A method for preparing silicon carbide single crystal based on controllable growth center

A technology of silicon carbide single crystal and silicon carbide seed is applied in the field of preparing silicon carbide single crystal based on a controllable growth center, which can solve the problems of increasing the probability of crystal cracking, reducing the yield of single crystal, and non-uniform polymorphism, and achieving Small internal stress, improved electrical uniformity, and small residual internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

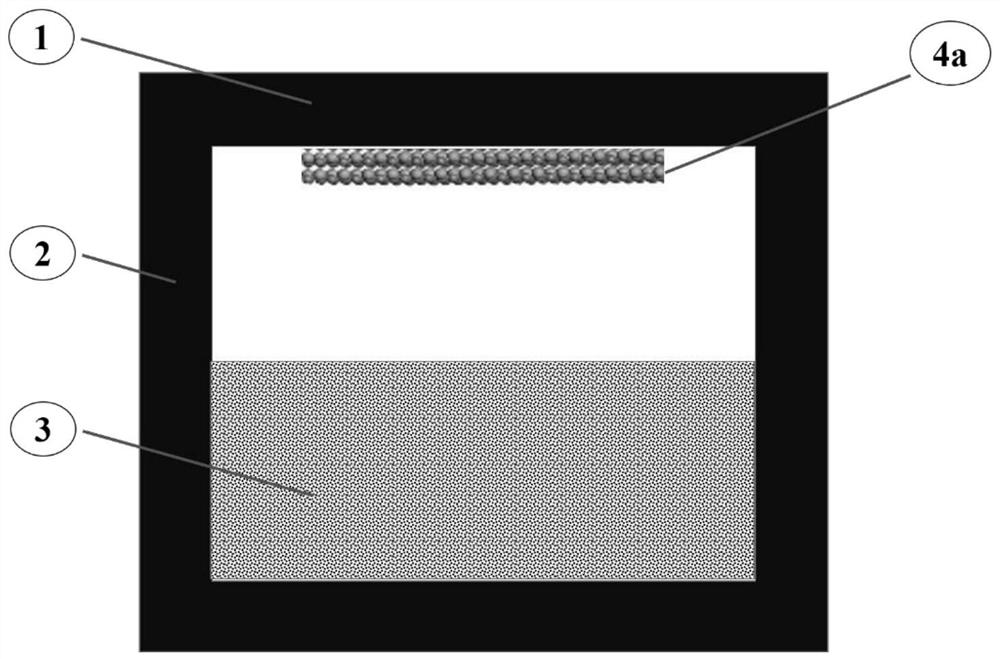

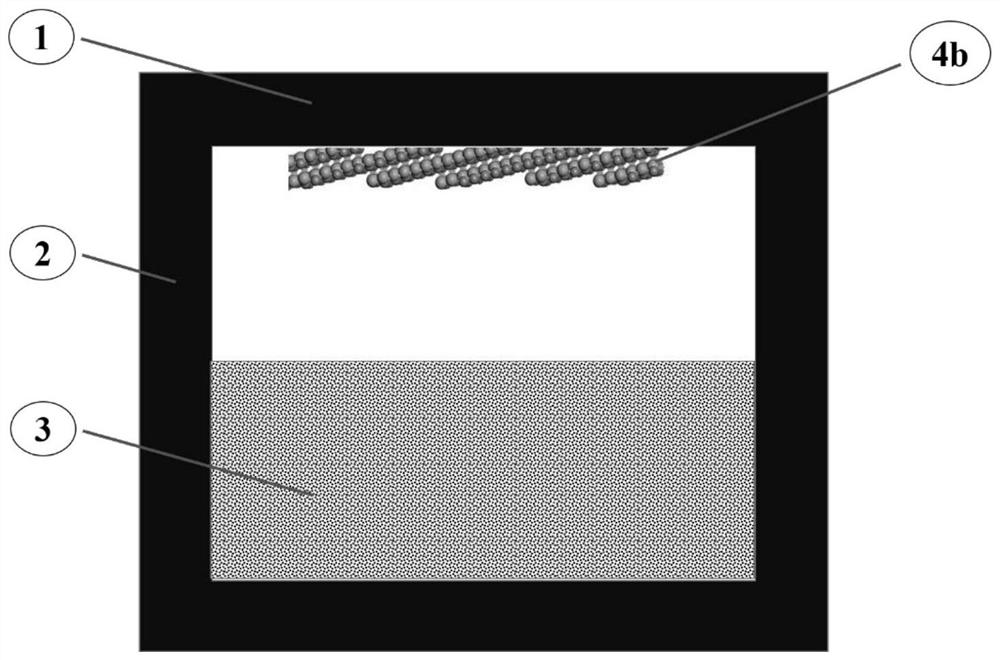

[0055] (1) Grinding and polishing a 4-inch silicon carbide seed crystal with a large diameter of 4° (diameter 105 mm) on both sides, so that the surface roughness is less than 0.3 nm and the flatness is 10 μm, and a silicon carbide seed crystal with a thickness of 500 μm is obtained. Then the surface is cleaned and packaged for use.

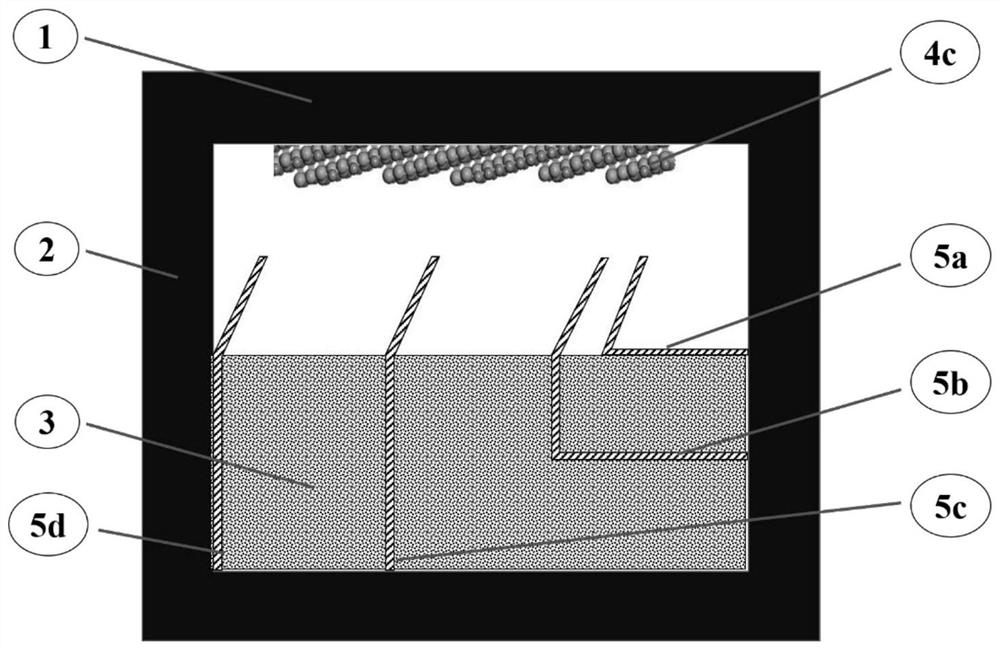

[0056] (2) Place a deflected growth component deflector in the powder and growth chamber: open four slots inside the graphite crucible tube, place four deflectors in the slots and fix them so that the deflectors The powder is divided into 3 regions with different volumes, and the part of the deflector located in the growth chamber is used to adjust the inclination angle of the component flow direction; the upper inclination angle of the deflector is 65 °, and the extension line of the deflector 5a is in line with the The edges of the large-diameter seed crystals just intersect, and the deflector not only plays the role of separating the silicon c...

Embodiment 2

[0063] (1) Grinding and polishing a 4-inch silicon carbide seed crystal with a large diameter of 5° (diameter 105 mm) on both sides, so that the surface roughness is less than 0.3 nm, and the flatness is 10 μm, and a silicon carbide seed crystal with a thickness of 500 μm is obtained. Then the surface is cleaned and packaged for use.

[0064] (2) Place a deflected growth component deflector in the powder and growth chamber: open four slots inside the graphite crucible tube, place four deflectors in the slots and fix them so that the deflectors The powder is divided into 3 different volume regions, and the part of the deflector located in the growth chamber is used to adjust the inclination angle of the component flow direction; the upper inclination angle of the deflector is 70 °, and the extension line of the deflector 5a is in line with the The edges of the large-diameter seed crystals just intersect, and the deflector not only plays the role of separating the silicon carbid...

Embodiment 3

[0070] (1) Grind and polish the 8-inch silicon carbide seed crystal with a large diameter of 8° on both sides, so that the surface roughness is less than 0.3nm, and the flatness is 10μm, and a silicon carbide seed crystal with a thickness of 500μm is obtained, and then the surface is cleaned. Clean and pack for use.

[0071] (2) Place a deflected growth component deflector in the powder and growth chamber: open four slots inside the graphite crucible tube, place four deflectors in the slots and fix them so that the deflectors The powder is divided into 3 regions with different volumes, and the part of the deflector located in the growth chamber is used to adjust the inclination angle of the component flow direction; the inclination angle of the upper part of the deflector is 75 °, and the extension line of the deflector 5a is in line with the The edges of the large-diameter seed crystals just intersect, and the deflector not only plays the role of separating the silicon carbid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com