Method for identifying and positioning flexible printed circuit (FPC) board plug

A technology for identifying positioning and plugs, applied in the field of identification and positioning, can solve the problems of low qualified rate of finished products and unsatisfactory cutting accuracy of plugs, etc., and achieve the effect of high qualified rate of finished products, improving cutting deviation and ensuring accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

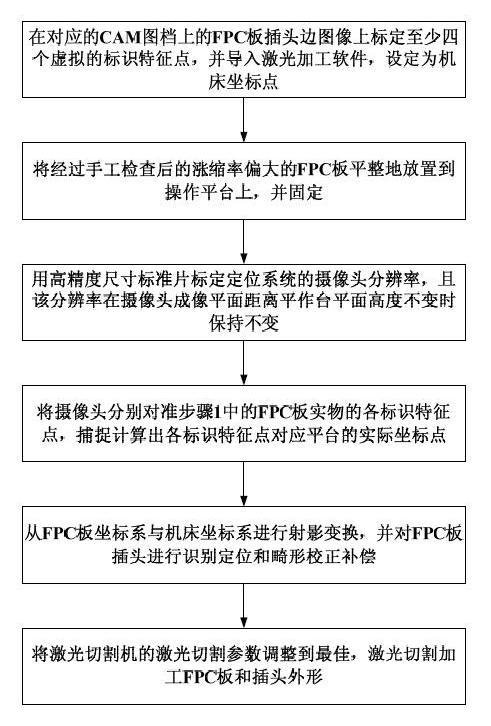

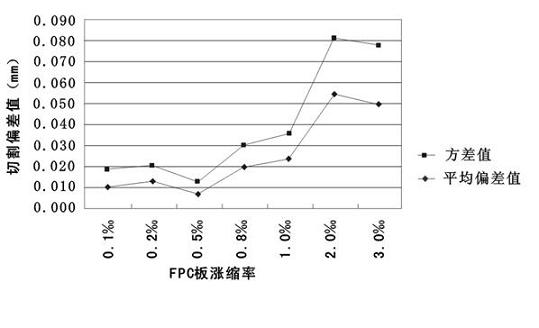

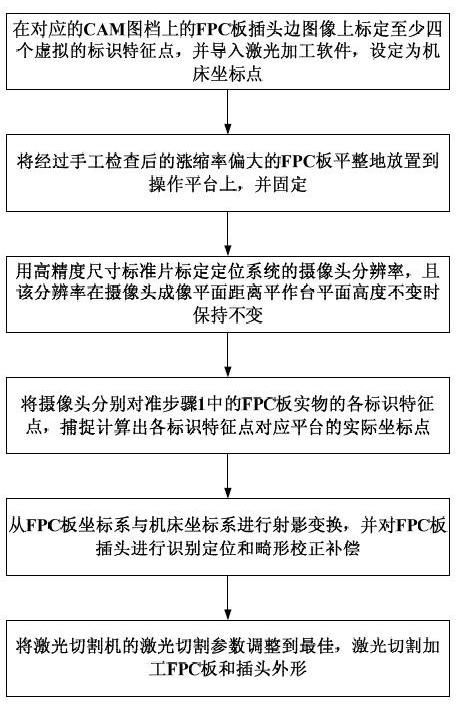

[0021] The gist of the present invention is to overcome the deficiencies of the prior art and provide a method for identifying and locating FPC board plugs. By using the CCD image recognition plug algorithm, the plug edge is used as a positioning reference point to perform distortion correction and compensation, thereby ensuring cutting accuracy. Capturing the feature points of various plugs with different shapes, and correspondingly transforming them into the coordinate system of the machine tool to complete the positioning. After applying the FPC board plug identification and positioning technology, the dimensional accuracy of the laser-cut plugs can be guaranteed, and the qualified rate of finished products is high.

[0022] The following will describe in detail with reference to the accompanying drawings in conjunction with the embodiments, so as to further explain the technical features and advantages of the present invention.

[0023] Method flow chart of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com