Pipe material conveying device and pipe conveying machine

A technology for conveying devices and pipe materials, which is applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., can solve problems such as difficult size detection, and achieve the effect of improving the output yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

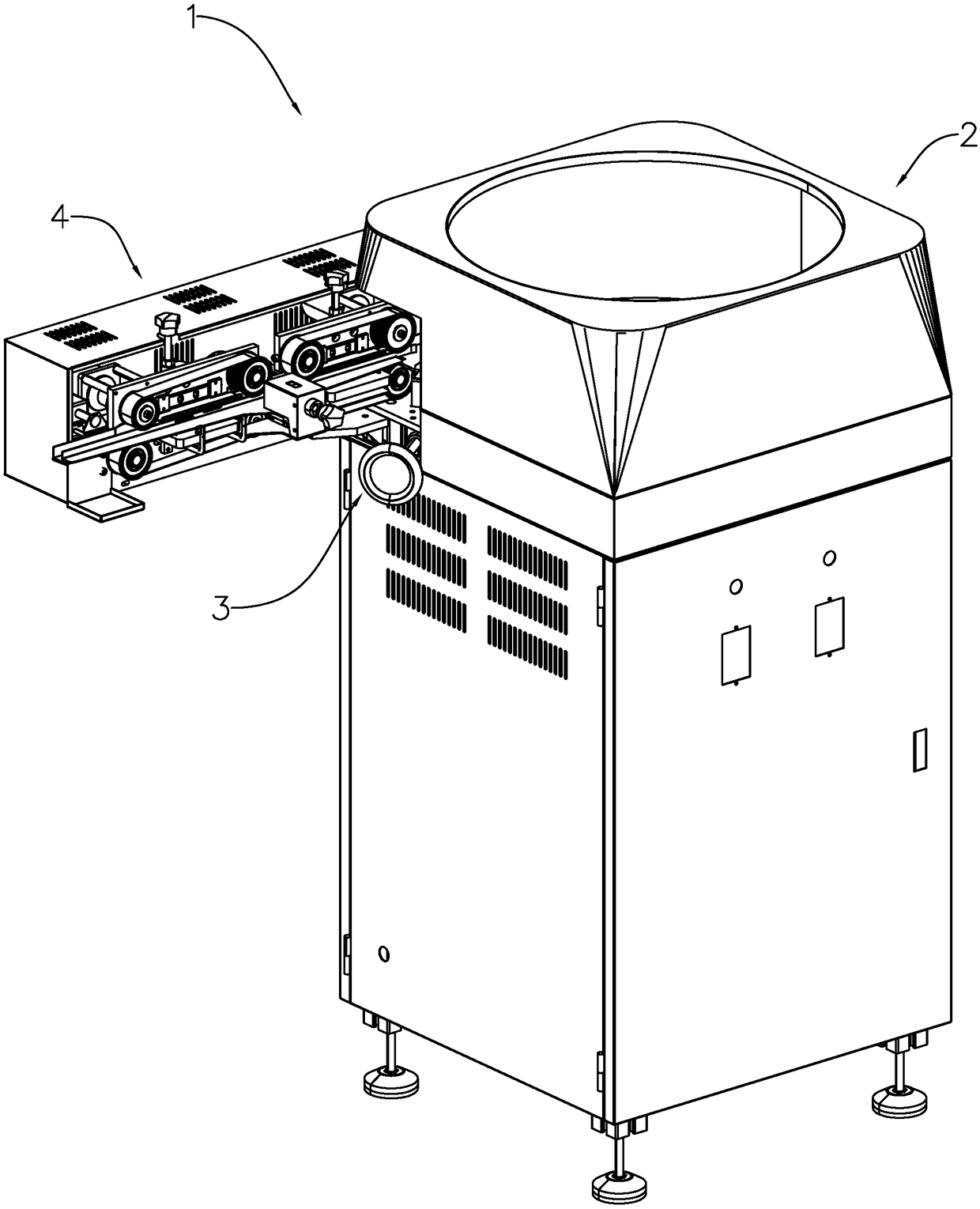

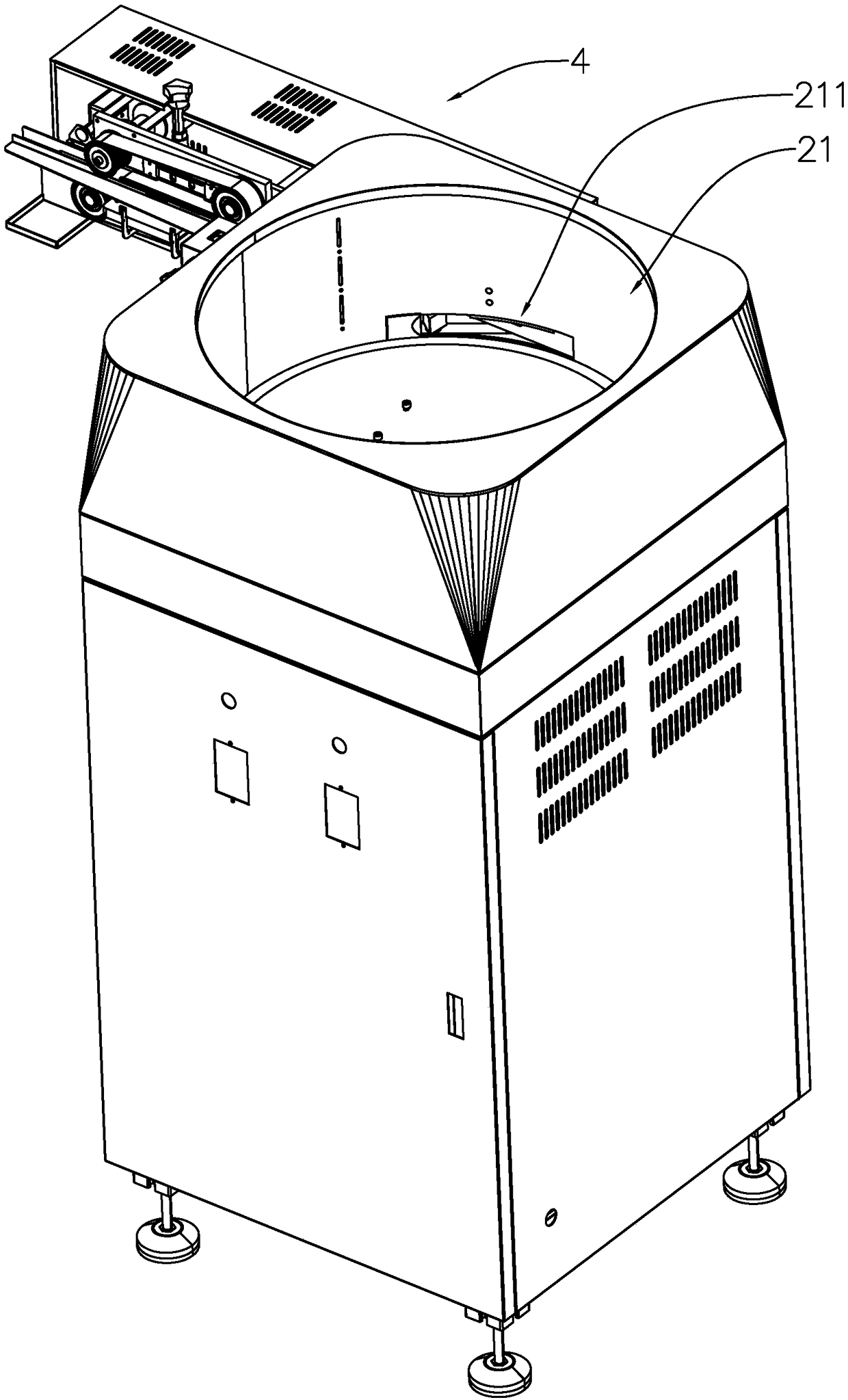

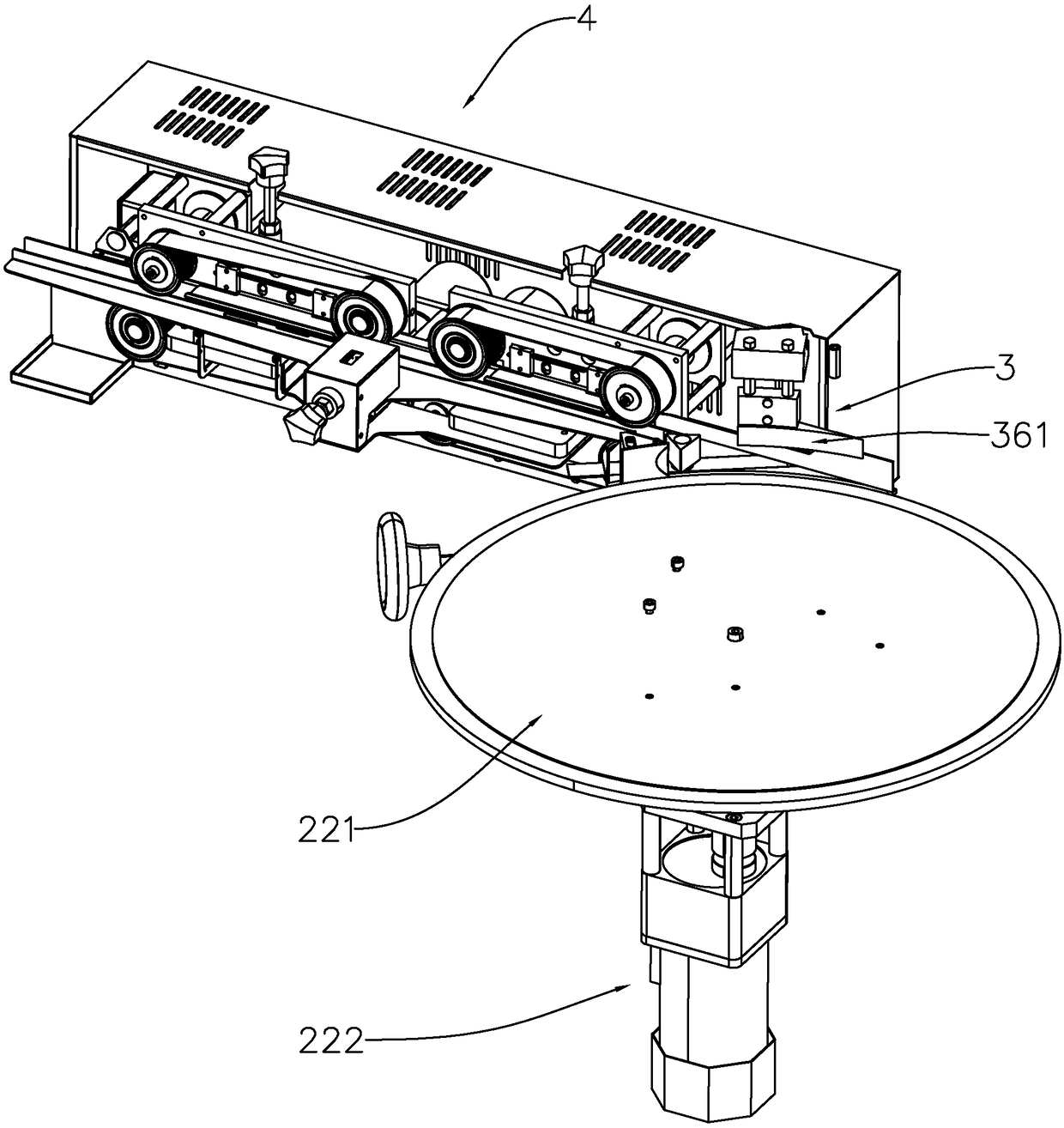

[0039] refer to Figure 1 to Figure 3 , the pipe feeding machine 1 includes a feeding device 2, an output port adjustment device 3 and a pipe material conveying device 4, a plurality of pipe materials are stored in the feeding device 2, and the feeding device 2 includes a driving device 222, a turntable 221 and a ring cover 21 , the ring cover 21 surrounds the outer periphery of the turntable 221, and the ring cover 21 is provided with an output port 211 along the circumferential direction, and the drive motor 222 drives the turntable 221 to rotate horizontally, so that the pipe material passes through the output port adjustment device 3 from the output port 211 to the pipe material conveying device 4 outputs.

[0040] refer to Figure 4 to Figure 6 , the output port adjustment device 3 includes a lateral movement assembly, a longitudinal movement assembly, a linkage assembly and a drive assembly 32, the longitudinal movement assembly includes a longitudinal movement bracket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com