Optical pump high-power vertical external cavity emitting laser

A high-power emitting laser technology, which is applied in lasers, laser components, semiconductor lasers, etc., can solve the problems of poor beam quality of semiconductor lasers, difficulty in achieving high-power laser output, and large volume of solid-state lasers, etc., to reduce the threshold current density , reduce cost, improve the effect of fill factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

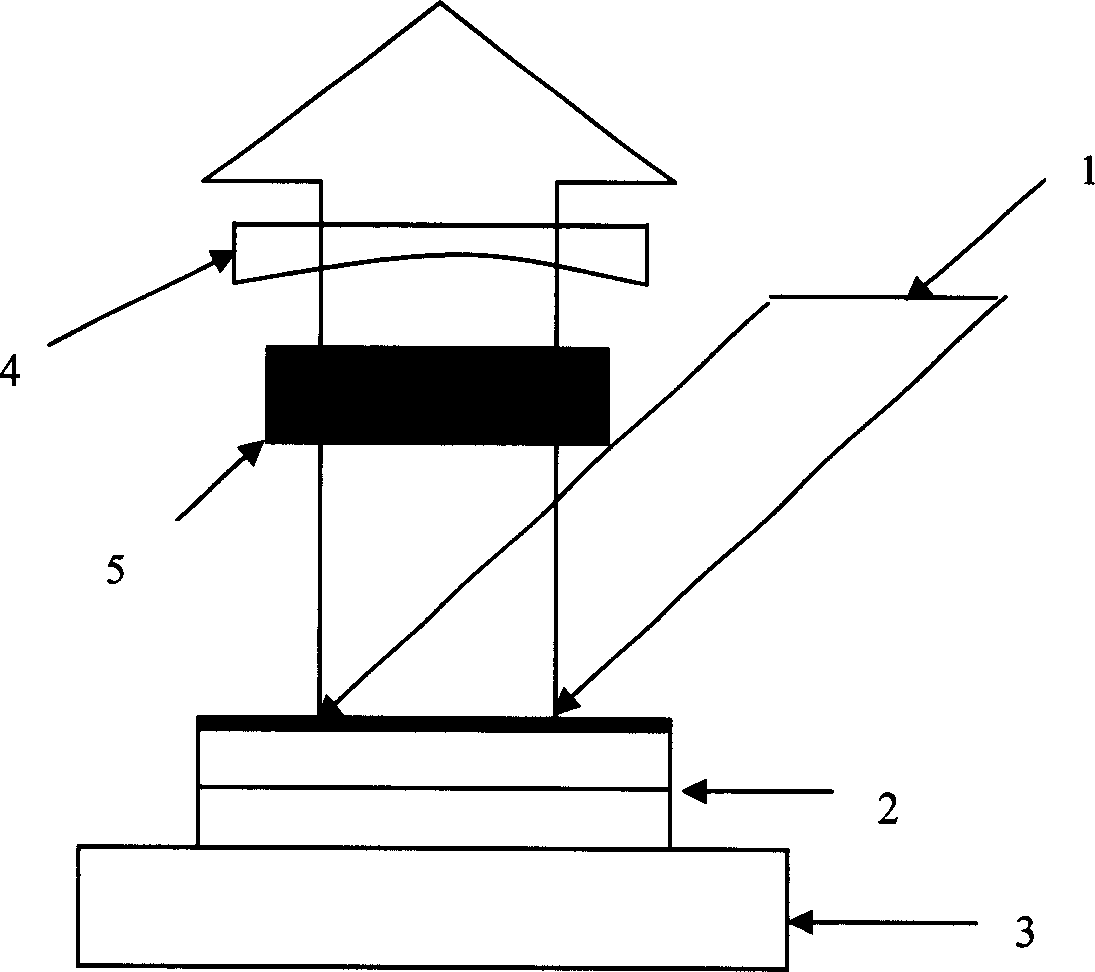

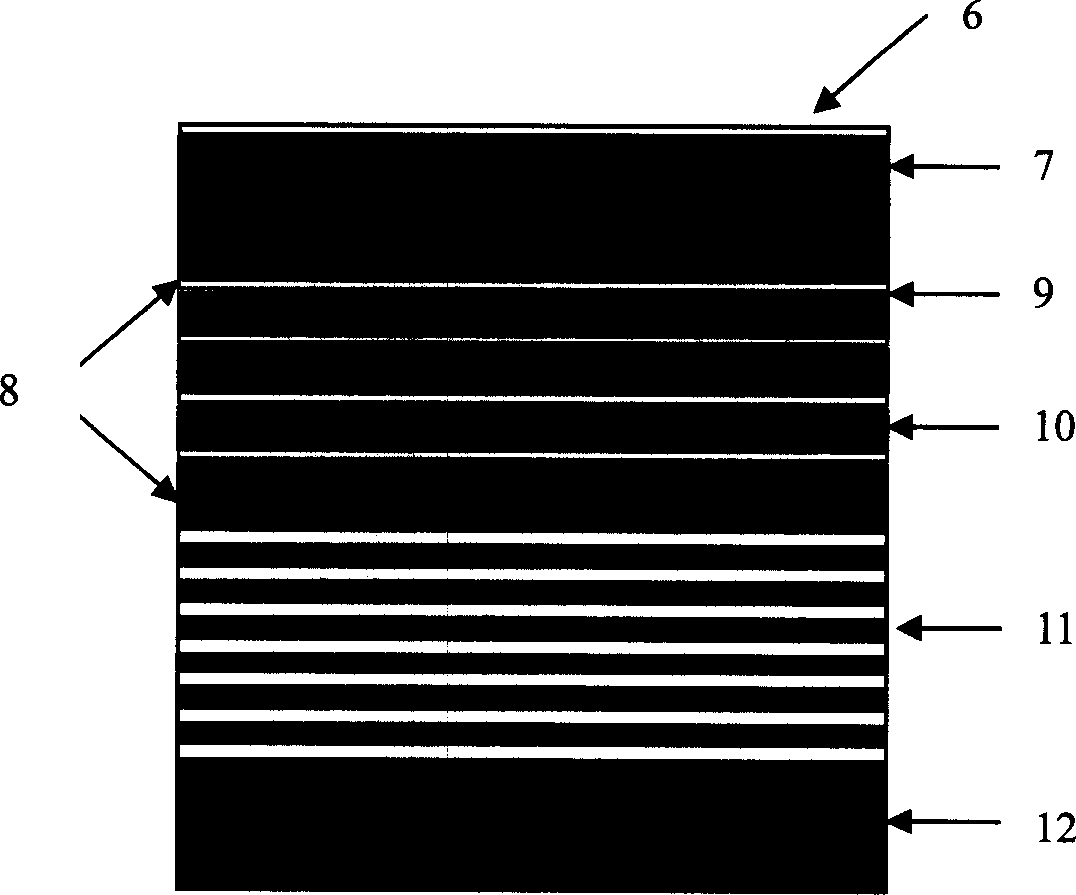

[0016] Such as figure 1 with figure 2 As shown, an optically pumped high-power vertical external-cavity surface-emitting laser includes: a pumping light source 1, an epitaxial wafer 2, a heat sink 3, an external cavity mirror 4, and a frequency-doubling crystal 5; , the pump light source 1 is an 800-810nm high-power fiber-coupled module. The epitaxial wafer 2 is composed of semiconductor materials, and the epitaxial wafer 2 includes: a window layer 6, a protective layer 7, an active region 8, a multilayer Bragg mirror 11 and a substrate 12; the window layer 6 is AlAs or Si 3 N 4 or HfO 2 or SiN x o y . The protective layer 7 is GaAs. The active region 8 is composed of a quantum well layer 9 and an absorbing layer 10; the laser output with a wavelength of 425nm-1800nm can be obtained by selecting different material systems for the active region 8. The quantum well layer 9 includes 2-3 quantum wells, which can repeat 9-21 periods, and can be made of InGaAs material fo...

Embodiment 2

[0018] Embodiment 2: the pumping light source in embodiment 1 is replaced by 975-1250nm high-power semiconductor laser, the window layer 6 is replaced by InP, the active region 8 is replaced by InGaAsP / InP material, and the multilayer Bragg reflector 11 is replaced by InP / InP InGaAsP, the substrate 12 is replaced by InP, and the external cavity mirror 4 is highly reflective to 1550nm light to obtain a vertical external cavity surface emitting laser with a laser output of 1550nm.

Embodiment 3

[0019] Embodiment 3: Replace the multilayer Bragg reflector 11 in Embodiments 1 and 2 with multilayer aluminum, silver, gold or platinum metal materials, and the rest of the components and structures are as above, and the laser output of 980nm or 1550nm can be realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com