Top-gate type thin film transistor and manufacturing method thereof

A thin-film transistor, top-gate technology, used in transistors, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as threshold voltage shift, TFT characteristic change, restricting the application of oxide TFT, etc., to improve stability, increase The effect of lithography times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

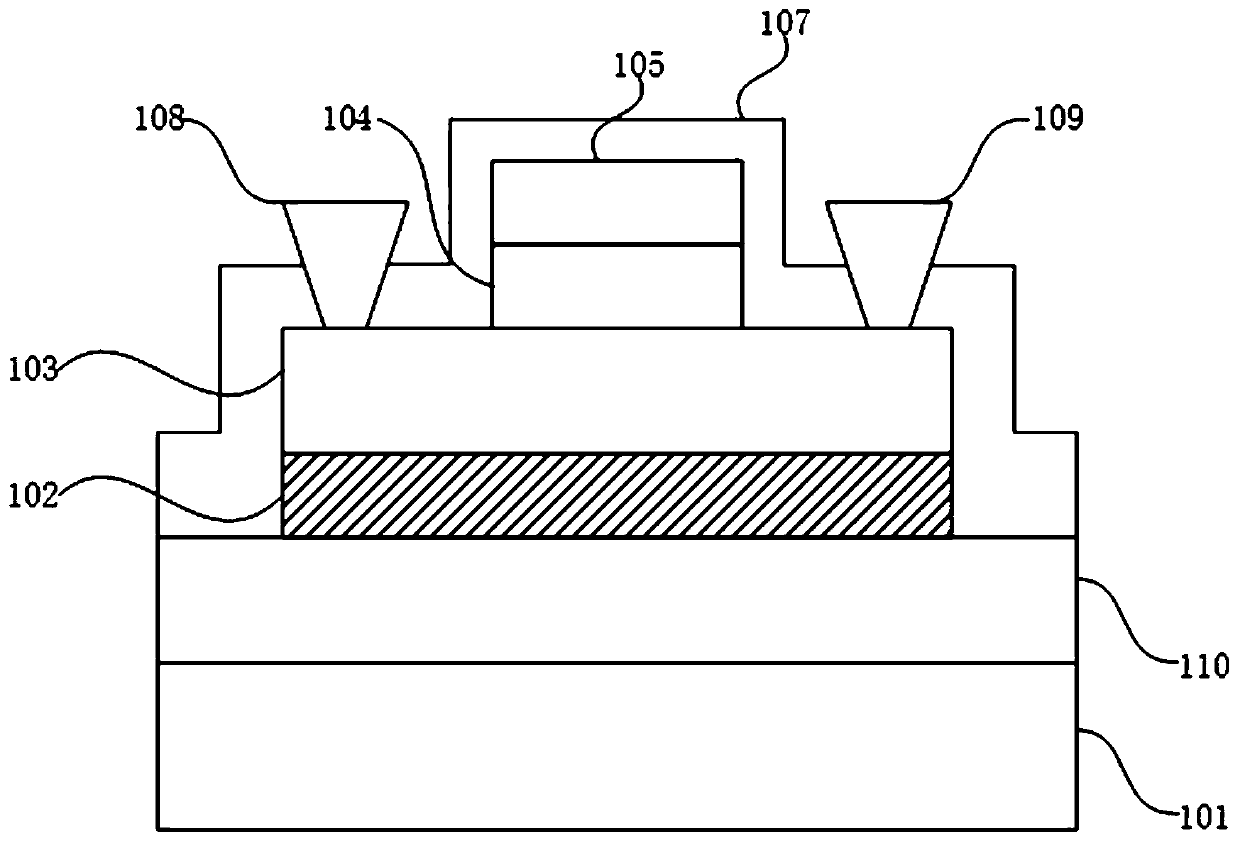

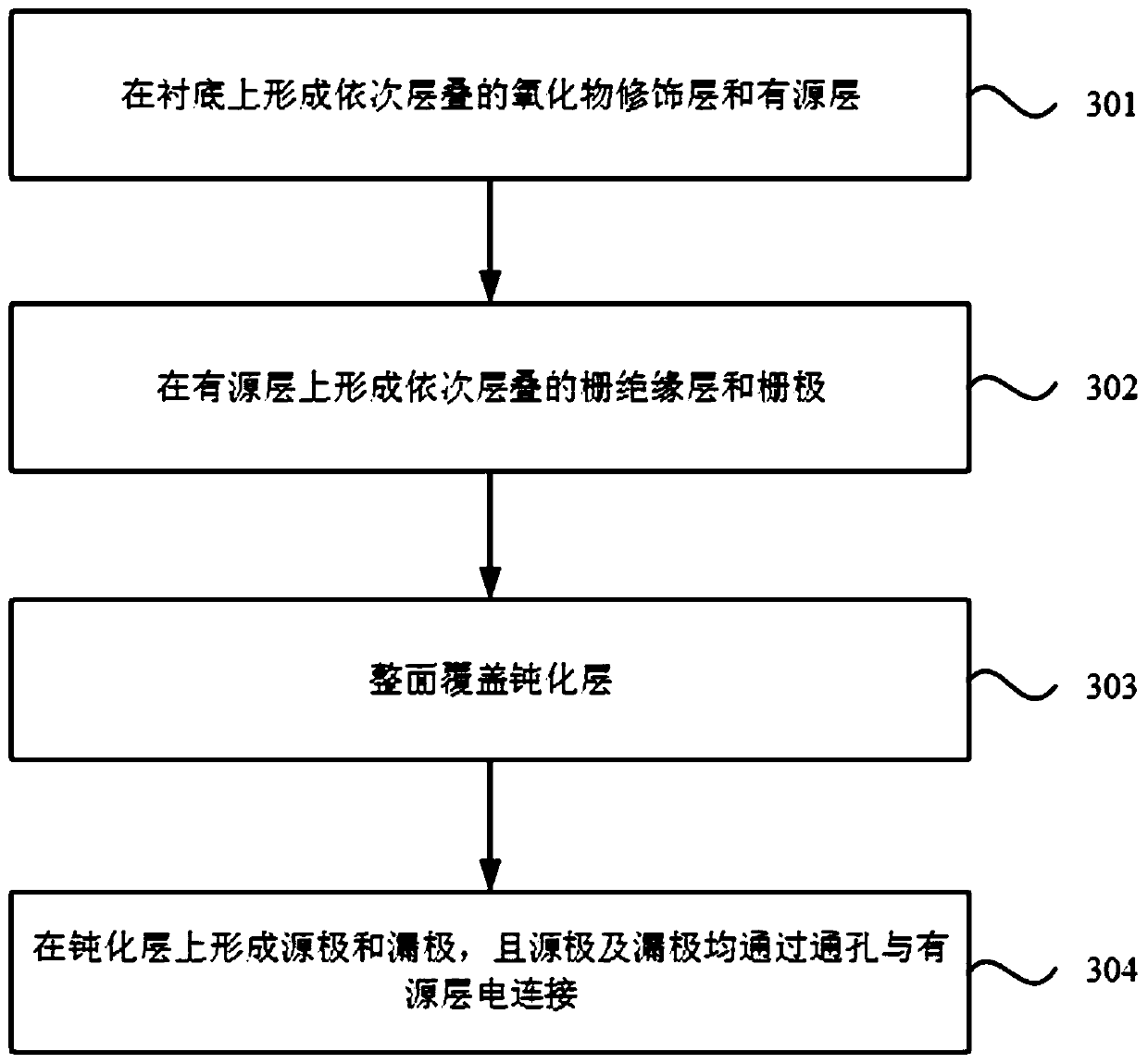

[0036] figure 1 For a schematic structural diagram of a top-gate thin film transistor provided in an embodiment of the present invention, refer to figure 1 , the top-gate thin film transistor includes a substrate 101, an oxide modification layer 102, an active layer 103, a gate insulating layer 104, a gate 105, a passivation layer 107, a source 108 and a drain 109;

[0037] The oxide modification layer 102 is disposed between the substrate 101 and the active layer 103 .

[0038] The threshold voltage of a top-gate TFT is usually related to the interface trap state density between the active layer and the insulating layer, while the charge trap density is mainly determined by the quality of the interface between the semiconductor layer and the insulating layer. When the material purity is low or the contact quality of the semiconducting layer / insulating layer interface is poor, the device usually has a large trap density. The charge traps existing at the interface will trap ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com