Preparation method of laminated anode of strong microcavity device

An anode and microcavity technology, which is applied in the field of strong microcavity devices, can solve the problems of no relatively mature and stable laminated anode preparation process, low light extraction efficiency, and impure light color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below with reference to the accompanying drawings, through the description of the embodiments, the specific embodiments of the present invention, such as the shape, structure, mutual position and connection relationship between the various parts, the role and working principle of the various parts, etc., will be further described. Detailed instructions:

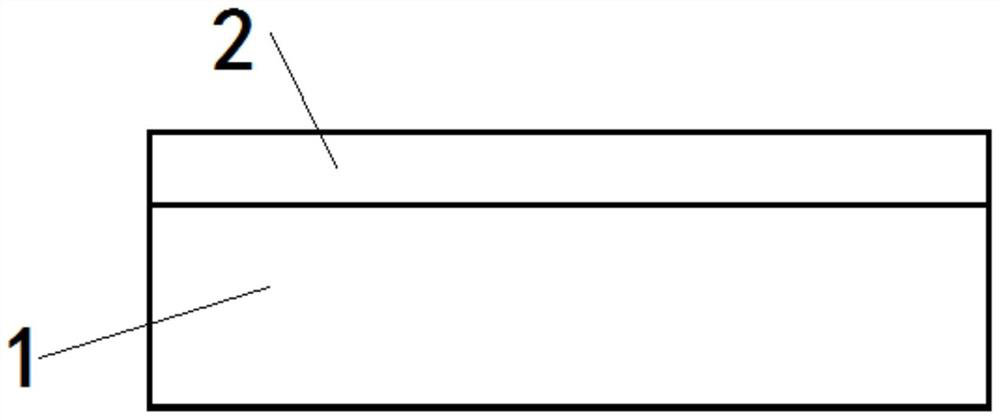

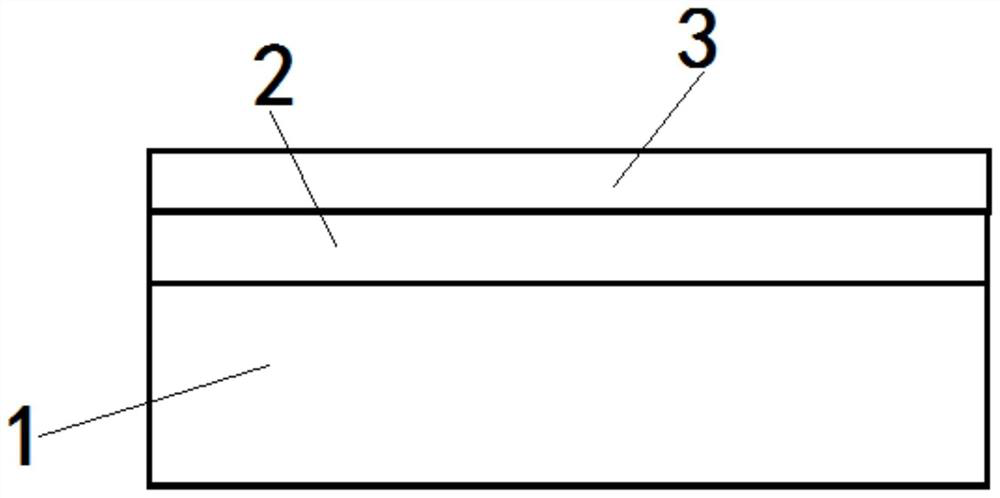

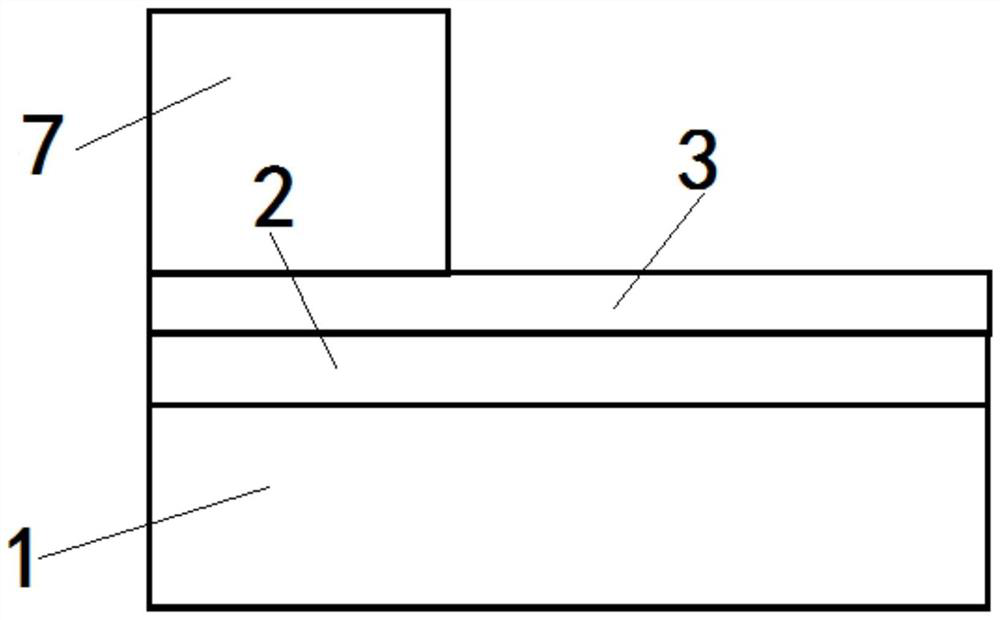

[0040] as attached figure 1 - attached Image 6Shown, the present invention is a kind of preparation method of strong microcavity device stacked anode, the steps of the preparation method of described strong microcavity device stacked anode are: S1. metal reflective layer and B anode film forming; S2.B -HM preparation; for B-HM preparation, the PECVD film formation process is performed on the wafer that has completed the B anode process, and the SiO or SiN film layer is selected, and the film thickness is selected from 3000A to 4000A; this film layer is selected to ensure that it meets the subsequent dry method Etchi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com