Cutting blade for machining screw thread

A technology for threading and inserting, applied in the field of indexable threading inserts, can solve the problems of easily damaged tools and inserts, can not be used as CNC machining, damage the machined surface, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

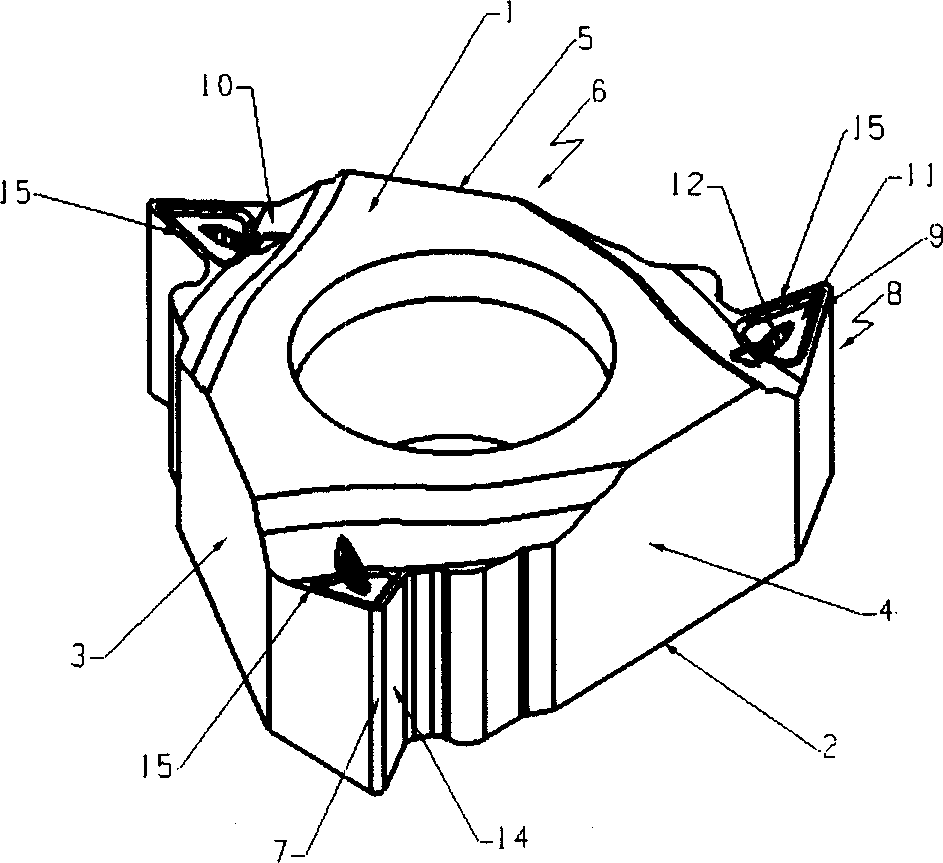

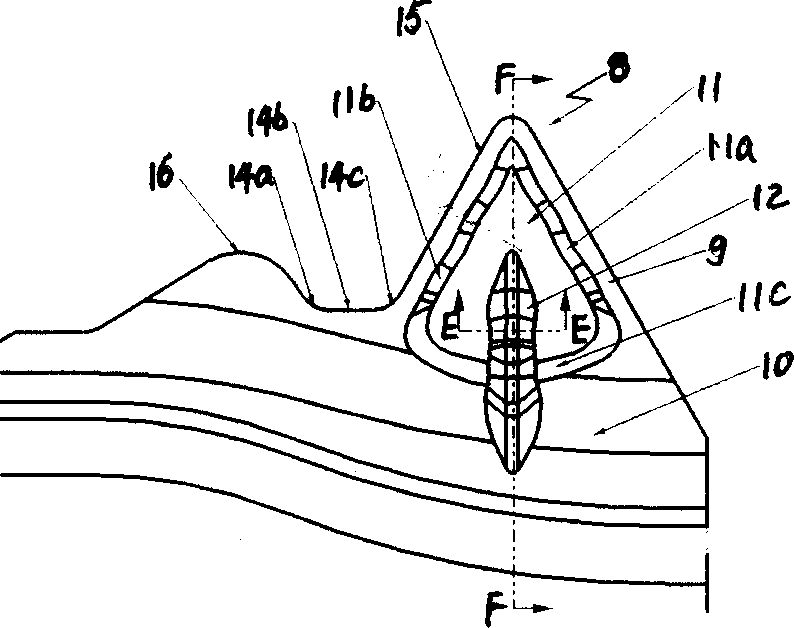

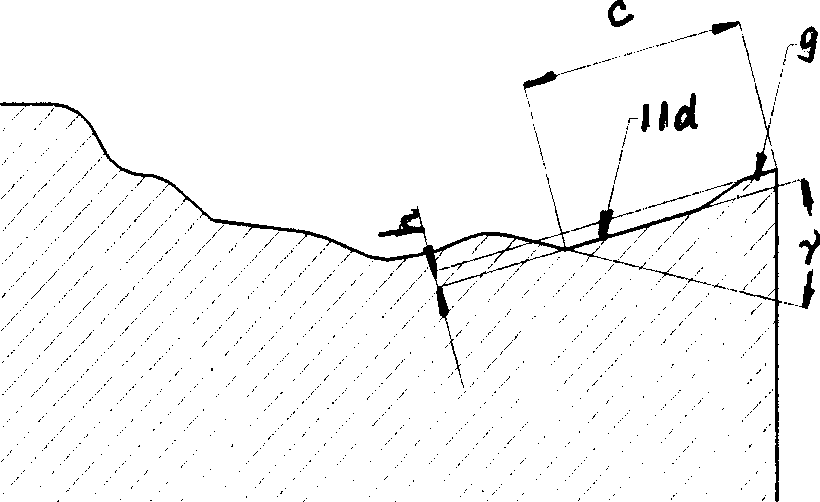

[0020] Such as Figure 1 to Figure 4 As shown, the indexable threading insert of the present invention comprises an insert body 6 and a cutting edge angle 8 composed of an upper surface 1, a lower surface 2 and three groups of side surfaces 3, 4, 5 connecting the above two surfaces; The side faces of the group are connected by arc surfaces 7 and form a cutting edge angle 8; the top surface of each cutting edge angle is a blade rake face 9 formed by a plane with the same angle with the upper and lower surfaces 1 and 2, and Three sets of side faces 3, 4, 5 intersect to form three cutting edges 15 respectively, and a wiper edge 14 is designed on one side of each cutting edge 15; the rake face 9 is connected with the blade body 6 through an arc surface 10; A fan-like groove 11 is designed in the rake face 9, and its angle bisector is located on the angle bisector of the cutting edge angle 8. The two side walls 11a, 11b of the groove 11 are wavy curved surfaces; the blade is also d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com