OLED display module, display device and preparation method of the display module

A technology for display modules and display screens, which is applied to identification devices, static indicators, instruments, etc., can solve the problems of lowering the yield rate of display modules and increasing the difficulty of design of display modules, so as to reduce design risks and ensure size, and the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

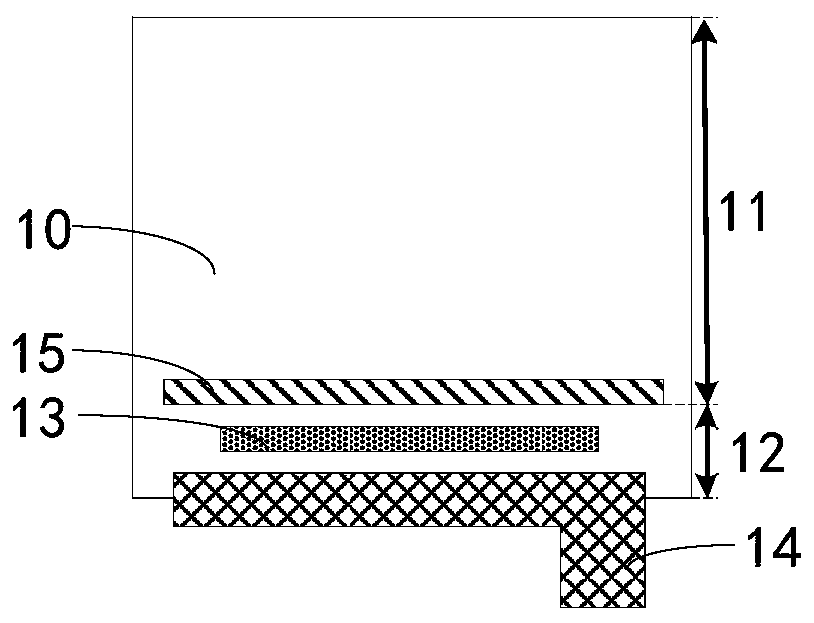

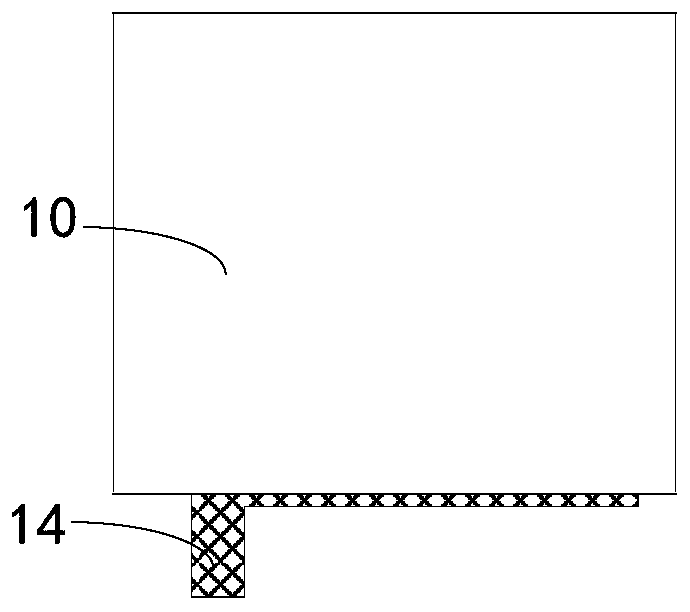

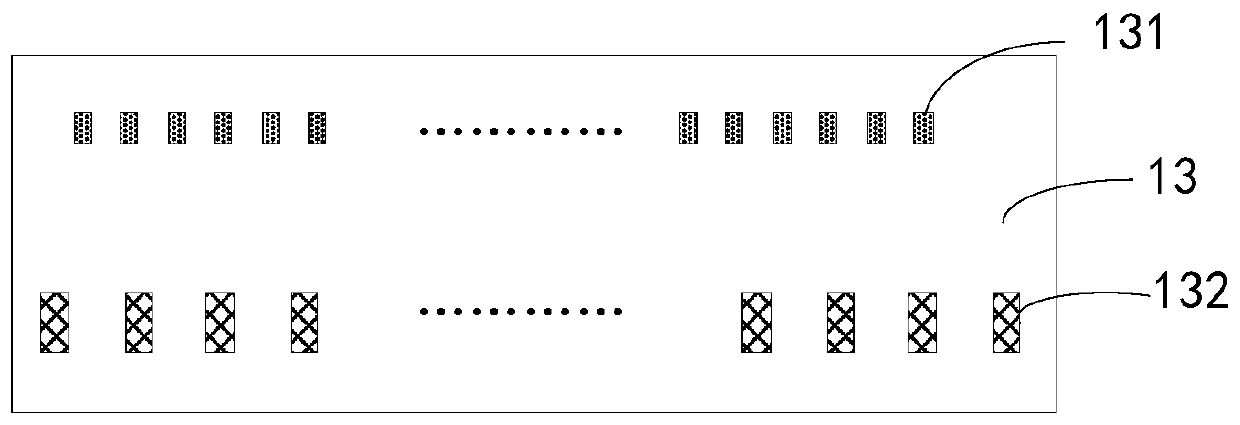

[0030] refer to Figure 3A and Figure 3B , in the first embodiment of the present invention, the OLED display module includes: an OLED display 20 , a source input terminal 21 , a conductive coating 22 , a driver chip 23 and a flexible circuit board 24 .

[0031] A source input terminal 21 is provided on the front of the OLED display 20 . In this embodiment, the source input terminal 21 includes a first source input terminal 211 and a second source input terminal 212, and the first source input terminal 211 and the second source input terminal 212 are arranged oppositely, which are located on the OLED display The upper and lower ends of the screen 20. It can be understood that, in other embodiments, the first source input terminal 211 and the second source input terminal 212 may also be located at opposite left and right ends of the OLED display 20 .

[0032] The conductive coating 22 is located on the back of the OLED display 20 , and the conductive coating 22 is electrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com