Patents

Literature

41results about How to "Improve output yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

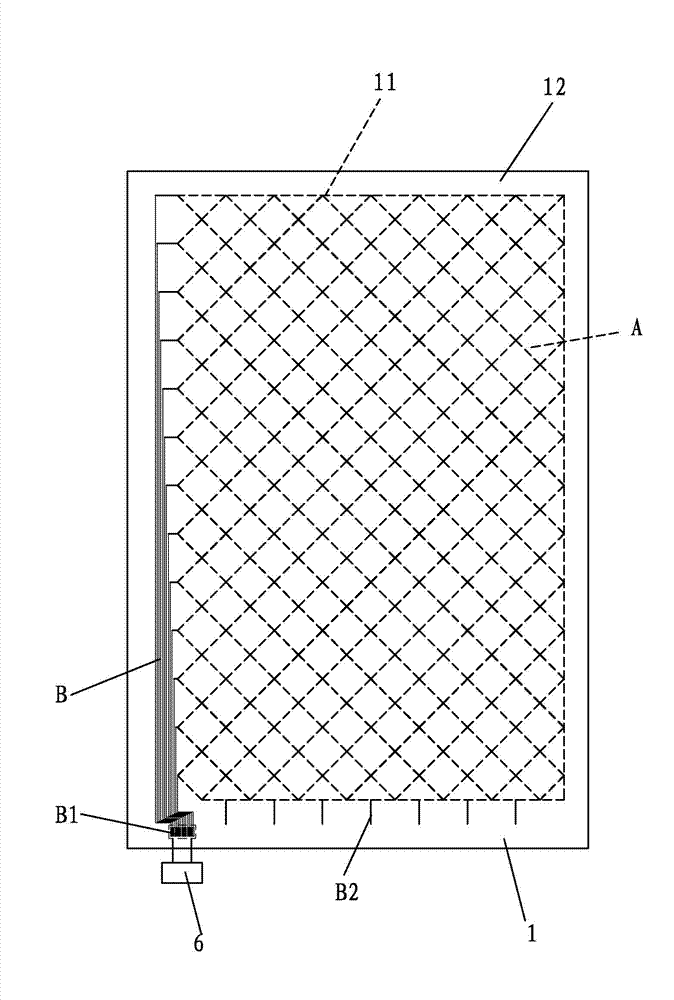

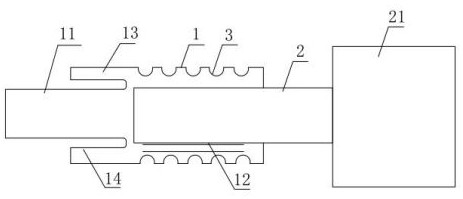

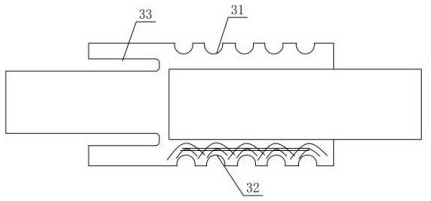

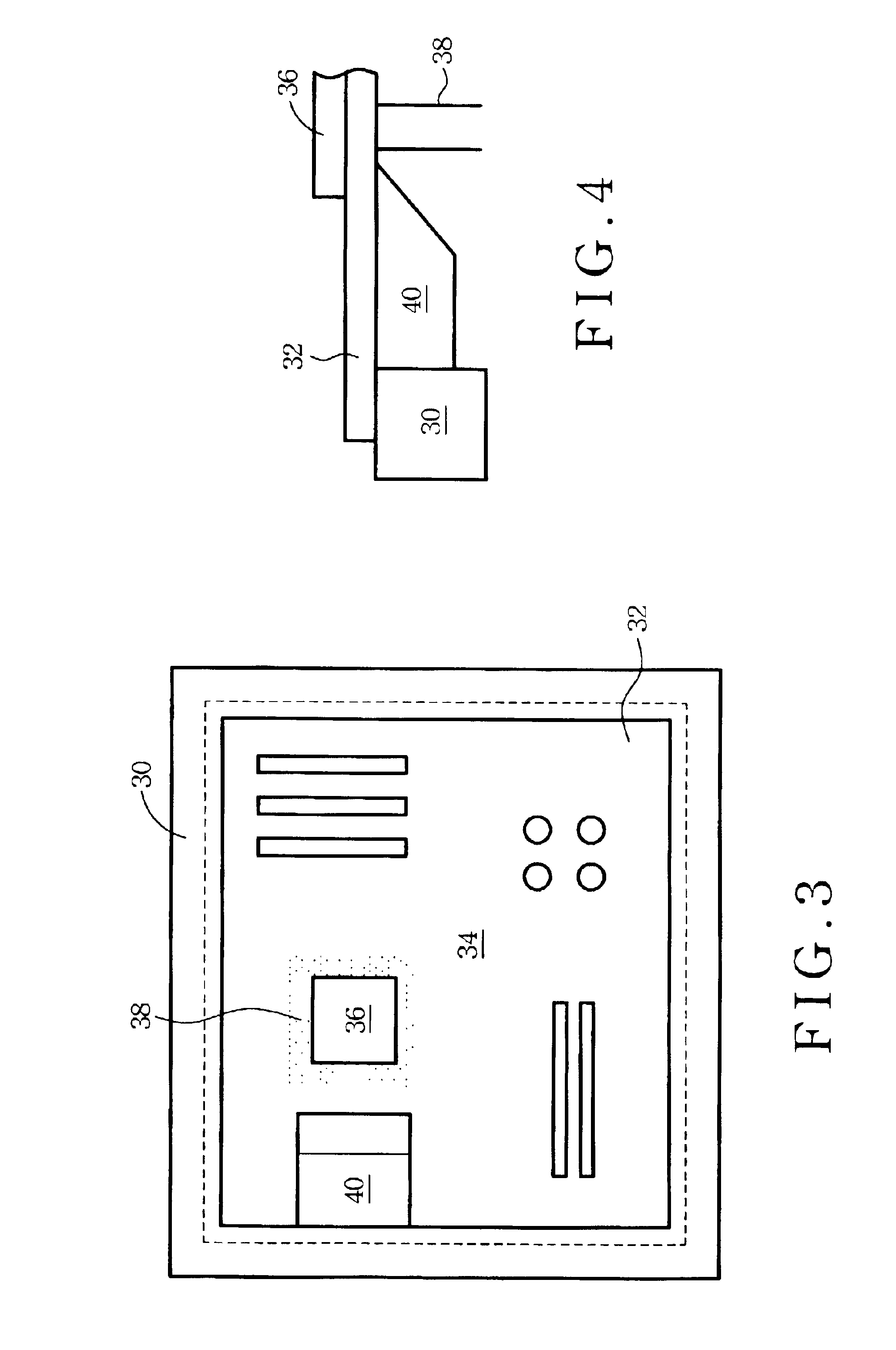

Display device

InactiveCN101901568AImprove test resultsEasy to useSemiconductor/solid-state device detailsSolid-state devicesDisplay deviceLaser cutting

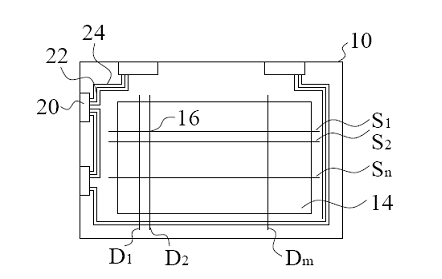

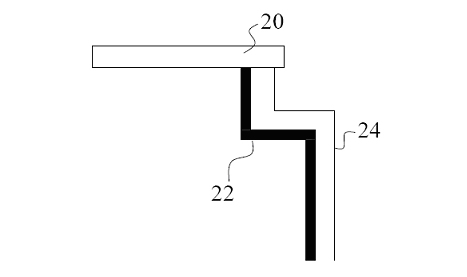

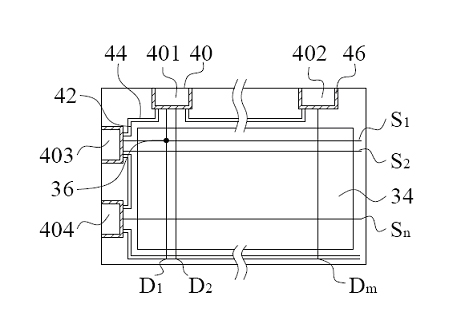

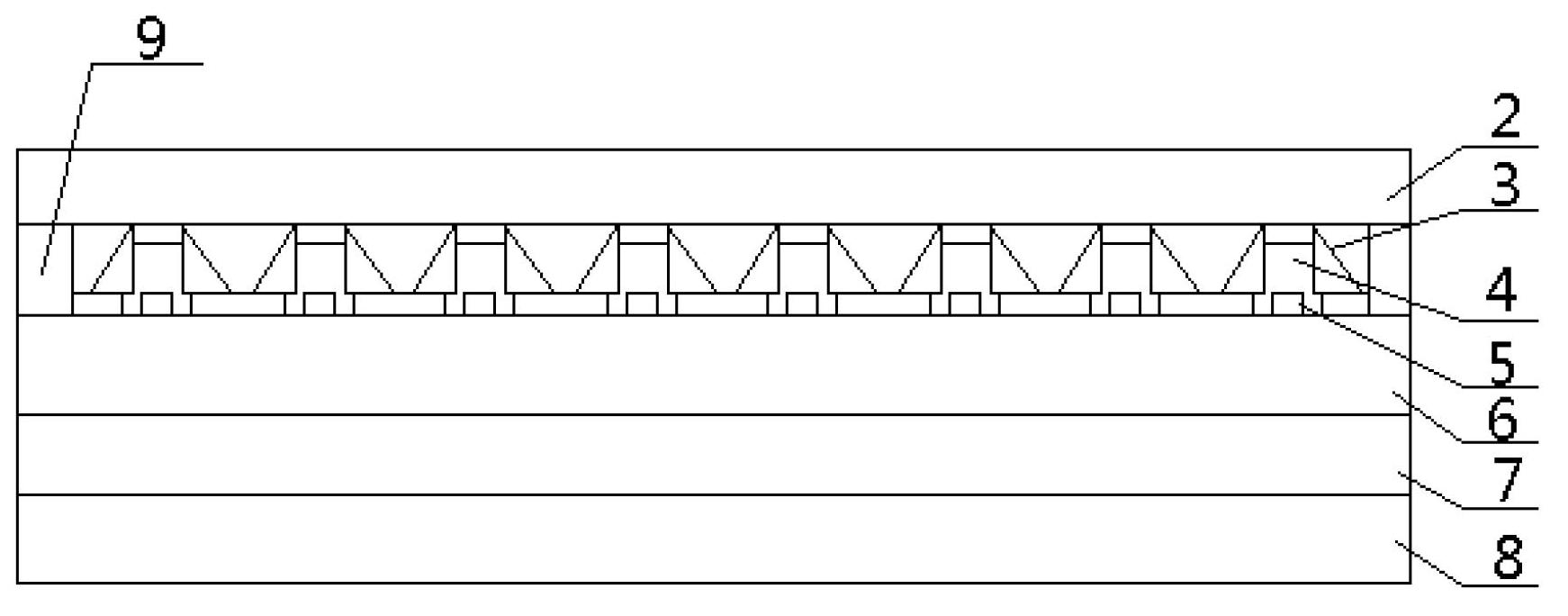

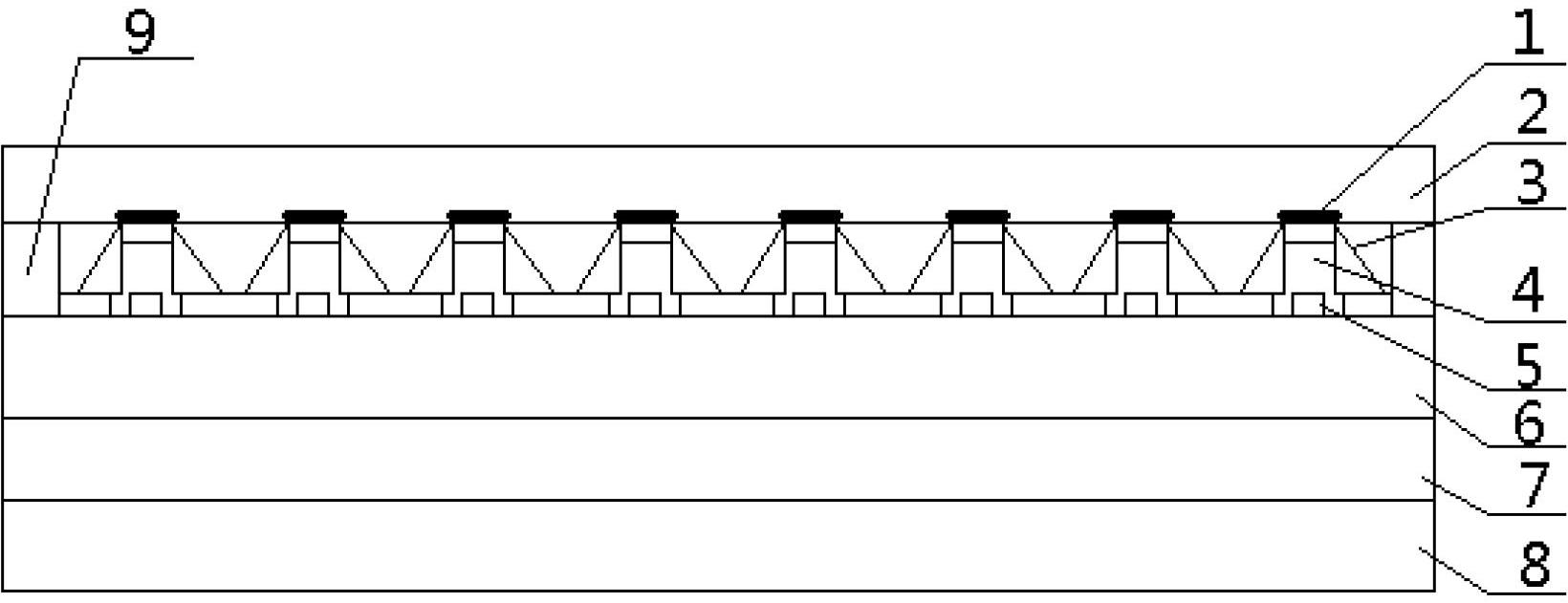

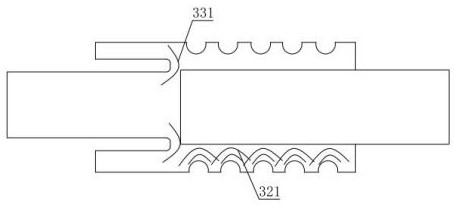

The invention discloses a peripheral wiring framework of a display device. By designing the wiring mode of a plurality of peripheral wires to be electrically connected a plurality of driving ICs or an a plurality of integrated circuit chips in the form of grate-shaped wiring, being capable of selectively separating some peripheral wires by means of laser cutting when using repair wires, and welding the peripheral wires with the repair wires, the display device improves the capability for the repair wires. The display device structurally comprises a display panel, at least one integrated circuit chip, at least one repair wire and at least one peripheral cable wire, wherein the display panel comprises a plurality of signal wires which include a plurality of data wires and a plurality of scanning wires, the at least one integrated circuit chip is electrically connected with the signal wires for driving the display panel to display an image, one ends of the at least one repair wire are connected with the integrated circuit chips, and the at least one peripheral wire is electrically connected with the integrated circuit chip in the form of grate-shaped wiring and is arranged parallel with the repair wires.

Owner:CPT DISPLAY TECH FUJIAN +1

Touch panel and manufacturing method thereof

InactiveCN102768586ALow priceImprove conductivityInput/output processes for data processingIndiumIndium tin oxide

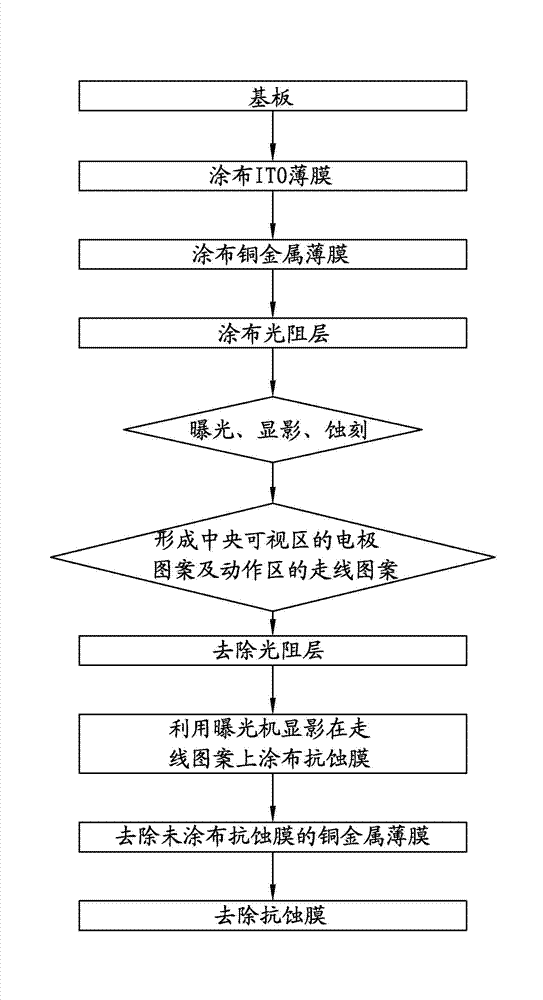

The invention discloses a touch panel and a manufacturing method of the panel. A tin indium oxide thin film and a copper metal thin film are coated on a transparent substrate in sequence, an electrode pattern is formed on each of the tin indium oxide thin film and the copper metal thin film in a central visible area of the substrate with a semiconductor etching technology, a routing pattern is formed in an action area outside the central visible area, an anti-corrosion film is coated in the action area, and the copper metal thin film within the central visible area is dissolved by a special solvent. According to the method disclosed by the invention, the touch panel can be manufactured through a full-etching process.

Owner:许明松

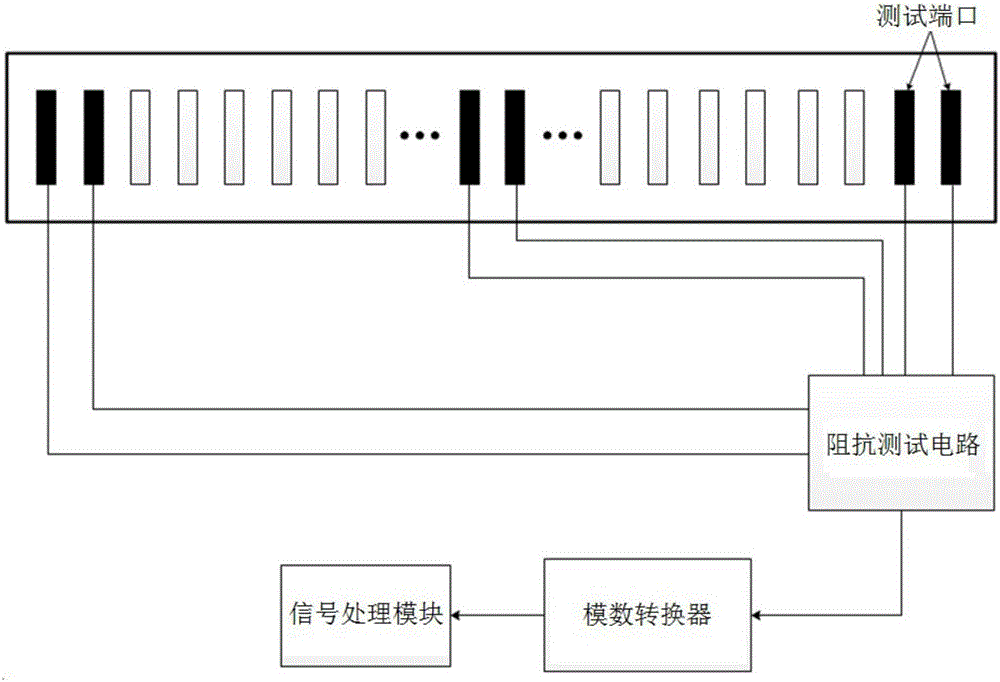

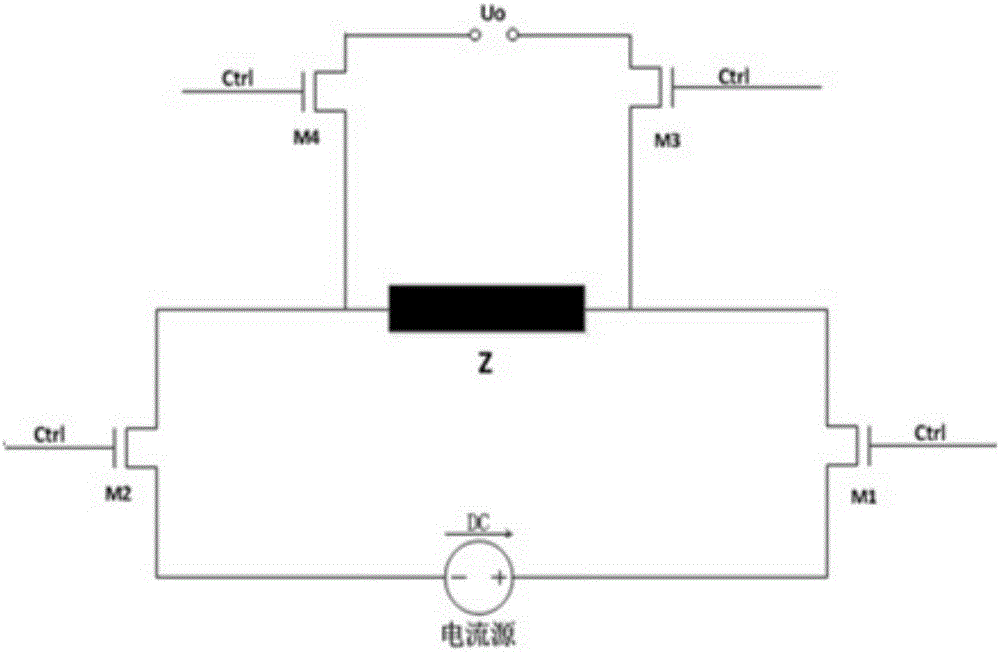

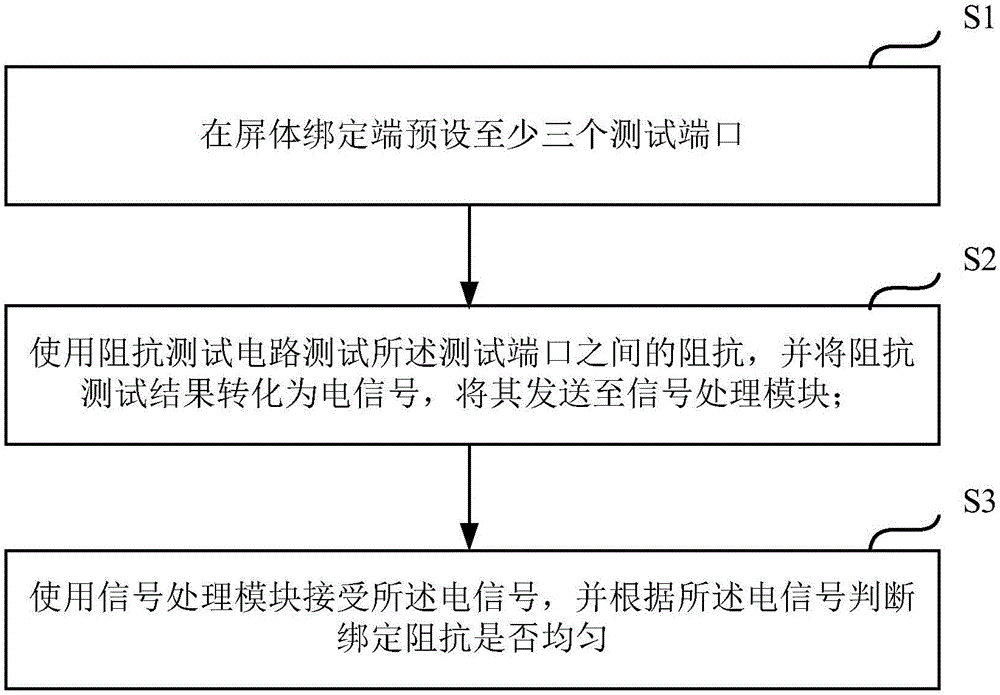

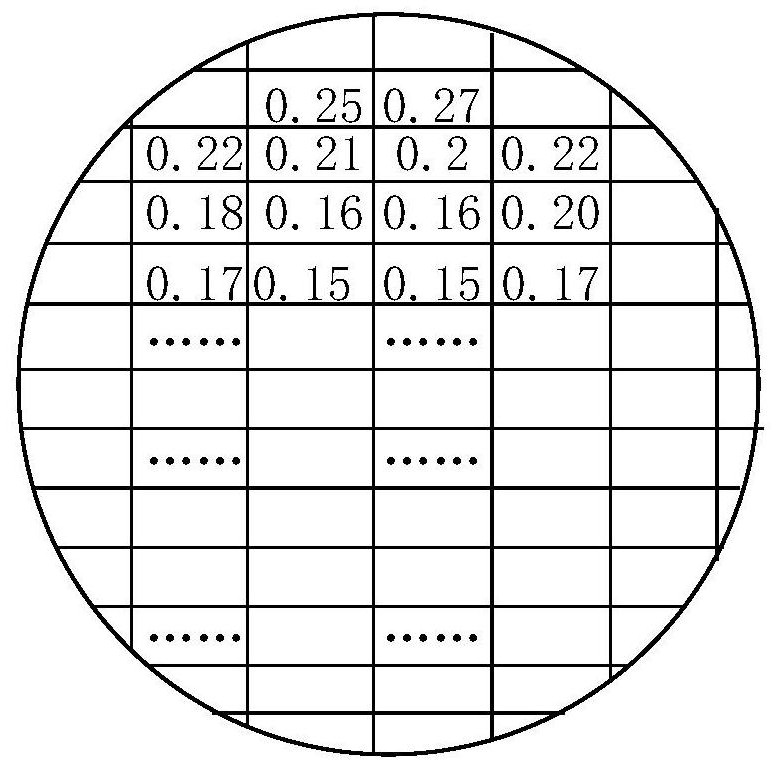

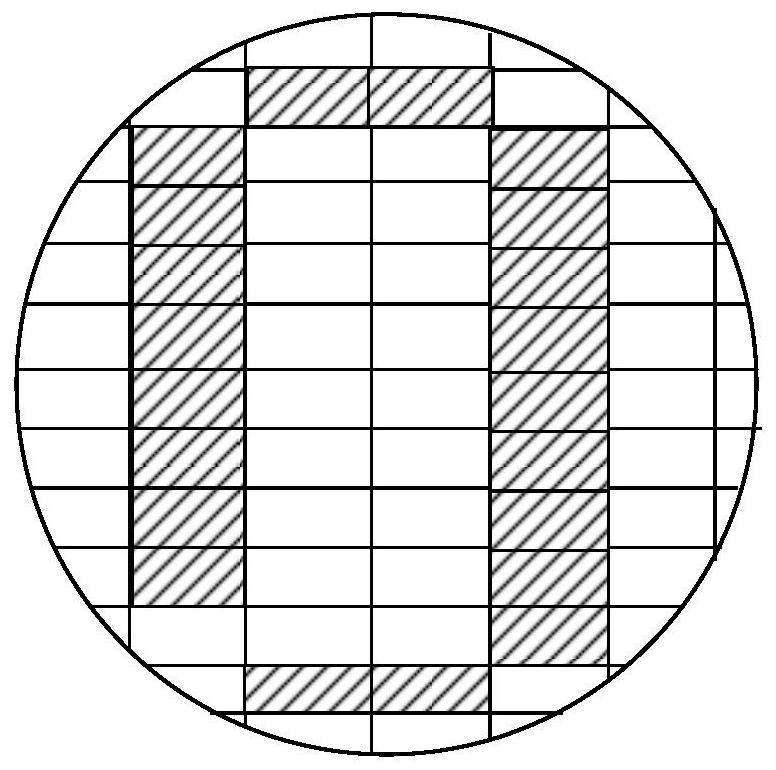

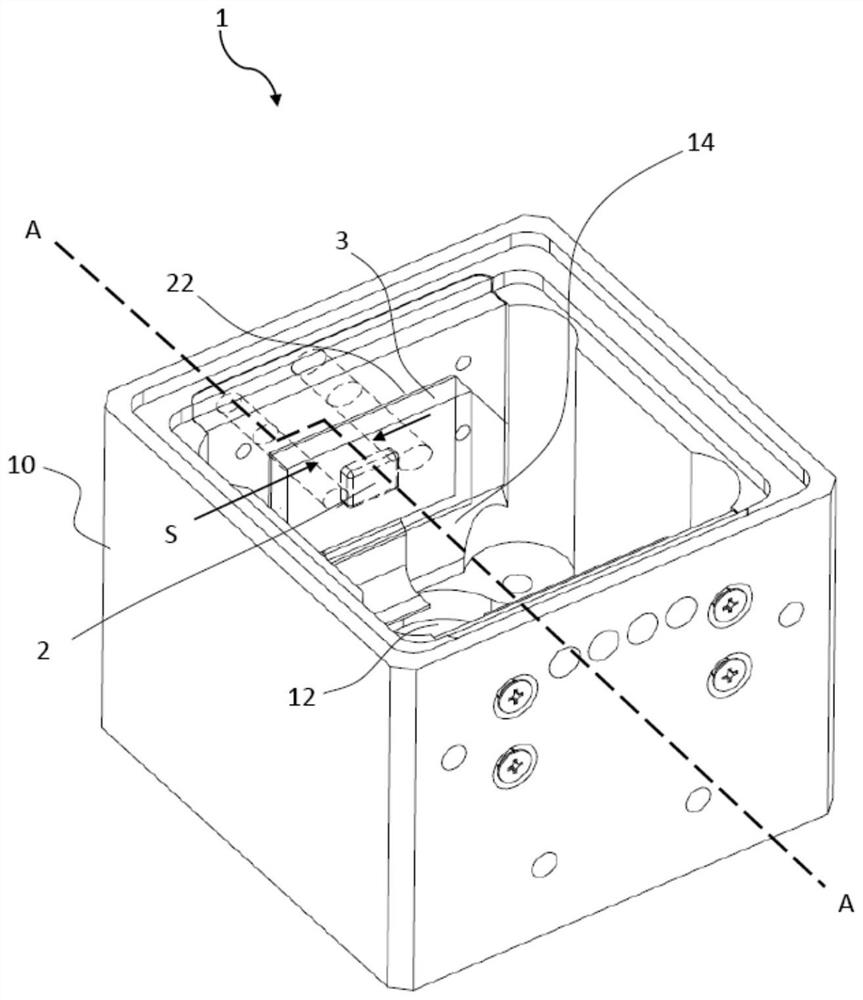

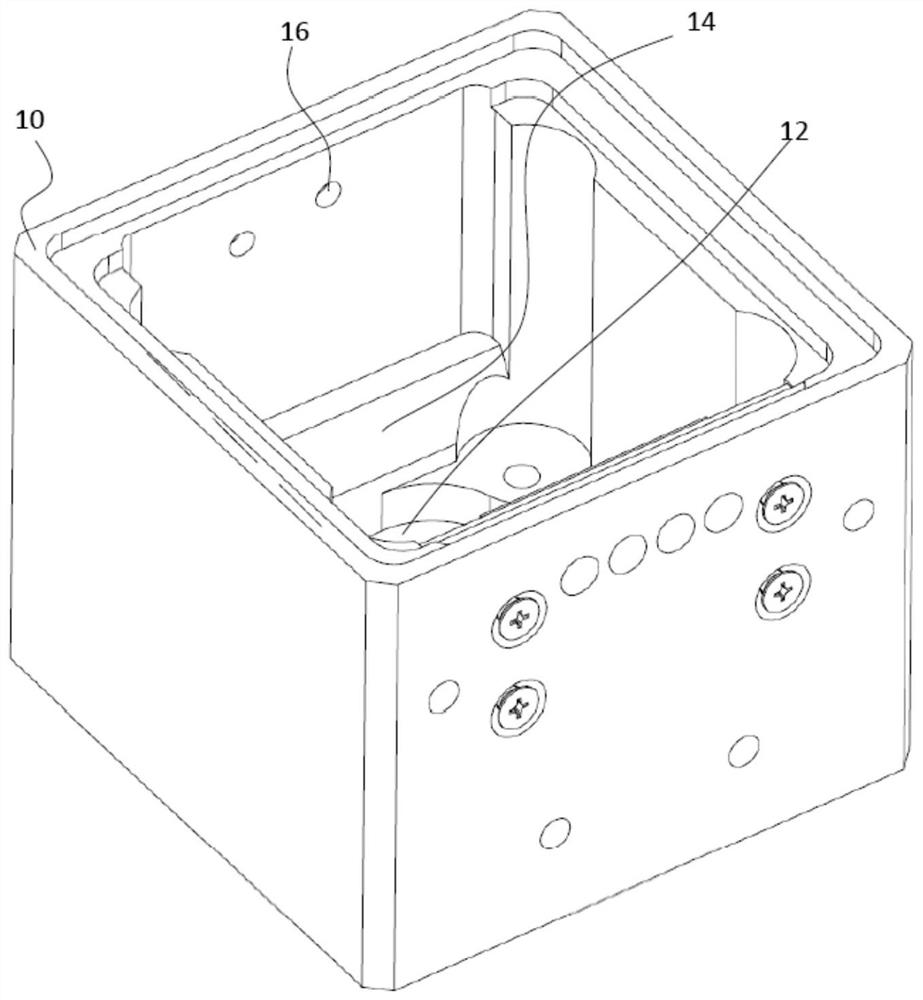

Detection device and detection method for binding impedance of display screen

InactiveCN106443192AQuick measurementNo manual operationImpedence measurementsComputer moduleMaterial resources

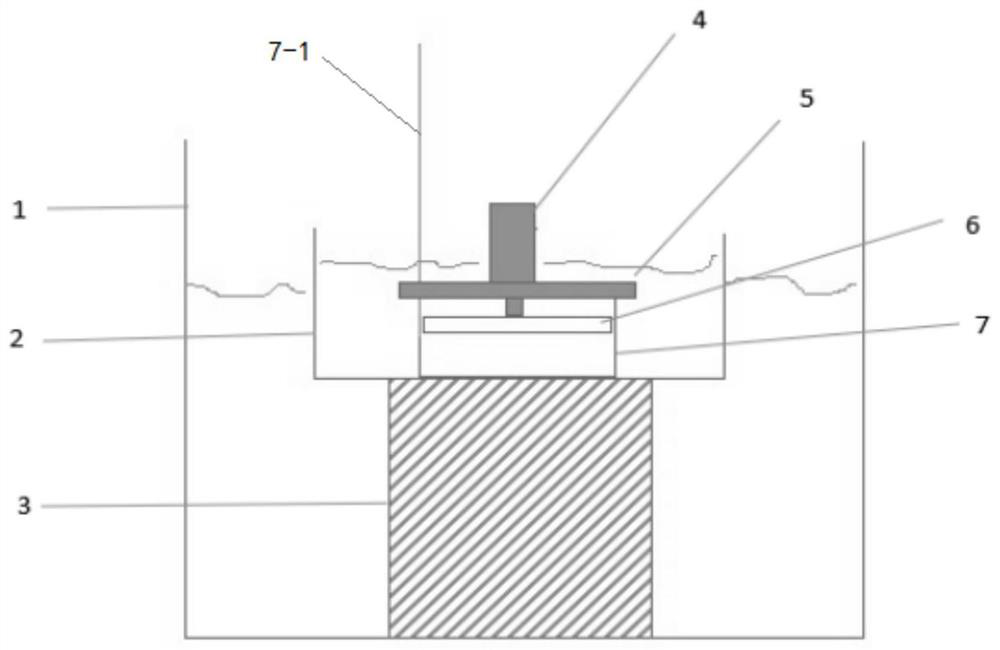

The invention discloses a detection device and a detection method for binding impedance of a display screen. The device comprises test ports, an impedance test circuit and a signal processing module, wherein the test ports are preset at the binding end of a screen body; the number of the test ports is greater than or equal to three; the impedance test circuit is connected with the test ports and the signal processing module; impedance among the test ports is converted into an electrical signal, and the electrical signal is transmitted to the signal processing module; the signal processing module receives the electrical signal, and whether the binding impedance is uniform or not is judged according to the electrical signal. By using the device and the method disclosed by the invention, the impedances at all the positions can be automatically detected and compared, and further whether the binding impedance is uniform or not is judged. Compared with a method for manually testing the binding impedance in the prior art, the detection method disclosed by the invention has the advantages that a large amount of human and material resources are saved, and the binding output yield is also improved.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

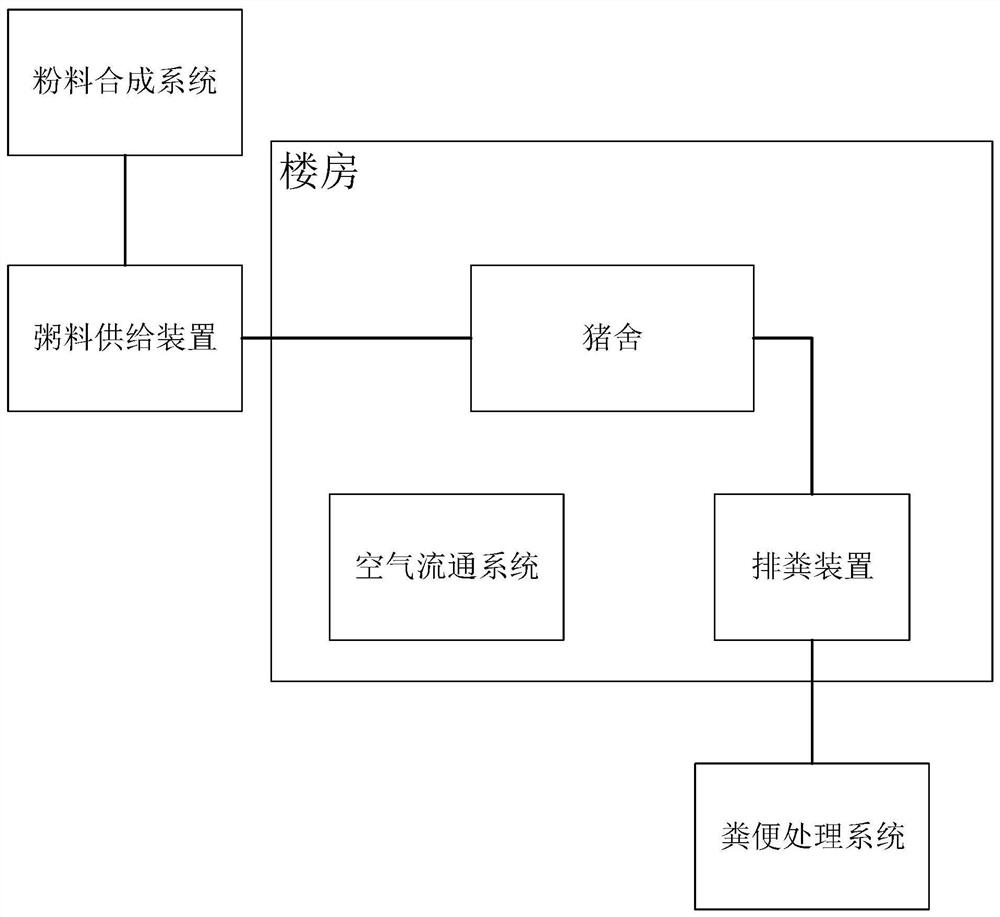

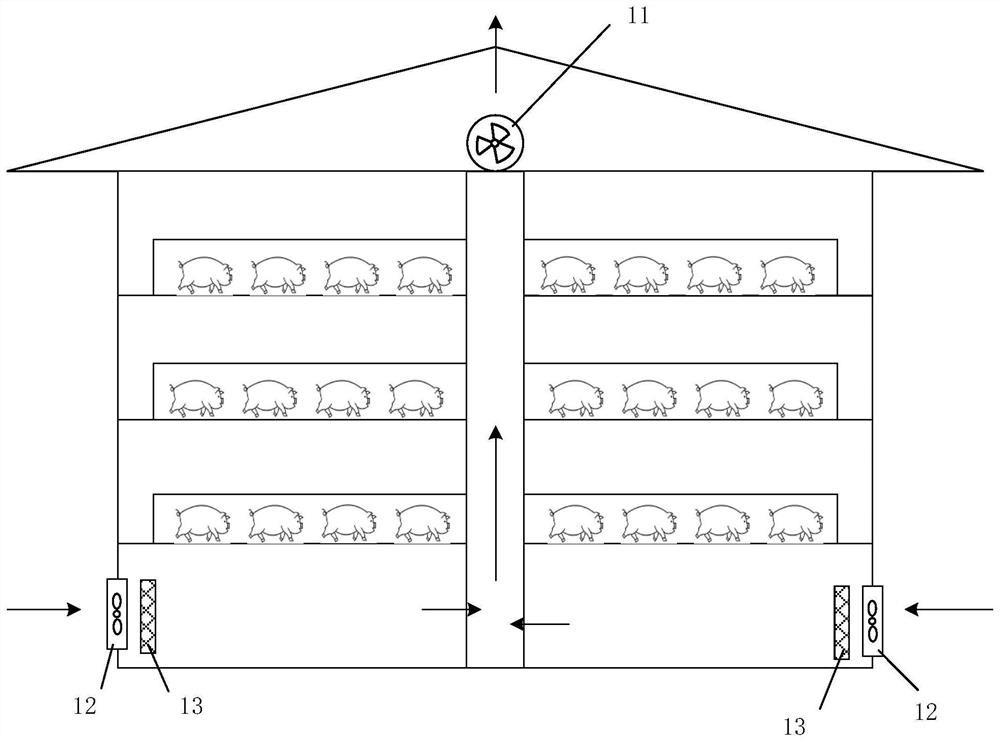

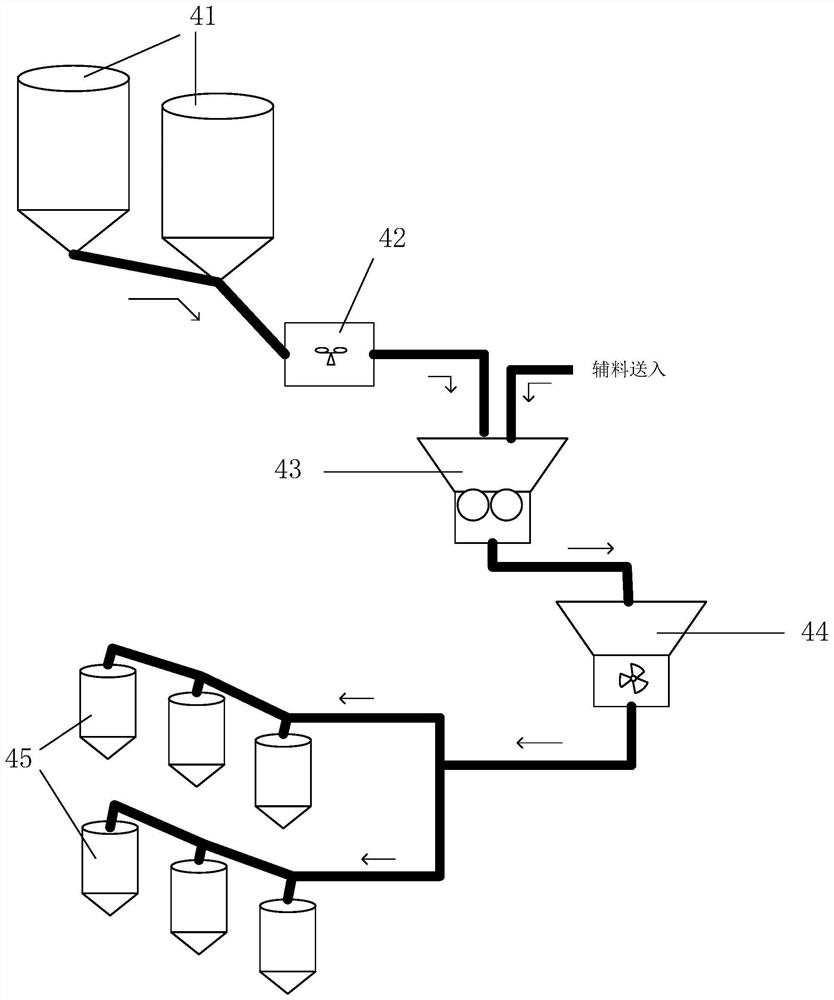

Ecological environment-friendly floor pig raising comprehensive system and pig raising method thereof

InactiveCN112273239AOptimal healthBest growth benefitFeeding-stuffAnimal watering devicesEcological environmentNutrition

The invention discloses an ecological environment-friendly floor pig raising comprehensive system which comprises a building, pig houses, an excrement treatment system, a powder synthesis system, a porridge supply device and an air circulation system. The pig houses are arranged in multiple floors of the building, excrement leakage plates and excrement discharge devices are sequentially arranged at the bottoms of the pig houses, and the excrement discharge devices are connected with the excrement treatment system; and the excrement treatment system is arranged outside the building and is lowerthan the excrement discharge devices, the porridge supply device is connected with the powder synthesis system and the pig houses, the powder synthesis system processes live pig feeding raw materialsand ingredients into powder according to a specific proportion, the porridge supply device converts the powder into porridge capable of being directly eaten by live pigs, and the air circulation system is arranged in the building. According to the ecological environment-friendly floor pig raising comprehensive system, on the basis of meeting the comfortable living environment and living habits ofthe pigs, meeting the nutritional requirements of the pigs at all stages and making good biological safety, the optimal health degree and the optimal growth benefit are achieved, additional income increase is achieved in combination with comprehensive utilization of excrement, labor is saved, and environment protection is achieved.

Owner:自贡市陈豕养猪有限公司

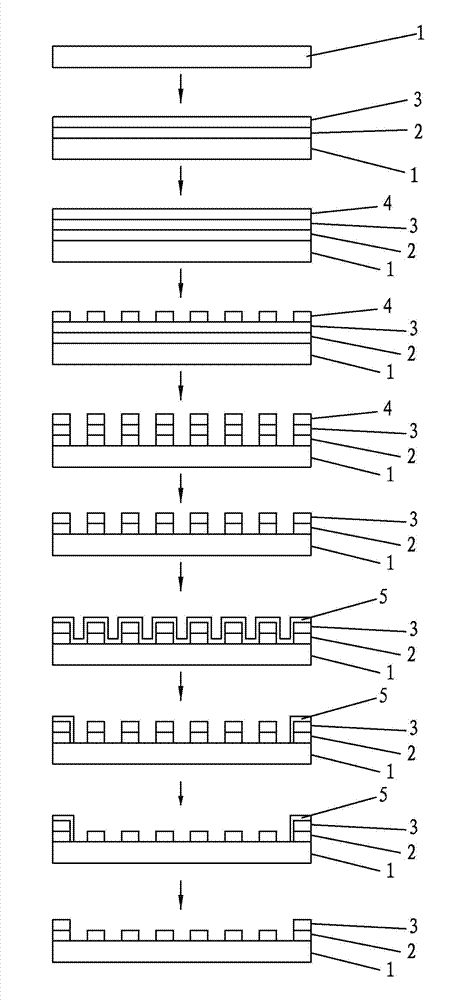

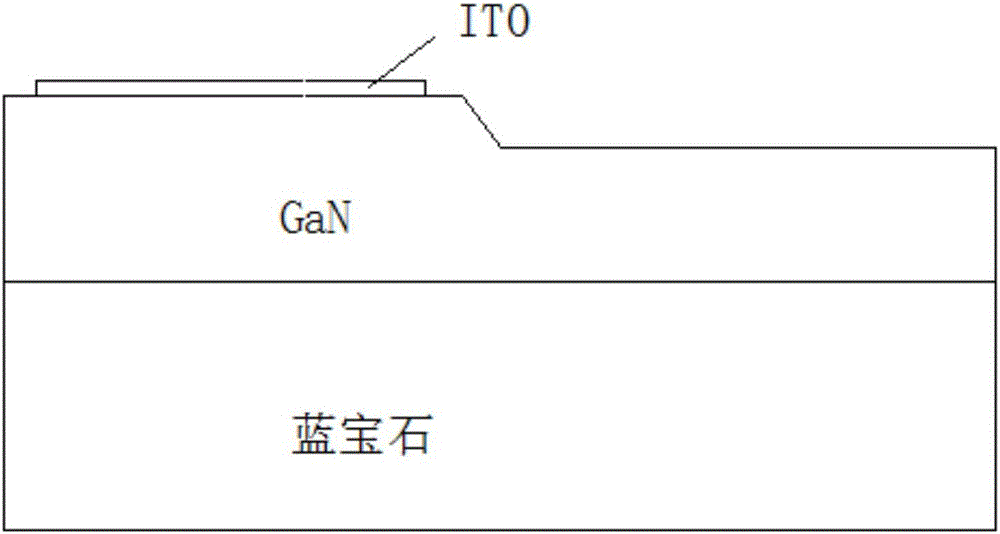

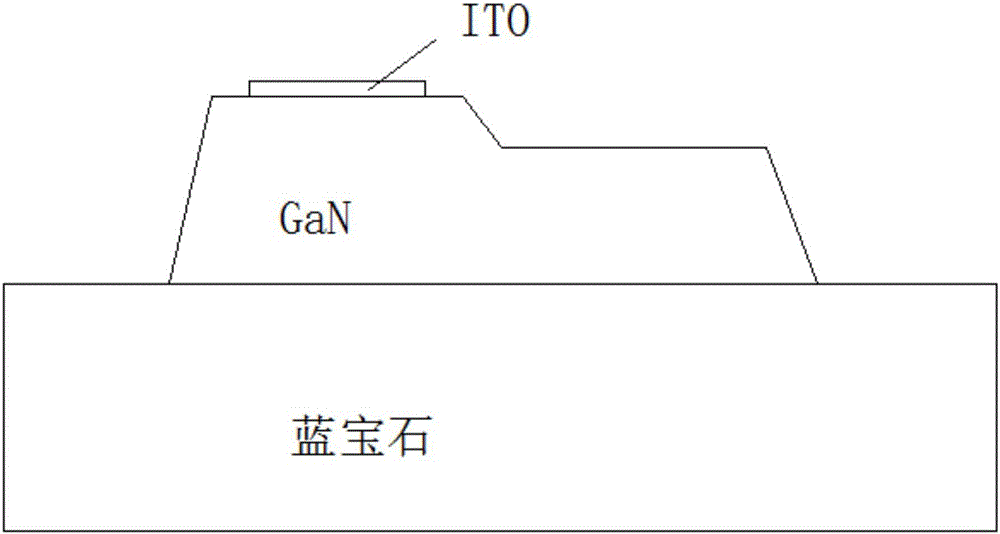

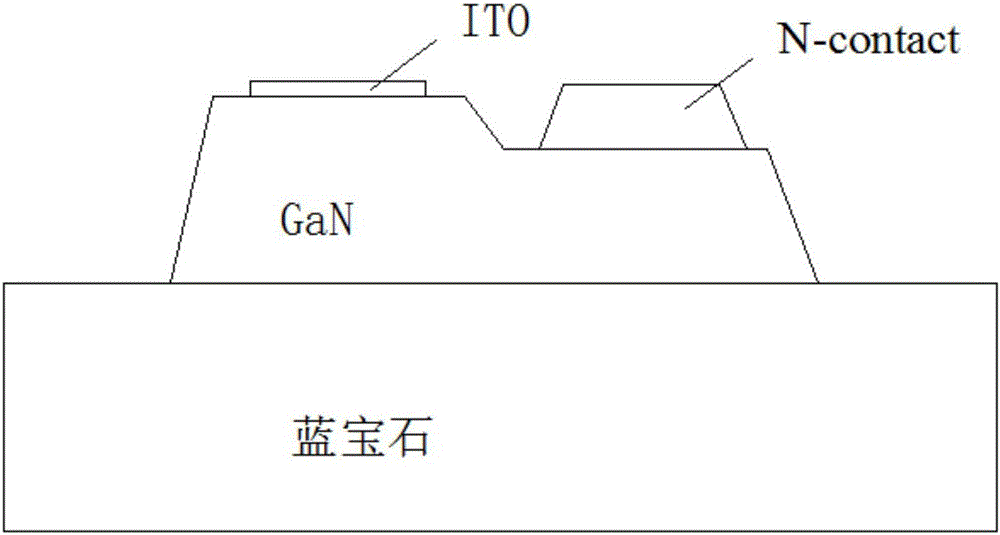

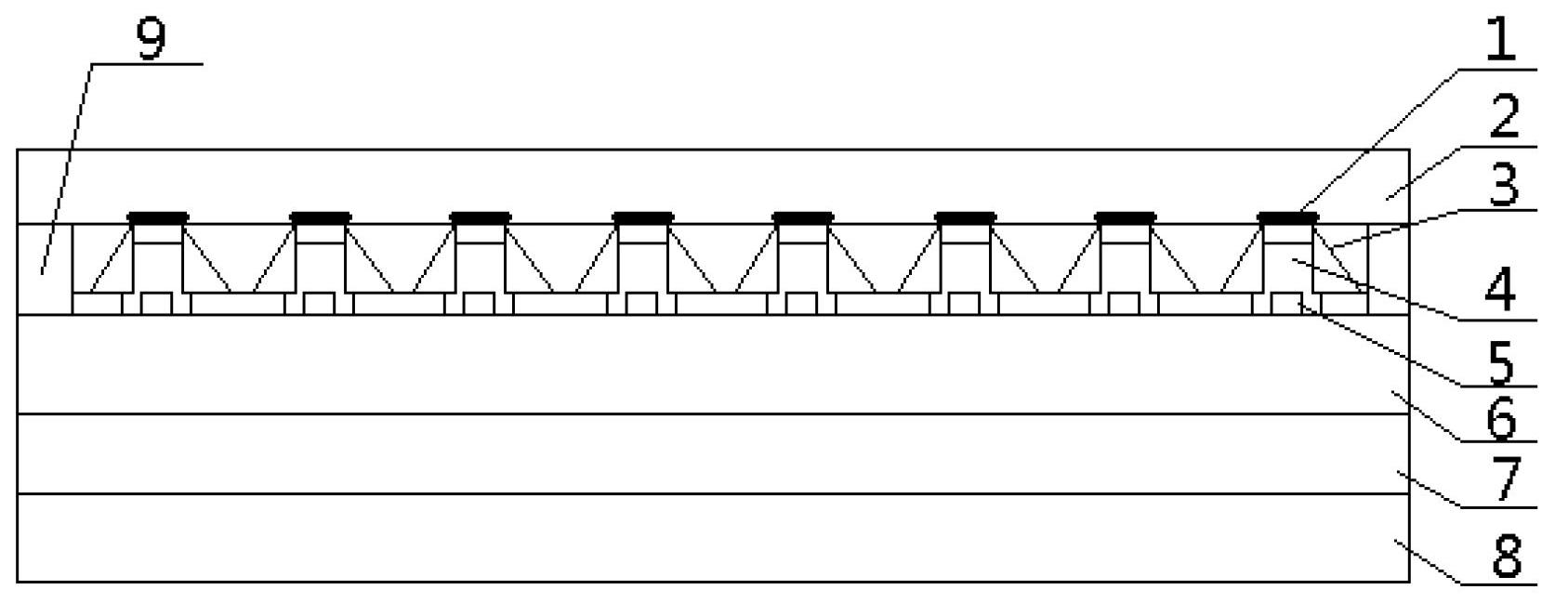

Method of manufacturing micro LED chip with flip structure

InactiveCN106653961AIncrease brightnessReduce energy consumptionSemiconductor devicesEngineeringMetal electrodes

The invention provides a method of manufacturing a micro LED chip with a flip structure. The method comprises the following steps: (1) single side polishing is selected to be carried out on a sapphire substrate to grow GaN epitaxy, an ITO film layer then grows, and Mesa photoetching first and then Isolation photoetching or Isolation photoetching first and then Mesa photoetching are carried out; (2) on a substrate after Mesa photoetching and Isolation photoetching are carried out in step (1), an N-contact pattern and a Passivation pattern are made in an N area; (3) photoetching is carried out on the substrate in the former step, a PN-contact pattern is made in a P area and the N area, vacuum evaporation is carried out on a metal electrode, the thickness is 1 to 3 mum, and a photoresist is removed; (4) an ITO film layer grows on the substrate in the former step, the thickness is 0.5 to 2 mum, photoetching is carried out, a specified pattern is etched, and the photoresist is removed; and (5) back grinding and polishing are carried out on the above substrate, the thickness range is 300 to 500 mum, and manufacturing is completed. The chip maximally utilizes the light emitting surface, and the chip with the same size can have higher brightness and lower energy consumption; and insulation protection is carried out on a possible electric leakage channel, and the electric leakage possibility generated to the chip due to a back process can be reduced.

Owner:合肥彩虹蓝光科技有限公司

Capacitive touch screen and process for manufacturing same

InactiveCN102693056AReduce photolithography processReduce stripping processInput/output processes for data processingElectrical conductorIndium tin oxide

The invention discloses a capacitive touch screen which comprises a substrate, an ITO (indium tin oxide) pattern layer, an insulation bridging layer and a jumping conductor pattern layer. The ITO pattern layer is arranged on the substrate, the insulation bridging layer covers the ITO pattern layer, the jumping conductor pattern layer covers the insulation bridging layer, and a black membrane pattern layer covers the jumping conductor pattern layer. A black membrane (BM) of the touch screen is manufactured by the process, after being exposed, the black membrane is only etched and is not peeled off, a low glare effect can be achieved, a peeling-off manufacturing procedure can be omitted, and yield is improved. Besides, the black membrane (BM) is used for shielding high glare generated by the jumping conductor pattern layer, and accordingly the appearance is improved.

Owner:WUHU TOKEN SCI

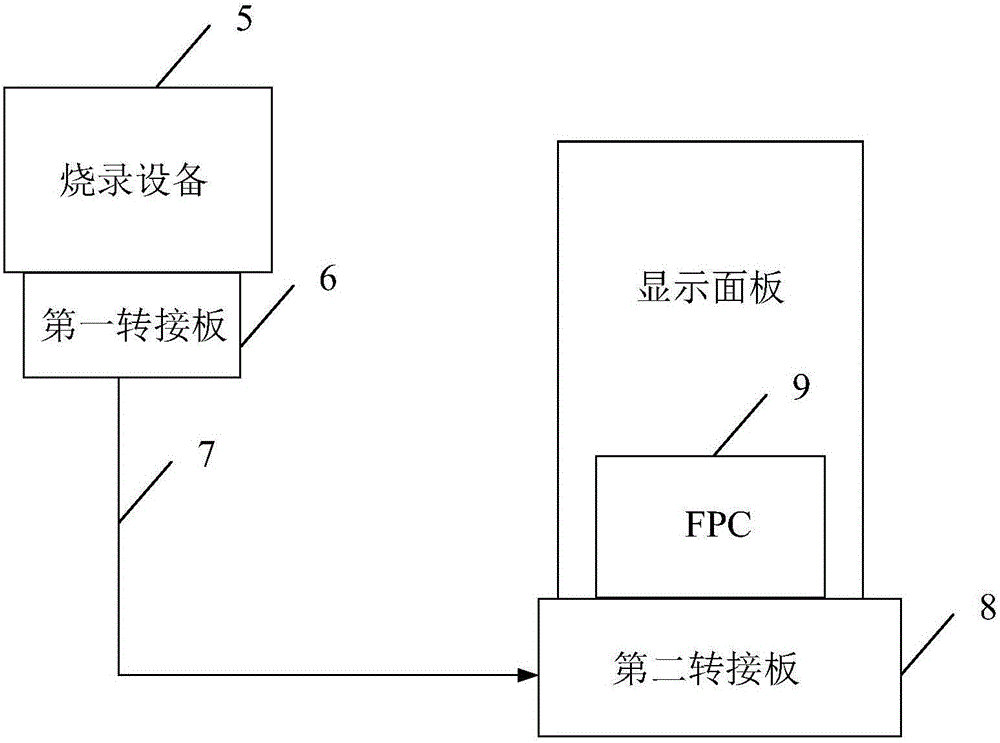

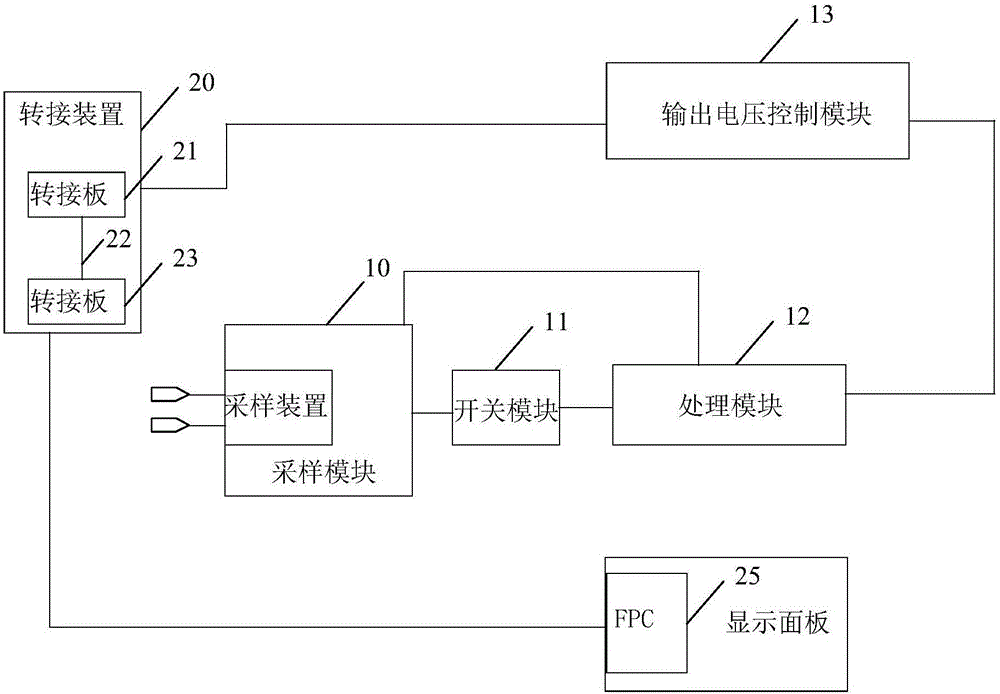

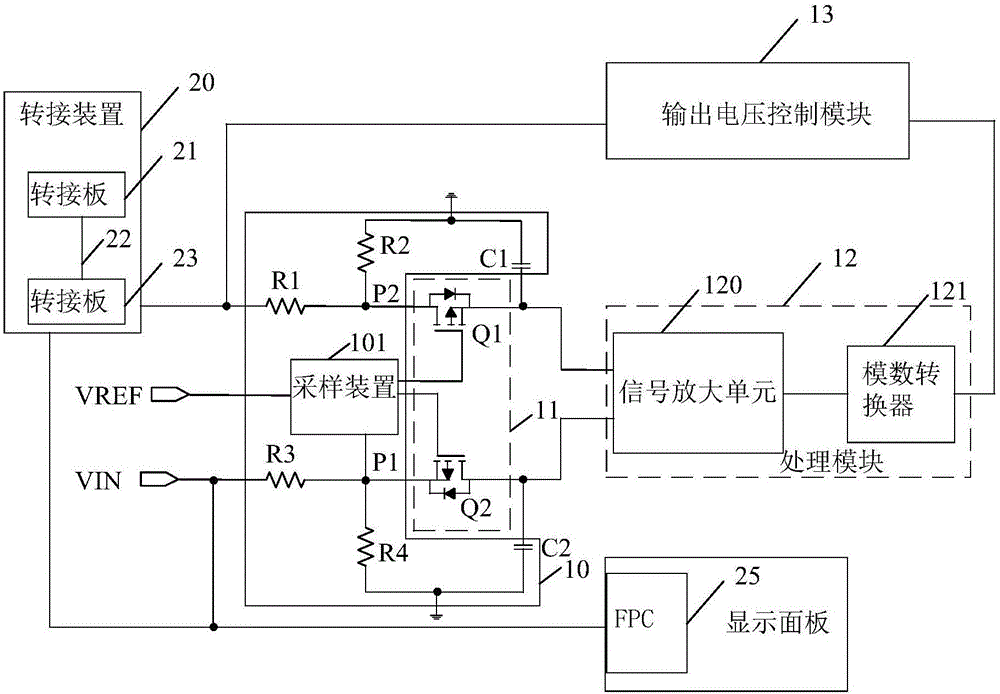

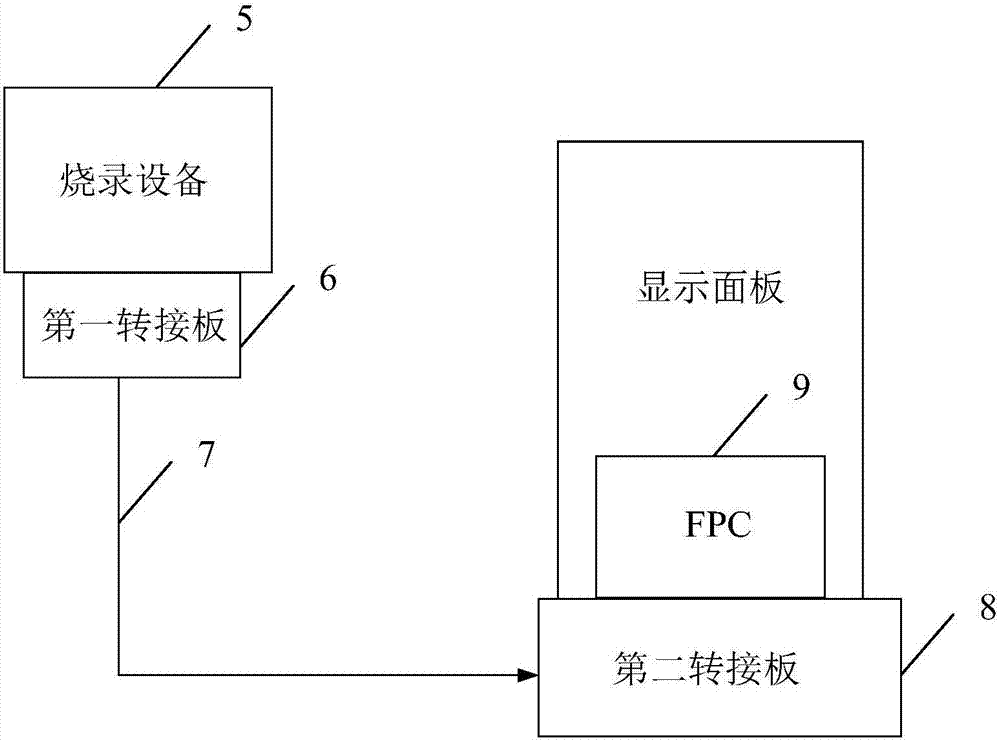

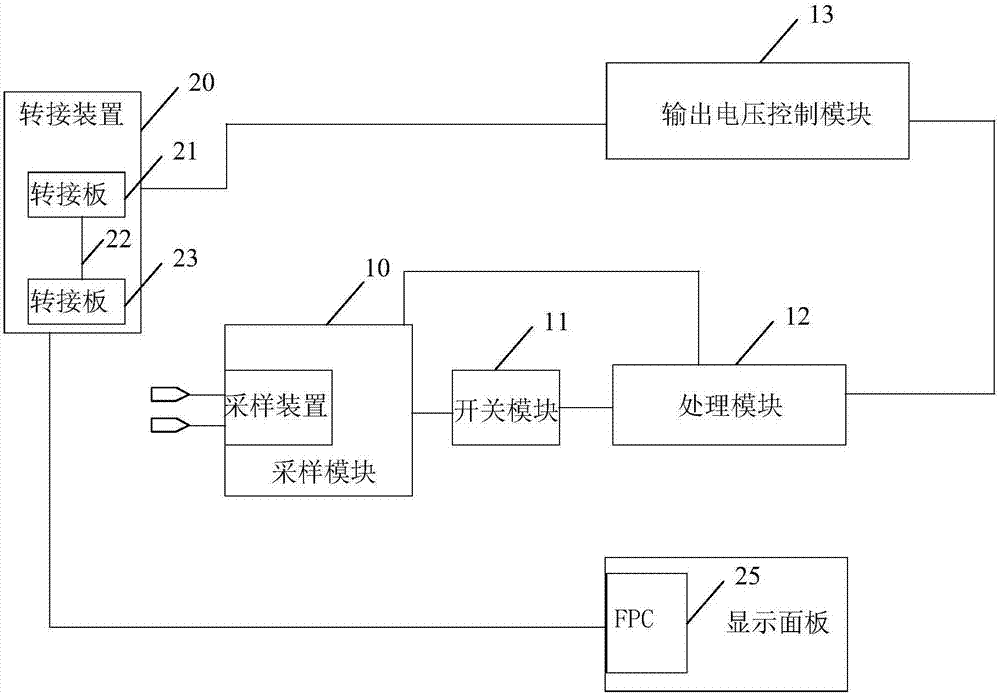

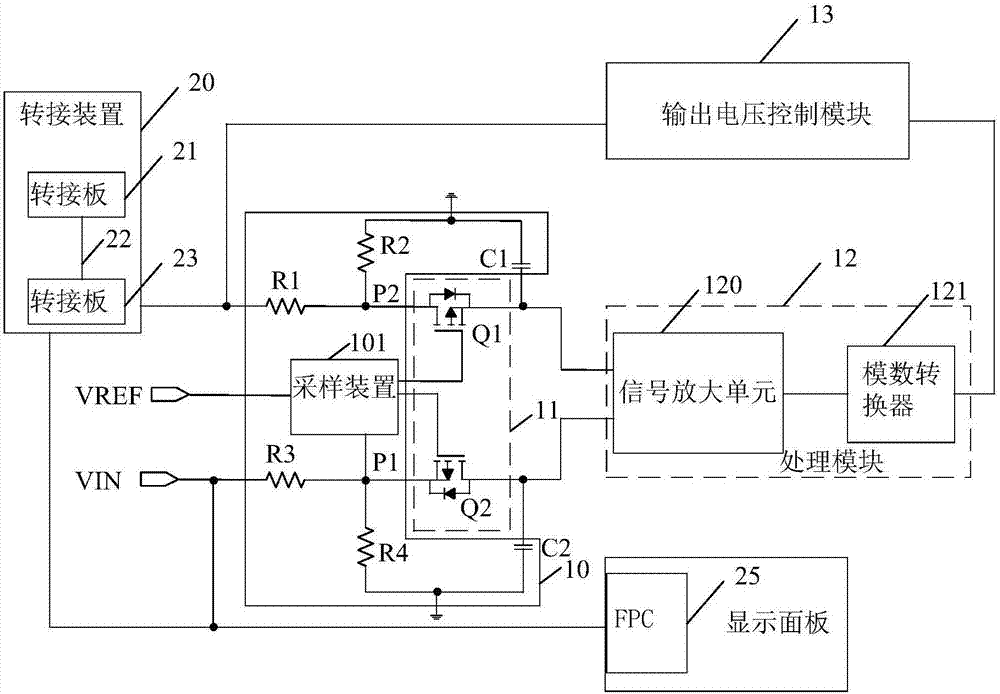

Voltage calibration circuit and burning equipment thereof

ActiveCN106125809AAccurate programming voltage parametersImprove output yieldSoftware simulation/interpretation/emulationSoftware deploymentControl signalComputer module

The embodiment of the invention discloses a voltage calibration circuit and burning equipment thereof. The circuit comprises a sampling module, a switch module, a processing module and an output voltage control module. A sampling device of the sampling module is used for comparing an input reference voltage received by the input end with an input voltage and then outputting a corresponding control signal to the switch module; the switch module is used for communicating a path between the sampling module and the processing module when a control signal is a communication control signal; the processing module is used for obtaining the input voltage and the output reference voltage and generating the pulse signal according to the obtained input voltage and the output reference voltage; the output voltage control module is used for generating the accurate burning output voltage on the basis of the control pulse signal provided by the processing module and then obtaining the accurate burning input voltage after switching of a switching device so as to provide the burning input voltage for a display panel. The voltage calibration circuit and the burning equipment thereof can provide the accurate burning voltage parameter for the display panel and ensure the reliability of the burning process.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

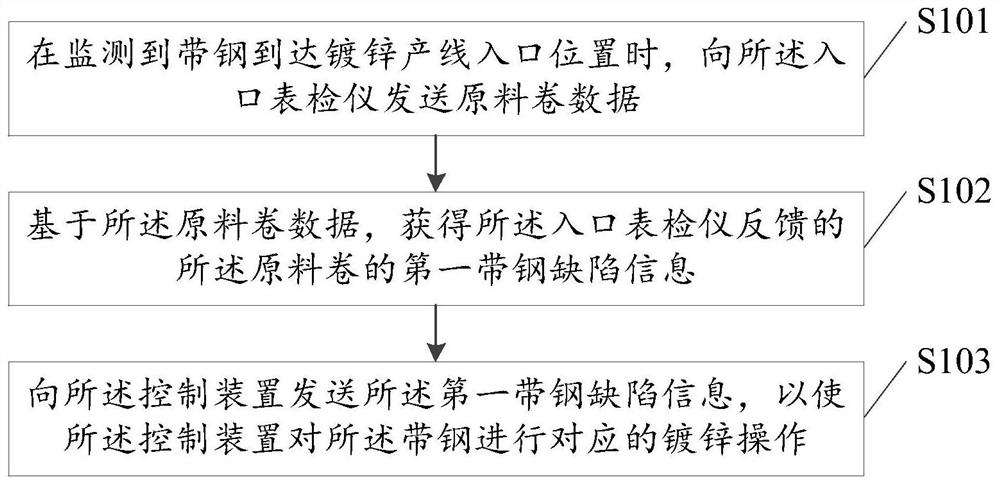

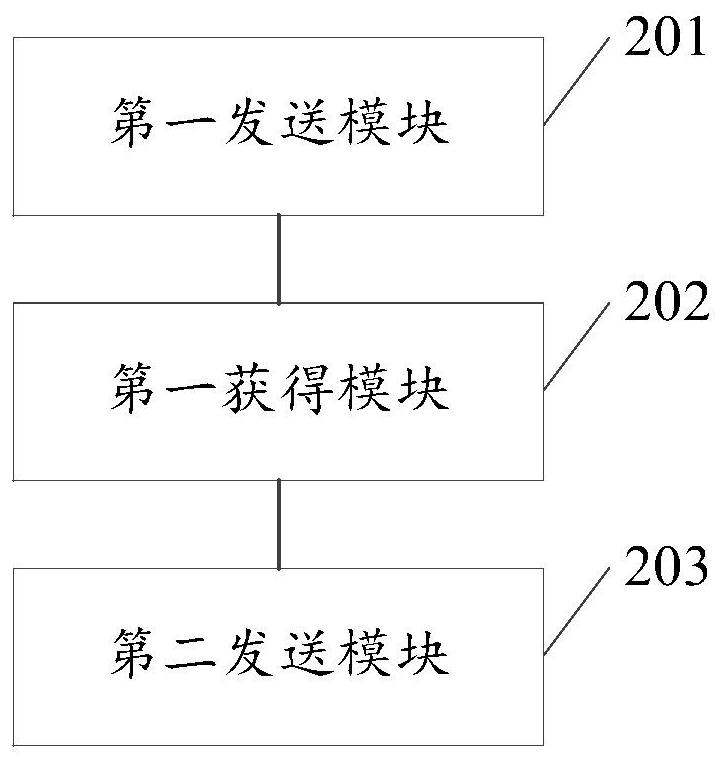

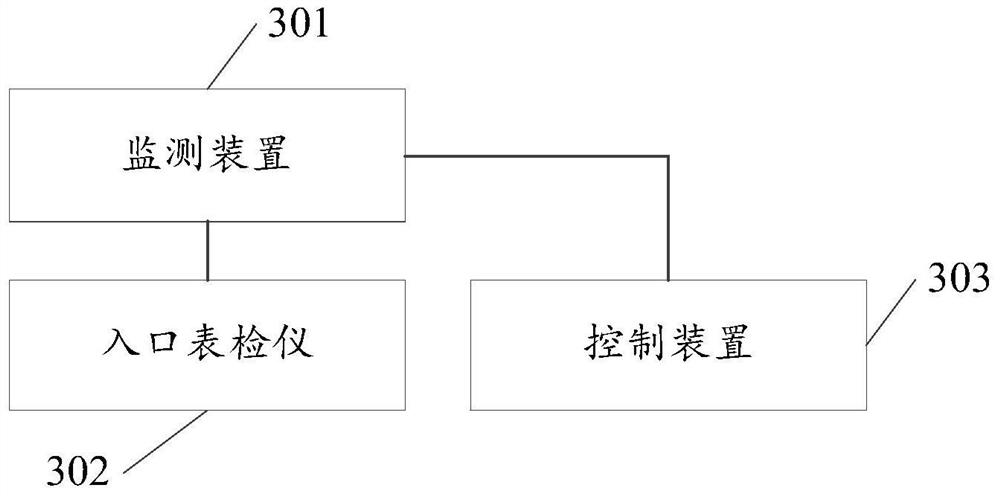

Galvanizing production line product quality monitoring method, device and system

PendingCN111695765AImprove output yieldSave resourcesResourcesManufacturing computing systemsTinningProduction line

The invention relates to the technical field of galvanizing production lines, in particular to a galvanizing production line product quality monitoring method, device and system. The method is appliedto a tinning production line monitoring system. The galvanizing production line monitoring system comprises an entrance surface detector at an entrance of a galvanizing production line, a device connected with the entrance surface detector, and a control device connected with the monitoring device, and the method comprises the following steps: when monitoring that strip steel reaches the entranceposition of the galvanizing production line, sending raw material coil data to the entrance surface detector; based on the raw material coil data, obtaining first strip steel defect information, fedback by the inlet surface detector, of the raw material coil; and sending the first strip steel defect information to the control device, so that the control device carries out corresponding galvanizing operation on the strip steel, the yield of steel coils is increased, and resources are effectively saved.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

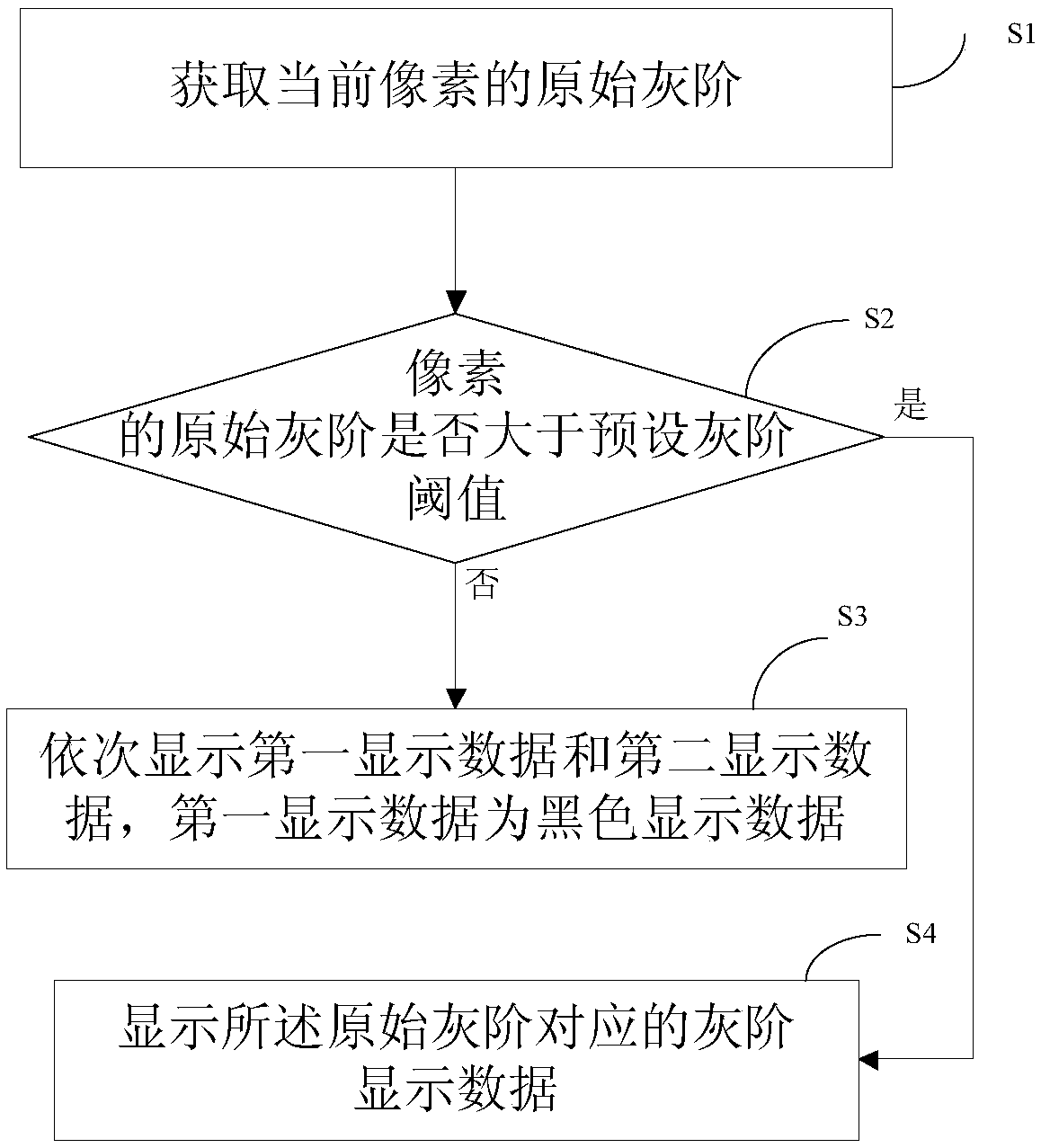

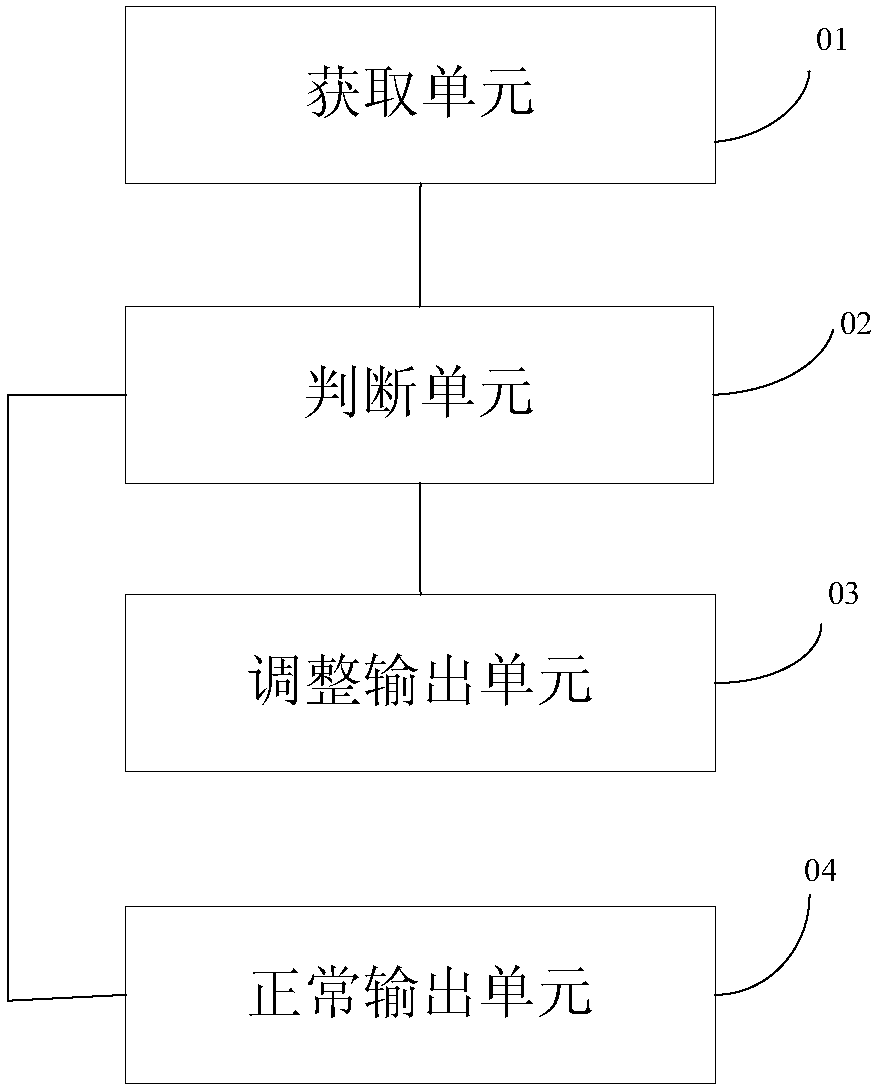

Display method and device

ActiveCN108573678AReduce mura phenomenonGuaranteed display effectStatic indicating devicesGray levelLightness

The invention provides a display method and device, and the method and device are used for reducing the mura phenomenon appearing during display. The method comprises the steps: obtaining an originalgray level of a current pixel, and then determining whether the original gray level of the pixel is greater than a preset gray level threshold or not; dividing the original gray scale into the first display data and second display data for the low gray level pixel if the original gray level of the pixel is not greater than the preset gray level threshold, and sequentially displaying the first display data and second display data, wherein the first display data is black display data, and the sum of the brightness of the first display data and the second display data is equal to the brightness of the original gray level of the pixel. In the scheme, the first display data is black display data, and a black interface enables the user's eyes not to observe the mura phenomenon during black graylevel display, and the brightness of the second display data increases, and the voltage needs to be lowered, wherein the lower the voltage, the more inconspicuous the mura of the type is, thereby achieving the effect of reducing the mura phenomenon, effectively improving or eliminating most of the horizontal mura of a screen, improving the display effect and improving the yield of the module.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

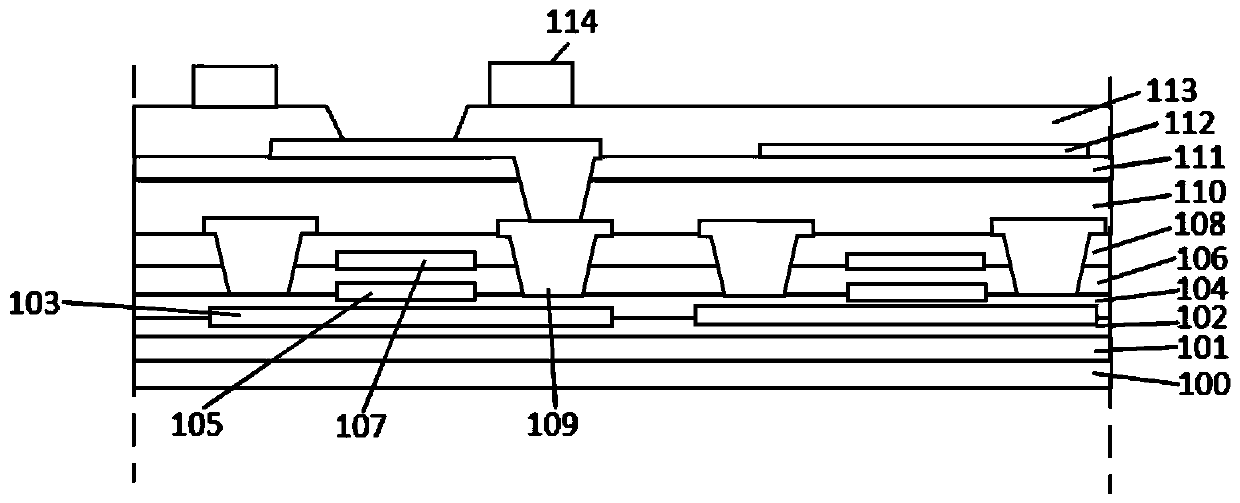

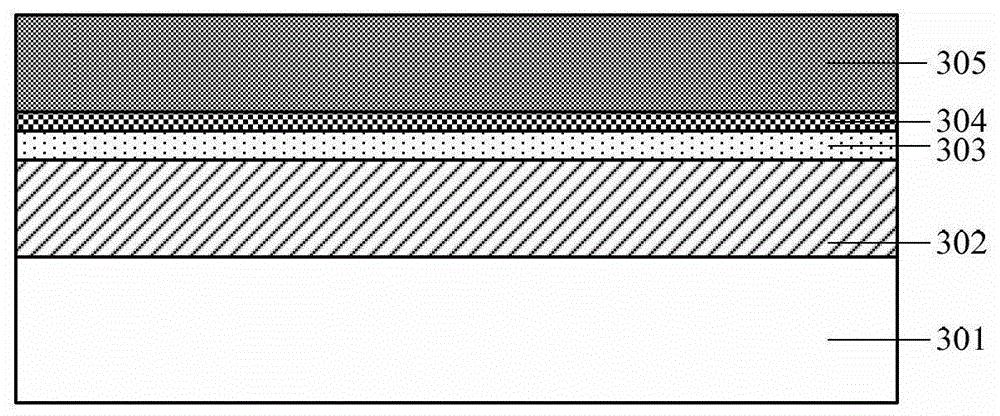

Display panel and display device

InactiveCN107706194AGuaranteed withstand voltageSo as not to damageSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceOptoelectronics

The invention discloses a display panel comprising a substrate thin film layer, an organic thin film layer disposed on the substrate thin film layer, a flat layer disposed on the organic thin film layer, and functional layers sequentially formed on the flat layer. The functional layers consist at least of an anode film layer. An inorganic insulating film layer is further arranged between the anodefilm layer and a pattern of the flat layer, and the inorganic insulating film layer is consistent with the pattern of the flat layer. The invention also discloses a display device. The display paneland the display device in the invention can be used to prevent the anode film layer from puncturing the organic thin film layer below, improve the adhesion between the anode film layer and the underlying film layer and ensure the normal driving of the circuit outside a display area and the normal image display.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

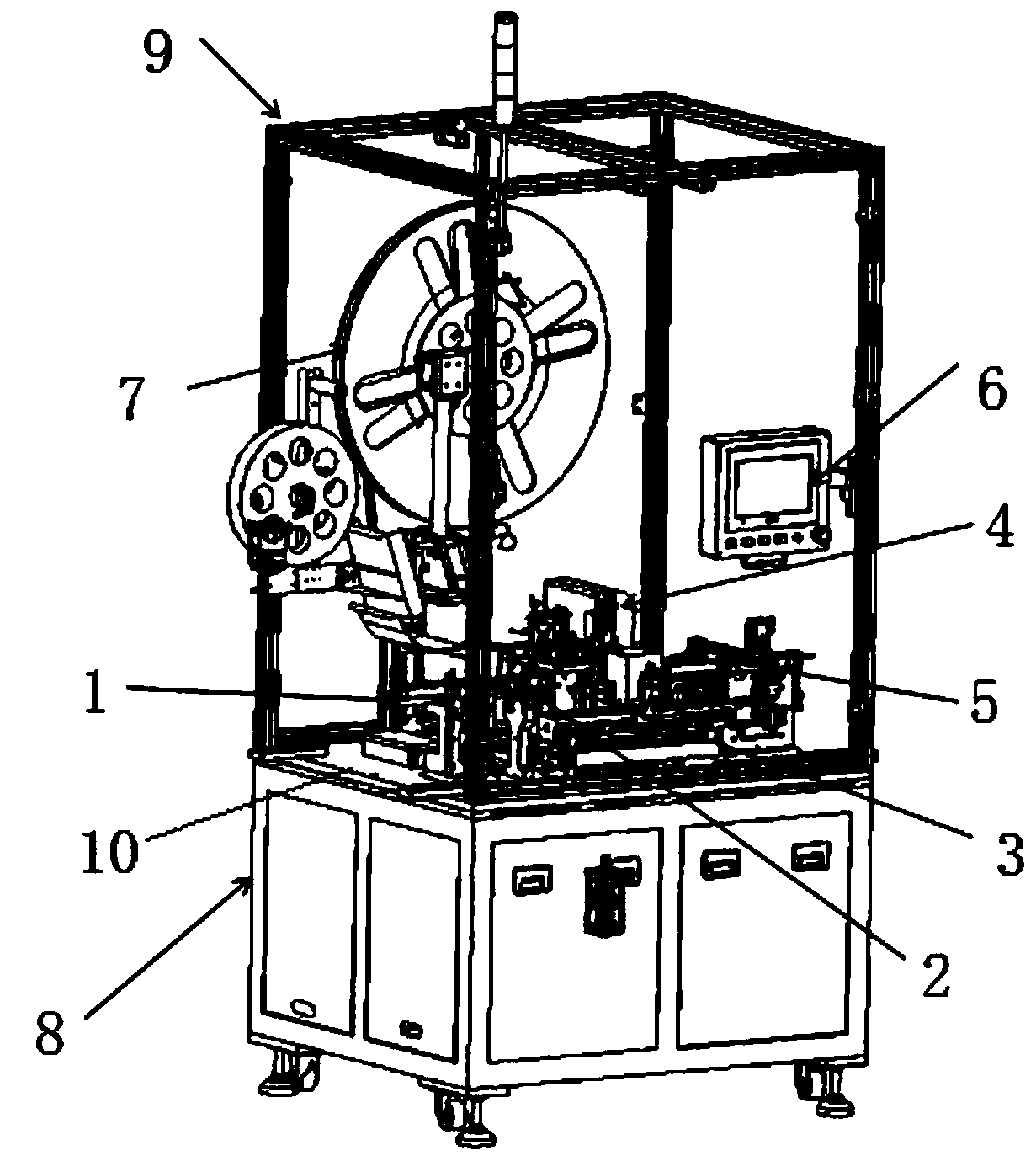

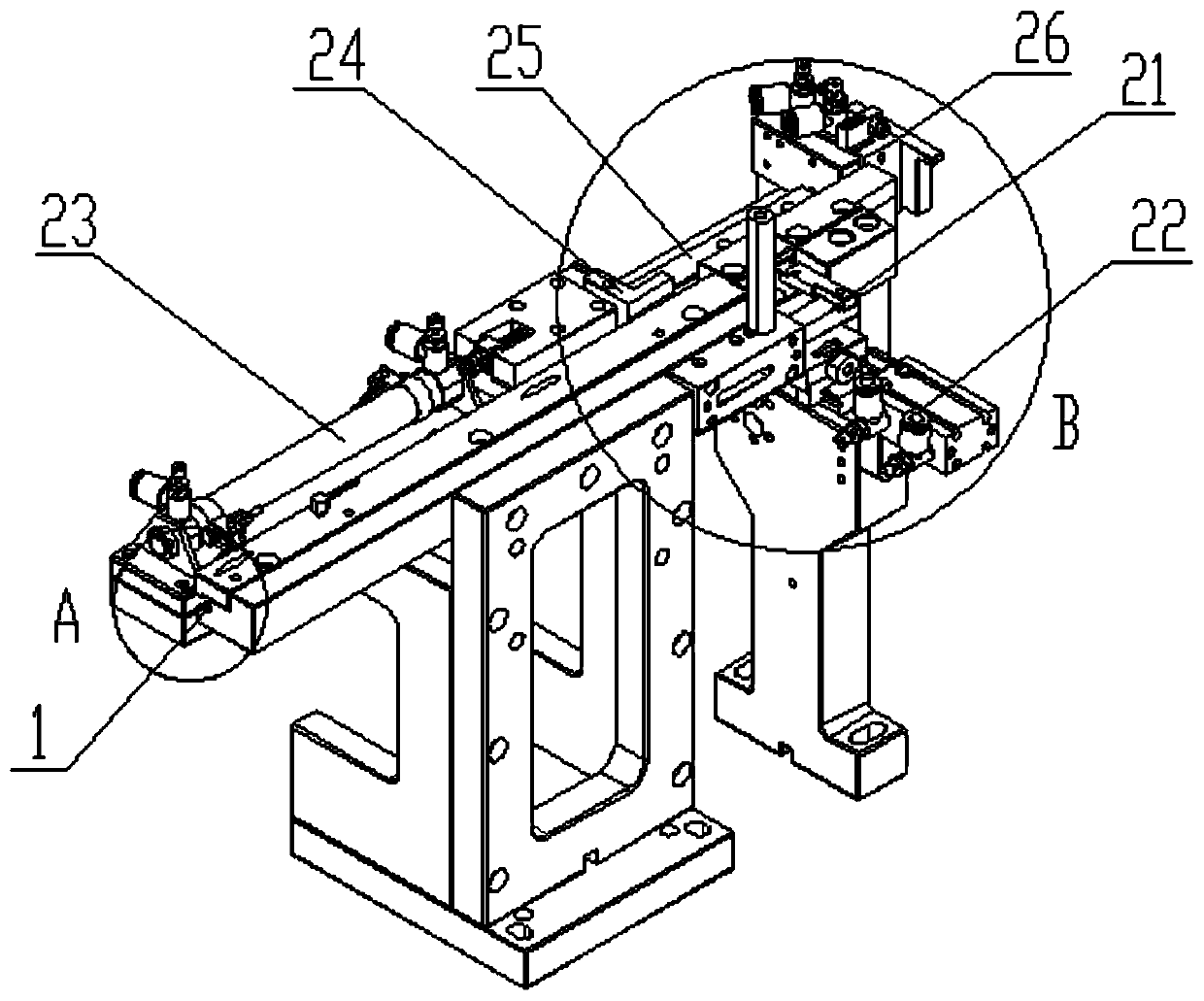

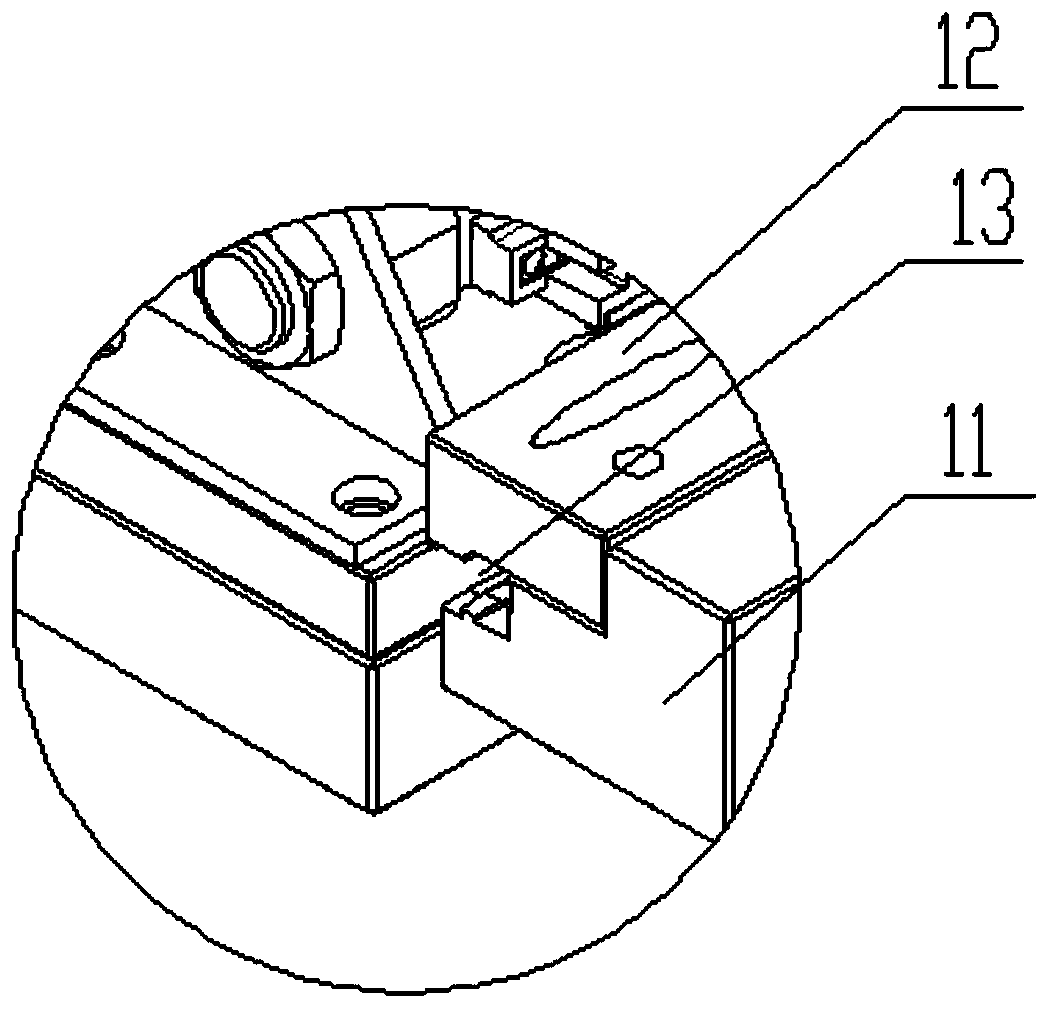

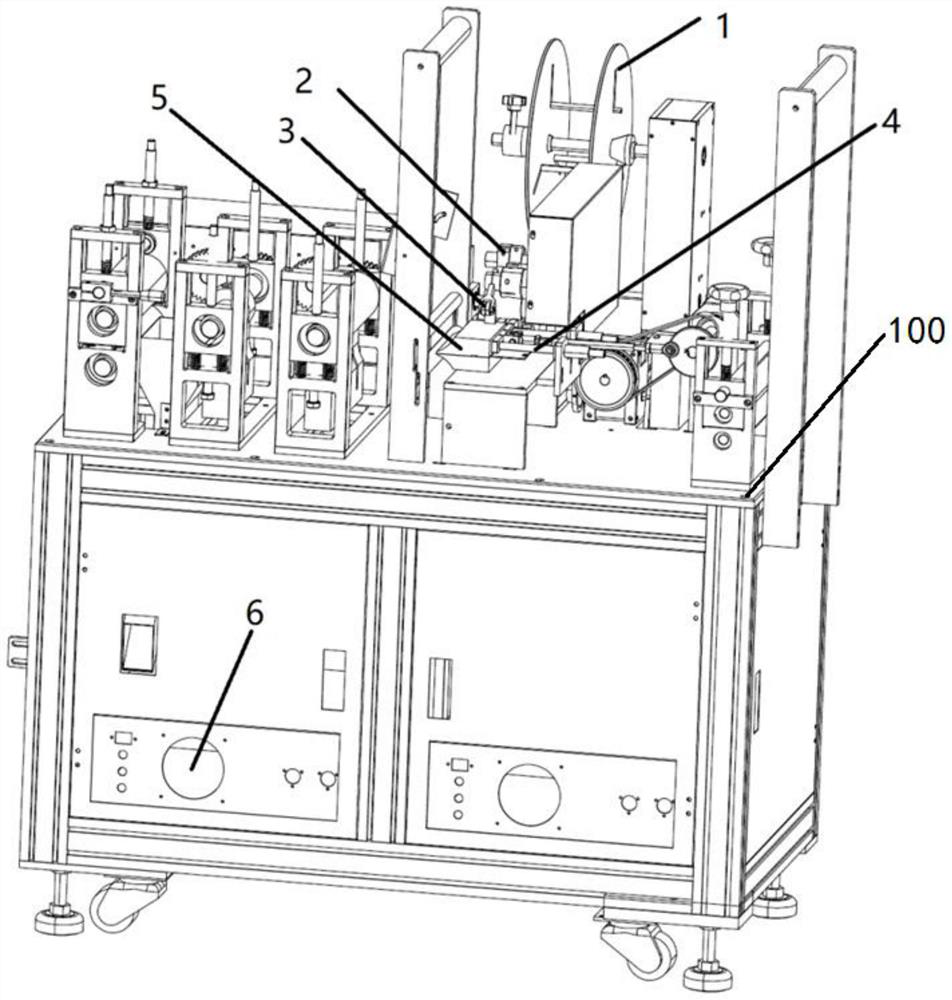

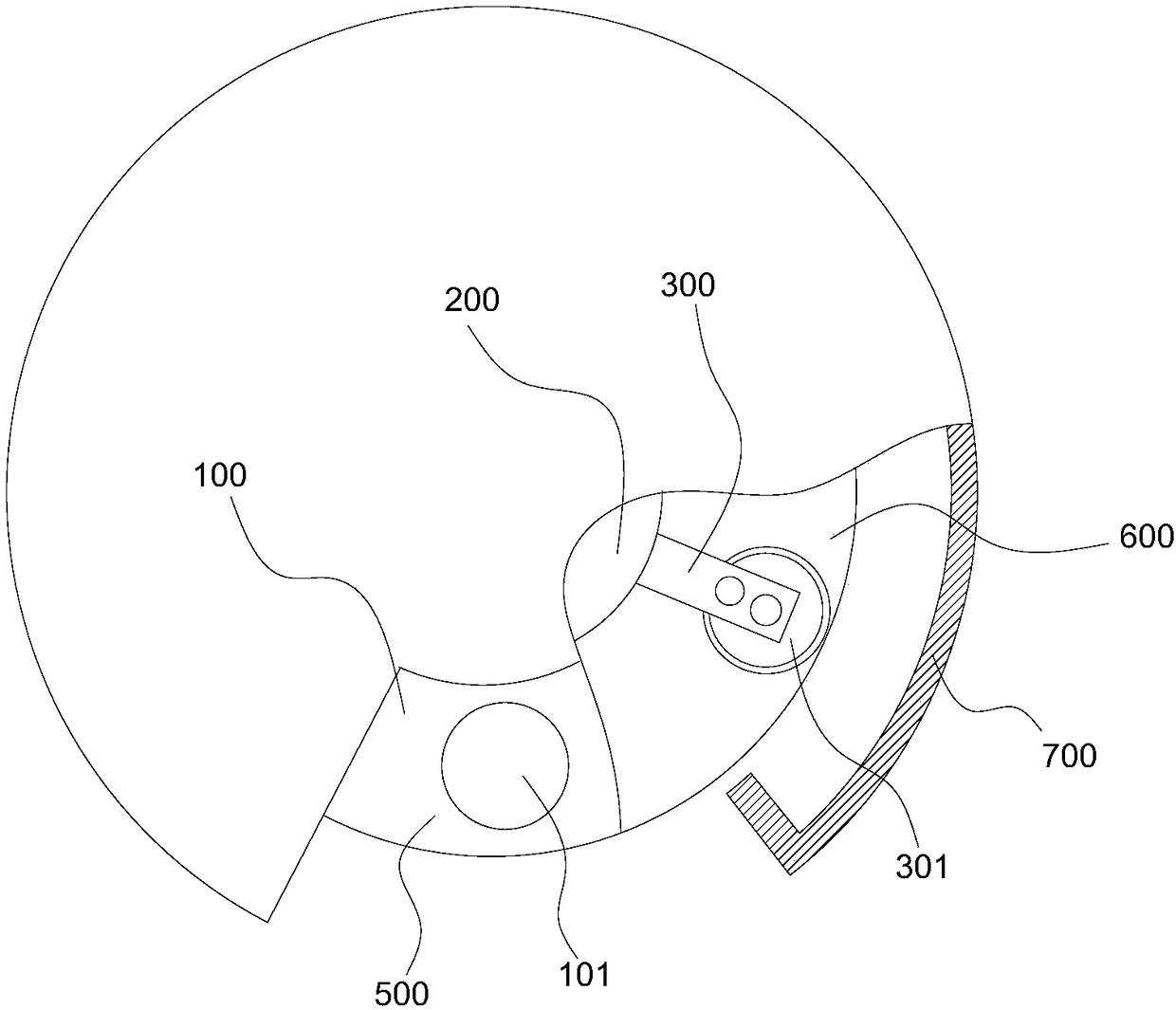

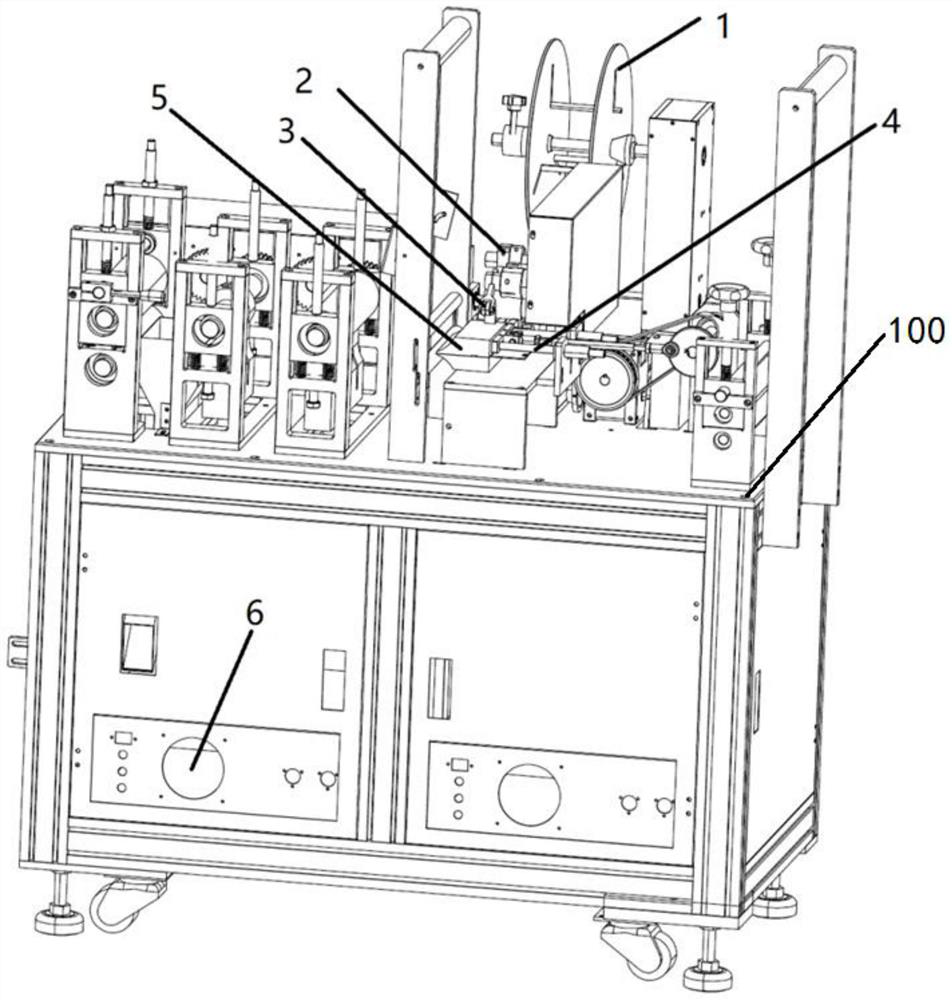

Small-pitch tilt terminal high-speed automatic pin inserting machine

PendingCN110137773AImprove assembly efficiencyImprove the labor intensity of manual workContact member manufacturingContact member assembly/disassemblyBoard-to-board connectorEngineering

The invention discloses a small-pitch tilt terminal high-speed automatic pin inserting machine and belongs to the field of manufacture of a small-pitch board-to-board connector. The small-pitch tilt terminal high-speed automatic pin inserting machine mainly comprises a rack and a workbench. The workbench is arranged in the middle portion of the rack. The workbench is provided with a feed chute, adislocation feeding mechanism, a rotating shift mechanism, a pin inserting mechanism and a final pressure mechanism in sequence. Through the mode above, the small-pitch tilt terminal high-speed automatic pin inserting machine can solve the problems that the assembly efficiency of existing products is low, the quality is not easy to guarantee, and the material utilization rate is low.

Owner:FCI NANTONG LTD

Fritting furnace for fritting back surface field of solar battery piece

InactiveCN102102948APivot support force reducedImprove back field qualityFinal product manufactureFurnace typesBack surface fieldEngineering

The invention relates to the technical field of a fritting furnace for fritting a back surface field of a solar battery piece. The fritting furnace comprises a battery piece transmission crawler belt; and a battery piece airflow floating device is arranged in a high-temperature fritting area of the fritting furnace additionally, and is arranged below the battery piece transmission crawler belt. In the fritting furnace, the battery piece airflow floating device is arranged below the battery piece transmission crawler belt by utilizing the contrast relation that the gravity of the battery piece is greater than friction generated by transmitting the battery piece, so that the fulcrum bracing force of the battery piece is reduced, the quality of the back surface field of the battery piece can be improved greatly, and the output yield of battery pieces is improved by 30 percent.

Owner:TRINA SOLAR CO LTD

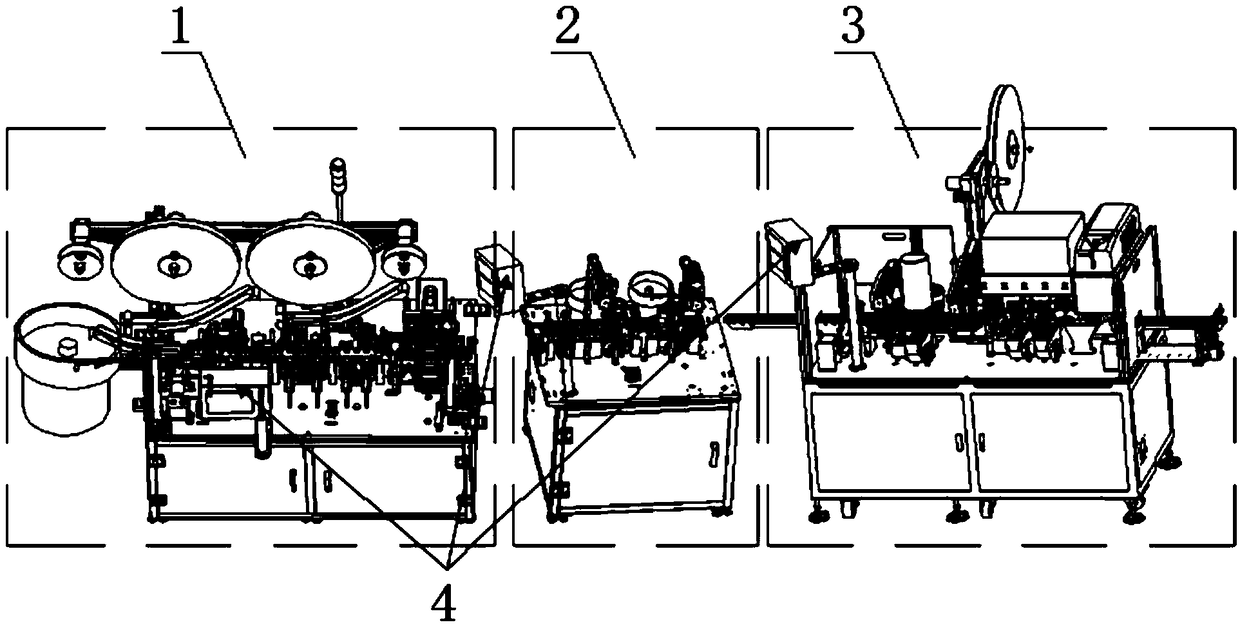

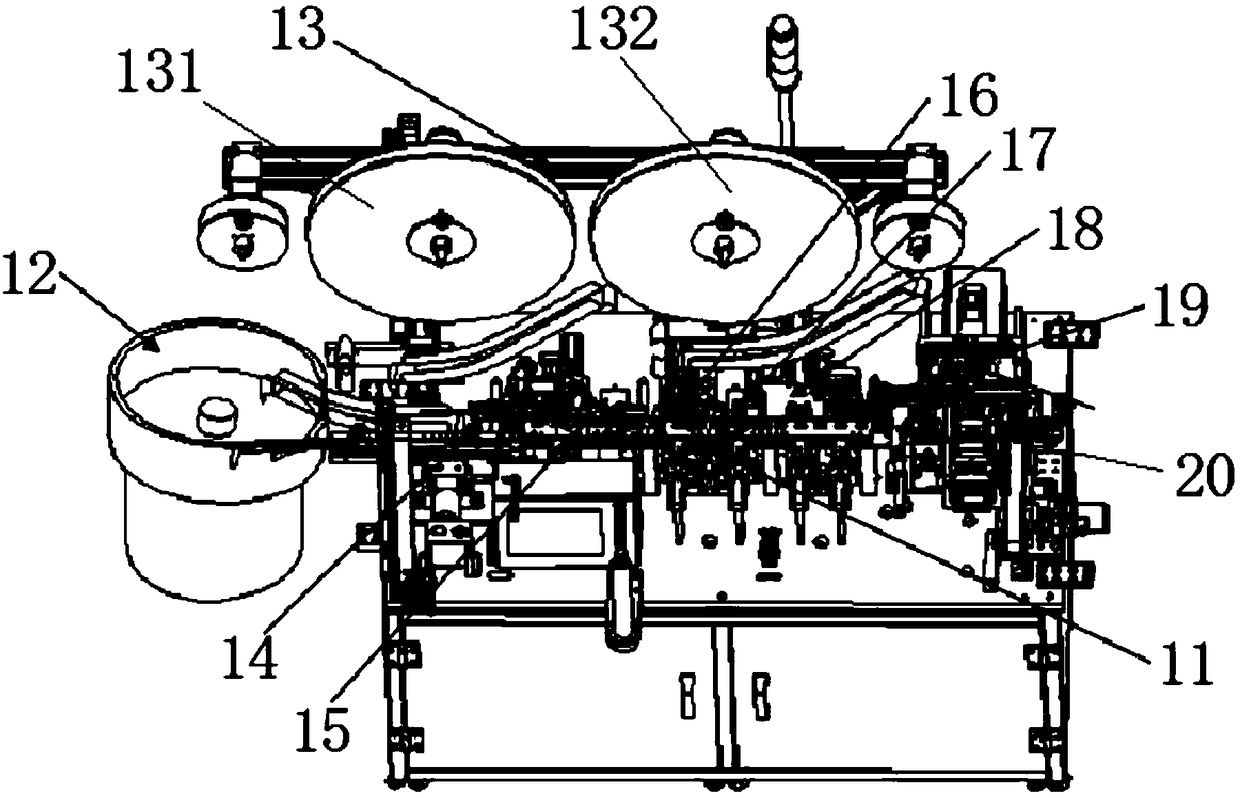

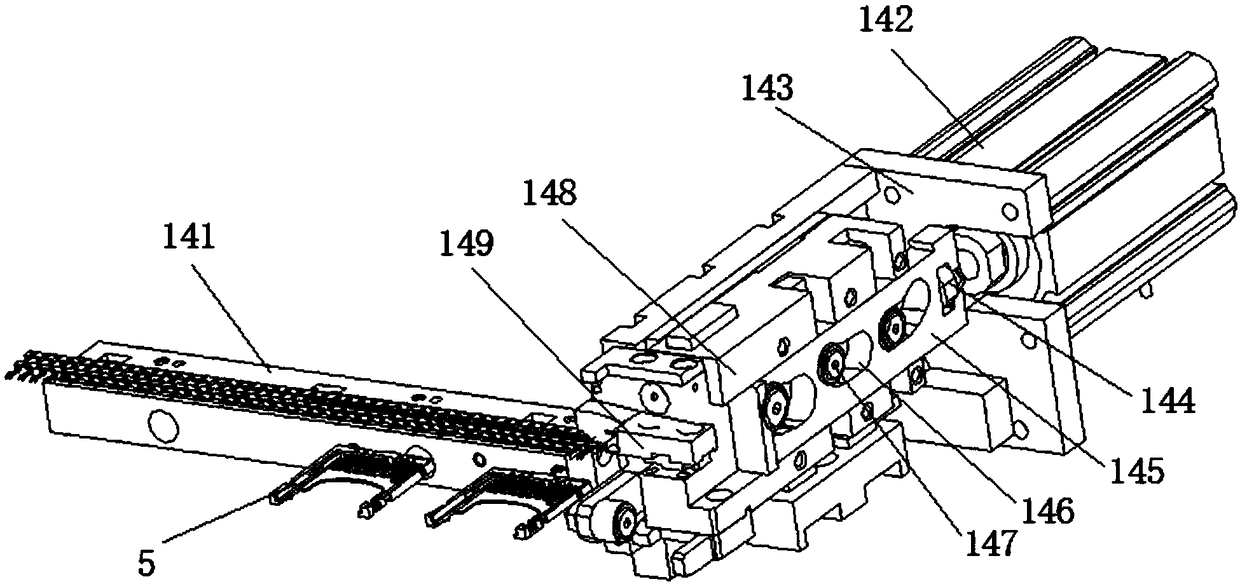

Automatic assembly and test apparatus for SD (secure digital) cards

PendingCN109262259AReduce labor intensityAvoid quality hazardsAssembly machinesHuman–machine interfaceEngineering

The invention discloses an automatic assembly and test apparatus for SD (secure digital) cards and belongs to the field of manufacture of electronic parts. The automatic assembly and test apparatus for SD cards mainly comprises assembly station A, assembly station B and a detection station; the assembly station A, the assembly station B and the detection station are connected via a conveyor belt and are each provided with a human-machine interface. Through the above approach, the automatic assembly and test apparatus for cards can provide improved efficiency of SD card assembly efficiency andreduced overall defective rate of products.

Owner:FCI NANTONG LTD

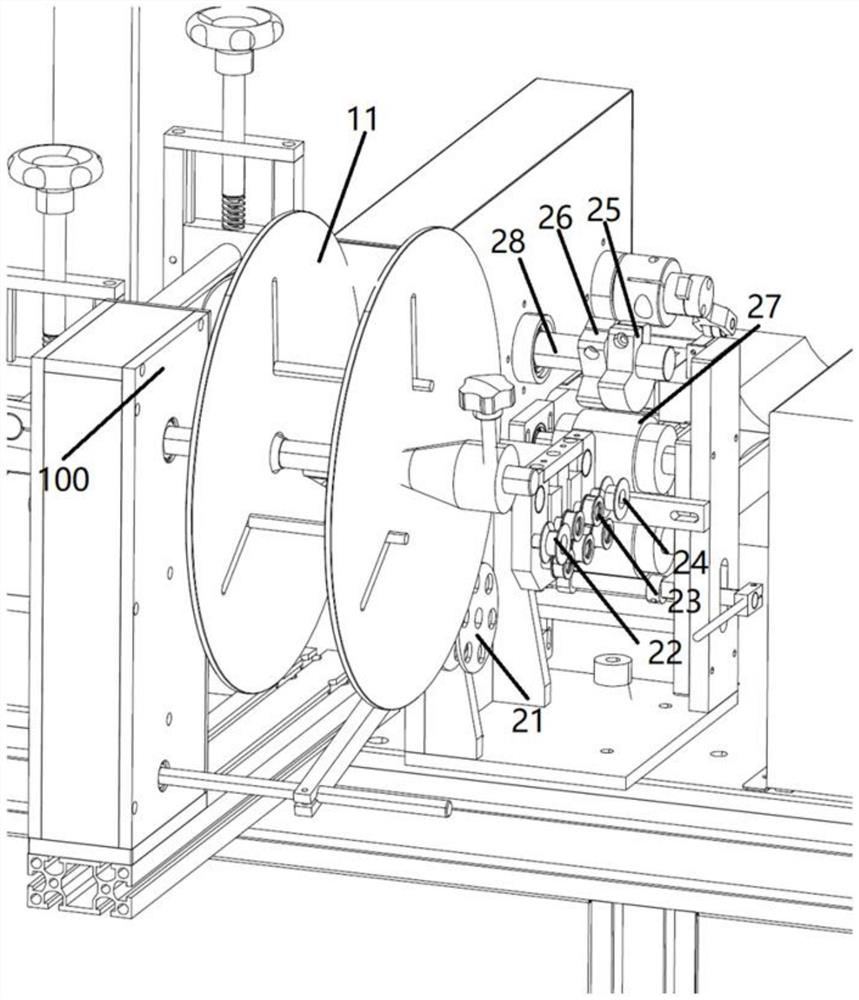

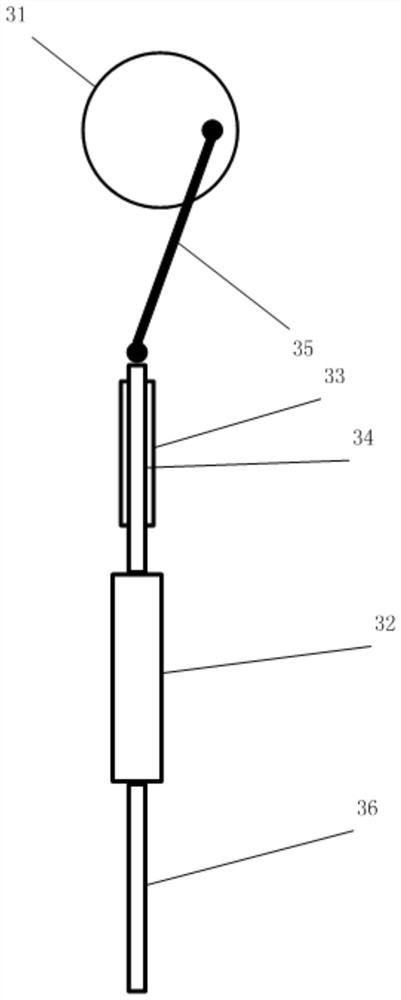

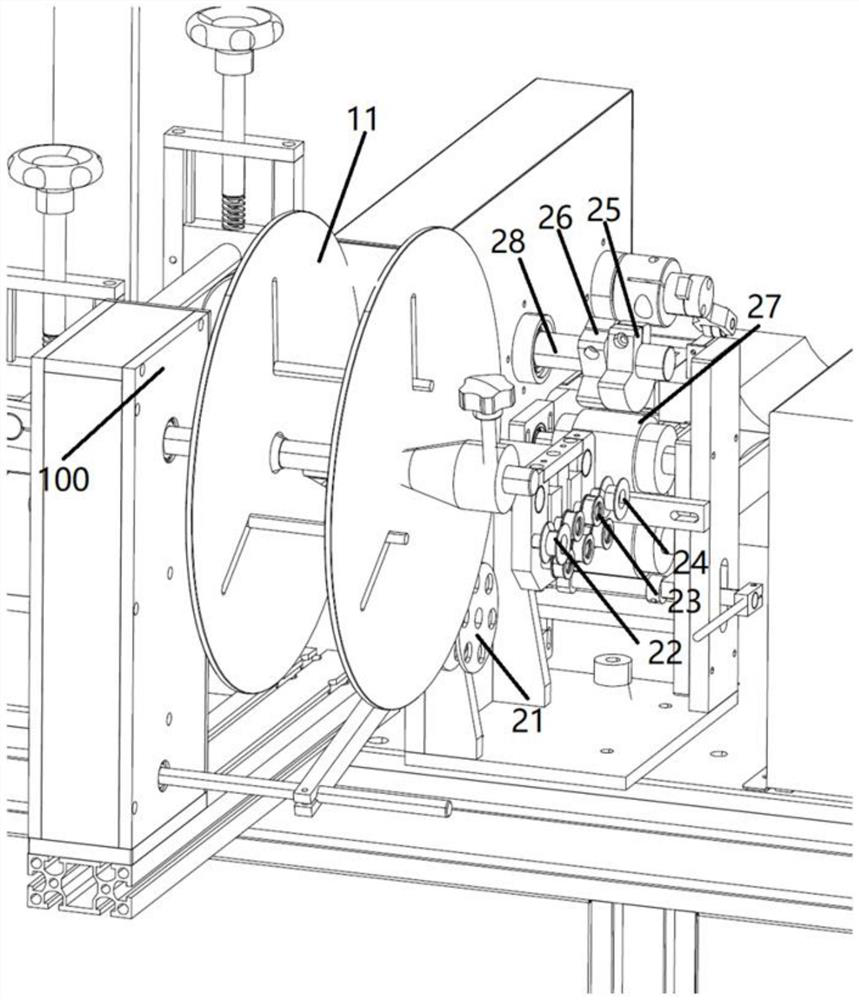

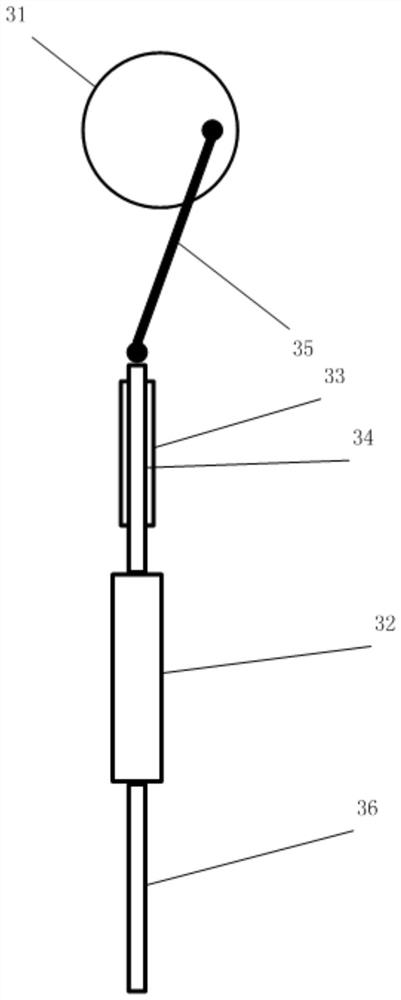

Intelligent nose wire discharging device and method of mask machine

ActiveCN111774502AImprove output yieldFilament handlingMetal working apparatusInformation processingNerve network

The invention discloses an intelligent nose wire discharging device and method of a mask machine. The device comprises a machine frame. A nose wire discharging mechanism, a nose wire straightening mechanism, a nose wire cutting mechanism, a nose wire pushing mechanism, a nose wire clamping block and a control module are arranged on the machine frame. The nose wire cutting mechanism comprises a power crank, a cutting connecting rod, a cutting guide rail, a cutting sliding block, an online cutting force adjusting device and a cutter. A photoelectric detection sensing module is arranged inside the nose wire clamping block. The control module is used for controlling working states of the nose wire discharging mechanism, the nose wire straightening mechanism, the nose wire cutting mechanism andthe nose wire pushing mechanism. According to the device and the method, data which are obtained after processing image information scanned by a linear CCD sensor assembly and metal signal intensityinformation detected by a metal sensor are input into a deep convolutional neural network, then online intelligent judgment is conducted on the pushing quality of nose wires, then the control module controls the nose wire cutting mechanism to conduct corresponding operation, online real-time adjustment on the cutting force of the cutter is completed, and the production yield is improved.

Owner:GUANGDONG HUST IND TECH RES INST

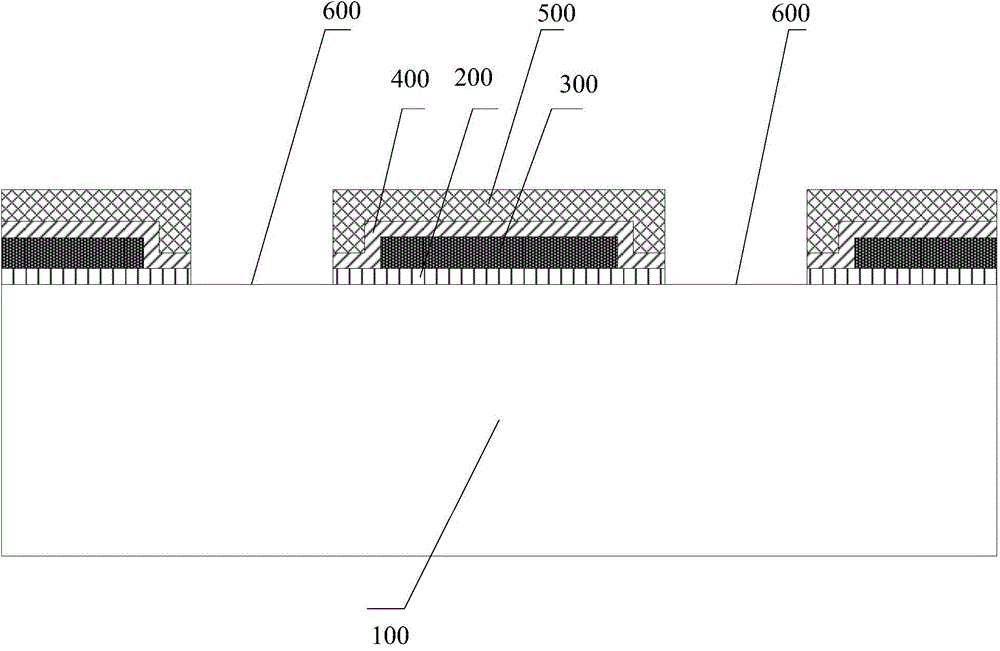

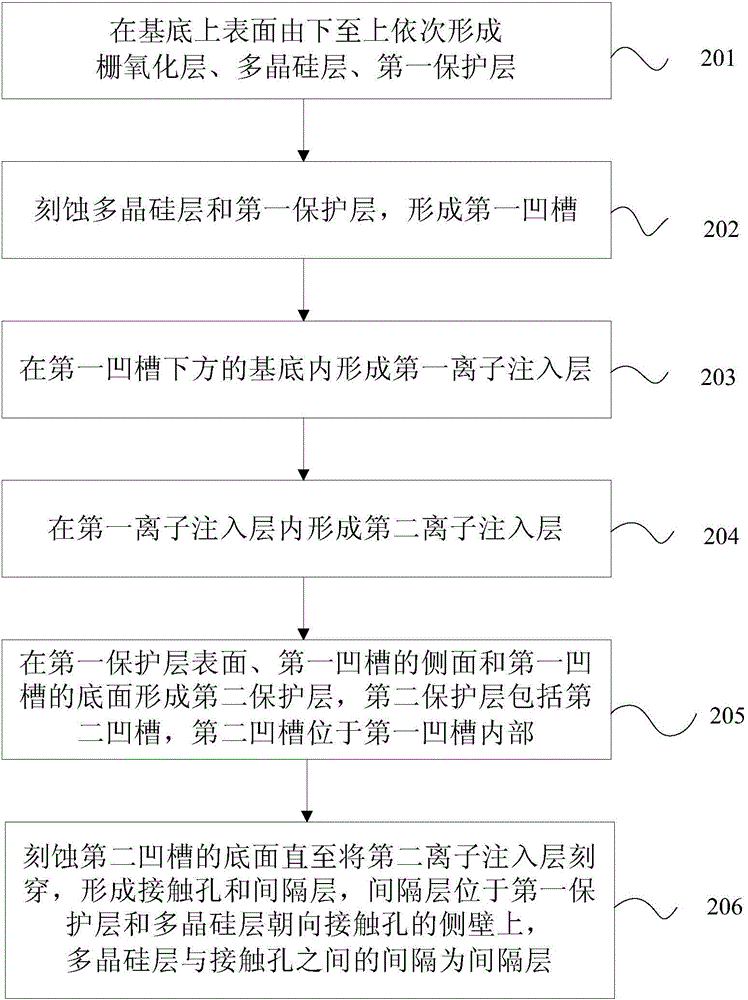

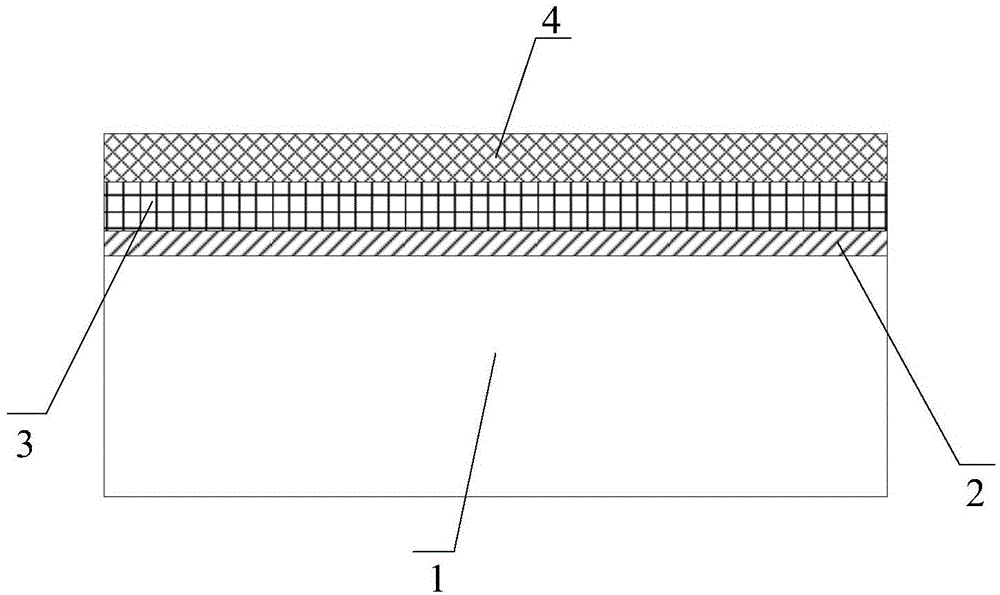

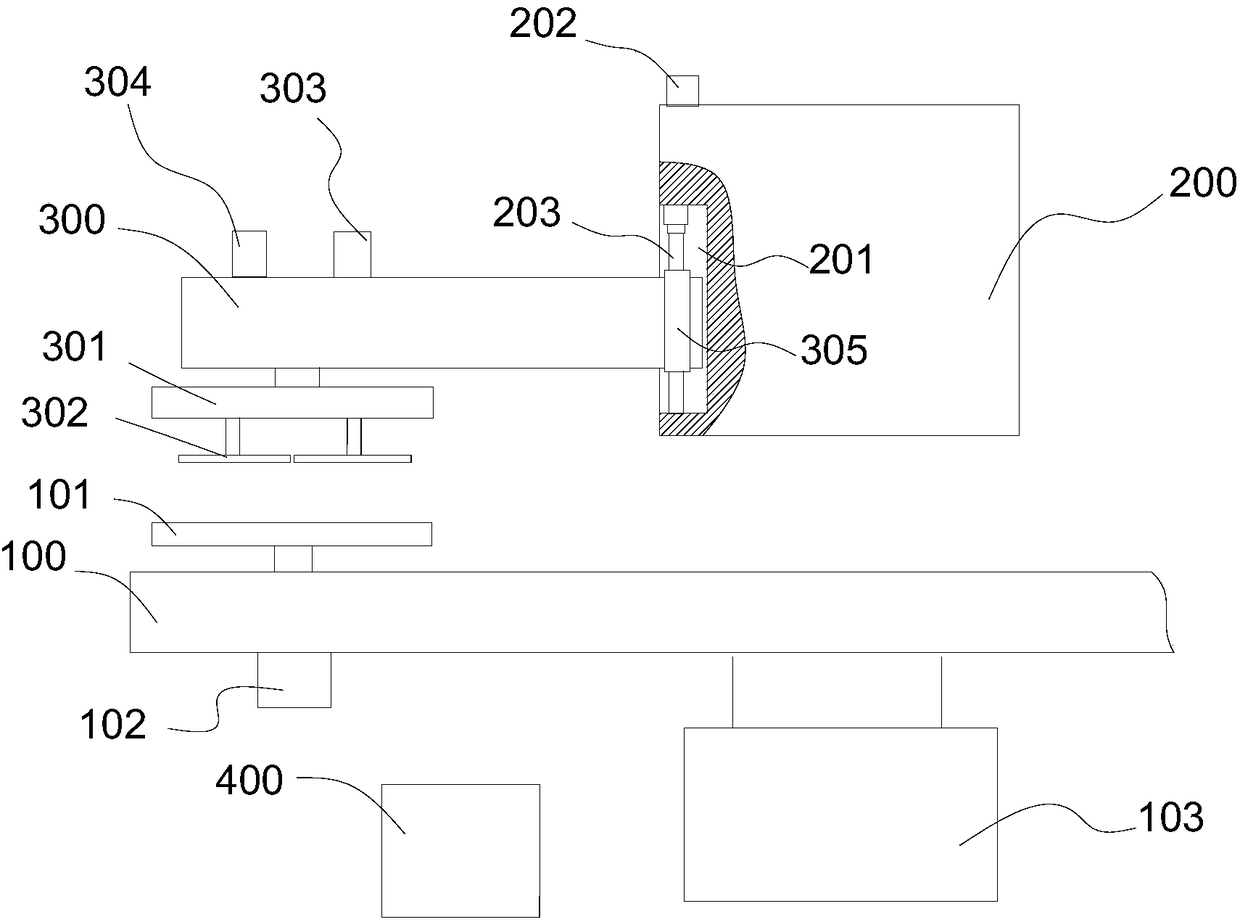

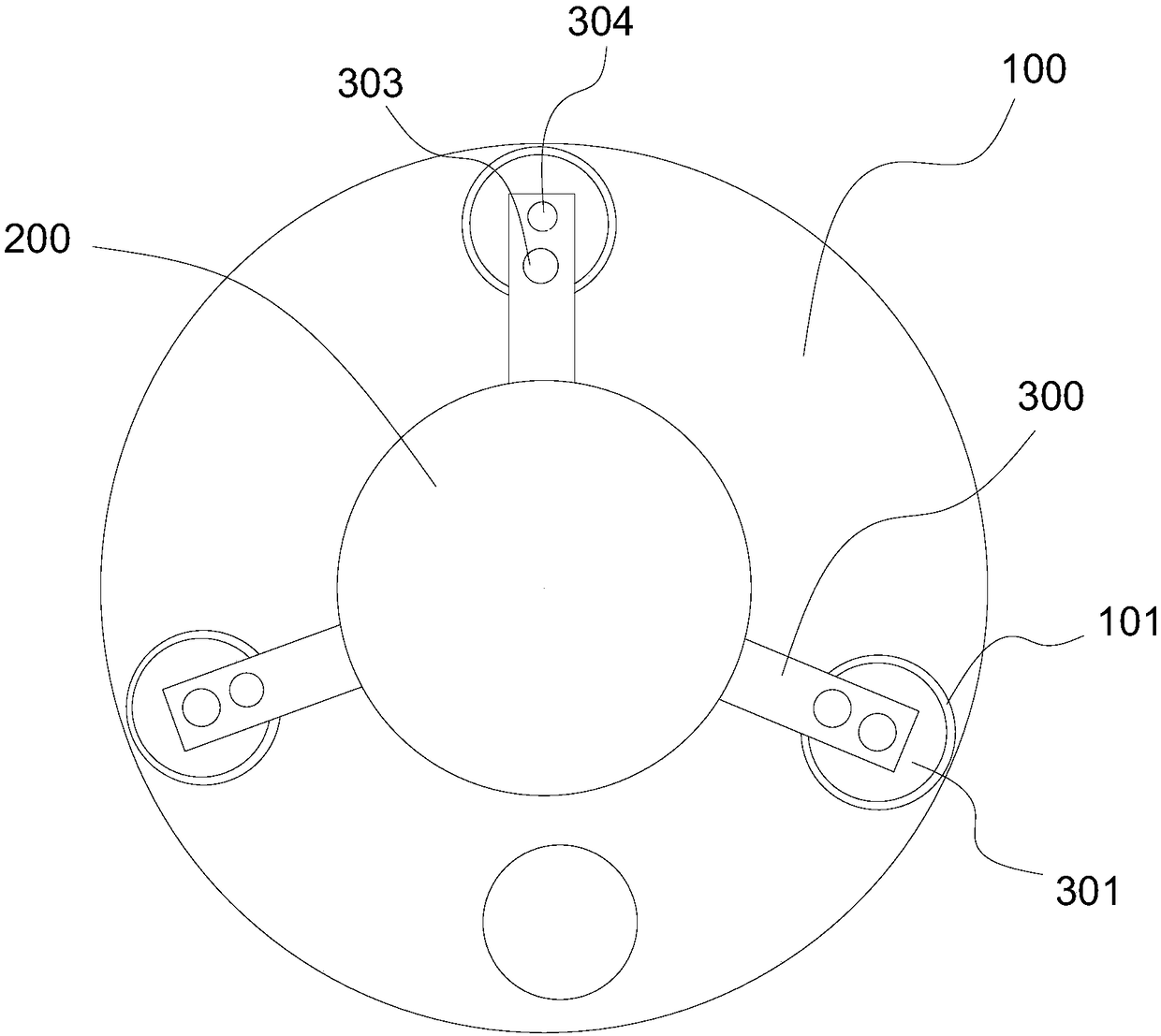

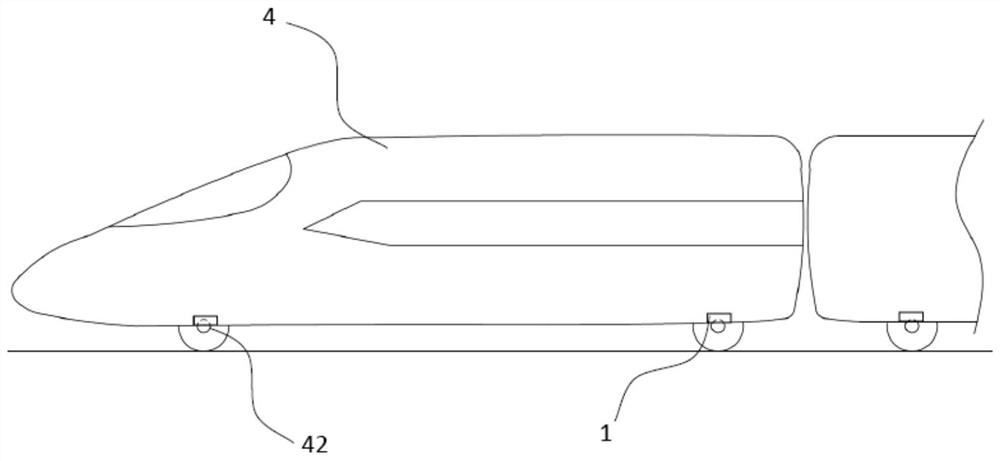

VDMOS device and manufacturing method therefor

ActiveCN106298928AImprove output yieldWill not cause offsetSemiconductor/solid-state device manufacturingSemiconductor devicesGate oxideProtection layer

The invention discloses a VDMOS device and a manufacturing method therefor. The manufacturing method comprises the steps of forming a gate oxide layer, a polysilicon layer and a first protection layer on the upper surface of a substrate from the bottom up in sequence; etching the polysilicon layer and the first protection layer to form first grooves; forming a first ion implantation layer in the substrate below the first grooves; forming a second ion implantation layer in the first ion implantation layer; forming a second protection layer on the surface of the first protection layer, the side surfaces and the bottom surfaces of the first grooves, wherein the second protection layer comprises second grooves which are formed in the corresponding first grooves; and etching the bottom surfaces of the second grooves until the second ion implantation layer is thoroughly etched to form contact holes and an interval layer. According to the VDMOS device and the manufacturing method therefor, the contact holes are formed by adopting a self-alignment way, so that offset of the contact holes is avoided, namely, the connection between the contact holes and the polysilicon layer is avoided, thereby improving the output yield of the device.

Owner:FOUNDER MICROELECTRONICS INT

Method of growing edible fungi in corn field

InactiveCN107432166AWill not reduce the areaIncrease profitPlant cultivationCultivating equipmentsHuskCorn flour

The invention discloses a method of growing edible fungi in corn field. The method comprises following steps: planting corn in summer; preparing culture medium material for edible fungi, fermenting, packaging, disinfecting and waiting to be inoculated; uniformly inoculating the edible fungi strain in the culture medium material; screening the strains; preparing material for the growth of the edible fungi, disinfecting and fermenting; after the corn grows to standard height, planting the edible fungi in the night-side of each row of the corn; managing the edible fungi, regularly spraying water to keep the humidity of soil; harvesting the mature edible fungi. According to the invention, edible fungi is planted in corn field; the growth of the edible fungi is facilitated by the shade of the corn; the fertilizer after the harvest of the fungi can be fertilizer for the core, therefore increasing the land utilization rate and the output yield of unit area so that the method has high economic value. After the harvest of corn, the straw, cob, corn husk and corn flour are used for producing edible fungi, which is energy saving; the material is comprehensively utilized and reused.

Owner:禄劝琼程美农业科技发展有限公司

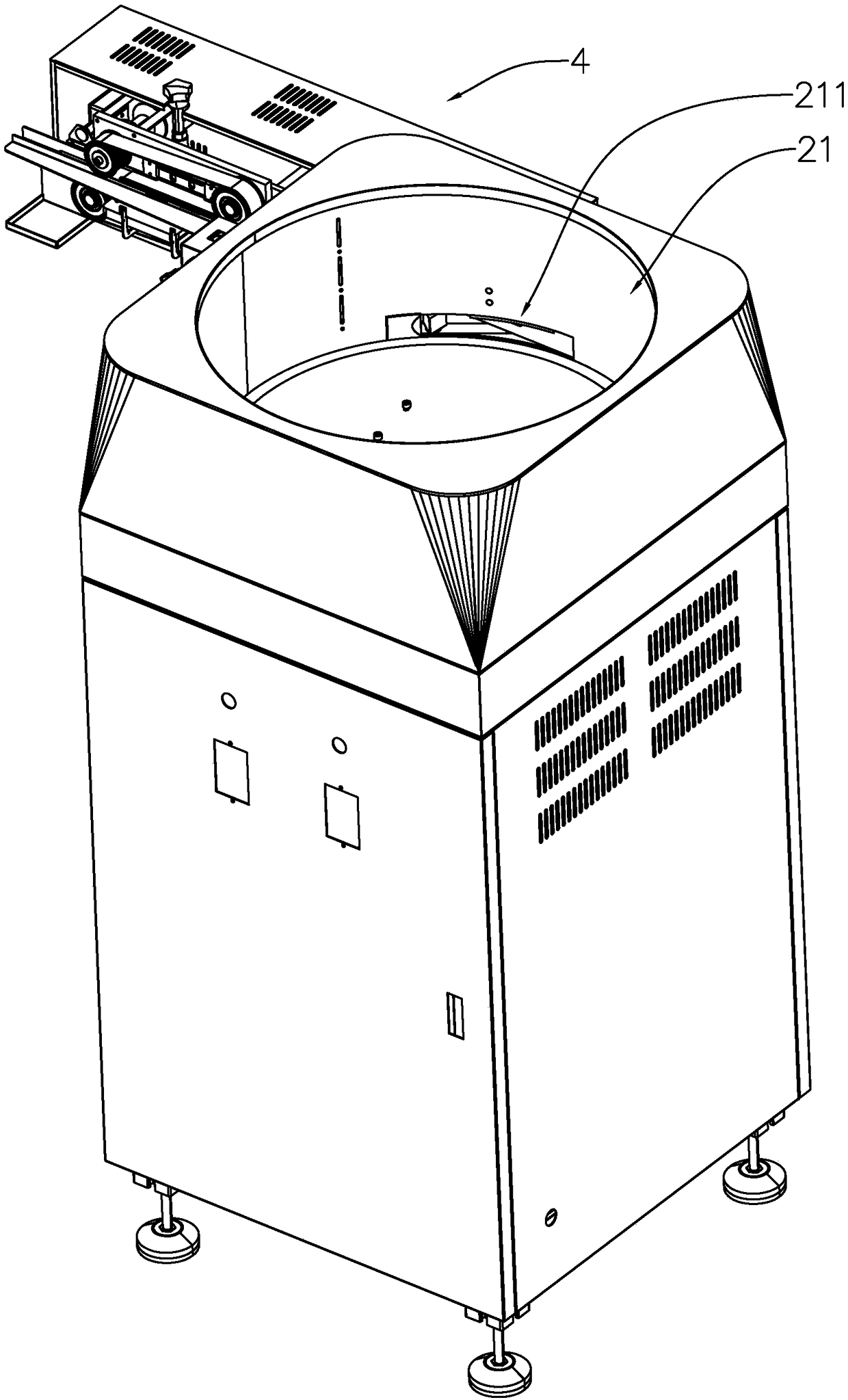

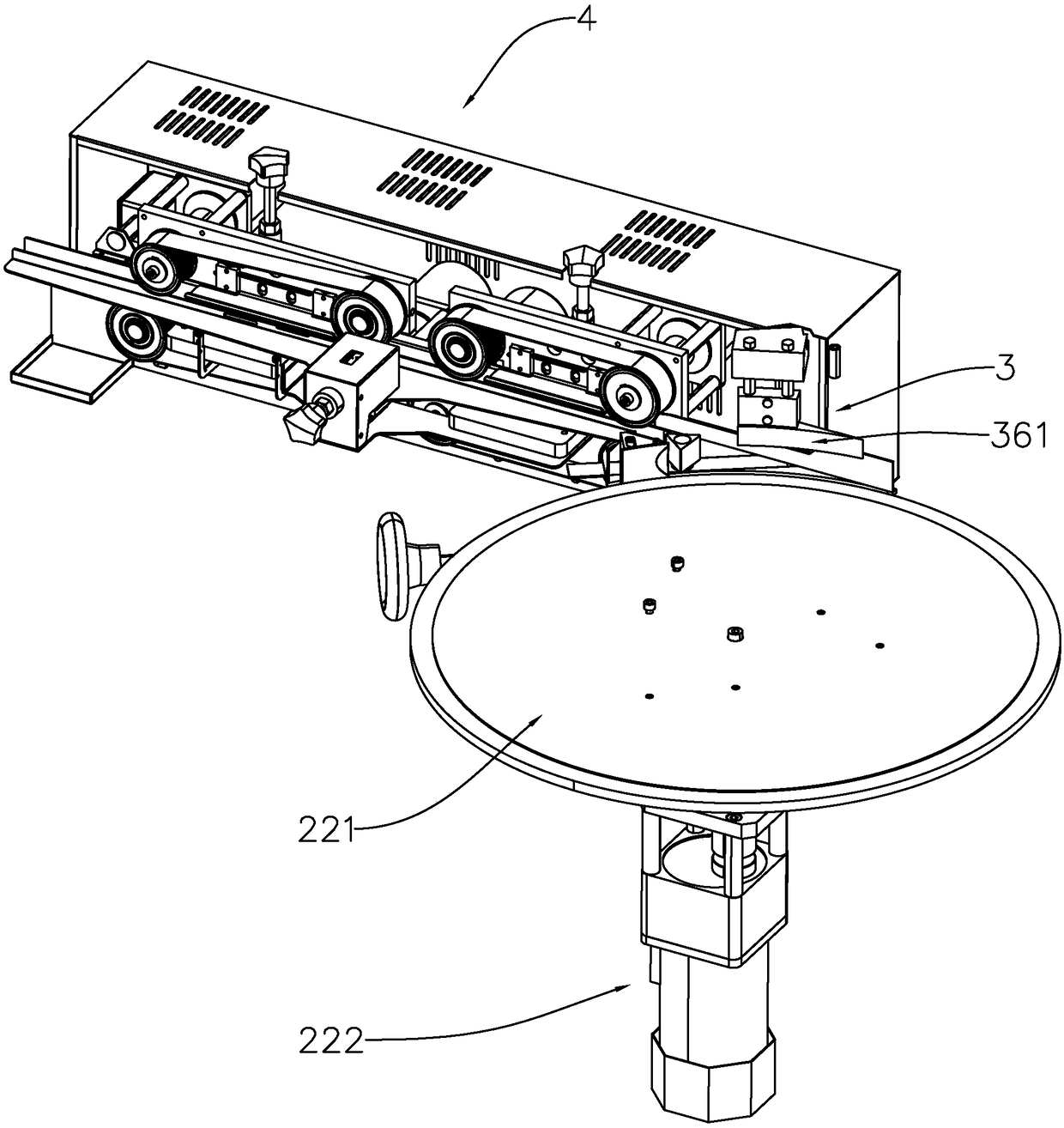

Novel multi-station high-efficiency polishing device for precise curved surface glass

The invention discloses a novel multi-station high-efficiency polishing device for precise curved surface glass. The polishing device comprises a stand column and a disc, wherein multiple cantileverscapable of moving up and down are arranged on the peripheral side wall of the stand column, and polishing mechanisms are arranged on the lower surface of the outer end of the cantilevers; each polishing mechanism comprises a polishing disc, a second motor used for driving the polishing disc, multiple polishing wheels and a third motor used for driving the polishing wheels; rotating shafts of the polishing discs are rotationally connected with the cantilevers; the polishing wheels are located below the polishing discs, the polishing wheels are distributed around the rotating shafts of the polishing discs, and the rotating shafts of the polishing wheels are connected with the polishing discs in a rotating mode; the disc is located below the stand column, and the disc is provided with a fourth motor; and multiple material discs are installed on the upper surface of the disc in the circumferential direction of the discs, and the material discs are driven by fifth motors. Compared with theprior art, the polishing device has the advantages that the polishing effect is good, and the yield of polished products can be improved.

Owner:江西普维智能科技有限公司

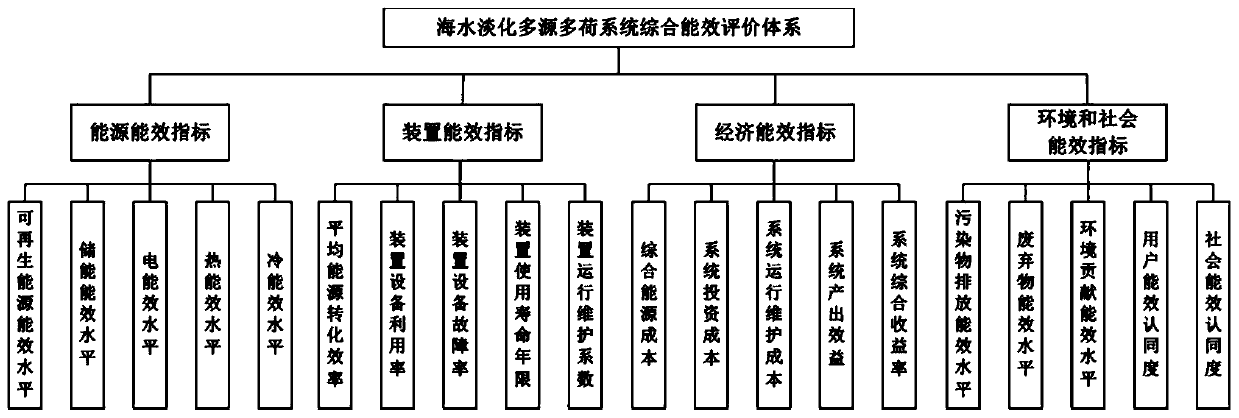

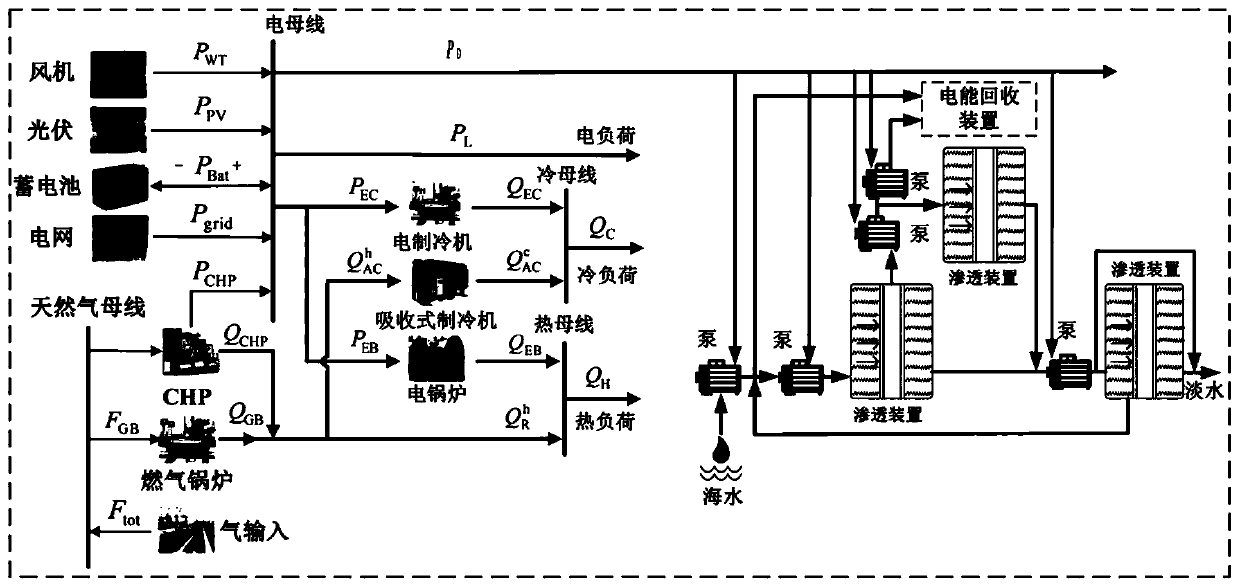

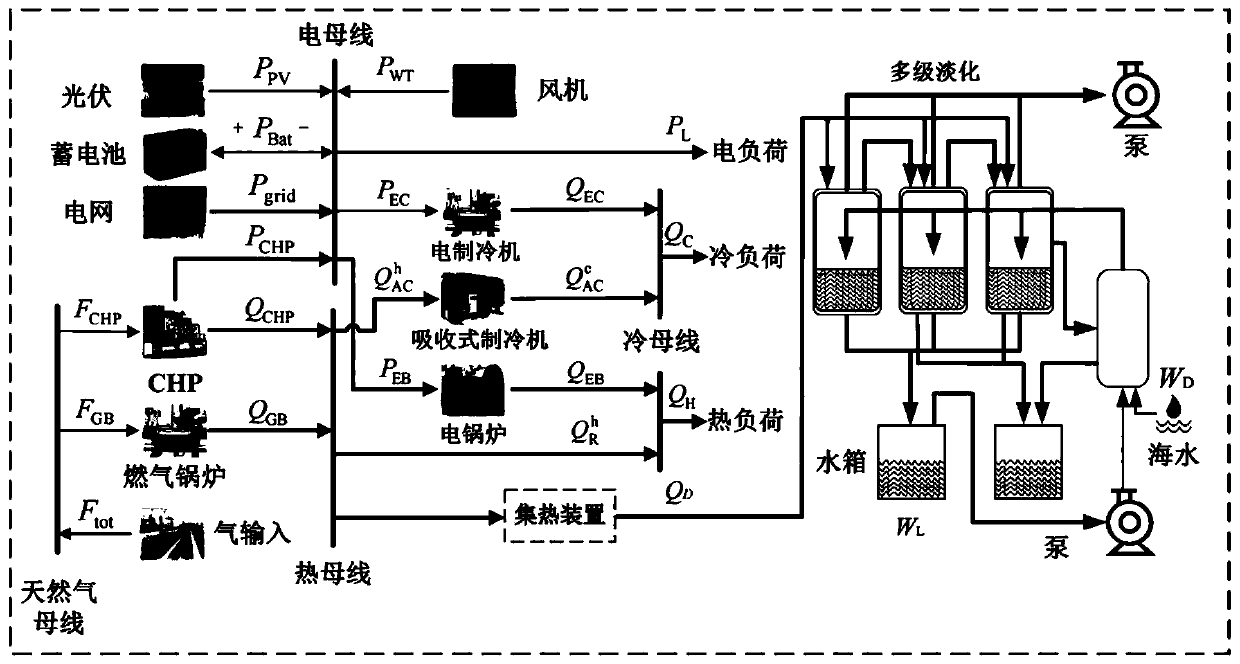

Construction method of comprehensive energy efficiency evaluation system of seawater desalination multi-source multi-load system

ActiveCN110110991AImprove utilization efficiencyImprove consumption levelTechnology managementResourcesEngineeringIndex system

Owner:TIANJIN UNIV +1

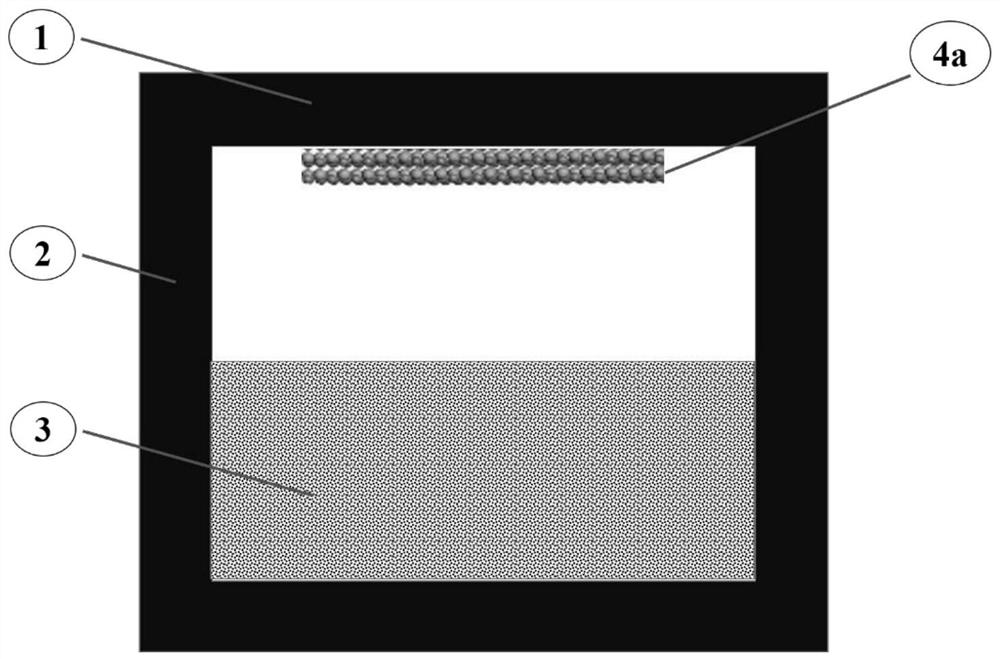

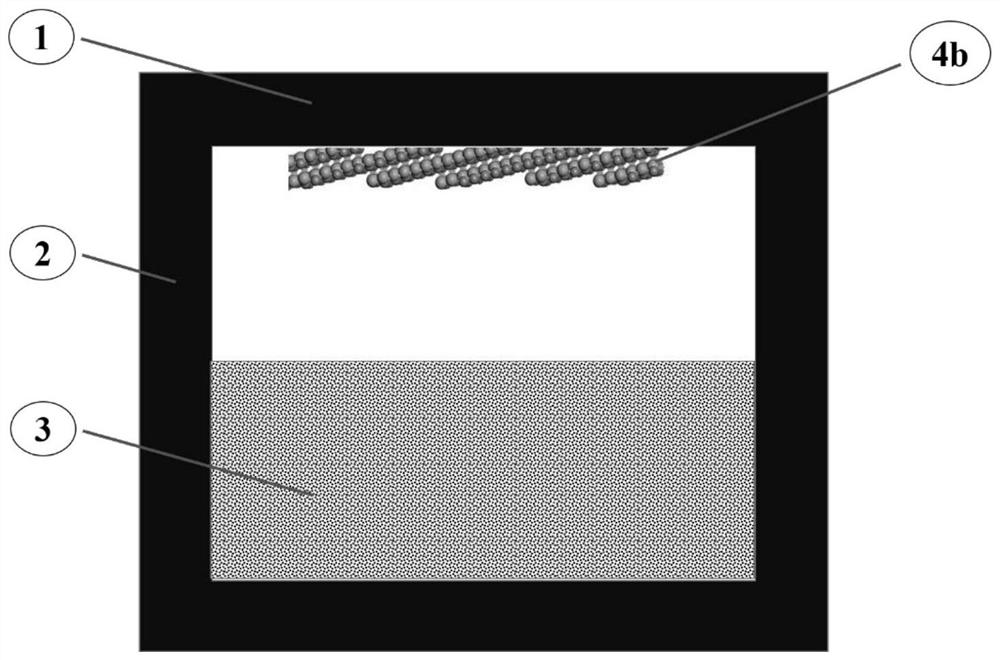

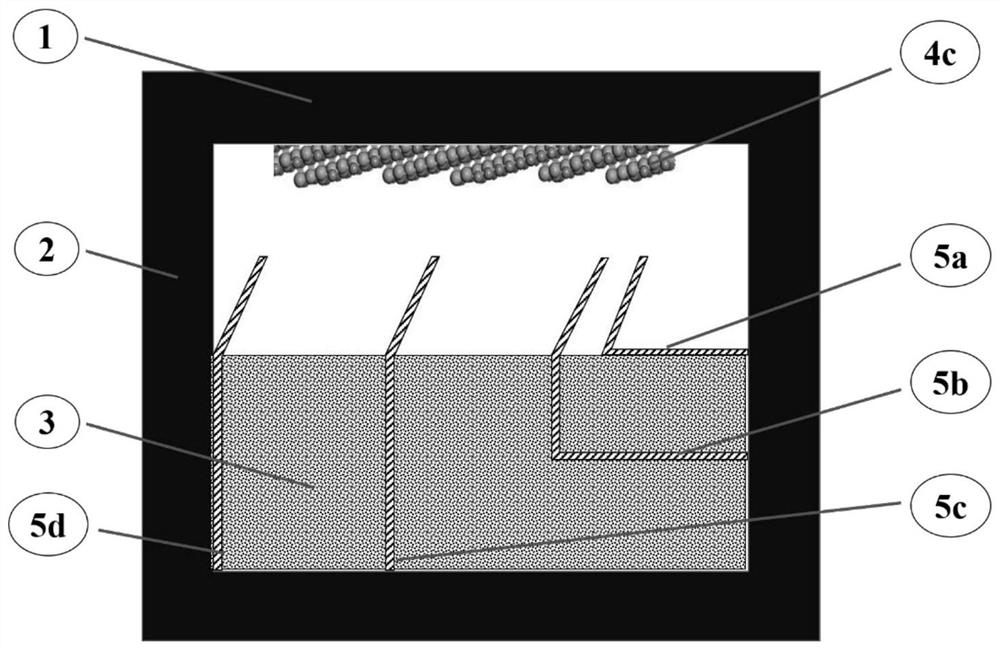

A method for preparing silicon carbide single crystal based on controllable growth center

ActiveCN110656376BImprove crystal qualityNo crackPolycrystalline material growthFrom condensed vaporsCarbide siliconNew energy

The invention discloses a method for preparing a silicon carbide single crystal based on a controllable growth center, belonging to the field of crystal growth. The present invention adjusts the transmission direction of the growth component flow and the flow density of the transport component by placing a deflected growth component flow guiding device in the powder and the growth chamber, preferentially forming a long and narrow growth center facet and keeping it at the edge of the growth surface Position, so that a balanced step flow growth mode can be maintained within the required single crystal diameter, and the crystal form of the seed crystal can be completely maintained, and finally a high-quality silicon carbide crystal with a single crystal form can be obtained. The high-quality silicon carbide single crystal prepared by the method of the present invention can be widely used in power electronics fields such as new energy electric vehicles, locomotive traction, industrial automation, uninterruptible power supplies, high-power charging piles, and energy Internet.

Owner:HEBEI SYNLIGHT CRYSTAL CO LTD +1

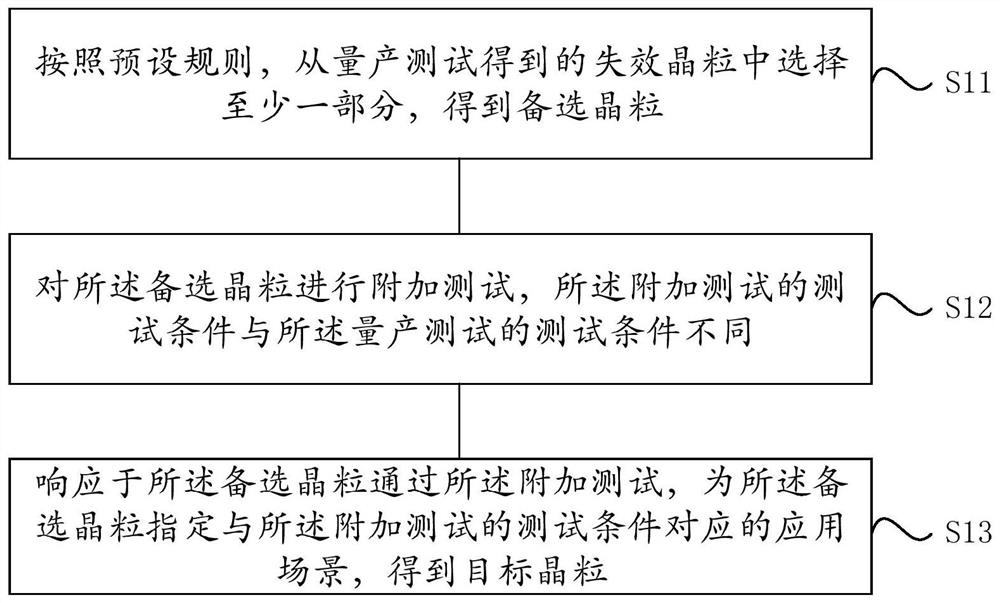

Chip testing method and device

ActiveCN113488401AImprove output yieldSemiconductor/solid-state device testing/measurementComputational physicsEngineering

The embodiment of the invention discloses a chip testing method and device, which relate to the technical field of semiconductor processing, and can effectively improve the yield of crystal grains. The method comprises the following steps of according to a preset rule, selecting at least one part of invalid crystal grains obtained by a mass production test to obtain alternative crystal grains, carrying out an additional test on the alternative crystal grains, wherein the test condition of the additional test is different from the test condition of the mass production test, and in response to the alternative crystal grain passing the additional test, appointing an application scene corresponding to a test condition of the additional test for the alternative crystal grain to obtain a target crystal grain. The method is suitable for chip testing.

Owner:HYGON INFORMATION TECH CO LTD

Anti-drifting structure for soldering tin of electronic component

InactiveCN114039219AIncrease echo resistanceBlock beyondSoldered/welded conductive connectionsElectrical connection printed elementsReflected wavesStructural engineering

The invention discloses an anti-drifting structure for soldering tin of an electronic component, which comprises a bonding pad, the tail end of the bonding pad is connected with a power-on circuit, a welding groove is formed in the bonding pad, a pin is inserted in the welding groove, and an anti-drifting assembly is arranged on the bonding pad; the anti-drifting assembly comprises an upper edge polygon, a lower edge polygon and a side edge polygon, and the upper edge polygon is arranged on the upper side face of the bonding pad. According to the anti-drifting structure for soldering tin of the electronic component, drifting, caused by reflow soldering tin, of the component on a circuit is reduced, the problem of breakage caused by stress concentration is solved, the yield of products is improved, the edge of the weld leg is designed into a polygon, the echo resistance of liquid soldering tin on the edge of the weld leg flowing outwards is increased, reflected waves can be generated; And meanwhile, the contact area of the edge of the welding pin and the pin of the component can be increased, and the opportunity of insufficient welding is avoided.

Owner:ZHUHAI HUACUI TECH CO LTD

System and method for wafer de-bonding

PendingCN113871322AAvoid problems such as dark cracksSolve problems such as dark cracksSemiconductor/solid-state device manufacturingWater bathsEngineering

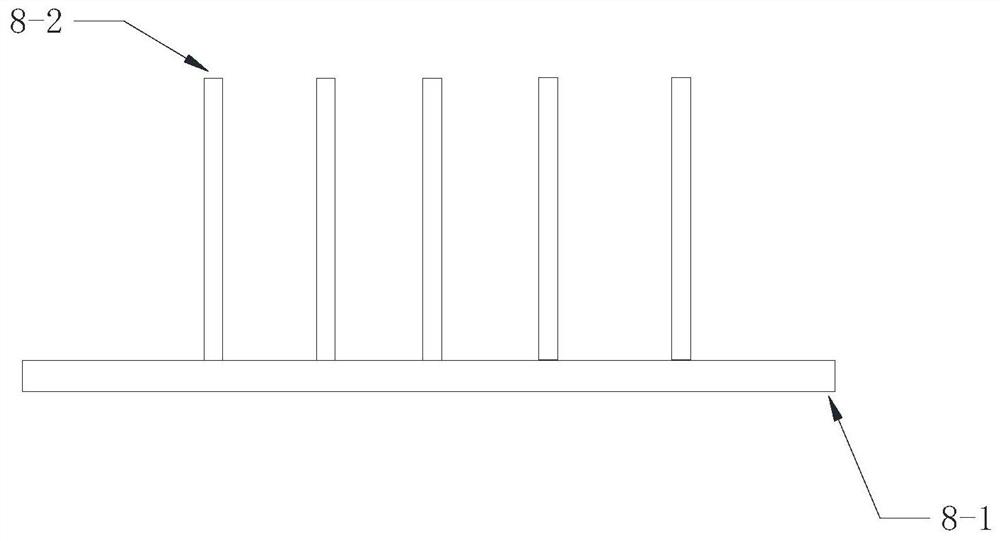

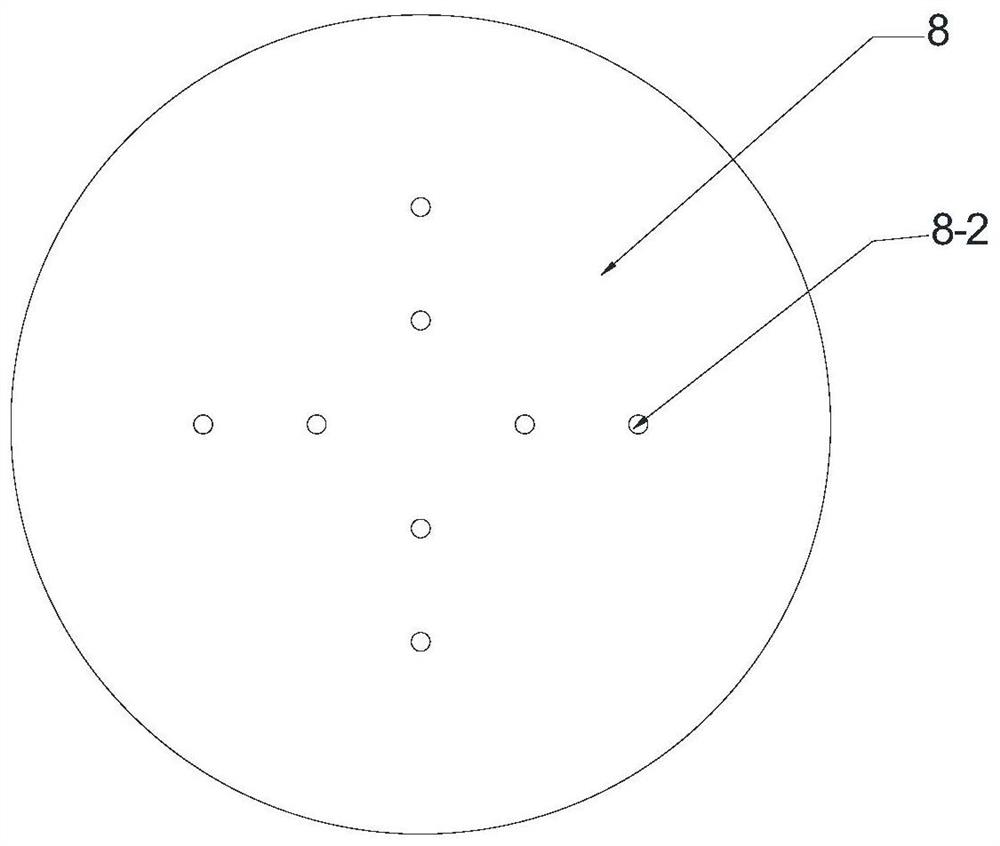

The invention discloses a system and method for wafer de-bonding. The system comprises a heating bath, a support, a de-bonding liquid tank, a wafer container and a connecting rod, wherein the heating bath is used for containing a water bath or an oil bath; the support is arranged in the heating bath; the de-bonding liquid tank is arranged on the support, and the de-bonding liquid tank is used for containing a de-bonding liquid; the wafer container is used for containing a wafer to be de-bonded, the wafer container is movable, and a plurality of holes are formed in the bottom wall and at least part of the side wall of the wafer container; and the connecting rod is used for fixing a ceramic plate of the wafer to be de-bonded. The system is simple in structure, easy to assemble and disassemble and wide in application, and can be temporarily assembled and disassembled in a normal wet process machine table slot; and in the wet de-bonding system, external force is avoided, and the problems of dark crack of the wafer and the like caused by non-uniform force output in the wafer pushing and de-bonding process after the chuck adsorption of the machine table are solved, so that the number of defective wafers is reduced, and the yield is improved.

Owner:华芯半导体研究院(北京)有限公司 +1

A nose wire intelligent feeding device and method for a mask machine

ActiveCN111774502BImprove output yieldFilament handlingMetal working apparatusInformation processingNerve network

The invention discloses a nose wire intelligent feeding device and method for a mask machine, which includes a frame, on which a nose wire feeding mechanism, a nose wire straightening mechanism, a nose wire cutting mechanism, a nose wire pushing mechanism, Nose wire clamping block and control module, the nose wire cutting mechanism includes a power crank, a cutting connecting rod, a cutting guide rail, a cutting slider, an online cutting force adjustment device and a cutter; the nose wire clamping block is equipped with a photoelectric detection sensor module, The control module is used to control the working states of the nose wire feeding mechanism, the nose wire straightening mechanism, the nose wire cutting mechanism and the nose wire pushing mechanism. In the present invention, the image information scanned by the linear CCD sensor component and the processed data of the metal signal strength information detected by the metal sensor are input into the deep convolutional neural network, so as to carry out online intelligent judgment on the pushing quality of the nose wire, and then through the control The module controls the nose wire cutting mechanism to perform corresponding operations, completes the online real-time adjustment of the cutting force of the cutter, and improves the output yield rate.

Owner:GUANGDONG HUST IND TECH RES INST

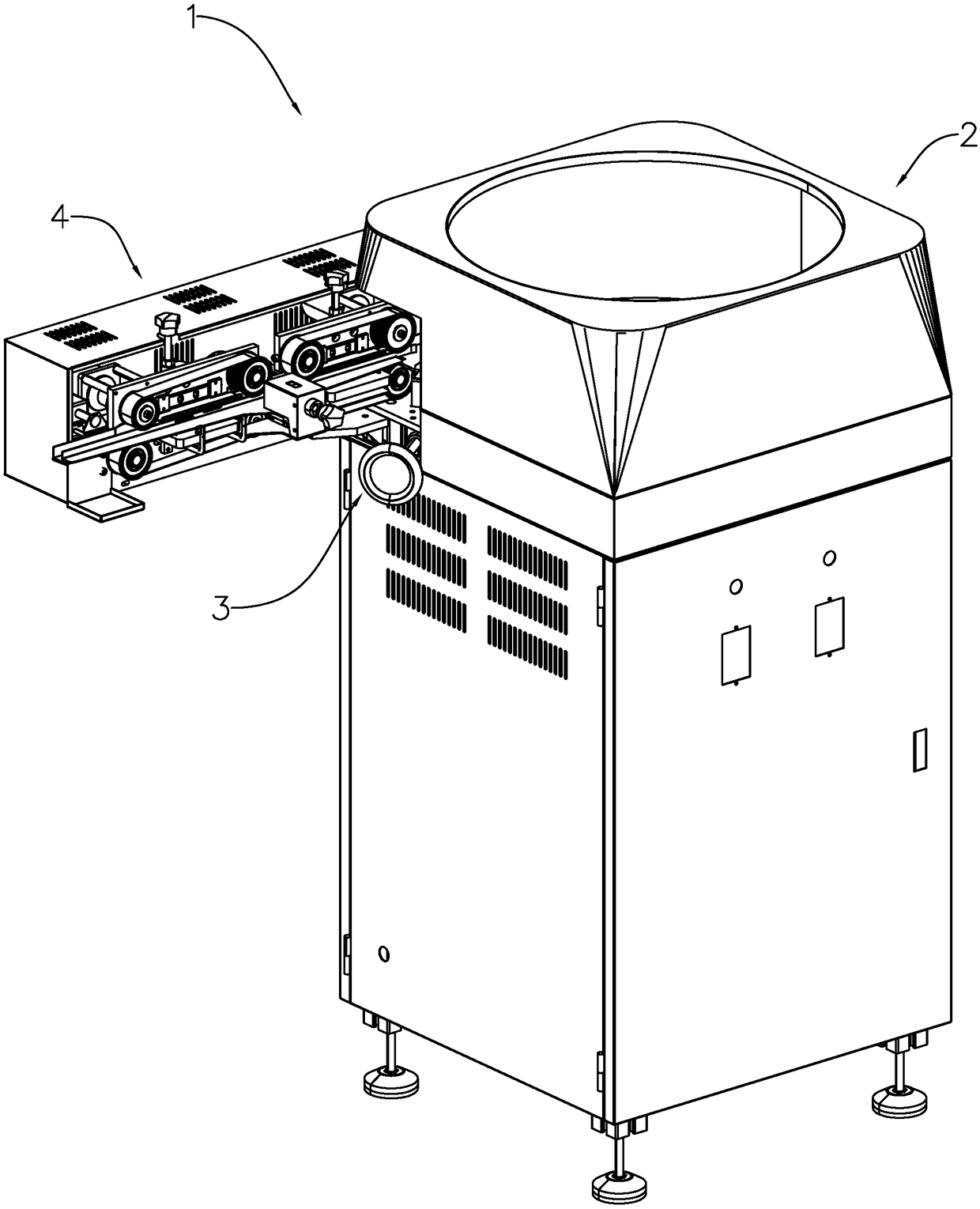

Pipe material conveying device and pipe conveying machine

PendingCN108840075AFast deliveryEfficient feedingConveyorsControl devices for conveyorsEngineeringPipe

The invention provides a pipe material conveying device and a pipe conveying machine. The pipe material conveying device comprises a first conveying assembly, a second conveying assembly and a detection assembly. The first conveying assembly and the second conveying assembly are sequentially arranged in the conveying direction. According to the first conveying assembly and the second conveying assembly, pipe materials are driven to move in the conveying direction through conveying belts. The conveying speed of the second conveying assembly is higher than that of the first conveying assembly. The detection assembly is located at the second conveying assembly and comprises a first detection unit and a second detection unit, wherein the first detection unit and the second detection unit are arranged in the conveying direction. The first detection unit and the second detection unit each face the conveying belt of the second conveying assembly. A pipe material detection distance is formed between the first detection unit and the second detection unit. The pipe materials are spaced by a certain distance through the speed difference, and furthermore, each pipe material is detected; the detection mode is that the two detection units are arranged in the conveying direction, and furthermore, dimension detection of the pipe materials is conducted in the conveying process of the second conveying assembly; and thus, the output yield is increased.

Owner:ZHUHAI ZHONGYA PACKAGE EQUIP

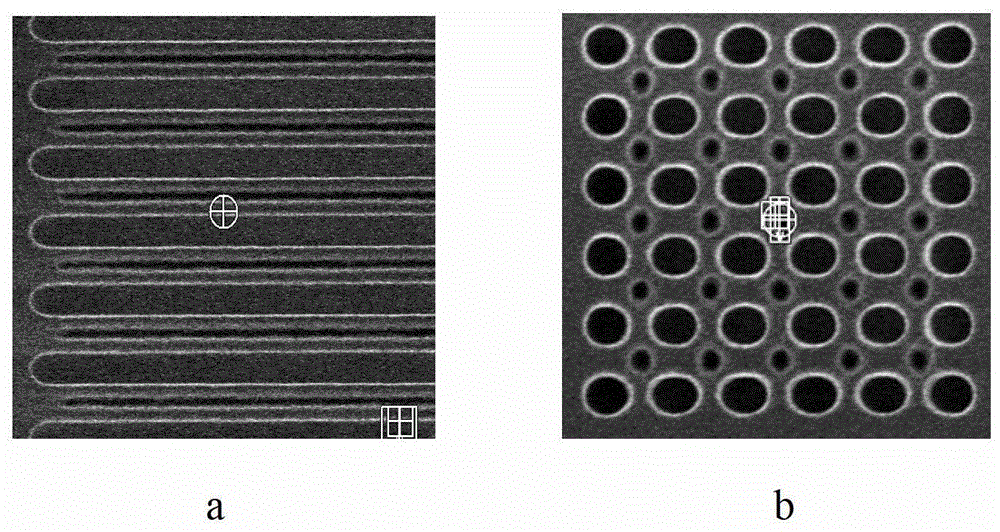

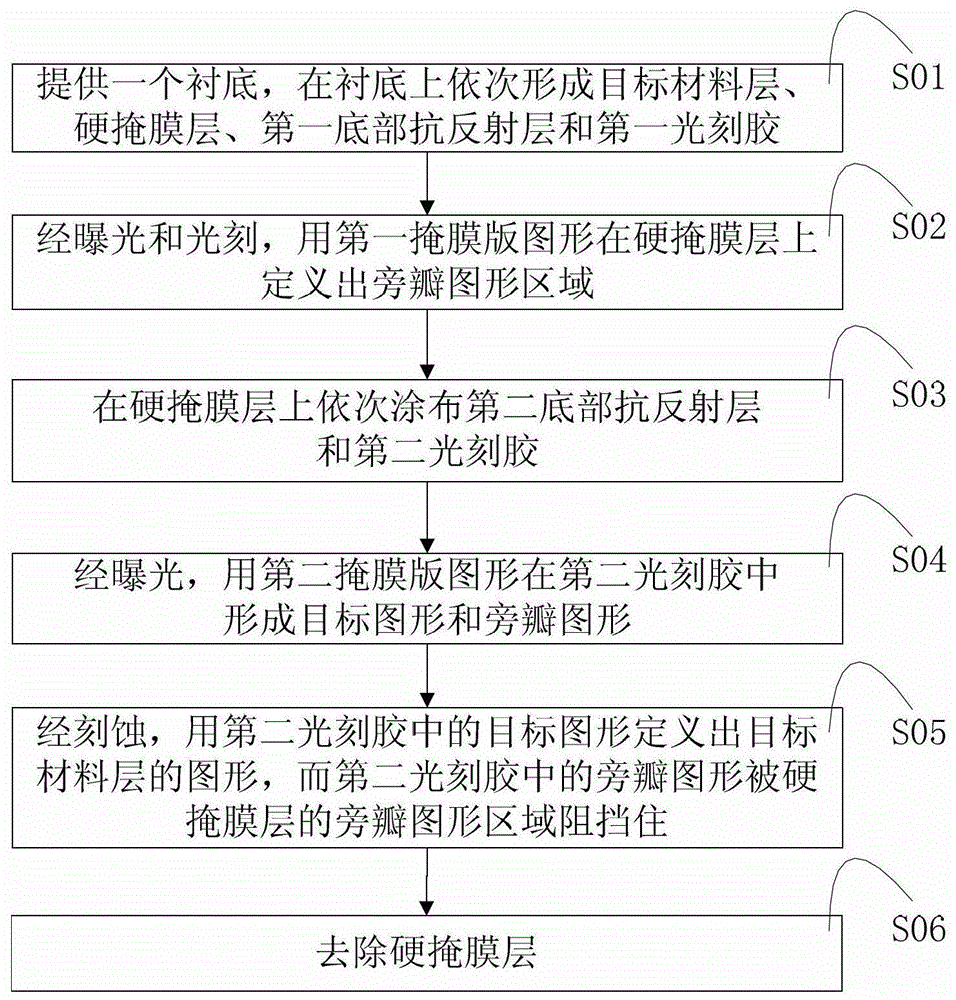

A Method of Eliminating Sidelobe Graphics

ActiveCN103050383BGuaranteed accuracyAvoid failurePhotomechanical apparatusSemiconductor/solid-state device manufacturingEtchingEngineering

The invention provides a method for eliminating a side lobe pattern. The method comprises the following steps of: providing a substrate, and forming a target material layer, a hard mask layer, a first bottom anti-reflection layer and a first photoresist on the substrate in sequence; exposing, performing photo-etching, and defining a side lobe pattern area on the hard mask layer by using a first mask pattern; coating a second bottom anti-reflection layer and a second photoresist on the hard mask layer in sequence; exposing, and forming a target pattern and a side lobe pattern in the second photoresist by using a second mask pattern; etching, defining a pattern of the target material layer by using a target pattern in the second photoresist, and blocking the side lobe pattern in the second photoresist through the side lobe pattern area of the hard mask layer; and removing the hard mask layer. Due to the adoption of the method, the side lobe pattern is effectively blocked on the hard mask layer, the side lobe pattern is eliminated from the pattern of the target material layer, the accuracy of a patterning process is ensured, circuit failures caused by the side lobe pattern are avoided, and the yield is further increased.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT

Vibration measurement component with precise positioning device for motion sensing parts in height direction

ActiveCN113607263BHigh installationReduce biasSubsonic/sonic/ultrasonic wave measurementUsing electrical meansVibration measurementMotion sensing

The invention discloses a vibration measurement assembly with a precise positioning device for a motion sensing element in the height direction, comprising: a body having a reference plane and an orthogonal setting plane perpendicular to the reference plane, the orthogonal setting plane has a plurality of distances away from each other The insertion port, and the distance between the insertion ports corresponds to the outer dimension of the above-mentioned motion sensing element in the height direction; the circuit board of the motion sensing element in the height direction is electrically welded; the positioning device includes: the plural shapes are respectively complementary to the insertion ports and a fixing unit whose size is not smaller than the above-mentioned corresponding insertion port, for being tightly coupled to the corresponding insertion port; and a pressing base extending from the fixing unit, having a butt surface close to the body and a back surface opposite to the abutment surface, the butt surface There is an abutting part on the top, which is used for abutting and holding the circuit board together with the above-mentioned height direction motion sensing element between the pressing base and the main body.

Owner:新力奇有限公司

OLED display module, display device and preparation method of the display module

ActiveCN106601141BGuaranteed sizeReduce Design RiskStatic indicating devicesIdentification meansFlexible circuitsDisplay device

Provided are an OLED display module and a manufacturing method thereof. The OLED display module comprises an OLED display screen (20) and a driver chip (21). The OLED display screen (20) is provided with a display signal input end (22). The driver chip (21) is fixed to a back surface of the OLED display screen (20) and is provided with a driving signal output end (211). Signals outputted by the driving signal output end (211) are led from at least two ends of the driver chip (21) and eventually inputted to the display signal input end (22). The OLED display module having the above structure can reduce design risk and increase yield.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

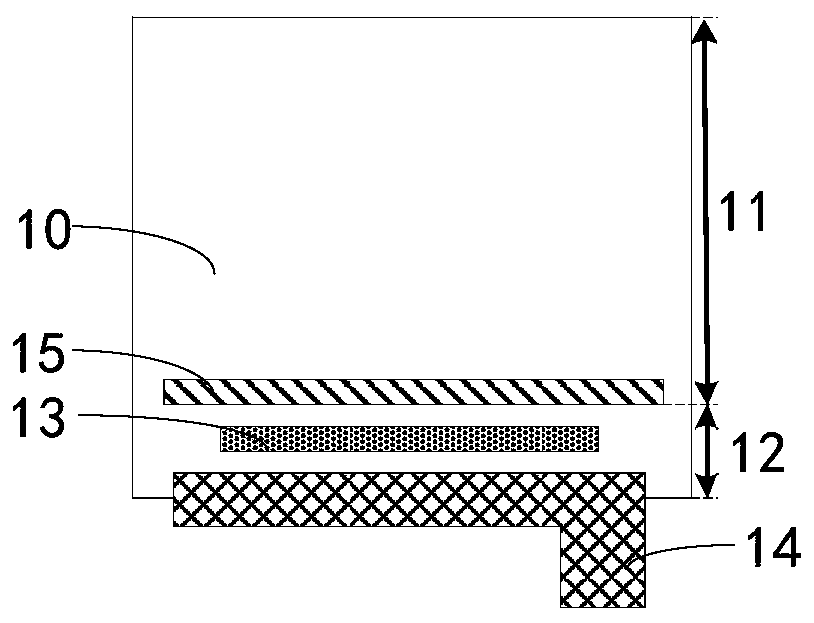

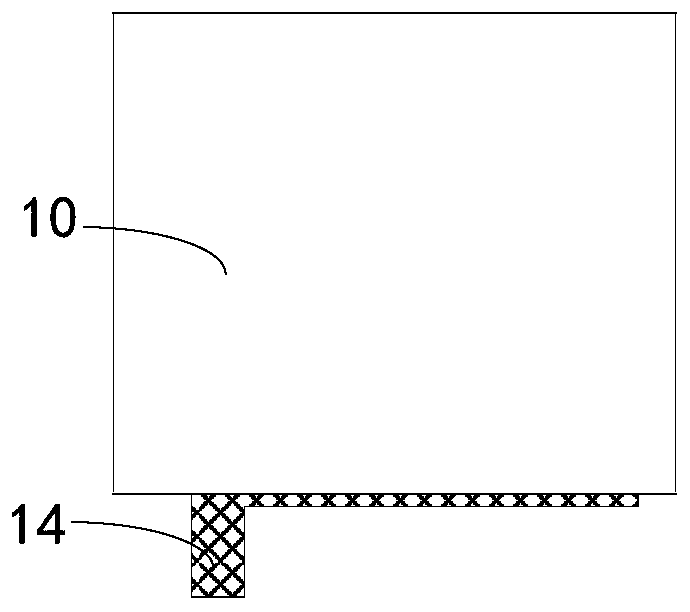

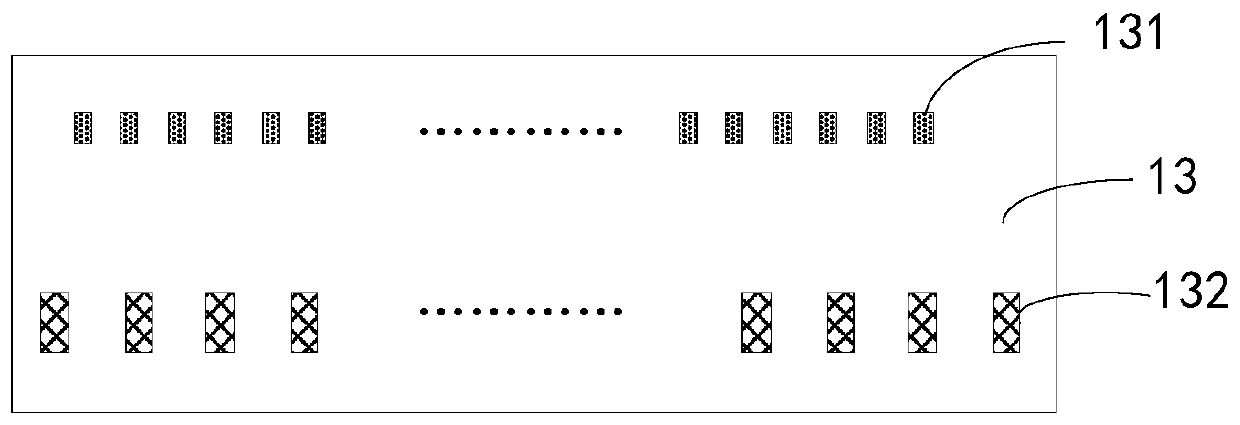

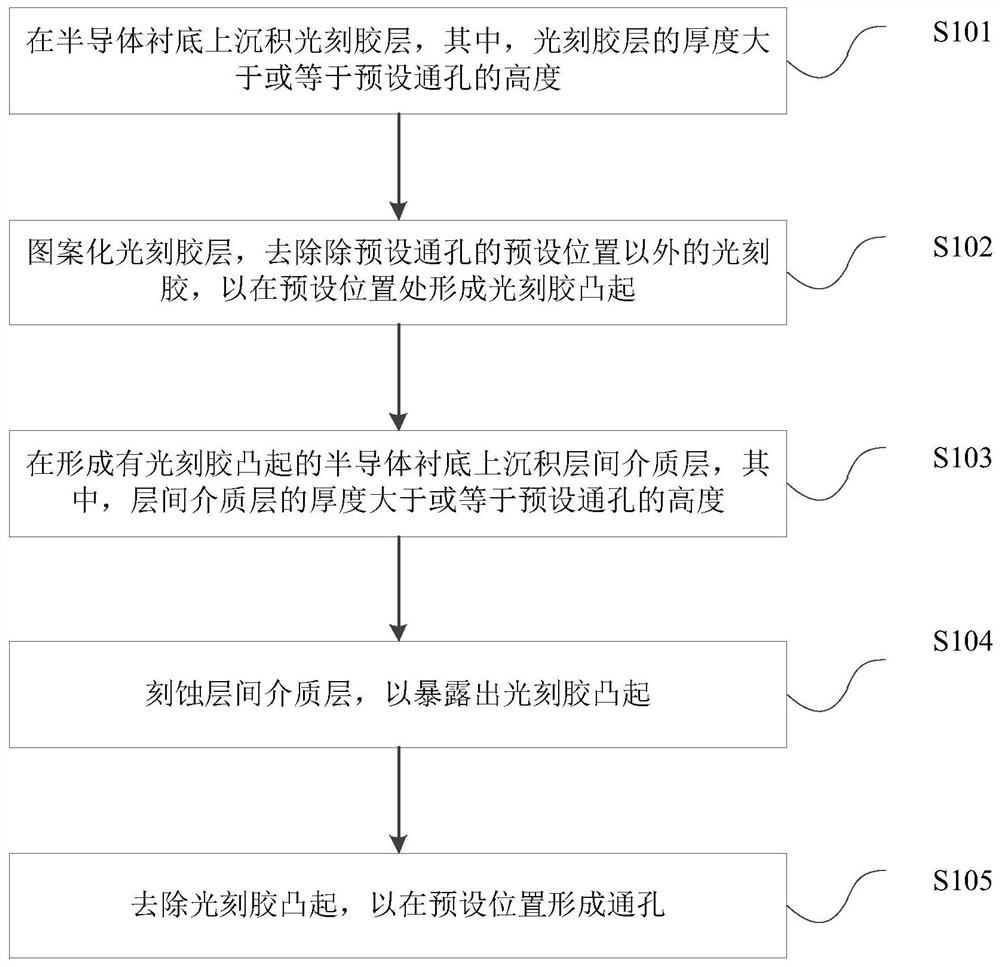

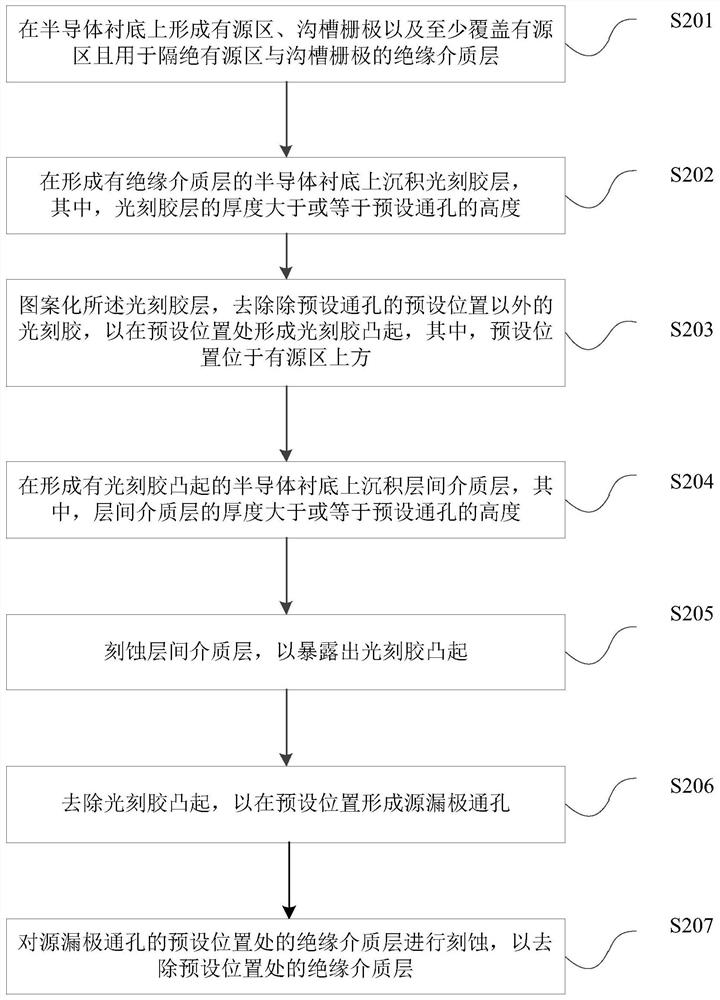

Through hole forming method

InactiveCN112701080AGood lookingImprove output yieldSemiconductor/solid-state device manufacturingDevice materialPhysical chemistry

The invention discloses a through hole forming method. The method comprises the following steps of: depositing a photoresist layer on a semiconductor substrate, removing photoresist except a preset position of a preset through hole by patterning the photoresist layer, forming a photoresist bulge at the preset position of the through hole, and depositing an interlayer dielectric layer to cover the semiconductor substrate on which the photoresist bulge is formed; and etching the deposited interlayer dielectric layer until exposing the photoresist bulge; and finally, removing the photoresist to form the through hole at the preset position. The position of the through hole which is directly formed in the interlayer dielectric layer by etching in the prior art is covered by the photoresist in advance, so that a certain aperture ratio is ensured, the shape of the through hole is improved, subsequent metal filling is facilitated, electric leakage can be reduced, the output yield of a semiconductor device is increased, and the performance of the semiconductor device is improved.

Owner:GREE ELECTRIC APPLIANCES INC

Tooling frame able to adhere to tin

InactiveUS6951299B2Improve output yieldSave labor costPrinted circuit assemblingWelding/cutting auxillary devicesSolderingEngineering

A tooling frame with an ability to adhere to tin is disclosed, which is a frame structure used to support a circuit board passing through a stannic furnace to be soldered. The tooling frame is characterized in that a tin adhesive apparatus having a tin adhesive material is mounted at an appropriate location of the tooling frame so as to suck surplus tin on said circuit board both after the circuit board is transported through the stannic furnace for tin filling and during tin shedding and to improve quality of soldering.

Owner:PEGATRON

Voltage calibration circuit and its programming equipment

ActiveCN106125809BAccurate programming voltage parametersImprove output yieldStatic indicating devicesSoftware simulation/interpretation/emulationControl signalHemt circuits

The embodiment of the invention discloses a voltage calibration circuit and burning equipment thereof. The circuit comprises a sampling module, a switch module, a processing module and an output voltage control module. A sampling device of the sampling module is used for comparing an input reference voltage received by the input end with an input voltage and then outputting a corresponding control signal to the switch module; the switch module is used for communicating a path between the sampling module and the processing module when a control signal is a communication control signal; the processing module is used for obtaining the input voltage and the output reference voltage and generating the pulse signal according to the obtained input voltage and the output reference voltage; the output voltage control module is used for generating the accurate burning output voltage on the basis of the control pulse signal provided by the processing module and then obtaining the accurate burning input voltage after switching of a switching device so as to provide the burning input voltage for a display panel. The voltage calibration circuit and the burning equipment thereof can provide the accurate burning voltage parameter for the display panel and ensure the reliability of the burning process.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com