Detection device and detection method for binding impedance of display screen

A technology of impedance detection and display screen, which is applied in the direction of impedance measurement, etc., can solve problems such as cost pressure, bonding process pressure is difficult to control, and large data errors, so as to save labor costs and improve the yield of bonding output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

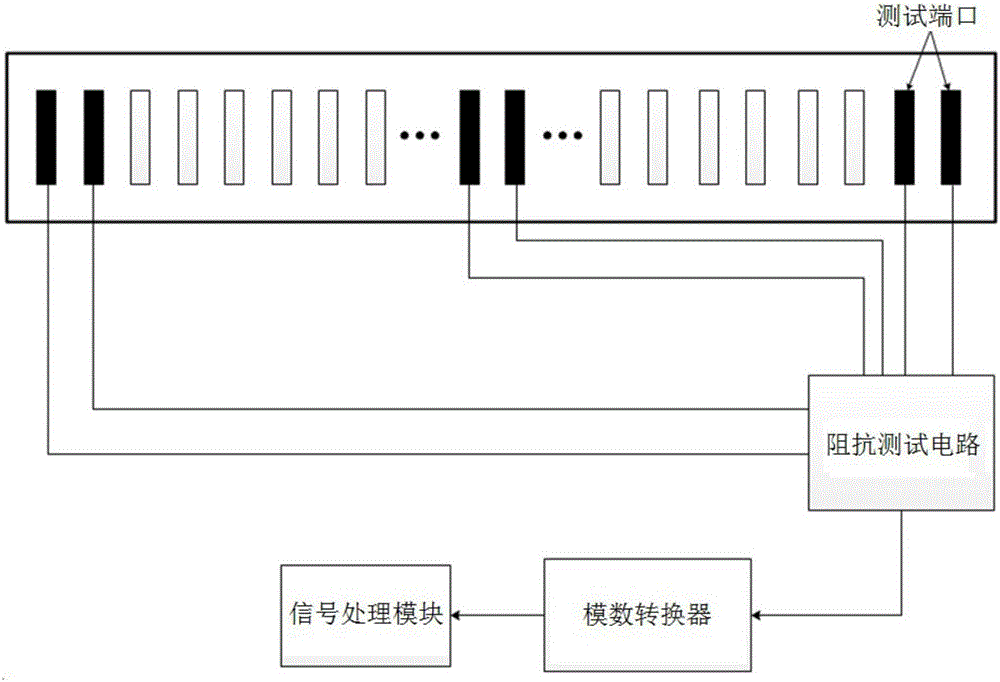

[0037] figure 1 is a schematic diagram of the device of this embodiment. Such as figure 1 As shown, the device includes:

[0038] Test port. The test port is preset at the binding end of the screen, and the impedance between the two test ports is the bonding impedance between the two test ports. The test ports are preferably evenly distributed at the binding end of the screen, and two adjacent test ports form a pair of test ports; when the bonding impedance is uniform, the impedance between each pair of test ports is also uniform.

[0039] Since impedances are to be compared, at least three test ports are required to provide at least two impedance test results for comparison.

[0040] The unit also includes:

[0041] Impedance test circuit. The impedance test circuit is used to test the impedance between the test ports, convert the impedance into an electrical signal and send it to the signal processing module.

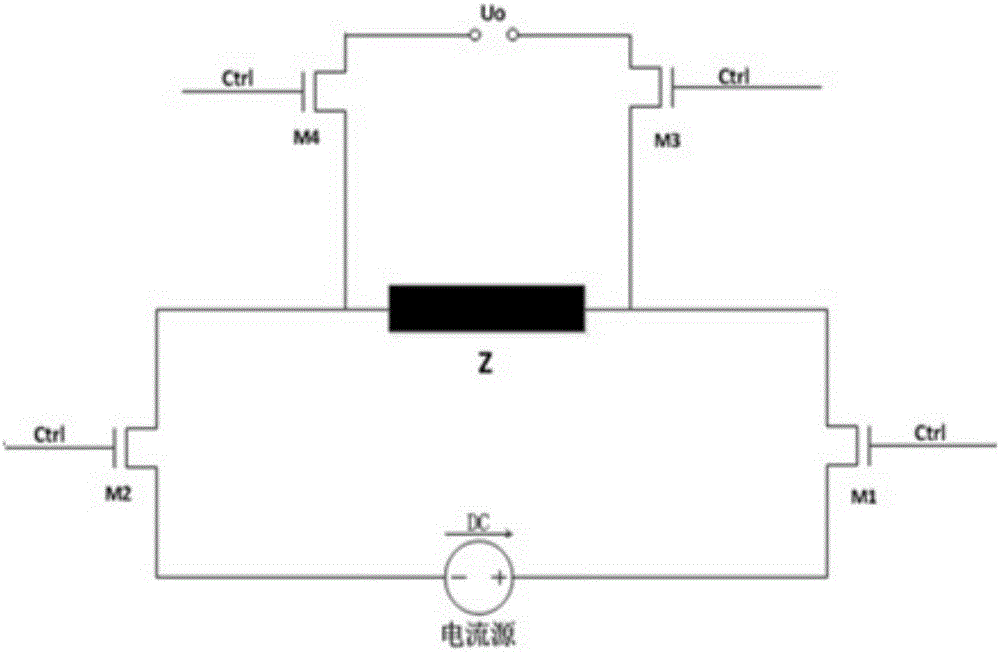

[0042] A typical impedance test circuit such as figure ...

Embodiment 2

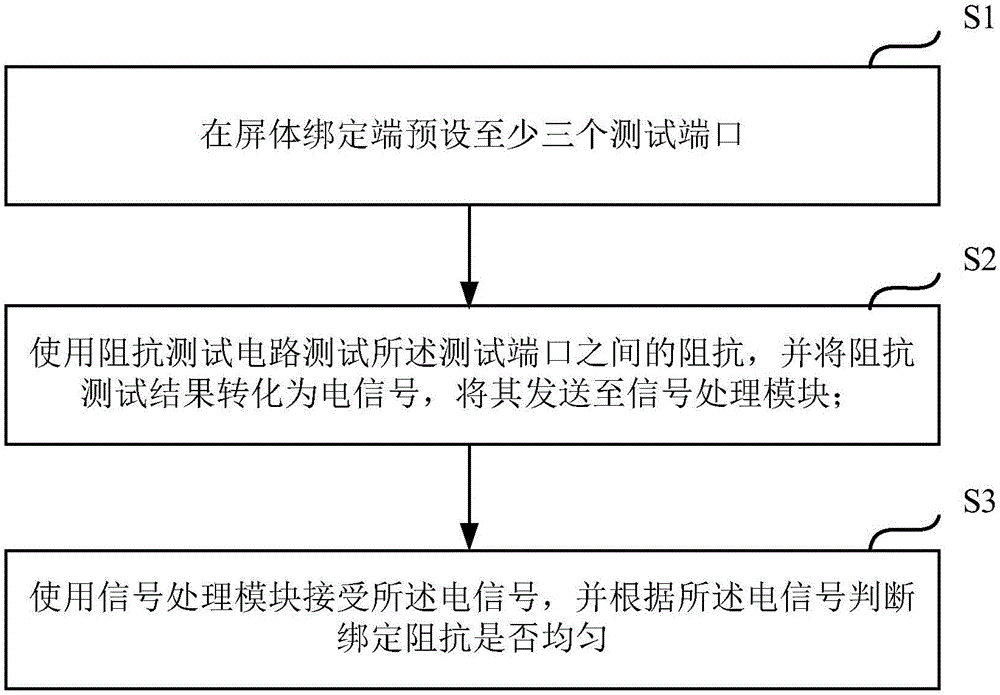

[0051] Based on the detailed analysis above, the embodiment of the present invention also proposes a display binding impedance detection method such as image 3 As shown, the method includes:

[0052] Preset test ports at the screen binding end, the number of the test ports is greater than or equal to three (step S1);

[0053] Use an impedance test circuit to test the impedance between the test ports, and convert the impedance test result into an electrical signal, and send it to the signal processing module (step S2);

[0054] Using a signal processing module to receive the electrical signal, and judge whether the binding impedance is uniform according to the electrical signal (step S3).

[0055] Preferably, in this embodiment, the following method is used to test the impedance between the test ports, and the impedance test result is converted into an electrical signal, which is sent to the signal processing module:

[0056] providing a current source connected to the test ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com