Touch panel and manufacturing method thereof

A touch panel and manufacturing method technology, applied in the direction of instruments, electrical digital data processing, input/output process of data processing, etc., can solve the problems of poor yield rate, labor-intensive, low production efficiency, etc., to improve output Yield rate, labor cost saving, and fast production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

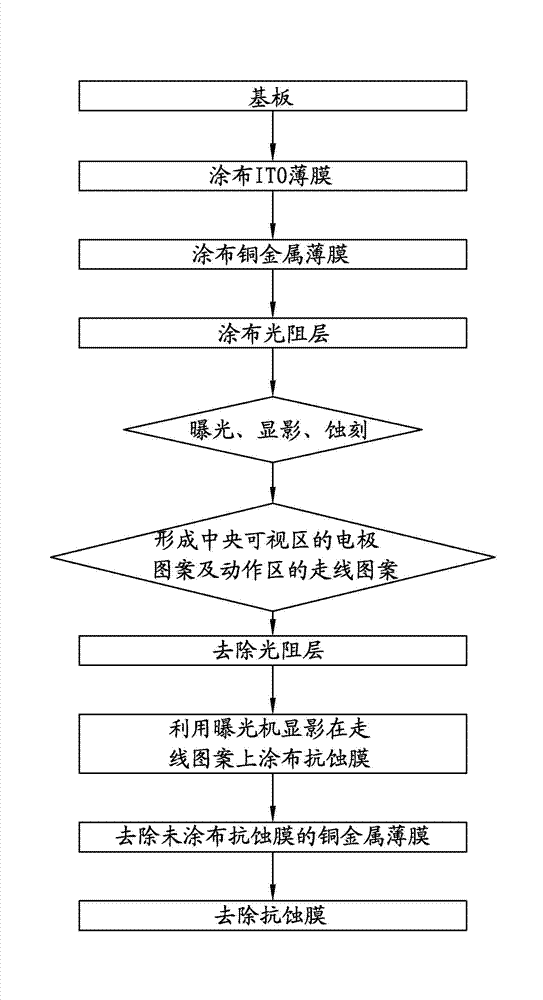

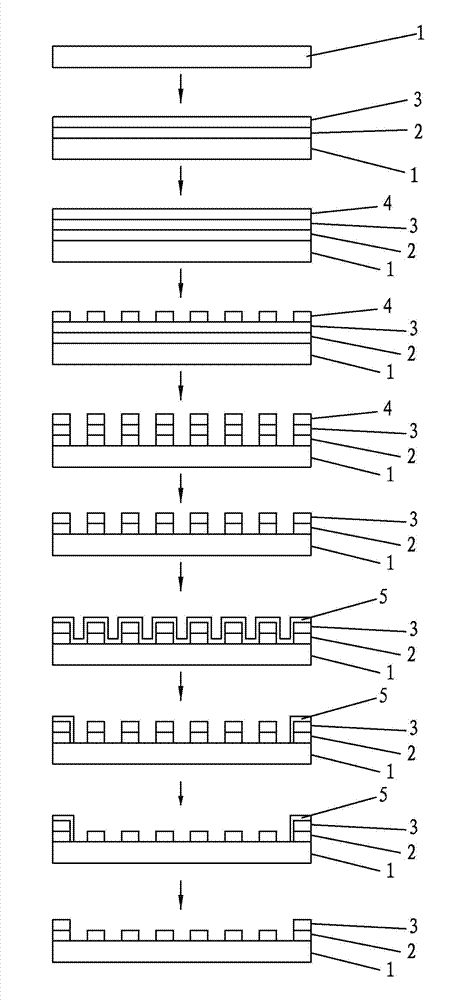

[0039] see figure 1 and figure 2 As shown, the steps of the manufacturing method of the touch panel of the present invention include:

[0040] A. Coating an indium tin oxide thin film 2 on a transparent substrate 1 by means of sputtering or vapor deposition, and coating a copper metal thin film 3 on the indium tin oxide thin film 2 .

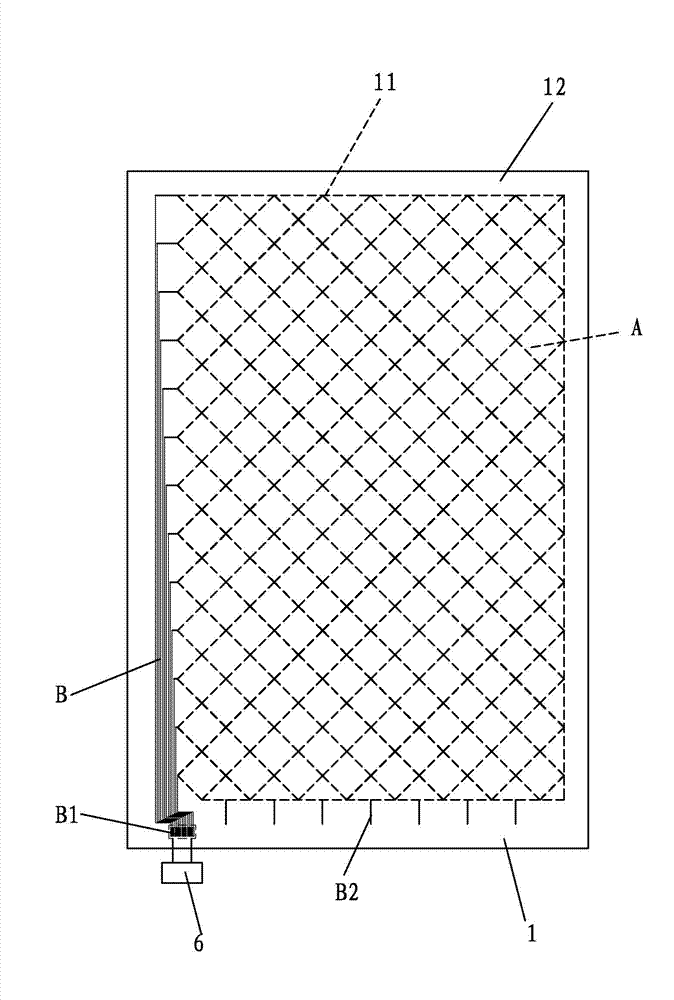

[0041] B. Coating a photoresist layer 4 on the aforementioned copper metal film 3 by using semiconductor etching technology, and after exposing and developing the photoresist layer 4, form each on the aforementioned indium tin oxide film 2 and copper metal film 3 by etching An electrode pattern A is located in a central viewing area 11 of the substrate 1, and a wiring pattern B is located in an action area 12 on the outer edge of the central viewing area 11 and connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com