Method based on 3D printing for manufacturing LED devices

An LED device, 3D printing technology, applied in semiconductor devices, circuits, electrical components, etc., can solve the problems of complex electrode formation process, photoresist pollution, epitaxial wafer ion damage, etc., to reduce lithography and etching steps, Fast molding speed, reducing the effect of photolithography and etching process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings.

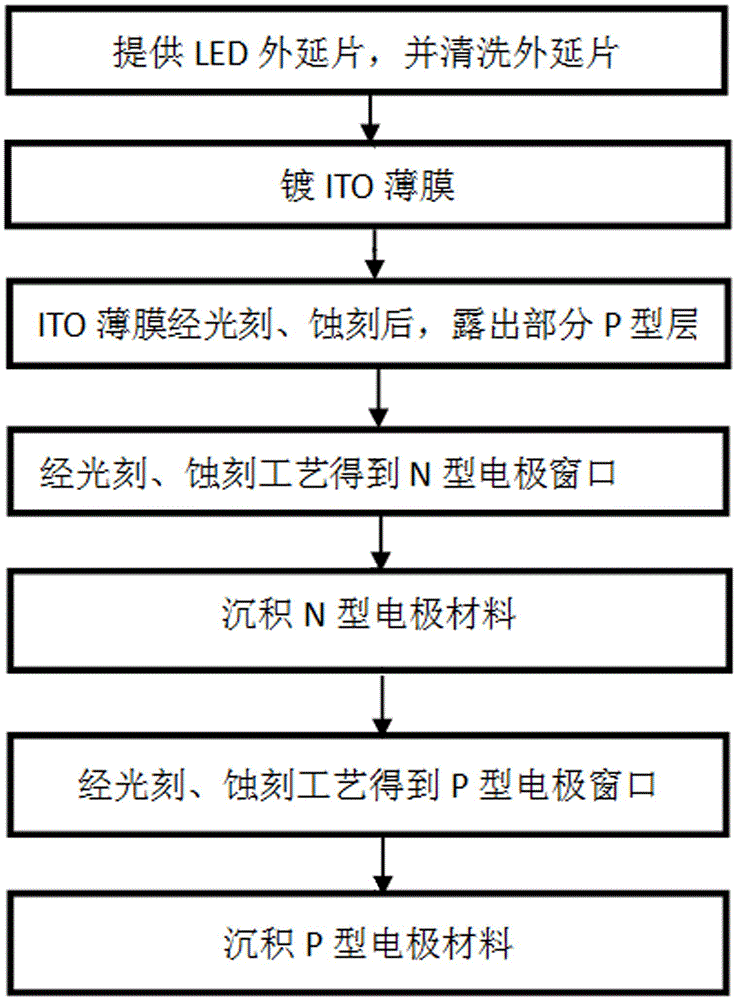

[0025] figure 1 It is the flow chart of traditional LED device electrode production. As shown in the figure, forming electrodes on epitaxial wafers requires multi-step photolithography and etching processes such as etching ITO film, etching n-type layer electrode window and p-type layer electrode window.

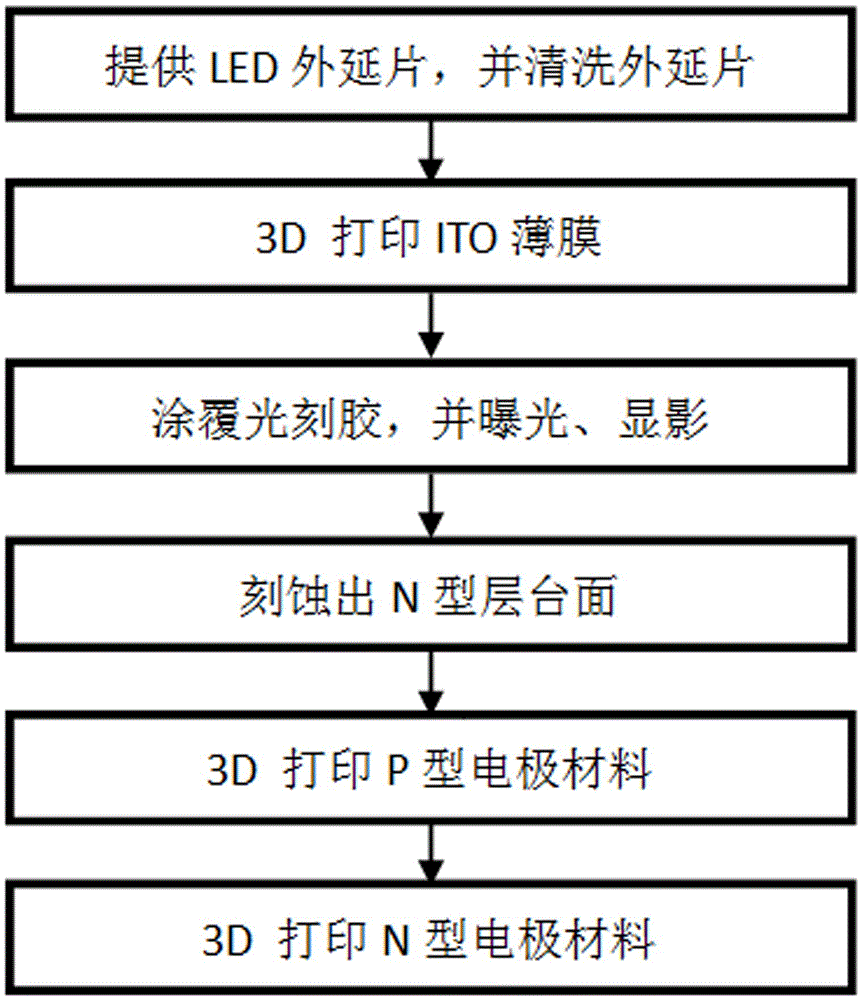

[0026] figure 2 The flow chart for making LED device electrodes based on 3D printing, as shown in the figure, to form electrodes on the epitaxial wafer, only one etching process is required to etch the epitaxial wafer to expose the n-type mesa, which greatly simplifies the process of LED device electrodes Process, shorten the production cycle. It can also reduce the probability of photoresist contamination and ion damage to the epitaxial wafer during the photolithogra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com