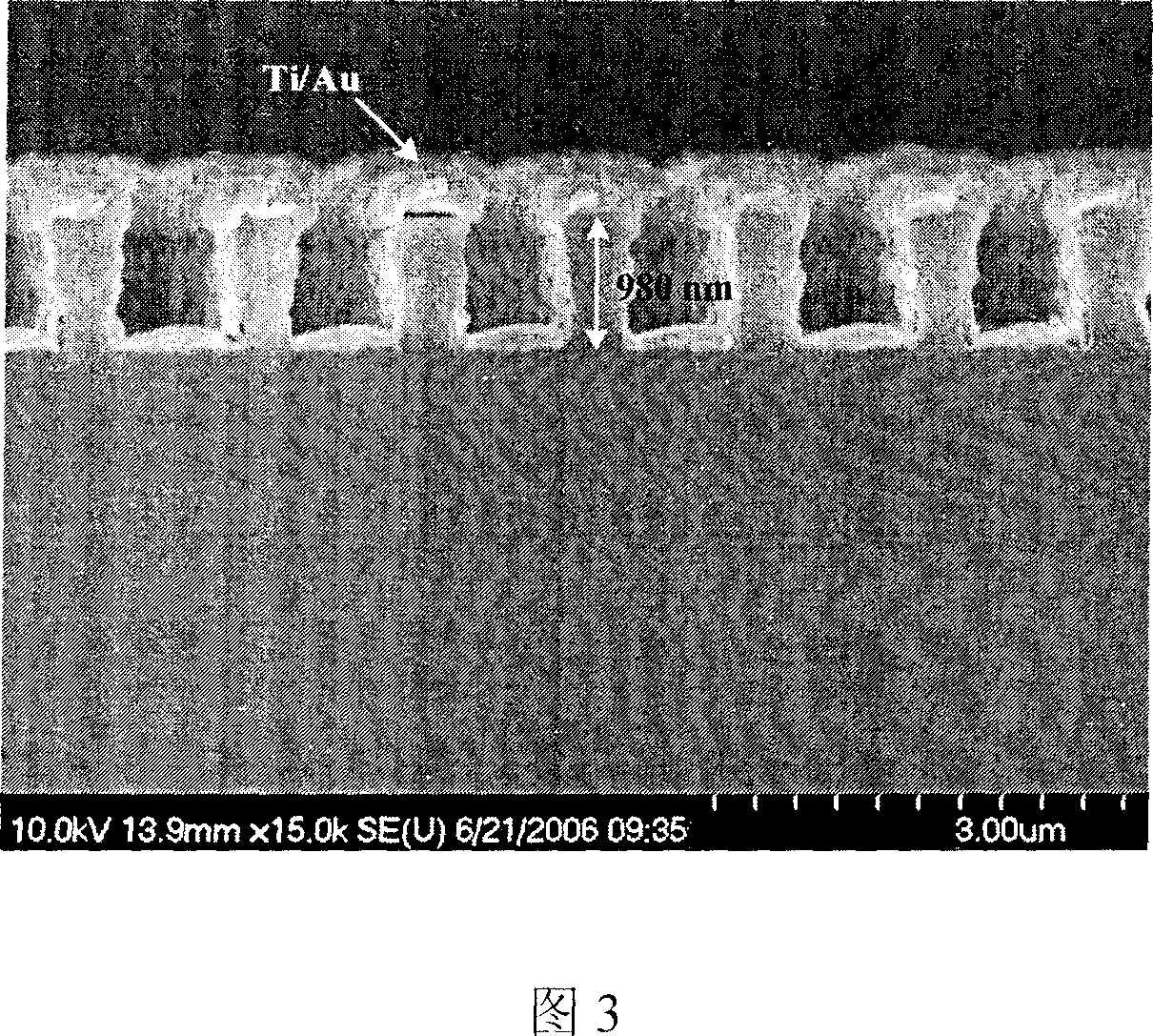

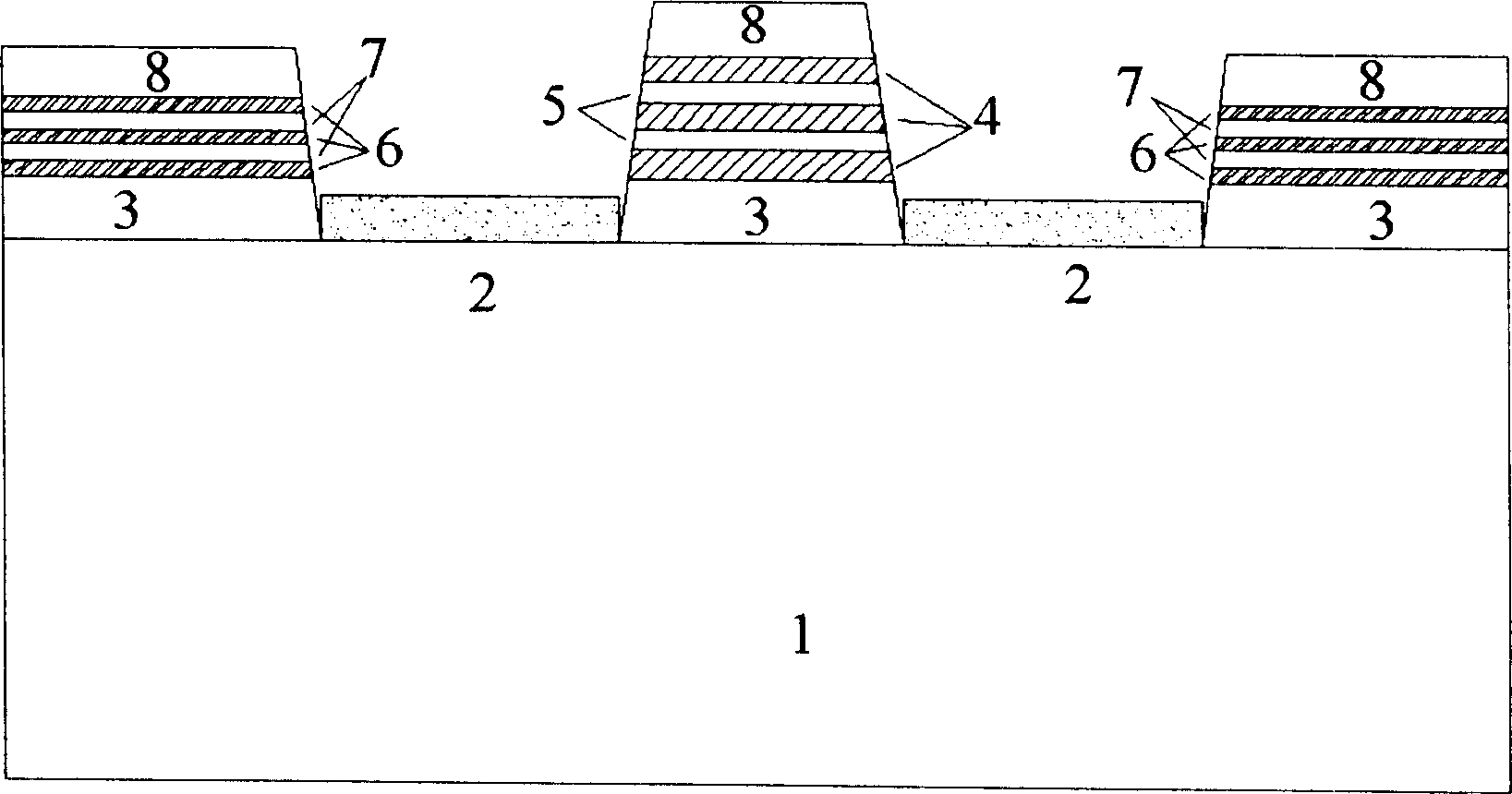

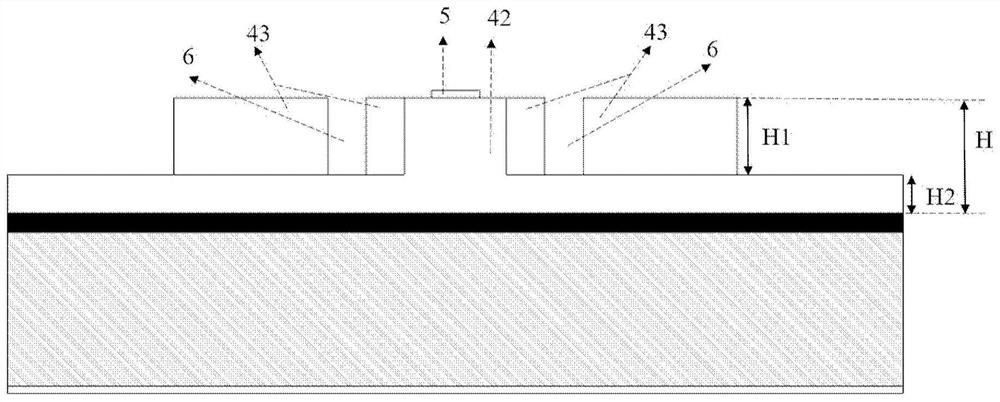

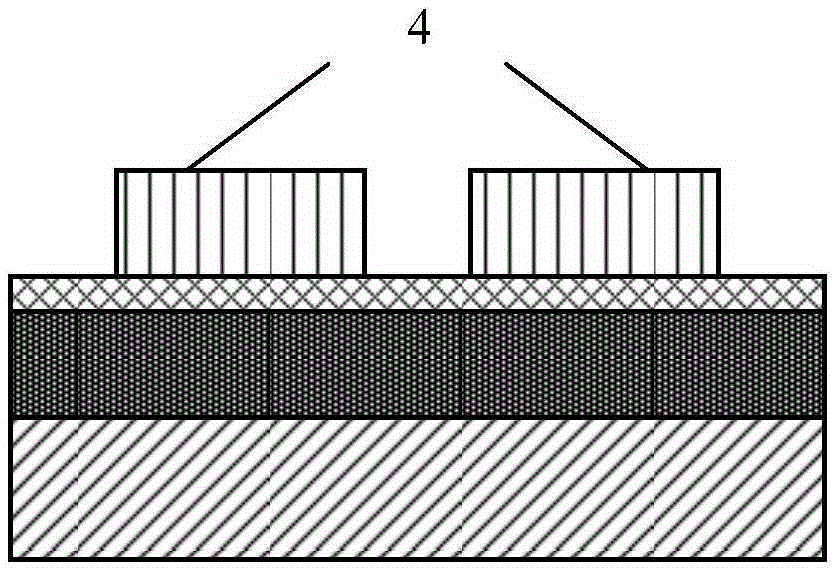

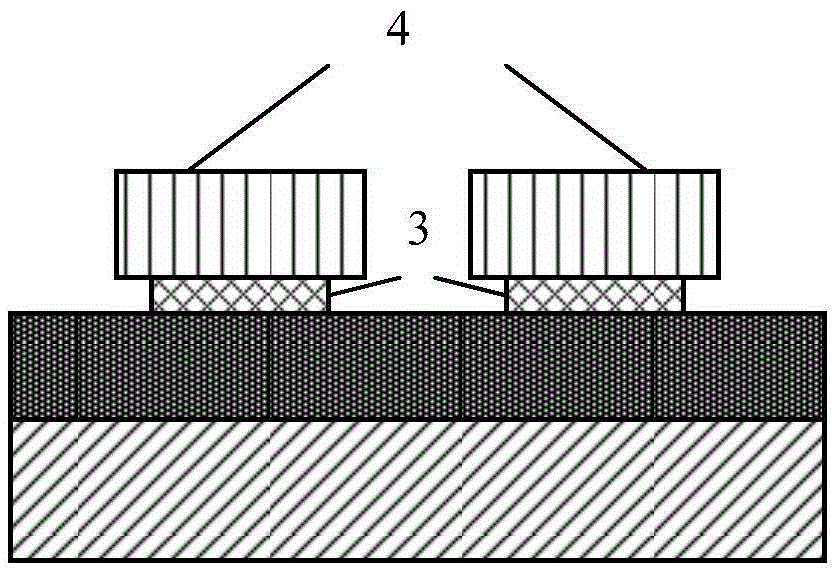

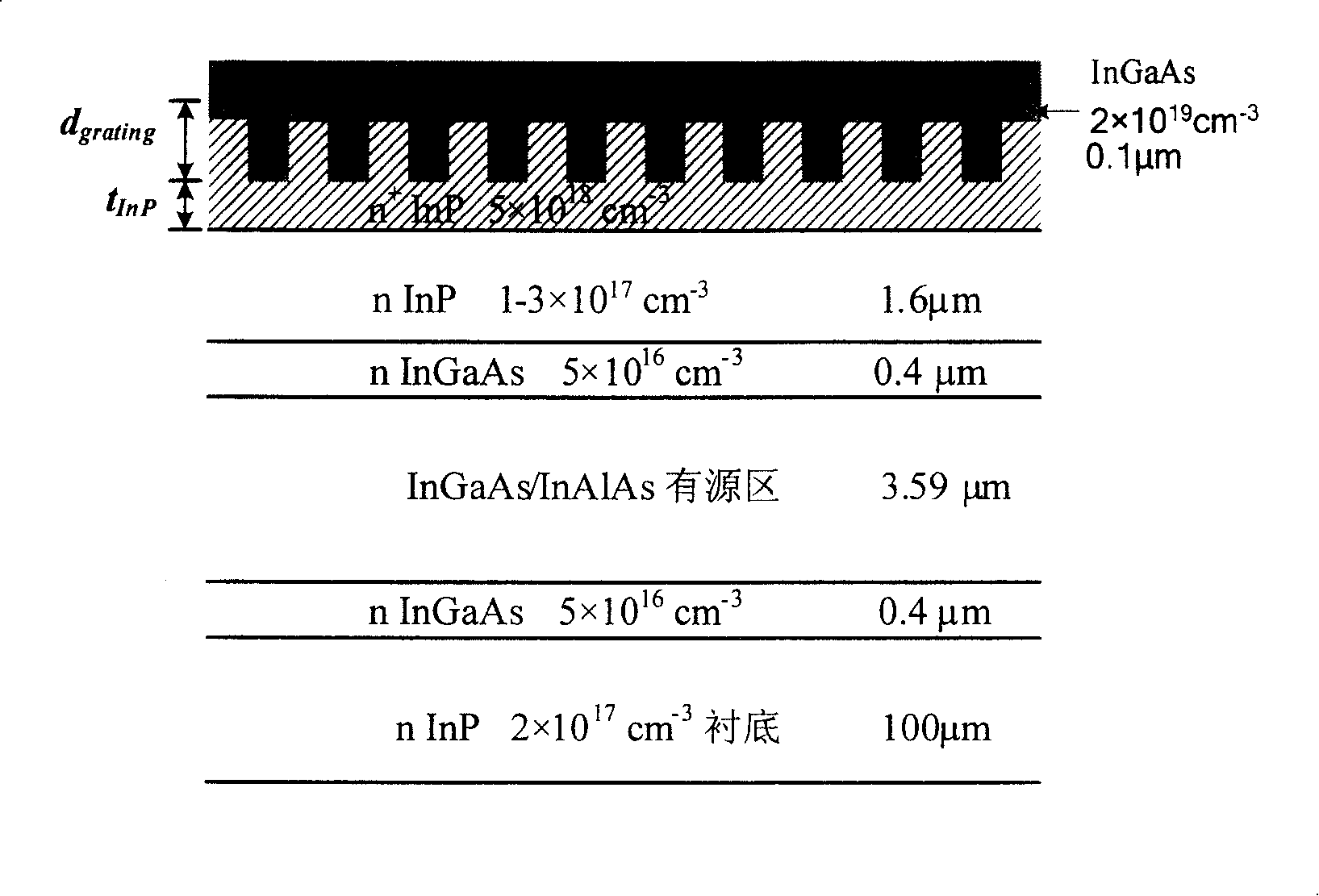

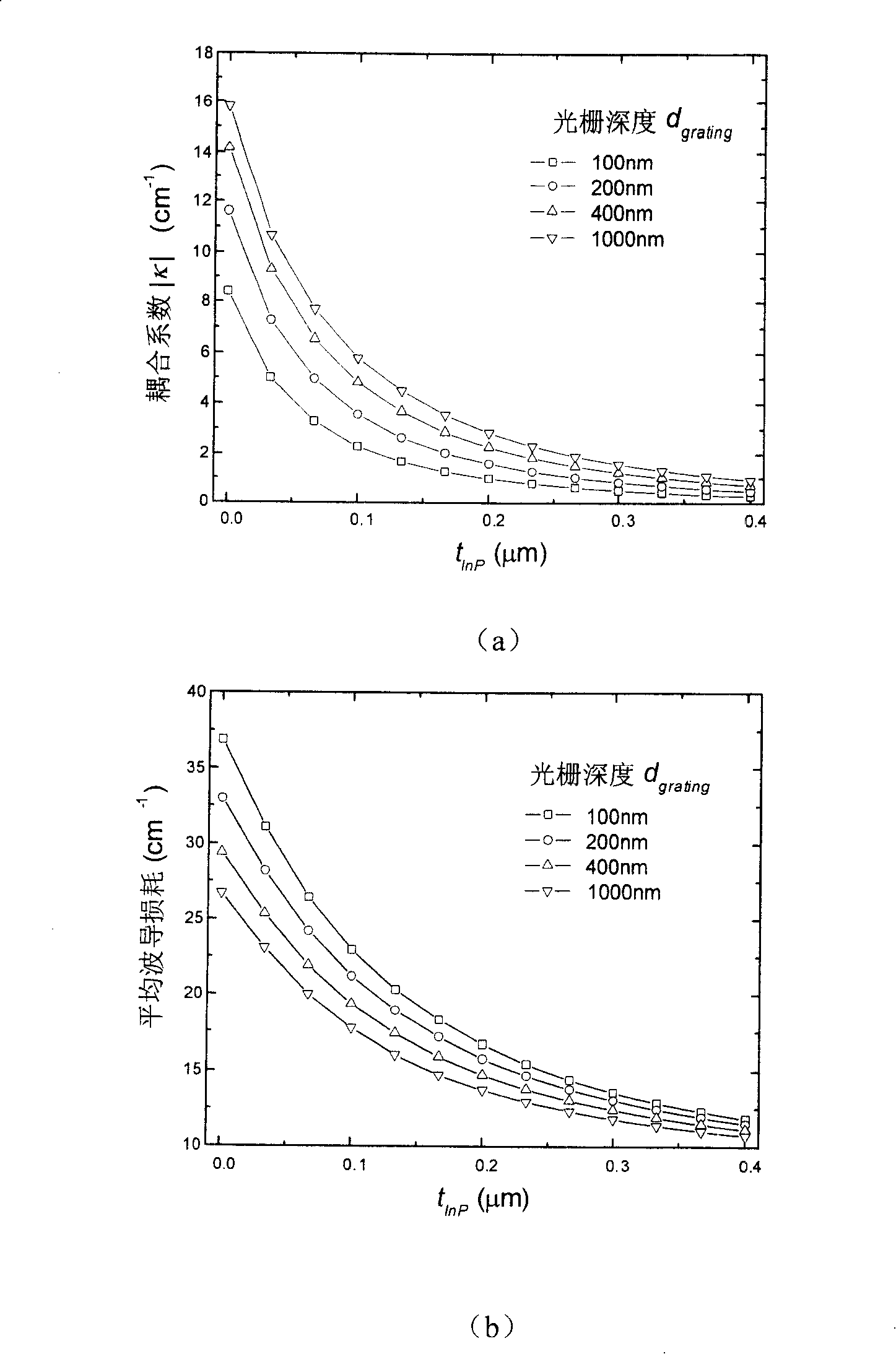

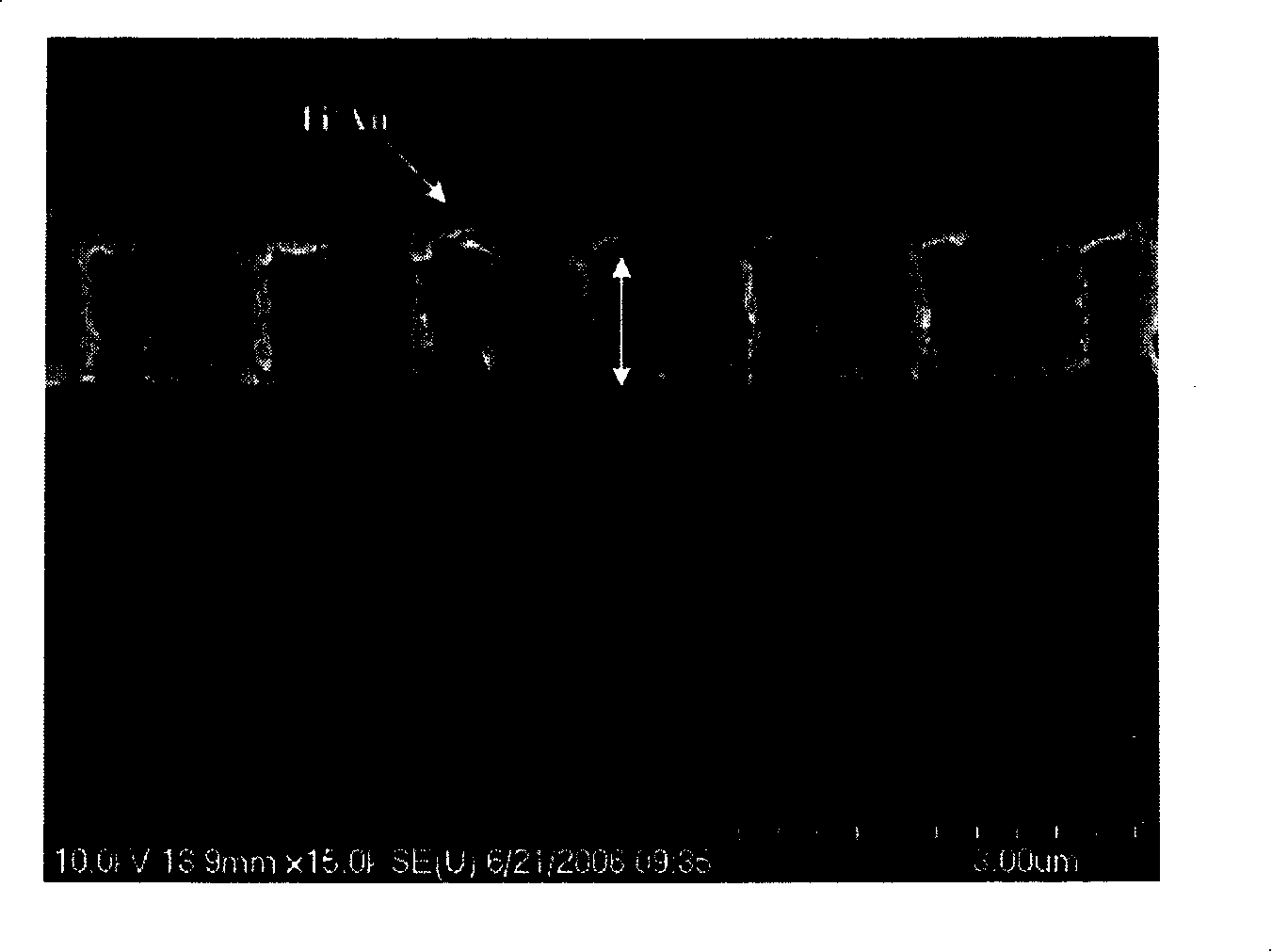

Method for preparing wave guide and grating structure of adjustable distributive feedback quantum cascade laser and above said grating

InactiveCN1945910AAppropriate distribution of feedback coupling coefficientsReduced waveguide lossOptical wave guidanceLaser detailsGratingQuantum cascade laser

This invention relates to a waveguide and a grating structure of an adjustable distribution feed back quanta cascade laser obtaining low threshold value current density and high side mode suppression ratio and a method for preparing first order grating of laser meeting the requirement, in which, the laser waveguide and the grating structure is a limit structure in the waveguide made up of a deep first order grating and a thin heavy doped semiconductor layer, said grating corrosion technology is to utilize the InGaAs / InP structure as the corrosion sacrificial layer of the grating and select different corroding liquid matches to get a grating structure with the depth adjustable and accuracy controllable.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Method for mixing organic gallium source selective zone growing indium-gallium-arsenic-phosphor multiple quantum well

InactiveCN1426143ALower threshold current densityImprove efficiencyLaser detailsLaser active region structureIndiumTwo generation

This invention relates to a method for generating In Ga As P multiquantum-well in mixed organic GA source selection zone in whith, when selecting to generate In GaAsP multiquantum-well, triethyl Ga and trimethyl In generation limitation layer and base and their generation well are applied; the quantum-well material applying this method has large strain for the well zone in selection generation zone, yet small strain in nonselection generation zone; the strain variation is small of the base and limitation layer in the two generation zones which makes the selected generation zone quantum-well have higher luminous effect, guaranteeing realization of high performance electric absorbing modulating DFB laser.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Preparation method of GaN based laser diode with naturally cleaved cavity surface

InactiveCN1808801AGuaranteed uniformityLower threshold current densityLaser detailsSemiconductor lasersCopper platingElectroplating

This invention provides one method to process GaN extending layer natural deavage surface as laser chamber lens by use of metal Cu as chop hot deposition and supportive underlay to improve laser chamber lens optical quality and the parts integrated property index to omit polishing and dividing procedures. This invention has GaN and LD laser tube core structure not eh GaN extending slice with same isolation and circle to the laser tube core and uses deavage laser as supporting and as LD chip final deposition.

Owner:DONGGUAN INST OF OPTO ELECTRONICS PEKING UNIV

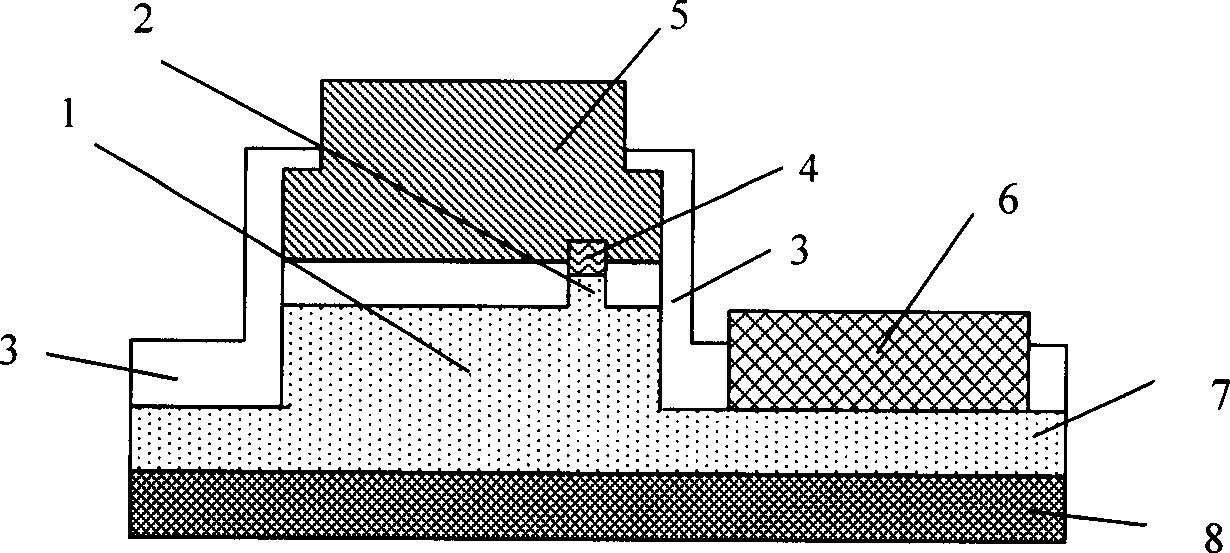

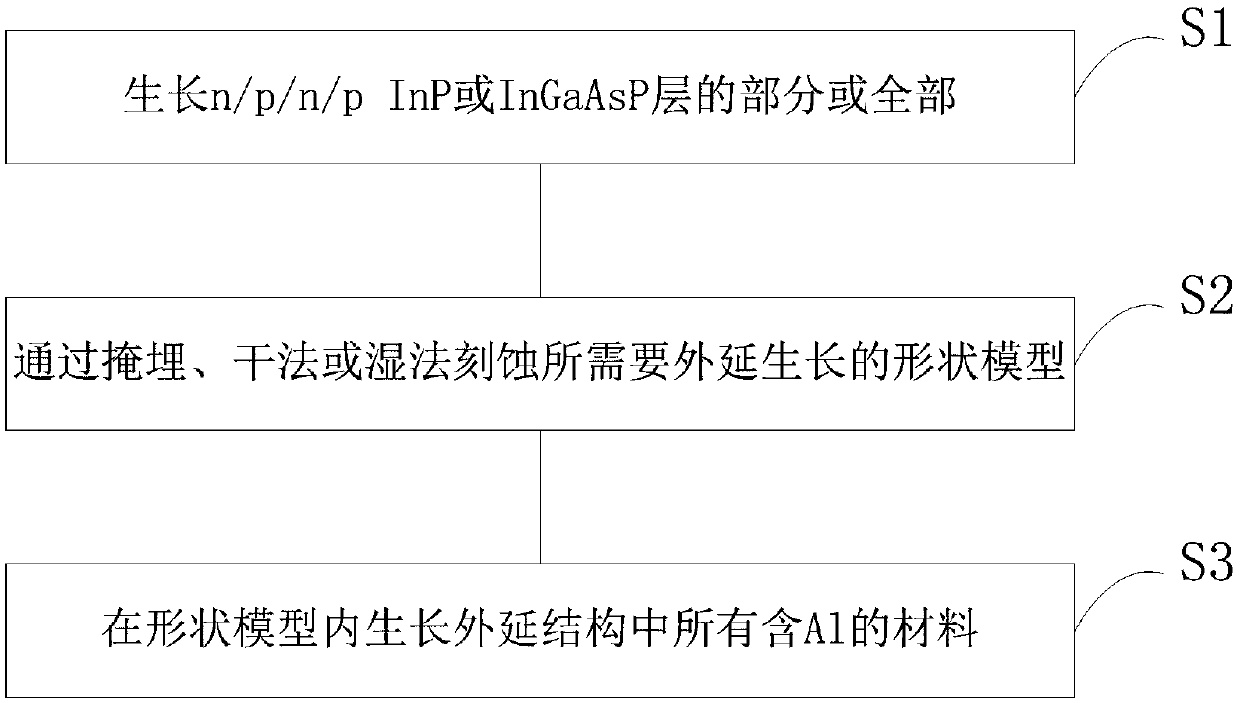

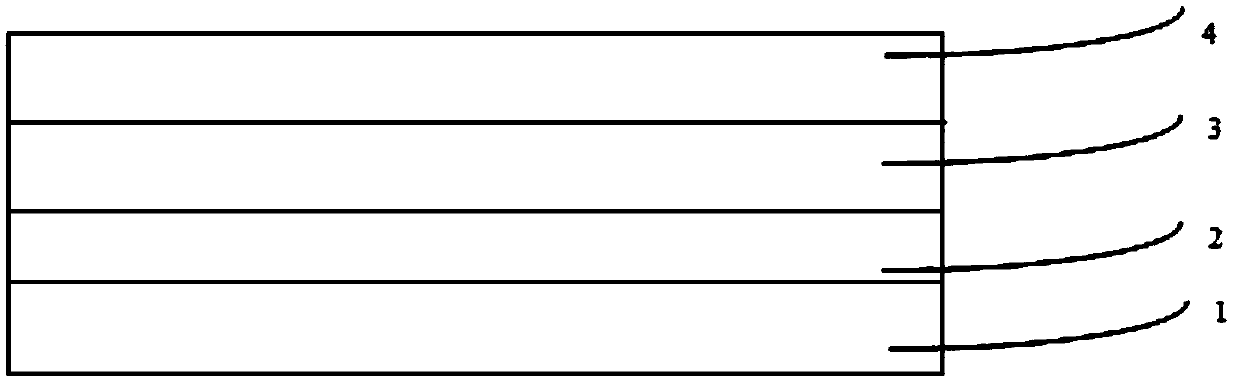

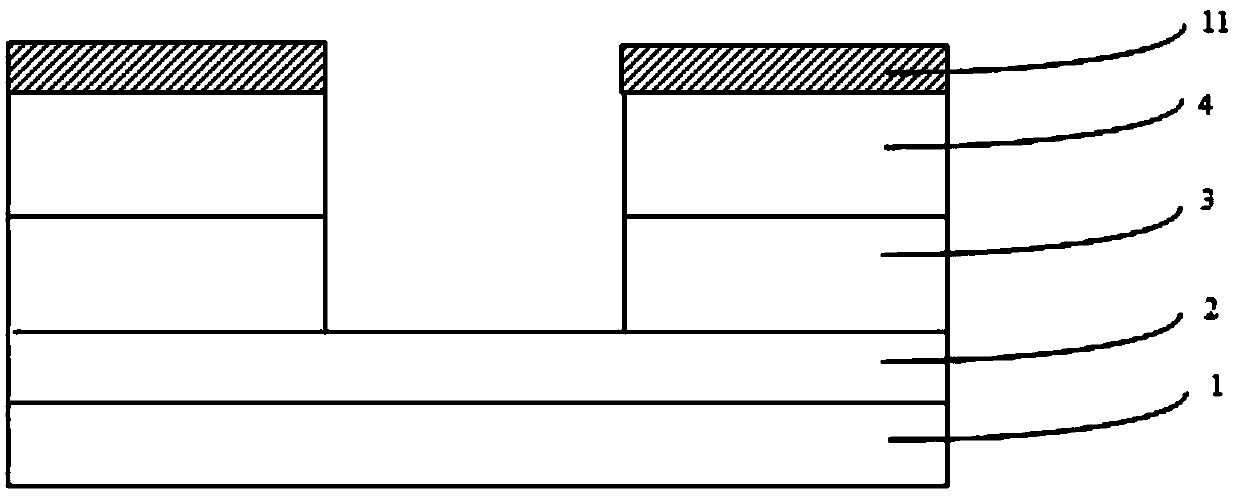

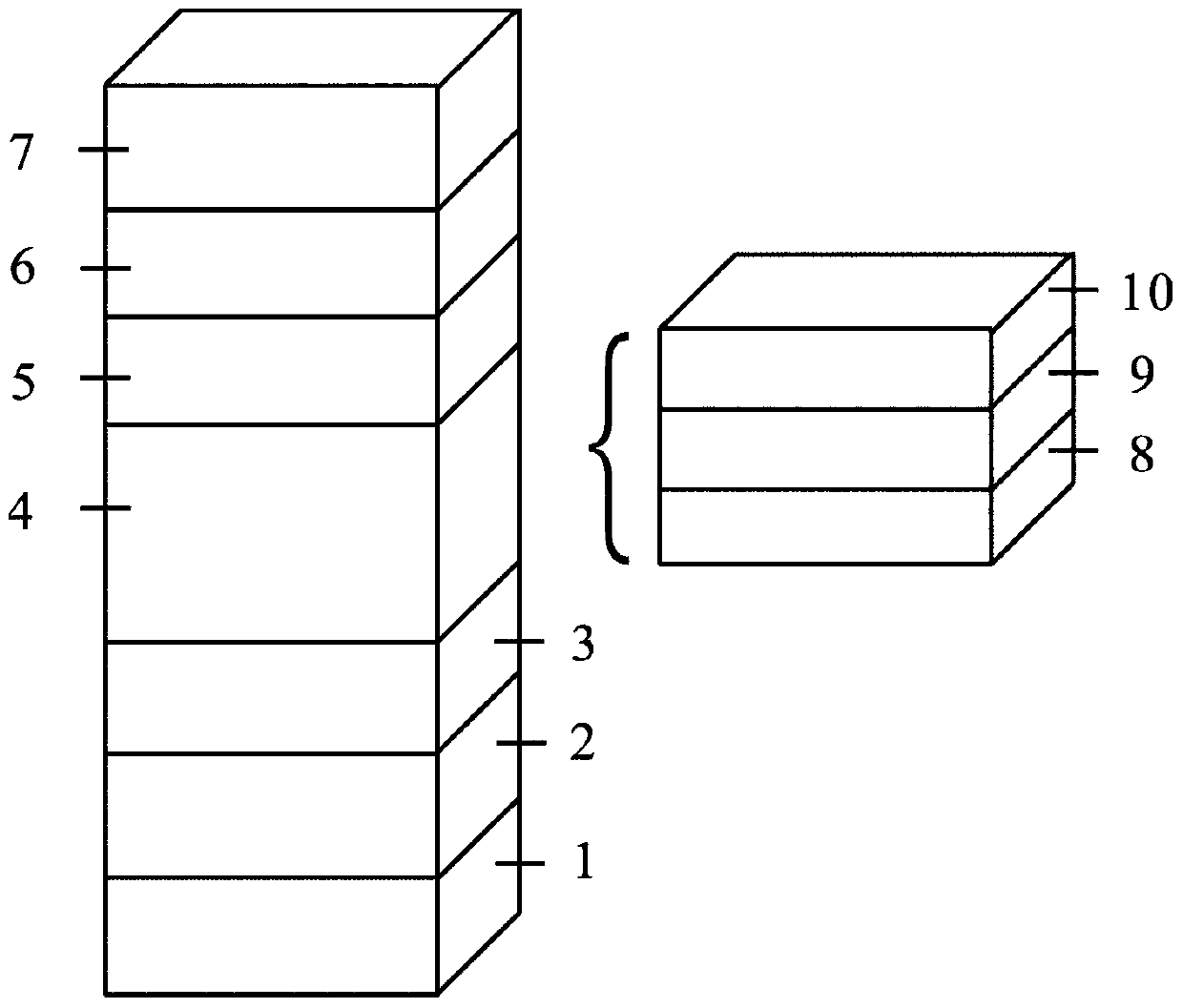

Epitaxial growth method and epitaxial layer with heterostructure buried

ActiveCN106300013ALower threshold current densityImprove high temperature characteristicsLaser detailsSemiconductor/solid-state device manufacturingQuantum efficiencyQuantum well

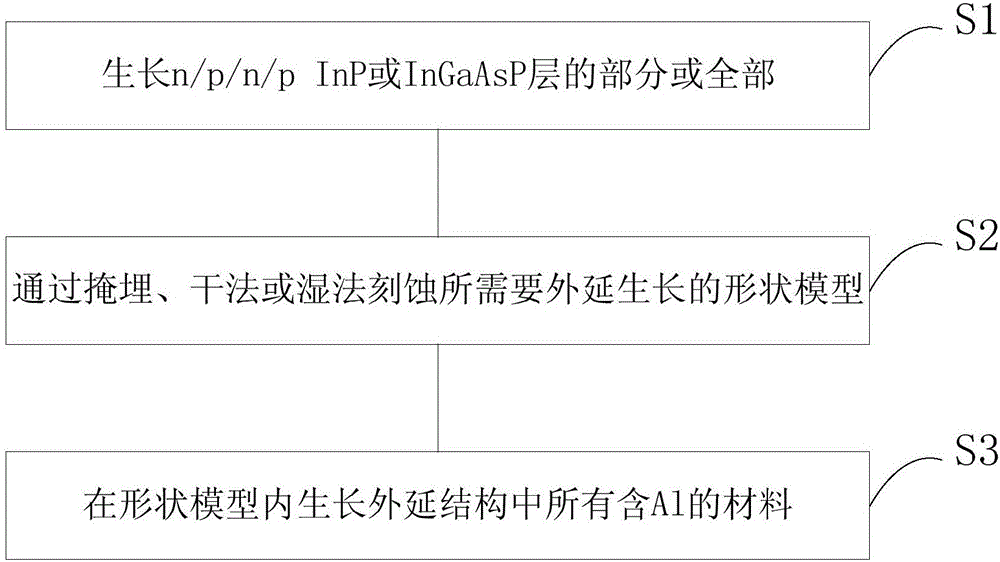

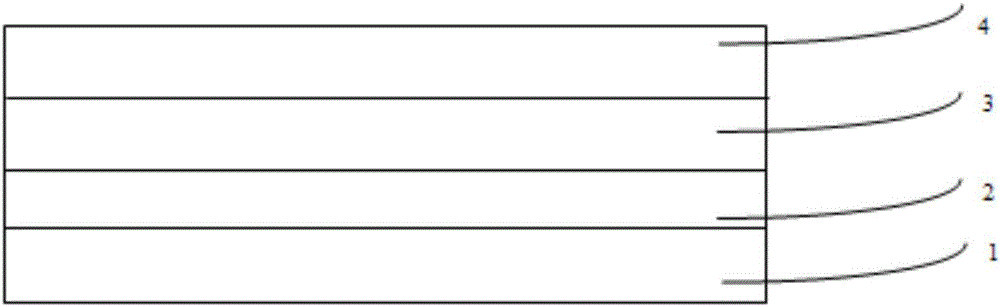

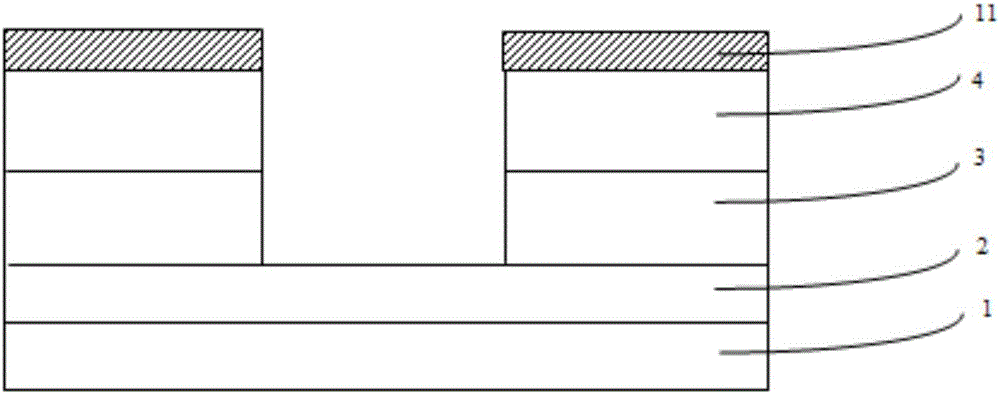

The invention relates to an epitaxial growth method and an epitaxial layer with a heterostructure buried. The epitaxial growth method includes following steps: S1, growing part of or all of an n / p / n / p InP or InGaAsP layer; S2, etching a shape model needing epitaxial growth through burying, a dry method or a wet method; S3, growing all material containing Al in an epitaxial structure in the shape model. Part of or all of an n / p / n / p structure is formed, the shape of the epitaxial layer needing growth is etched, and the epitaxial layer is grown in the shape. By utilizing the method, the advantages of AlGaInAs / InP materials and BH technology can be combined effectively to grow an efficient laser device epitaxial structure, effects of avoiding Al oxidation, lowering auger recombination and interband adsorption and improving high-temperature characteristics of devices are realized, threshold current density of a laser device is reduced, and feature temperature of an active layer material and external quantum efficiency, internal quantum efficiency and conversion efficiency of an active area quantum well are increased.

Owner:WUHAN HUAGONG GENUINE OPTICS TECH

Extension developing method for high-power semiconductor quanta point laser material

InactiveCN100511734CHigh planar densityGood size uniformityLaser detailsSemiconductor lasersMicrometerQuantum dot

This invention relates to semiconductor laser technique field and provides one InGaAs / GaAs SK growth high intensity quantum point extension layer structure to realize this extension molecule beam semiconductor quantum laser materials method. Through accurate control molecule beam extension growing condition and using submolecule single layer to control quantum points component, extensive thickness, shape structure to realize room temperature PL spectrum of 1.02-1.08 micrometer band.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

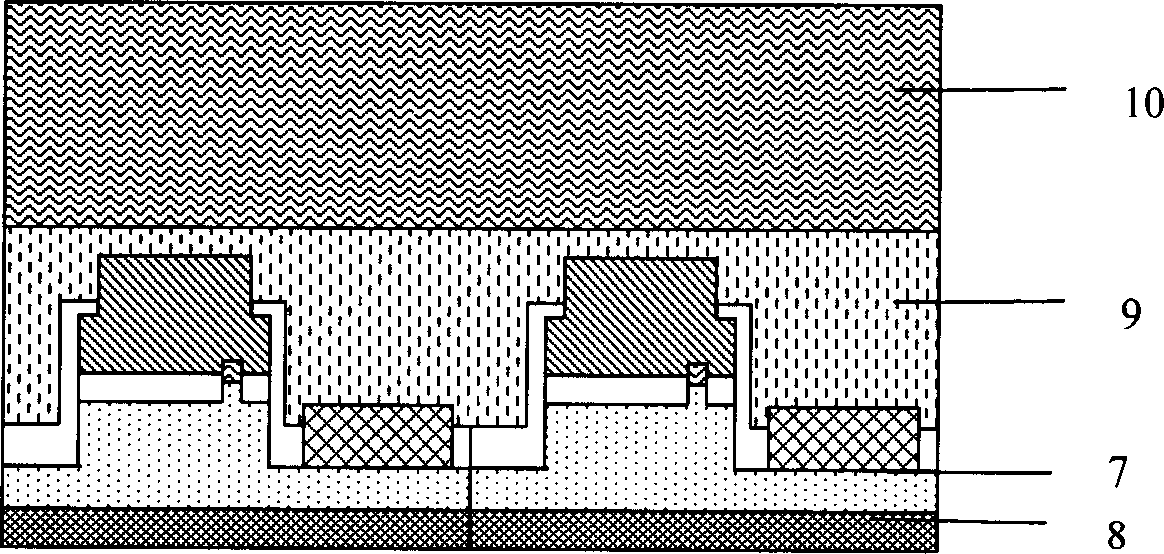

Method for preparing GaN basal keel type laser diode

The invention discloses a method for preparing a GaN basal keel type laser diode. The method comprises the following steps: firstly, using a P-area contact metal electrode as a light blocking layer on the top of a keel before the keel is subjected to dry etching, subsequently coating a negative photosensitivity thermocuring coating adhesive by using a spinning coating technique; secondly, performing secondary photoetching by using a back exposure technique, wherein the light blocking layer can effectively prevent the photoresist on the top of the keel from being exposed by ultraviolet light, so that photoetched patterns are achieved; finally, obtaining an insulating layer with complete and regular structure through a high-temperature curing method according to the properties of the negative photosensitivity thermocuring coating adhesive. The method has the characteristics that the problems that the conventional keel laser electrode windows are difficult to align and the insulating layer windowing condition is difficult to control are solved.

Owner:北京燕园中镓半导体工程研发中心有限公司 +1

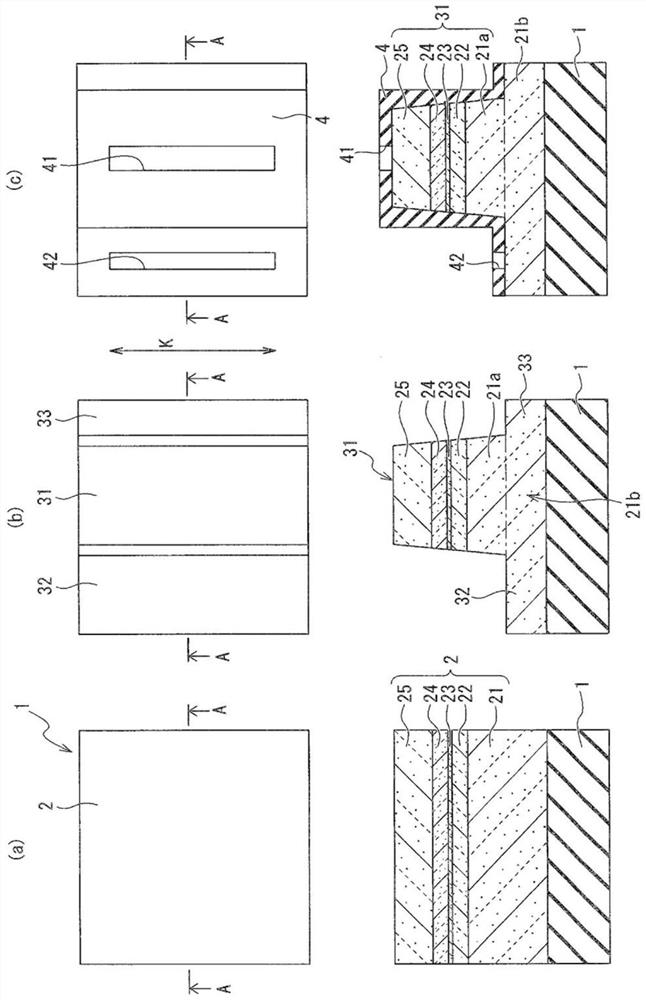

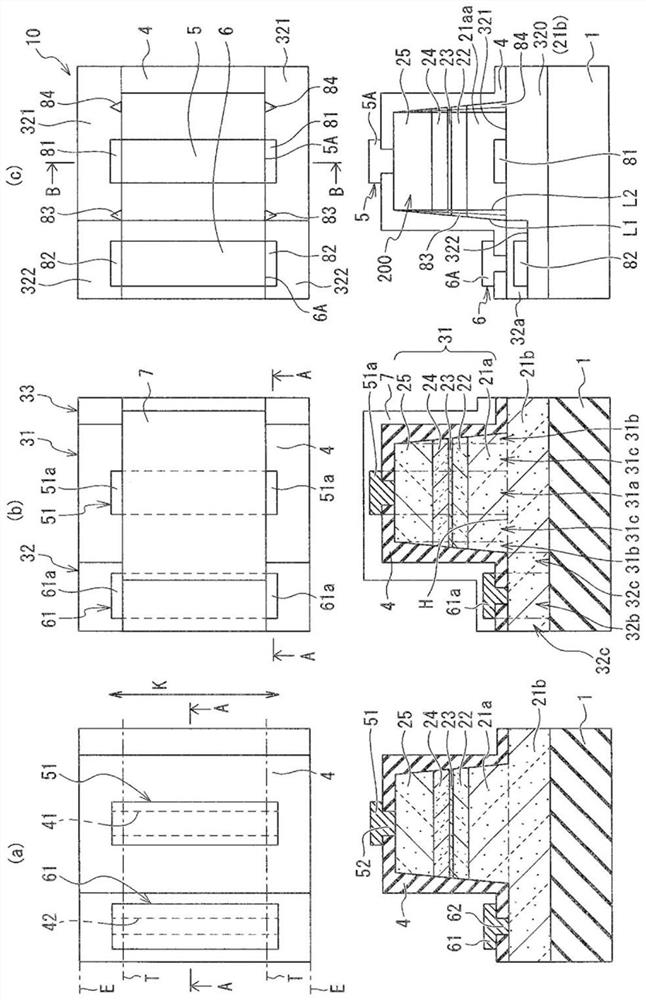

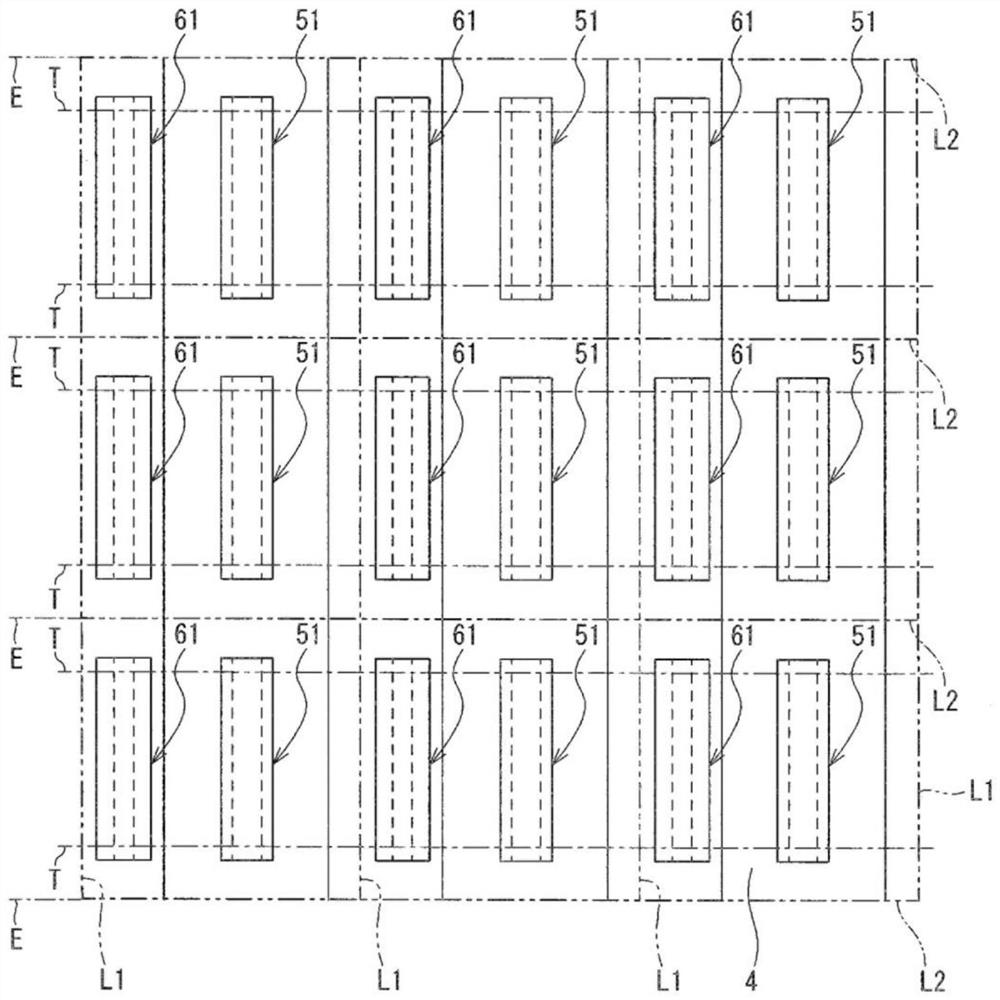

Method for manufacturing semiconductor laser diode and semiconductor laser diode

PendingCN113497406AIncreased durabilityLower threshold current densityOptical wave guidanceLaser detailsThreshold currentSemiconductor

A diode in which the threshold current density for laser oscillation is reduced is provided as a Fabry-Perot semiconductor laser diode obtained through a step of forming a resonator end face using an etching technology. A method for manufacturing a semiconductor laser diode includes a step of forming a plurality of semiconductor laser diodes on a substrate, and then dividing the substrate into each semiconductor laser diode. The method includes a step of forming a laminate on the substrate; a step of etching the laminate to separate the laminate into a portion serving as a resonance region and the other portion; an electrode layer forming step of forming a layer forming the second electrode on the second semiconductor layer of the laminate between positions where a resonator end face is formed in the resonance region and divided; after the electrode layer forming step, an etching step of simultaneously or sequentially performing the removal of a portion formed at a position on the outer side relative to the resonator end face of the layer serving as the second electrode and the formation the resonator end face.

Owner:ASAHI KASEI KK

Method for mixing organic gallium source selective zone growing indium-gallium-arsenic-phosphor multiple quantum well

InactiveCN1209861CLower threshold current densityImprove efficiencyLaser detailsLaser active region structureElectro-absorption modulatorIndium

The method for growing indium gallium arsenide phosphorus multiple quantum wells in selected regions by mixing organic gallium sources in the present invention is to use triethylgallium and trimethylindium to grow confinement layers and barriers when selectively growing indium gallium arsenide phosphorus multiple quantum wells, and three Methylgallium and trimethylindium growth wells; the quantum well material grown by this method has a large strain in the selective growth region, while in the non-selective growth region, the well region has a small strain; the barrier and the confinement layer are in The strain change of the two growth regions is very small, which makes the quantum well with the selective growth region have high luminous efficiency, and ensures the realization of high-performance electroabsorption modulation DFB laser.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

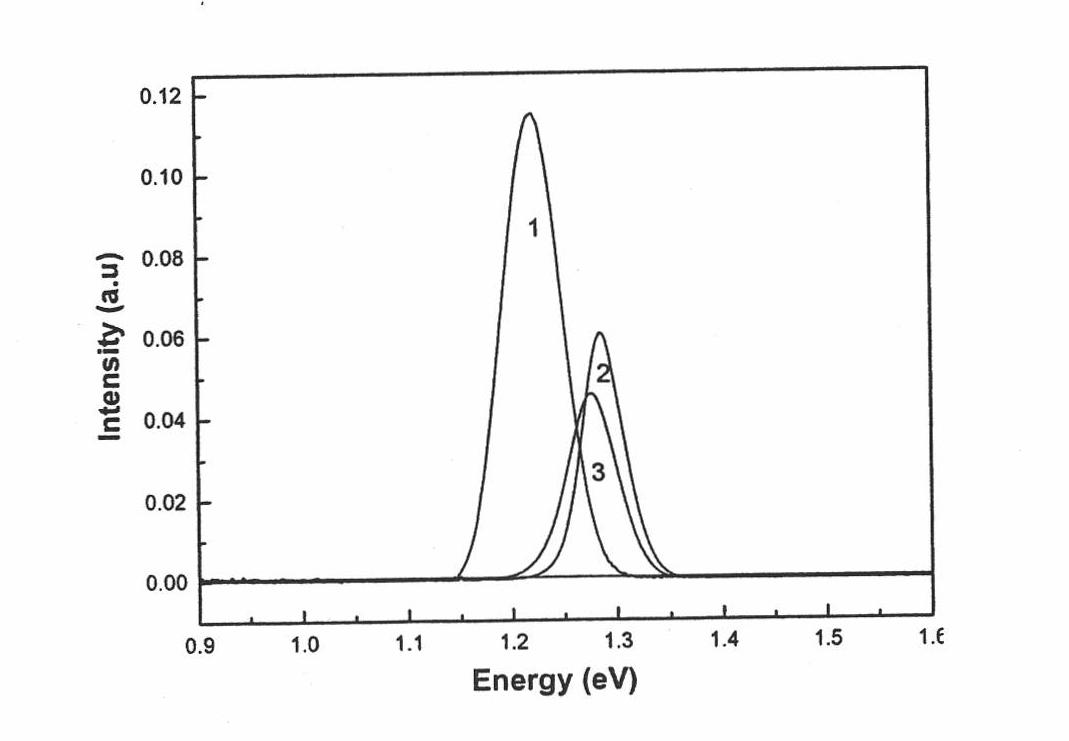

InGaAs/GaAs quantum dot epitaxial structure in wave band between 1.02 to 1.08 micrometer and manufacturing method thereof

InactiveCN101505034AHigh planar densityGood size uniformityLaser active region structurePerformance indexLayer thickness

The invention relates to the technical field of semiconductor lasers, provides an InGaAs / GaAs quantum dot epitaxial structure with 1.02 to 1.08 micron wave band, and an epitaxial growing method for a molecular beam high-power semiconductor quantum dot laser material for realizing the epitaxial structure. The a PL spectrum with 1.02 to 1.08 micron wave band at room temperature can illuminate by precisely controlling the molecular beam epitaxial growing condition, namely using the alternative growth of a monoatomic layer to control components, epitaxial layer thickness, appearance structure and the like of the quantum dot and has high luminous efficiency. The method is applied to a pumping source of an optical fiber laser, greatly reduces the device volume and the manufacturing cost and keeps good performance index of the quantum dot laser, such as reducing the threshold current of the laser, reducing the power consumption, improving the temperature stability and the like.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

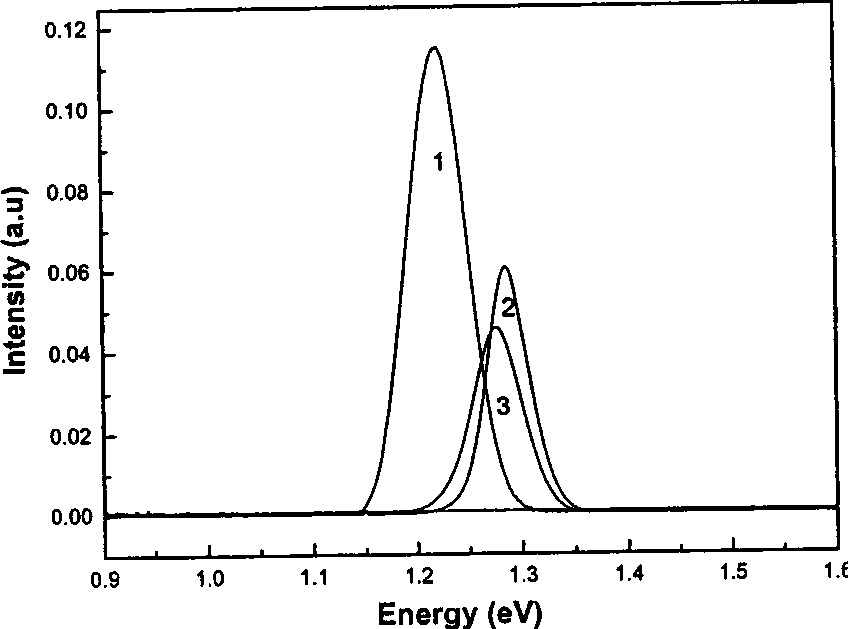

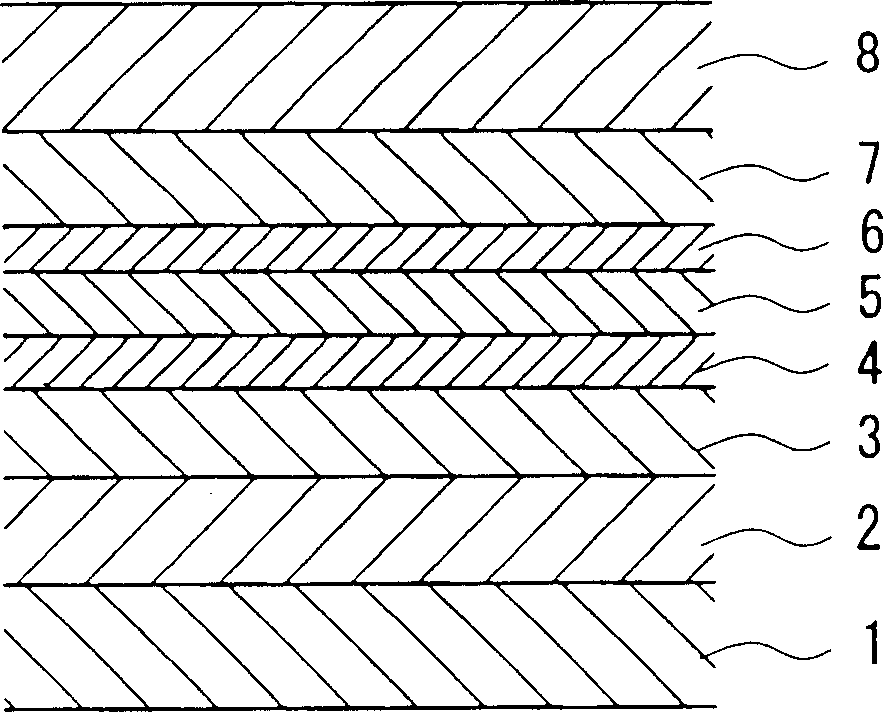

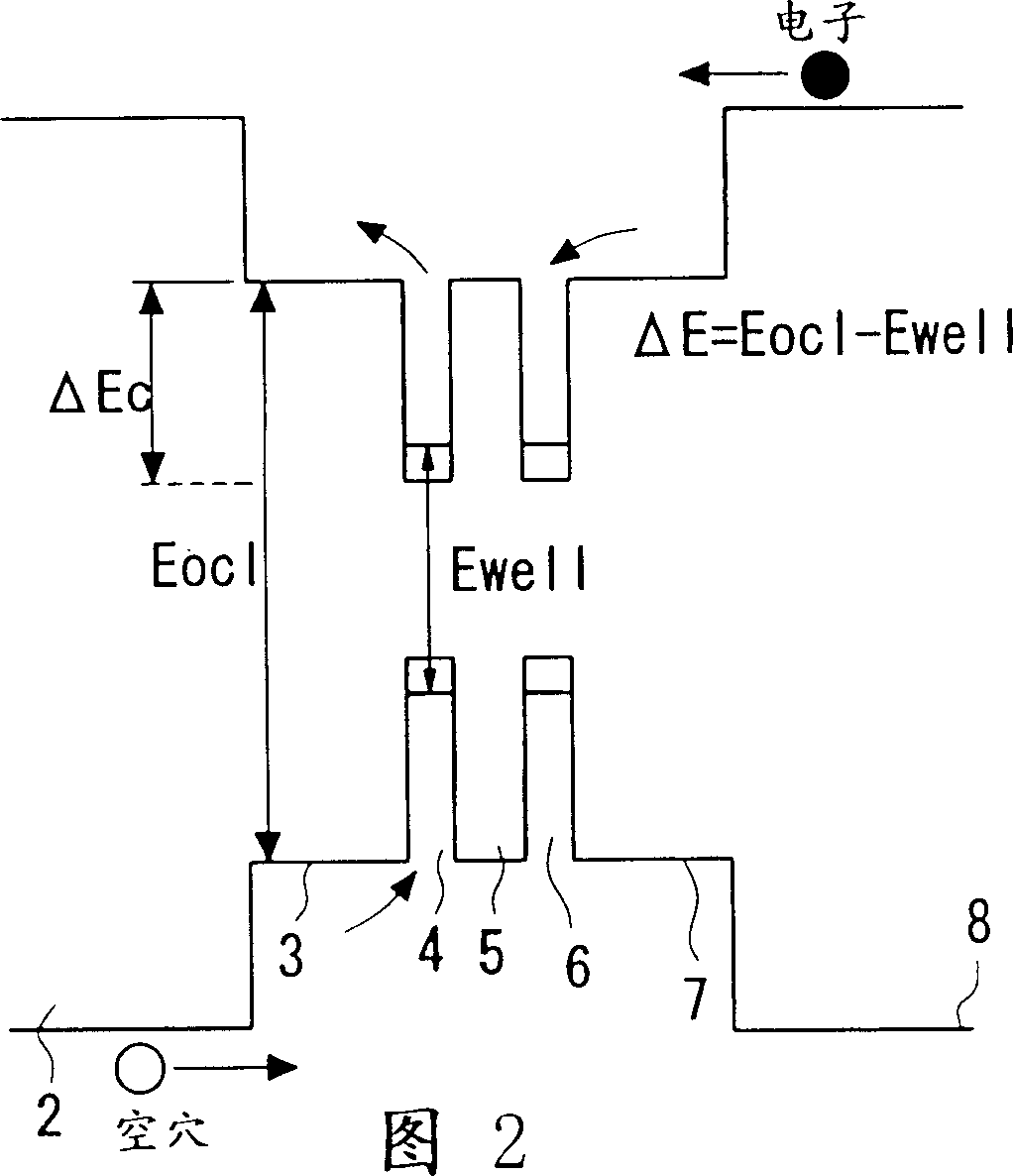

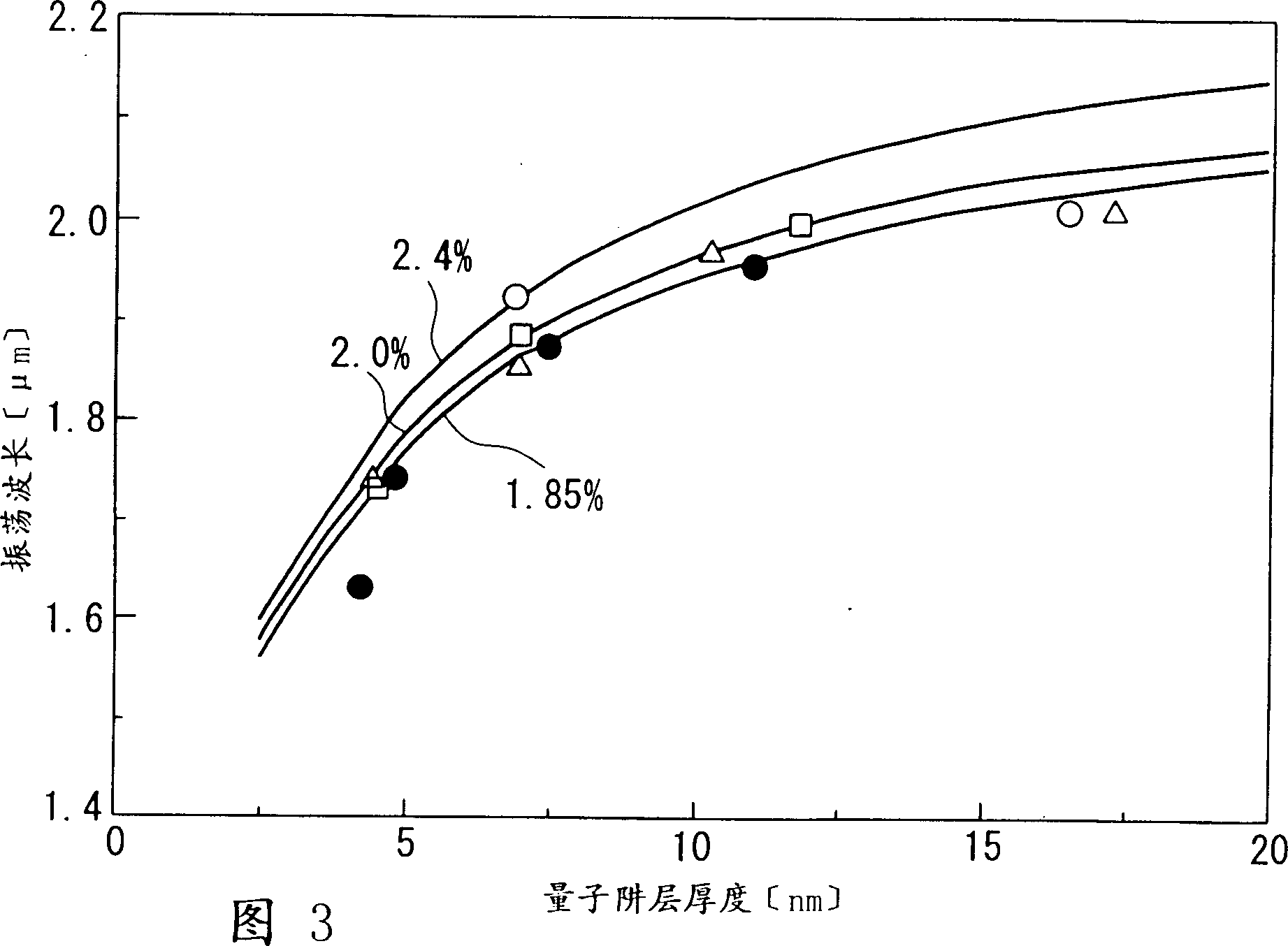

Semiconductor laser

InactiveCN1118120CLower threshold current densitySuppresses optical absorption lossLaser detailsLaser active region structureWide fieldQuantum well

A semiconductor laser in the wavelength band of 1.3-1.55 mu m has been developed conventionally but a semiconductor laser in the wavelength band of 2 mu m, for which a wide field of technological application is expected, has not been developed sufficiently. A high-performance semiconductor laser oscillating in a wavelenght band of 2 mu m, specifically a compression strain quantum well semiconductor laser employing InGaAs / InGaAsP material oscillating in 2 mu m wavelength band, characterized in that the difference DELTA E between the band gap Eocl of an optical confinement layer and the emission transition energy Ewell between the ground levels of a quantum well layer is 275-300 meV.

Owner:NIPPON SANSO CORP

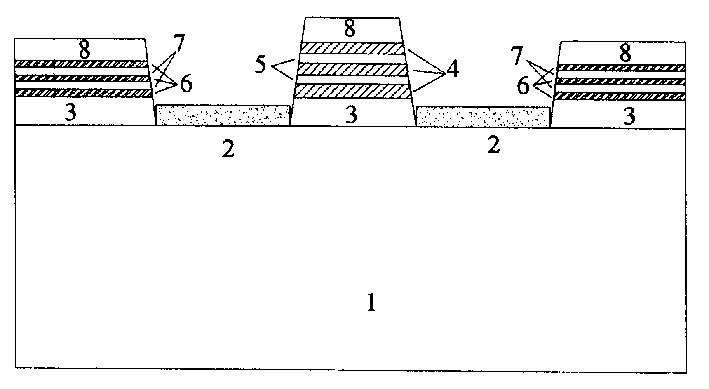

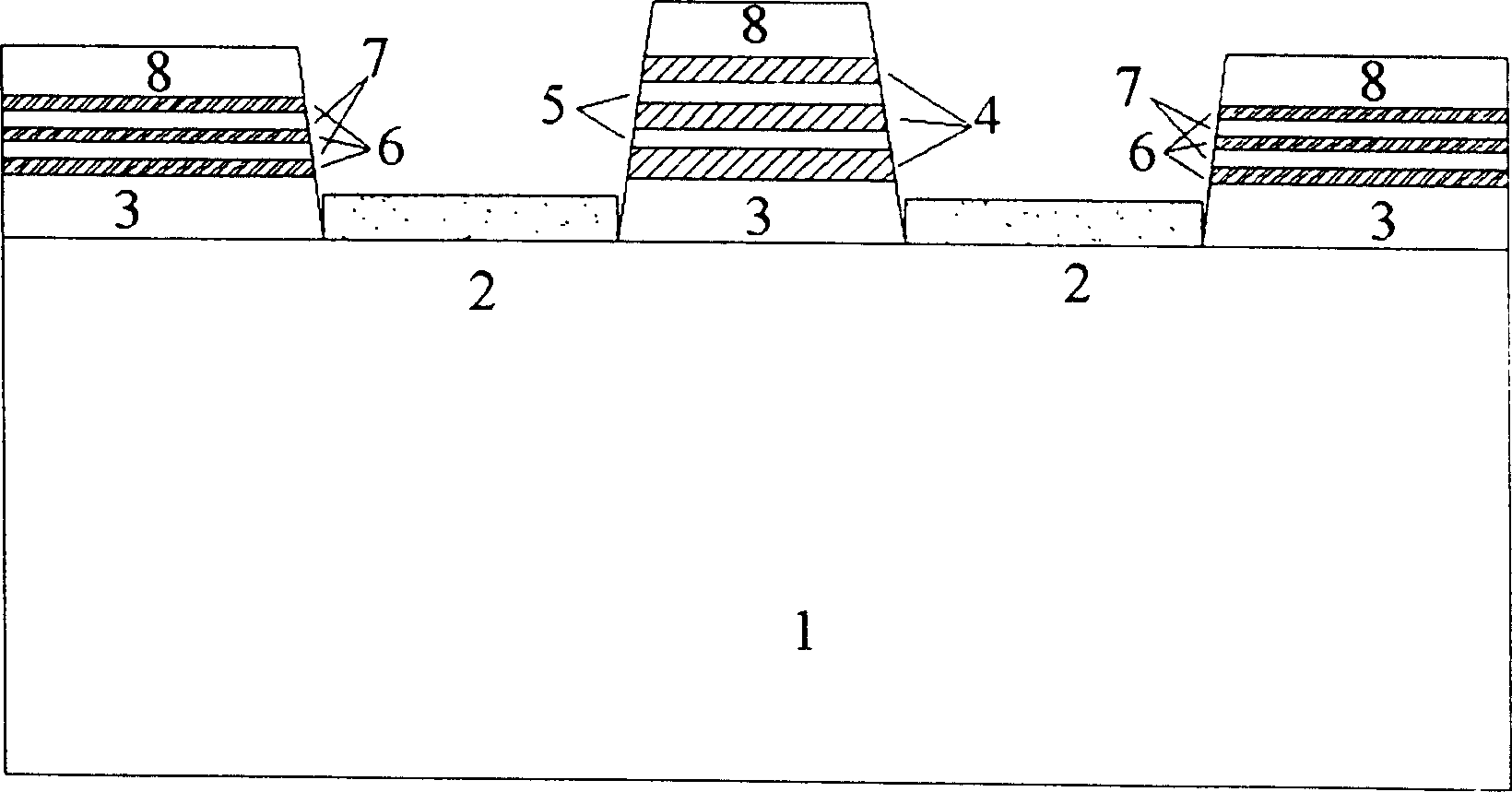

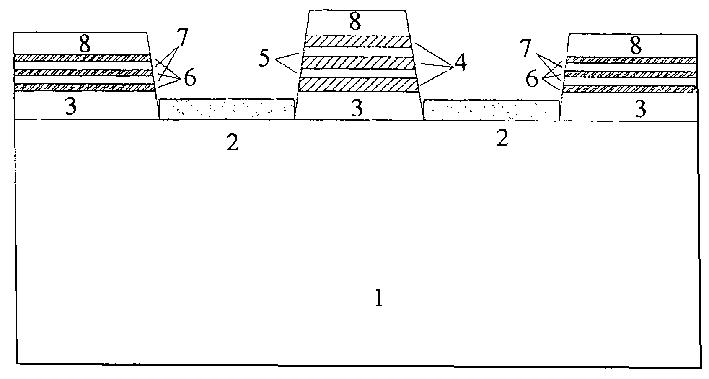

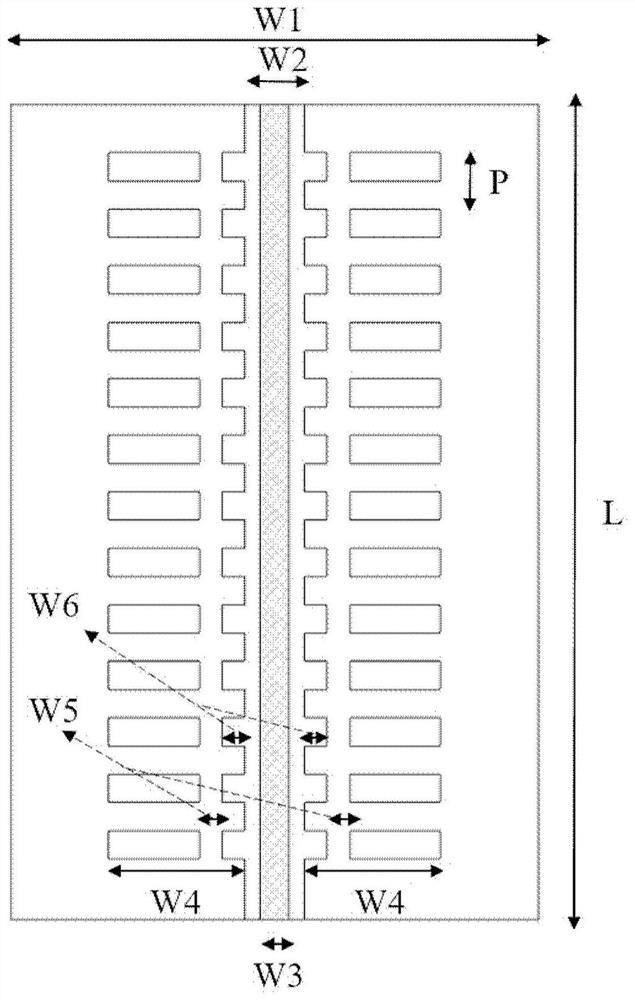

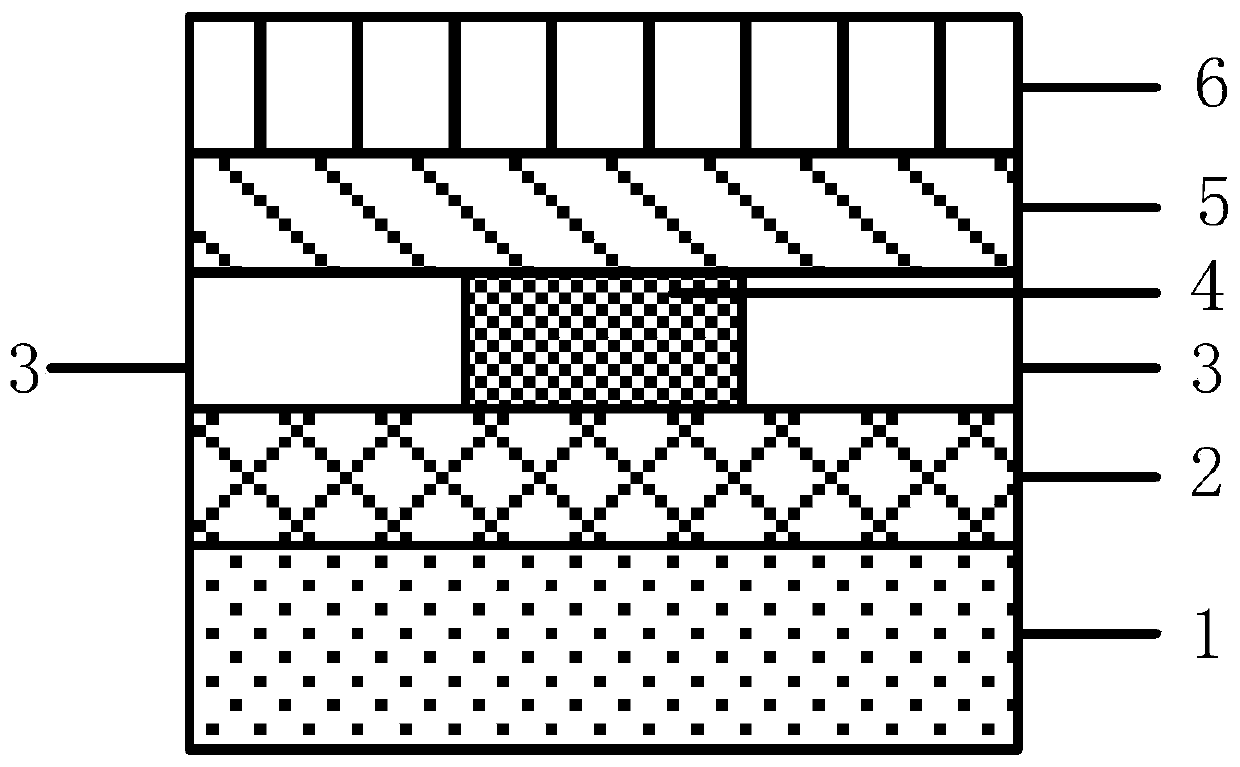

Lateral composite grating DFB laser structure and application

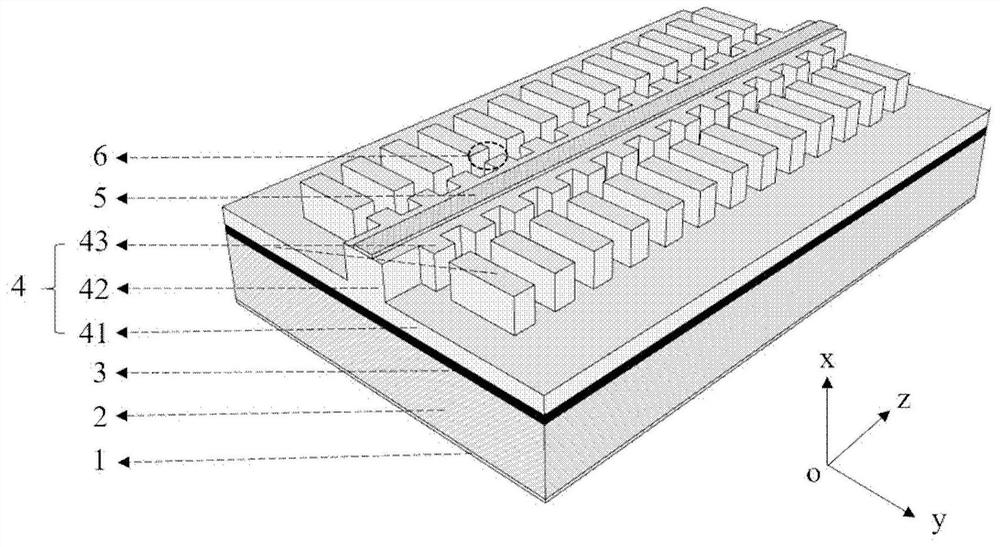

PendingCN112688164AReduce carrier leakageLower threshold current densityOptical wave guidanceLaser detailsErbium lasersSurface electrode

The invention discloses a lateral composite grating DFB laser structure and application. The lateral composite grating DFB laser structure comprises an N-surface electrode layer, the N type waveguide layer arranged on the N-surface electrode layer, an active layer arranged on the N type waveguide layer, a P type waveguide layer arranged on the active layer and a P-surface electrode layer. The P type waveguide layer comprises a non-etched P type waveguide layer, a ridge waveguide and high-order surface lateral gratings, the ridge waveguide and the high-order surface lateral grating are both arranged on the non-etched P type waveguide layer, the high-order surface lateral gratings are arranged on the two sides of the ridge waveguide, and slot areas are arranged at the joint of the high-order surface lateral gratings and the ridge waveguide; and the P-surface electrode layer is disposed on the ridge waveguide. According to the invention, the slot is introduced near the joint of the high-order surface lateral grating and the ridge waveguide for electric isolation, so that carrier leakage caused by the lateral grating during electric injection can be reduced, the threshold current density of the laser is reduced, the slope efficiency is improved, and narrow-linewidth and high-power laser output is realized.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

InGaAs/GaAs quantum dot epitaxial structure in wave band between 1.02 to 1.08 micrometer and manufacturing method thereof

InactiveCN101505034BHigh planar densityGood size uniformityLaser active region structurePerformance indexLayer thickness

The invention relates to the technical field of semiconductor lasers, provides an InGaAs / GaAs quantum dot epitaxial structure with 1.02 to 1.08 micron wave band, and an epitaxial growing method for a molecular beam high-power semiconductor quantum dot laser material for realizing the epitaxial structure. The a PL spectrum with 1.02 to 1.08 micron wave band at room temperature can illuminate by precisely controlling the molecular beam epitaxial growing condition, namely using the alternative growth of a monoatomic layer to control components, epitaxial layer thickness, appearance structure andthe like of the quantum dot and has high luminous efficiency. The method is applied to a pumping source of an optical fiber laser, greatly reduces the device volume and the manufacturing cost and keeps good performance index of the quantum dot laser, such as reducing the threshold current of the laser, reducing the power consumption, improving the temperature stability and the like.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

A short-wavelength algainp red semiconductor laser

ActiveCN105390937BLow refractive indexIncreased light limiting factorLaser detailsSemiconductor lasersLower limitOhmic contact

A short wavelength AlGaInP red light semiconductor laser structurally comprises a substrate, a lower buffer layer, a lower limiting layer, a lower waveguide layer, a quantum well layer, an upper waveguide layer, an upper limiting layer, an upper buffer layer and an ohmic contact layer in sequence from the bottom to the top; the lower buffer layer is an AlxIn1-xP component gradual change layer, and x linearly gradually changes to 0.6 from 0.5; the upper buffer layer is an AlyIn1-yP component gradual change layer, and y linearly gradually changes to 0.5 from 0.6; the upper waveguide layer and lower waveguide layer are both (AlzGa1-z)0.6In0.4P; the lower limiting layer and upper limiting layer are both Al0.6In0.4P. By the AlInP component gradual change buffer layer, an In component of the limiting layers and the waveguide layers is reduced to 0.4, the refraction index of a material of the limiting layers is reduced, a bandgap of a material of the waveguide layers is increased, photons and carriers are better limited, and meanwhile, the quantum well layer can obtain short wavelength light of 590-620nm under a lower strain condition.

Owner:Shandong Huaguang Optoelectronics Co. Ltd.

Fabrication method of gan-based ridge laser diode

ActiveCN103618212BGood ohmic contactReduce contact resistanceOptical wave guidanceLaser detailsAdhesiveKeel

The invention discloses a method for preparing a GaN basal keel type laser diode. The method comprises the following steps: firstly, using a P-area contact metal electrode as a light blocking layer on the top of a keel before the keel is subjected to dry etching, subsequently coating a negative photosensitivity thermocuring coating adhesive by using a spinning coating technique; secondly, performing secondary photoetching by using a back exposure technique, wherein the light blocking layer can effectively prevent the photoresist on the top of the keel from being exposed by ultraviolet light, so that photoetched patterns are achieved; finally, obtaining an insulating layer with complete and regular structure through a high-temperature curing method according to the properties of the negative photosensitivity thermocuring coating adhesive. The method has the characteristics that the problems that the conventional keel laser electrode windows are difficult to align and the insulating layer windowing condition is difficult to control are solved.

Owner:北京燕园中镓半导体工程研发中心有限公司 +1

Method for preparing wave guide and grating structure of adjustable distributive feedback quantum cascade laser and above said grating

InactiveCN100405681CAppropriate distribution of feedback coupling coefficientsReduced waveguide lossOptical wave guidanceLaser detailsGratingQuantum cascade laser

This invention relates to a waveguide and a grating structure of an adjustable distribution feed back quanta cascade laser obtaining low threshold value current density and high side mode suppression ratio and a method for preparing first order grating of laser meeting the requirement, in which, the laser waveguide and the grating structure is a limit structure in the waveguide made up of a deep first order grating and a thin heavy doped semiconductor layer, said grating corrosion technology is to utilize the InGaAs / InP structure as the corrosion sacrificial layer of the grating and select different corroding liquid matches to get a grating structure with the depth adjustable and accuracy controllable.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

A kind of epitaxial growth method and the epitaxial layer of buried heterostructure

ActiveCN106300013BLower threshold current densityImprove high temperature characteristicsLaser detailsSemiconductor/solid-state device manufacturingQuantum efficiencyQuantum well

The invention relates to an epitaxial growth method and an epitaxial layer for burying a heterostructure, comprising the following steps: S1, growing part or all of an n / p / n / p InP or InGaAsP layer; S2, by burying, dry method or wet method Etch the shape model of the epitaxial growth required; S3, grow all Al-containing materials in the epitaxial structure in the shape model. In the present invention, part or all of the n / p / n / p structure is formed first, and then the shape of the epitaxial layer to be grown is etched, and then the epitaxial layer is grown therein. The method of the invention can effectively combine the advantages of AlGaInAs / InP material and BH technology to grow a high-efficiency laser epitaxial structure, so as to avoid Al oxidation, reduce Auger recombination, inter-band absorption, and improve the high temperature characteristics of the device. The threshold current density of the laser is reduced, the characteristic temperature of the active layer material and the external quantum efficiency, internal quantum efficiency and conversion efficiency of the quantum well in the active region are improved.

Owner:WUHAN HUAGONG GENUINE OPTICS TECH

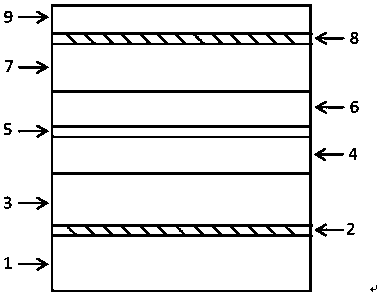

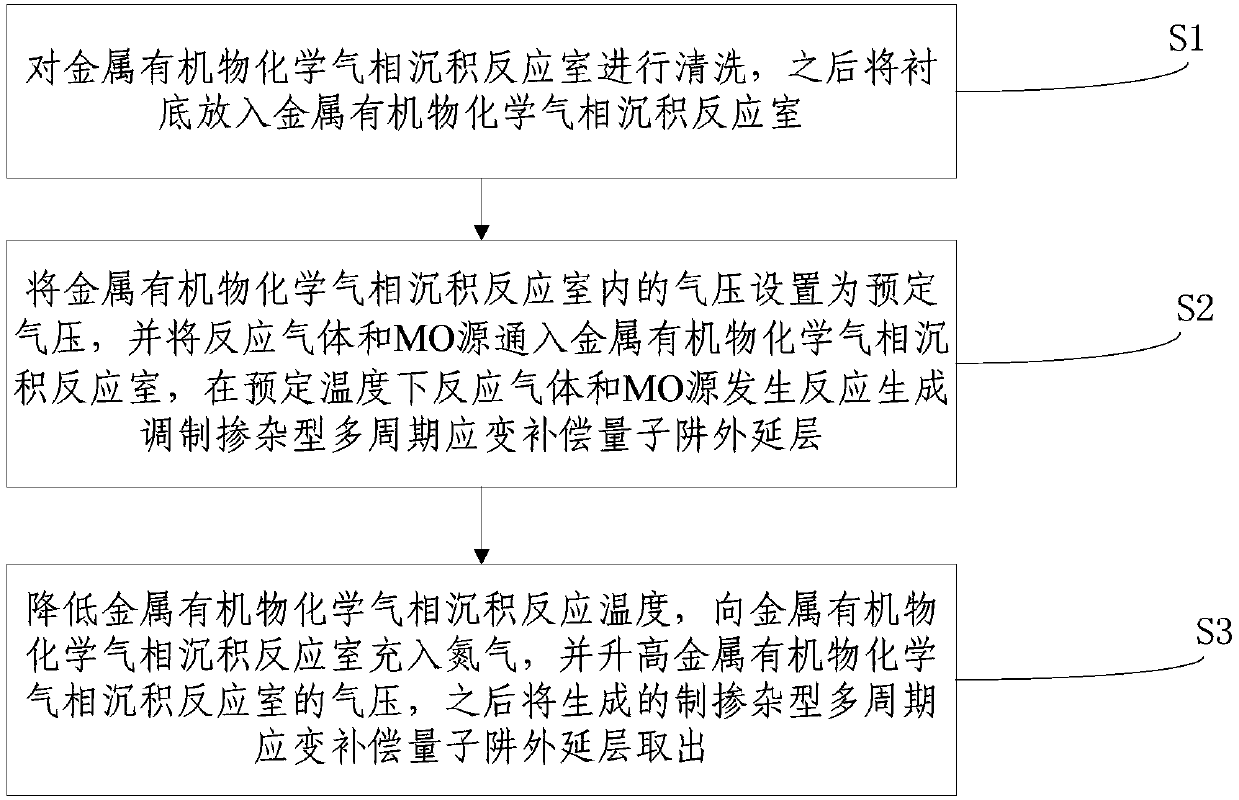

Manufacturing method of quantum dot laser

ActiveCN114725778AReduce processing costsFast growth ratePolycrystalline material growthLaser detailsMaterial growthPhysical chemistry

The invention discloses a manufacturing method of a quantum dot laser, which comprises the following steps: in MOCVD (Metal Organic Chemical Vapor Deposition) equipment, sequentially growing an n-type limiting layer and an n-type waveguide layer on a substrate to obtain a preliminary sample; and transferring the preliminary sample to MBE equipment, and then sequentially growing a quantum dot active region, a p-type waveguide layer, an electron limiting layer, a p-type limiting layer and a p-type contact layer on the n-type waveguide layer. The GaN-based quantum dot laser has the advantages that the MOCVD process is low in cost and high in growth rate, and the MBE process is good in low-dimensional material growth and is prepared on p-GaN, so that the prepared GaN-based quantum dot laser has the characteristics of high-temperature stability, low threshold current density and the like.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

A quantum dot interband cascade laser

ActiveCN105977788BLower threshold current densityStrengthen restrictionsLaser detailsLaser active region structureLower limitQuantum dot

The application discloses an antimonide quantum dot interband cascade laser. The laser is prepared by sequentially preparing a lower confinement layer, a lower waveguide layer, a cascade region, an upper waveguide layer, an upper confinement layer and an InAs contact layer on a GaSb substrate. The laser disclosed in this application uses the quantum dot active region as the active region of the interband cascade laser, and utilizes the characteristics of the quantum dot material to effectively confine and utilize the carriers, so that the interband cascade laser has more The low threshold current density and wide gain spectrum characteristics can effectively improve the performance of interband cascaded lasers.

Owner:CHANGCHUN UNIV OF SCI & TECH

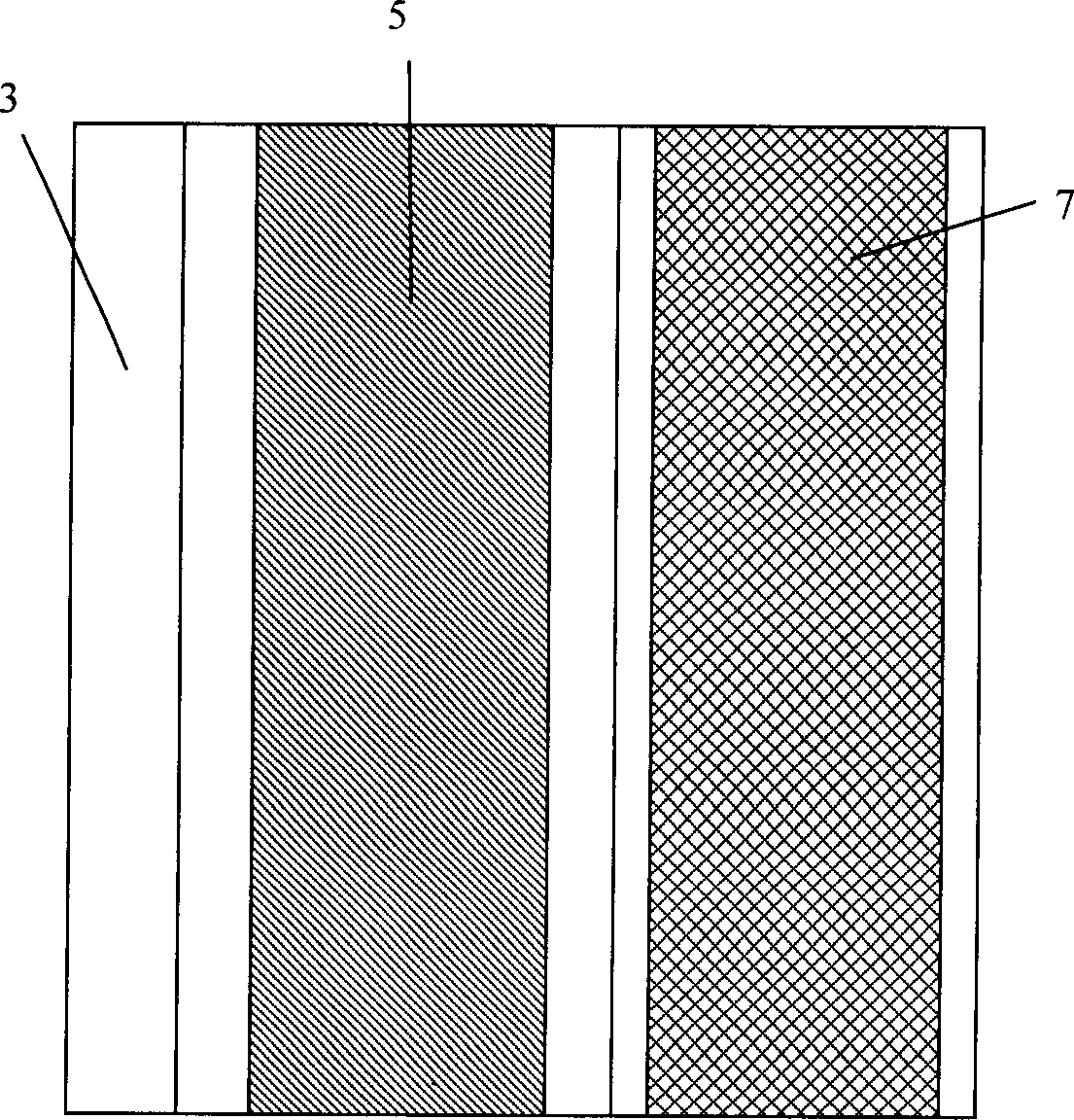

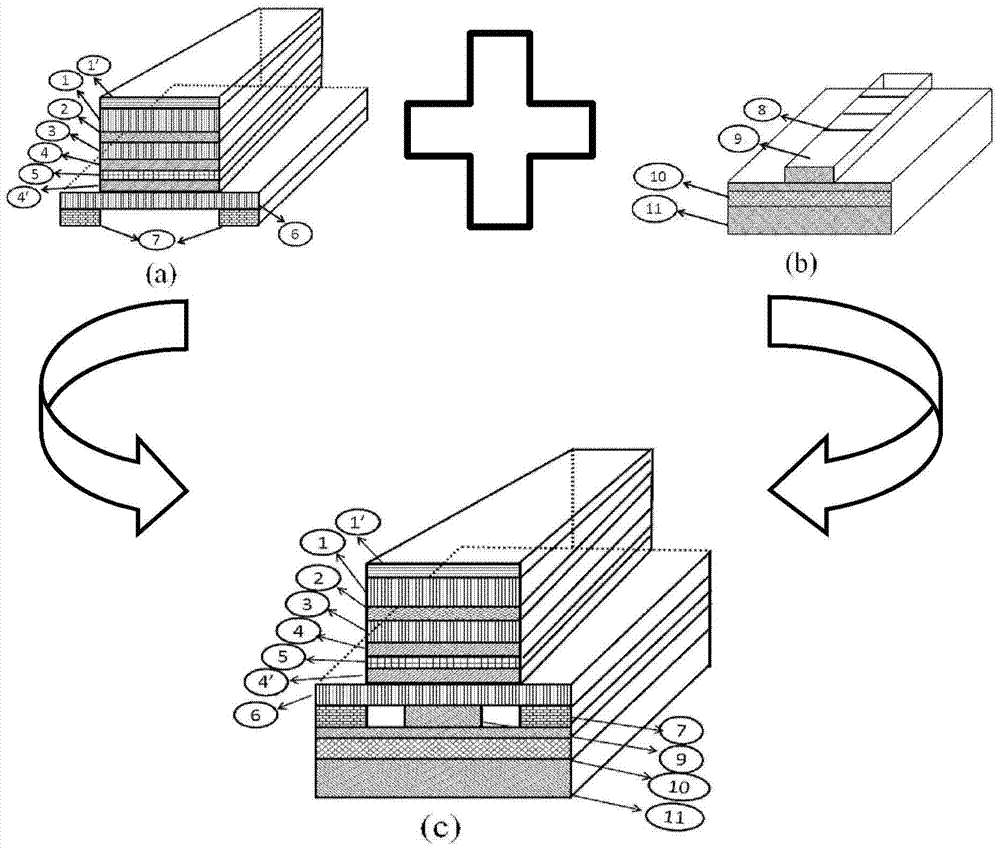

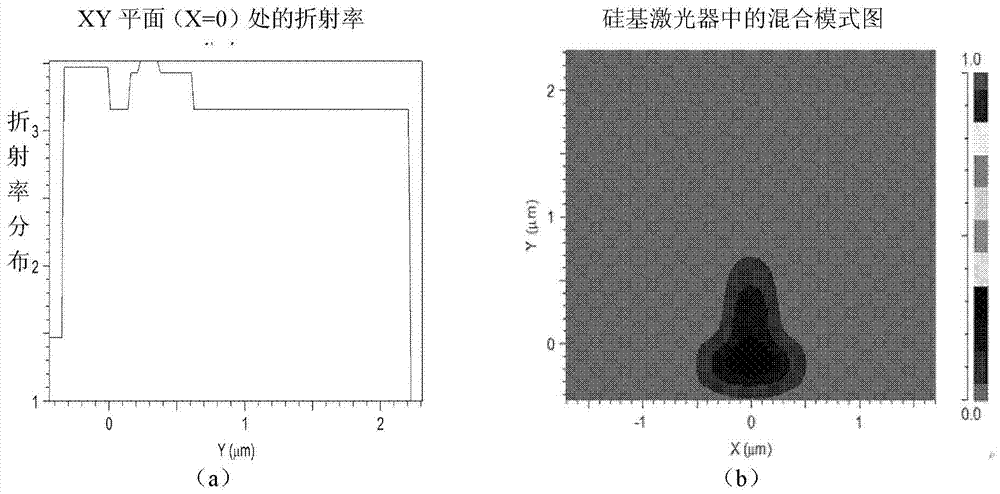

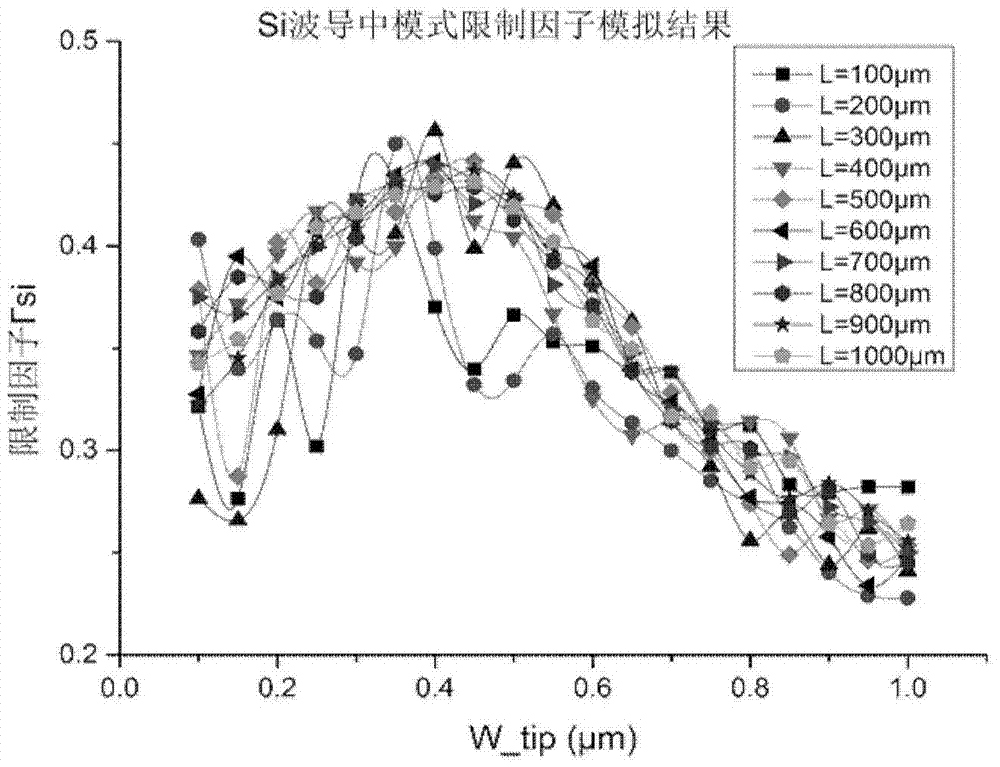

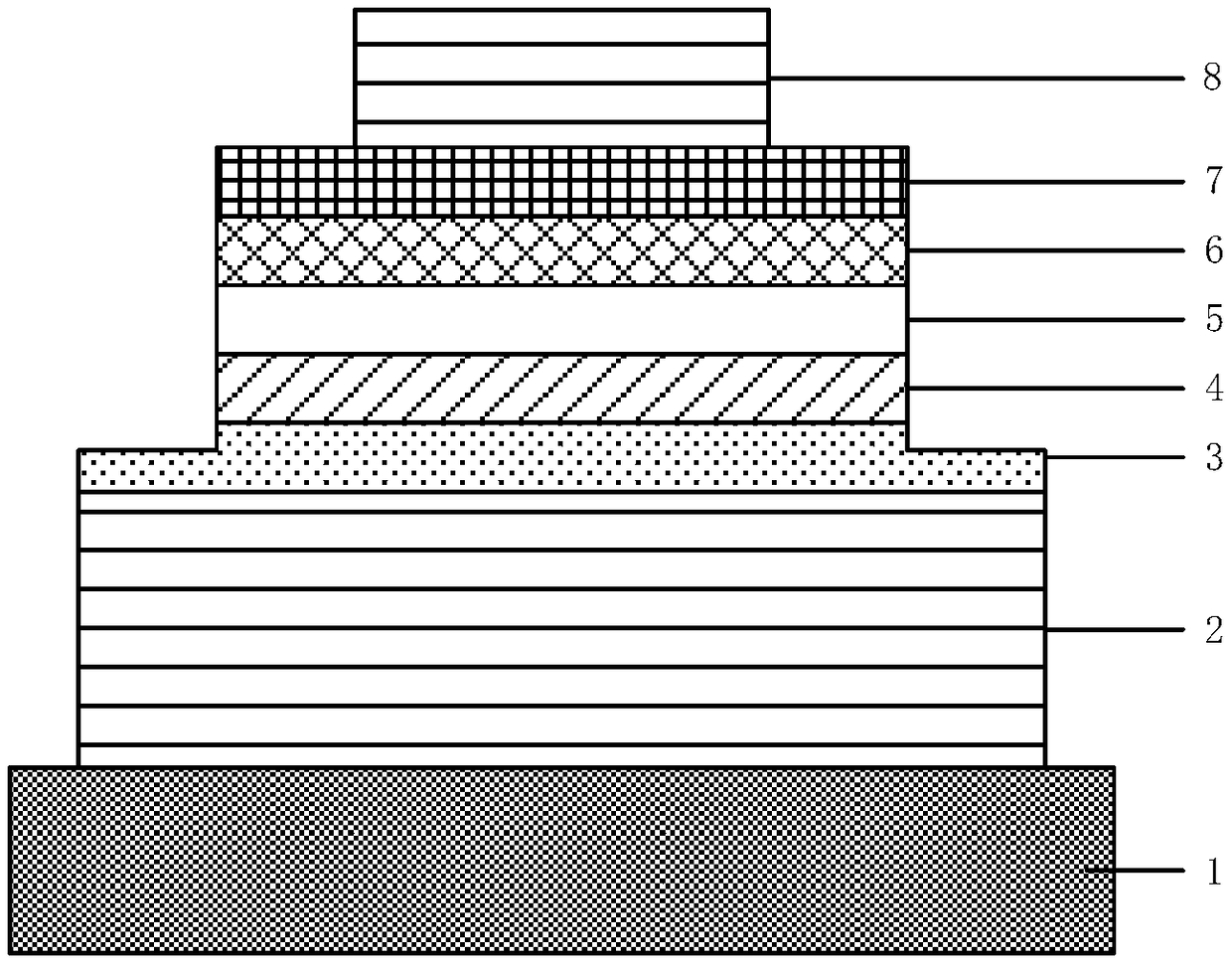

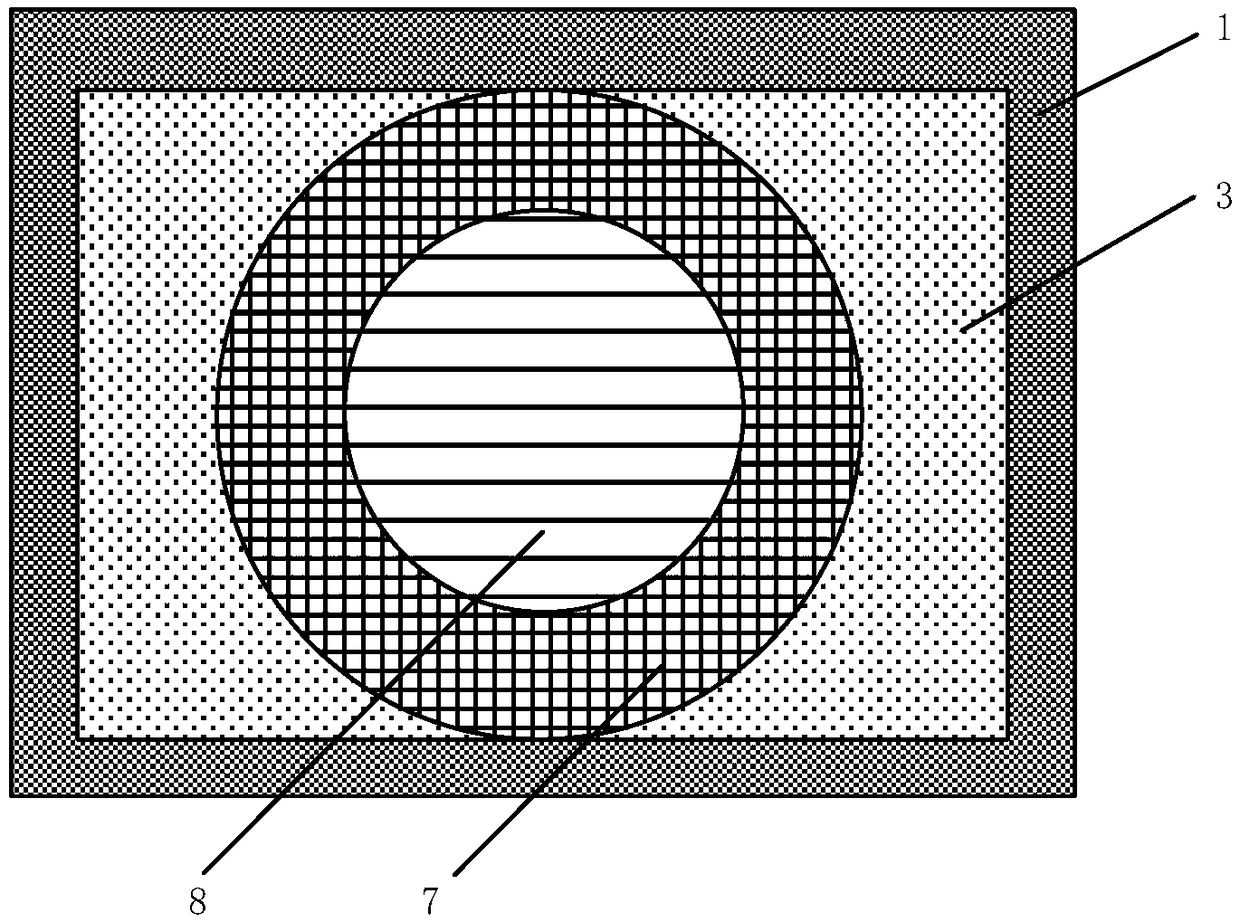

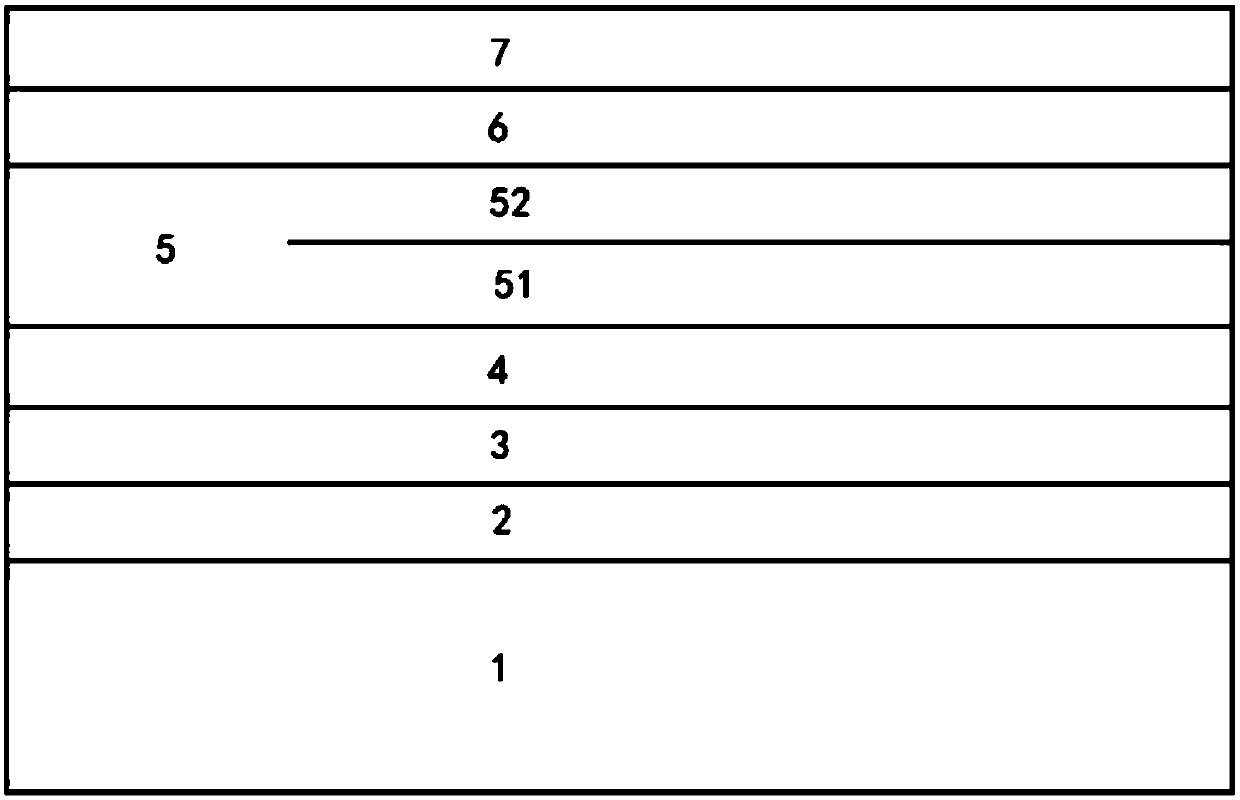

A single-mode silicon-based hybrid laser light source with silicon waveguide output

ActiveCN104092096BEasy to makeLow costOptical wave guidanceLaser detailsLaser lightSingle mode waveguides

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

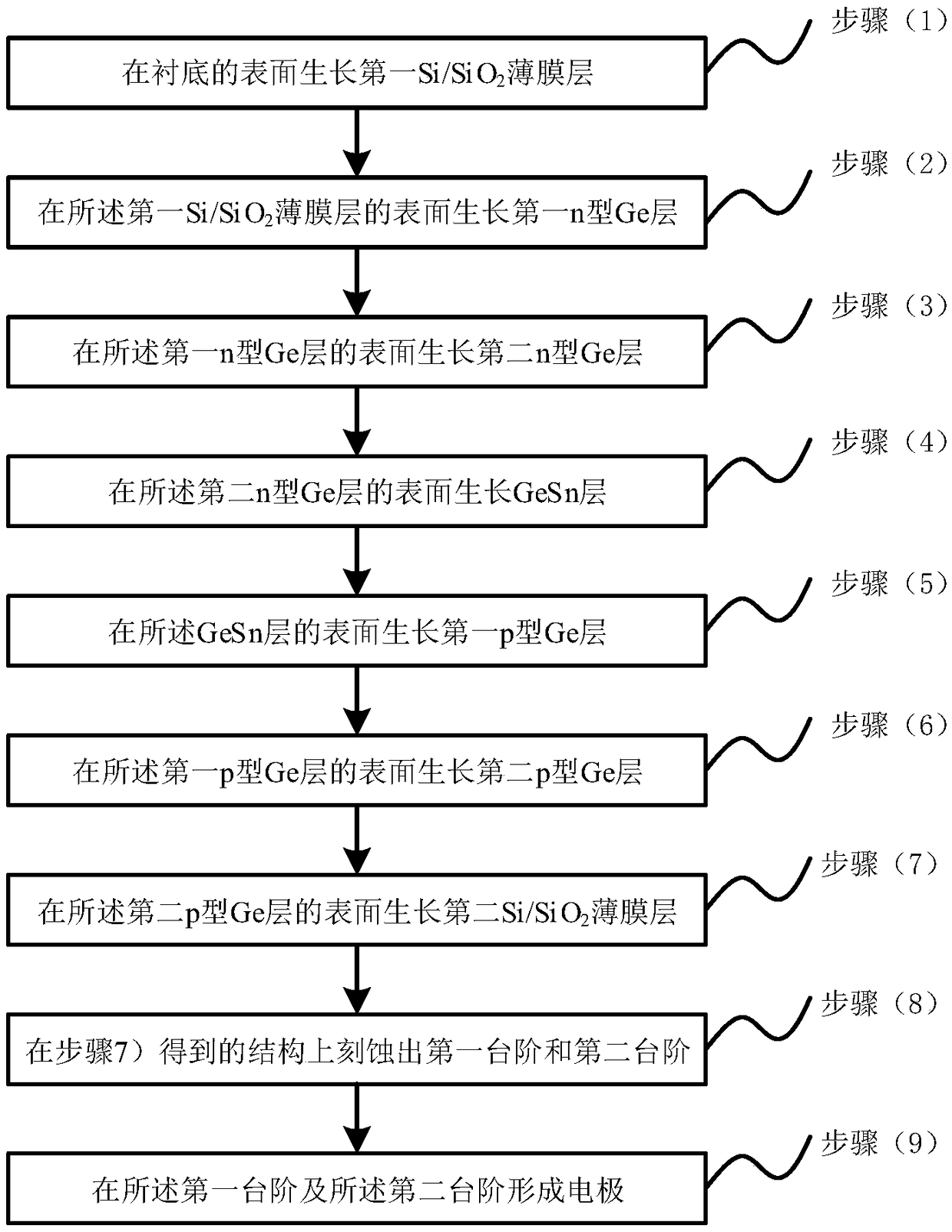

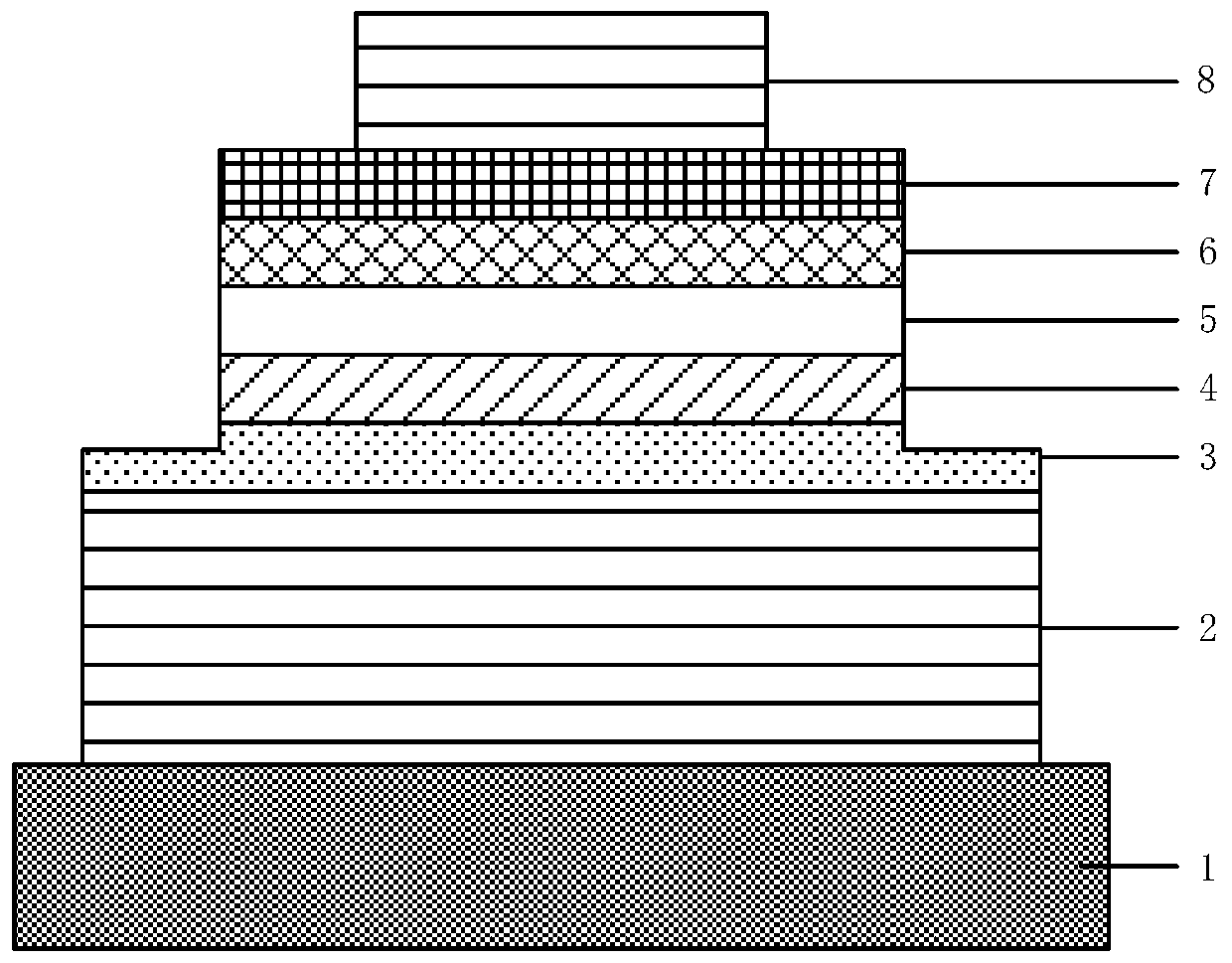

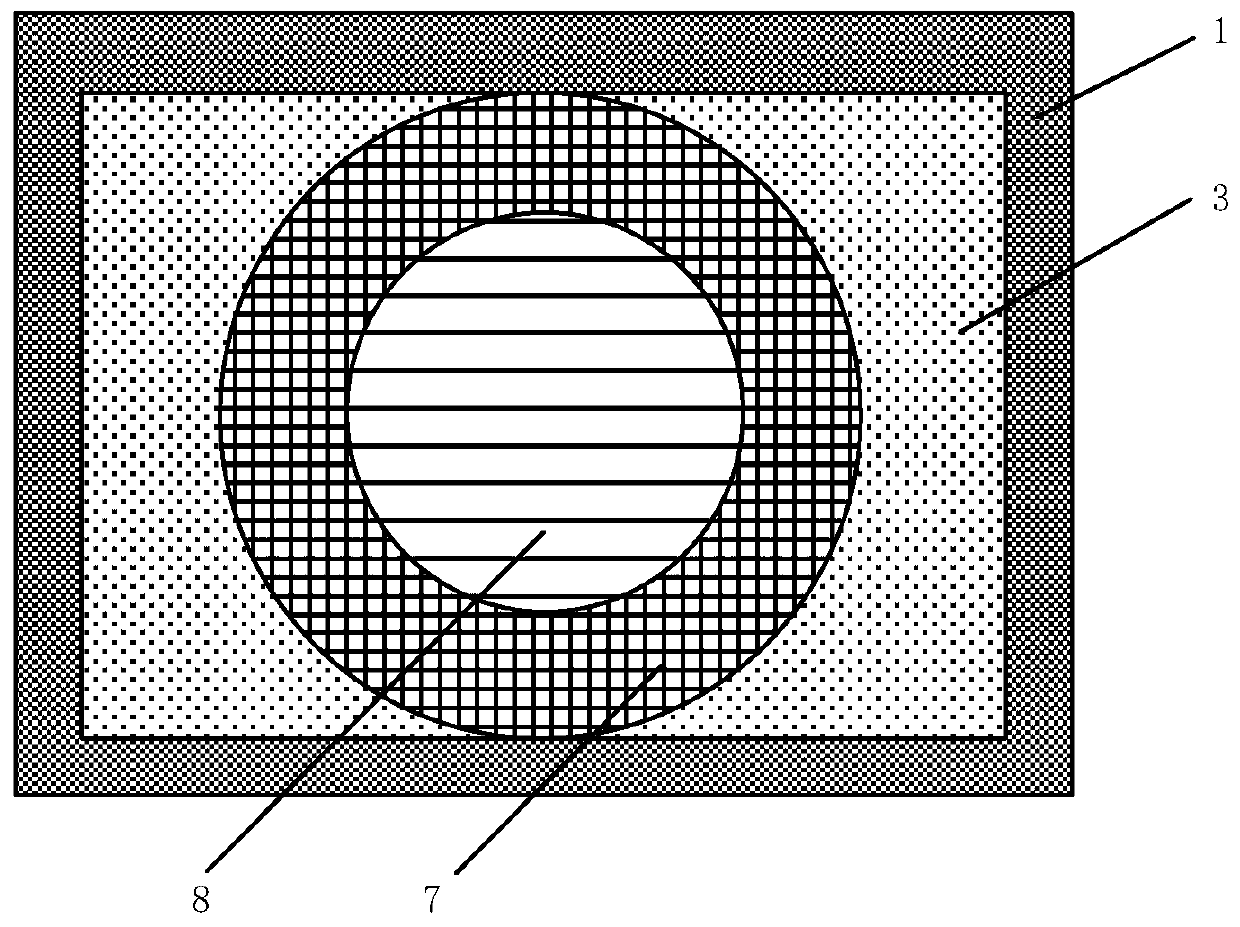

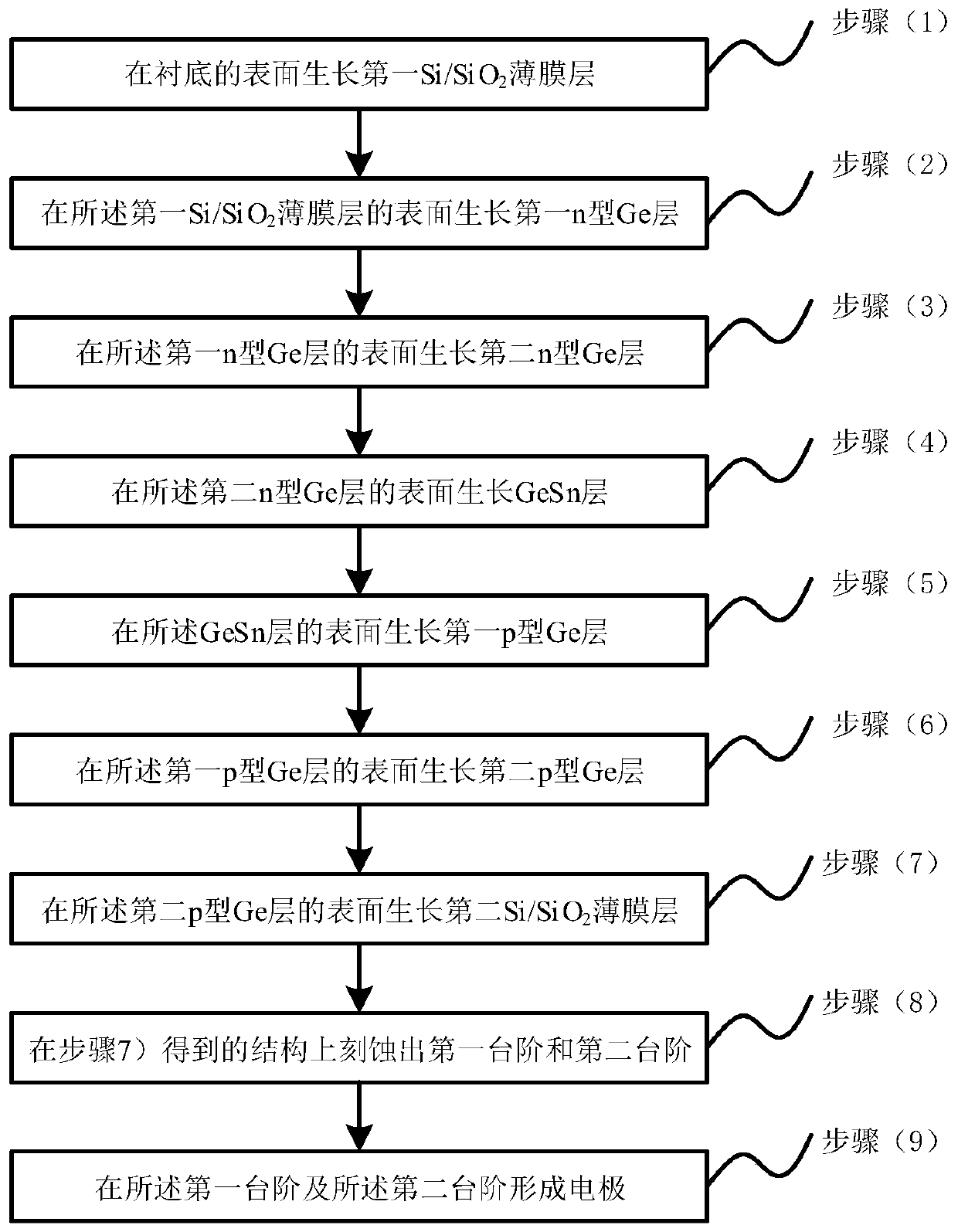

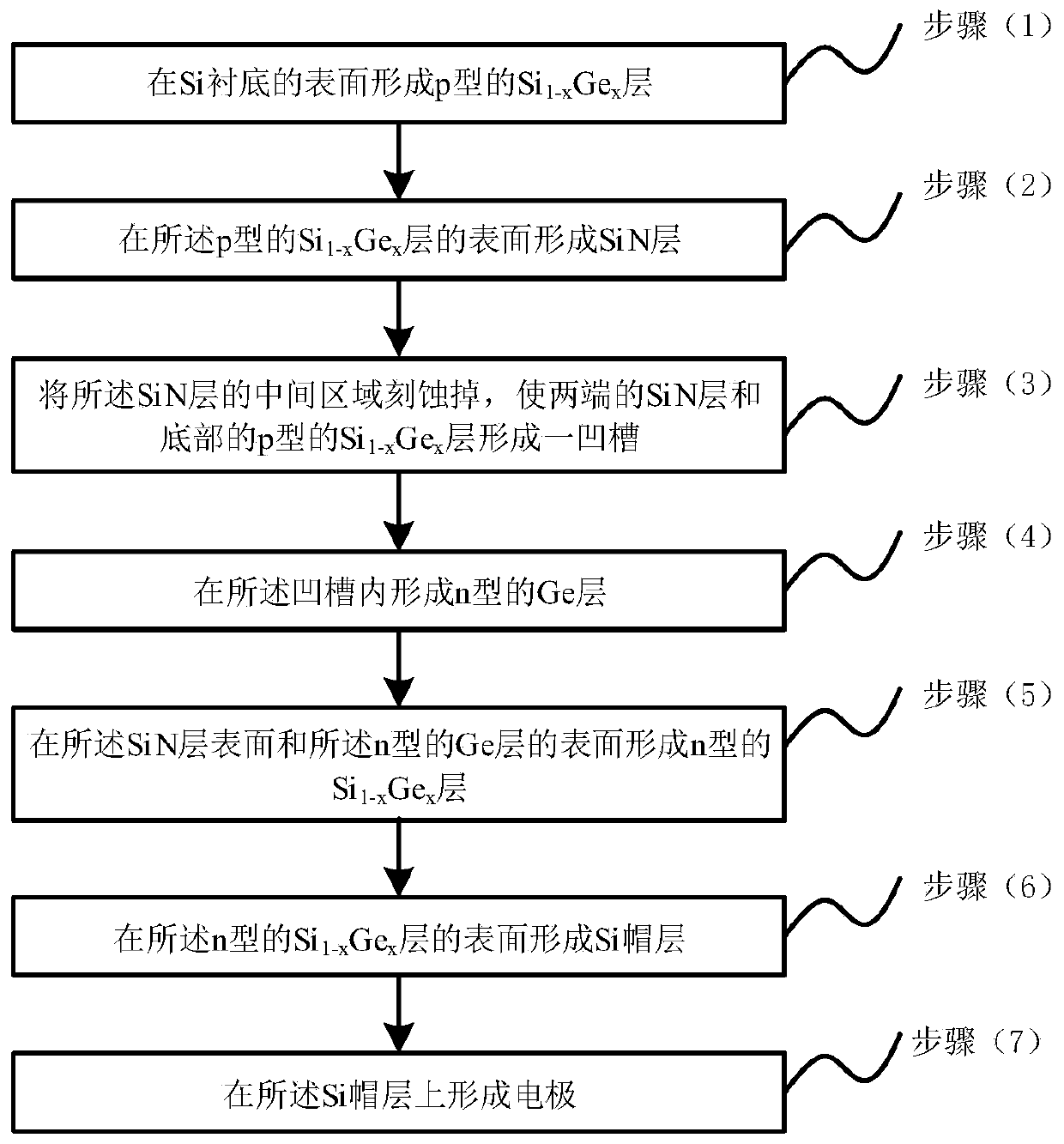

Ge/GeSn heterojunction laser and preparation method thereof

ActiveCN109244829AImprove efficiencyLower threshold current densityLaser detailsLaser active region structureLaserThreshold current

The invention discloses a Ge / GeSn heterojunction laser and a preparation method thereof. The method includes: growing a first Bragg reflective mirror layer on the surface of a substrate; growing a first n-type Ge layer on the surface of the first Bragg mirror layer; growing a second n-type Ge layer on the surface of the first n-type Ge layer; growing a GeSn layer on the surface of the second n-type Ge layer; growing a first p-type Ge layer on the surface of the GeSn layer; growing a second p-type Ge layer on the surface of the first p-type Ge layer; growing a second Bragg mirror layer on the surface of the second p-type Ge layer; etching a first cylinder and a second cylinder on the obtained structure; forming an electrode at the first step and the second step; finally forming a Ge / GeSn heterojunction lase is finally formed. The invention adopts GeSn material instead of traditional single Ge material to improve luminescence efficiency; By using P-I-N structure reduces the threshold current density. In addition, the preparation method of the invention is simple in process.

Owner:XIDIAN UNIV

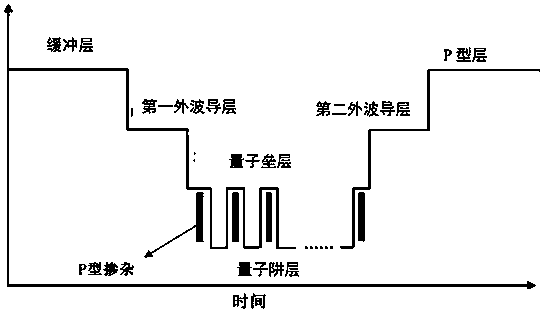

Modulated doped multi-period strain-compensated quantum well epitaxial layer and its growth method

ActiveCN105932543BImprove high temperature characteristicsSimple structureLaser detailsSemiconductor lasersGas phaseLinearity

The invention discloses a modulation-doped multi-period strain-compensated quantum well epitaxial layer and a growth method thereof. Air pressure in a metal organic chemical vapor deposition reaction chamber is set as predetermined air pressure and reaction gas and an MO source are piped into the metal organic chemical vapor deposition reaction chamber, and the reaction gas and the MO source react under predetermined temperature so as to generate the modulation-doped multi-period strain-compensated quantum well epitaxial layer, wherein the reaction gas is phosphorane and arsine; and the MO source is trimethylaluminum, trimethylindium, trimethylgallium, triethylgallium, P-type doped source dimethylzinc or P-type doped source diethylzinc. The modulation-doped multi-period strain-compensated quantum well epitaxial layer generated by the method is a high-linearity AlGaInAs quantum well epitaxial layer, and compressive strain is increased so that auger recombination and interband absorption can be reduced, and the effect of improving the high temperature characteristic of the device and the external quantum efficiency, the internal quantum efficiency and the conversion efficiency of an active area quantum well and enhancing relaxation oscillation frequency can be achieved.

Owner:WUHAN HUAGONG GENUINE OPTICS TECH CO LTD

Ge/gesn heterojunction laser and its preparation method

ActiveCN109244829BImprove efficiencyLower threshold current densityLaser detailsLaser active region structureHeterojunctionPhysical chemistry

The invention discloses a Ge / GeSn heterojunction laser and a preparation method thereof. The method includes: growing a first Bragg reflective mirror layer on the surface of a substrate; growing a first n-type Ge layer on the surface of the first Bragg mirror layer; growing a second n-type Ge layer on the surface of the first n-type Ge layer; growing a GeSn layer on the surface of the second n-type Ge layer; growing a first p-type Ge layer on the surface of the GeSn layer; growing a second p-type Ge layer on the surface of the first p-type Ge layer; growing a second Bragg mirror layer on the surface of the second p-type Ge layer; etching a first cylinder and a second cylinder on the obtained structure; forming an electrode at the first step and the second step; finally forming a Ge / GeSn heterojunction lase is finally formed. The invention adopts GeSn material instead of traditional single Ge material to improve luminescence efficiency; By using P-I-N structure reduces the threshold current density. In addition, the preparation method of the invention is simple in process.

Owner:XIDIAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com