Method for manufacturing color filter substrate

A technology of color filter and manufacturing method, which is applied in the direction of optical filter, photographic plate-making process of pattern surface, optics, etc., can solve problems such as unevenness of the surface of the flat layer, affecting the display quality of the liquid crystal display panel, etc., to avoid the surface Unevenness, the effect of improving display quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

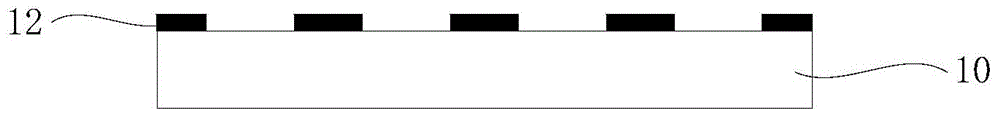

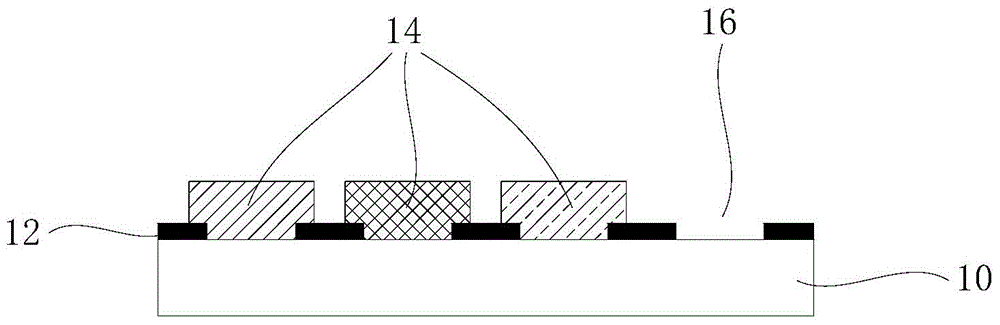

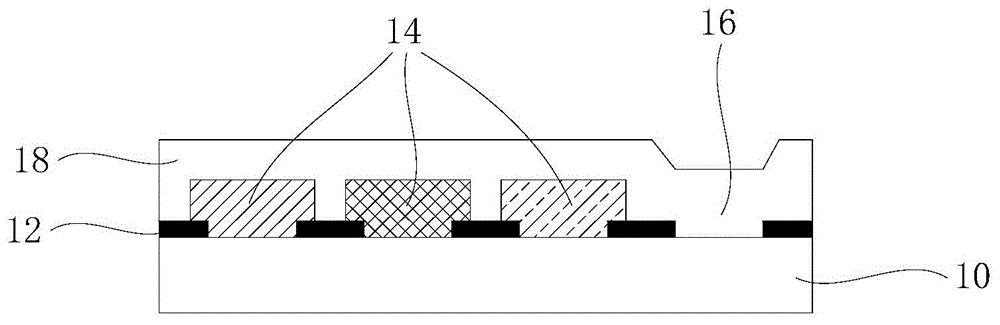

[0022] Figure 1A to Figure 1E is a schematic diagram of the manufacturing method of the color filter substrate according to the first embodiment of the present invention. In the first embodiment, the display mode of the liquid crystal display panel with the color filter substrate may be, for example, a vertical alignment (VA) mode or a twisted nematic (TN) display mode.

[0023] First, please refer to Figure 1A , providing a substrate 10, such as an insulating transparent substrate, which is defined as a color filter substrate, usually referred to as an upper substrate; then, a black matrix (black matrix) light-shielding portion 12 is formed on the substrate 10, wherein the black The material of the matrix light-shielding part 12 can be black resin or metal chromium, for example, a black resin with a certain thickness is made by a yellow light process, preferably a polymer material mixed with acrylic and carbon, or a certain thickness is also made by a yellow light process. ...

no. 2 example

[0029] In the second embodiment according to the present invention, the method before forming the spacer 24 is the same as that of the first embodiment, that is, the method before forming the spacer 24 in the second embodiment can refer to Figure 1A to Figure 1D . Here, to avoid redundant description, only the differences from the method of forming the spacers 24 in the first embodiment are described in the second embodiment.

[0030] First of all, it should be noted that the display mode of the liquid crystal display panel with the color filter substrate of the second embodiment may be, for example, a fringe field switching (FFS) mode or an in-plane switching (IPS) display mode.

[0031] figure 2 is a schematic diagram of a spacer forming method according to a second embodiment of the present invention.

[0032] refer to figure 2 After the surface of the transparent photoresist layer 18 is flat, it is beneficial to subsequently deposit the electrode layer 22 on the tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com