Fast recovery diode and manufacturing method thereof

A fast recovery, diode technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of limited improvement and high manufacturing cost, and achieve the effects of reducing vibration, improving safe working area, and avoiding surface leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 The manufacturing method of the fast recovery diode of the present invention

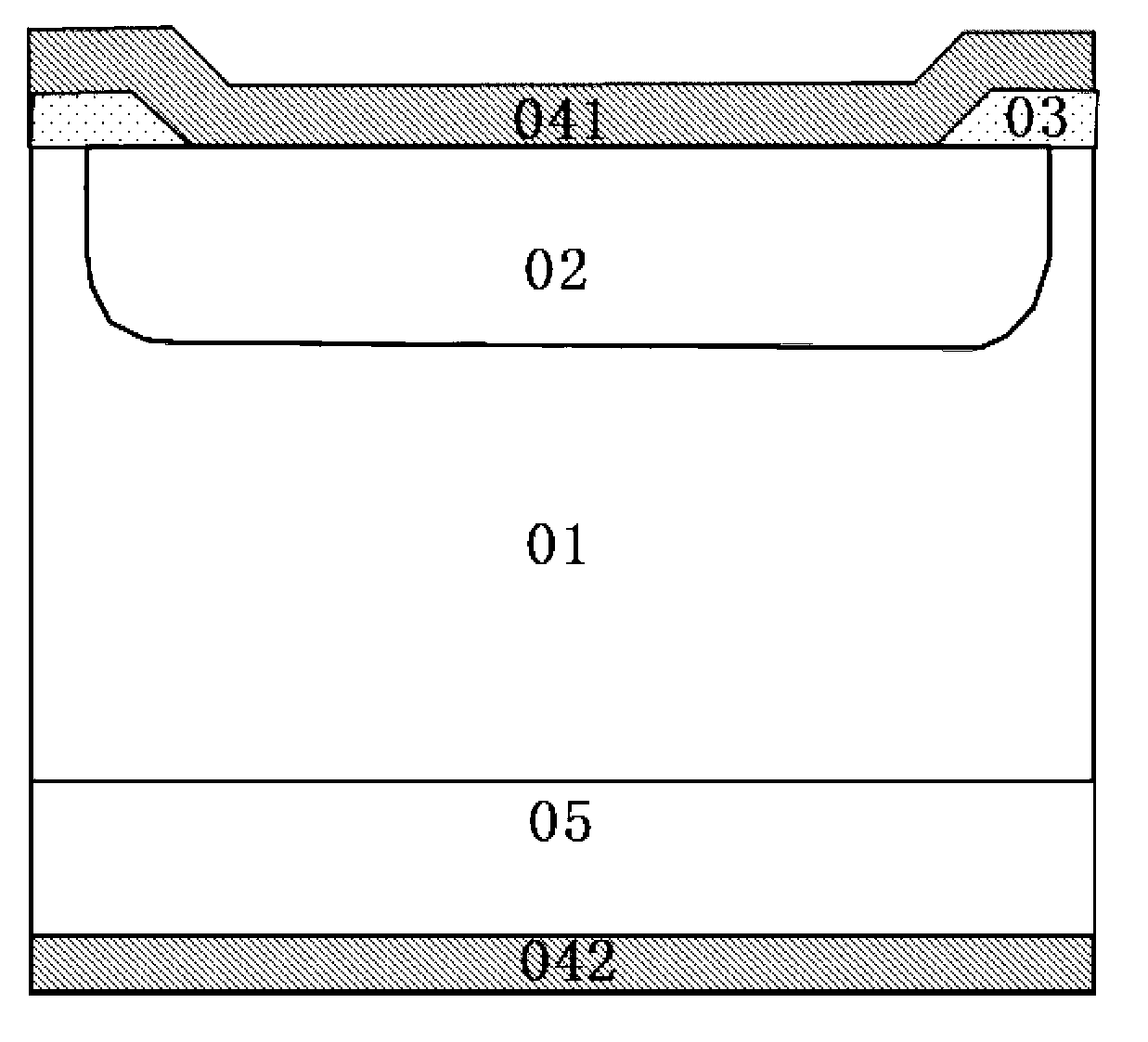

[0034] 1) Field oxidation: After cleaning the uniformly doped N-type silicon substrate 01, a high-temperature oxidation method is used to grow a 1-4um oxide layer 03 on the surface of the silicon wafer, such as: Figure 7 shown. N-type silicon substrate 01 can be prepared by using epitaxial wafer or single wafer. Considering the current technology level and cost control, the former is more suitable for medium and low voltage products, and the latter is more suitable for the development of medium and high voltage devices;

[0035] 2) Doping window etching: After the processes of gluing, exposing, developing, oxide layer etching and degumming, the P-type doped ion implantation window D is photolithographically obtained, such as Figure 8 shown;

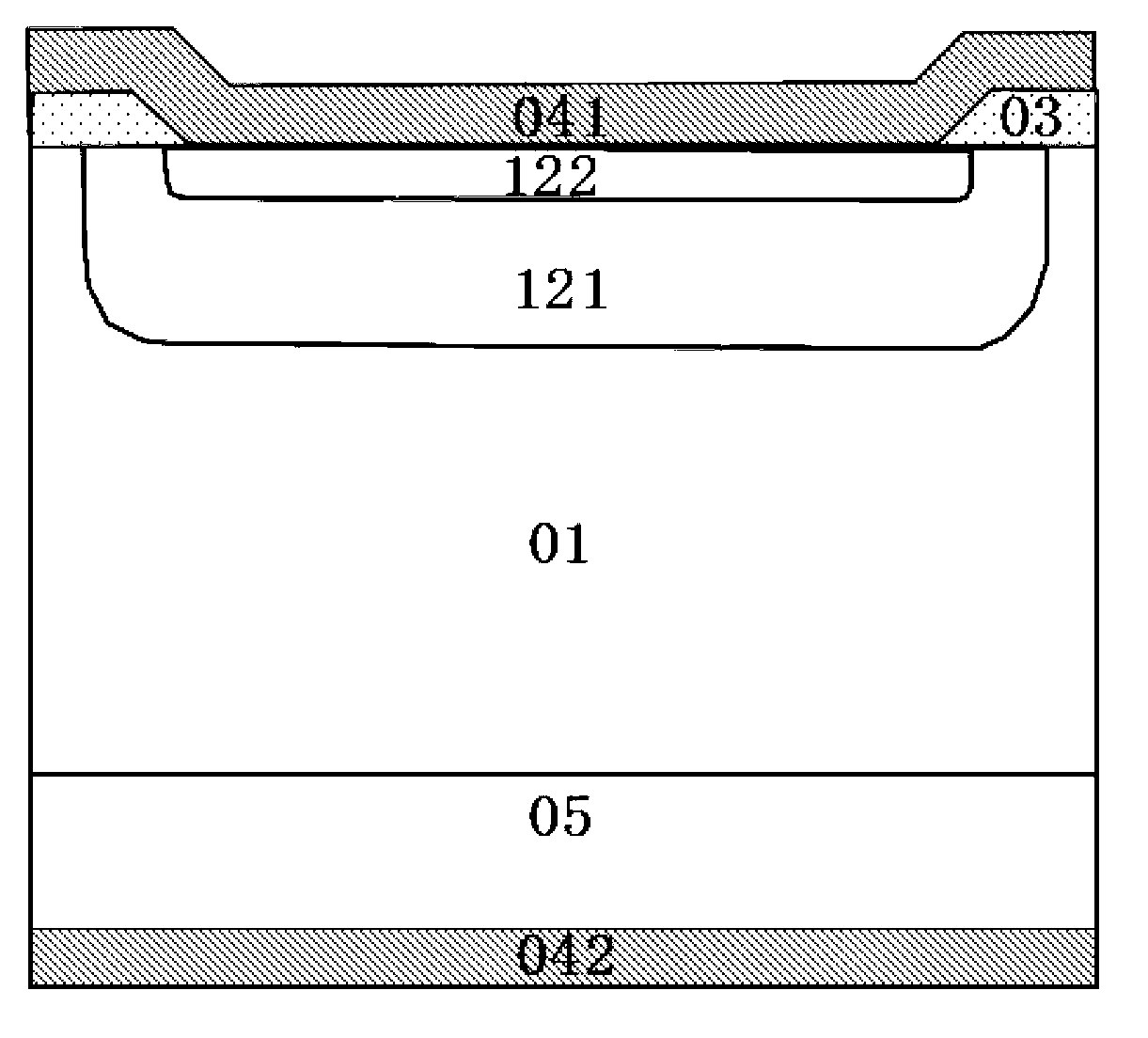

[0036] 3) Doping of the emitter region: the oxide layer 03 is used as an implantation masking window, and P-type impurities are implant...

Embodiment 2

[0042] In the emission region, the overlapping P-type regions 322 in a wave shape are realized by means of local implantation of P-type ions 321 and high-temperature push junctions. The top view shape of the implantation window of the P-type ion 321 can be diversified, such as regular hexagon, square, circle and interdigital shape, etc., such as Figure 4 shown.

Embodiment 3

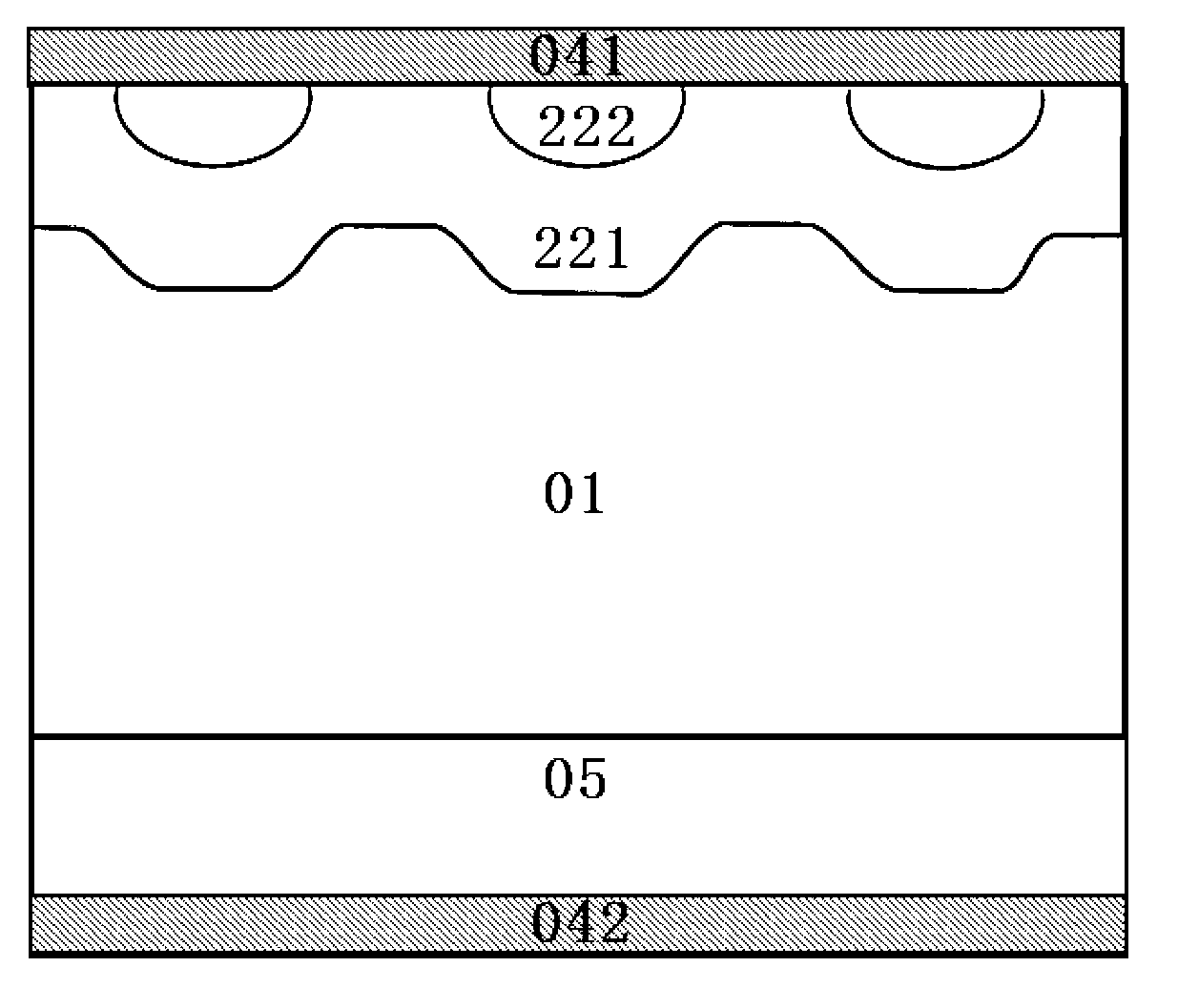

[0044] The implantation windows 321 of P-type ions are equally spaced, and the ion implantation windows are regular hexagons, such as Figure 5 shown.

[0045] After implantation through the regular hexagonal implantation window, a wavy P-type doping structure with high (highly doped P region HP) and low concentration (lowly doped P region LP) is formed, such as Image 6 322 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com