Through hole forming method

A photoresist and preset position technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of affecting the metal filling effect, difficult to control the etching morphology, and insufficient etching amount, etc., to achieve increased The effect of output yield, improvement of semiconductor device performance, and improvement of morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

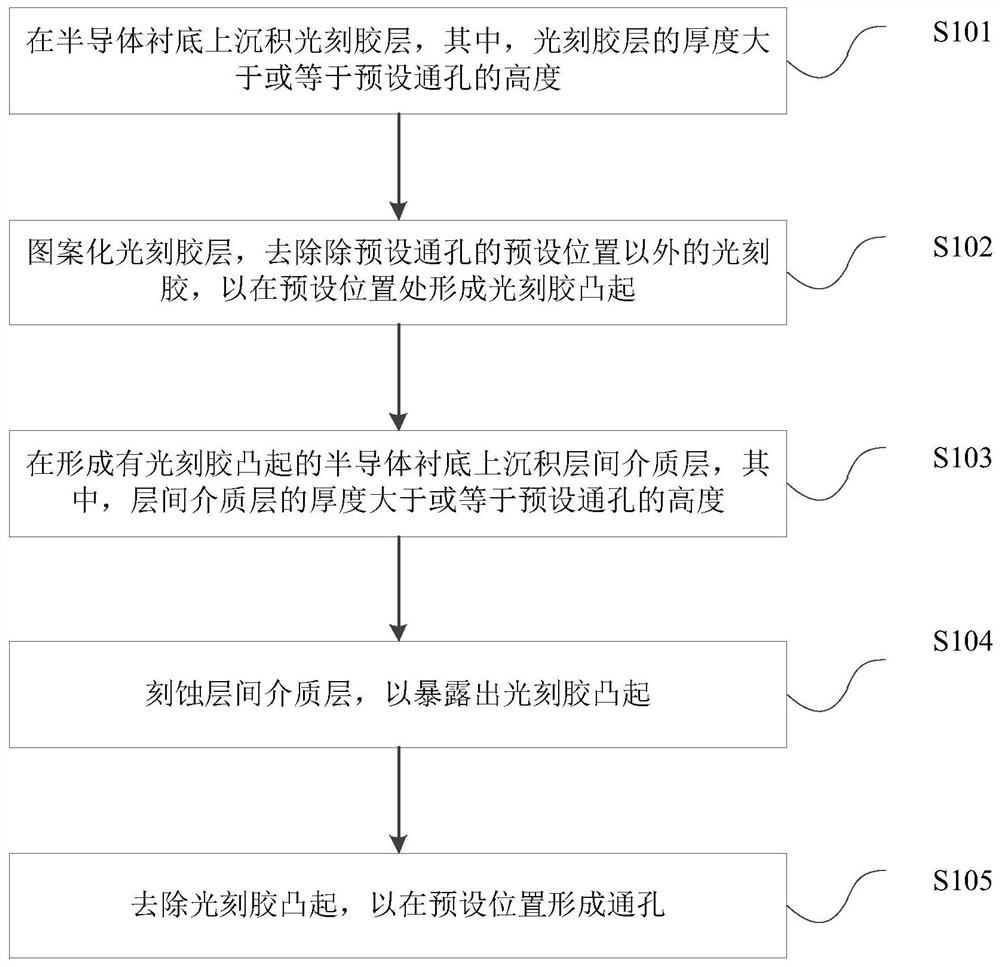

[0048] see figure 1 as shown, figure 1 It is a schematic flowchart of a method for forming a through hole provided in the embodiment of the present application, including step S101 to step S105.

[0049] In step S101 , a photoresist layer is deposited on the semiconductor substrate, wherein the thickness of the photoresist layer is greater than or equal to the height of the predetermined via hole.

[0050] This step can be to deposit a photoresist layer with a uniform thickness on the semiconductor substrate by spin coating. After the photoresist layer is formed, the photoresist layer can also be pre-baked to improve the photoresist layer in the subsequent exposure process. The exposure accuracy of the adhesive layer.

[0051] Wherein, since the photoresist layer needs to be able to form a photoresist protrusion at the preset position of the preset through hole in advance, the deposition thickness of the photoresist layer needs to be greater than or equal to the height of th...

Embodiment 2

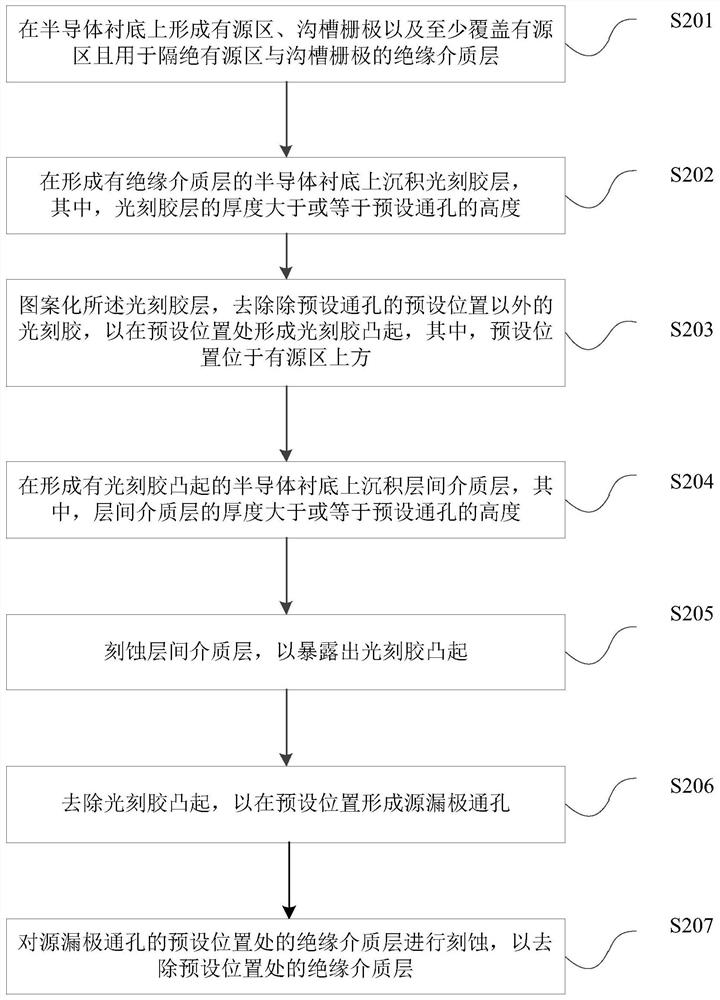

[0065] figure 2 It shows a schematic flowchart of the method for manufacturing semiconductor source-drain through holes provided by Embodiment 2 of the present application, including steps S201 to S207.

[0066] In step S201 , an active region, a trench gate, and an insulating dielectric layer covering at least the active region and used to isolate the active region and the trench gate are formed on a semiconductor substrate.

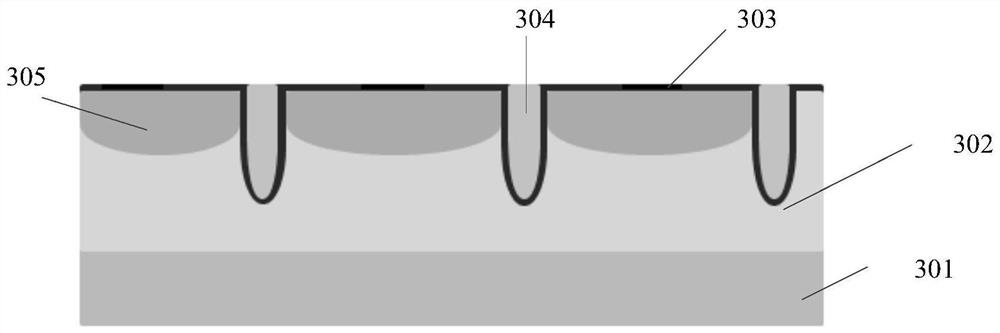

[0067] As an example, referring to FIG. 3(1), this step may specifically include providing a semiconductor substrate 301, growing an epitaxial layer 302 on the semiconductor substrate 301, and forming an epitaxial layer 302 by dry etching or wet etching. The groove of gate is formed on the layer 302, adopts chemical vapor deposition or the method of oxidizing the substrate to form a layer of insulating dielectric layer 303 covering the sidewall of the gate trench and the surface of the substrate, and the insulating dielectric layer 303 covered with Ma...

Embodiment 3

[0088] see Figure 4 , Figure 4A schematic flowchart of a method for manufacturing a semiconductor gate through hole provided by an embodiment of the present application is shown, including steps S401 to S406.

[0089] In step S401 , an active region, a trench gate, and an insulating dielectric layer covering at least the active region and used to isolate the active region and the trench gate are formed on a semiconductor substrate.

[0090] In step S402, a photoresist layer is deposited on the semiconductor substrate on which the insulating medium layer is formed, wherein the thickness of the photoresist layer is greater than or equal to the height of the predetermined via hole.

[0091] In this embodiment of the present application, steps S401 to S402 may be the same as steps S201 to S202 in Embodiment 2, and for the sake of brevity, details are not repeated here.

[0092] In step S403, the photoresist layer is patterned, and the photoresist is removed except the preset p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com