Patents

Literature

145results about How to "Reduce photolithography process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

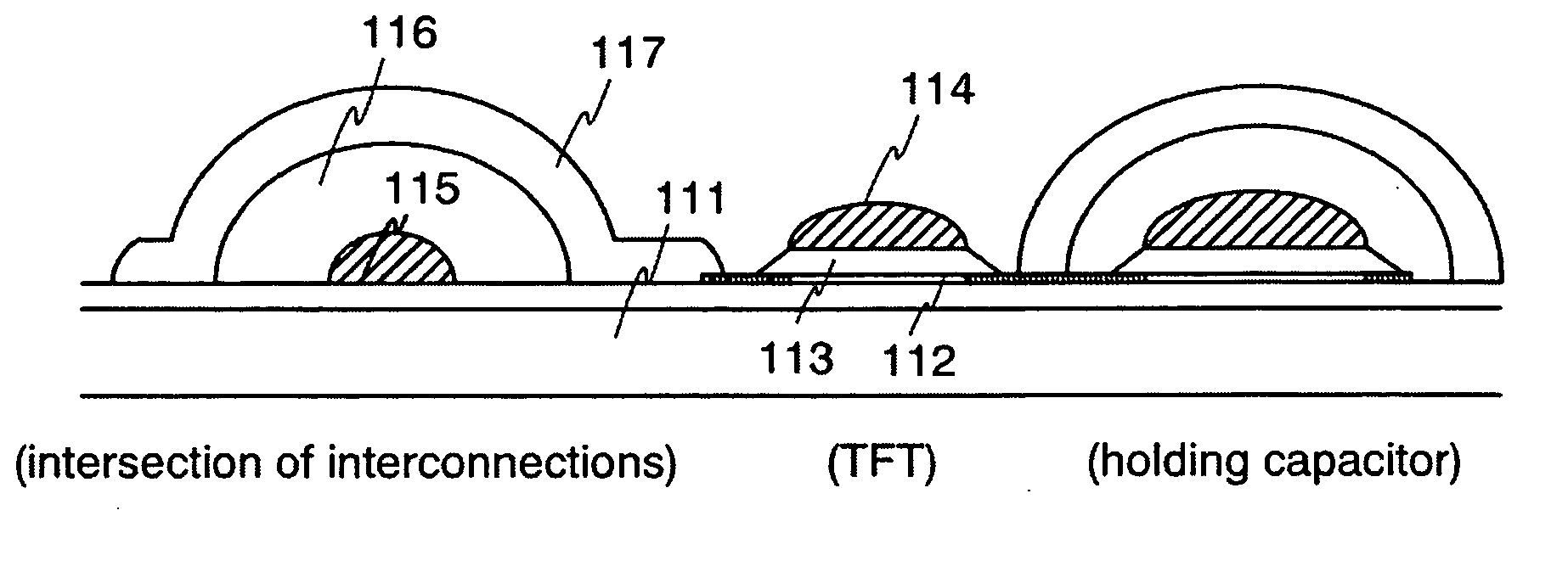

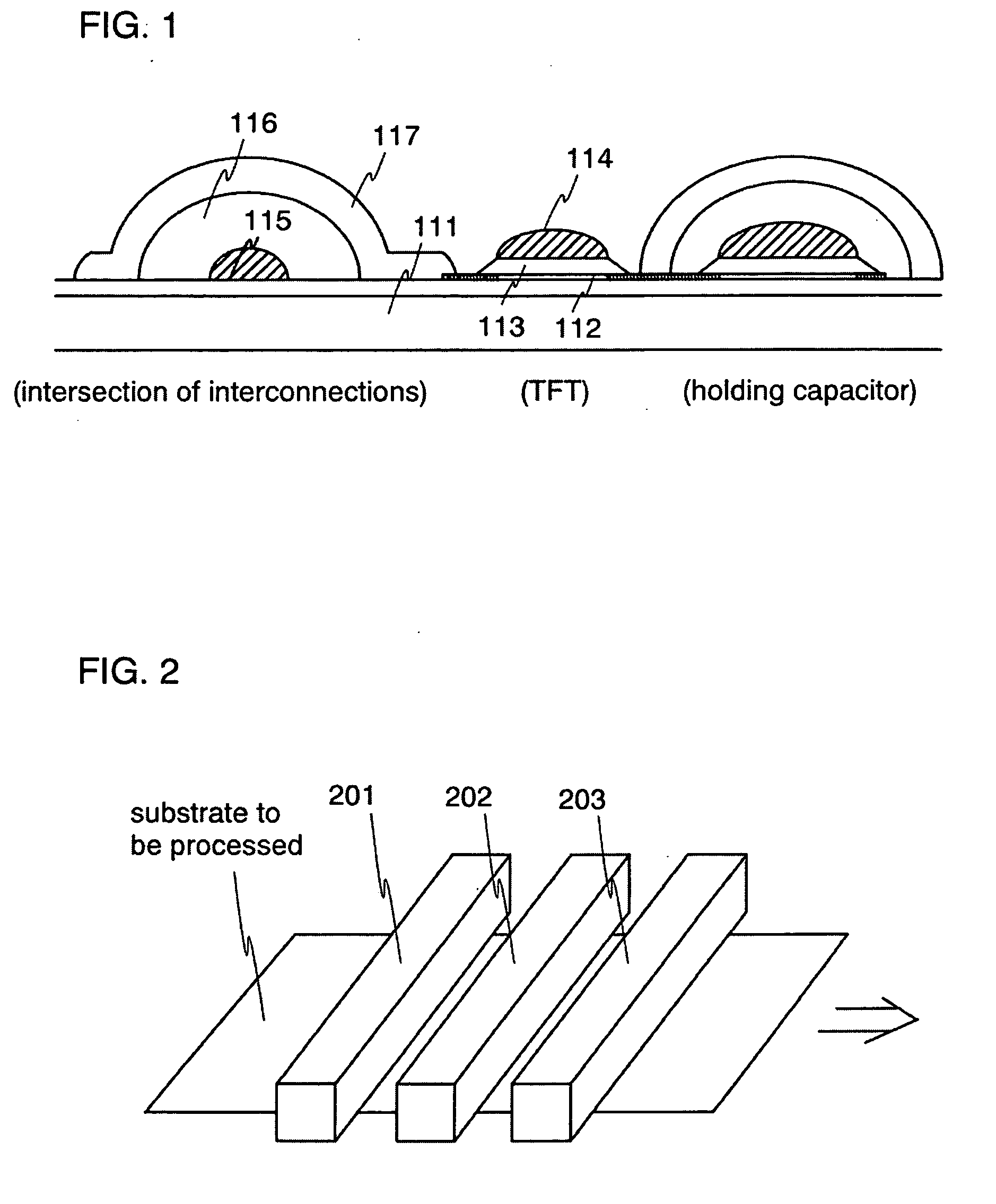

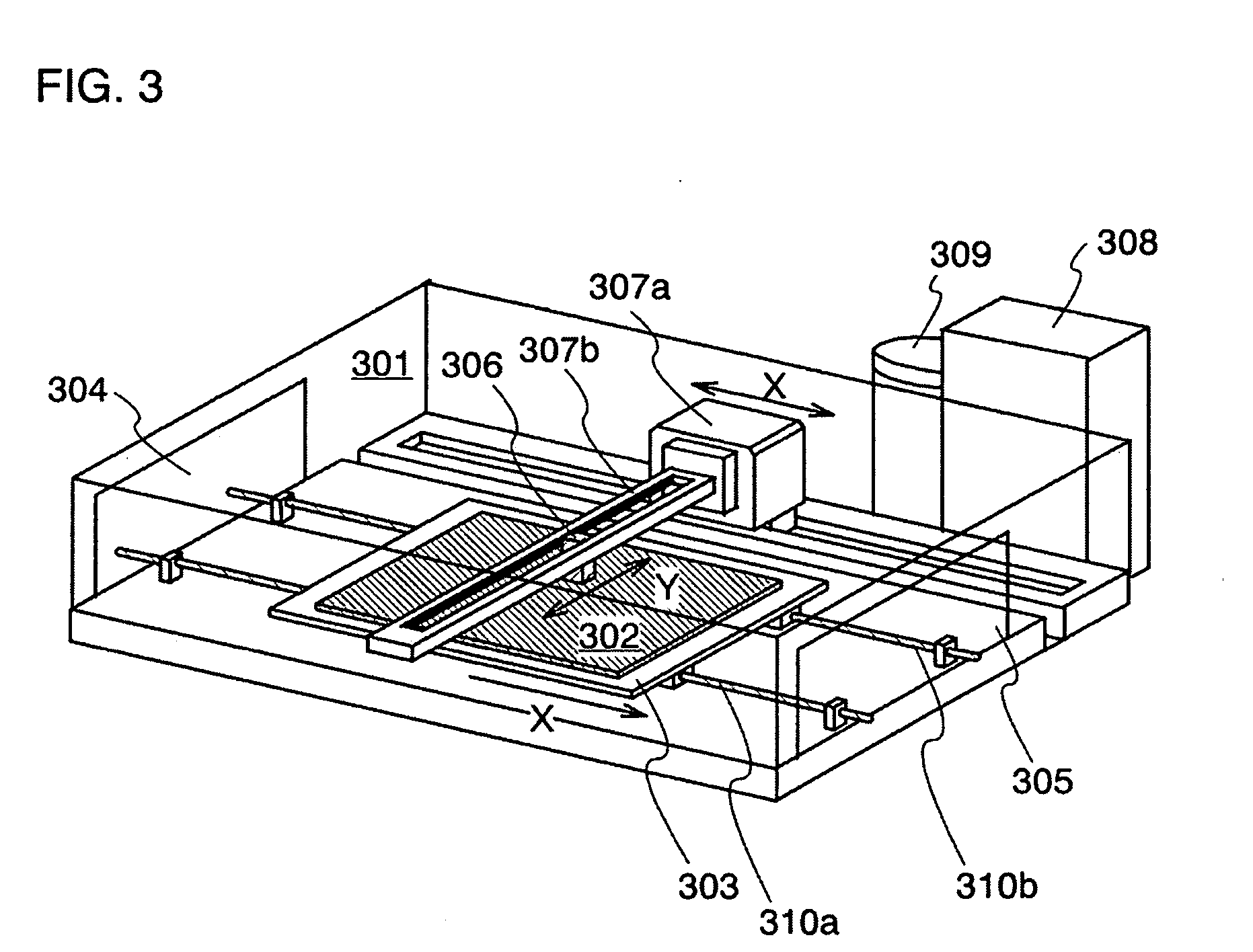

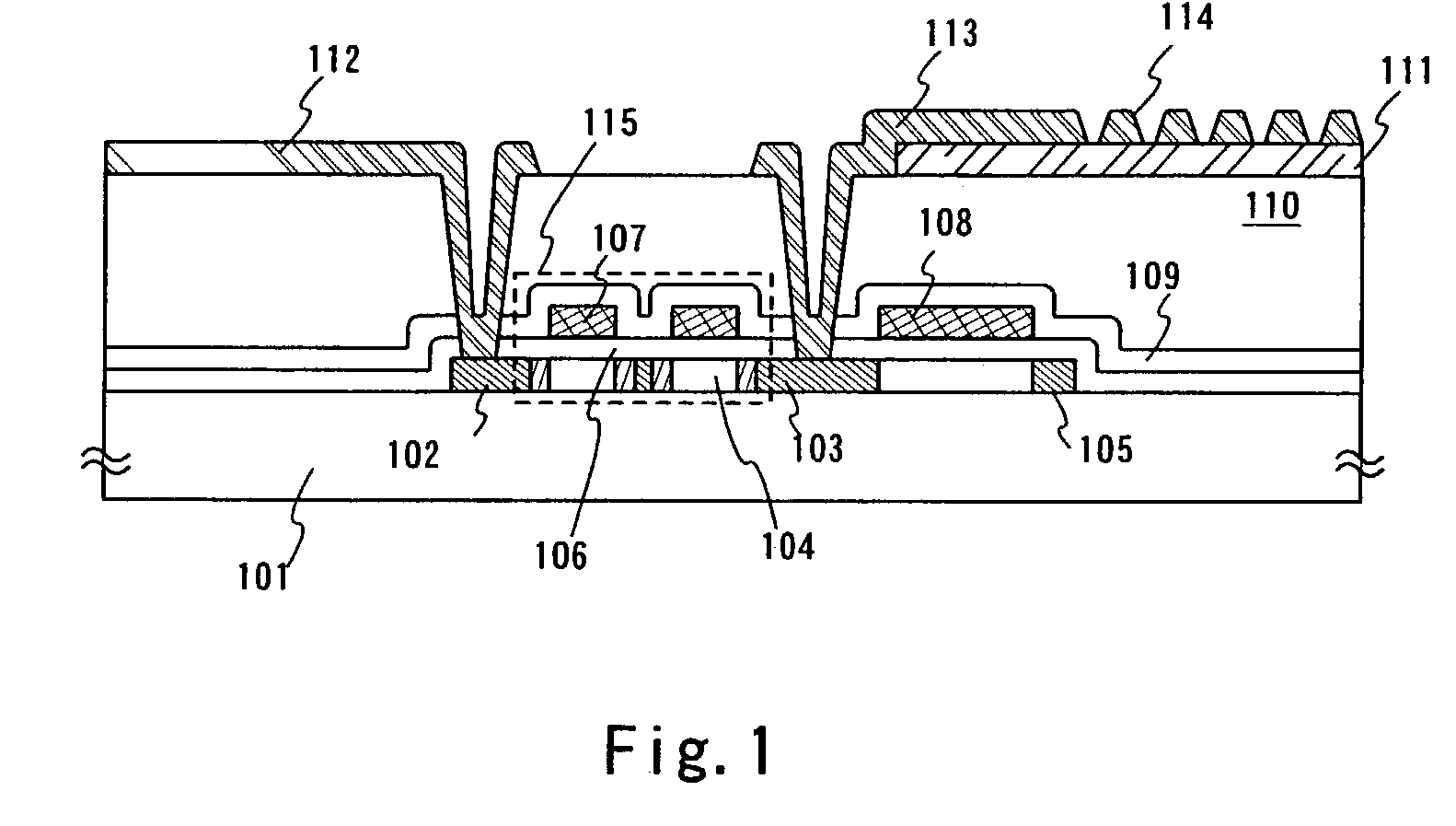

Semiconductor device and manufacturing method thereof

InactiveUS20070181945A1Low costReduce in quantitySolid-state devicesSemiconductor/solid-state device manufacturingDevice materialEngineering

An island-like interlayer insulating film is formed selectively in a region where a source interconnection and a gate interconnection intersect. For example, by use of ink jet method, a solution containing an insulating material is dropped on a region where the gate interconnection and the source interconnection intersect or a region where a holding capacitor is formed, that enable to reduce a photolithography process and to reduce the number of masks that are used in a TFT

Owner:SEMICON ENERGY LAB CO LTD

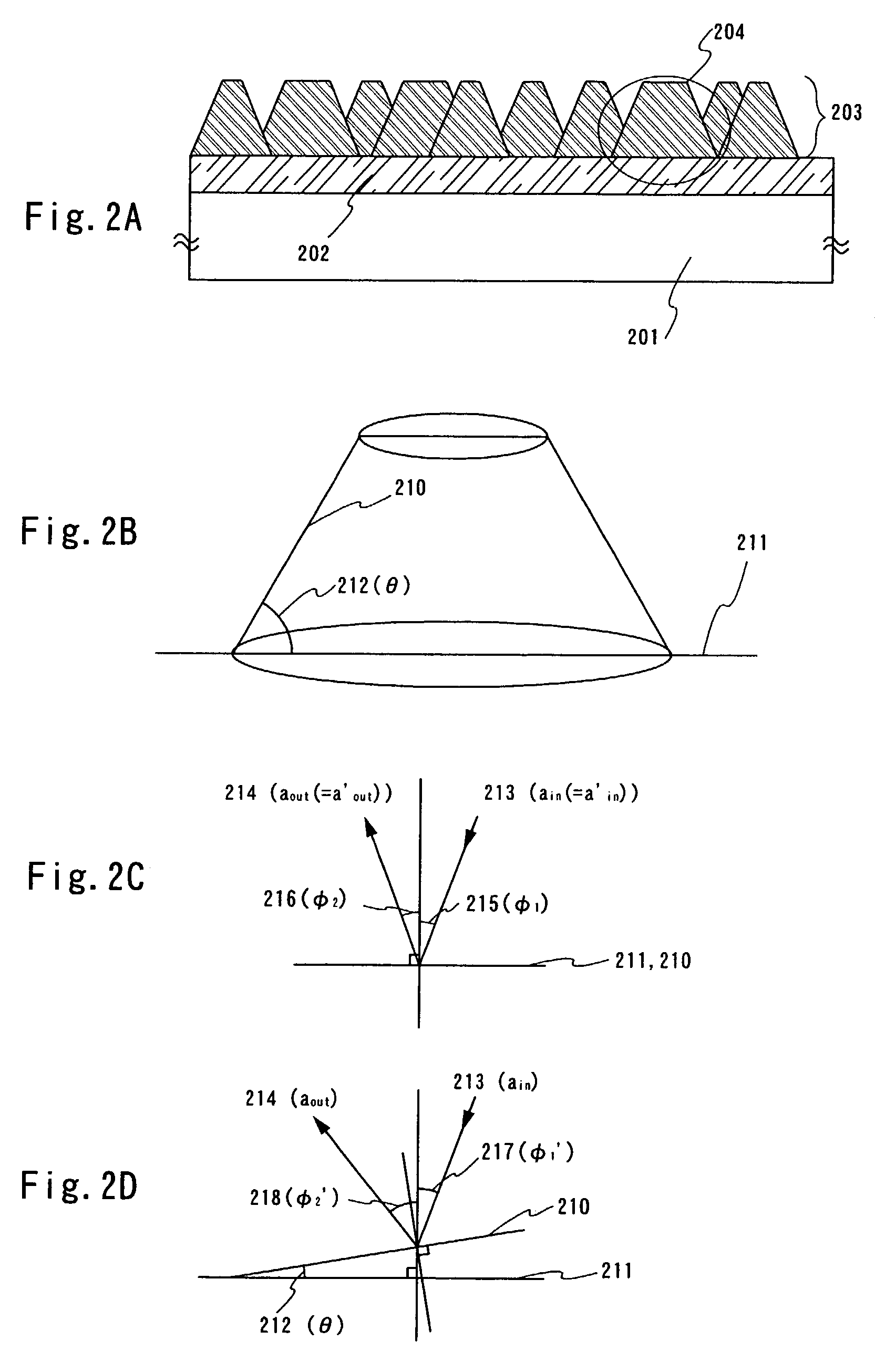

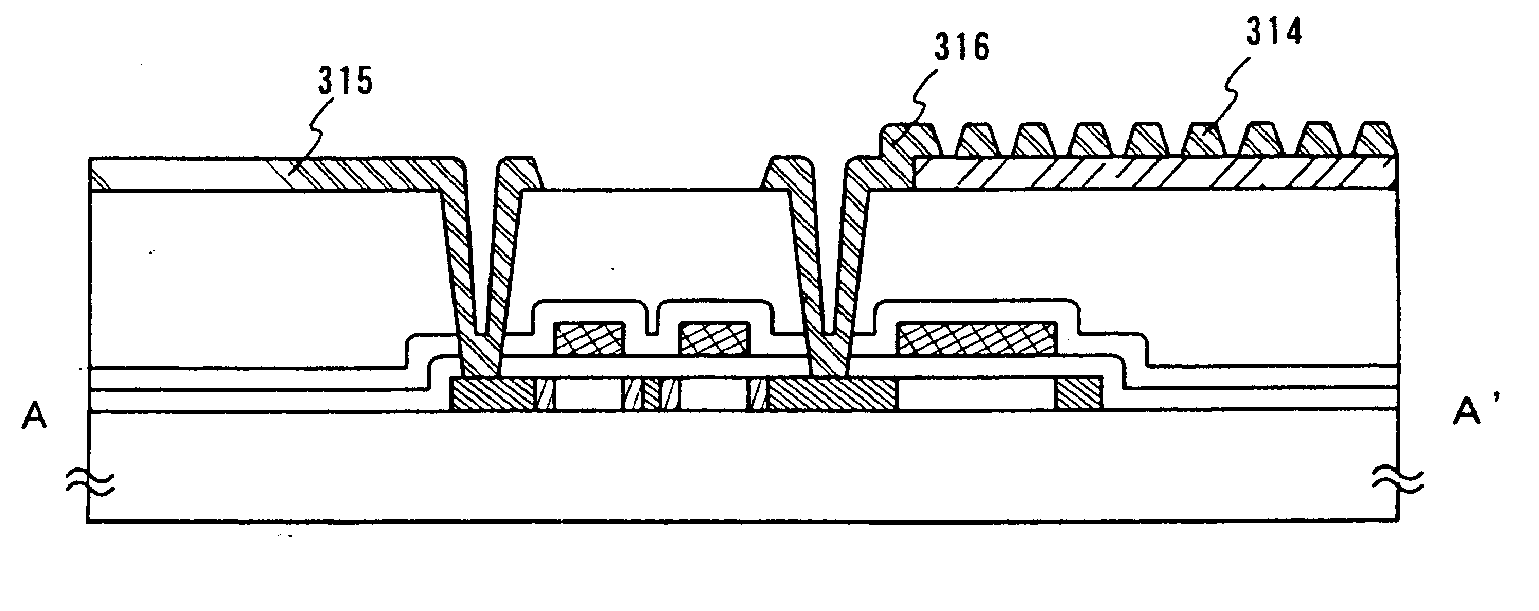

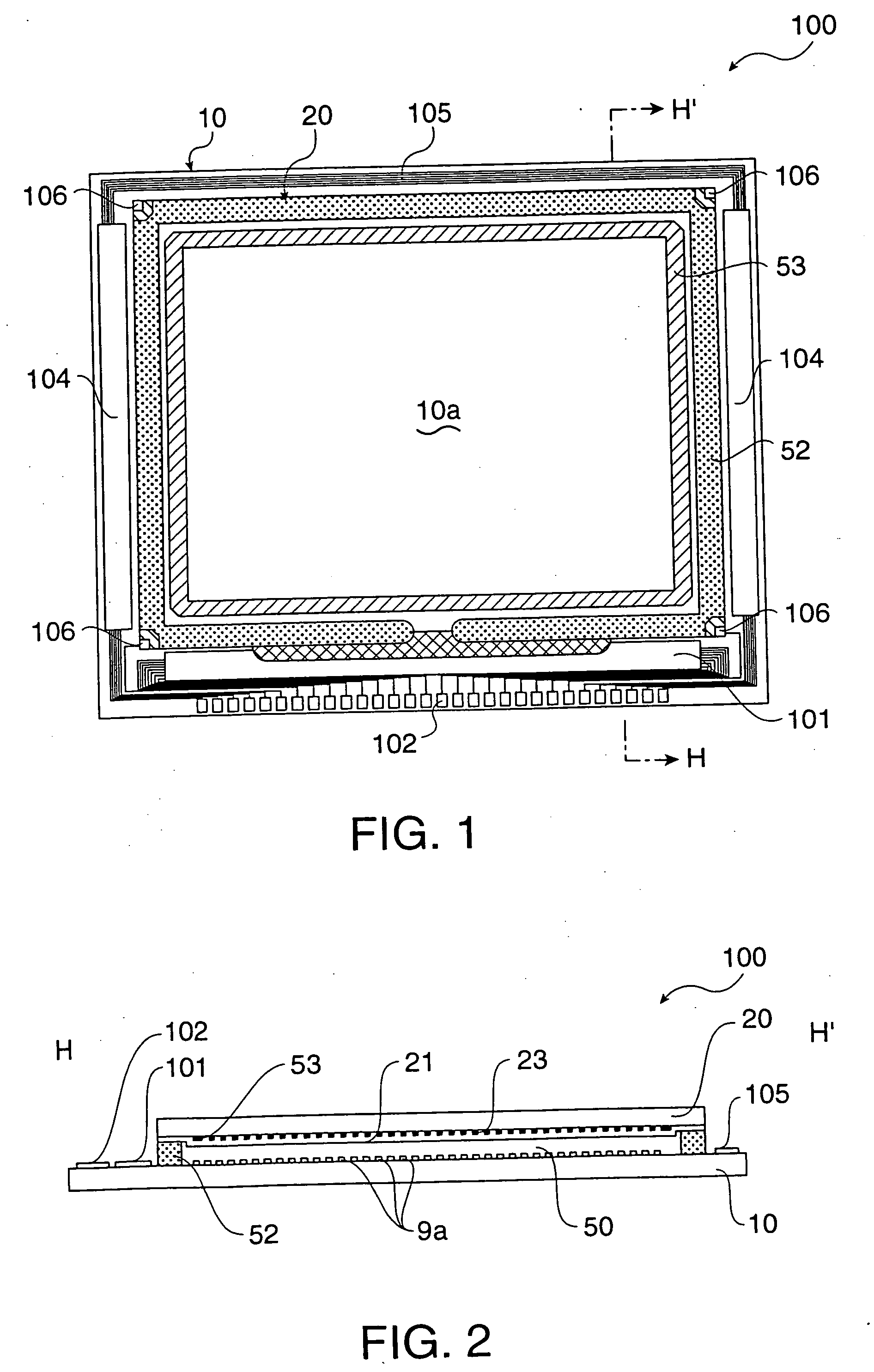

Liquid crystal display device

InactiveUS7053969B2Low costImprove productivityTransistorSolid-state devicesVisibilityConvex structure

It is an object to provide a display having high visibility and a transflective type liquid crystal display device having a reflection electrode having a concavo-convex structure formed without especially increasing the process. During manufacturing a transflective liquid crystal display device, a reflection electrode of a plurality of irregularly arranged island-like patterns and a transparent electrode of a transparent conductive film are layered in forming an electrode having transparent and reflection electrodes thereby having a concavo-convex form to enhance the scattering ability of light and hence the visibility of display. Furthermore, because the plurality of irregularly arranged island-like patterns can be formed simultaneous with an interconnection, a concavo-convex structure can be formed during the manufacturing process without especially increasing the patterning process only for forming a concavo-convex structure. It is accordingly possible to greatly reduce cost and improve productivity.

Owner:SEMICON ENERGY LAB CO LTD

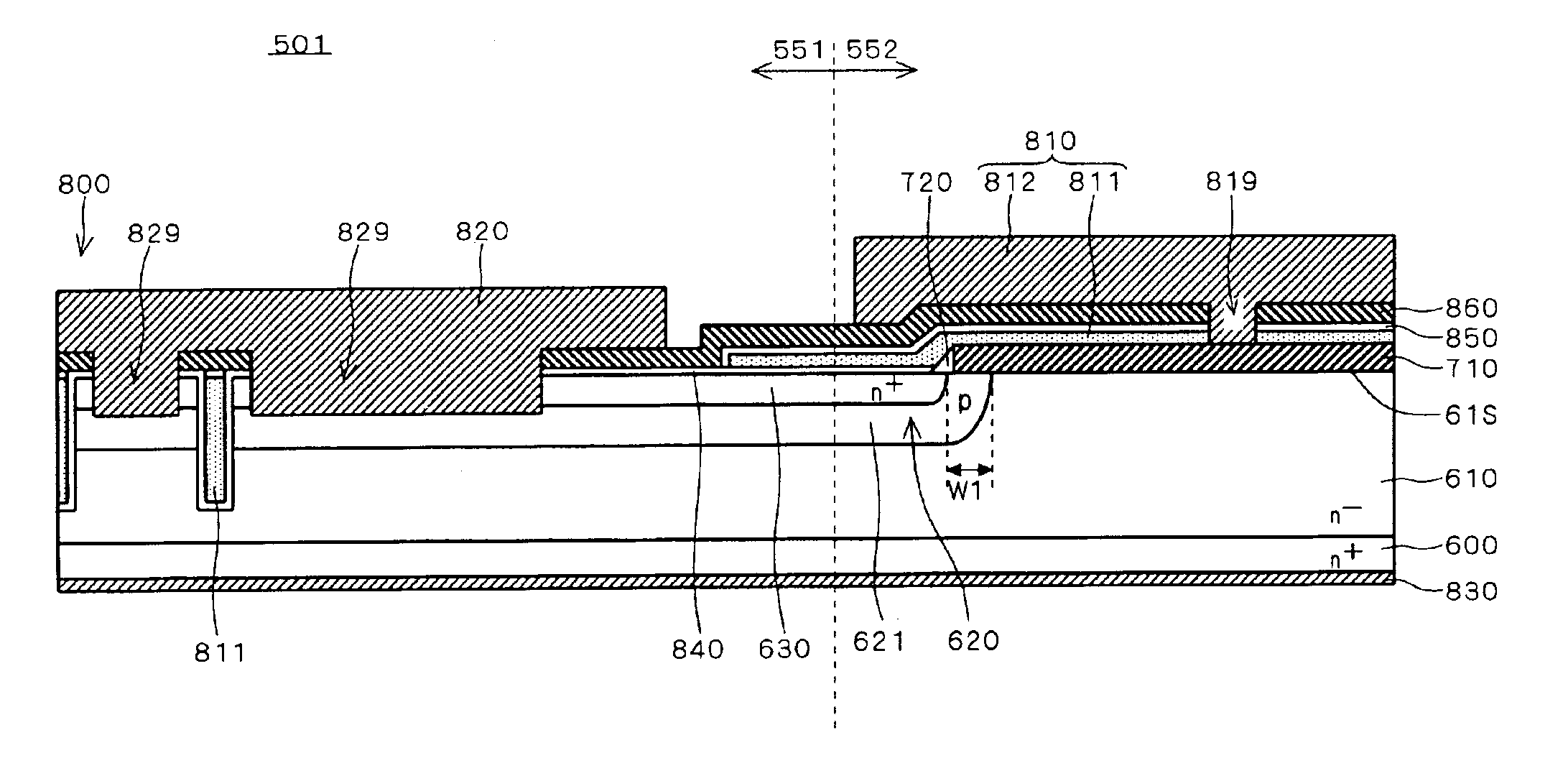

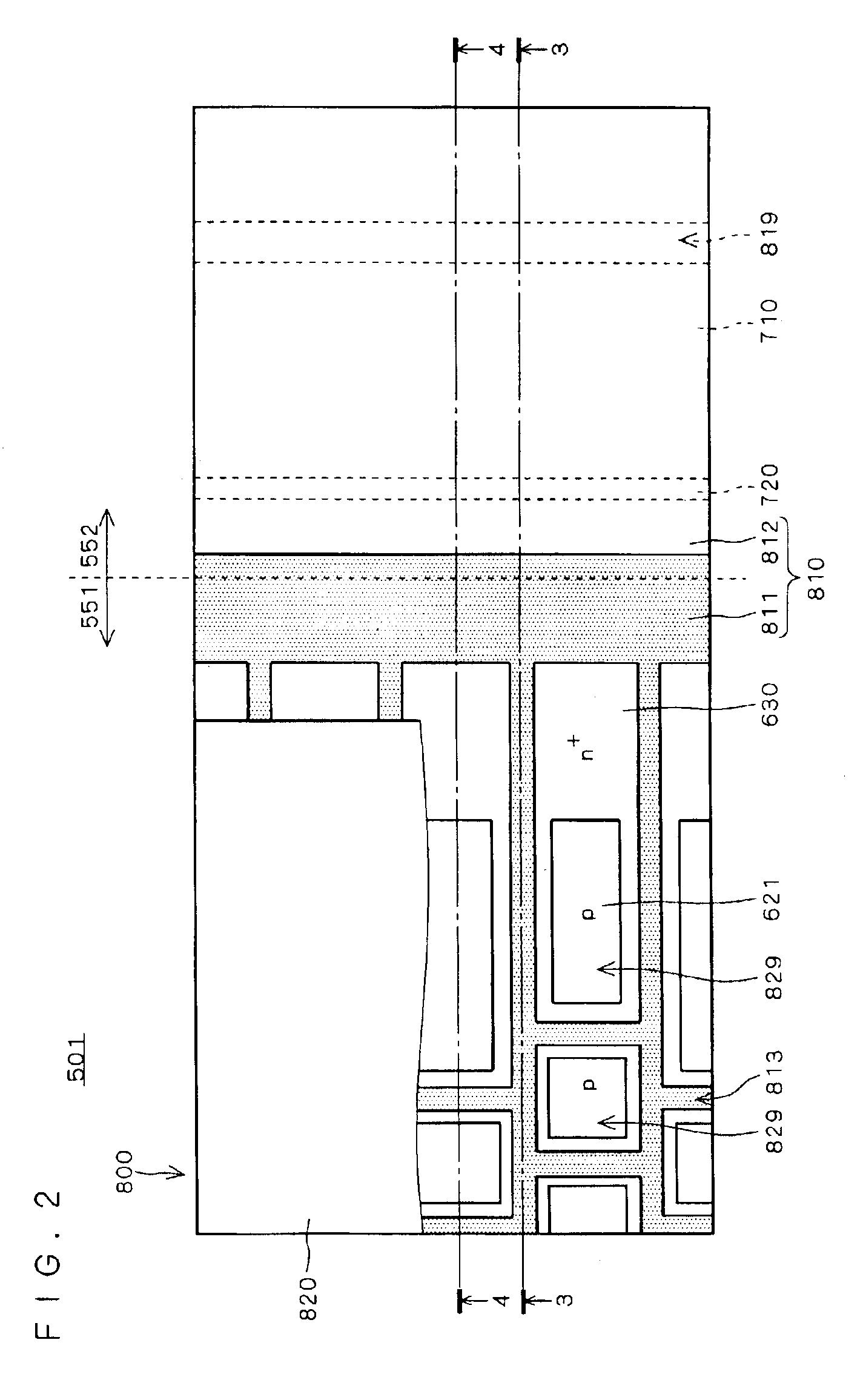

Power semiconductor device having semiconductor-layer-forming position controlled by ion implantation without using photoresist pattern, and method of manufacturing such power semiconductor device

InactiveUS6927455B2Reduce decreaseLower breakdown voltageSemiconductor/solid-state device manufacturingSemiconductor devicesPower semiconductor devicePosition control

A first insulator (710) having an opening within a central region (551) is formed on a main surface (61S) of an epitaxial layer (610). Then, p-type impurities are ion implanted through the opening of the first insulator (710) and then heat treatment is carried out, thereby to form a p base layer (621) in the main surface (61S). An insulating film is formed to fill in the opening and then etched back, thereby to form a second insulator (720) on a side surface (71W) of the first insulator (710). Under conditions where the second insulator (720) is present, n-type impurities are ion implanted through the opening and then heat treatment is carried out, thereby to form an n+ source layer (630) in the main surface (61S) of the p base layer (621).

Owner:MITSUBISHI ELECTRIC CORP

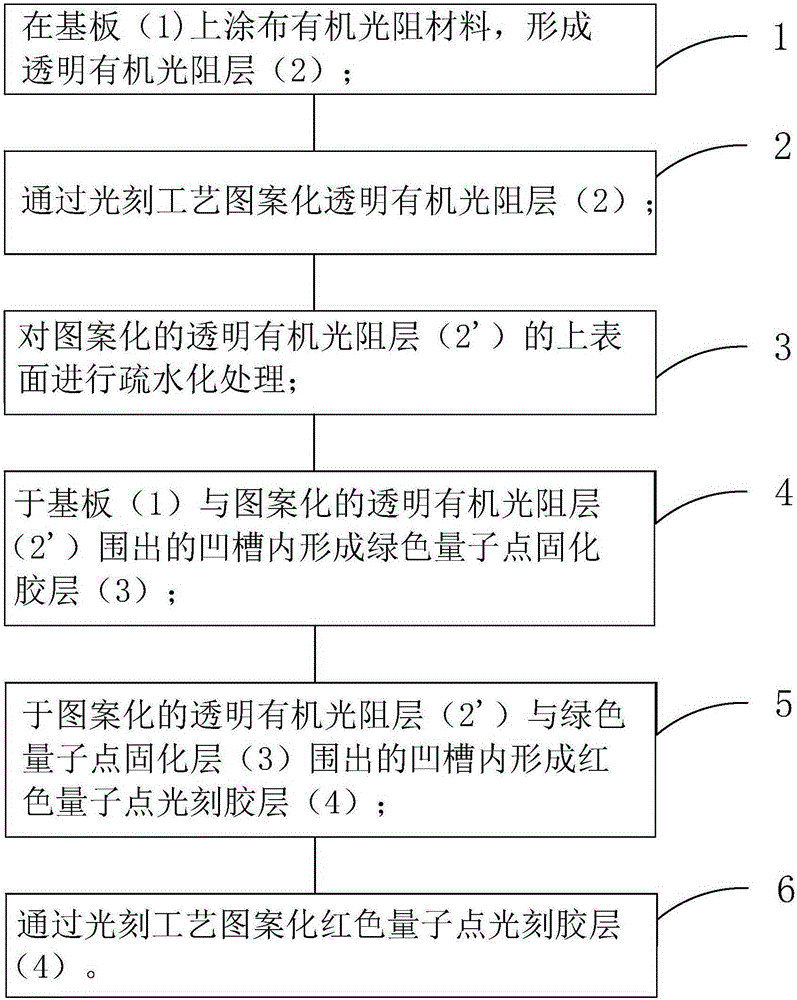

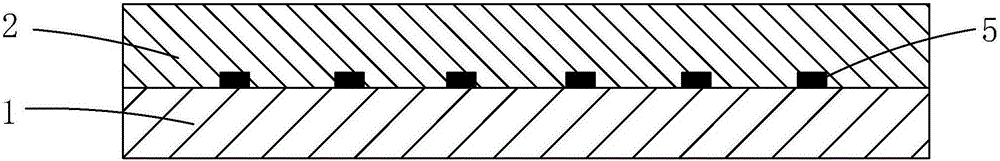

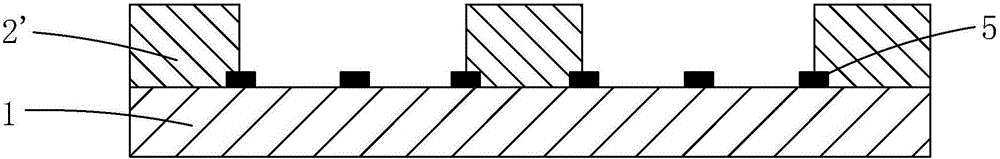

Method for making quantum dot color film

ActiveCN105242442AReduce photolithography processSimple processPhotomechanical apparatusNon-linear opticsQuantum dotColor film

The invention provides a method for making a quantum dot color film. The method for making the quantum dot color film comprises photoetching transparent organic photoresistive material to form a blue sub-pixel portion of a quantum dot color film, making a transparent organic photoresistive layer hydrophobic, coating a green quantum dot curing glue and a red quantum dot photoresist on corresponding areas in order with the help of hydrophobicity to obtain a green quantum dot curing glue layer and a red quantum dot photoresist layer on the same in order, photoetching a portion of red quantum dot photoresist layer to obtain a green sub-pixel portion and a red sub-pixel portion of the quantum dot color film. Compared with a conventional method for making a quantum dot color film, one photoetching process can be reduced, the making process can be greatly simplified, the cost can be reduced, the production efficiency can be raised, only one kind of quantum pot photoetching glue needs developing, and the difficulty and cost of development are reduced.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

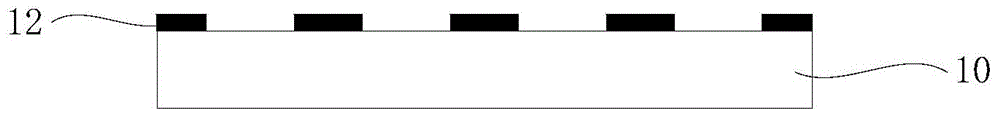

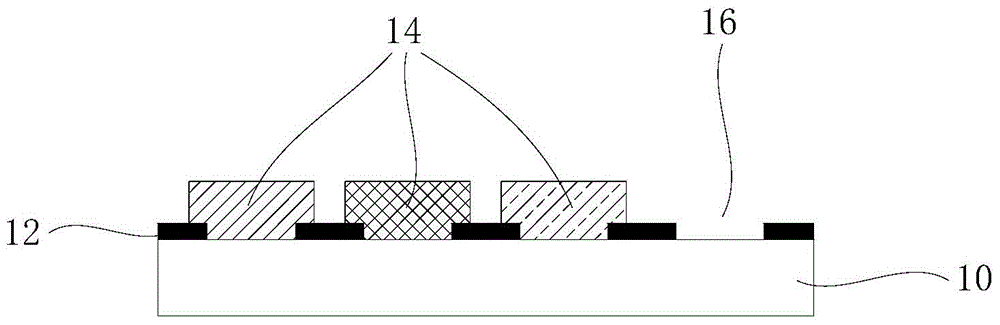

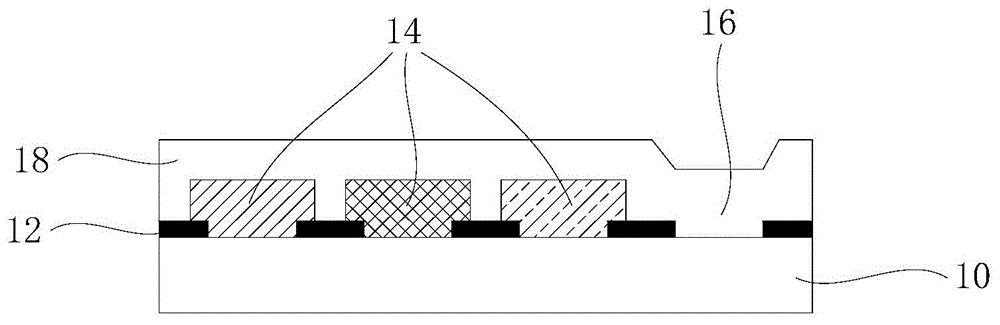

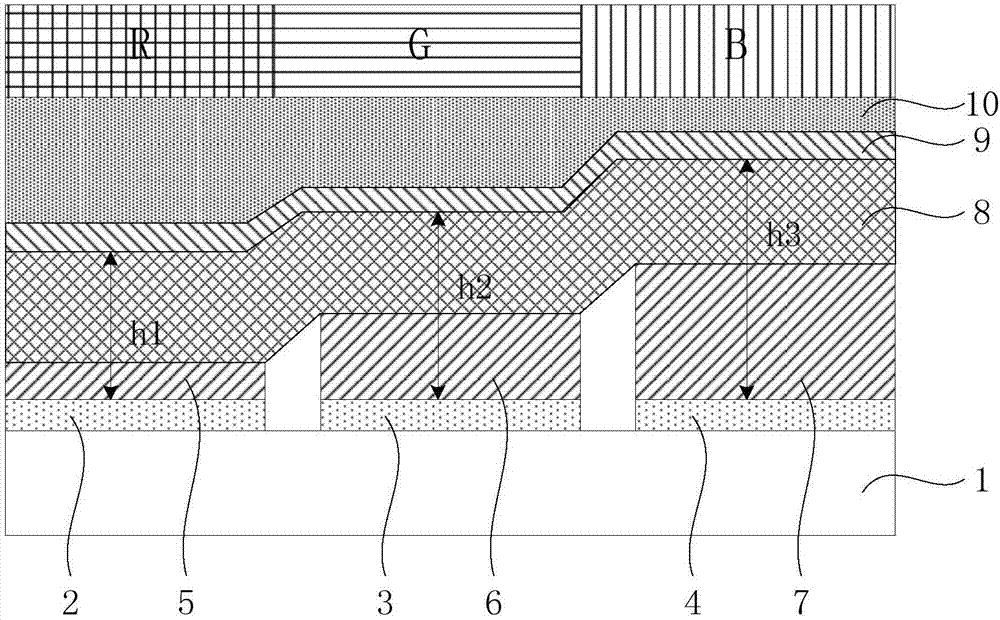

Method for manufacturing color filter substrate

InactiveCN104678639AWon't dentAvoid uneven surfacesOptical filtersPhotomechanical coating apparatusColor gelWhite light

The invention discloses a method for manufacturing a color filter substrate. The method comprises the following steps of providing a substrate (10); forming a light shielding portion (12) on the substrate (10); forming a color filter, which comprises a colorful portion (14) and an opening portion (16), on the substrate (10); covering the substrate (10) by using a flat layer (18) which is filled in the opening portion (16); photoetching the flat layer (18); and forming a spacer (24) on the photoetched flat layer (18). A transparent light resistance layer is filled in the opening portion and serves as a white light resistor, and the surface of the transparent light resistance layer is flattened by using a photoetching technology. Compared with the prior art, the method for manufacturing the color filter substrate has the advantages that a white color resistor photoetching manufacture procedure is omitted, the transparent light resistance layer on the opening portion cannot be sunken, irregularity of the surface of the transparent light resistance layer is avoided, and the display quality of a manufactured liquid crystal display panel is improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

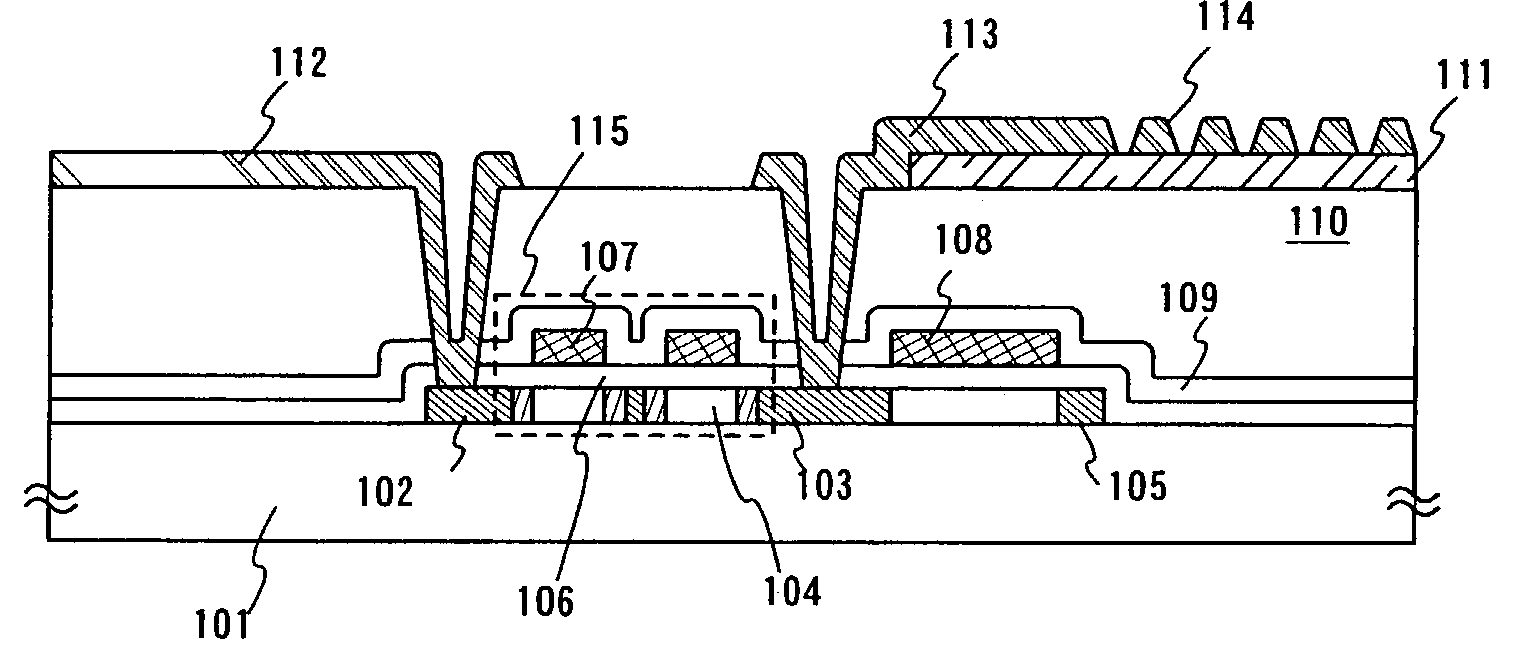

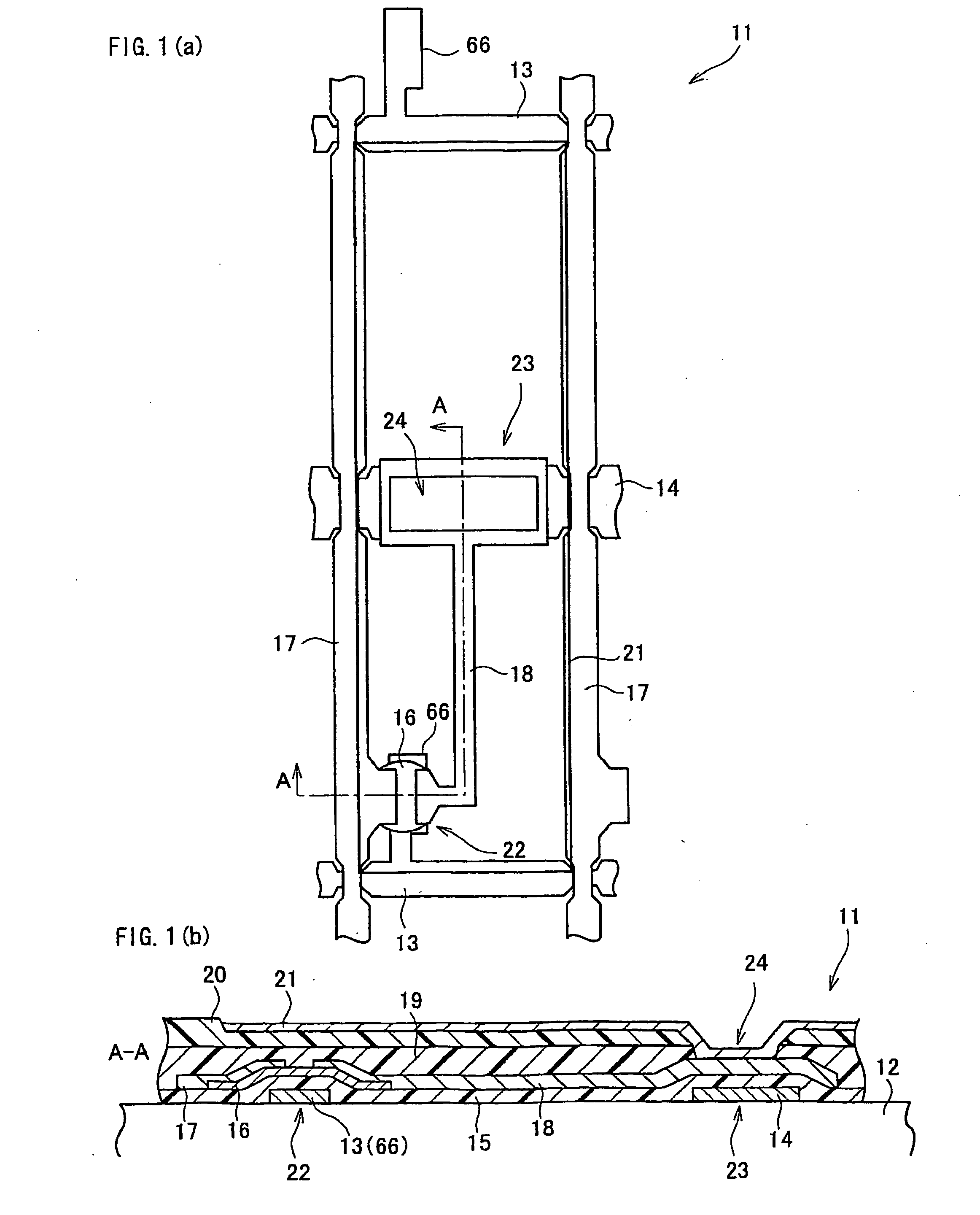

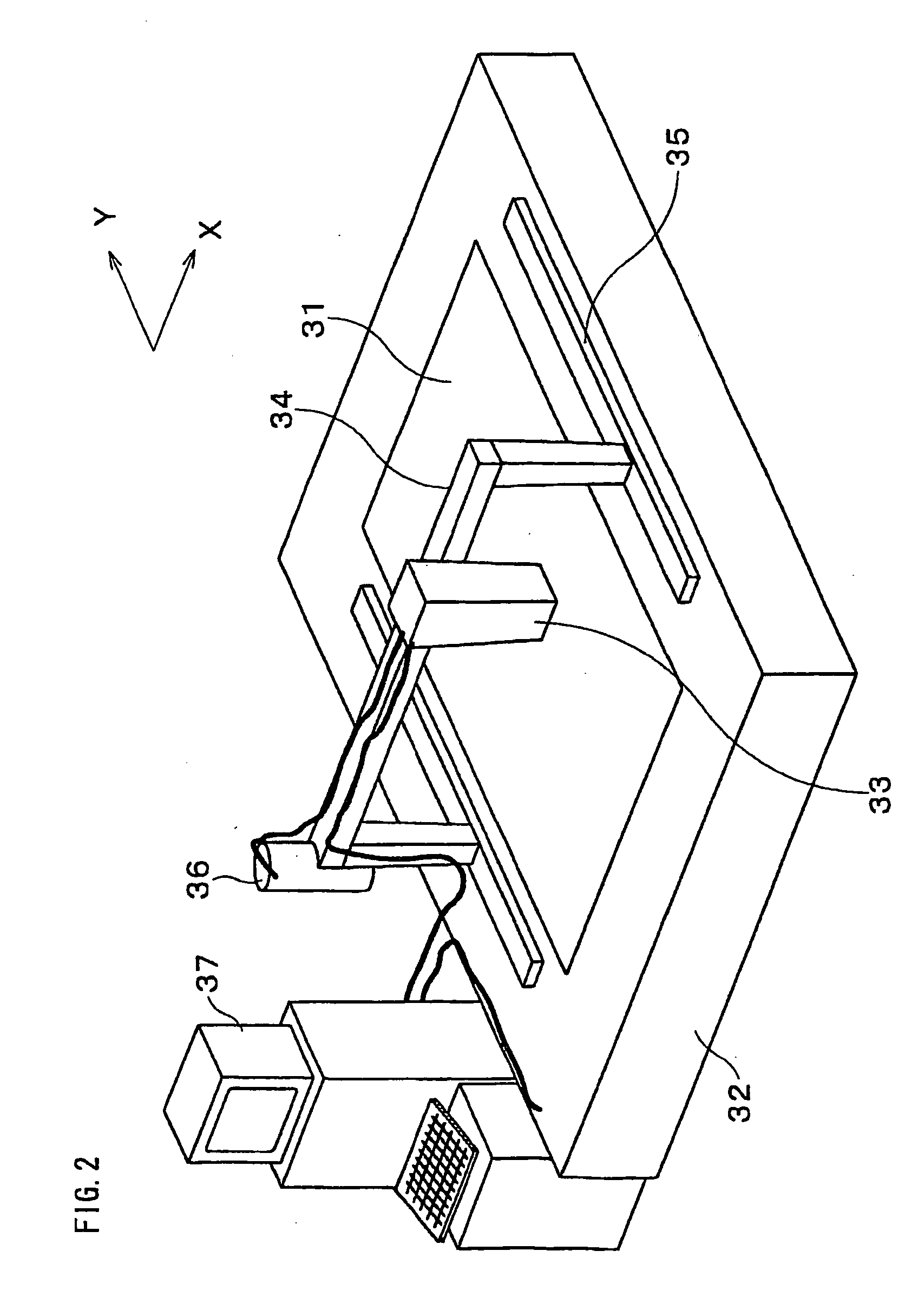

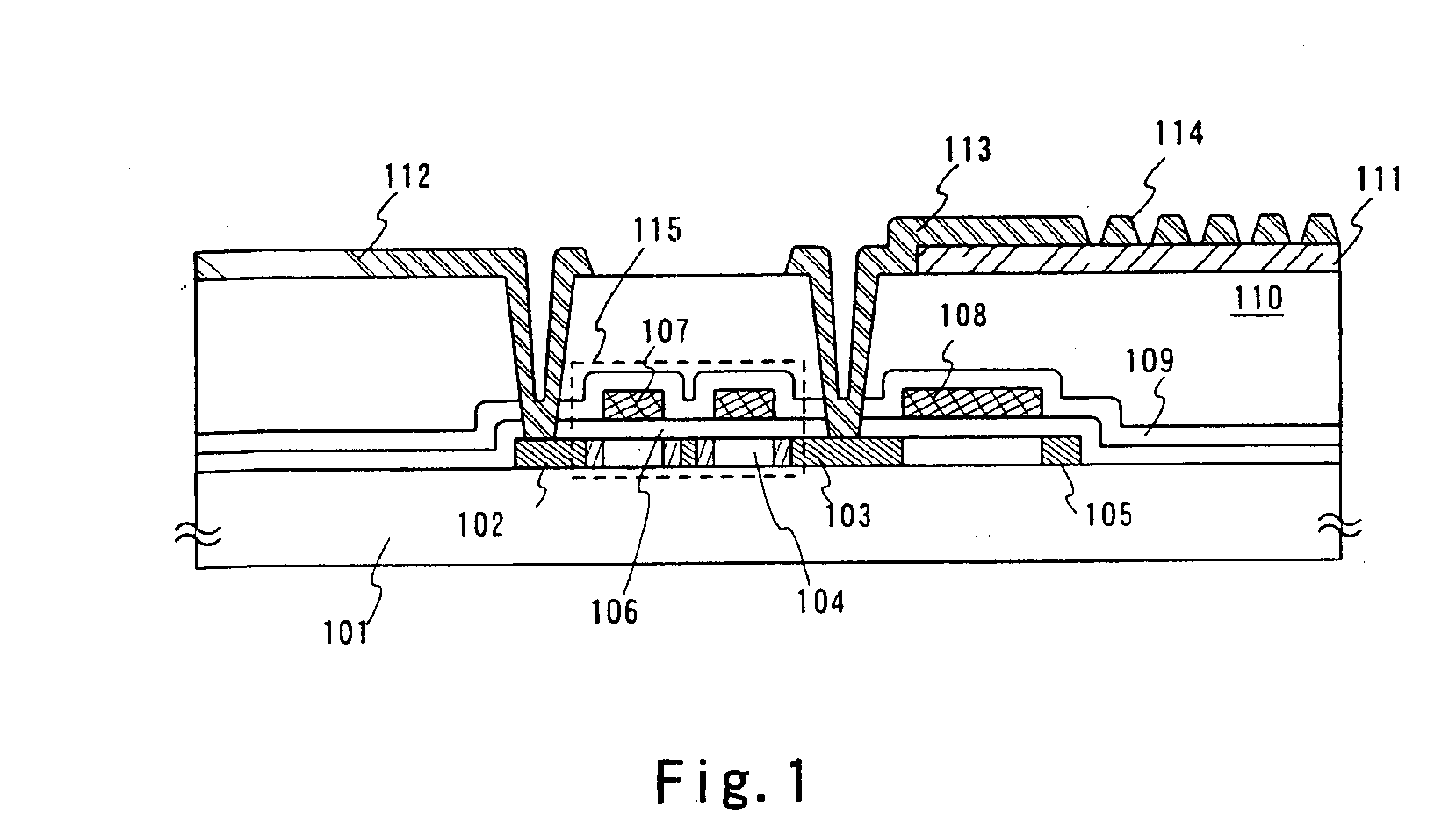

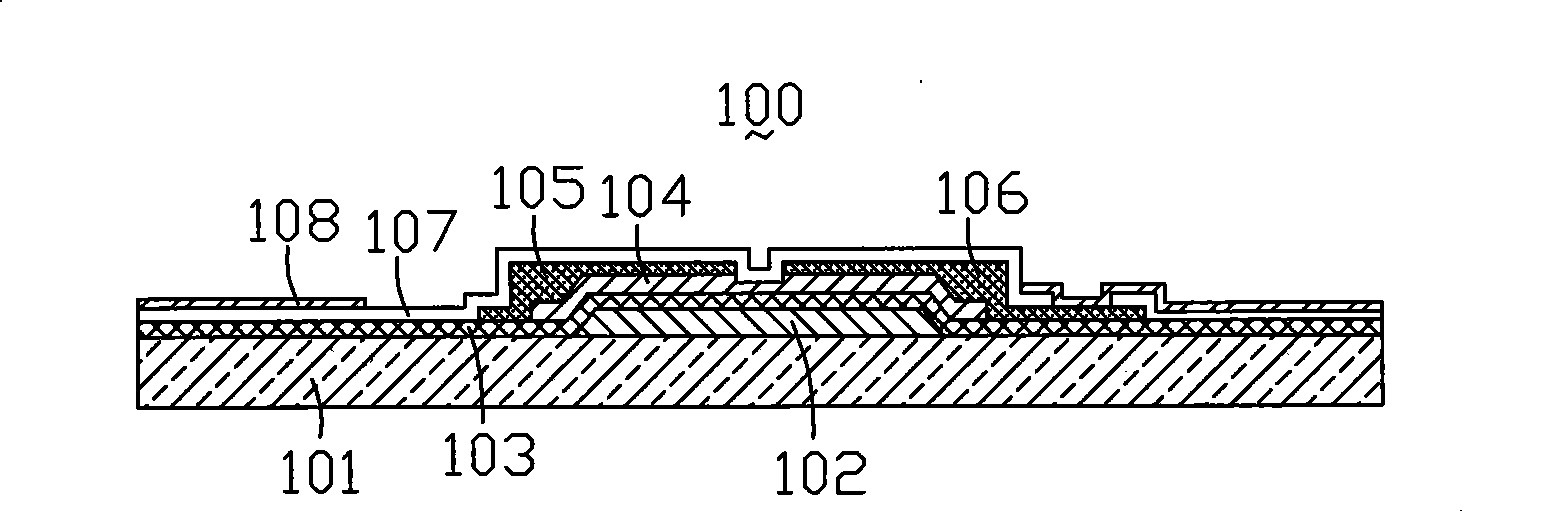

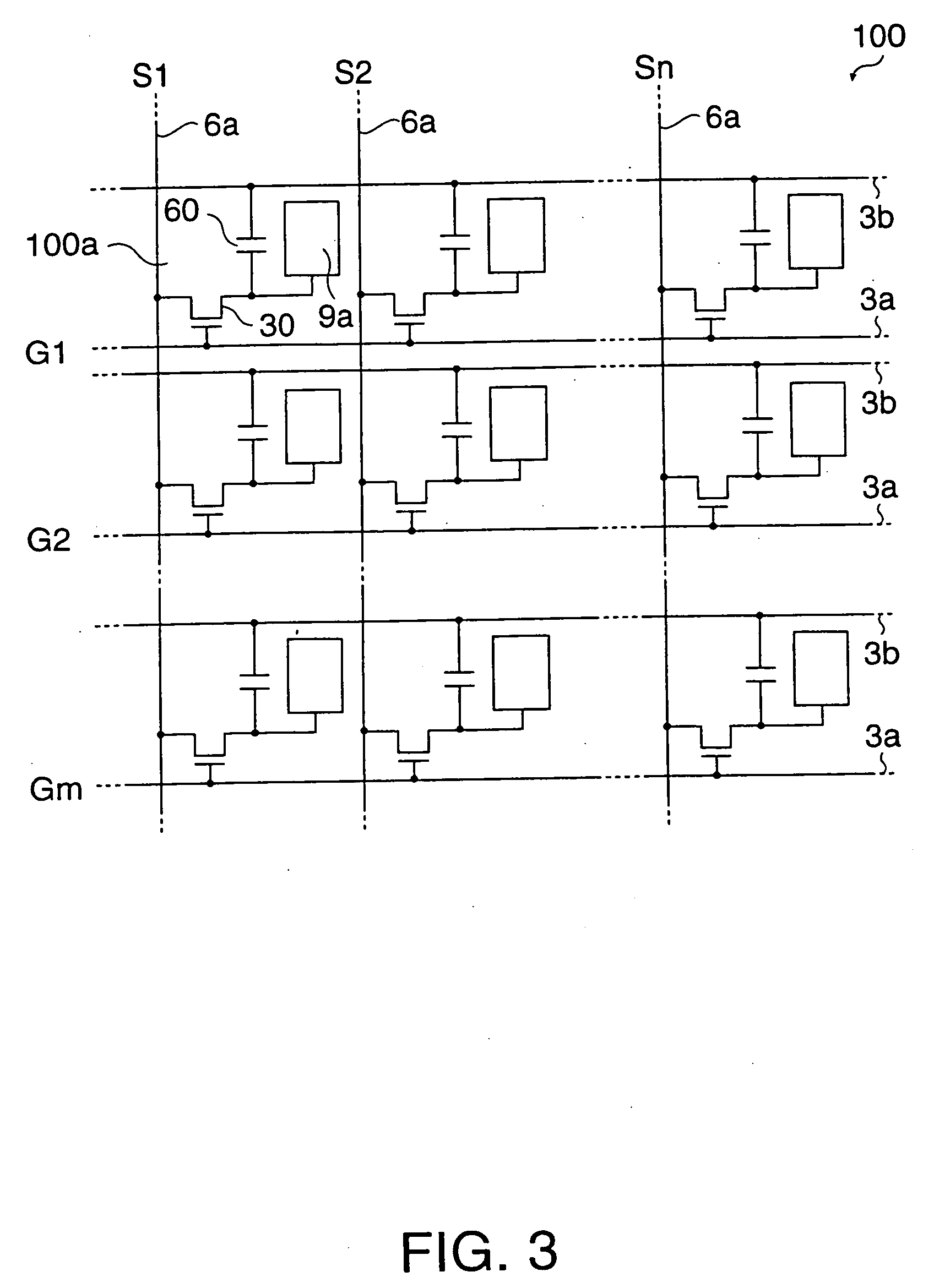

Tft array substrate, liquid crystal display device, manufacturing methods of tft array substrate and liquid crystal display device, and electronic device

InactiveUS20060086937A1Small amountReduce production processTransistorSemiconductor/solid-state device detailsResistInsulation layer

A TFT array substrate includes a thin film transistor section in which a gate electrode is formed on a substrate, and a semiconductor layer is formed on the gate electrode via a gate insulation layer. The semiconductor layer of this TFT array substrate has a shape formed by dropping a droplet. Accordingly, it is possible to directly forming a semiconductor layer, or a resist layer for forming the semiconductor layer, by dropping a droplet(s). On this account, the present invention allows the use of an inkjet method, thus reducing costs and numbers of manufacturing processes.

Owner:SHARP KK

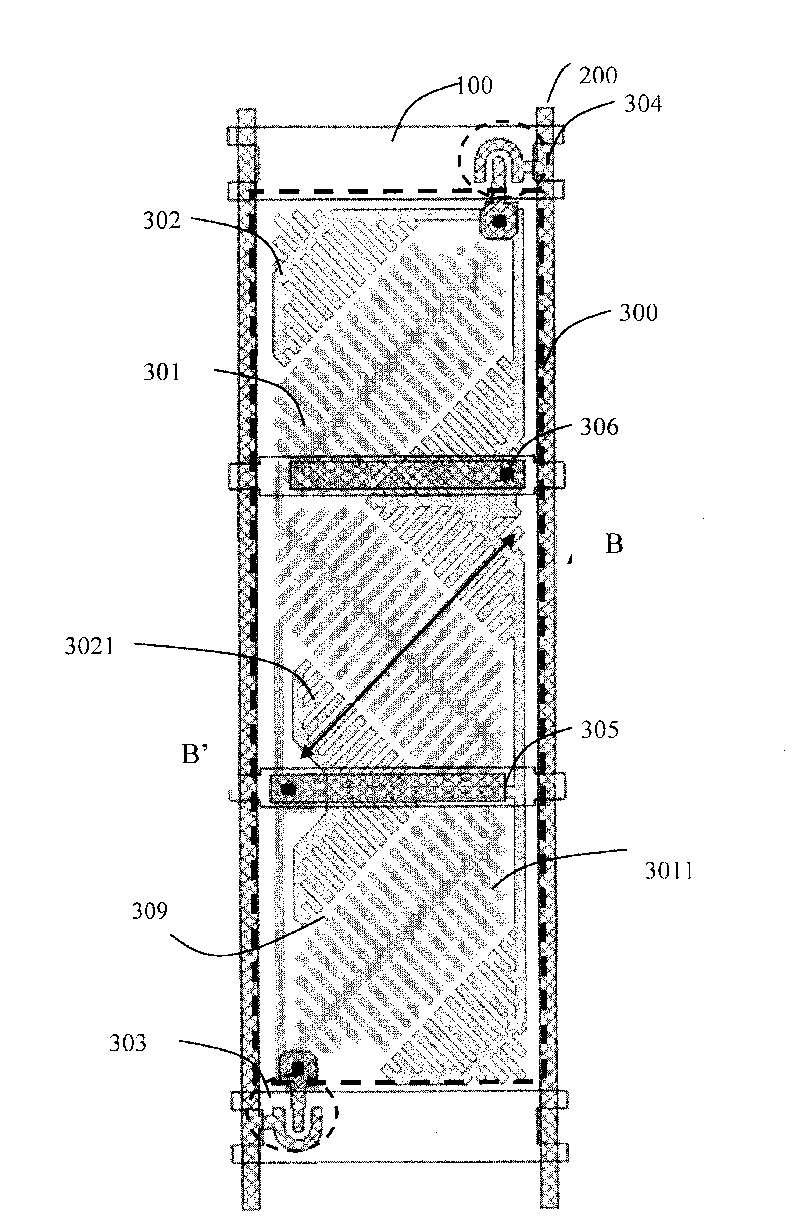

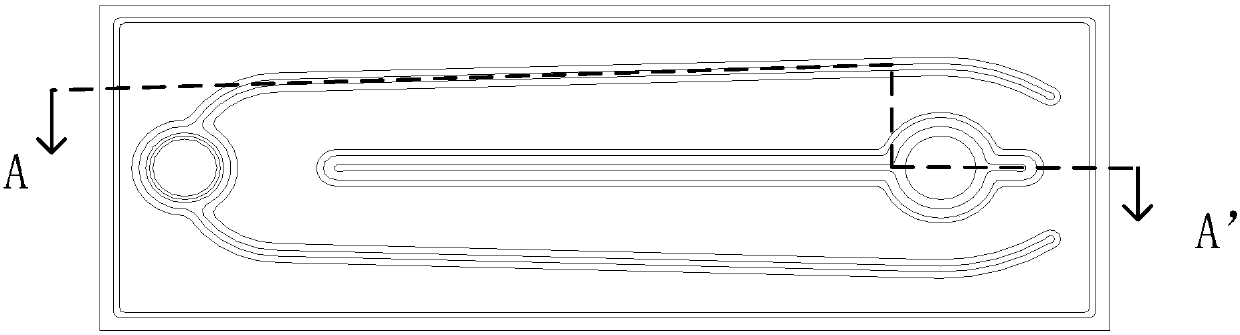

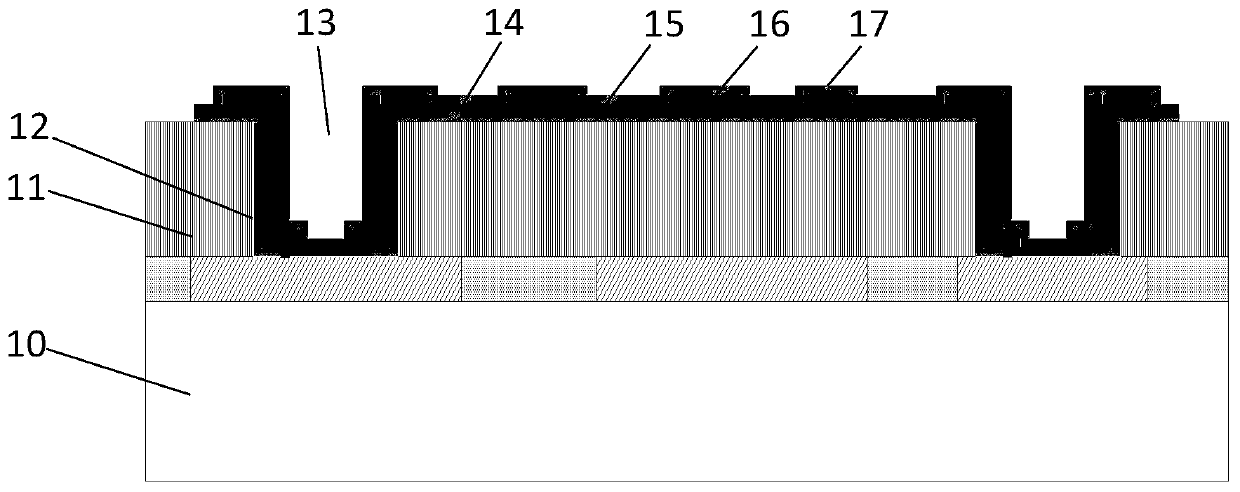

Wafer level vacuum packaging method of MEMS (Micro-electromechanical System) component

ActiveCN101780942AReduce pollutionImprove performanceDecorative surface effectsChemical vapor deposition coatingEngineeringMachining process

The invention discloses a wafer level vacuum packaging method of an MEMS (Micro-electromechanical System) component, which realizes the packaging of a packaging cover plate and the MEMS component by adopting an eutectic bonding technology. The method comprises the steps of: (1) carrying out double-side polishing on the packaging cover plate; (2) depositing insulating media on two sides of the packaging cover plate; (3) preparing a metal film which is used for metal-silicon bonding on the packaging cover plate; (4) preparing an electrode outlet through hole; and (5) carrying out bonding packaging on the packaging cover plate and the MEMS component. By preparing the metal film which is used for metal-silicon bonding on the packaging cover plate, the invention omits the process for preparing bonding metal layer during processing the MEMS component, reduces the pollution of metal to MEMS components in production process, improves the process compatibility and further improves the performance of the MEMS components.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

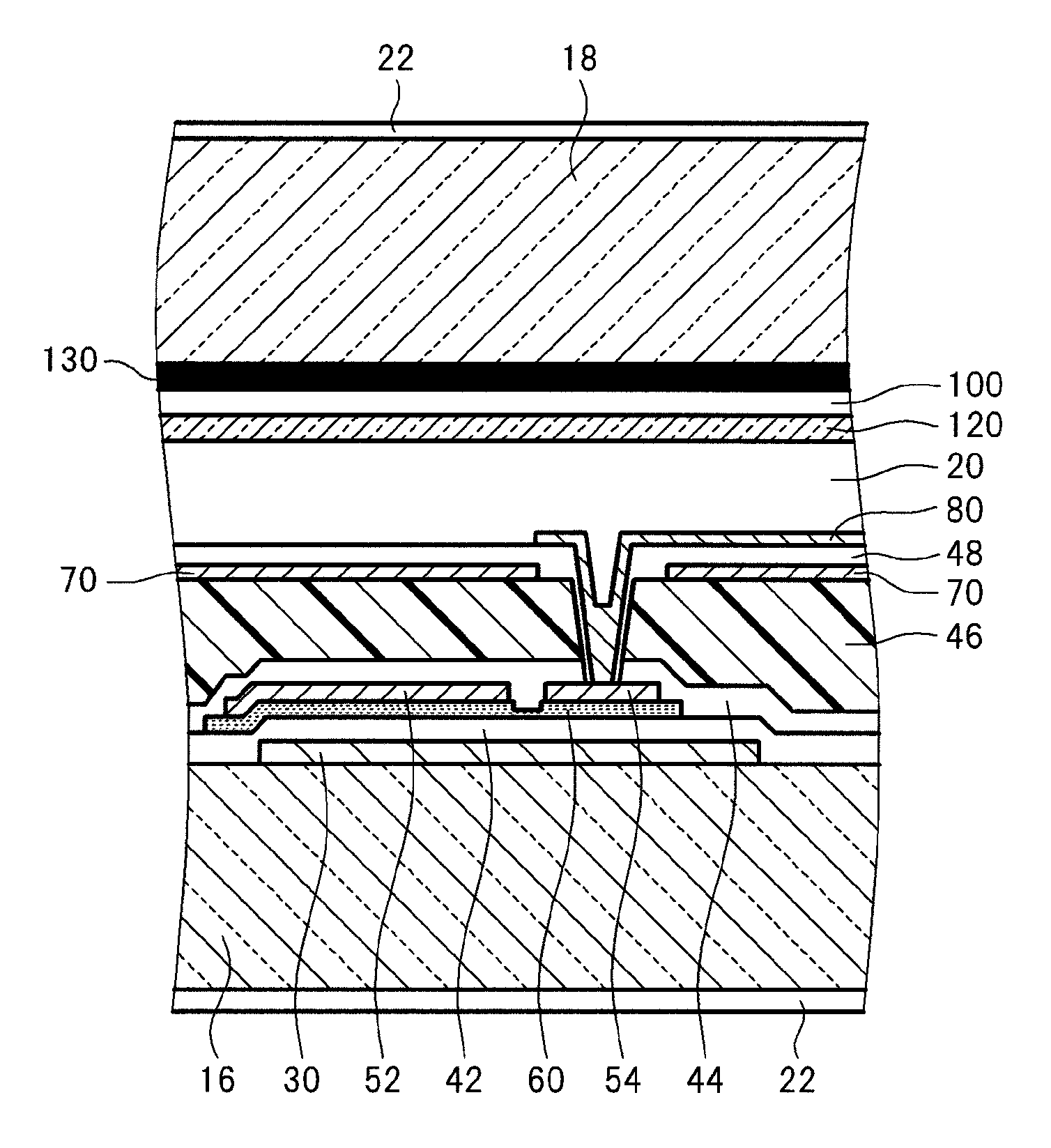

Method for manufacturing liquid crystal display device

InactiveUS20110111543A1Reduce decreaseReduce photolithography processSolid-state devicesSemiconductor/solid-state device manufacturingResistLiquid-crystal display

A thin-film transistor including a gate electrode, a drain electrode, and a source electrode is formed. A first insulating film is formed so as to cover the thin-film transistor. A second insulating film is formed on the first insulating film. A transparent conductive film is formed on the second insulating film. An etching resist which is patterned by a photolithography process is formed on the transparent conductive film. A first transparent electrode is formed by patterning the transparent conductive film by a first etching using the etching resist. A penetration hole is formed in the second insulating film at a position above one of the drain electrode and the source electrode by a second etching which is performed using the etching resist on a surface of the second insulating film exposed from the first transparent electrode.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

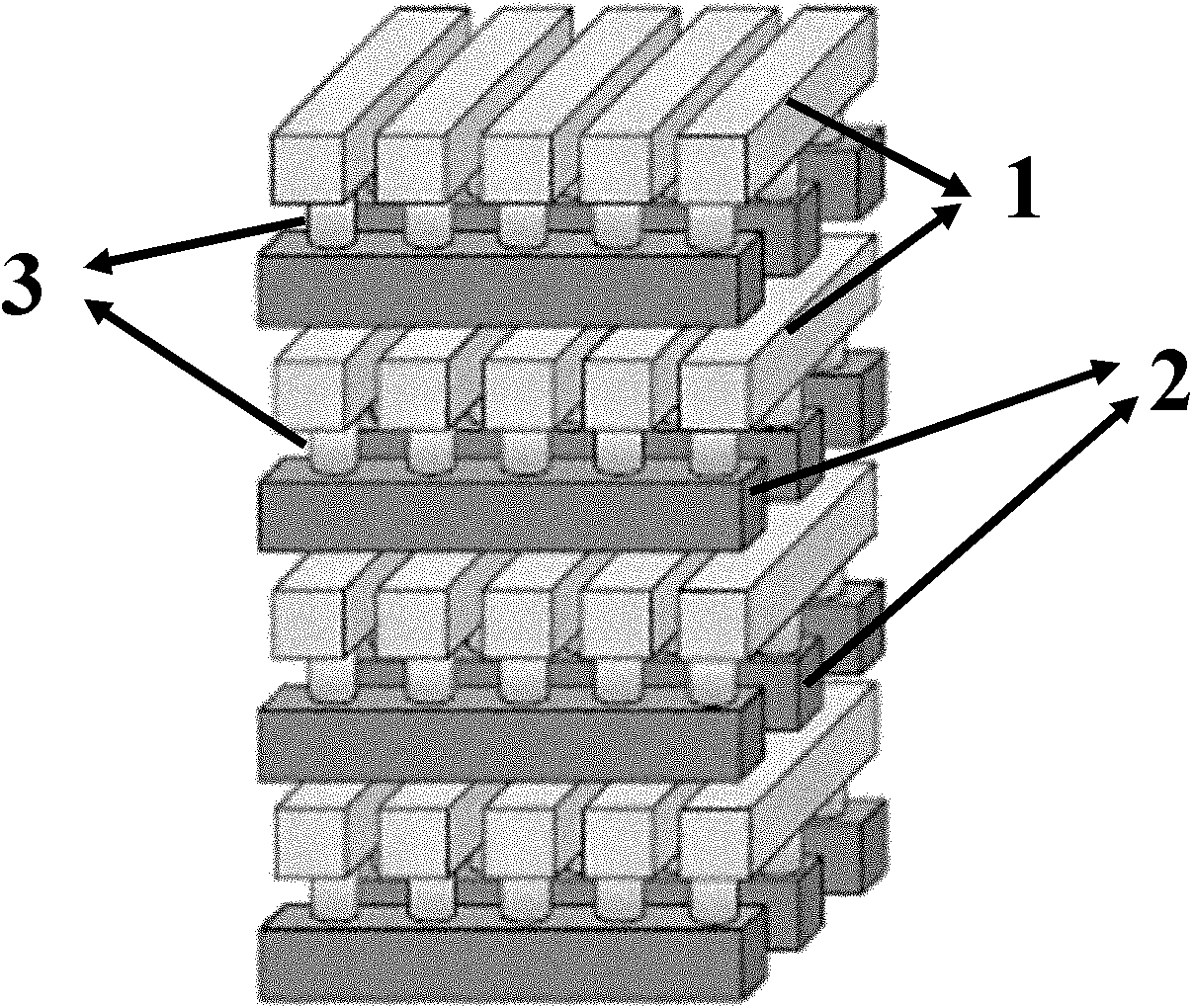

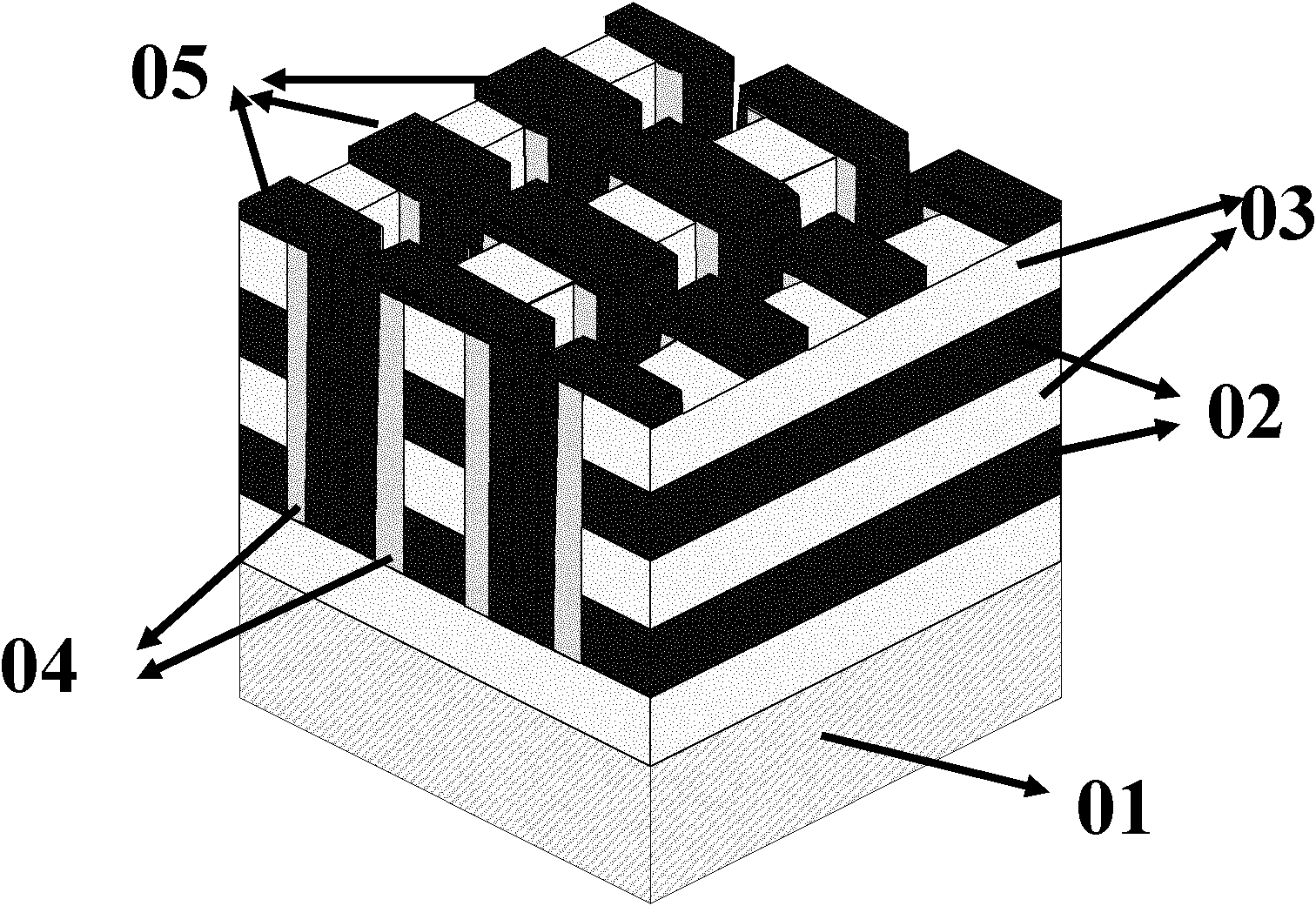

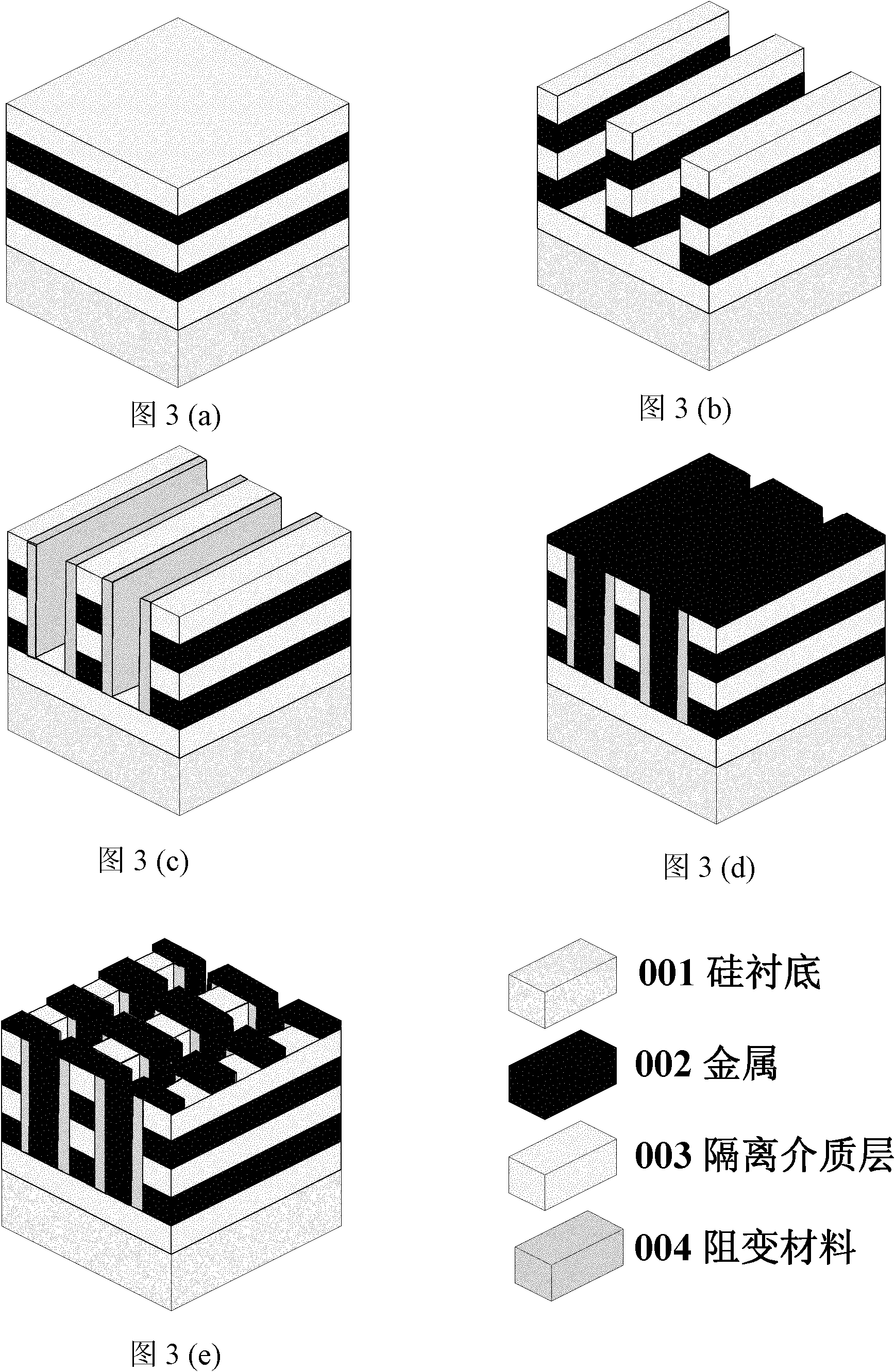

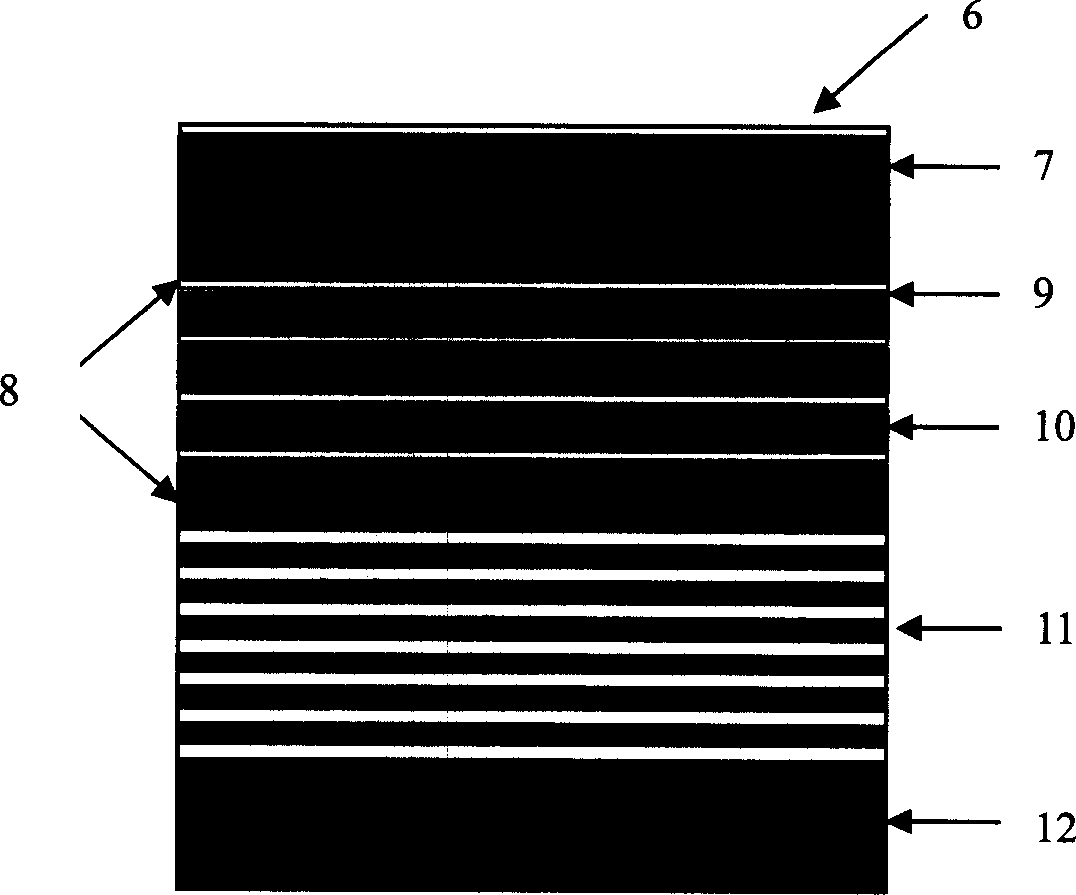

Three-dimensional nonvolatile memory array and preparation method thereof

InactiveCN101976676ASmall sizeReduce photolithography processSolid-state devicesSemiconductor devicesVery large scale integrated circuitsManufacturing technology

The invention provides a three-dimensional nonvolatile memory array and a preparation method thereof, and belongs to the technical field of a nonvolatile memory in the manufacturing technology of super-large-scale integration. The three-dimensional nonvolatile memory array comprises a substrate and a bottom electrode / isolation medium stack structure; a deep groove is etched on the bottom electrode / isolation medium stack structure; a variable-resistance material and a top electrode layer are deposited on the side wall of the deep groove; the bottom electrode and the top electrode are crossed on the side wall of the deep groove; and a variable-resistance material is arranged between the cross points; each cross point forms a variable-resistance memory unit; all the variable-resistance memory units form a three-dimensional variable-resistance memory array; and the three-dimensional variable-resistance memories in the array are isolated by the isolation medium layer. The invention can improve the storage density of the variable-resistance memory, while simplifying the process and reducing the process cost.

Owner:PEKING UNIV

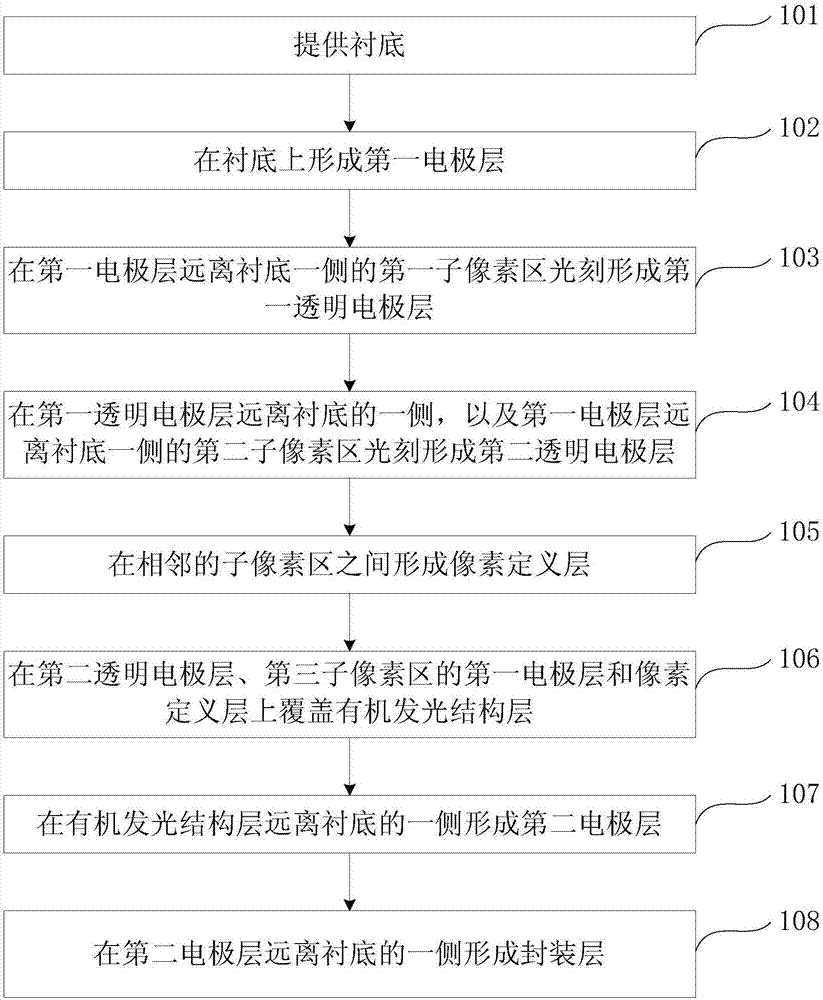

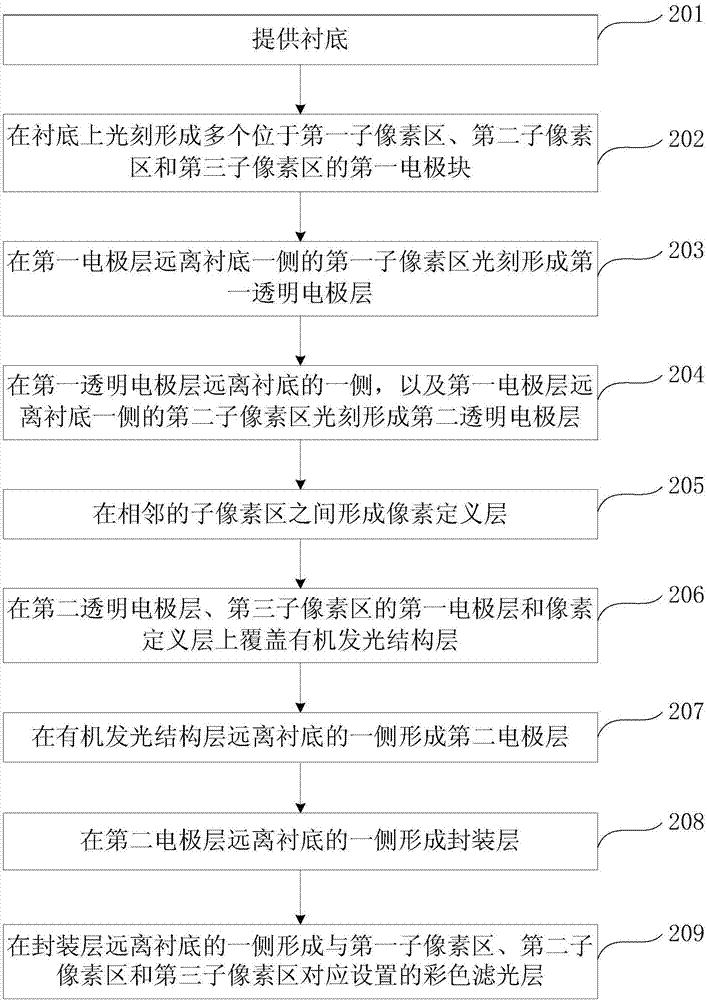

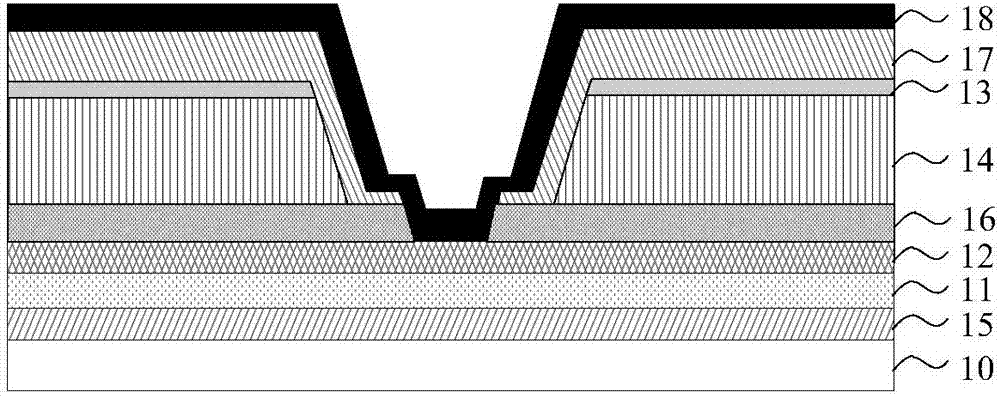

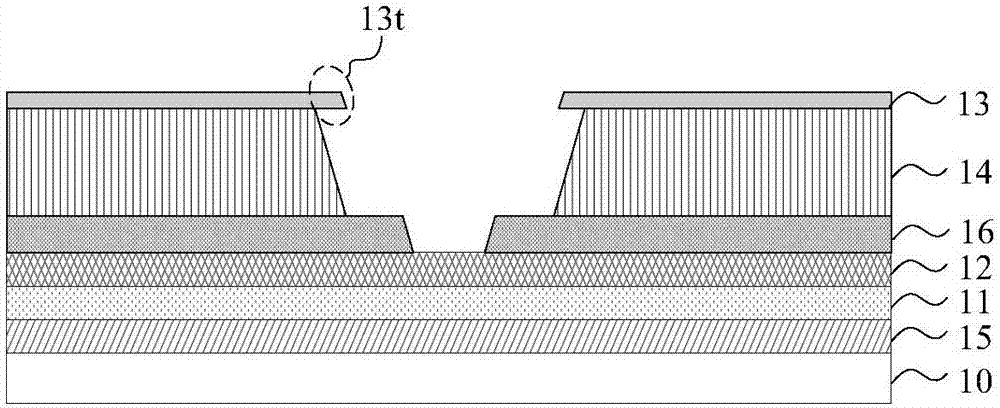

Preparation method of display panel, display panel, and display device

ActiveCN107154424ASimple manufacturing processAvoid Microcavity EffectSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceGreen-light

The invention discloses a preparation method of a display panel, the display panel, and a display device. The preparation method of the display panel comprises steps that a substrate is provided; a first electrode layer is disposed on the substrate; a first transparent electrode layer is disposed on the first sub-pixel region of the side of the first electrode layer away from the substrate by adopting a photolithography technology; second transparent electrode layers are disposed on the side of the first transparent electrode layer away from the substrate and the second sub-pixel region of the side of the first electrode layer away from the substrate; pixel definition layers are disposed between adjacent sub-pixel regions; an organic light-emitting structure layer is disposed on the second transparent electrode layers, a first electrode layer of a third sub-pixel region, and the pixel definition layers, and at least comprises an organic light-emitting layer; a second electrode layer is disposed on the side of the organic light-emitting structure layer away from the substrate. A problem of difficulty in realizing simultaneous enhancement of red light, green light, and blue light emitted by the display panel is improved, and the preparation technology of the display panel is simplified.

Owner:GUANG ZHOU NEW VISION OPTO ELECTRONICS TECH

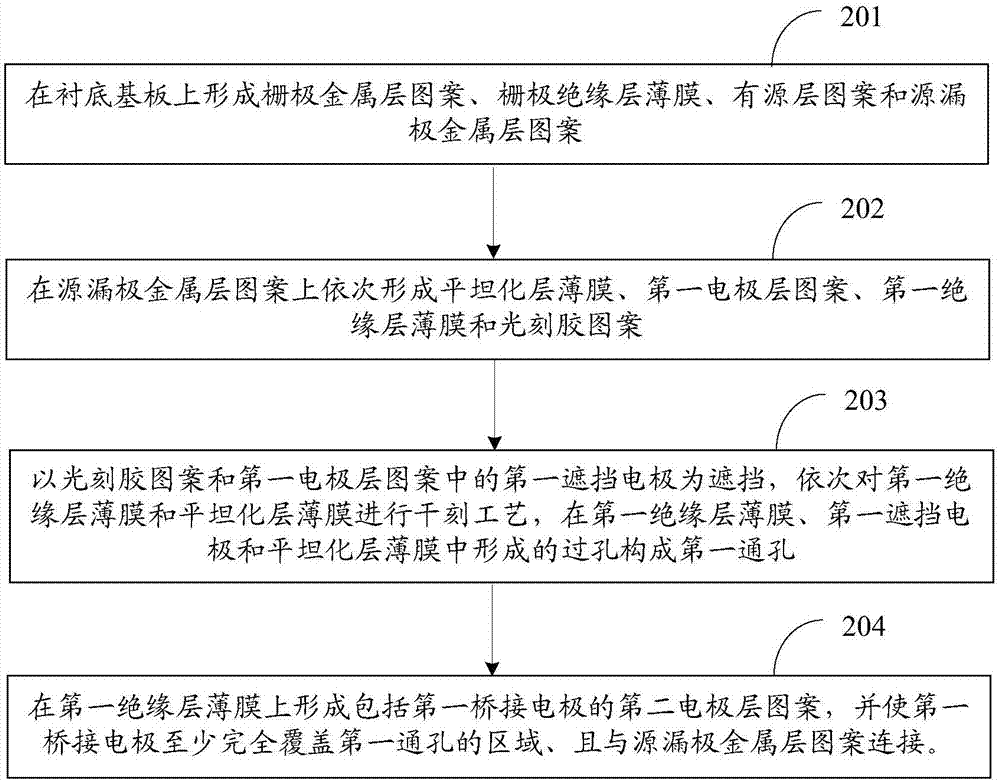

Array substrate and manufacturing method therefor and display apparatus

ActiveCN107316839AMeet etching requirementsIncrease opening ratioSolid-state devicesSemiconductor/solid-state device manufacturingPhotolithographyEngineering

The invention relates to an array substrate and a manufacturing method therefor and a display apparatus, and aims to solve the problem of a relatively complex manufacturing process of a TFT substrate, so that an effective mode for reducing photolithography techniques without lowering product yield is needed urgently. The manufacturing method comprises the steps of forming a gate metal layer pattern, a gate insulating layer thin film, an active layer pattern and source and drain metal layer patterns on a substrate; forming a planarization layer thin film, a first electrode layer pattern, a first insulating layer thin film and a photoresist pattern on the source and drain metal layer patterns in sequence; performing a dry etching process on the first insulating layer thin film and the planarization layer thin film in sequence, wherein via holes formed in the first insulating layer thin film, a first shielding electrode and the planarization layer thin film form a first through hole; and forming a second electrode layer pattern which comprises a first bridging electrode on the first insulating layer thin film, and enabling the first bridging electrode to at least fully cover the first through hole region and to be connected with the source and drain metal layer patterns.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

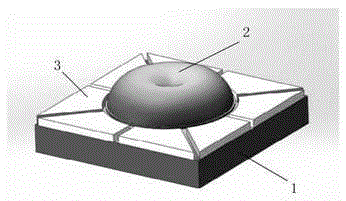

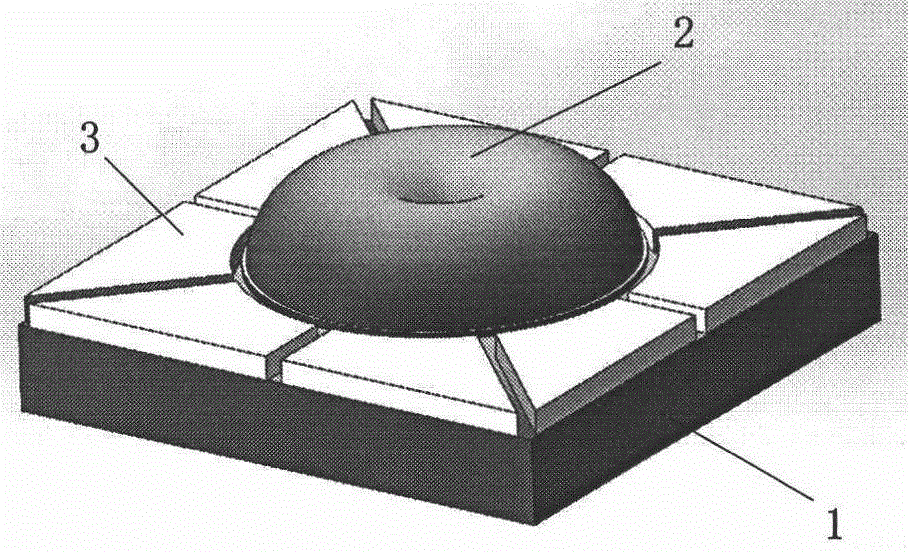

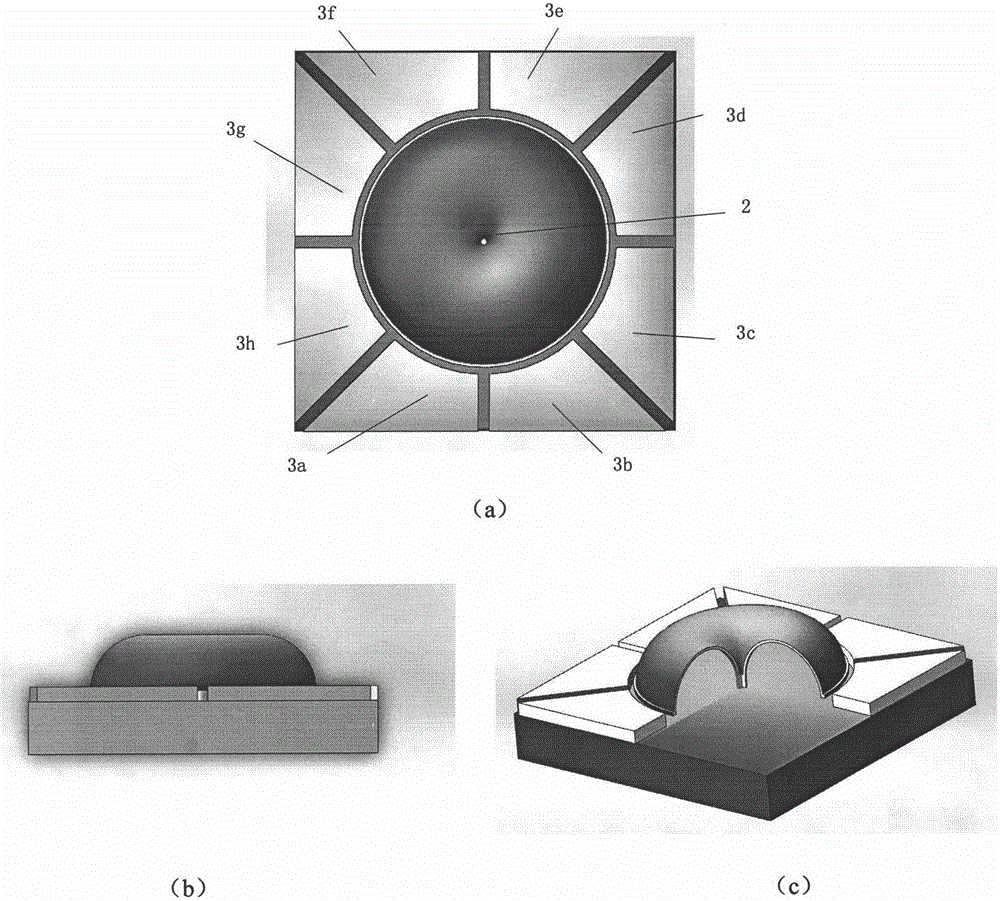

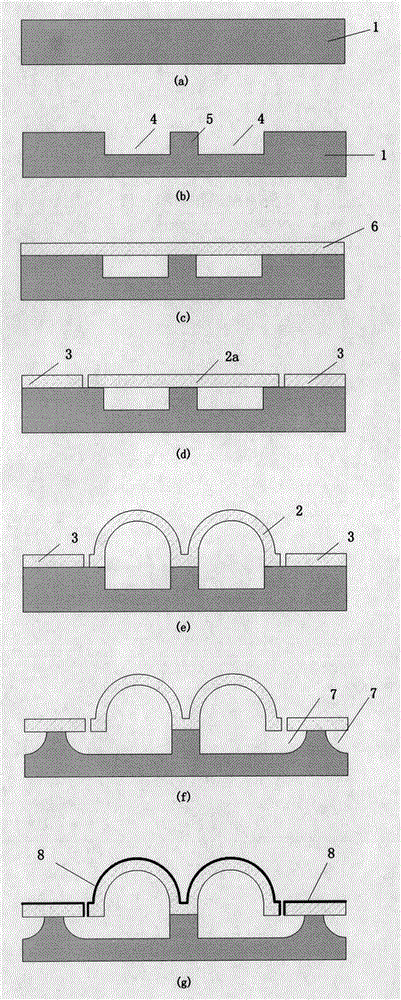

Micro-hemispherical resonant gyroscope based on borosilicate glass annealing forming and manufacturing method thereof

ActiveCN105424019AIncrease etch rateReduce surface stressSpeed measurement using gyroscopic effectsGyroscopes/turn-sensitive devicesSurface stressGyroscope

The invention discloses a micro-hemispherical resonant gyroscope based on borosilicate glass annealing forming and a manufacturing method thereof. A silicon wafer serves as a substrate to form a silicon substrate. A cylindrical cavity and a center supporting column in the circle center of the cavity are etched on the upper surface of the silicon wafer. The center supporting column is connected with the center of a hemispherical harmonic oscillator to form a suspended structure. Meanwhile, eight flat-plate electrodes are evenly distributed around the hemispherical harmonic oscillator and on the periphery of the cylindrical cavity of the upper surface of the silicon wafer. The eight flat-plate electrodes are composed of four drive electrodes and four detection electrodes, all the drive electrodes, the detection electrodes and the hemispherical harmonic oscillator are not in contact and have same gaps, and the drive electrodes and the detection electrodes are sequentially distributed at intervals. The glass metal blowing type micro-hemispherical resonant gyroscope manufactured through the method has stable performance and a wider application range because of the advantages of being simple in structure, low in surface stress, high in symmetry and the like.

Owner:NANJING UNIV OF SCI & TECH

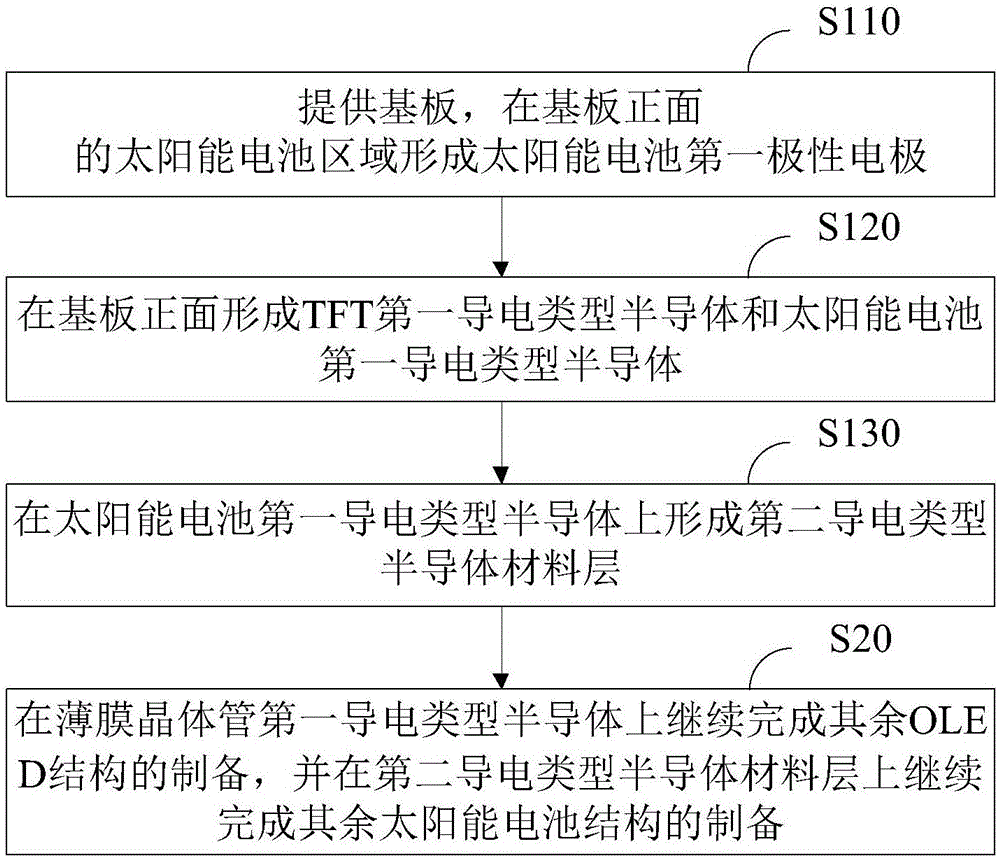

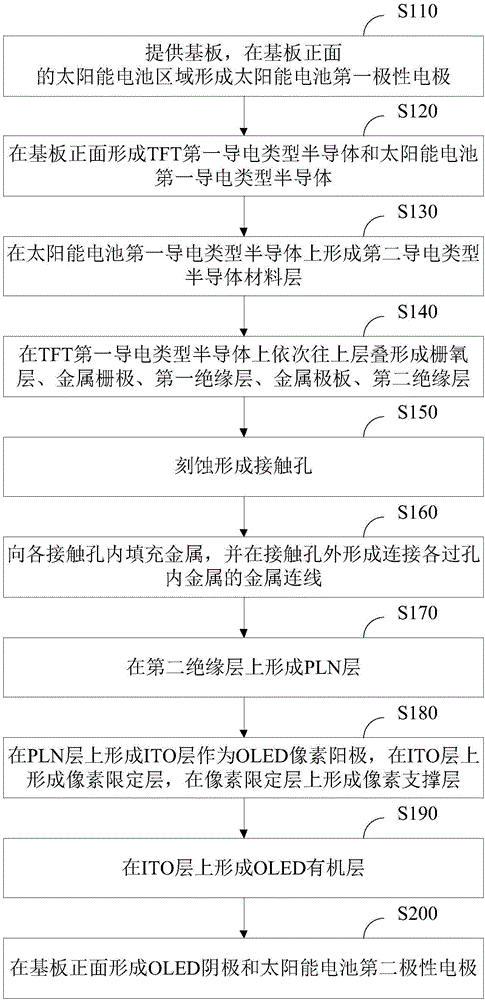

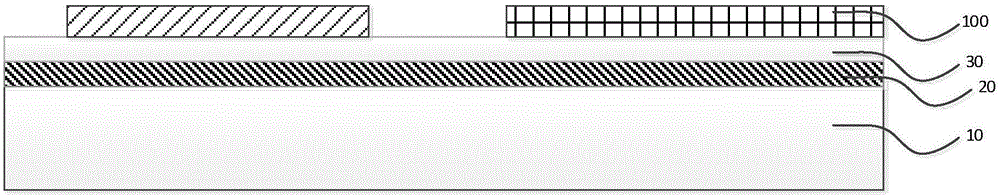

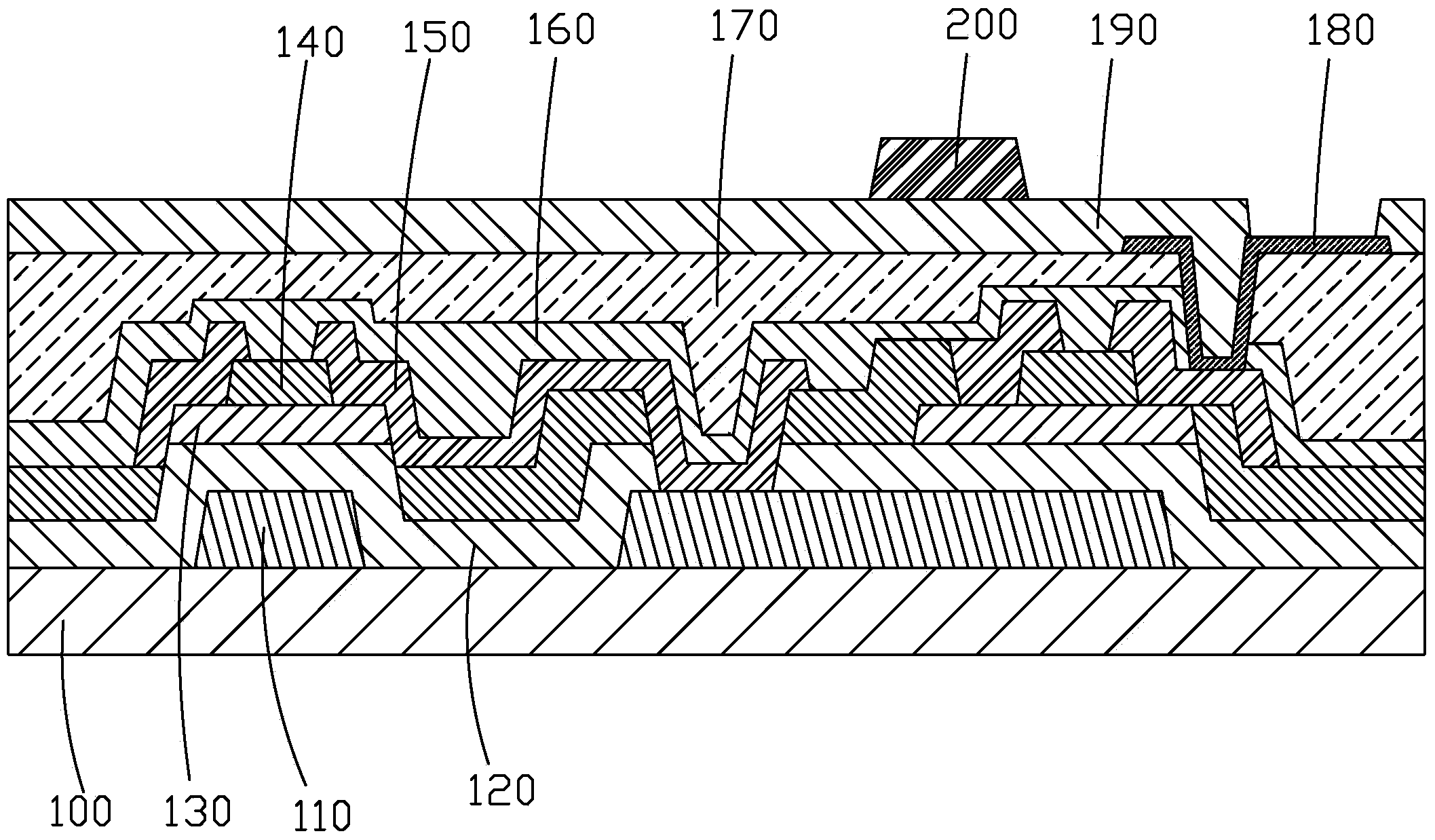

OLED display device integrated with solar cell and manufacturing method thereof, and OLED watch

ActiveCN106409878AReduce photolithography processVisual indicationsSolid-state devicesSemiconductor materialsDisplay device

The invention relates to an OLED display device integrated with a solar cell and a manufacturing method thereof, and an OLED watch. The OLED display device integrated with a solar cell comprises an OLED area and a solar cell area. In the manufacturing method of the OLED display device integrated with a solar cell, a TFT first conductivity type semiconductor in the OLED area and a solar cell first conductivity type semiconductor in the solar cell area are formed by performing a photolithography and etching process on a first conductivity type semiconductor material layer, and an OLED cathode in the OLED area and a solar cell second polarity electrode in the solar cell area are formed by performing a photolithography and etching process on a metal layer. Thus, the number of times that the photolithography and etching process is performed is reduced by one and the number of masks needed is reduced by one in each step, and the process time and cost are saved.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

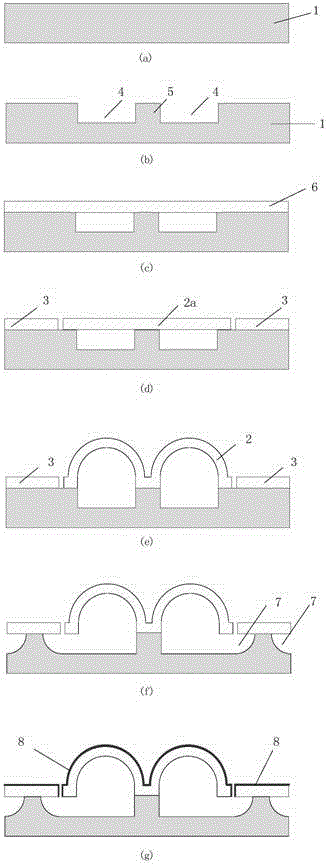

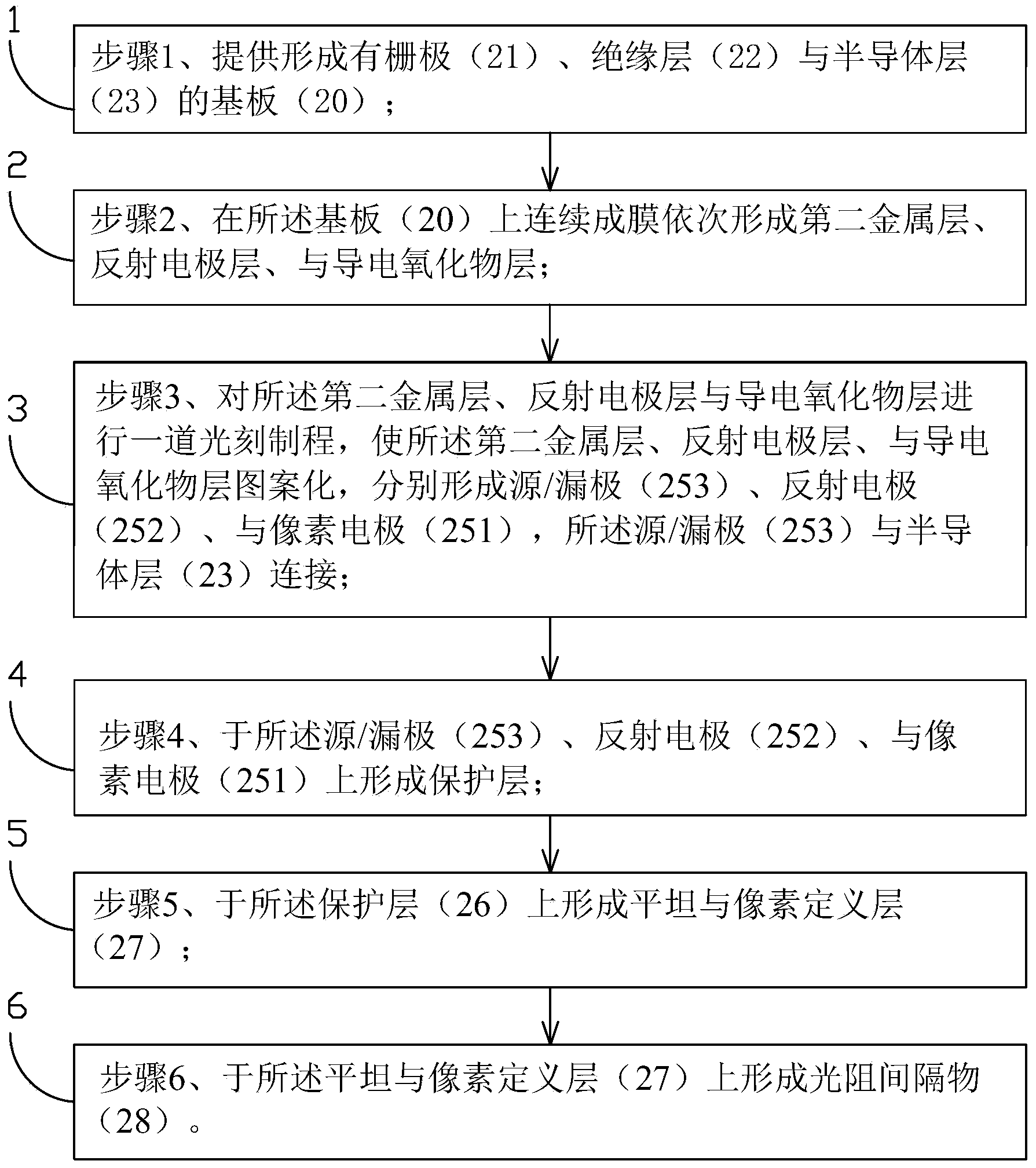

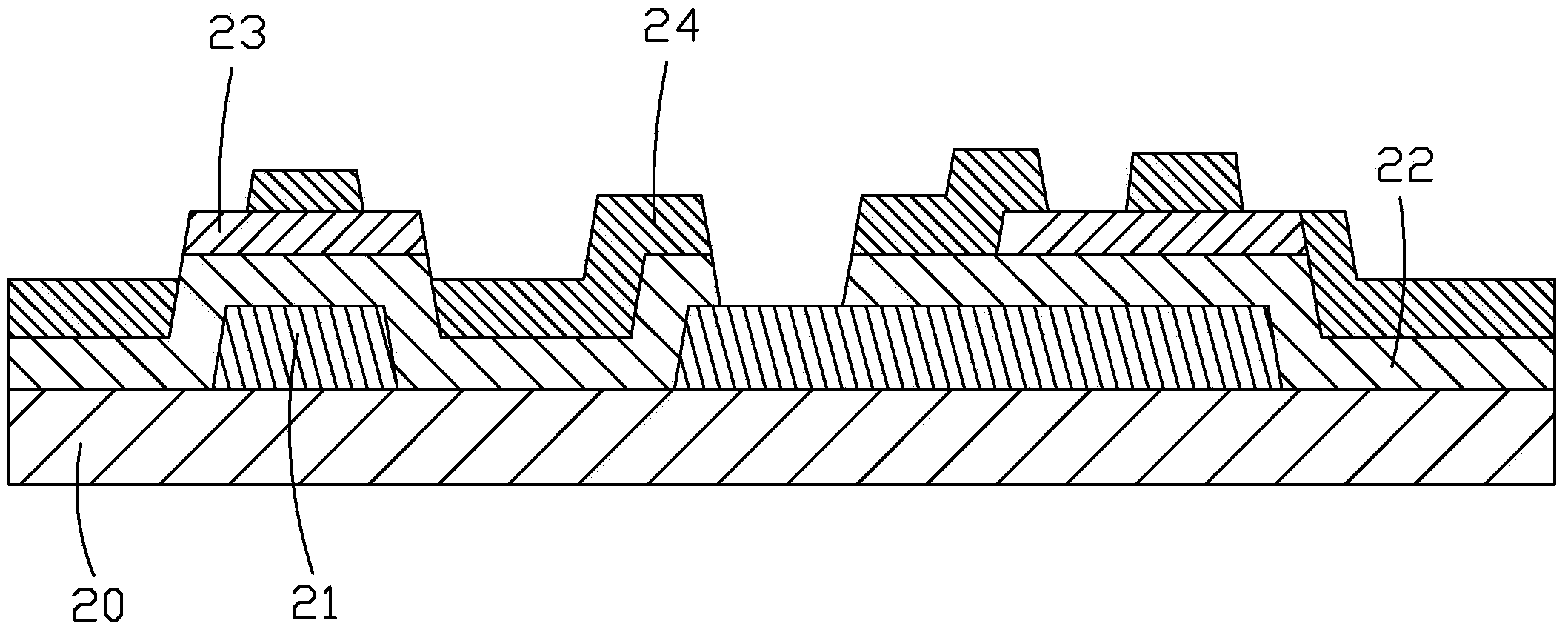

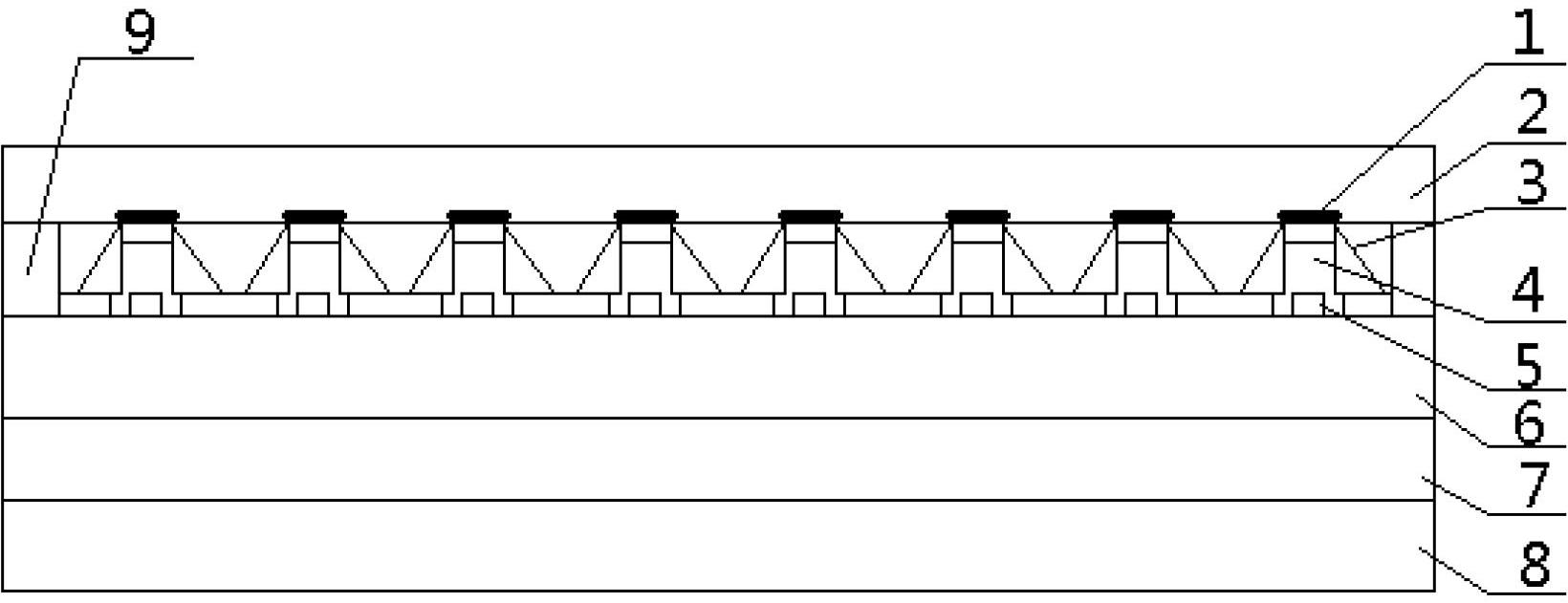

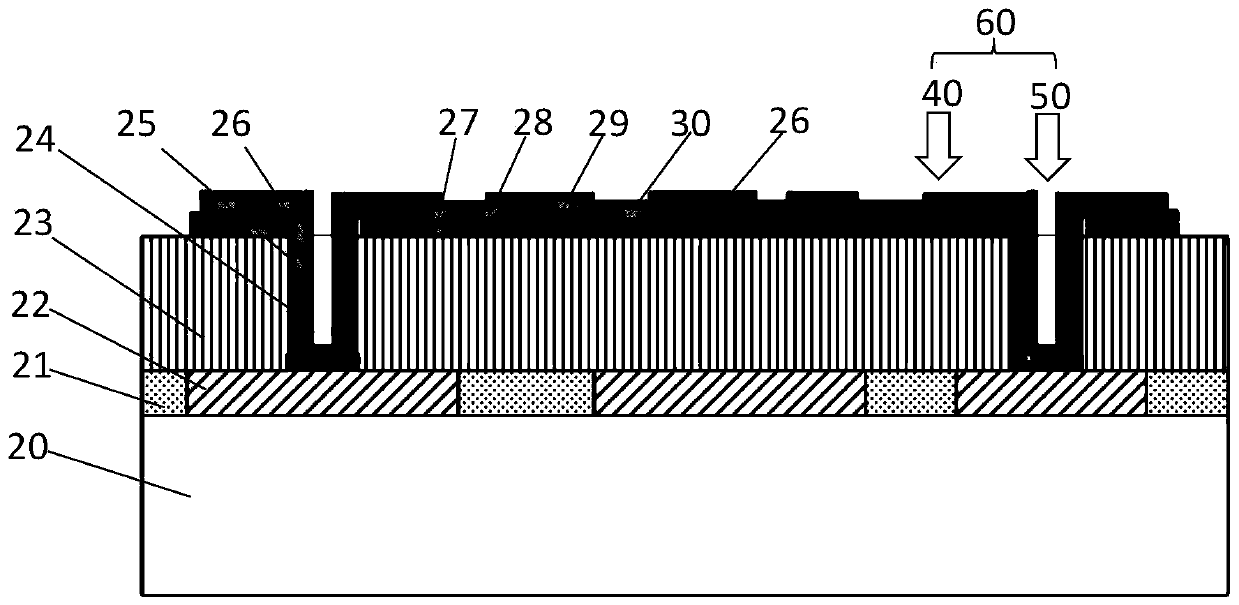

TFT (thin film transistor) backboard manufacturing method and TFT backboard structure

InactiveCN104037129AIncrease productivityReduce photolithography processSolid-state devicesSemiconductor/solid-state device manufacturingInsulation layerSemiconductor

The invention provides a TFT (thin film transistor) backboard manufacturing method and a TFT backboard structure. The TFT backboard manufacturing method includes steps of 1, providing a substrate (20) with a grid electrode (21), an insulation layer (22) and a semiconductor layer (23); 2, continuously filming to sequentially form a second metal layer, a reflecting electrode layer and a conductive oxide layer on the substrate (20); 3, subjecting the second metal layer, the reflecting electrode layer and the conductive oxide layer to photoetching processing so as to pattern the same, respectively forming source / drain electrodes (253), reflecting electrodes (252) and pixel electrodes (251) and connecting the source / drain electrodes (253) with the semiconductor layer (23); 4, forming a protecting layer on the source / drain electrode (253), the reflecting electrodes (252) and the pixel electrodes (251); 5, forming a flat pixel definition layer (27) on the protecting layer (26); 6, forming a photoresistance spacer (28) on the flat pixel definition layer (27).

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Fast recovery diode and manufacturing method thereof

ActiveCN103022154AReduce shockImprove safe work areaSemiconductor/solid-state device manufacturingSemiconductor devicesReverse recoveryIntrinsics

The invention discloses a fast recovery diode and a manufacturing method of the fast recovery diode. The diode disclosed by the invention comprises an anodic diffusion P-type doped region, an evenly-doped intrinsic region, a cathodic diffusion N-type region, anode and cathode metal layers, wherein the anodic diffusion P-type doped region is a P-type doped region provided with alternated high and low concentrations and formed by locally pouring through a mask plate. Compared with the prior art, the diode disclosed by the invention has the characteristics of low inverse peak current IRRM, short reverse recovery time trr and high reverse recovery softness.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +1

Liquid crystal display panel and liquid crystal display device

ActiveCN101738802AIncrease contrastReduce photolithography processStatic indicating devicesNon-linear opticsColor gelEngineering

The invention provides a liquid crystal display panel and a liquid crystal display device, comprising a first substrate, a second substrate and a liquid crystal layer, wherein the first substrate and the second substrate are arranged opposite to each other, and the liquid crystal layer is clamped between two substrates, the first substrate comprises a plurality of pixel regions defined by a plurality of scanning lines and a plurality of data lines, and the pixel regions at least comprise a first sub-pixel electrode and a second sub-pixel electrode, a first film transistor and a second film transistor. The first sub-pixel electrode and the second sub-pixel electrode are electrically isolated from each other and the polarities of the first sub-pixel electrode and the second sub-pixel electrode are opposite when the liquid crystal display panel operates; the first sub-pixel electrode and the second sub-pixel electrode are nested with each other, wherein the first sub-pixel electrode is provided with at least one nesting region extending into the second sub-pixel electrode, and the second sub-pixel electrode is provided with at least one nesting region extending into the first sub-pixel electrode. The liquid crystal display panel saves photoetching process of a projection structure and a gap in the process of manufacturing a color filter substrate, simplifies the process, reduces the cost and improves the contrast ratio at the same time.

Owner:KUSN INFOVISION OPTOELECTRONICS

Micro-hemispherical resonator gyroscope based on borosilicate glass annealing forming and preparing method

InactiveCN105021179AIncrease etch rateReduce surface stressSpeed measurement using gyroscopic effectsGyroscopes/turn-sensitive devicesSurface stressHemispherical resonator gyroscope

The invention discloses a micro-hemispherical resonator gyroscope based on borosilicate glass annealing forming and a preparing method of the micro-hemispherical resonator gyroscope. A silicon wafer is used as a substrate to form a silicon substrate, a cylindrical cavity and a center supporting pillar in the circle center of the cavity are etched on the upper surface of the silicon wafer, and the center supporting pillar is connected with the center of a hemispherical resonator to form a suspension structure. Meanwhile, eight flat plate type electrodes are evenly distributed on the periphery of the cylindrical cavity in the upper surface of the silicon wafer and around the hemispherical resonator, and the eight flat plate type electrodes are composed of the four driving electrodes and the four detection electrodes. All the driving electrodes and all the detection electrodes are not in contact with the hemispherical resonator, identical gaps exist, and the driving electrodes and the detection electrodes are arranged in sequence alternately. The prepared glass metal blowing type micro-hemispherical resonator gyroscope has the advantages of being simple in structure, low in surface stress, high in symmetry and the like, and therefore the micro-hemispherical resonator gyroscope can have stable performance and a wider application range.

Owner:NANJING UNIV OF SCI & TECH

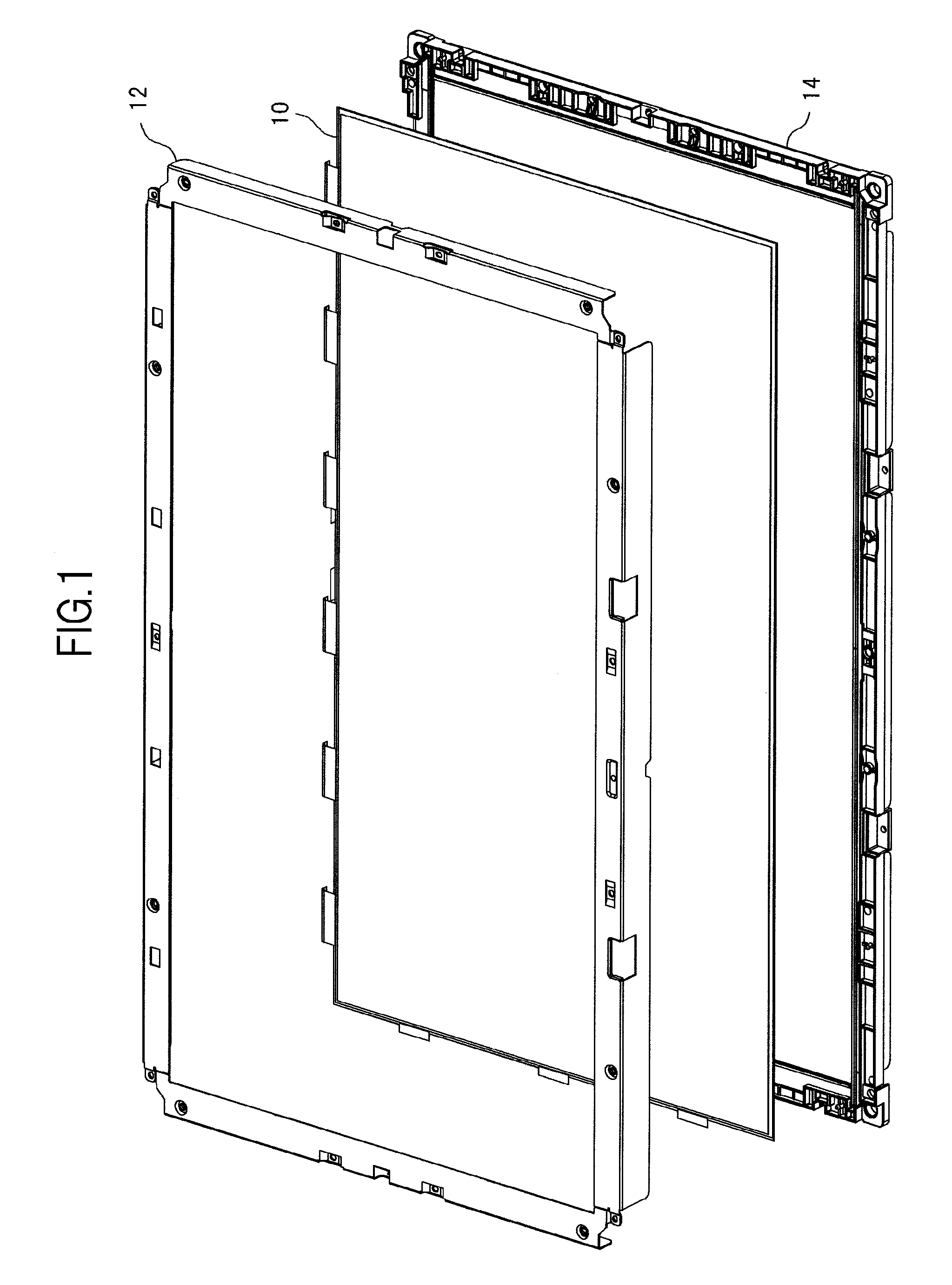

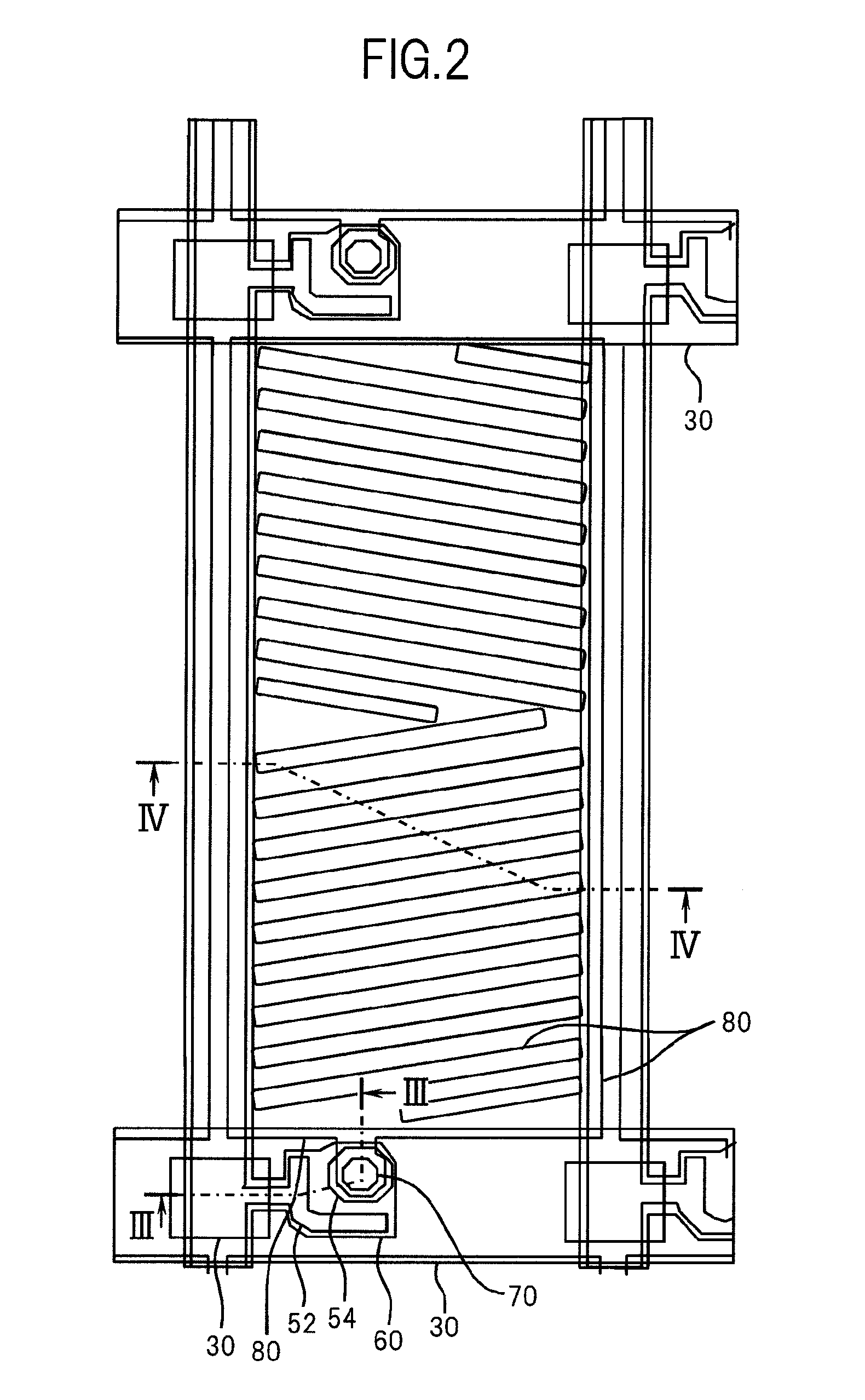

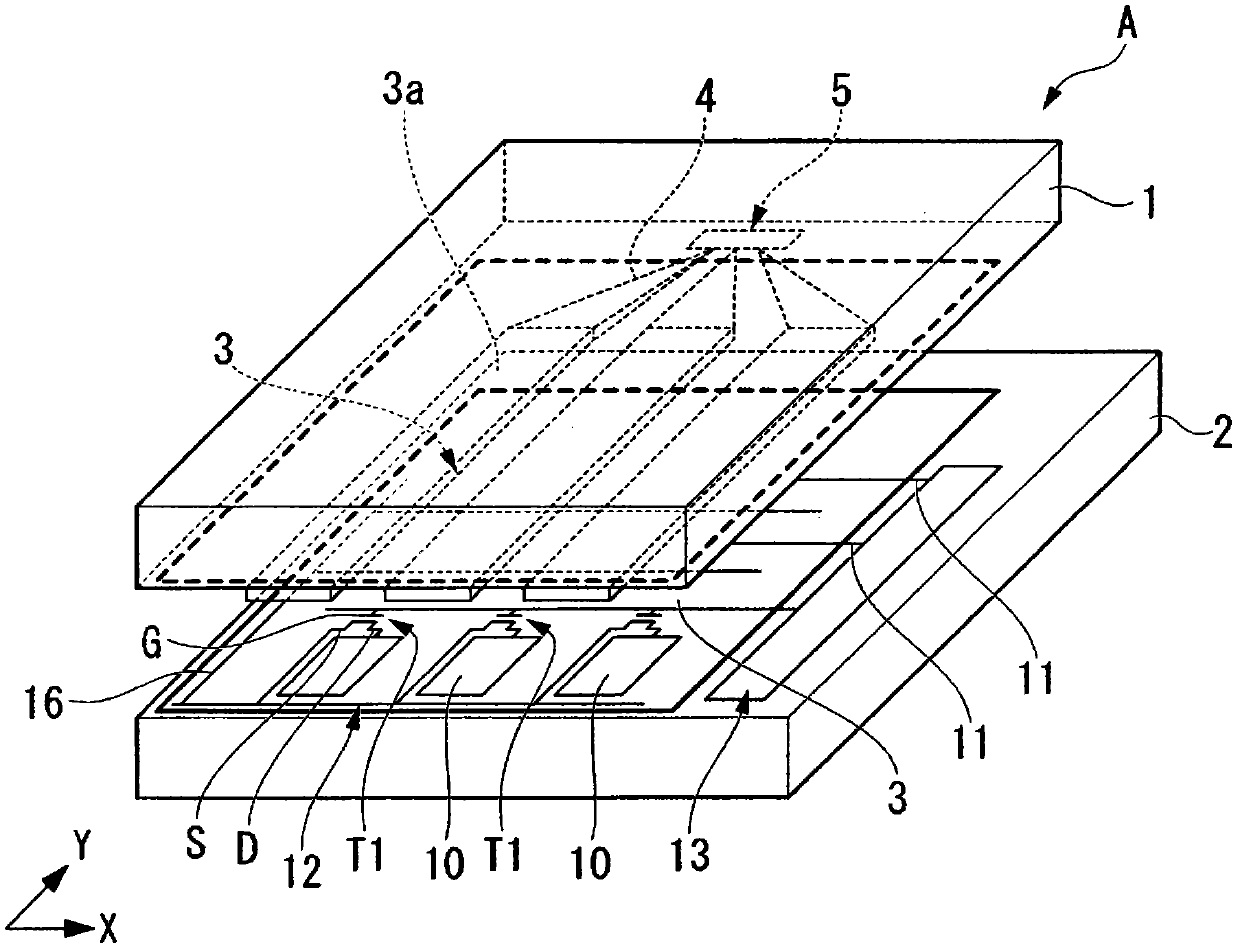

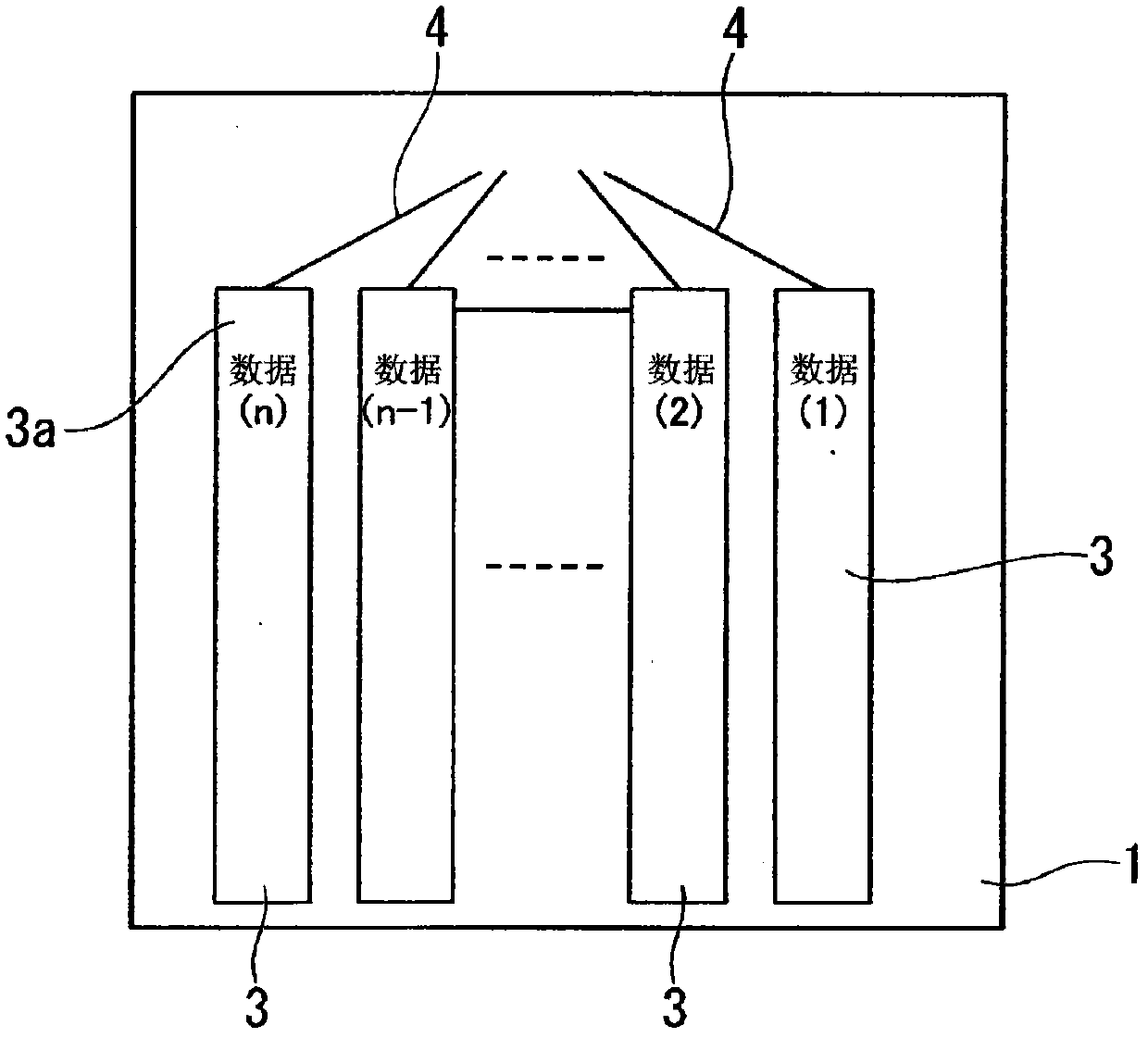

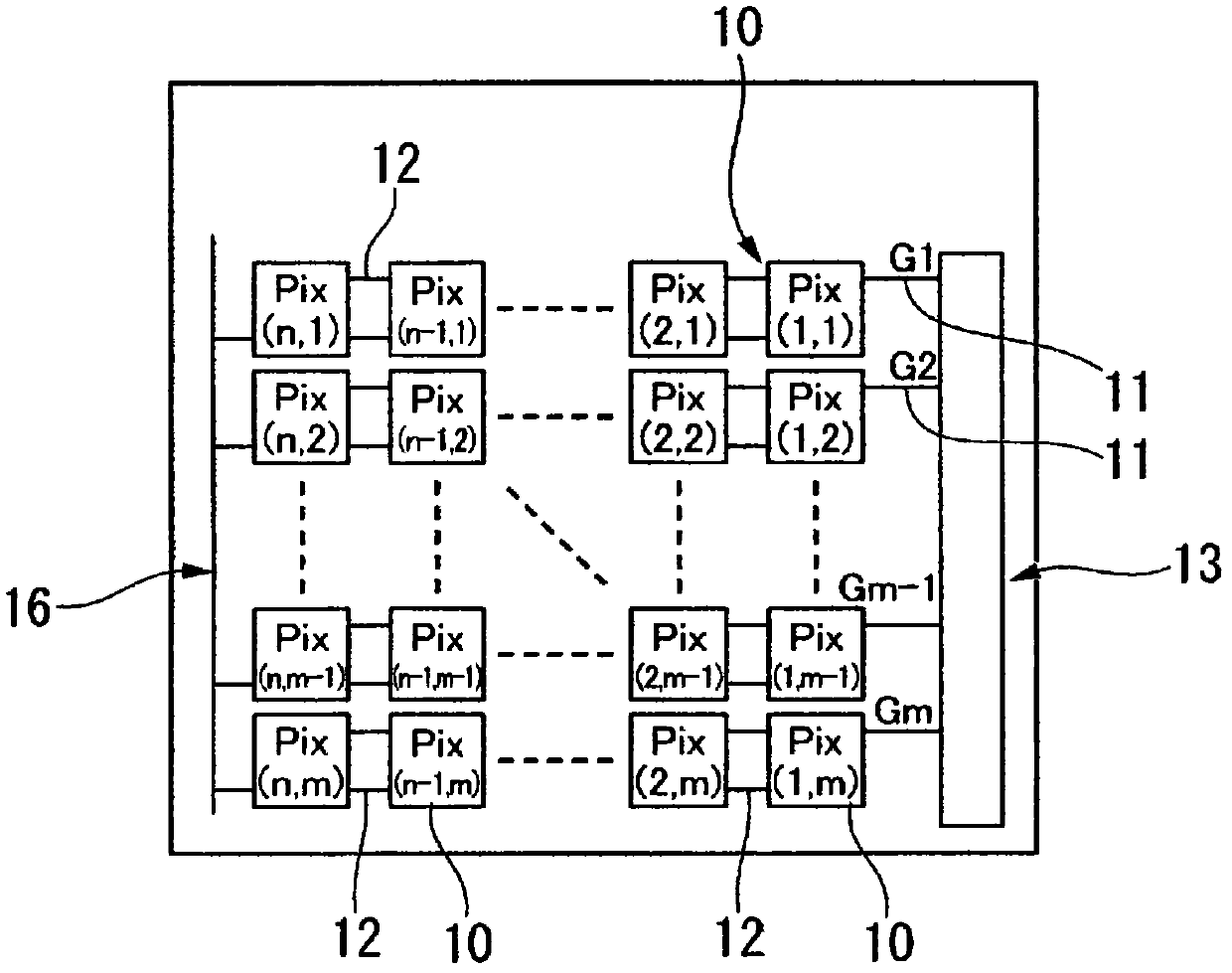

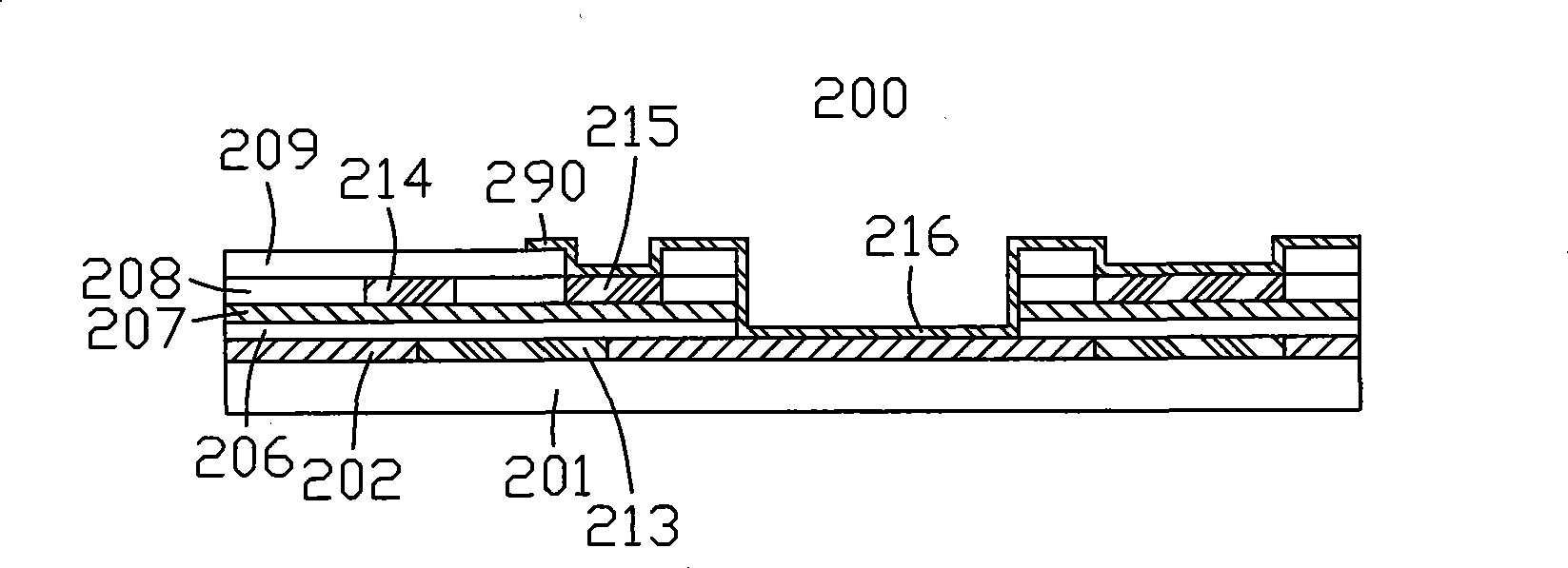

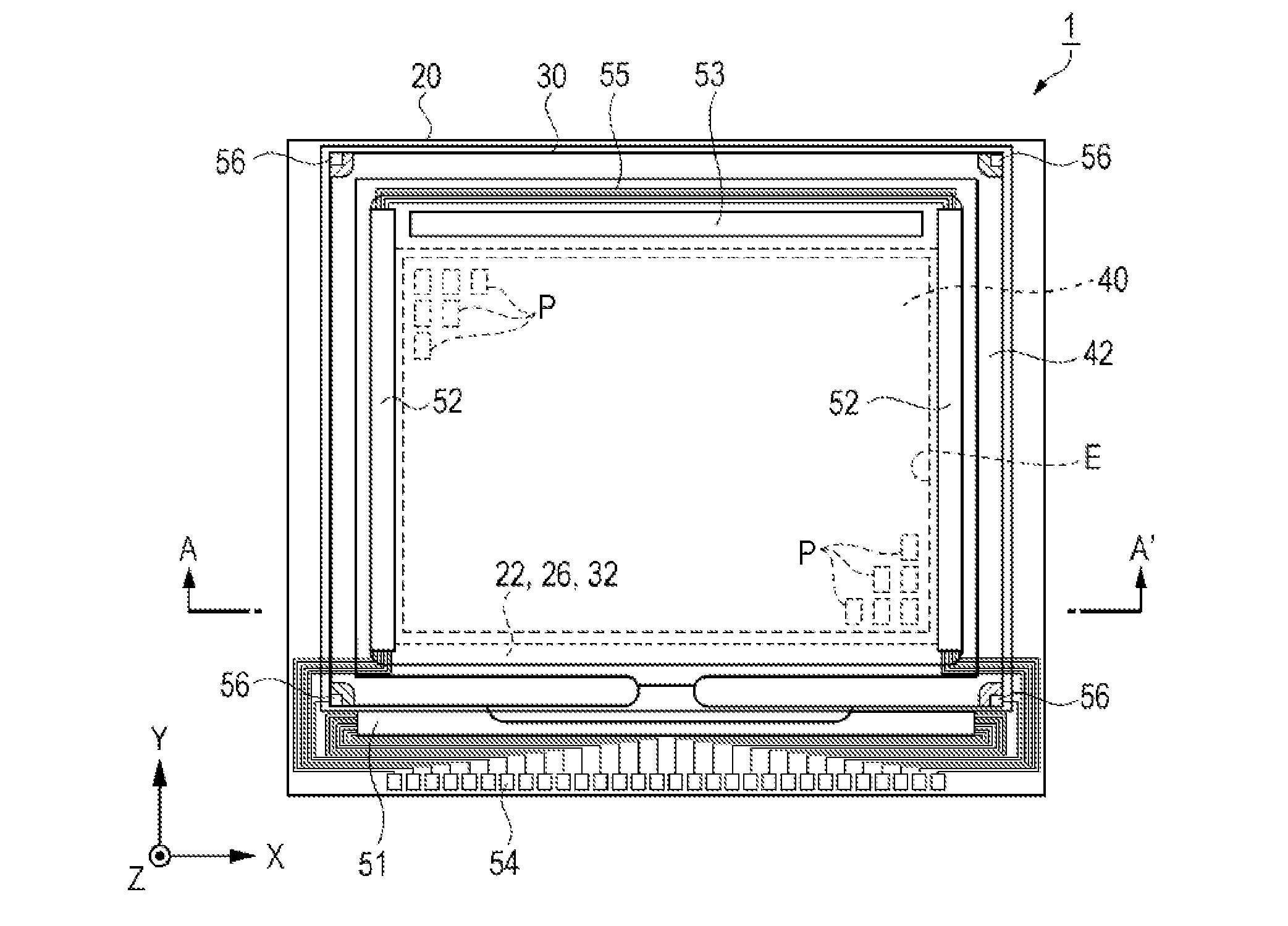

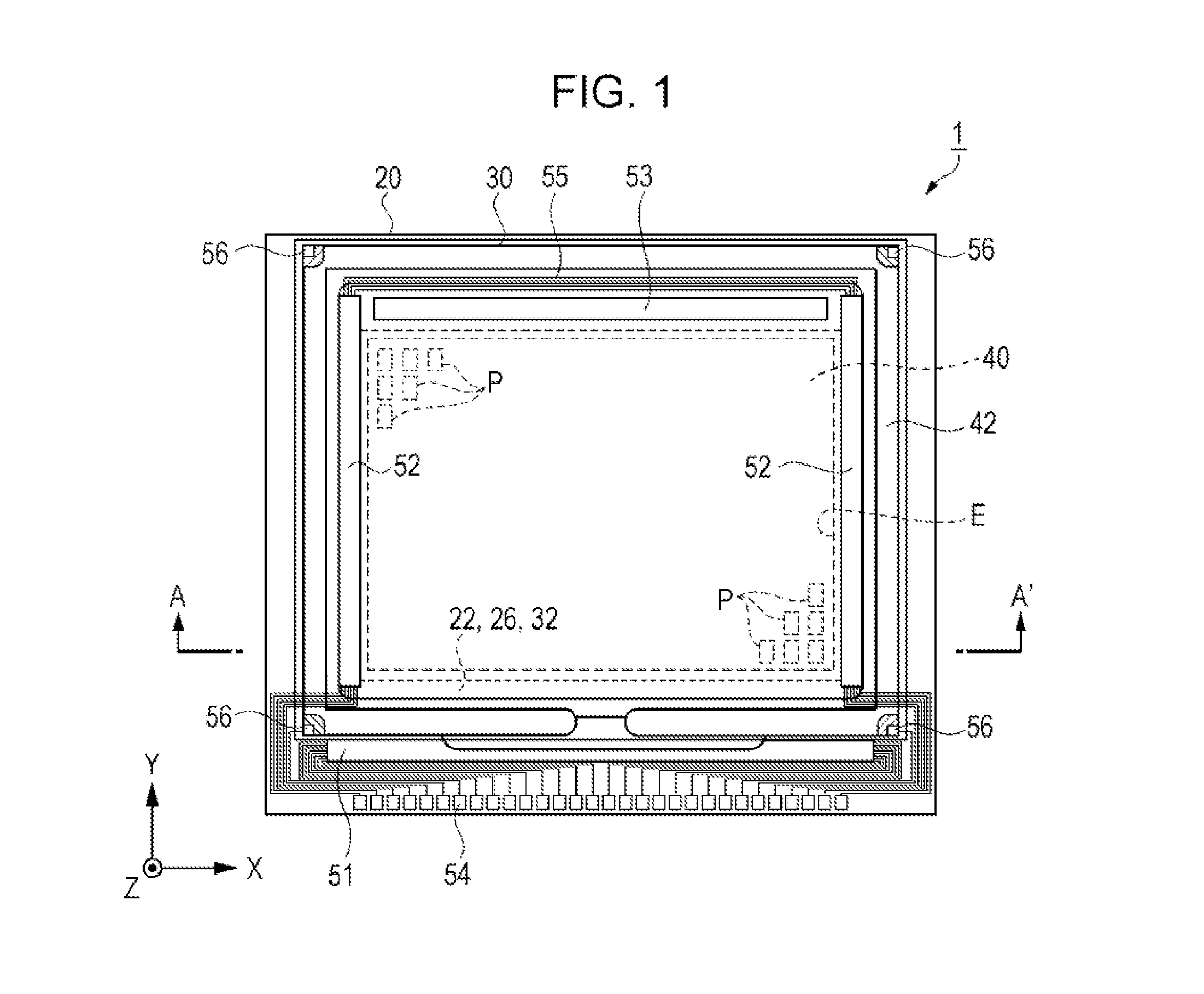

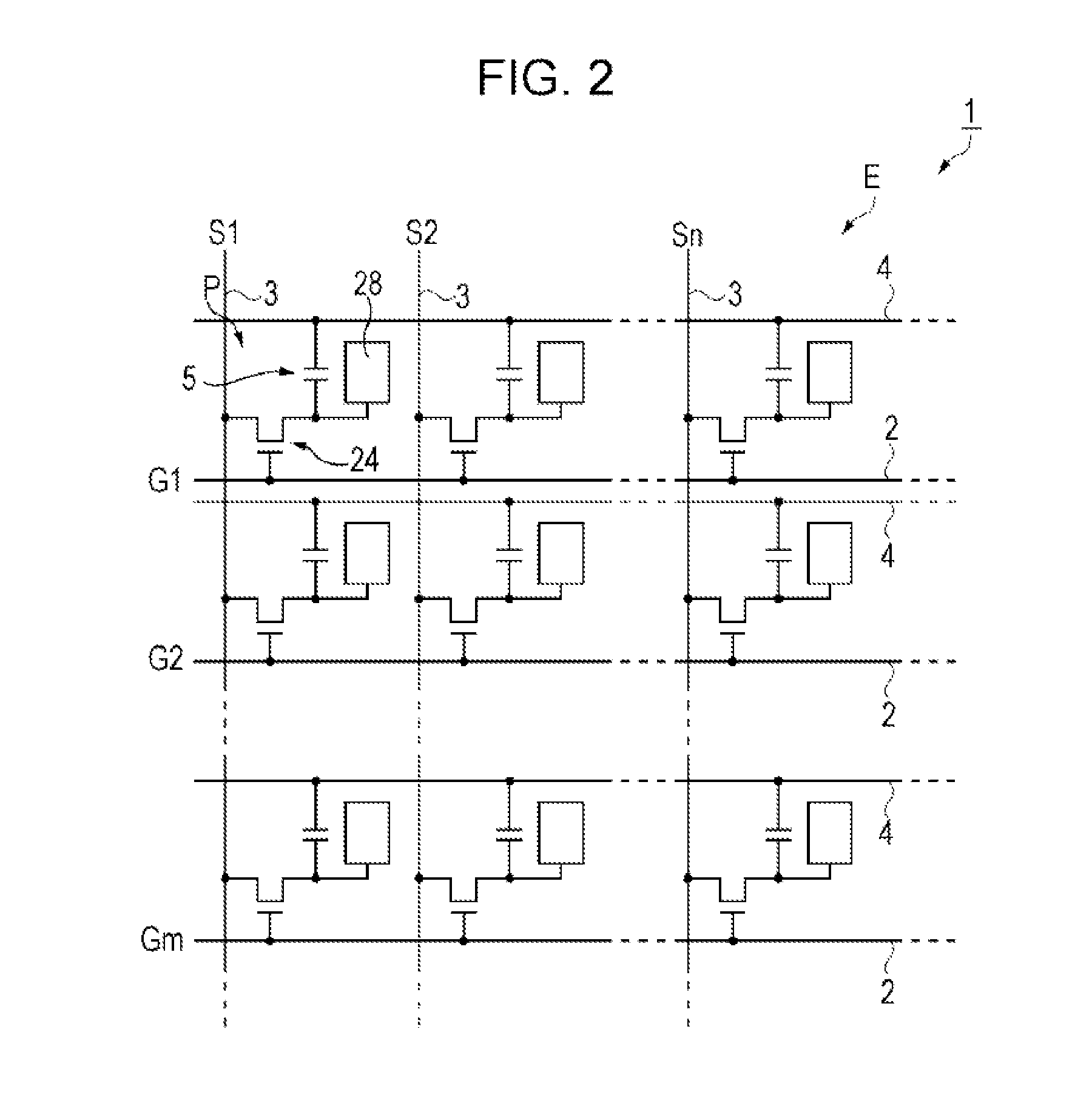

Display device, and method for producing array substrate for display device

InactiveCN102822884AReduce the process of film formationReduce photolithography processTransistorSolid-state devicesDisplay deviceEngineering

Disclosed is a display device provided with: a plurality of stripe-shaped data electrodes (3) which are formed on a first substrate (1) and which extend in the vertical direction; a plurality of scanning lines (11) and a plurality of reference signal lines (12) which are formed on the second substrate (2) and which extend in the horizontal direction; a plurality of pixel electrodes (10) which are formed on the second substrate (2) and which are arranged in the form of a matrix; a plurality of switching elements (T1) which are formed on the second substrate (2), turns on or off by means of the plurality of scanning lines (11), and is disposed between the plurality of reference signal lines (12) and the plurality of pixel electrodes (10); and an oxide semiconductor layer (22) which is disposed between a source electrode (21) and a drain electrode (20). The oxide semiconductor layer (22) is formed with the switching elements (T1) with an insulating layer (23) therebetween in the vicinity of a gate electrode (11a), and is provided with the pixel electrodes (10) which are connected to the source electrode (21) or the drain electrode (20). The source electrode (21) or the drain electrode (20) that is connected to the pixel electrode (10) is formed from the same material as the pixel electrode (10). The source electrode (21) and the drain electrode (20) are formed from a film which was formed at the same time.

Owner:SHARP KK

Liquid Crystal Display Device

ActiveUS20060197883A1Ability of lightLight visibilityTransistorSolid-state devicesVisibilityConvex structure

Owner:SEMICON ENERGY LAB CO LTD

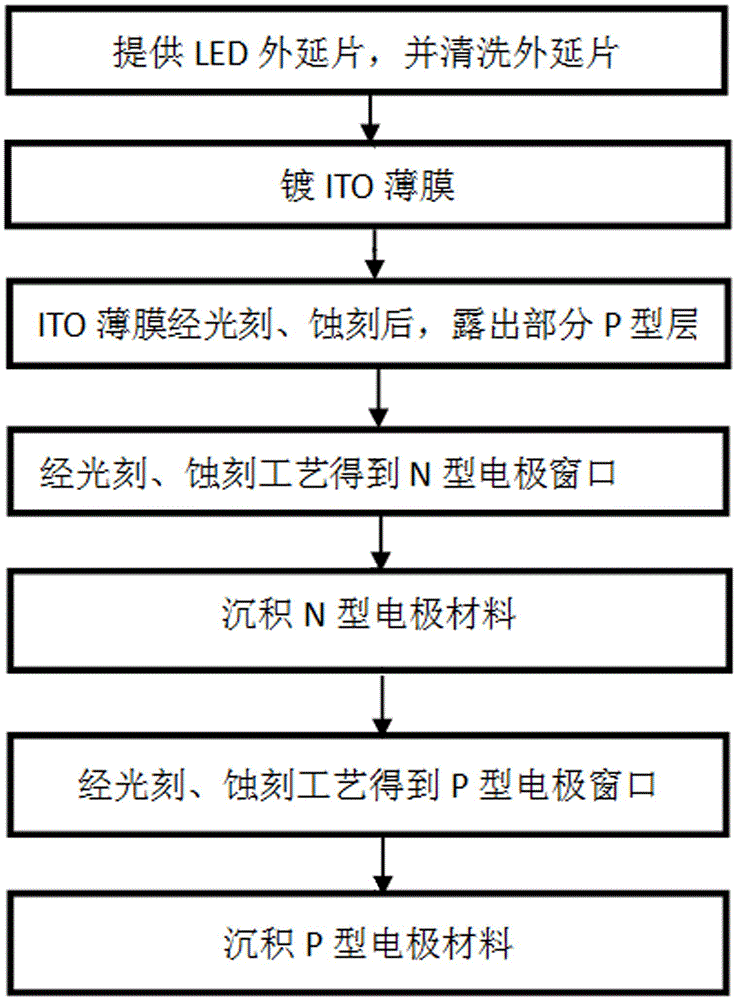

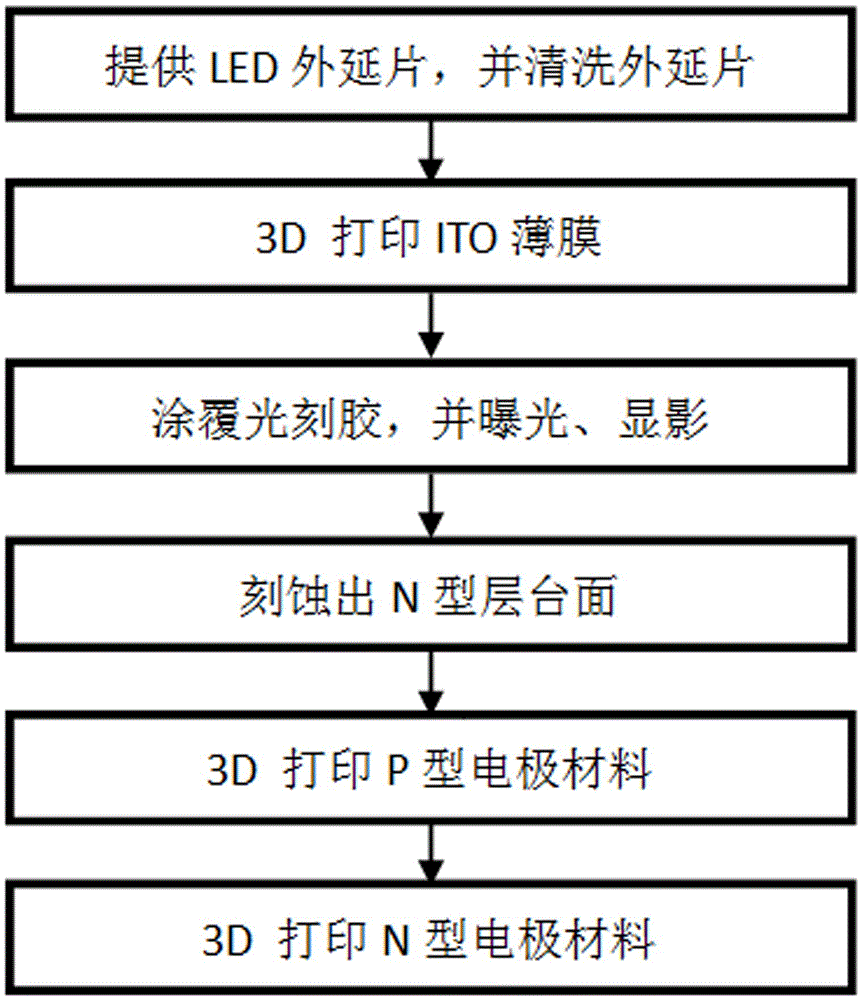

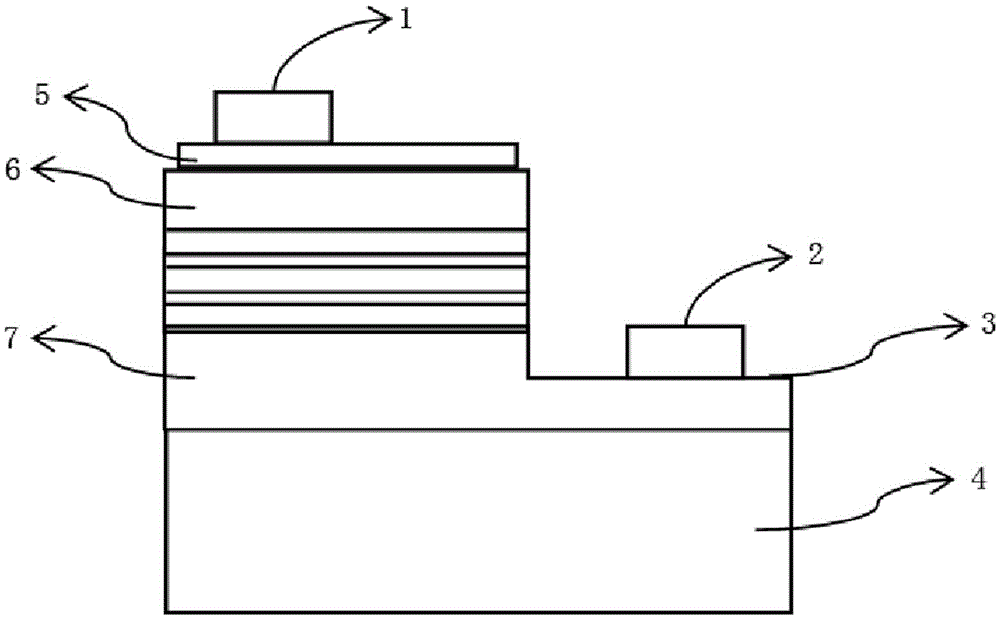

Method based on 3D printing for manufacturing LED devices

ActiveCN105576099AImprove light extraction efficiencyThe process steps are simpleSemiconductor devicesQuantum wellEngineering

The invention belongs to the photoelectron device field and particularly relates to a method based on 3D printing for manufacturing LED devices. According to the method, epitaxial wafer which at least has a buffer layer, an N-type layer, a multi-period quantum well active layer and a P-type layer and is generated by MOCVD or MBE is taken as a substrate material, an ITO conduction layer is printed on a P-type layer table top through 3D printing, an N-type layer table top is then etched, and N-type electrode and P-type electrode layers are then printed. The LED device electrode structure is formed through 3D printing, steps of photoetching and corrosion in an electrode manufacturing process can not only be reduced, the production period is shortened, pollution and damage to the epitaxial wafer in a photoetching and corrosion process can be reduced, damage of a high temperature annealing process during electrode formation to the quantum well active region interface structure can be reduced, and thereby light emitting efficiency of the LED devices can be improved.

Owner:TAIYUAN UNIV OF TECH

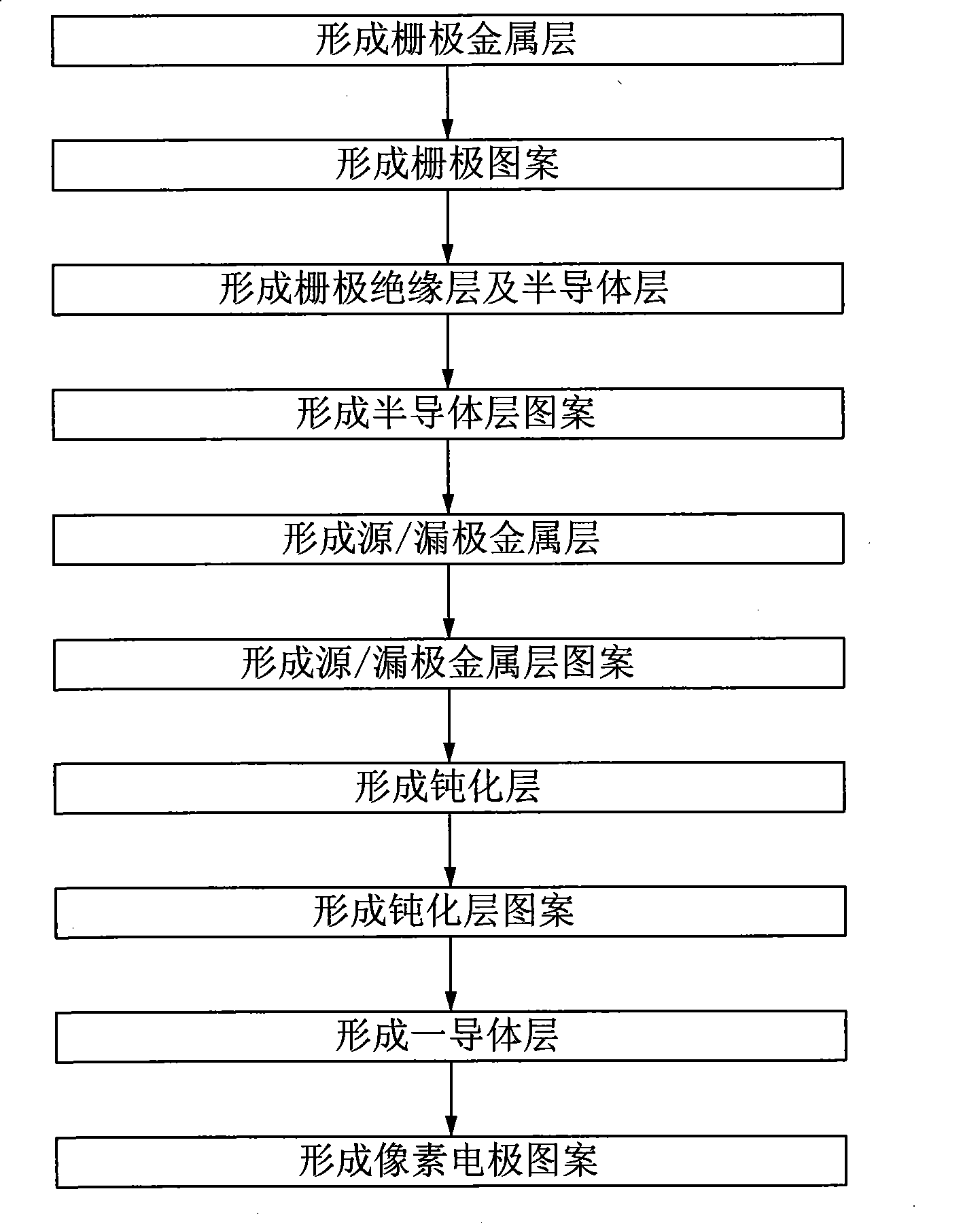

Thin-film transistor manufacturing method

InactiveCN101364572AReduce the number of photolithographySimple processSemiconductor/solid-state device manufacturingElectrical conductorSemiconductor

The invention relates to a method for manufacturing a thin-film transistor baseplate, which comprises the following steps: an insulating base is provided; a grid groove is formed on the insulating base; a grid metal layer is deposited; chemical and mechanical grinding is performed to the grid metal layer to form a grid electrode; a grid insulating layer, a semiconductor layer and a first passivation layer are deposited in sequence; a source electrode groove and a drain electrode are formed; a source / drain electrode metal layer is deposited; chemical and mechanical grinding is performed to the source / drain electrode metal layer to form a source electrode and a drain electrode; a second passivation layer is deposited; a pixel electrode groove is formed and the drain electrode is exposed; a conductor layer is deposited; and a pixel electrode is formed.

Owner:INNOCOM TECH SHENZHEN +1

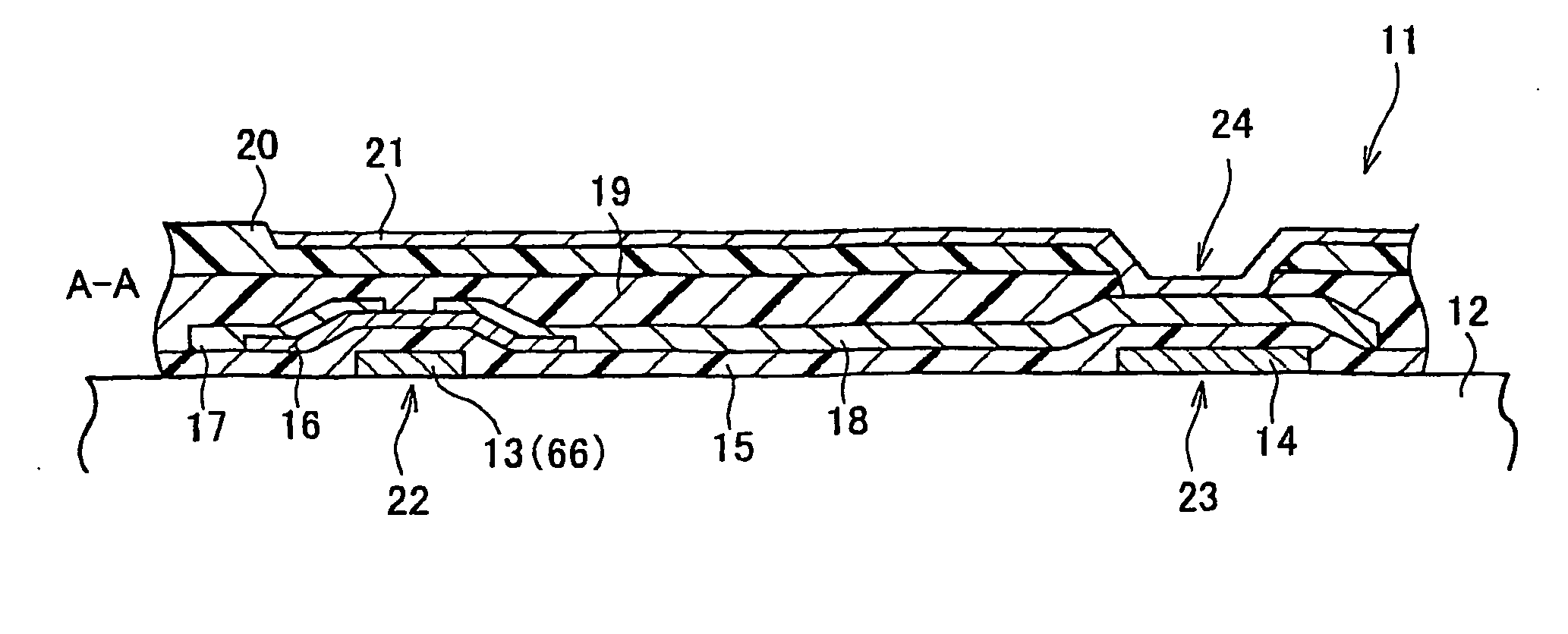

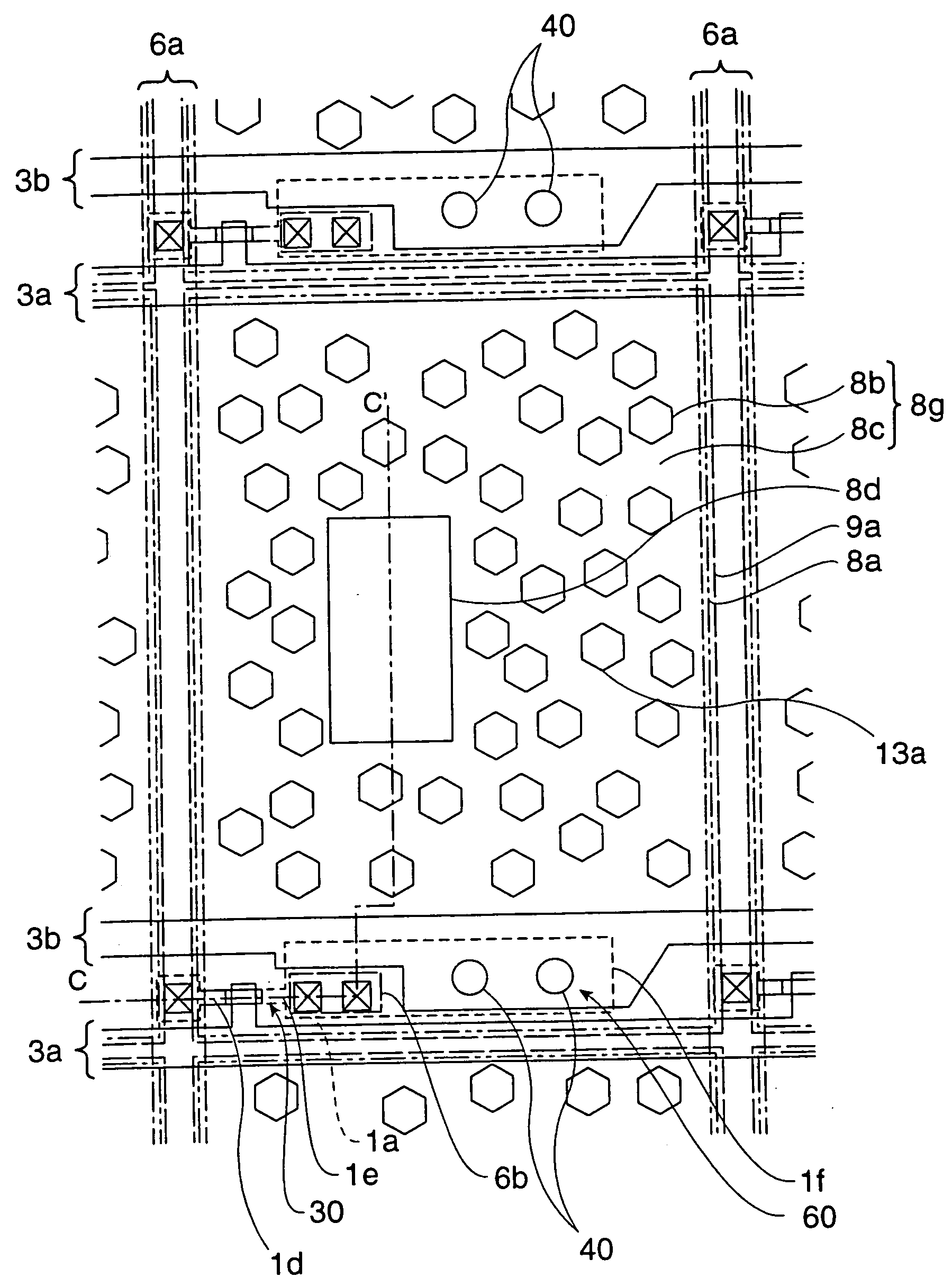

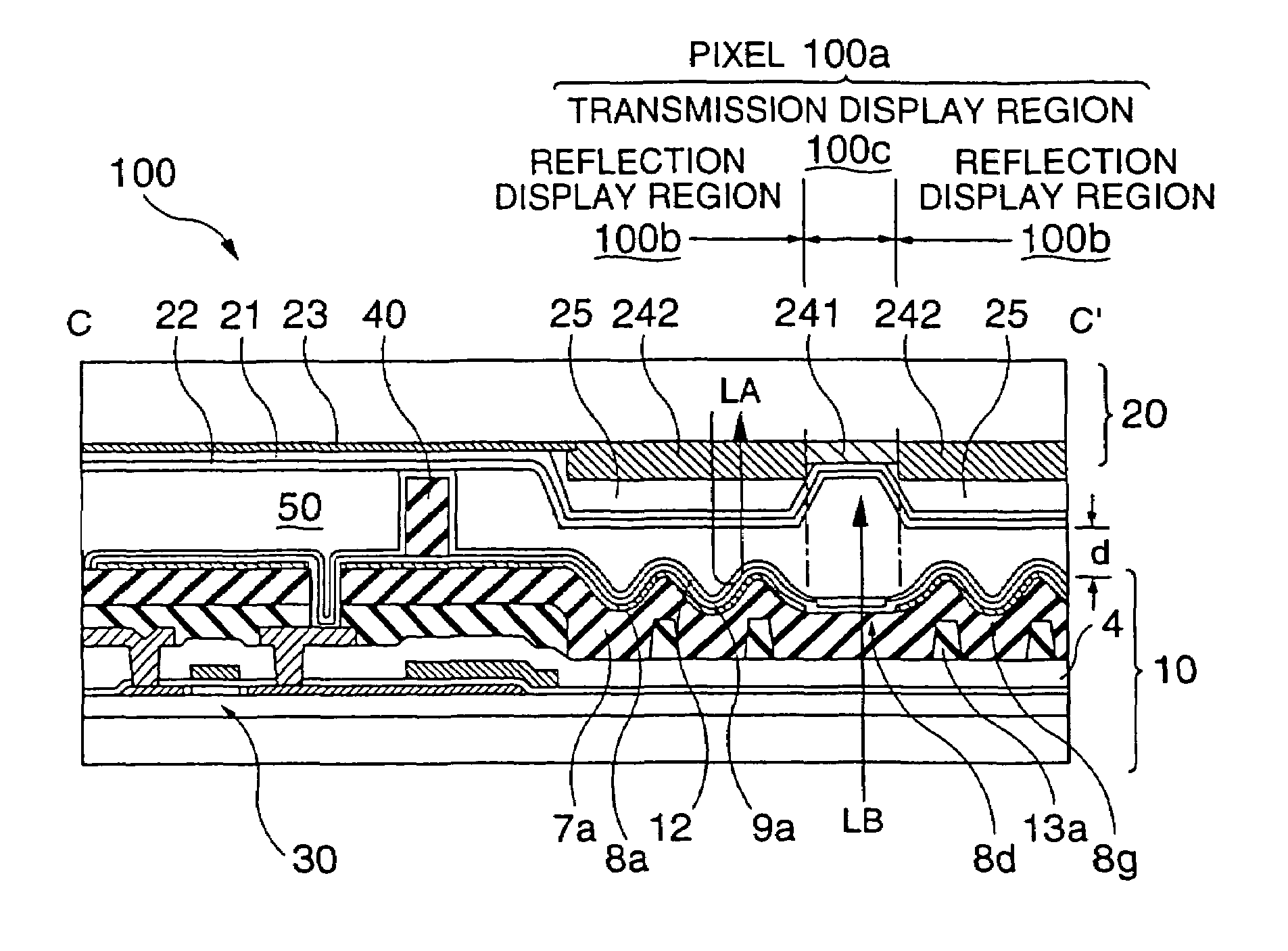

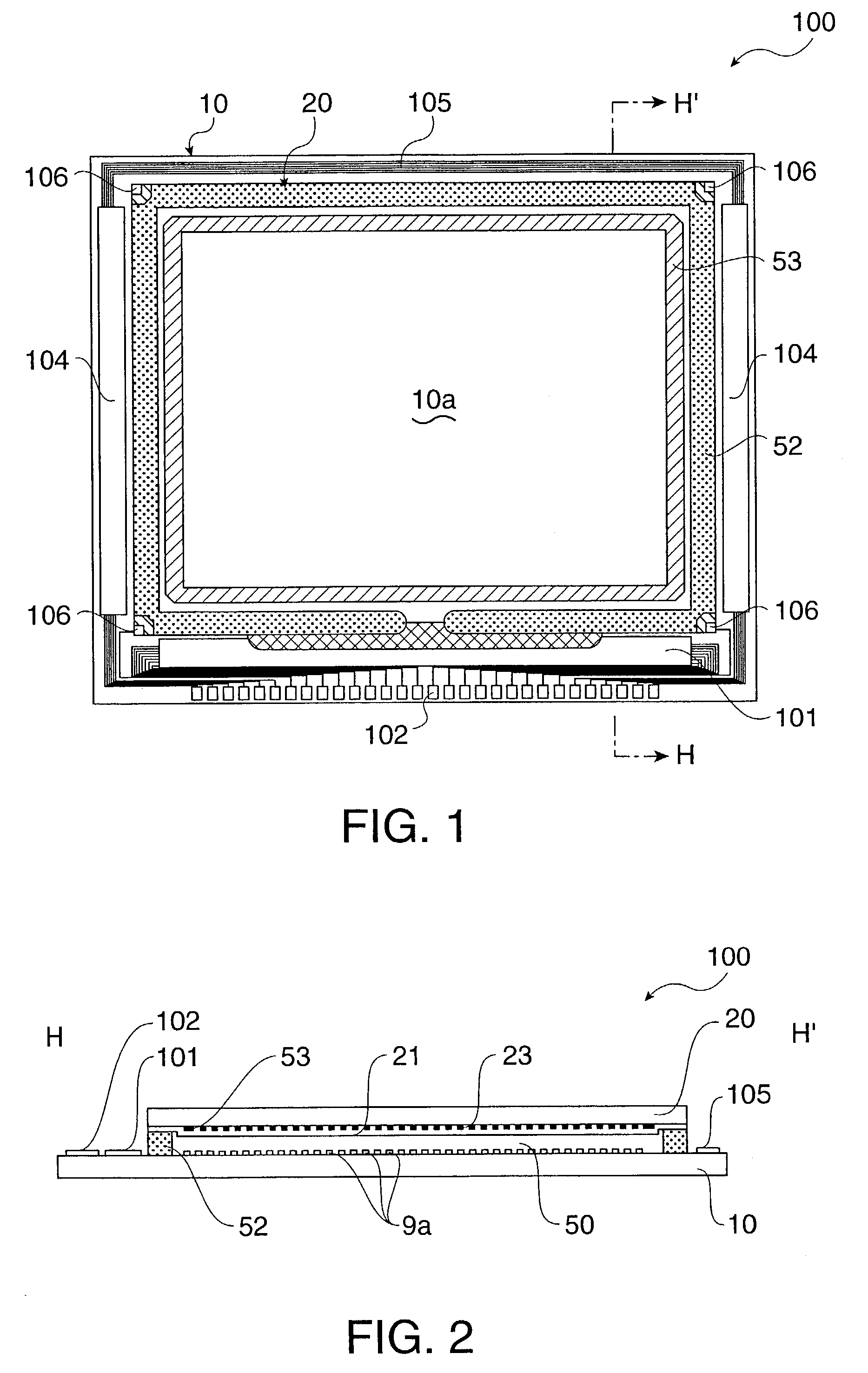

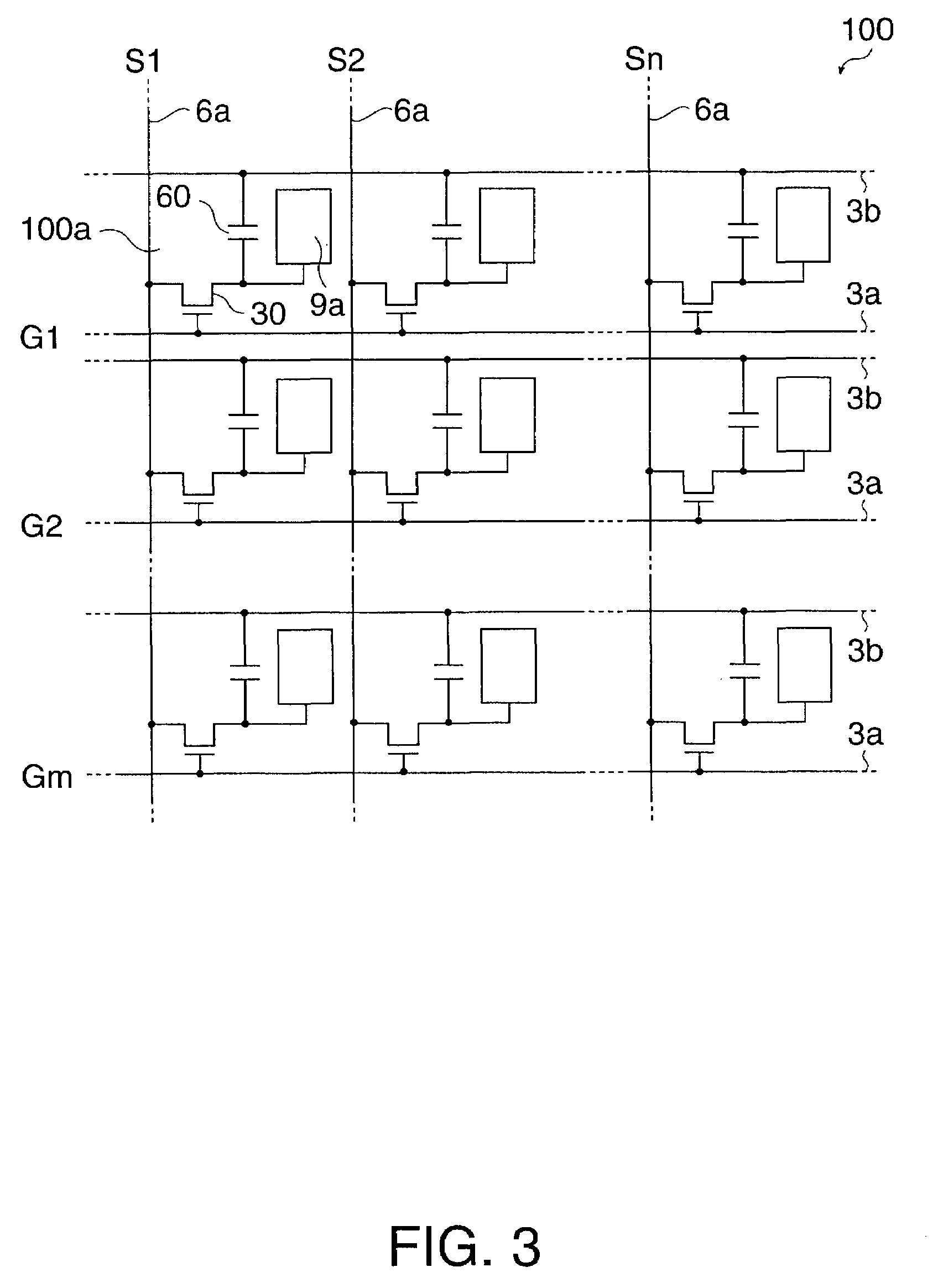

Transflective liquid crystal device and electronic apparatus using the same

InactiveUS20050213005A1Wide chromaticity regionEnlarge regionNon-linear opticsLiquid-crystal displayLayer thickness

The invention provides a transflective liquid crystal device and an electronic apparatus using the same which do not cause a non-uniformity in the substrate gap, even though a layer-thickness adjusting layer is formed so that the layer thickness balance of a liquid crystal layer between a transmission display region and a reflection display region is optimized thereby. Below a counter electrode of a counter substrate of a transflective liquid crystal device, a color filter for transmission display, being thin and having a wide chromaticity region, is formed in a transmission display region, and a color filter for reflection display, being thick and having a narrow chromaticity region, is formed in a reflection display region. Further, the interval between a TFT array substrate and the counter substrate is adjusted by a columnar protrusion formed on the TFT array substrate, and a gap material is not dispersed between the TFT array substrate and the counter substrate.

Owner:BOE TECH GRP CO LTD

Capacitive touch screen and process for manufacturing same

InactiveCN102693056AReduce photolithography processReduce stripping processInput/output processes for data processingElectrical conductorIndium tin oxide

The invention discloses a capacitive touch screen which comprises a substrate, an ITO (indium tin oxide) pattern layer, an insulation bridging layer and a jumping conductor pattern layer. The ITO pattern layer is arranged on the substrate, the insulation bridging layer covers the ITO pattern layer, the jumping conductor pattern layer covers the insulation bridging layer, and a black membrane pattern layer covers the jumping conductor pattern layer. A black membrane (BM) of the touch screen is manufactured by the process, after being exposed, the black membrane is only etched and is not peeled off, a low glare effect can be achieved, a peeling-off manufacturing procedure can be omitted, and yield is improved. Besides, the black membrane (BM) is used for shielding high glare generated by the jumping conductor pattern layer, and accordingly the appearance is improved.

Owner:WUHU TOKEN SCI

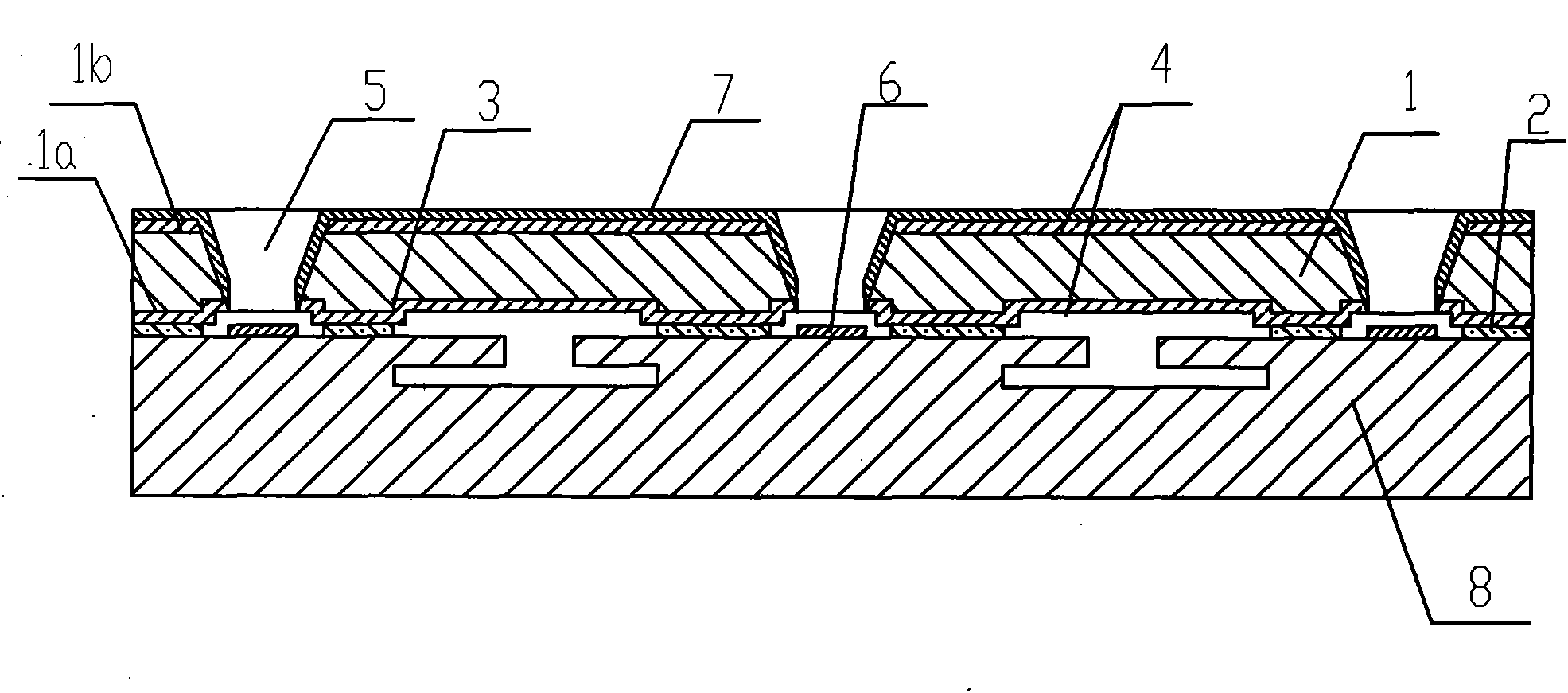

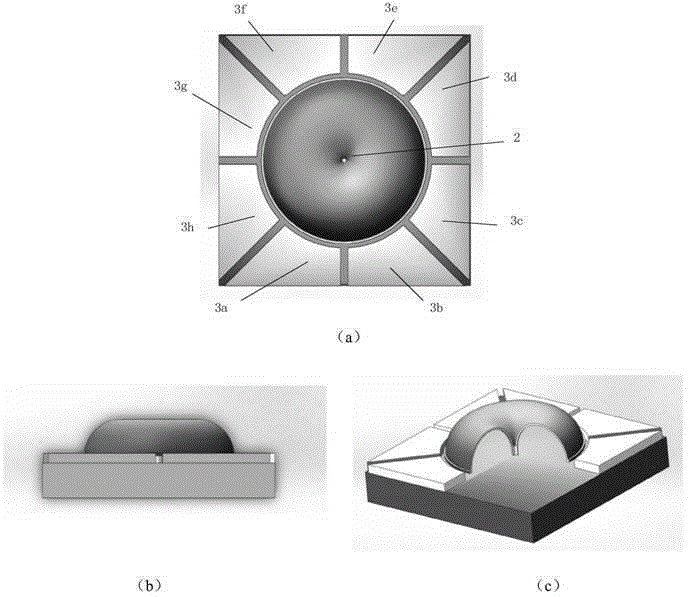

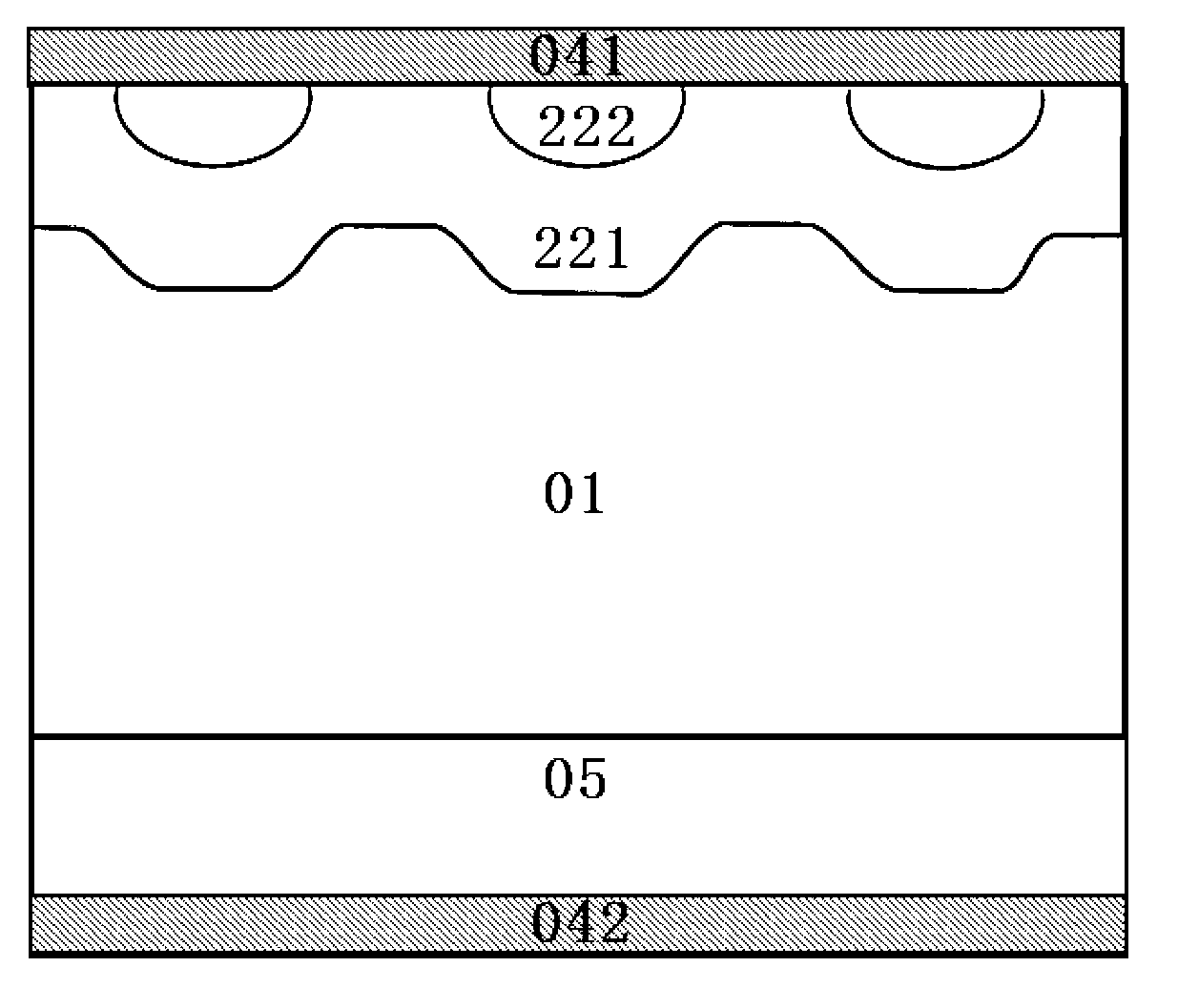

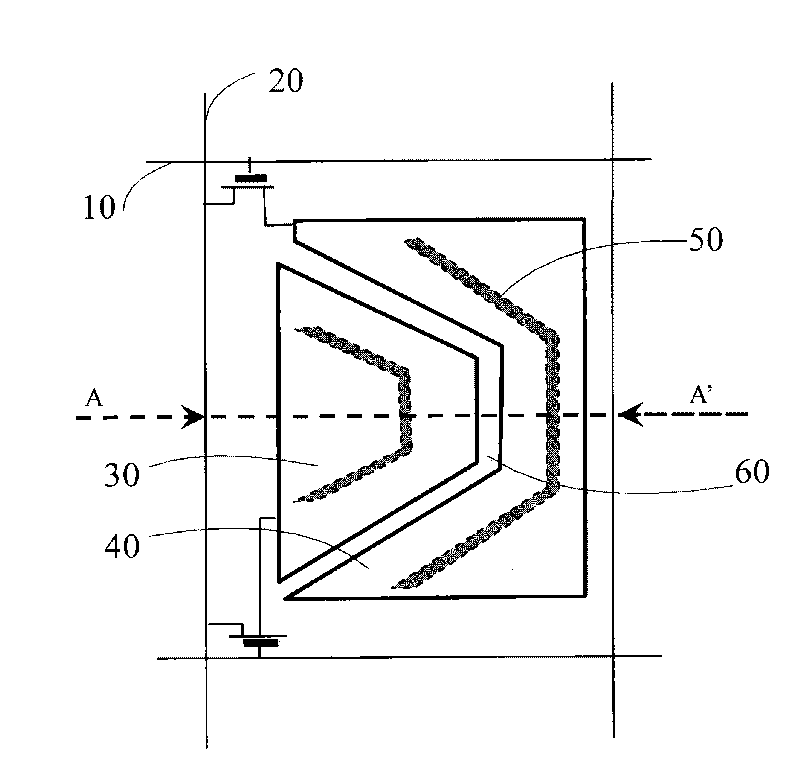

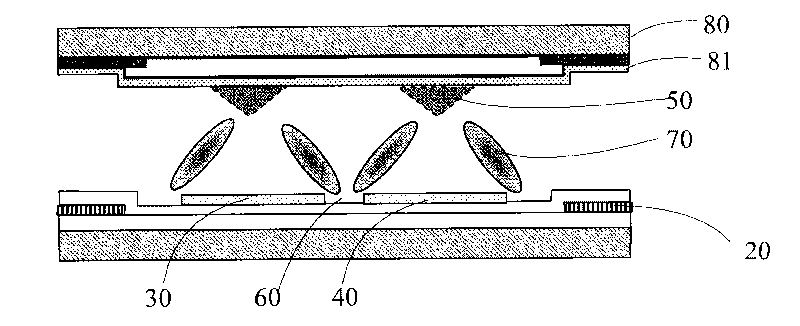

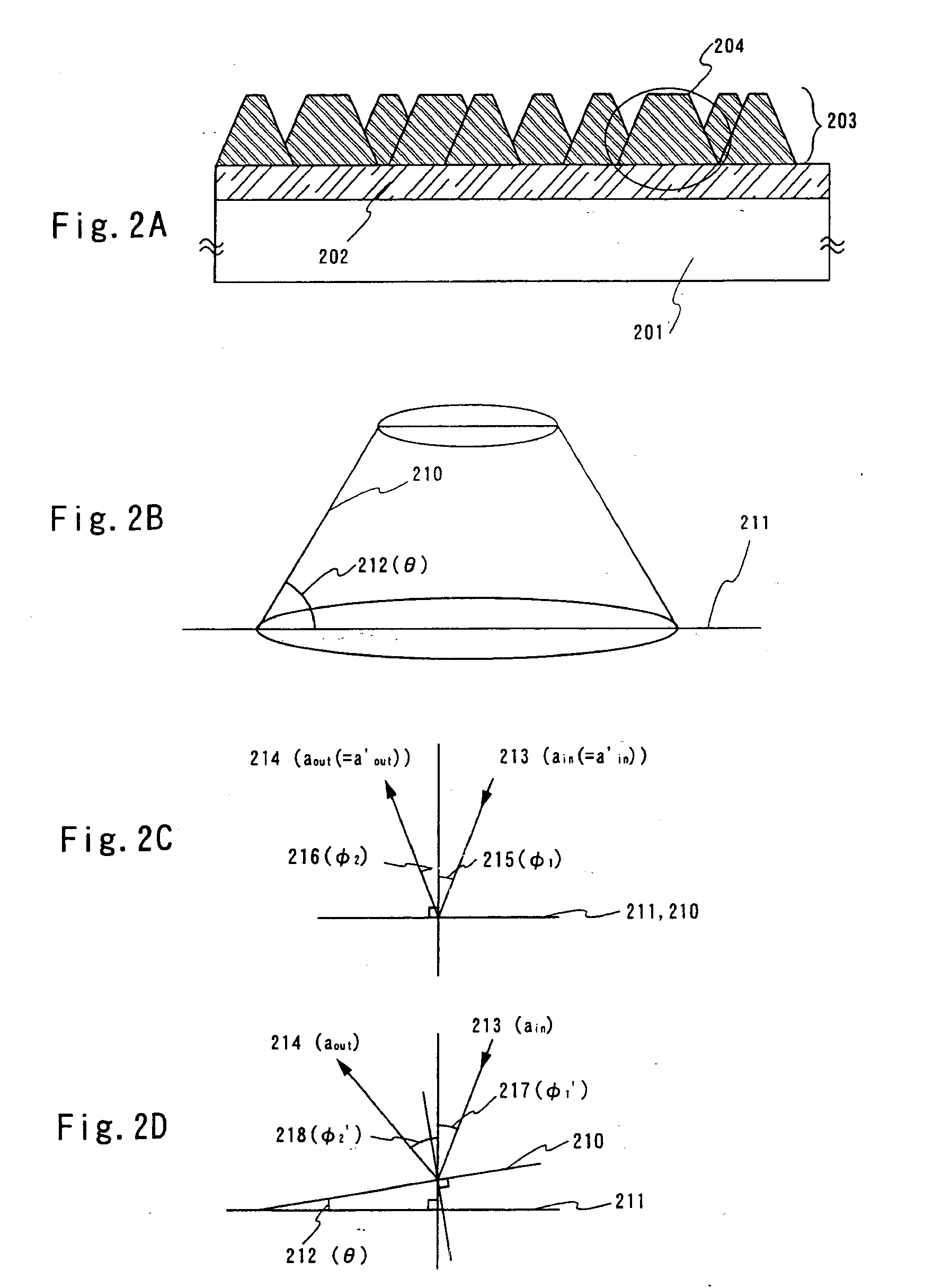

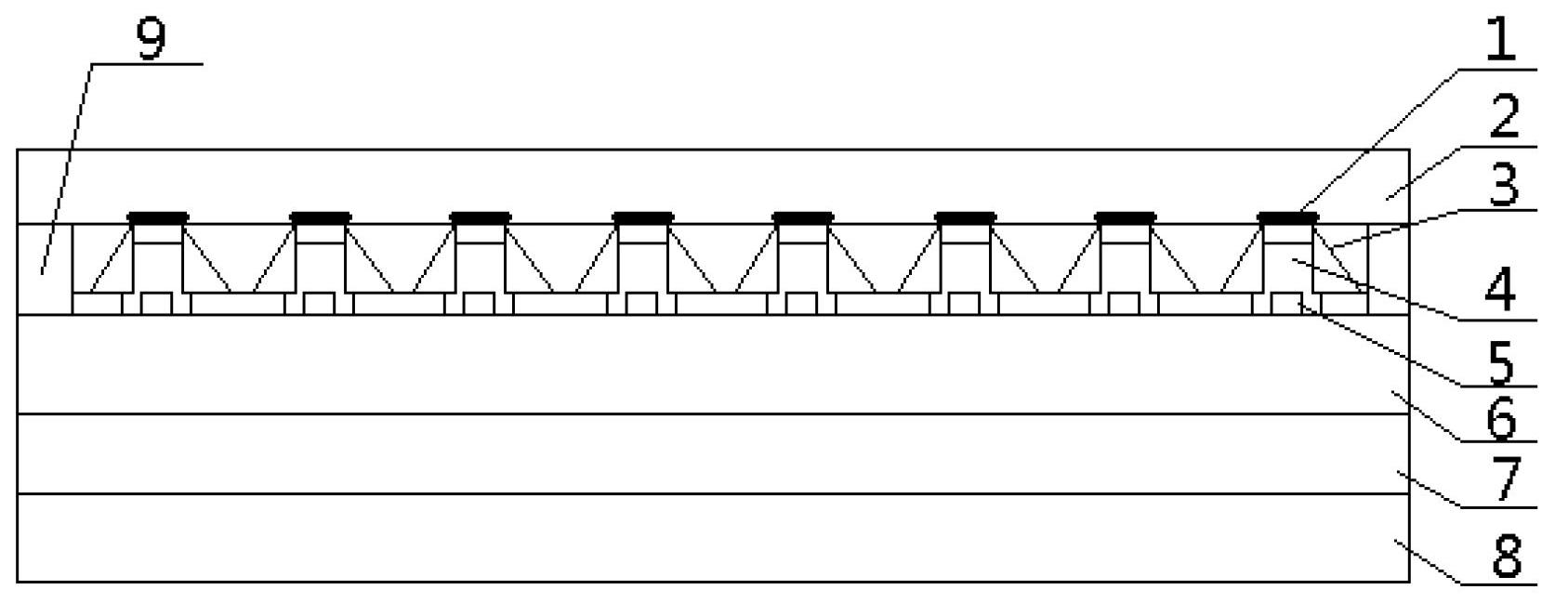

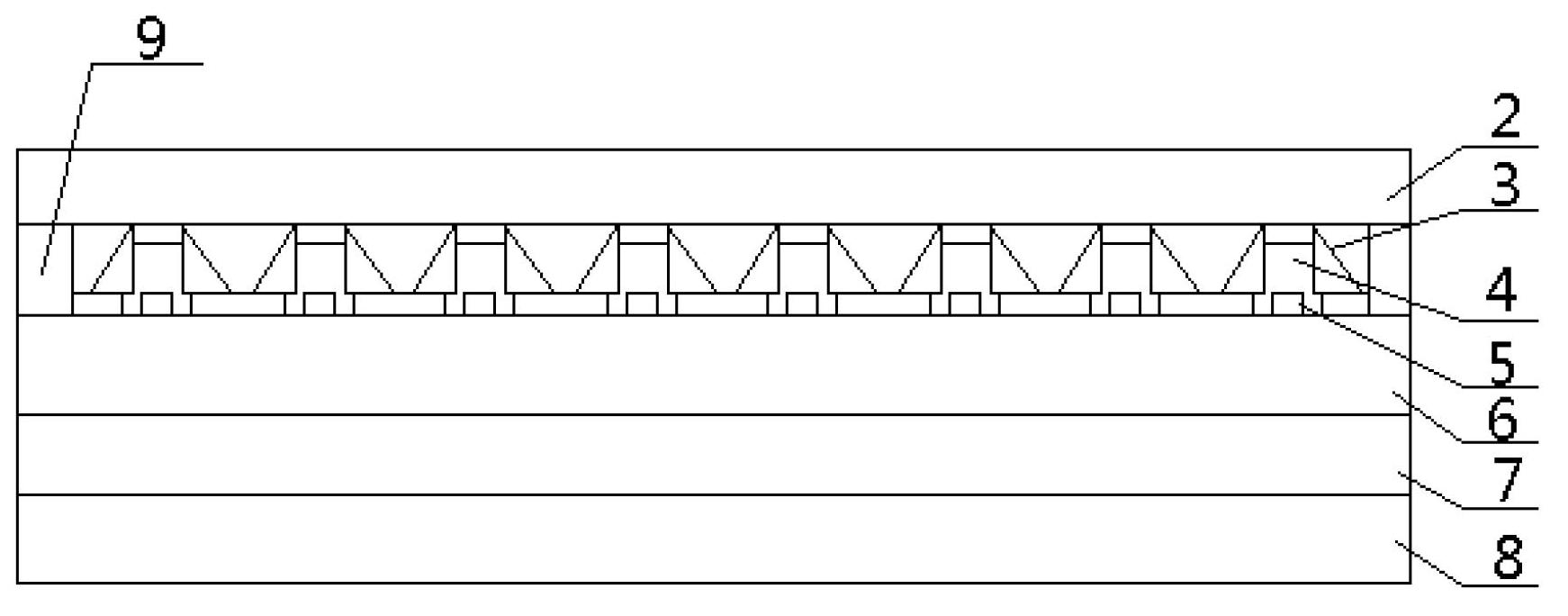

Micro lens array substrate, electro-optical device, and electronic apparatus

ActiveUS20140118664A1Improve efficiencyRelieve pressureProjectorsColor photographyOptical transparencyRefractive index

A micro lens array substrate includes a substrate having optical transparency and a lens layer having optical transparency and a different refractive index from that of the substrate, which is formed in such a manner as to fill in a concave portion arranged in one surface of the substrate in the X-direction, the Y-direction, and the W-direction. A through-hole is provided in the lens layer, between the adjacent concave portions in the W-direction in the lens layer, and the lens layer is continuous between the adjacent concave portions in the X-direction or in the Y-direction.

Owner:SEIKO EPSON CORP

Transflective liquid crystal device and electronic apparatus using the same

InactiveUS6977701B2Reduce photolithography processLower Reliability RequirementsNon-linear opticsLiquid-crystal displayOptoelectronics

The invention provides a transflective liquid crystal device and an electronic apparatus using the same which do not cause a non-uniformity in the substrate gap, even though a layer-thickness adjusting layer is formed so that the layer thickness balance of a liquid crystal layer between a transmission display region and a reflection display region is optimized thereby. Below a counter electrode of a counter substrate of a transflective liquid crystal device, a color filter for transmission display, being thin and having a wide chromaticity region, is formed in a transmission display region, and a color filter for reflection display, being thick and having a narrow chromaticity region, is formed in a reflection display region. Further, the interval between a TFT array substrate and the counter substrate is adjusted by a columnar protrusion formed on the TFT array substrate, and a gap material is not dispersed between the TFT array substrate and the counter substrate.

Owner:BOE TECH GRP CO LTD

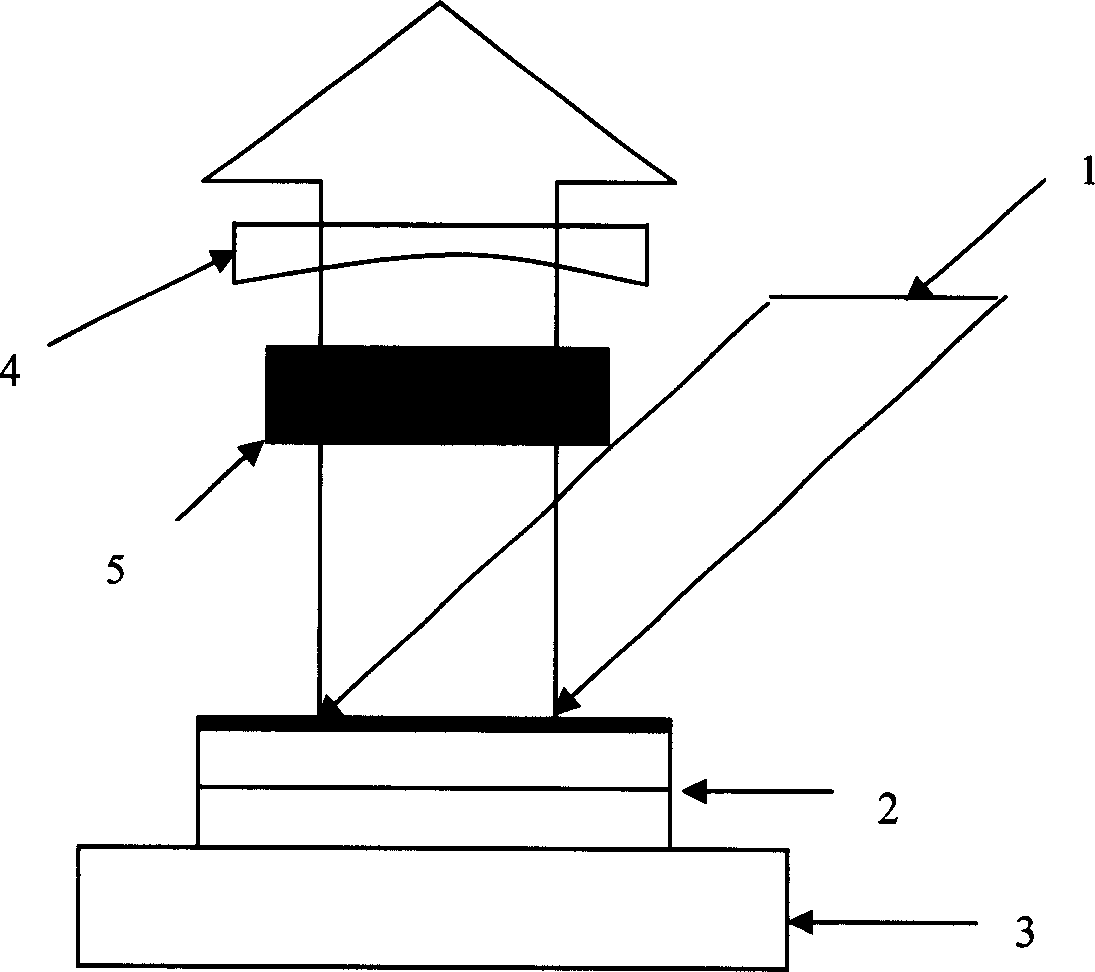

Optical pump high-power vertical external cavity emitting laser

InactiveCN1710763ASimple processReduce photolithography processLaser detailsSemiconductor lasersEtchingProtection layer

Structure of the disclosed laser includes pump light source, epitaxial wafer, heat sink, outer cavity mirror, and double frequency crystal. The epitaxial wafer includes window layer, protection layer, active area, multiple layered Bragg reflector, and substrate. The active area includes quanta trap layer, and absorbing layer. Characters are that quanta trap layer includes light pumped vertical outer cavity face emission in high power of 2-3 pieces of quanta traps so as to raise fill factor of laser, efficiency of outer quanta trap, output power of device, and lowers current density of threshold value. The invention obtains circular symmetrical, linear polarized laser output in high power near to diffraction limit. Using the light pump mode, the invention possesses features of simplifying technique, reducing procedures such as photo etching, preparing poles, hard coat etc, and cost, as well as raising yield.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Light-emitting diode and manufacturing method thereof

InactiveCN107808914AReduce material costsReduce photolithography processSemiconductor devicesMetal electrodesLight-emitting diode

The present application provides a light-emitting diode and a manufacturing method thereof. In the light-emitting diode manufacturing method provided in the present application, on the one hand, the passivation layer is located between the second metal electrode and the transparent conductive layer, and via holes are formed on the passivation layer, so that The second metal electrode and the transparent conductive layer are electrically connected through the via hole on the passivation layer under the finger of the second metal electrode, so that the current is expanded, thereby playing the role of the current blocking layer in the prior art, and then can The current blocking layer is removed, saving the material cost of the current blocking layer. On the other hand, due to the manufacturing method of the light emitting diode provided in the present application, the current blocking layer is removed, and at least one photolithography process of the current blocking layer can be reduced, thereby reducing the cost of the photolithography process and simplifying the process.

Owner:XIAMEN CHANGELIGHT CO LTD

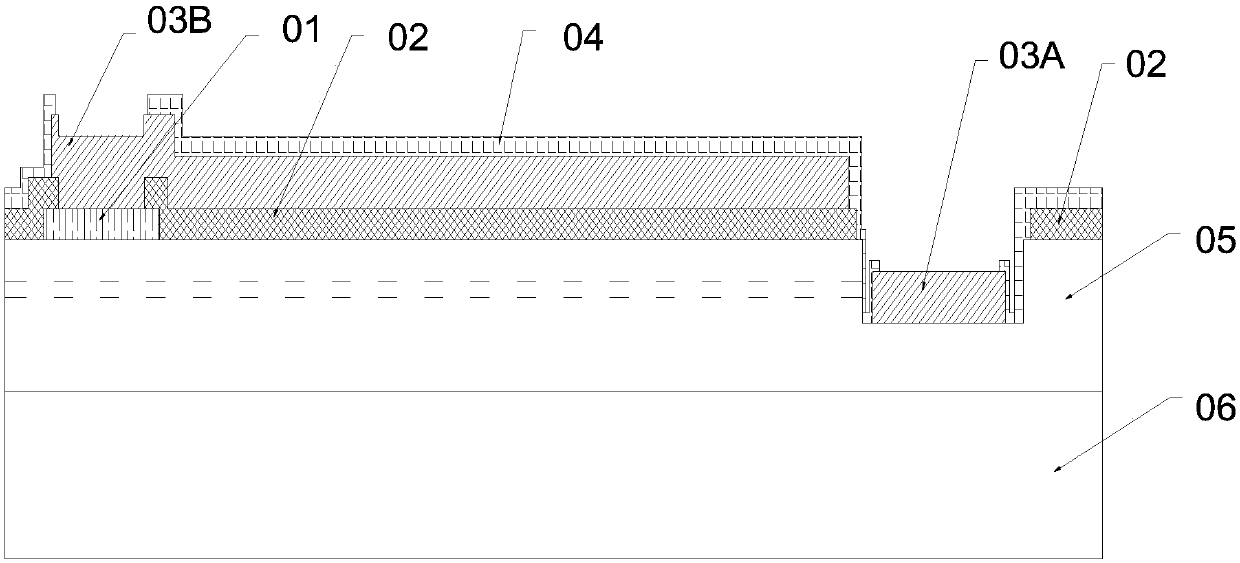

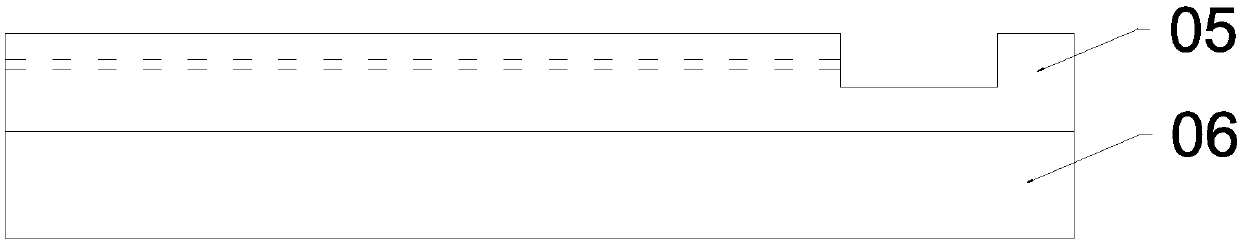

Infrared detector structure with high filling factor and manufacturing method thereof

ActiveCN110120437AReduce areaReduce photolithography processSemiconductor devicesElectrical connectionFilling factor

The invention discloses an infrared detector structure with a high filling factor. The structure comprises a micro-bridge structure arranged on a substrate, and the micro-bridge structure comprises amicro-bridge floor, a support and an electric connection hole. The micro-bridge floor is sequentially provided with a first release protection layer, an infrared sensitive layer, a first metal electrode layer and a second release protection layer from bottom to top; a second metal electrode layer and a third release protection layer are sequentially arranged on the surface of the inner walls of the support and the electric connection hole; the second metal electrode layer is led out from an opening at the top of the inner walls of the support and electric connection hole, and is electrically connected with the first metal electrode layer; the second metal electrode layer achieves the electrical connection with the substrate through the support and the bottom opening of the electric connection hole, and the third release protection layer is led out from the support and the upper end opening part of the inner wall of the electric connection hole and is connected with the second release protection layer. The structure can further improve the product performance while improving the filling factor. The invention further discloses a manufacturing method of the infrared detector structurewith the high filling factor.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT

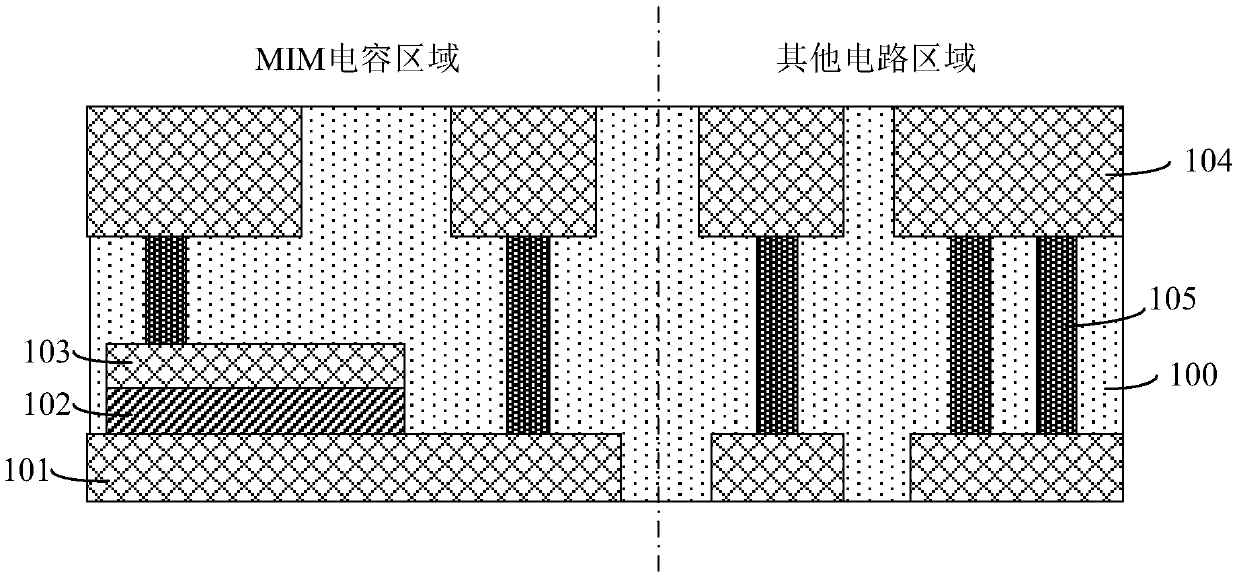

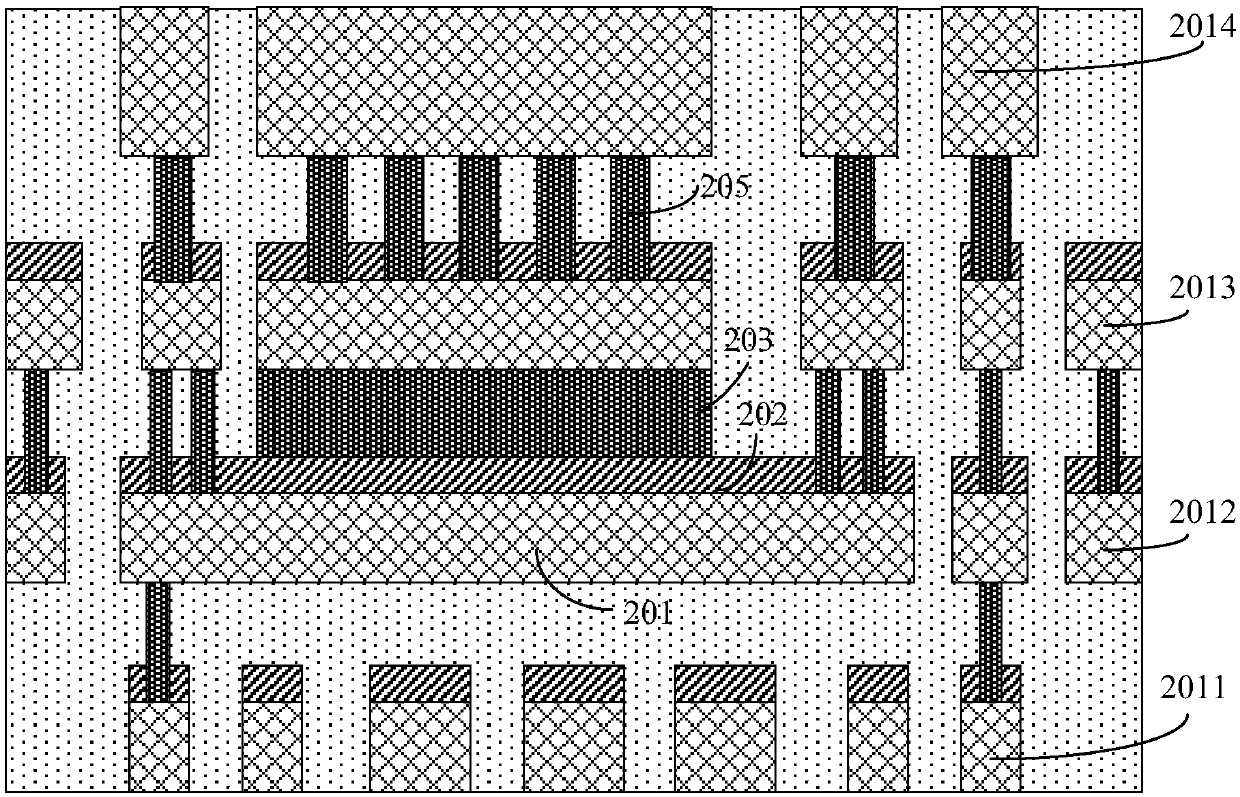

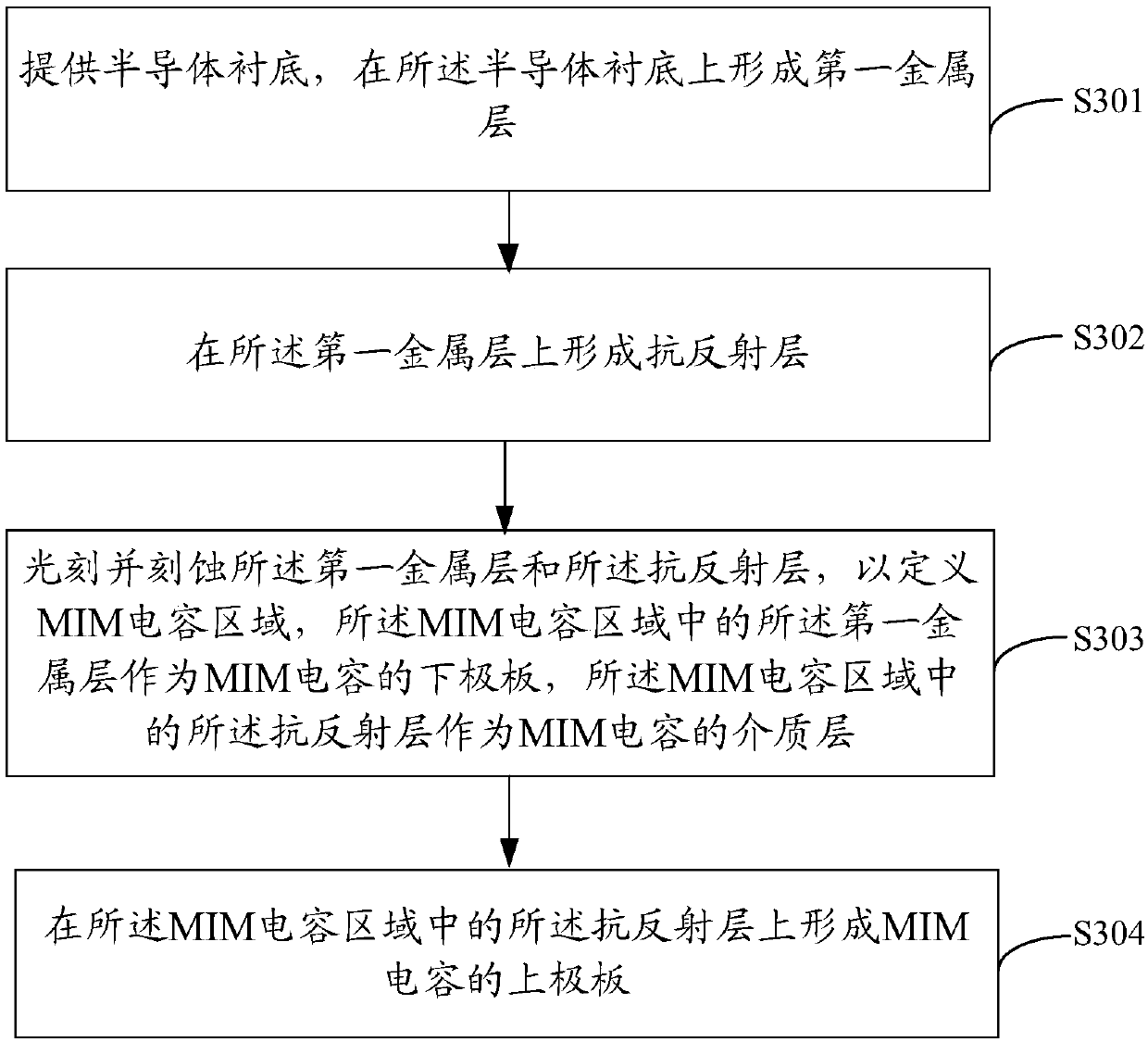

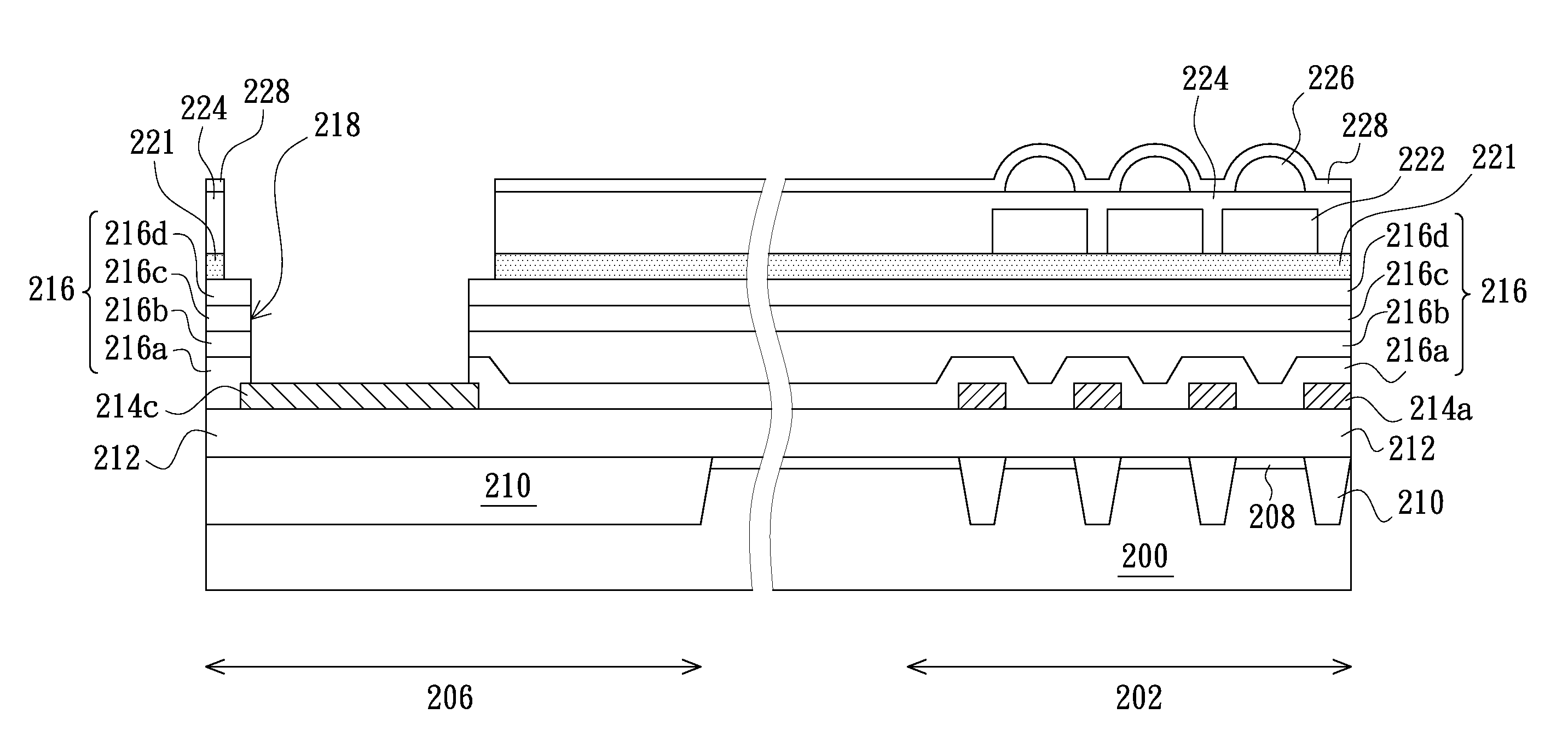

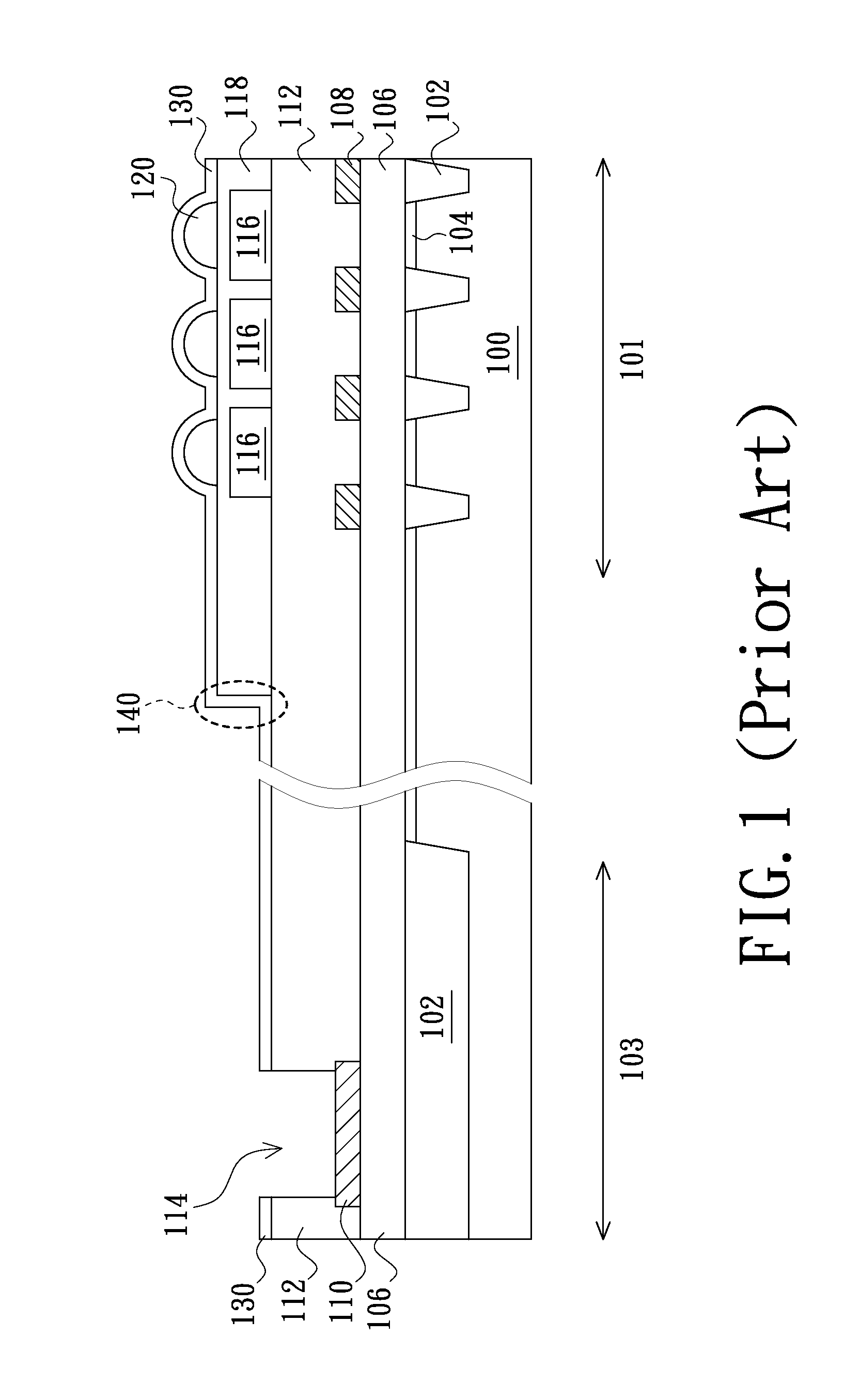

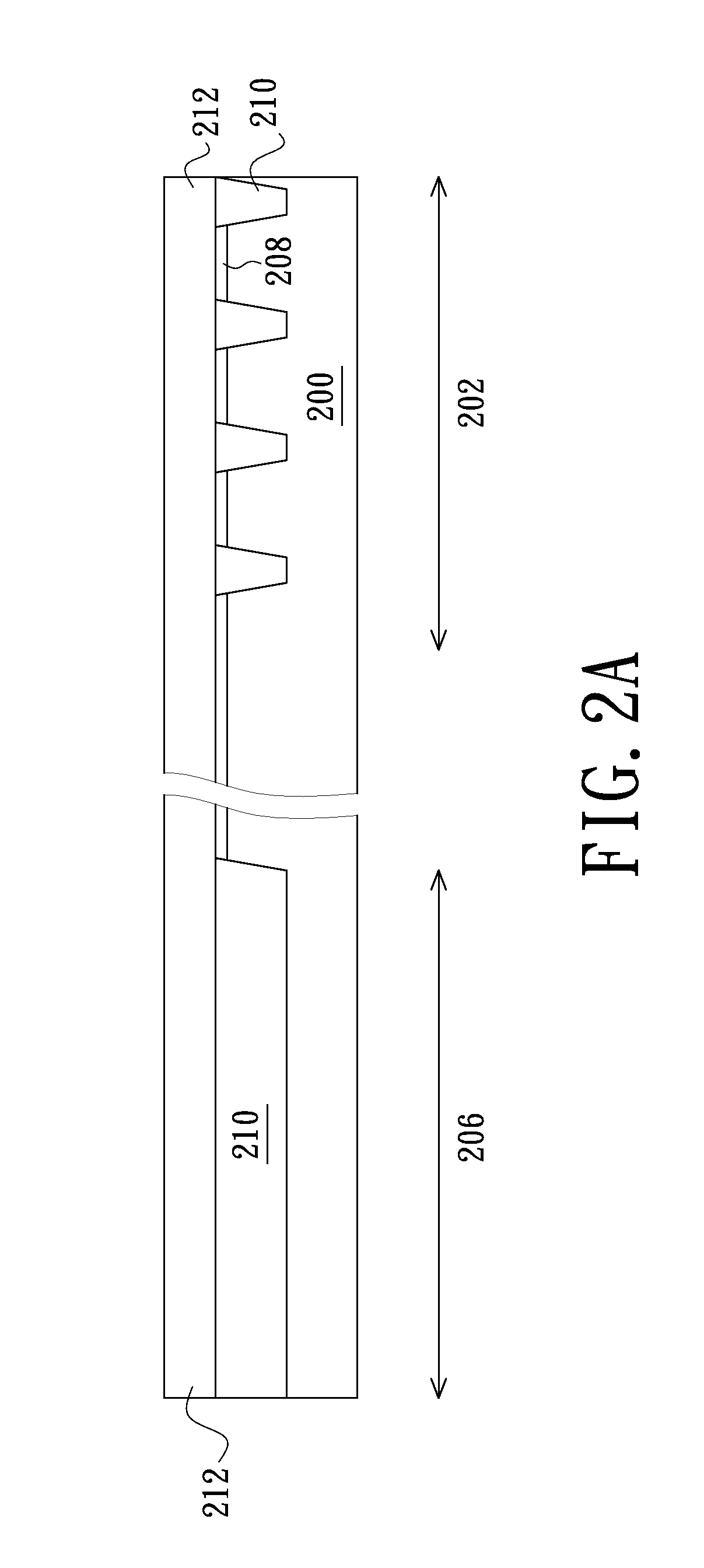

MIM capacitor and manufacturing method thereof

ActiveCN111199953AReduce photolithography processReduce the number of etchSemiconductor/solid-state device detailsSolid-state devicesCapacitanceLithography process

The invention provides an MIM capacitor and a manufacturing method thereof. The manufacturing method comprises the steps of providing a semiconductor substrate, and forming a first metal layer on thesemiconductor substrate; forming an anti-reflection layer on the first metal layer; photoetching and etching the first metal layer and the anti-reflection layer to define an MIM capacitor region, wherein the first metal layer in the MIM capacitor region serves as a lower pole plate of the MIM capacitor, and the anti-reflection layer in the MIM capacitor region serves as a dielectric layer of the MIM capacitor; and forming an upper pole plate of the MIM capacitor on the anti-reflection layer in the MIM capacitor region. According to the manufacturing method provided by the invention, the anti-reflection layer reserved in the etched area is used as a dielectric layer of the capacitor at the same time, the etched area is continuously filled with metal to serve as the upper pole plate, an additional capacitor dielectric layer does not need to be manufactured, an additional photoetching process is not needed for defining the upper pole plate area any more, and the photoetching and etching frequency is reduced, so that the process cost is reduced, and the process period is shortened.

Owner:CSMC TECH FAB2 CO LTD

Method of fabricating image sensor and reworking method thereof

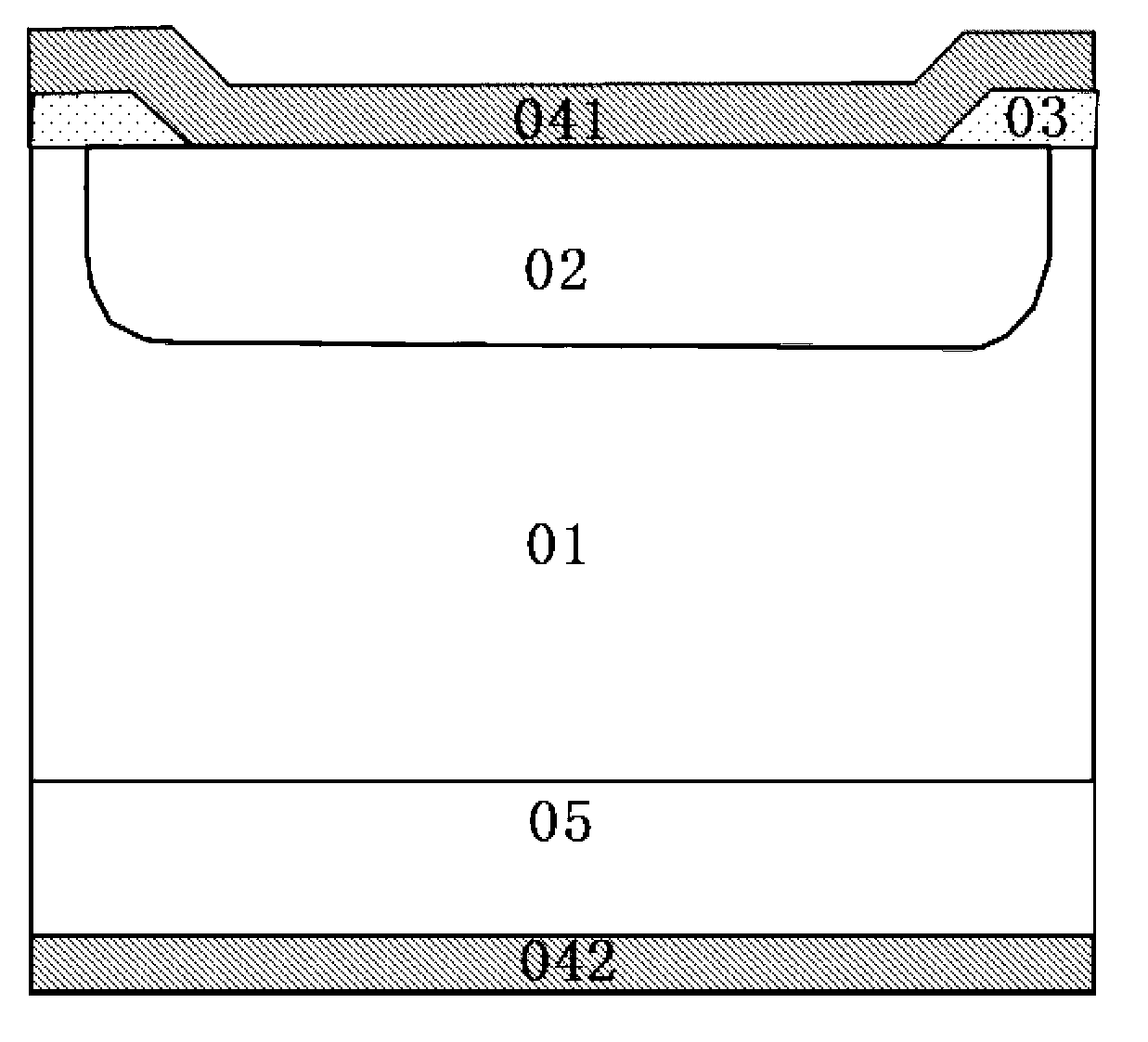

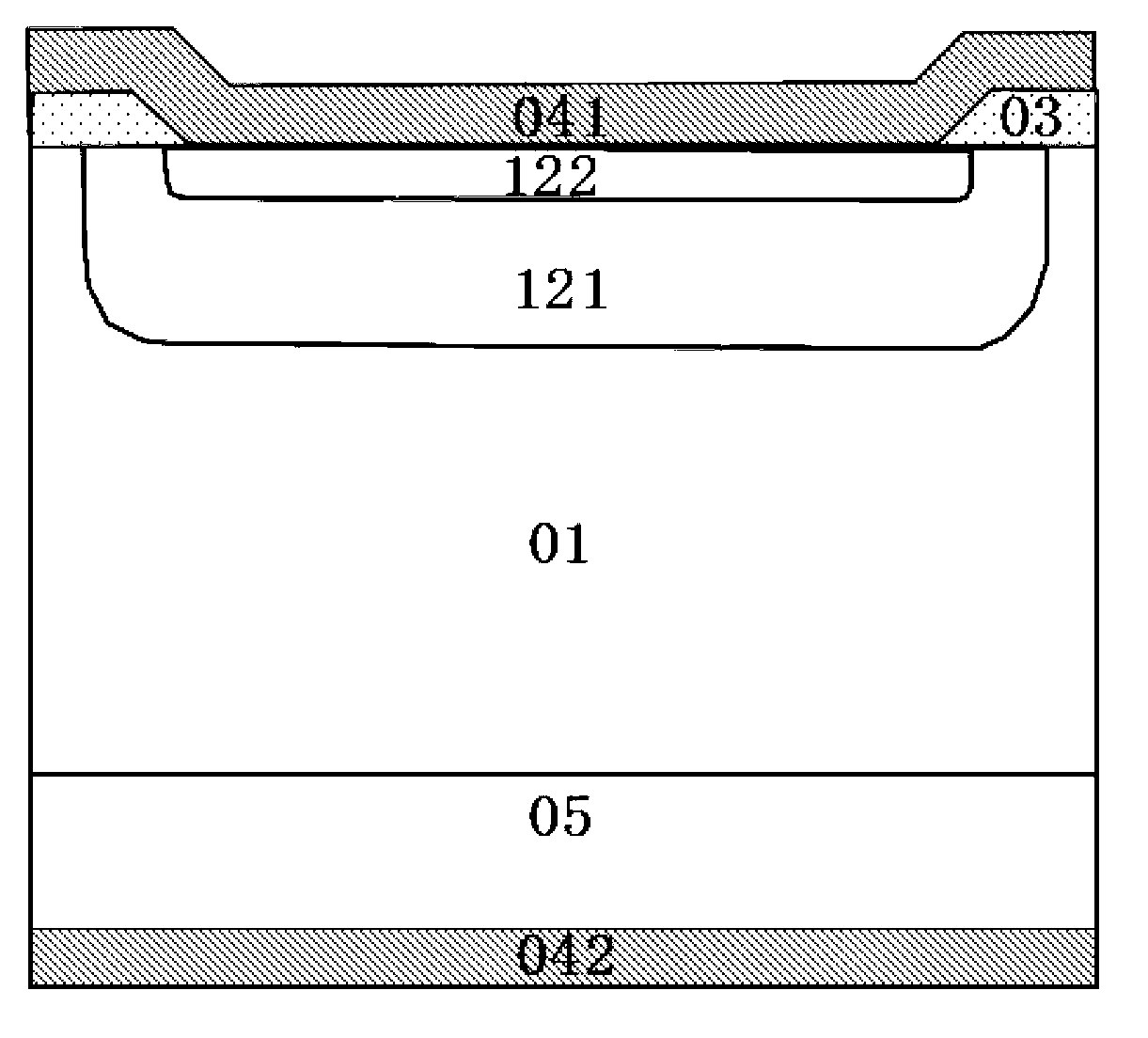

ActiveUS20110212567A1Reduce photolithography processSimplify the manufacturing processSolid-state devicesSemiconductor/solid-state device manufacturingColor filter arrayPixel array

A method of fabricating an image sensor device is provided. First, a substrate comprising a pixel array region and a pad region is provided. A patterned metal layer and a first planarization layer having an opening exposing the patterned metal layer in the pad region are sequentially formed on the substrate. A color filter array is formed on the first planarization layer in the pixel array region. A second planarization layer is formed to cover the color filter array and filled into the opening. A plurality of microlens is formed above the color filter array on the second planarization layer. A capping layer is conformally formed on the microlens and the second planarization layer. An etching step is performed to remove the capping layer and the second planarization layer in the opening so as to expose the patterned metal layer in the pad region.

Owner:UNITED MICROELECTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com