Thin-film transistor manufacturing method

A technology for thin film transistors and a manufacturing method, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of complex process and high cost of thin film transistor substrates, and achieve the effect of reducing the number of lithography, reducing costs, and simplifying the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

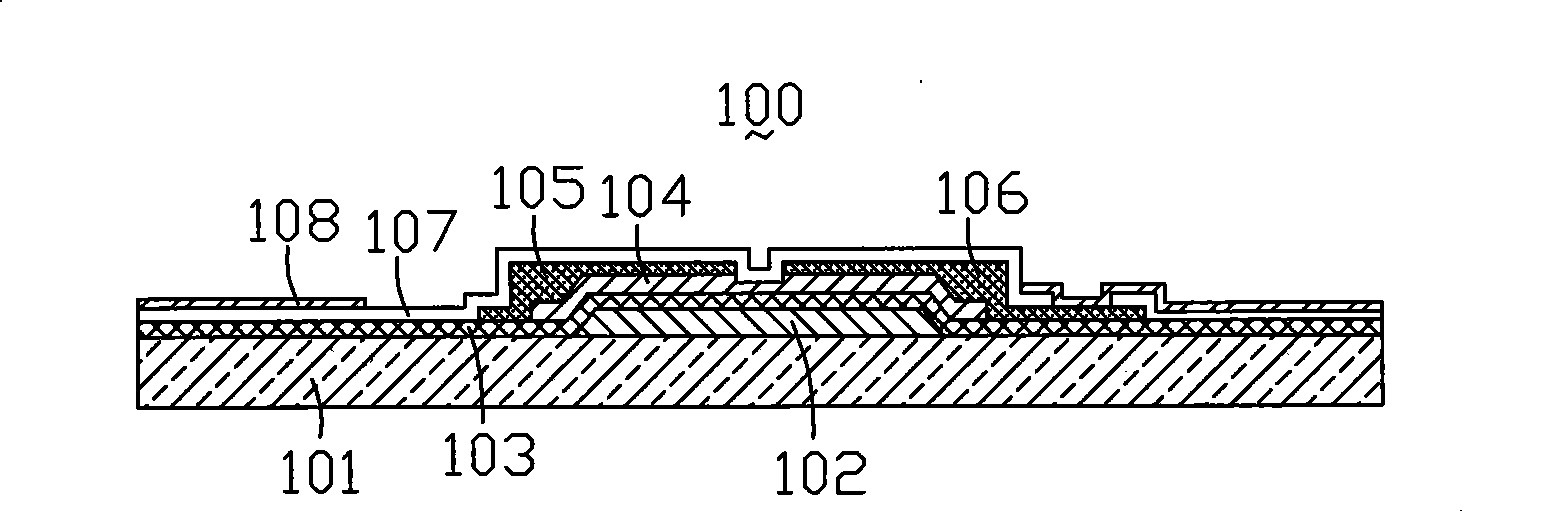

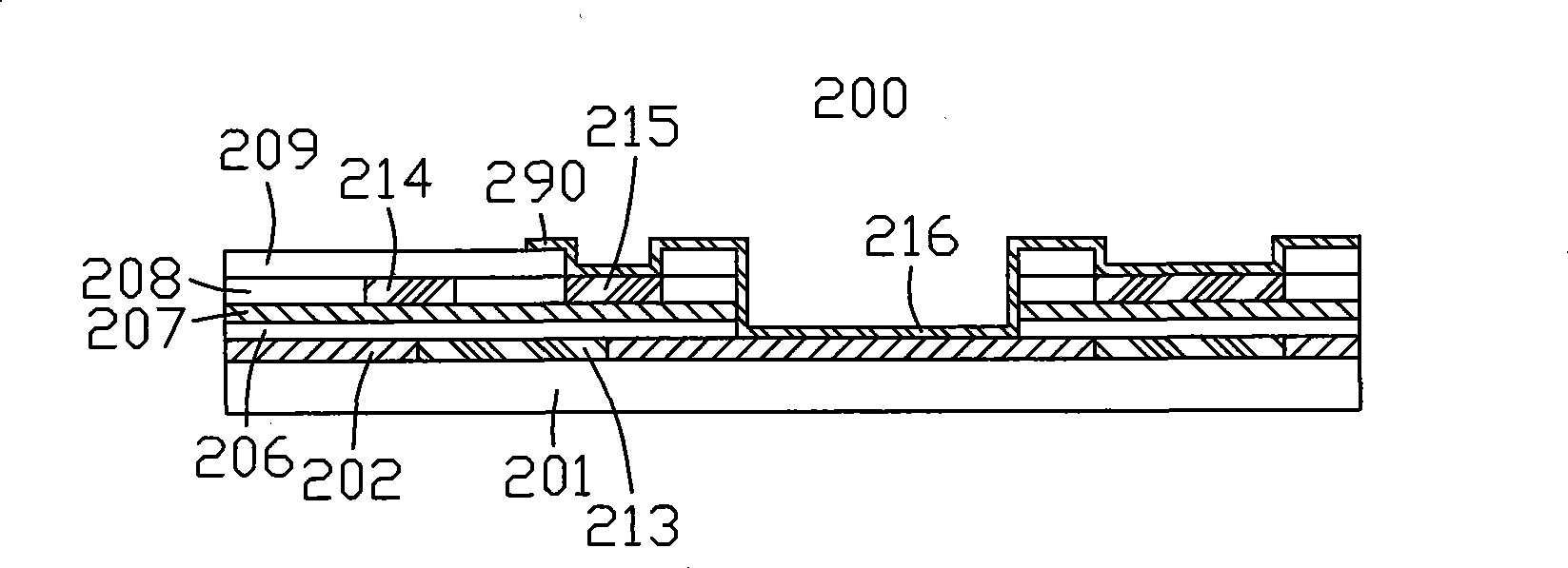

[0029] see image 3 , is a schematic structural view of the thin film transistor substrate manufactured by the manufacturing method of the thin film transistor substrate of the present invention. The TFT substrate 200 includes an insulating base 201, a gate 213 disposed on the insulating base 201, a first gate insulating layer 202, and a second gate disposed on the first gate insulating layer 202 in sequence. Pole insulating layer 206 and semiconductor layer 207, a first passivation layer 208 arranged on the semiconductor layer 207, a source electrode 214 and a drain electrode 215, a second passivation layer arranged on the semiconductor layer 207 and the source electrode 214 layer 209 and a pixel electrode 216 disposed on the drain electrode 215 and the first gate insulating layer 202 .

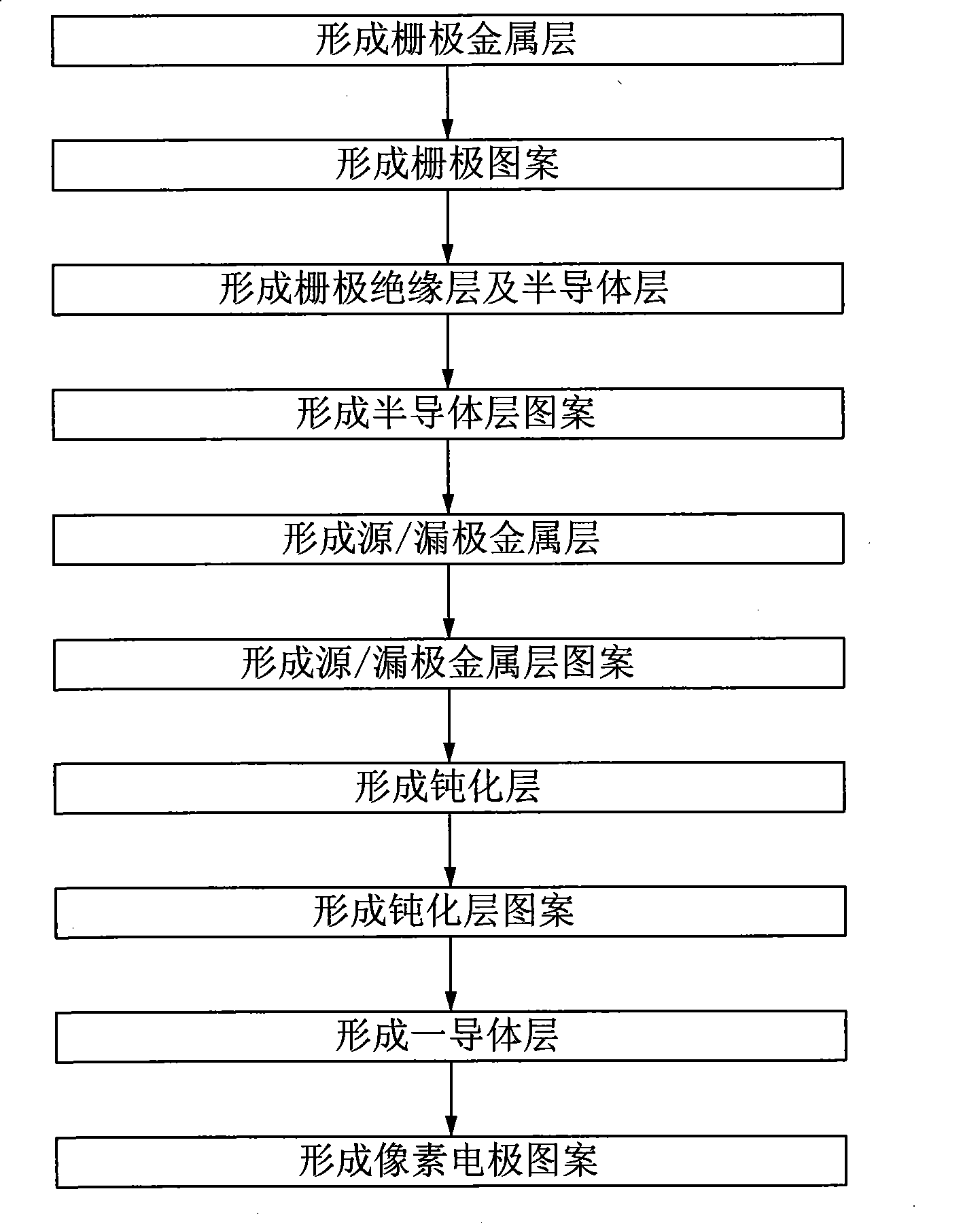

[0030] see Figure 4 , is a flow chart of a preferred embodiment of the thin film transistor substrate manufacturing method. The manufacturing method of the thin film transistor substrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com