Capacitive touch screen and process for manufacturing same

A technology of capacitive touch screen and manufacturing process, which is applied in the direction of electrical digital data processing, instrumentation, input/output process of data processing, etc., can solve the problems of high manufacturing difficulty, glare, and easy collision, etc., to improve the appearance level, Improve output yield and reduce glare

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

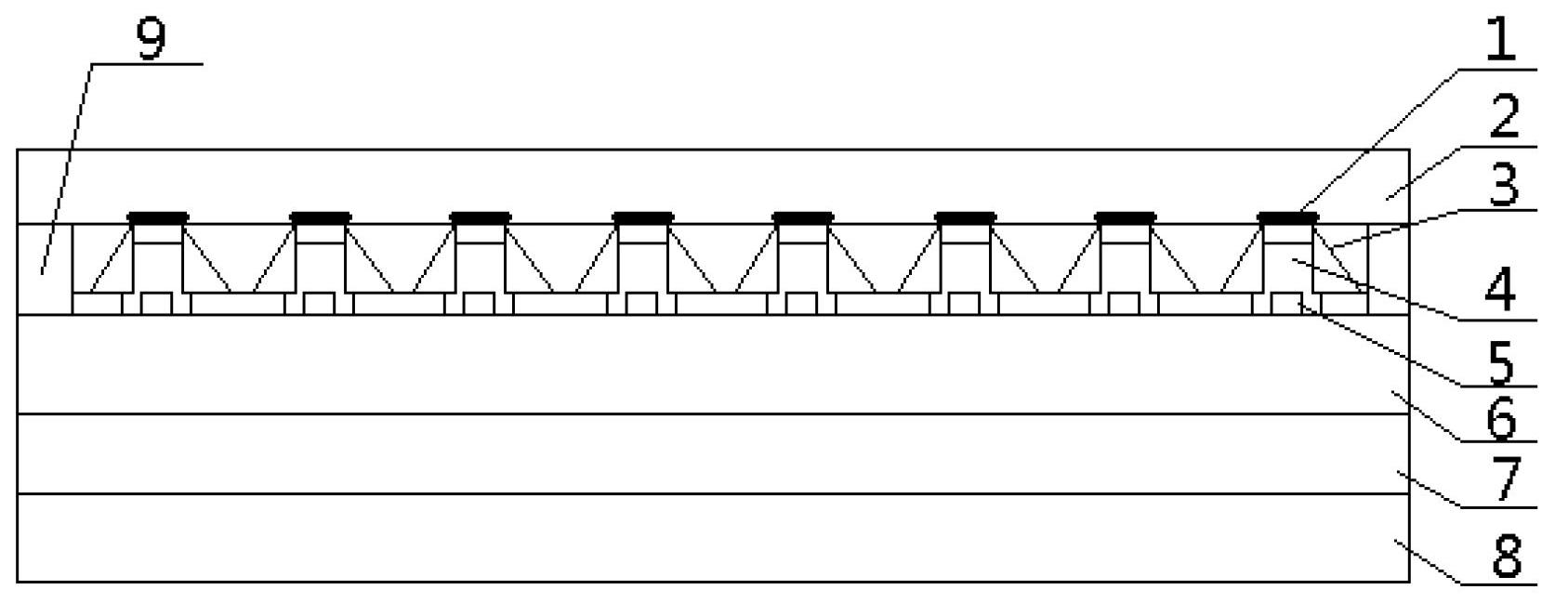

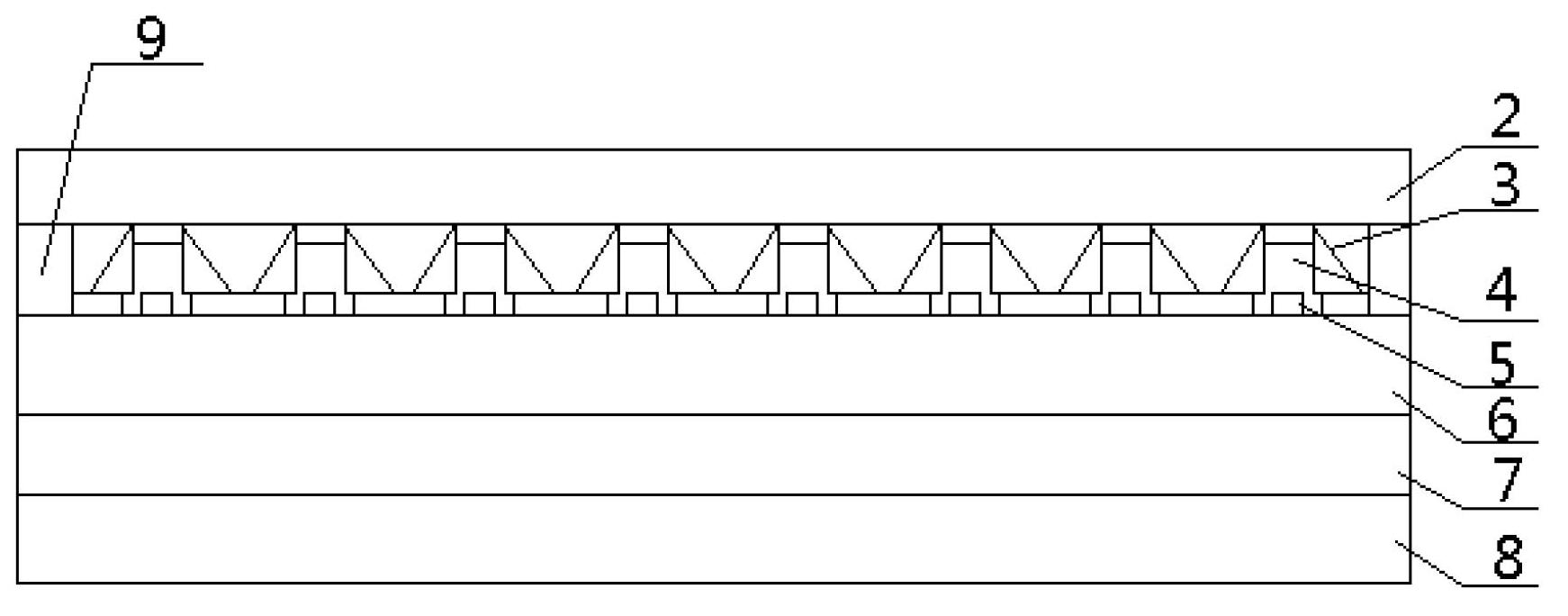

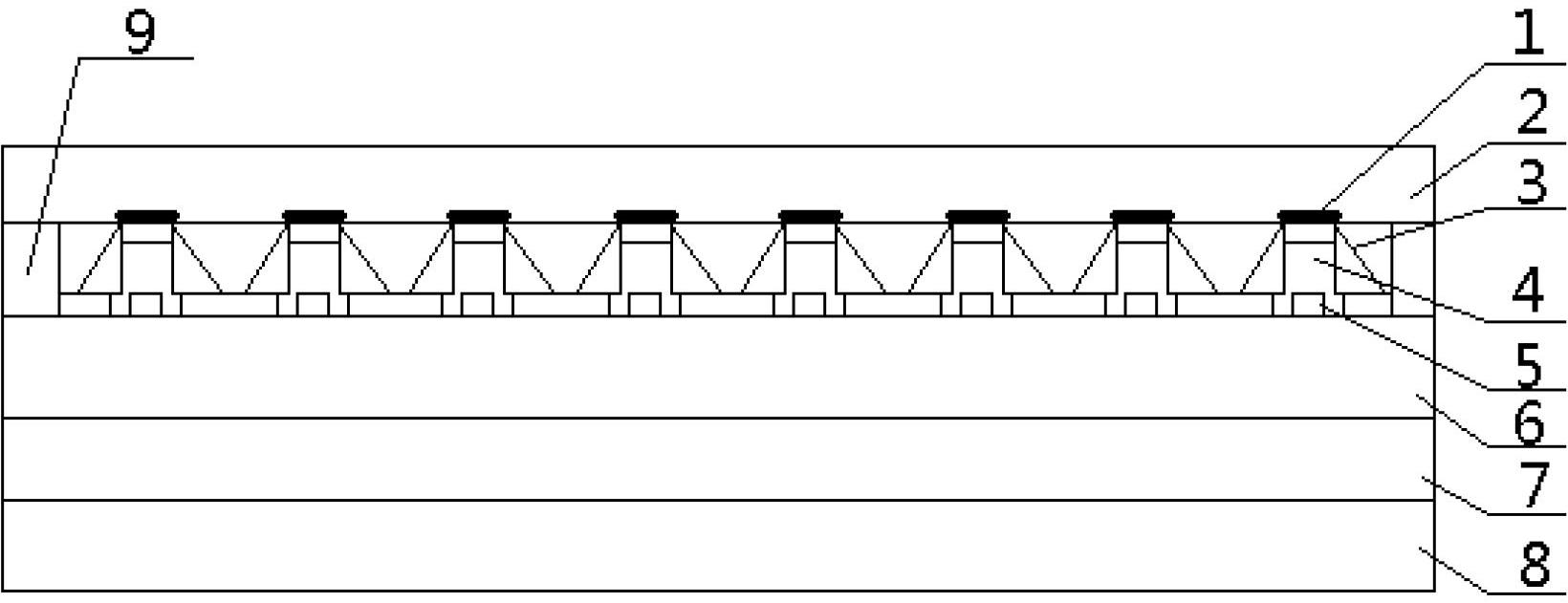

[0024] See figure 1 It can be seen that the capacitive touch screen is provided with a glass substrate 6, one side of the substrate is provided with an ITO layer 5, and the substrate 6 is surrounded by metal lines 9 around this side. Each line of the ITO layer is wrapped with a POC insulating bridging layer 4, which is insulated The bridging layer 4 is covered with a jumping conductor layer 3. The jumping conductor layer 3 can be coated with ITO or metal conductive material. The jumping conductor layer 3 is also covered with a black film (BM) layer 1. Film layer 1 is used to shield the glare caused by the metal (mo / al / mo) jumping conductor. The pattern structure of the above-mentioned ITO layer 5, insulating bridge layer 4, jumping conductor layer 3, and black film layer 1 are the same and overlap each other to form the touch portion of the capacitive touch screen. In addition, the patterns of the jumping conductor layer 3 and the black film layer 1 are completely overlapped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com