Patents

Literature

75results about How to "Avoid uneven surfaces" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

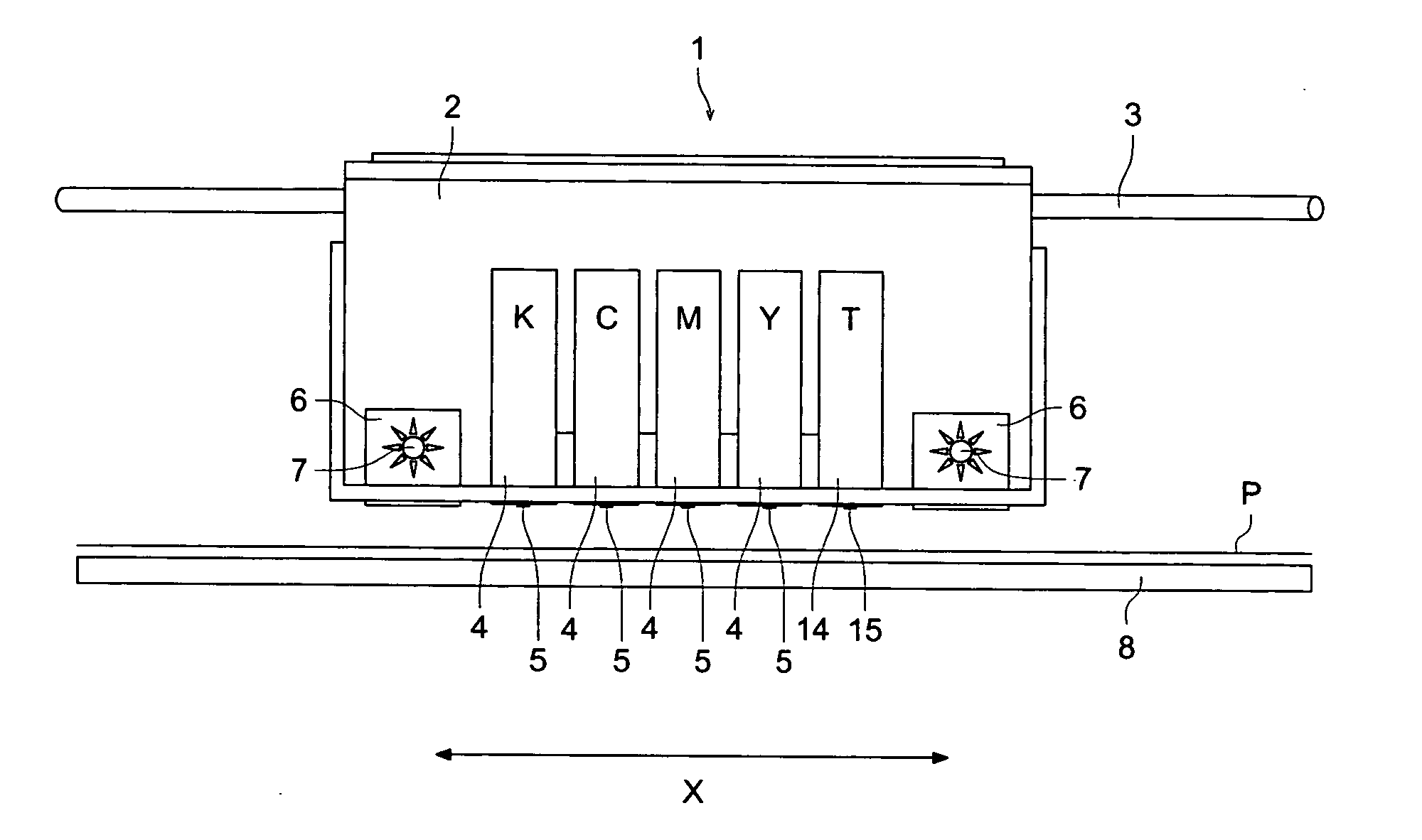

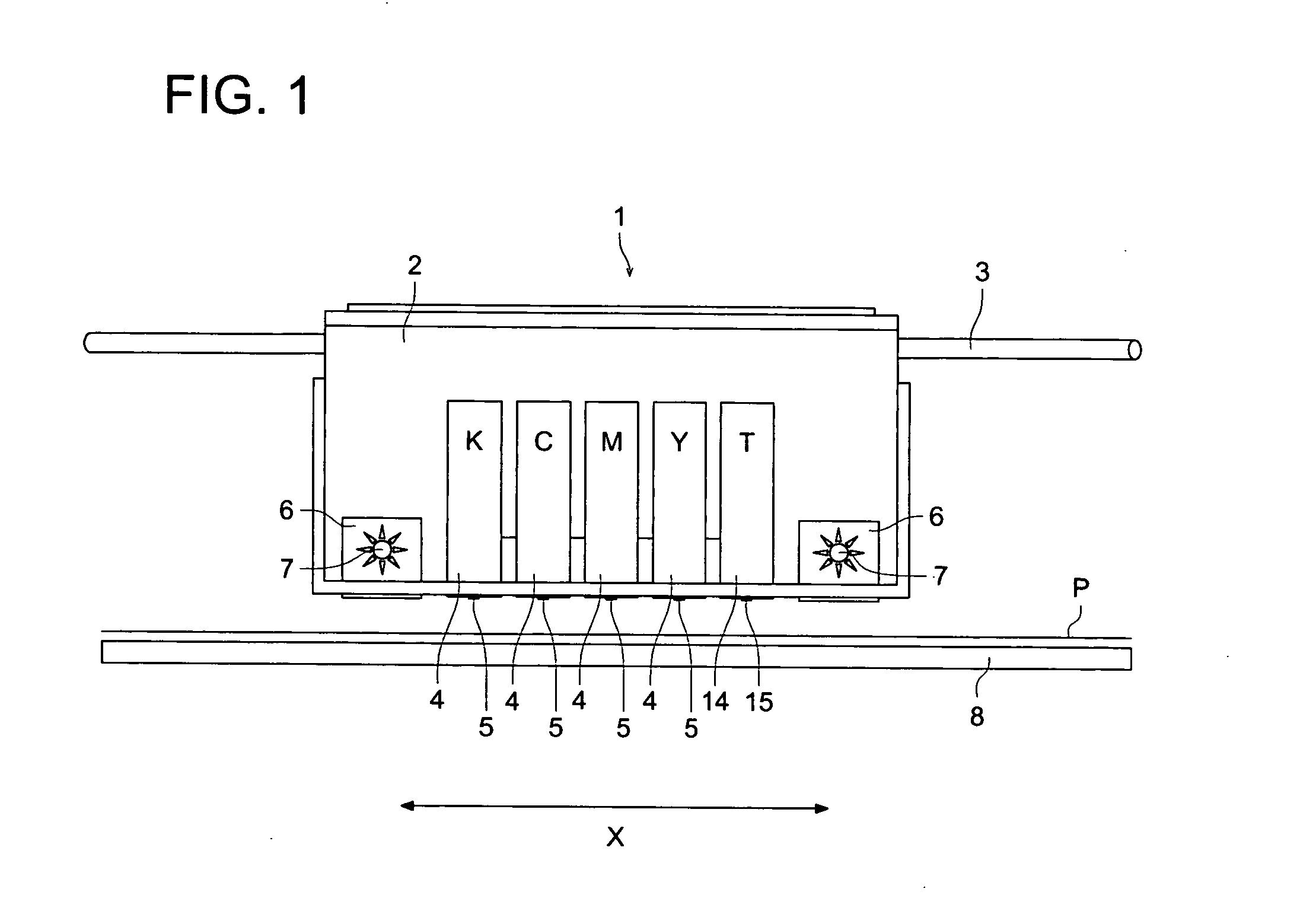

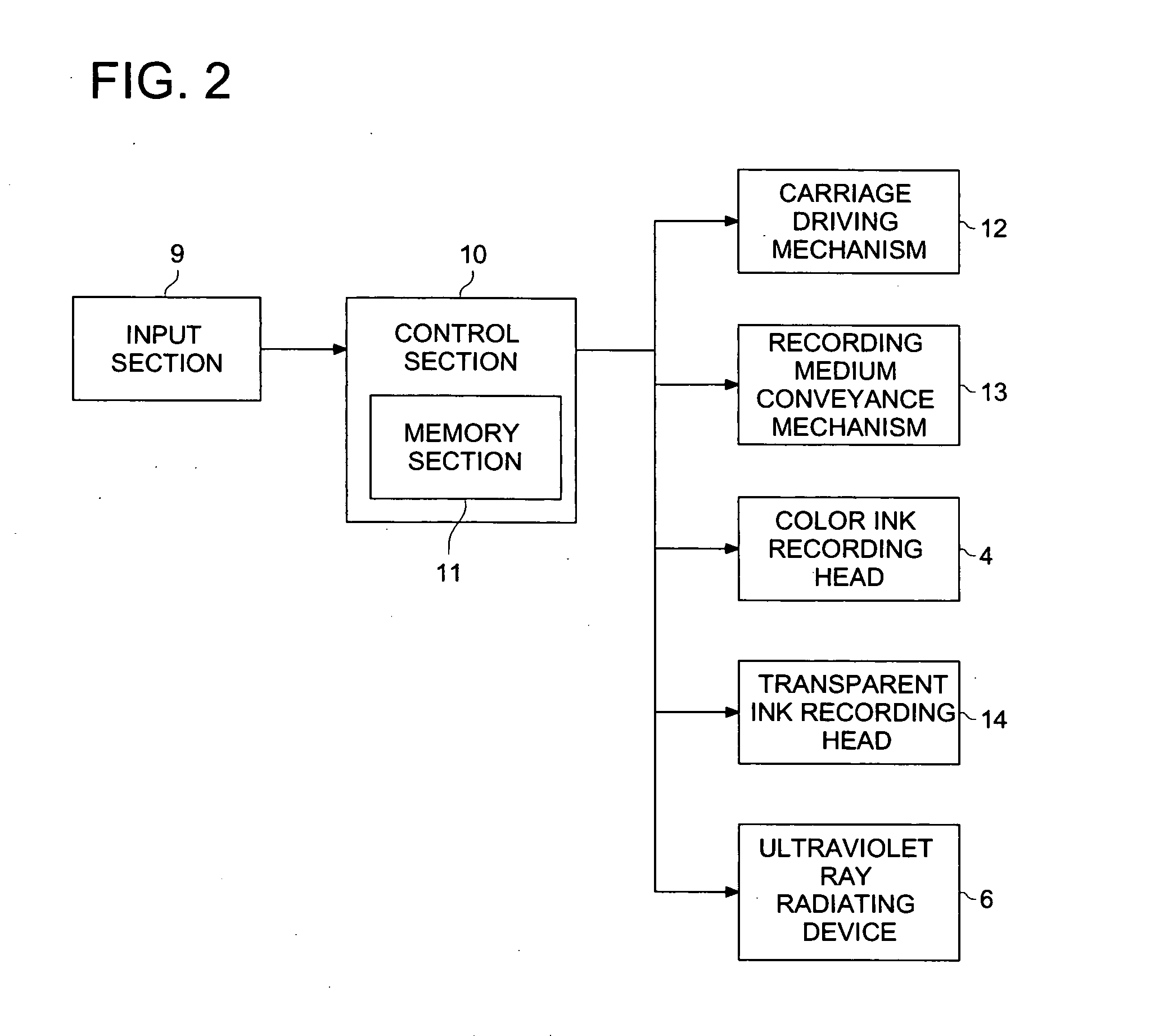

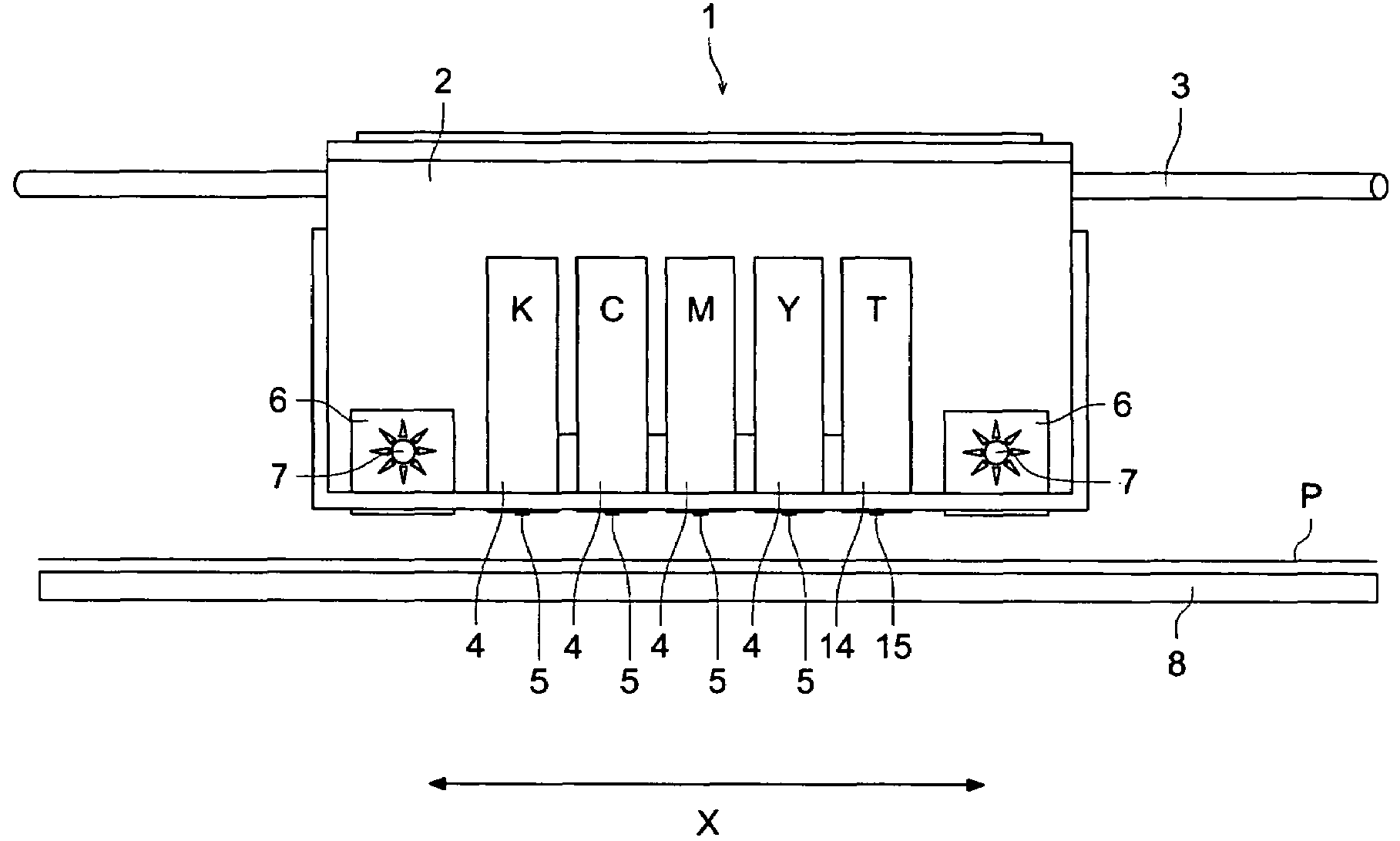

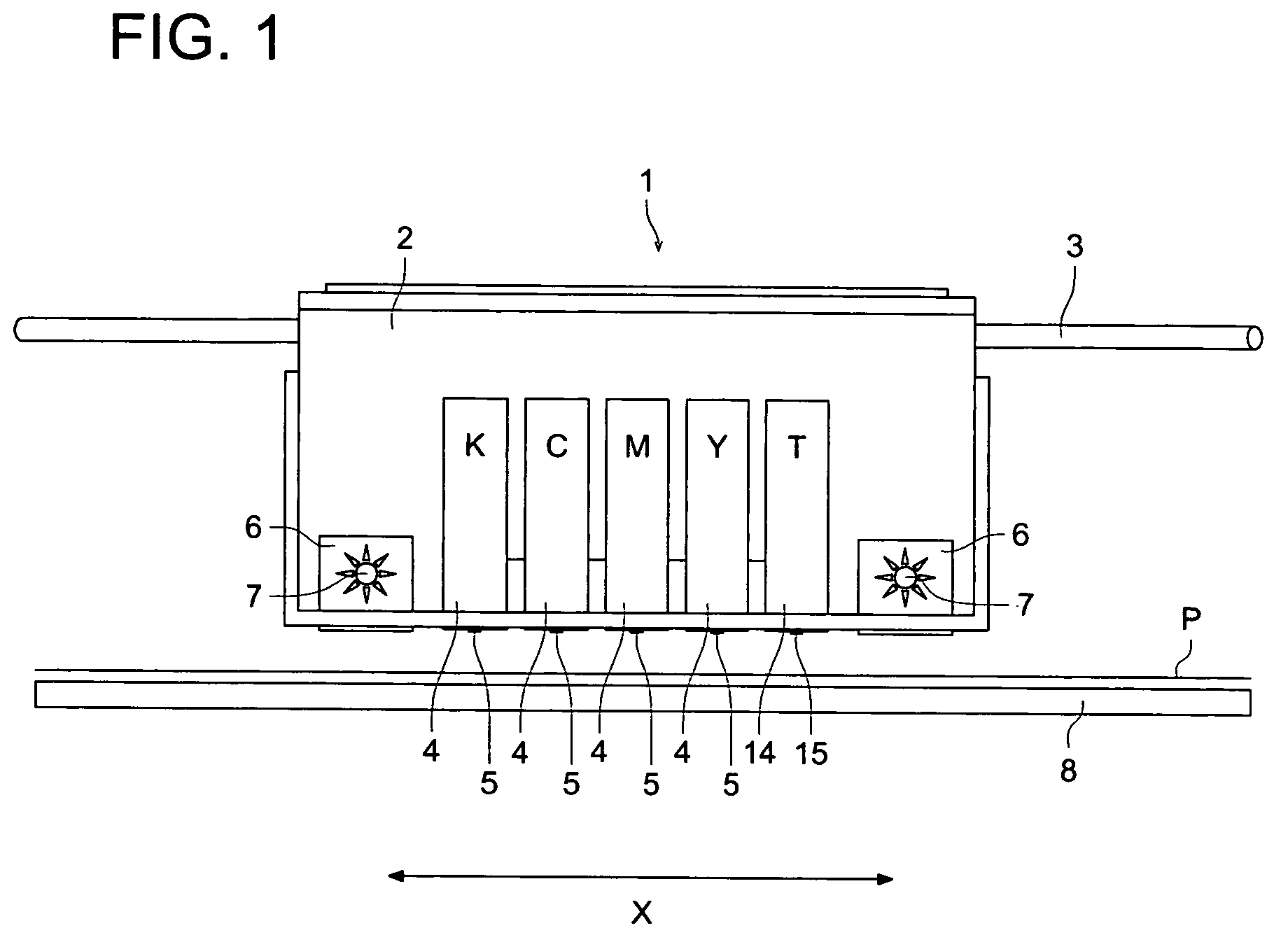

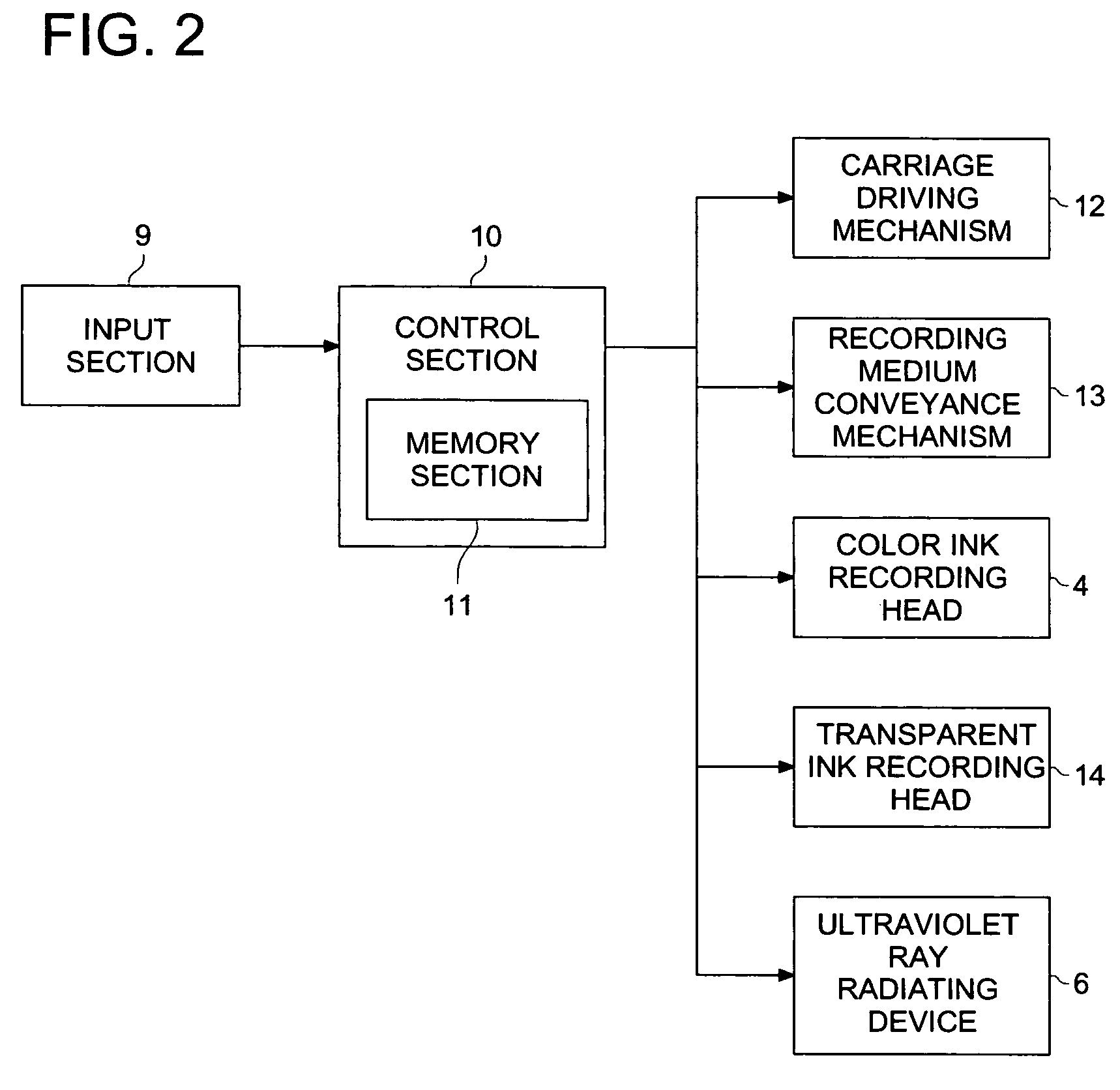

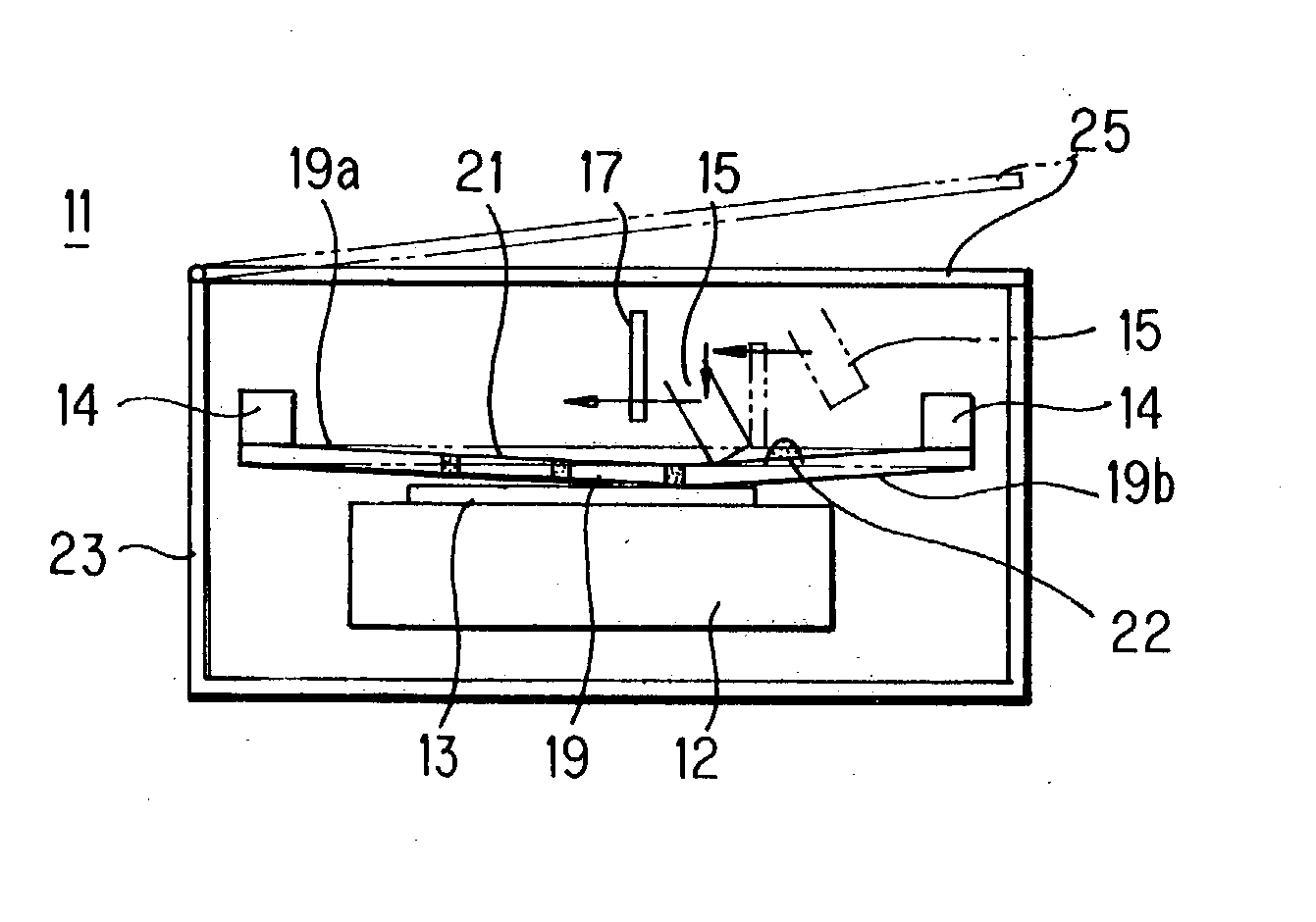

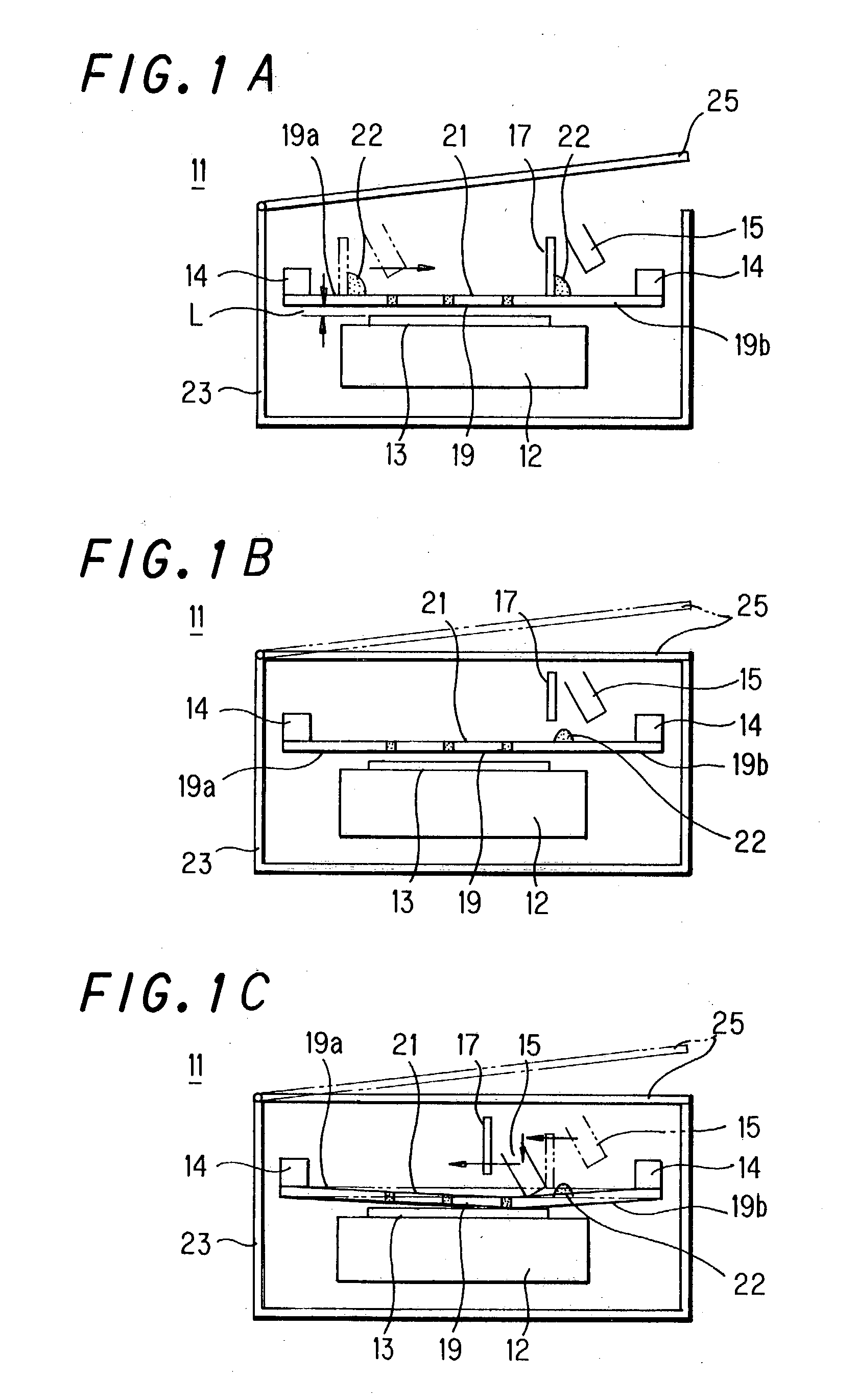

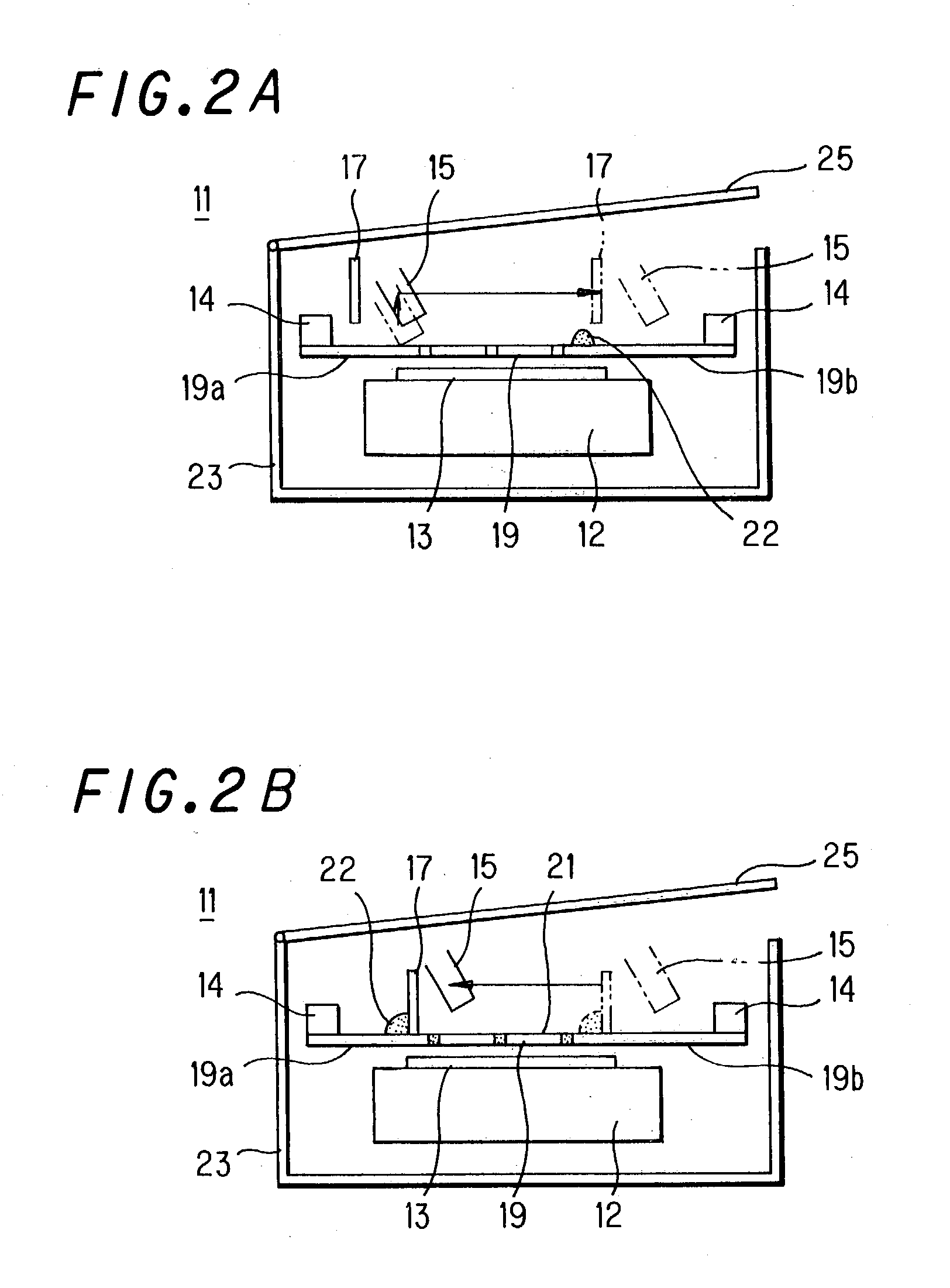

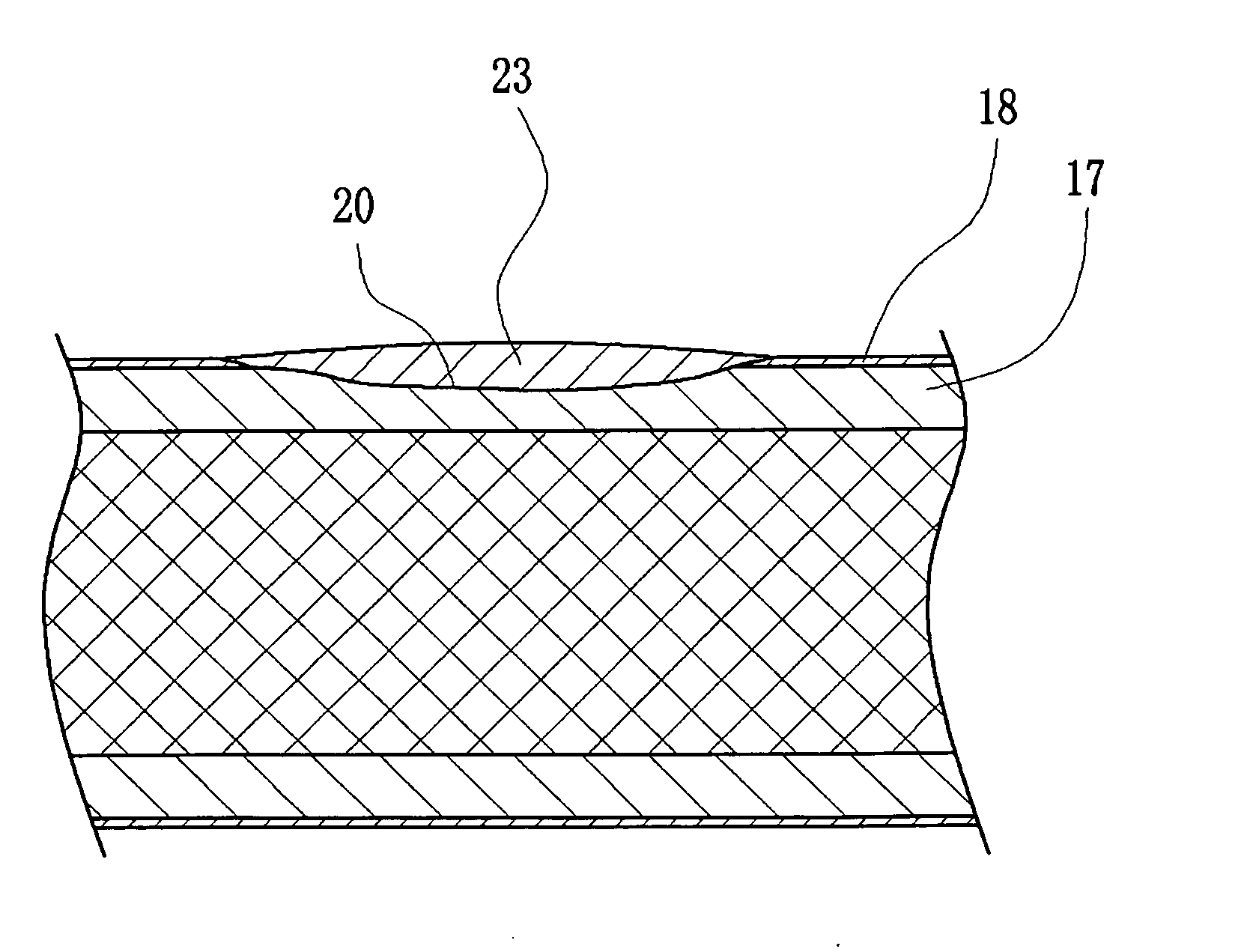

Image recording apparatus

InactiveUS20050046684A1Efficiently and effectively producedUniform reflectionPrintingImage recordingRecording head

An image recording apparatus which performs color image recording, including: a color ink recording head which jets photo-curable color ink droplets onto a recording medium; a transparent ink recording head which jets photo-curable transparent ink droplets onto a recording medium; and a light radiating device for radiating light rays onto the color ink droplets and transparent ink droplets, on the recording medium; a control section for judging the amount of color ink droplets to be jetted, and for controlling the amount of transparent ink droplets to be jetted, based on the determined amount.

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

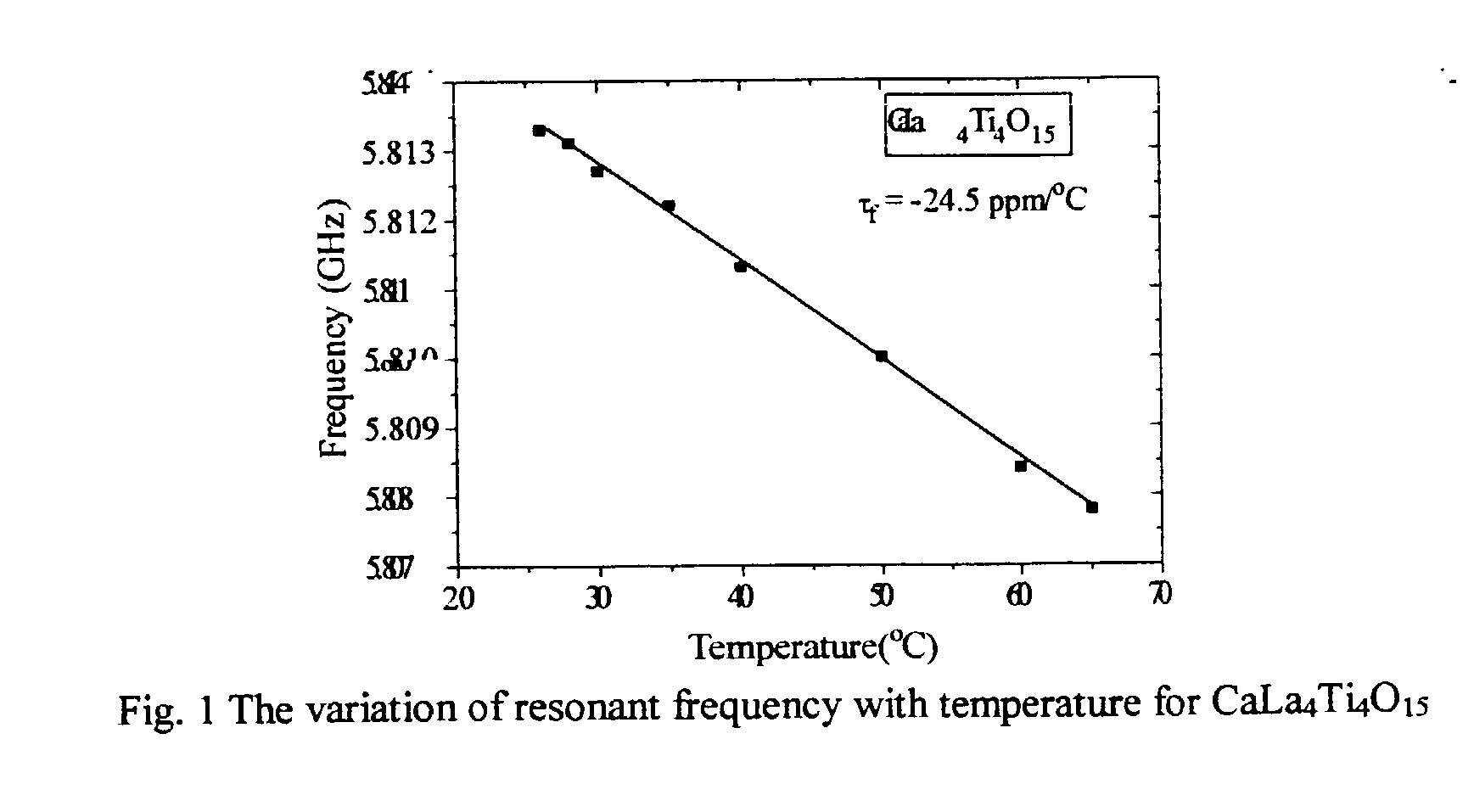

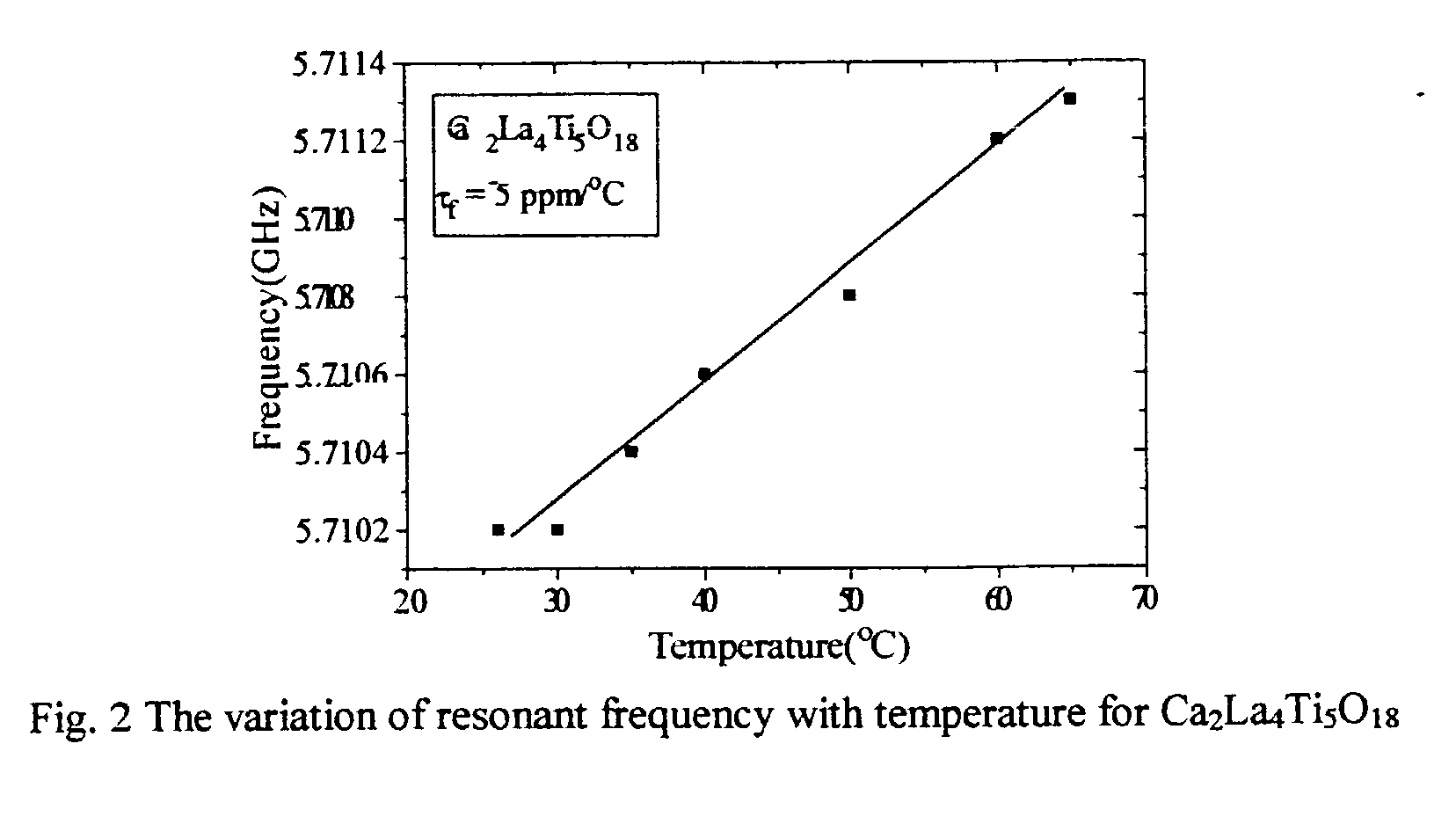

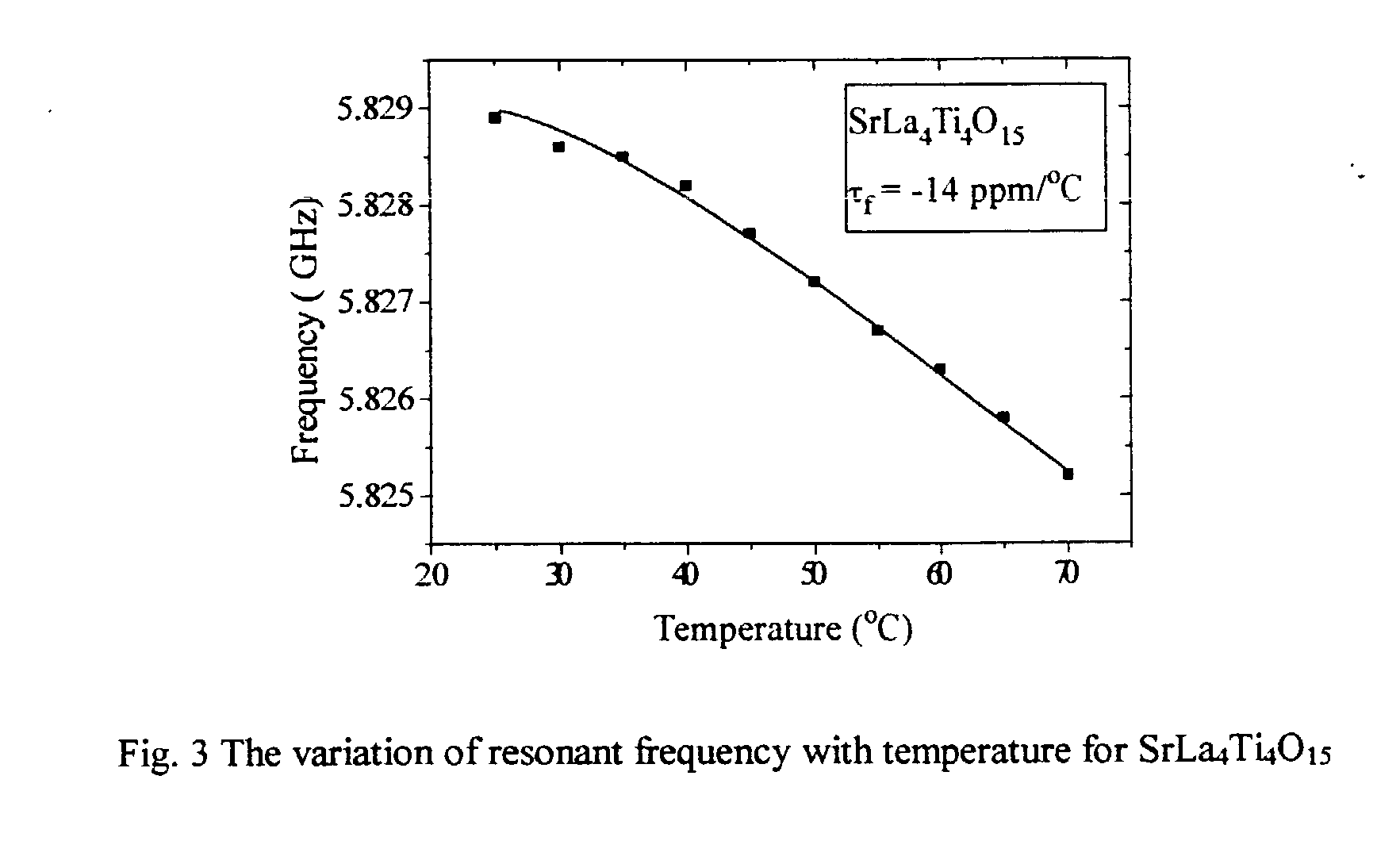

Microwave dielectric ceramic composition of the formula xMO-yLa2O3-zTiO2 (M= Sr, Ca; x:y:z = 1:2:4, 2:2:5, 1:2:5 or 1:4:9), method of manufacture thereof and devices comprising the same

InactiveUS20030181312A1Maximize microwave dielectric propertyAvoid uneven surfacesFixed capacitor dielectricResonatorsDielectricMicrowave

A microwave dielectric ceramic composition comprises a composition of the formula xMO-yLa2O3-zTiO2 wherein M is selected from Sr and Ca and x:y:z=1:2:4, 2:2:5, 1:2:5, 1:4:9.

Owner:COUNCIL OF SCI & IND RES

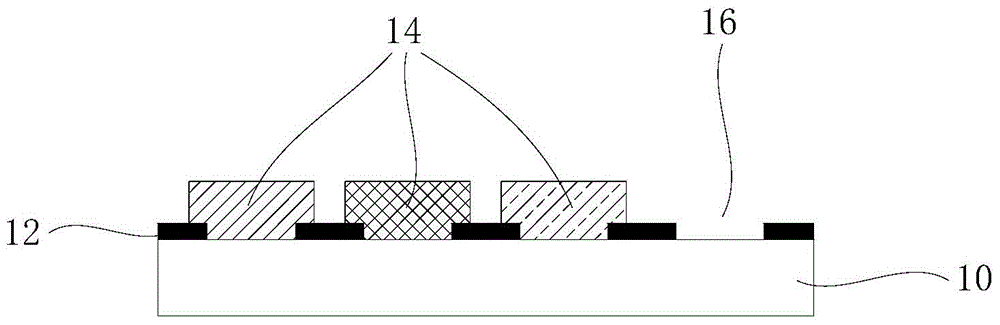

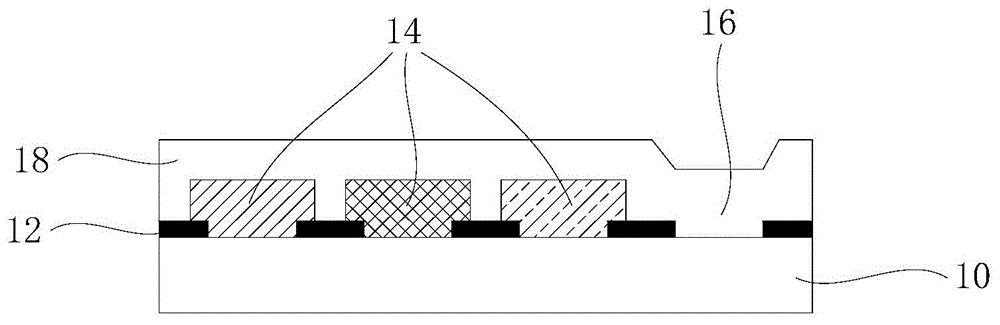

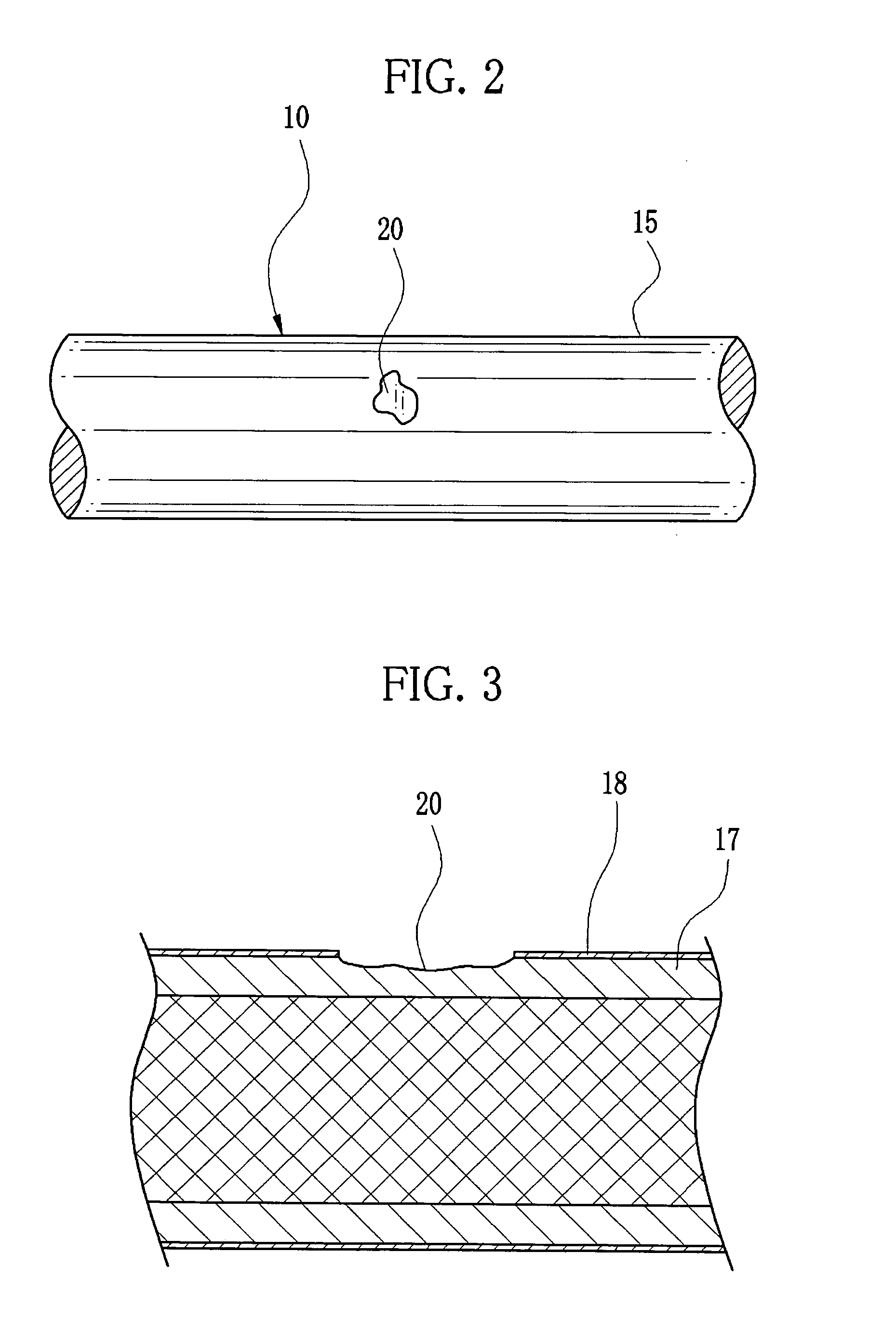

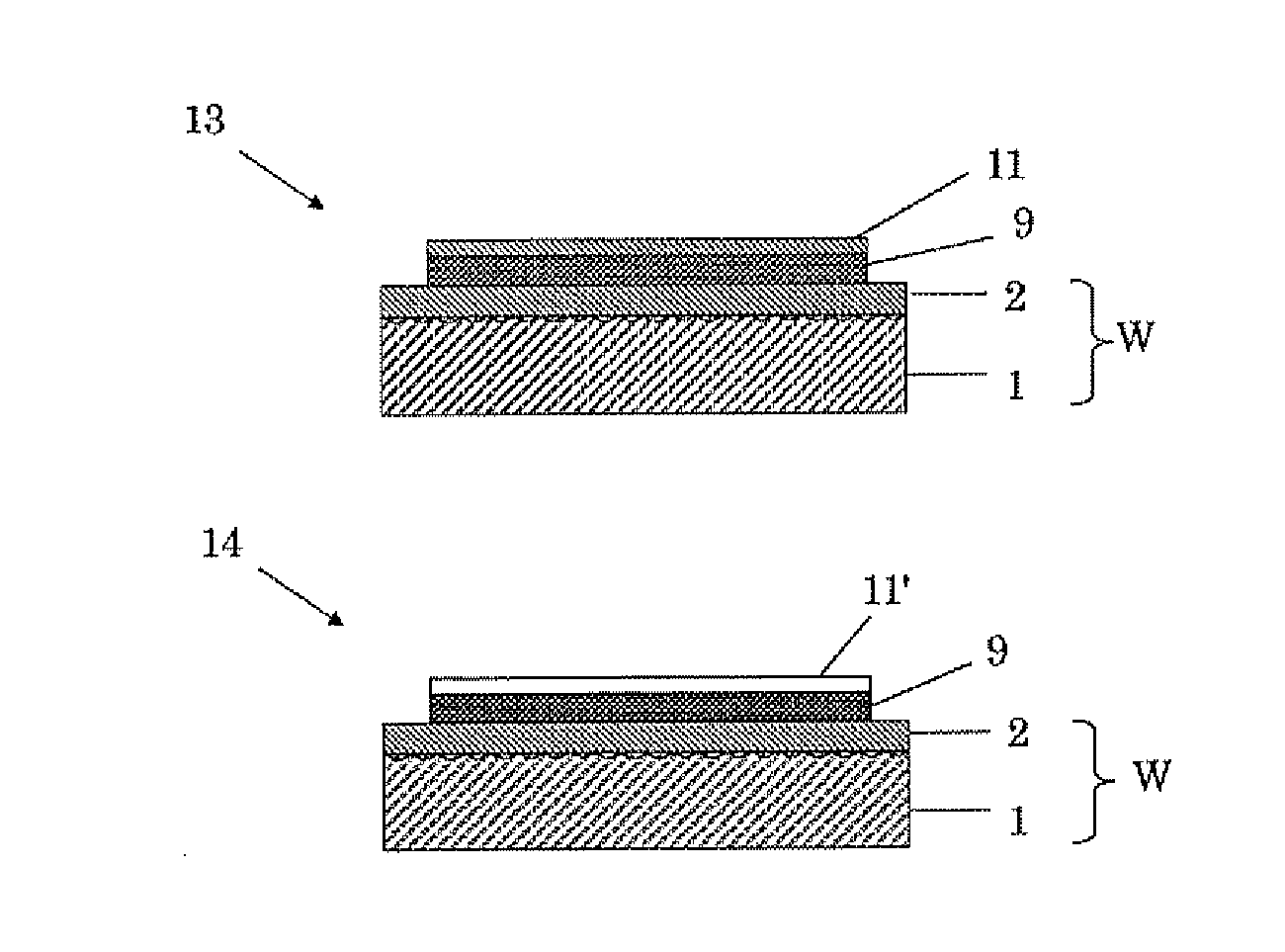

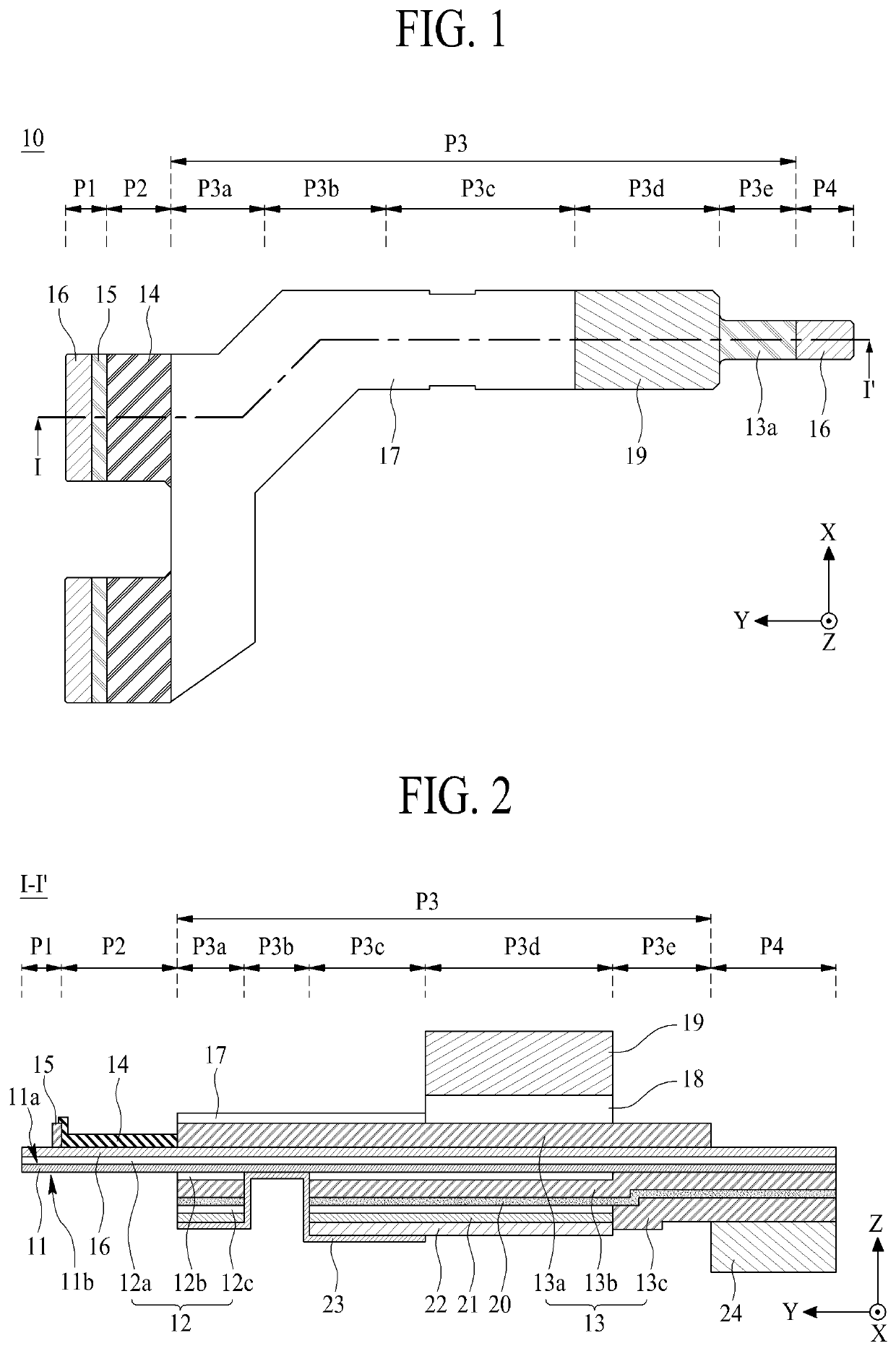

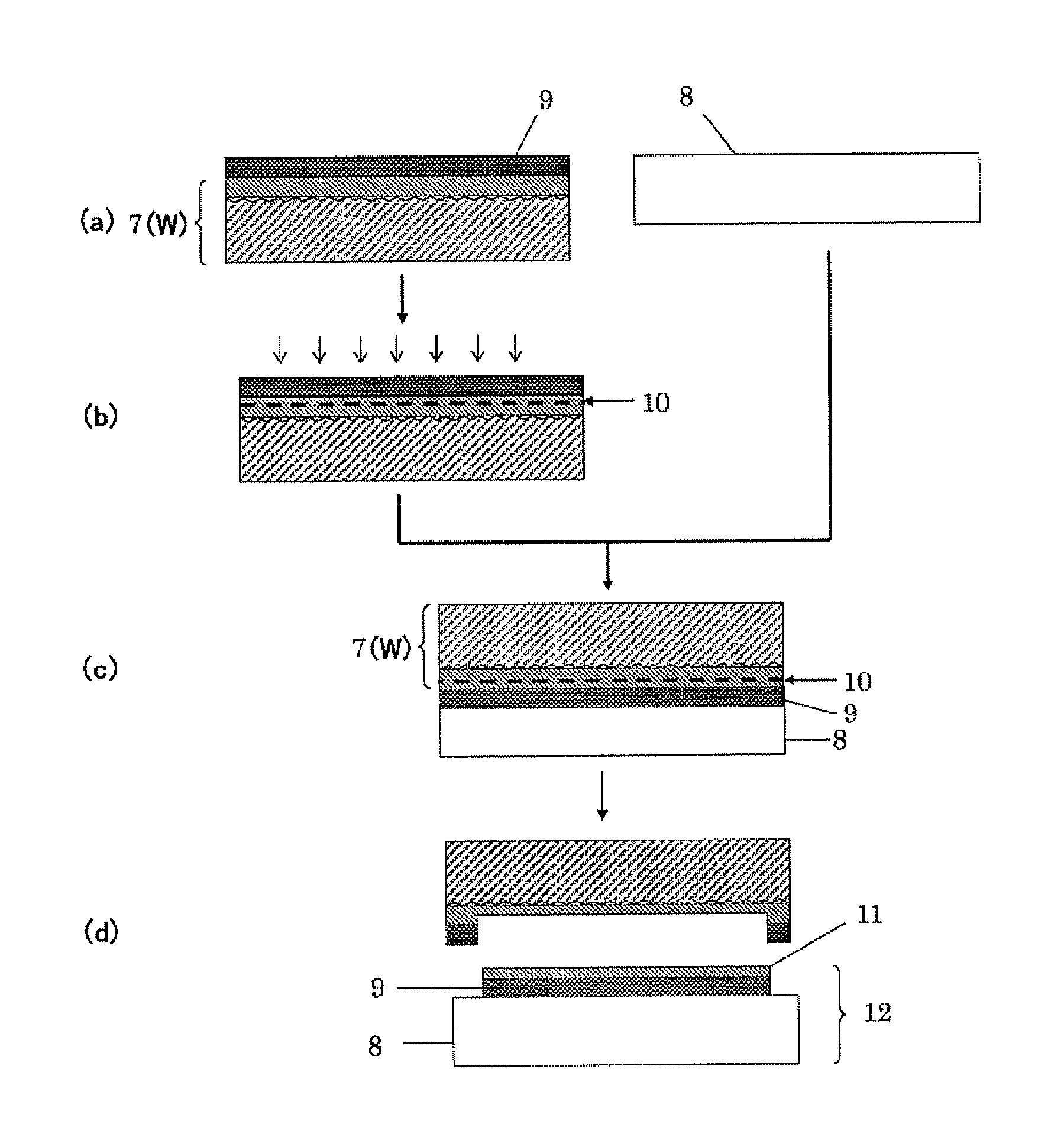

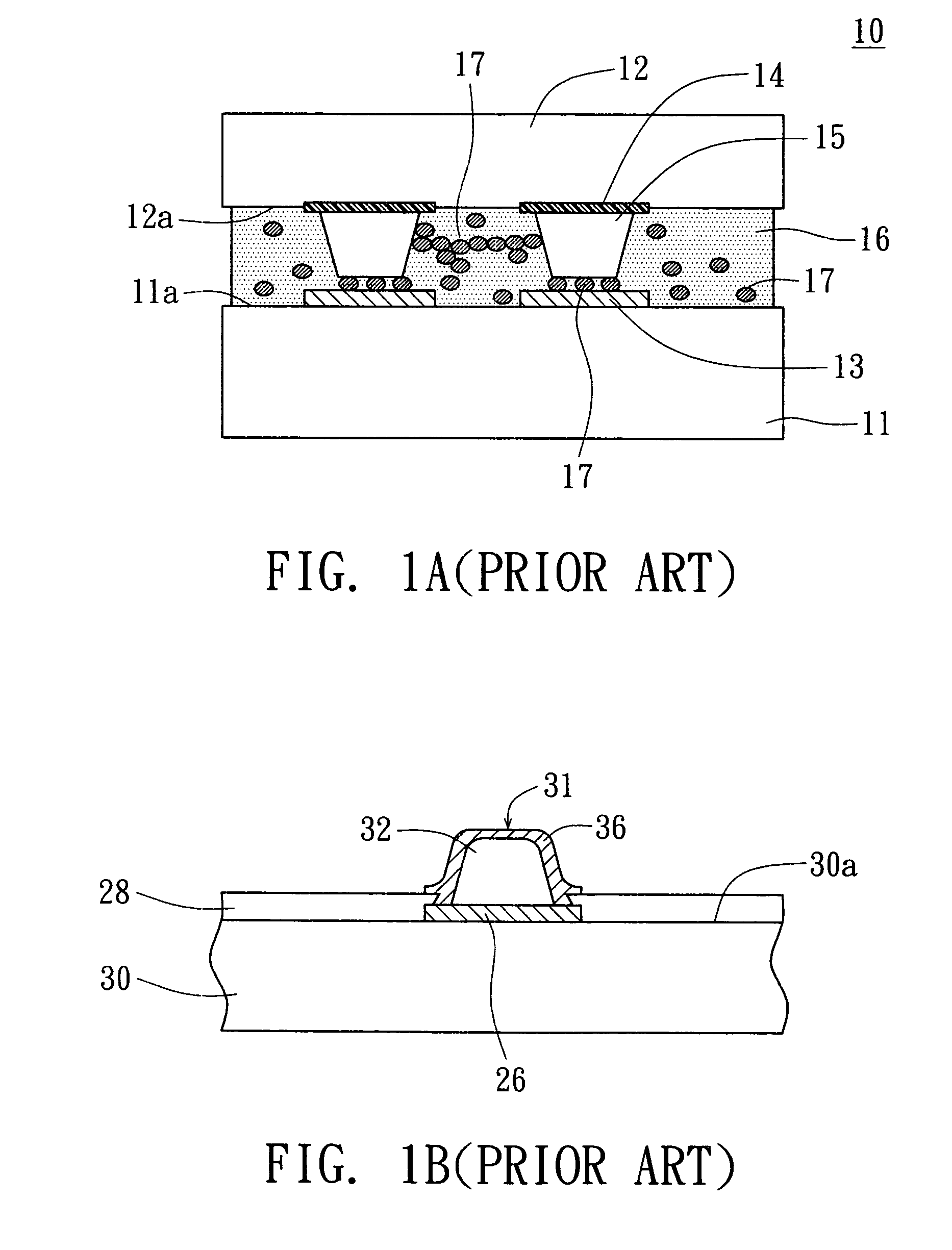

Method for manufacturing color filter substrate

InactiveCN104678639AWon't dentAvoid uneven surfacesOptical filtersPhotomechanical coating apparatusColor gelWhite light

The invention discloses a method for manufacturing a color filter substrate. The method comprises the following steps of providing a substrate (10); forming a light shielding portion (12) on the substrate (10); forming a color filter, which comprises a colorful portion (14) and an opening portion (16), on the substrate (10); covering the substrate (10) by using a flat layer (18) which is filled in the opening portion (16); photoetching the flat layer (18); and forming a spacer (24) on the photoetched flat layer (18). A transparent light resistance layer is filled in the opening portion and serves as a white light resistor, and the surface of the transparent light resistance layer is flattened by using a photoetching technology. Compared with the prior art, the method for manufacturing the color filter substrate has the advantages that a white color resistor photoetching manufacture procedure is omitted, the transparent light resistance layer on the opening portion cannot be sunken, irregularity of the surface of the transparent light resistance layer is avoided, and the display quality of a manufactured liquid crystal display panel is improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Image recording apparatus

An image recording apparatus which performs color image recording, including:a color ink recording head which jets photo-curable color ink droplets onto a recording medium;a transparent ink recording head which jets photo-curable transparent ink droplets onto a recording medium; anda light radiating device for radiating light rays onto the color ink droplets and transparent ink droplets, on the recording medium;a control section for judging the amount of color ink droplets to be jetted, and for controlling the amount of transparent ink droplets to be jetted, based on the determined amount.

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

Special environment-friendly combined polyether for sprayed pipeline and preparation method of special environment-friendly combined polyether

The invention discloses special environment-friendly combined polyether for a sprayed pipeline and a preparation method of the special environment-friendly combined polyether. The special environment-friendly combined polyether is composed of a component A and a component B, wherein the component A is composed of polyethylene-polypropylene glycol, polyester polyol, a crosslinking agent, a foam stabilizer, a catalyst and a foaming agent; the component B is polymethylene polyphenyl polyisocyanate. By using the special environment-friendly combined polyether, the problems of inside cracking, heart rot and surface roughness of sprayed foam are solved, the aim of completely protecting the environment is achieved, meanwhile, the bonding property of the foam and a base material is improved, and the production requirement of the process is met.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

Screen printing method

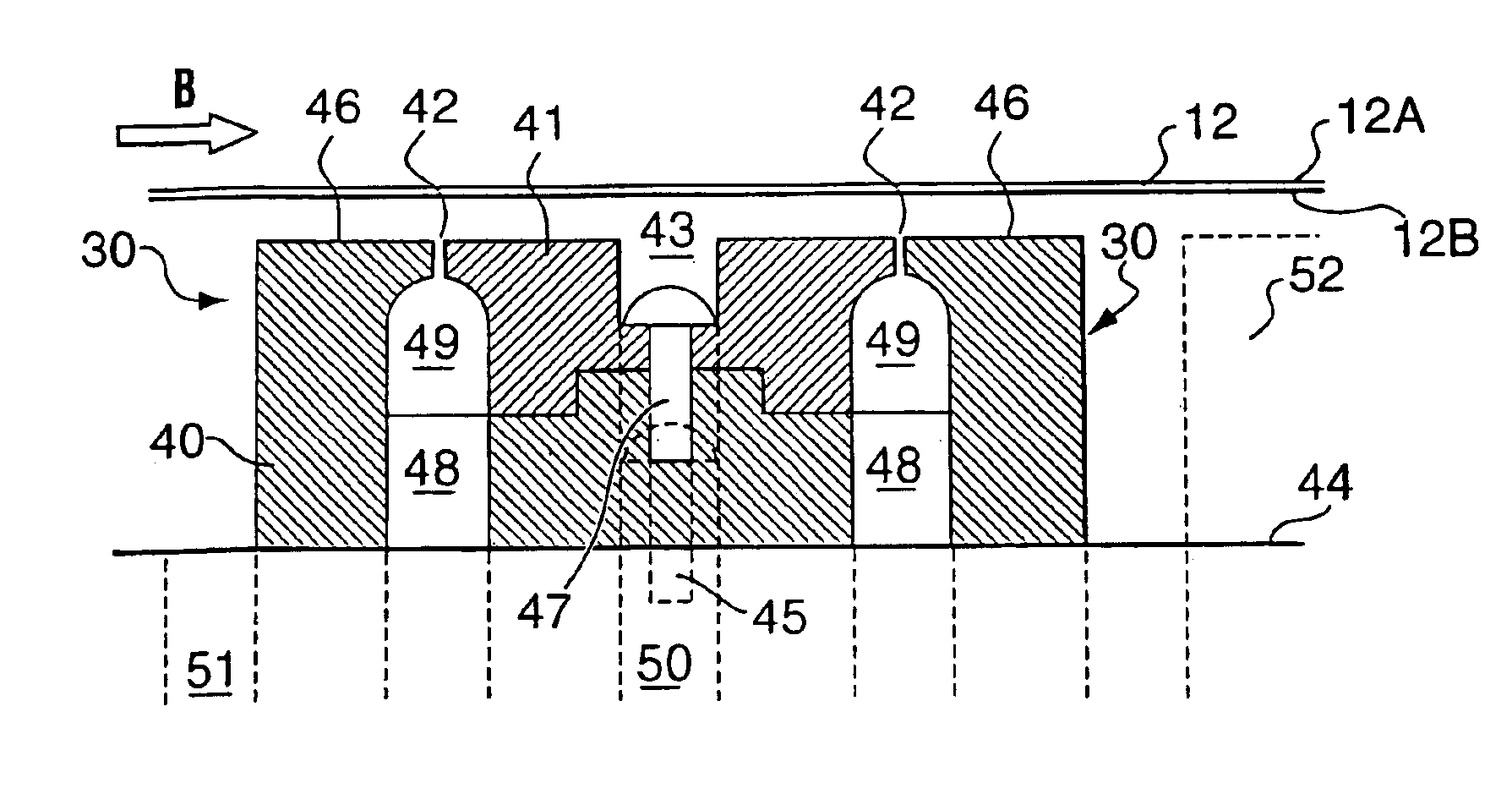

InactiveUS20030188645A1Avoid uneven surfacesAvoid excess materialInking apparatusScreen printersScreen printingEngineering

Disclosed are a screen printing method which is carried out by placing a material to be printed at a predetermined portion of a printing table, feeding a paste state or ink state coating material to a surface of a screen plate for printing, and sliding the surface of the screen plate by using a squeegee to carry out screen printing, the method comprises the steps of a coating step in which the above-mentioned paste state or ink state coating material is covering on the surface of the screen plate for printing with a thin thickness, and a printing step in which the paste state or ink state coating material coated on the surface of the screen plate for printing is printed to a material to be printed by the above-mentioned squeegee under vacuum or atmospheric pressure, and after the above-mentioned coating step, a degassing step is provided to degas bubbles in the coated material by changing the pressure from high vacuum state to atmospheric pressure or low vacuum state.

Owner:NEW LONG SEIMITSU INDS

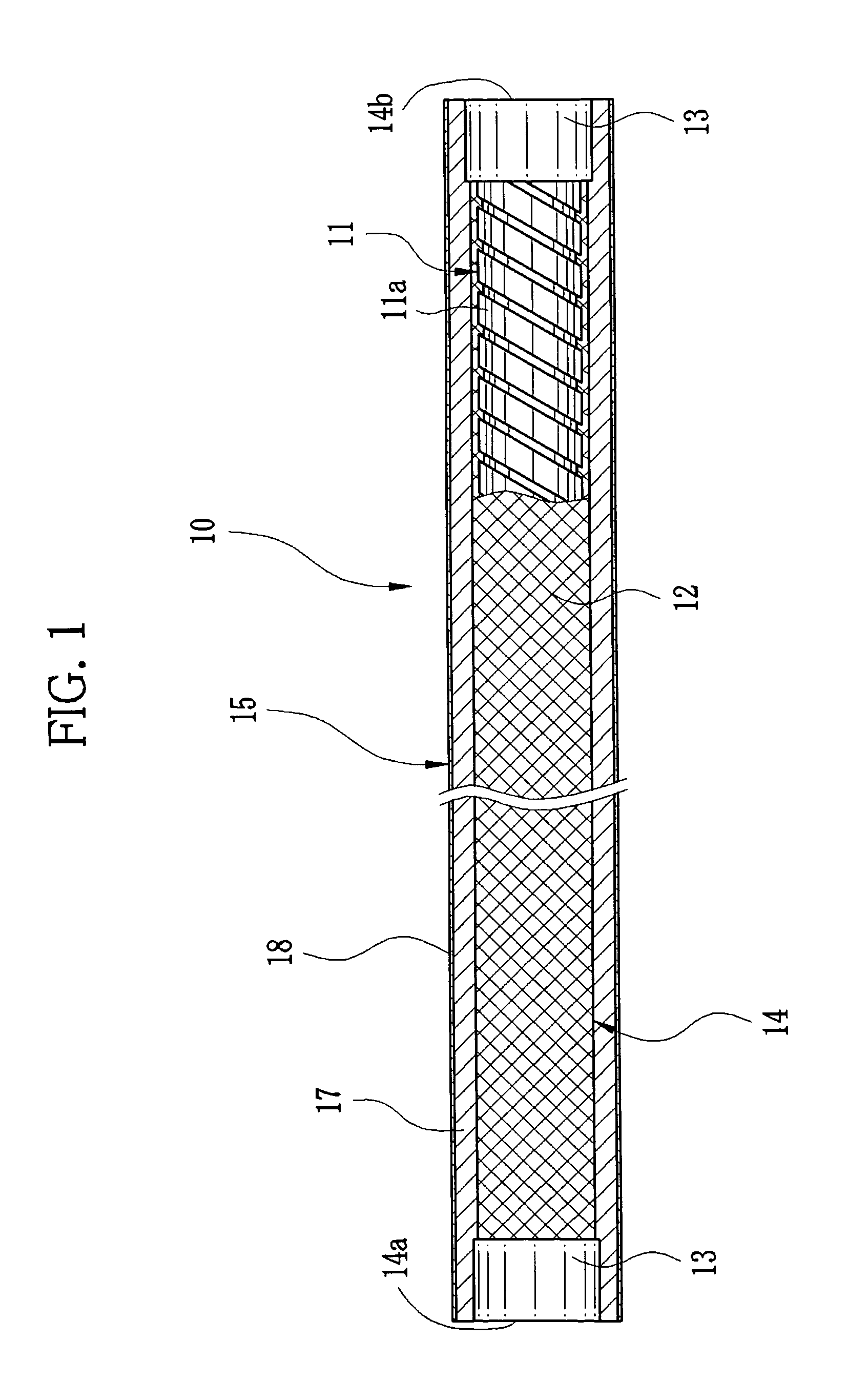

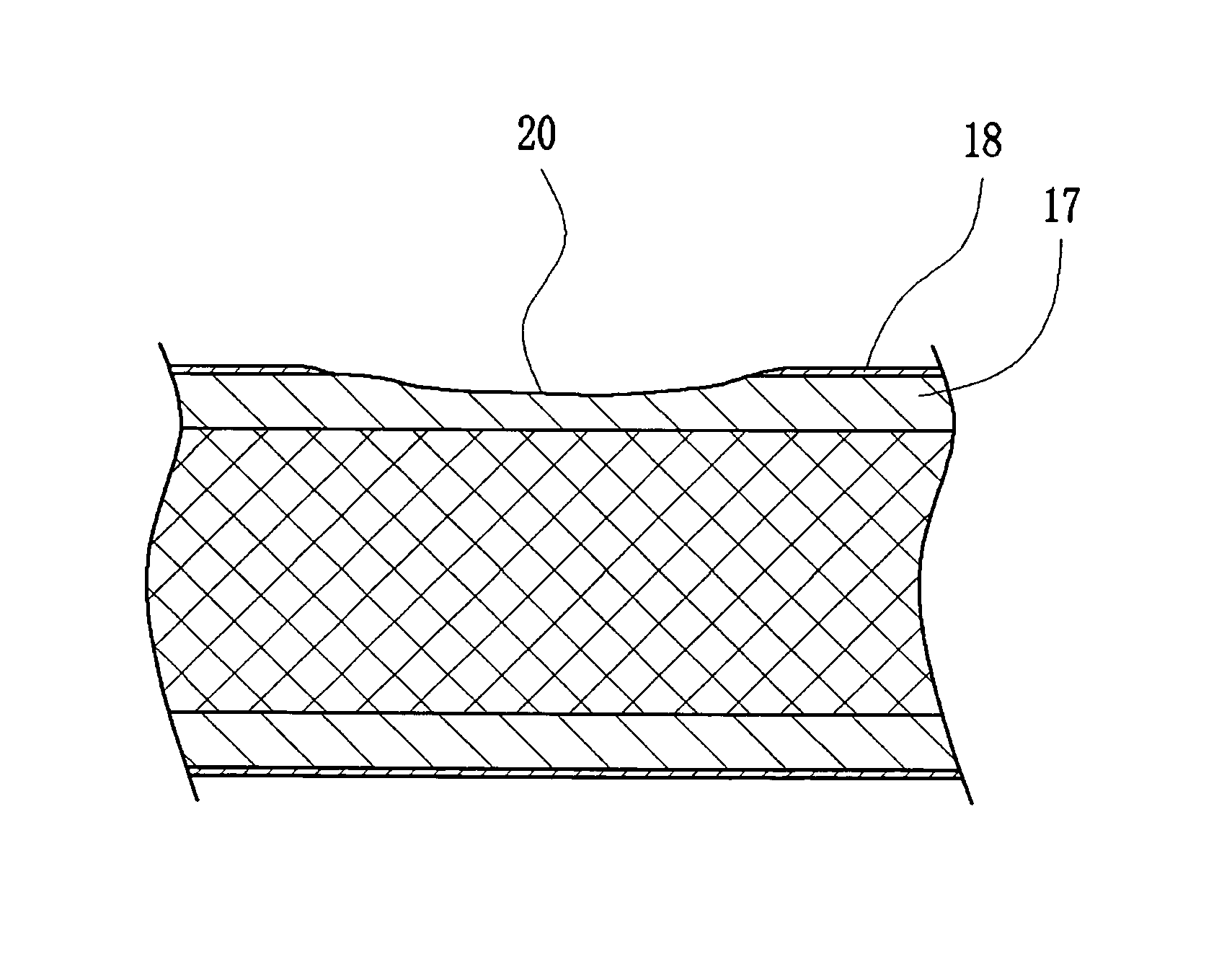

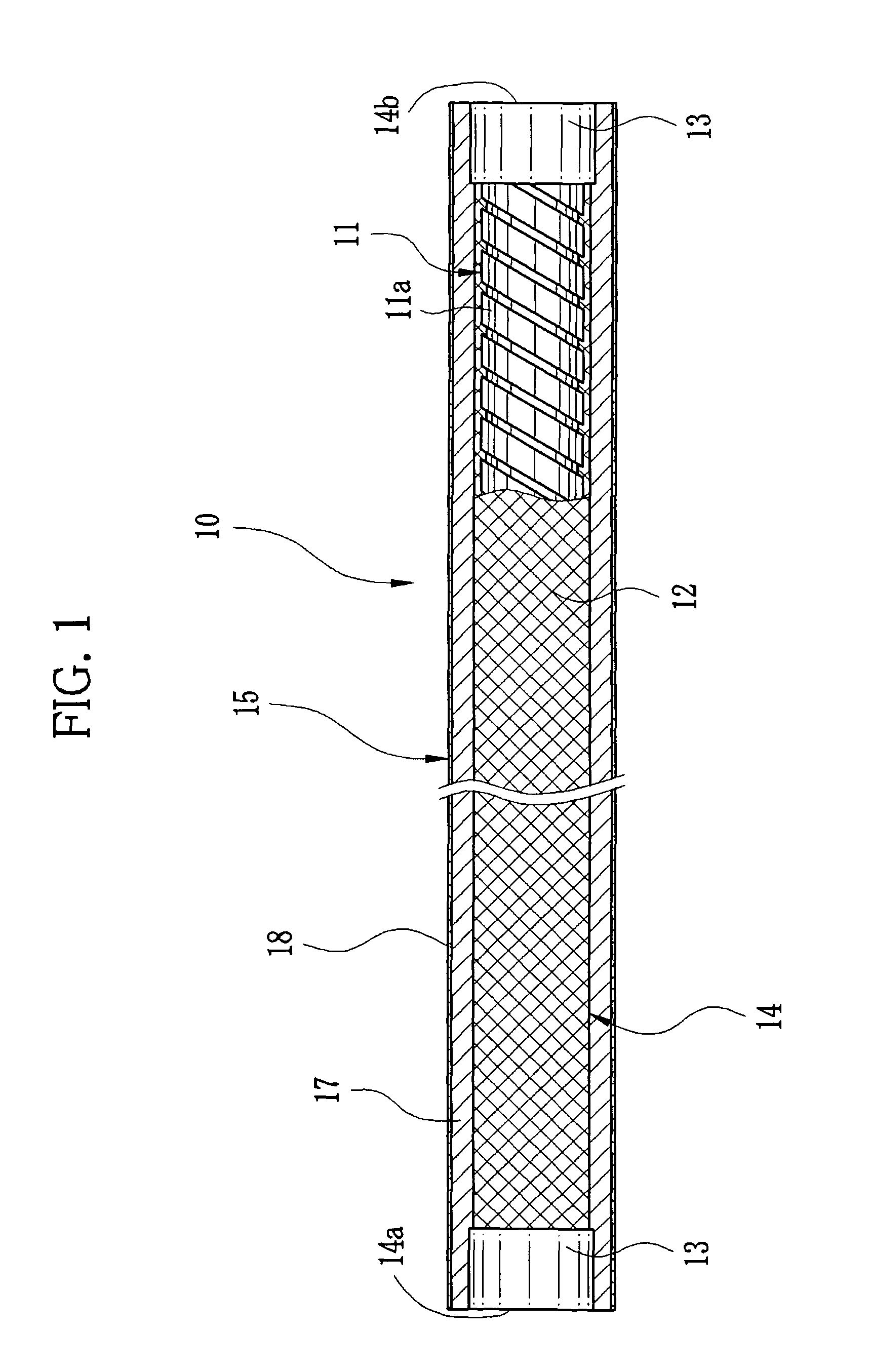

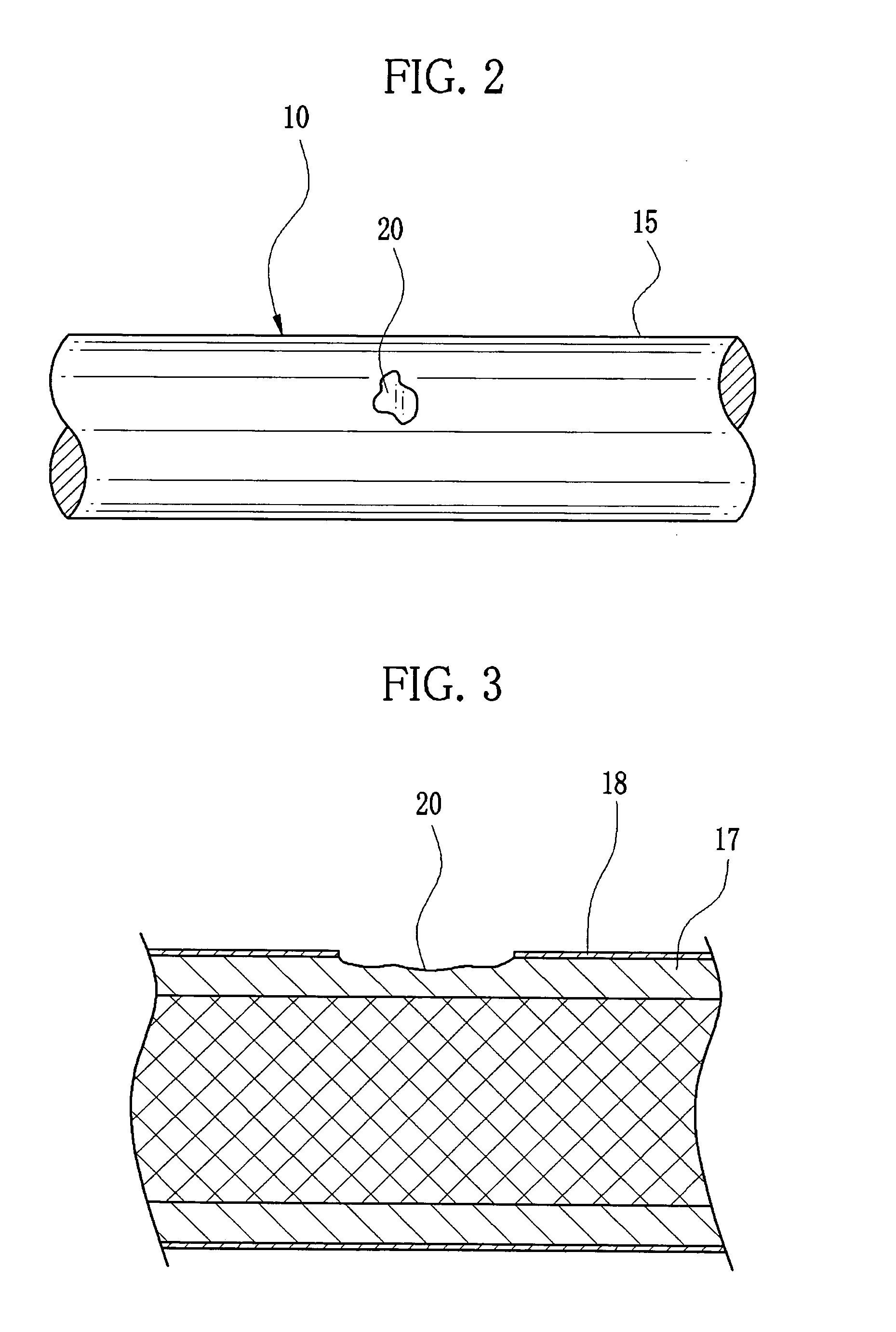

Method for repairing flexible tube

ActiveUS20100000621A1Avoid uneven surfacesSurface irregularities of the repaired flexible tube are preventedEndoscopesPipe elementsRepair materialEngineering

Around a damaged area of a jacket of a flexible tube, a top coat layer whose adhesion to a polymer layer is weak is peeled off with an adhesive tape. The damaged area and its immediate surrounding area are sanded, and then wiped with ethanol for cleaning. A main agent and a hardening agent are heated and defoamed while being mixed to prepare a repair material. The repair material is applied to the damaged area and the immediate surrounding area. A heat shrink tube is opened along slits in an end portion and covers the flexible tube. The heat shrink tube is shrunk with hot air, pressing the repair material and making it flush with a surface of the jacket. The flexible tube is heated with an electric hot plate to harden the repair material. Thereafter, the heat shrink tube is peeled off from the flexible tube.

Owner:FUJIFILM CORP

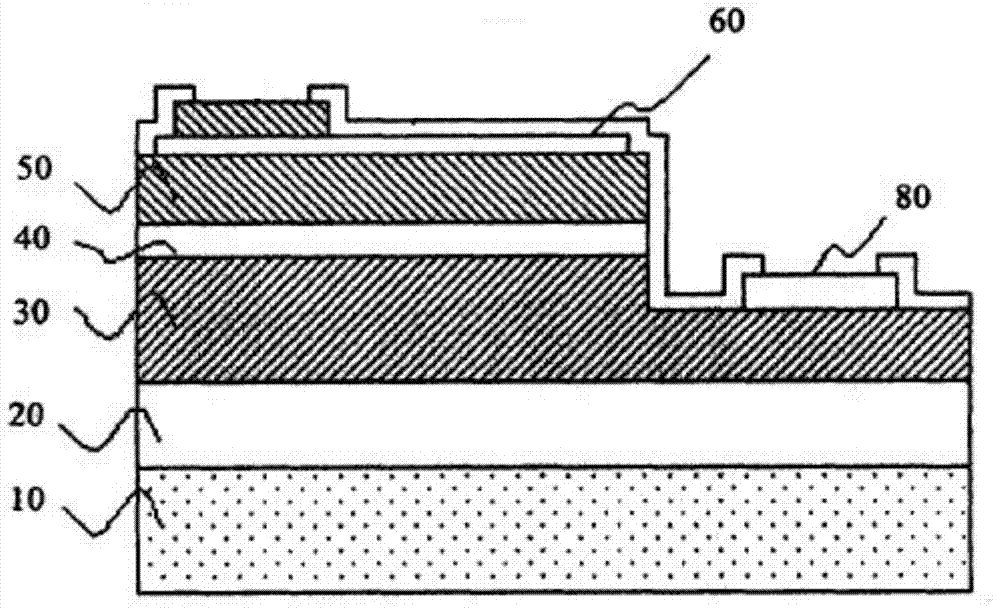

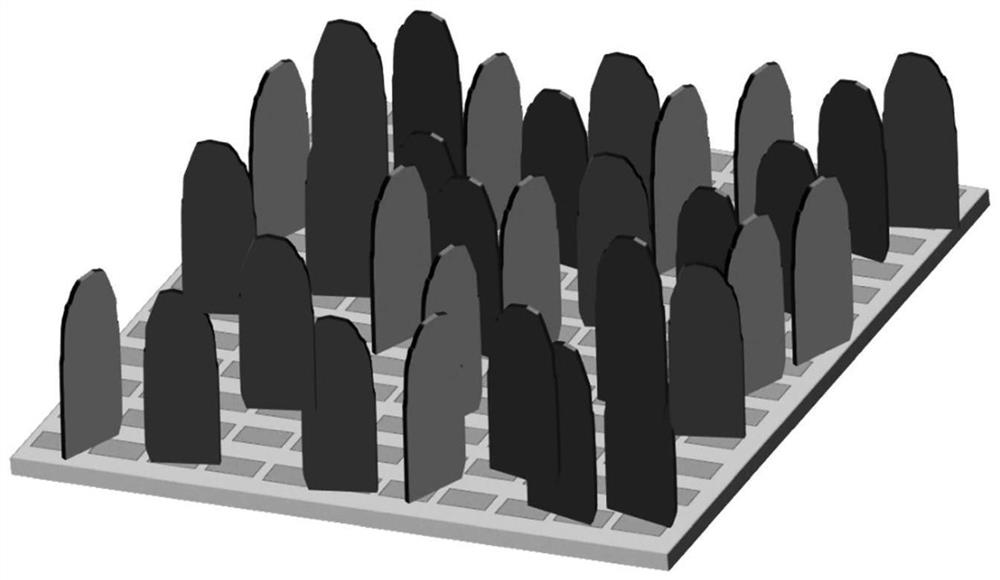

Semiconductor light-emitting device and manufacturing method thereof

ActiveCN104733579AImprove recombination radiation efficiencyAvoid uneven surfacesSemiconductor devicesIndiumQuantum well

The invention discloses a semiconductor light-emitting device and a manufacturing method thereof. The semiconductor light-emitting device comprises a substrate, a crystallizing layer formed on the substrate, a gallium nitride buffering layer, an N-type gallium nitride layer, a transition layer, a multi-quantum-well layer and a P-type gallium nitride layer and further comprises a low-temperature gallium nitride layer and a stress release layer, wherein the low-temperature gallium nitride layer is formed on the N-type gallium nitride layer, a plurality of concave pits are formed in the low-temperature gallium nitride layer, the thickness of the stress release layer is smaller than 100 nm, the stress release layer is composed of 1-K layers of Inx(k)Ga1- x(K)N which are sequentially formed on the low-temperature gallium nitride layer, the thickness d<k> of the kth layer of Inx(k)Ga1- x(K)N is smaller than the thickness d<k-1> of the (k-1)th layer of Inx(k-1)Ga1- x(K-1)N, x(k) is larger than x(k-1), k is equal to 1,...,K, and K is smaller than or equal to 5; the concave pits are covered with the P-type gallium nitride layer. The number of the InGaN layers in the stress release layer and the overall thickness are adjusted according to In components of quantum wells so that the In components of the InGaN layers can be gradually increased from the bottom layer to the surface, the thickness is gradually reduced, and the purpose of gradually releasing stress is achieved.

Owner:扬州德豪润达光电有限公司

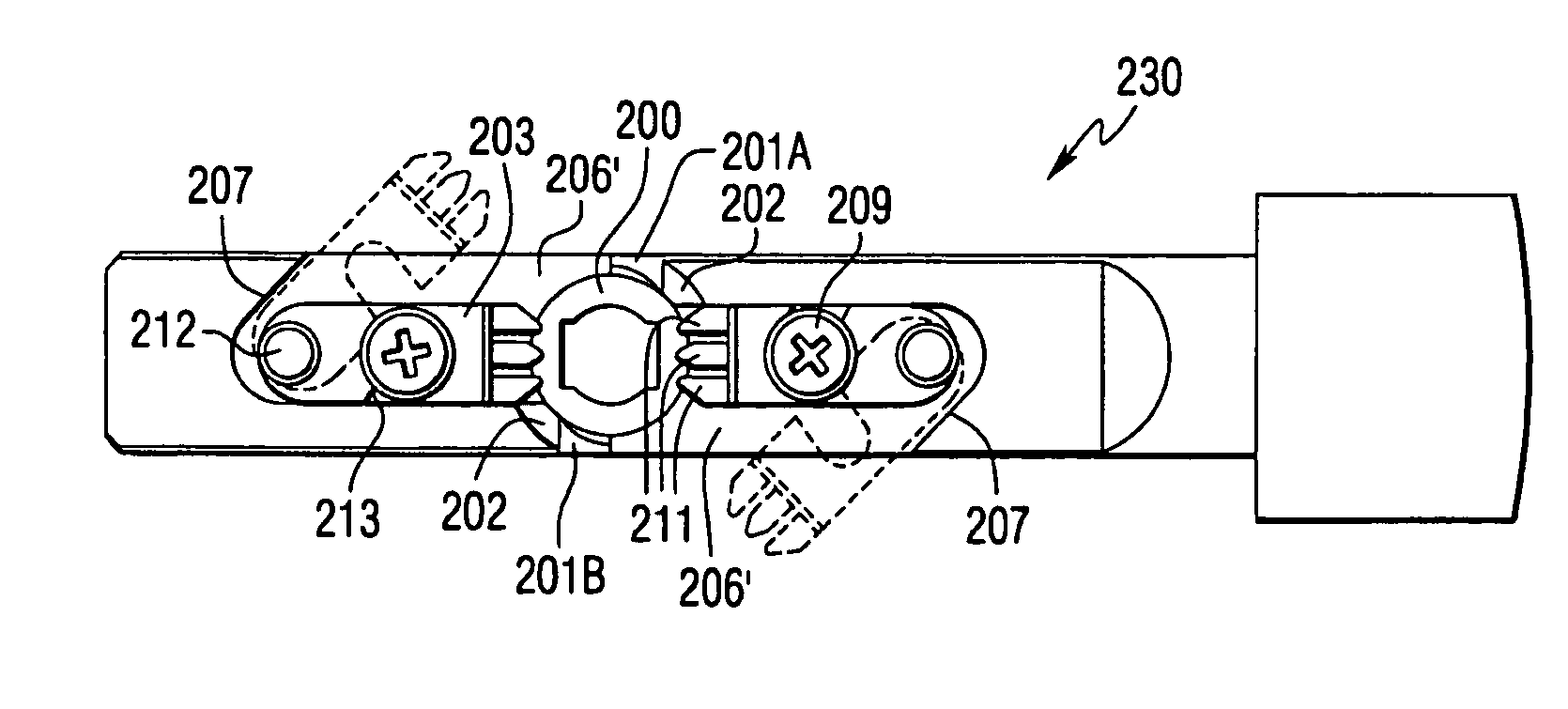

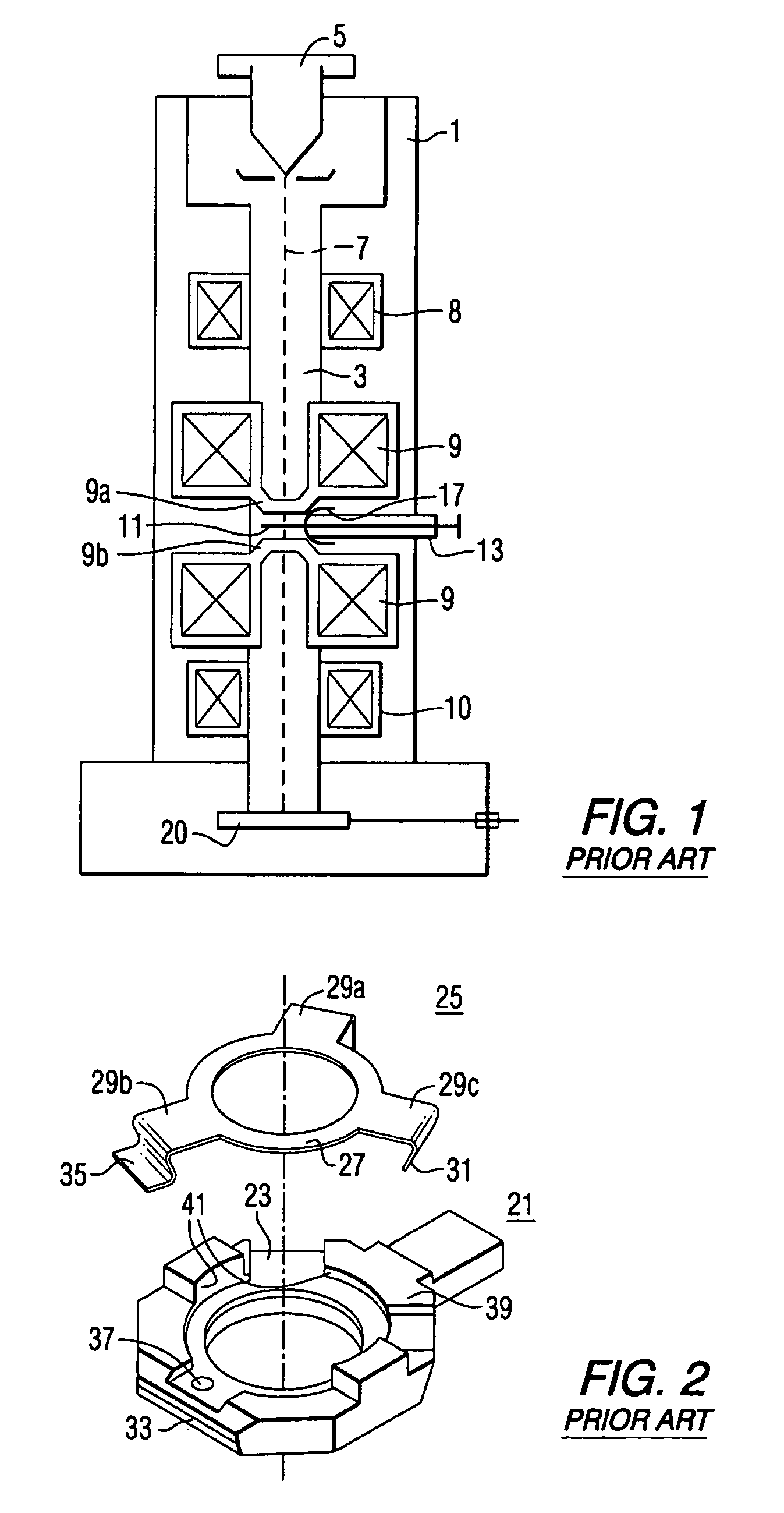

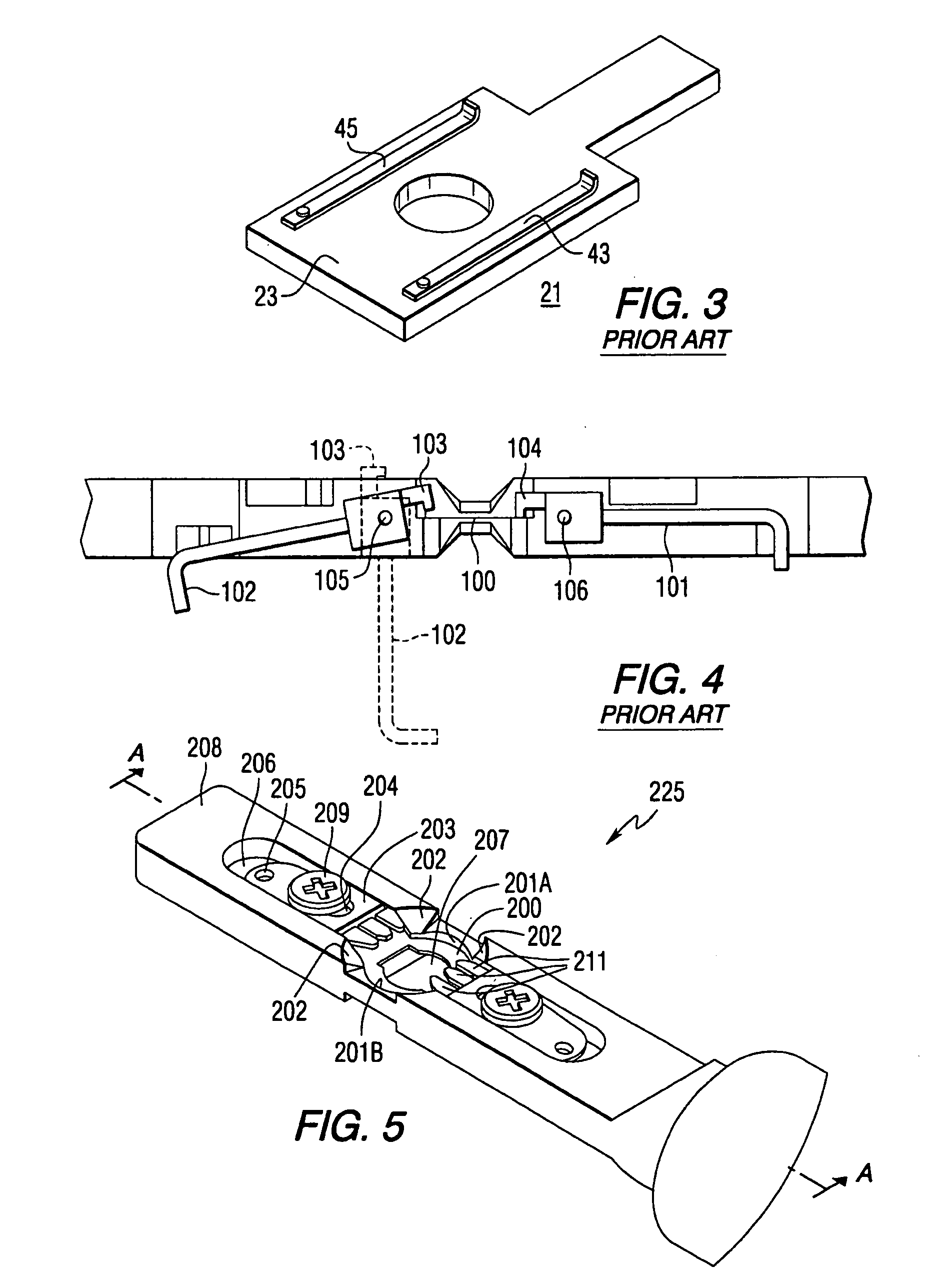

Specimen holding apparatus

InactiveUS7219565B2Simpler and reliable processPrecise visual alignmentElectric discharge tubesForce measurementBiomedical engineeringSupport surface

Owner:E A FISCHIONE INSTR

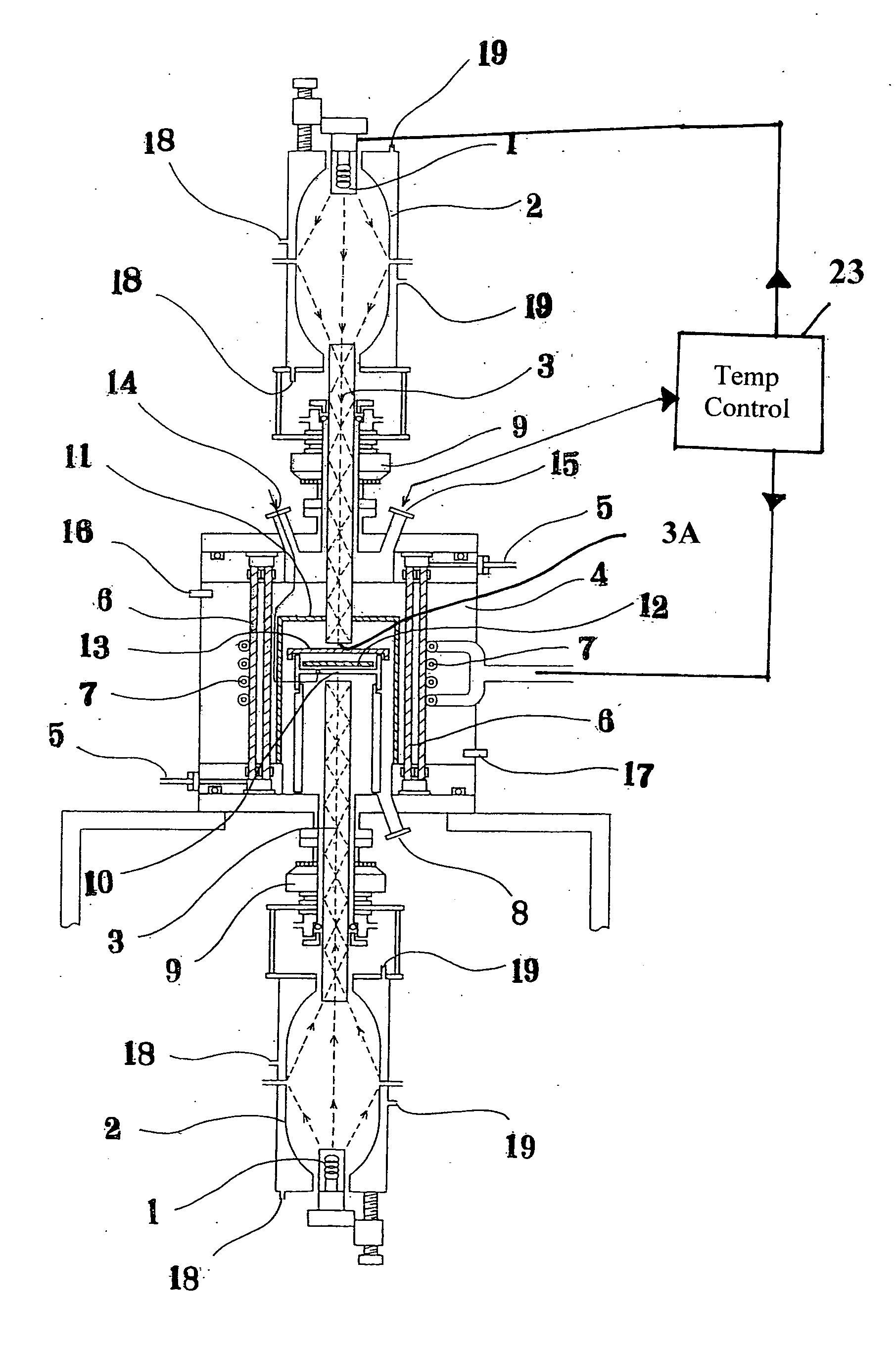

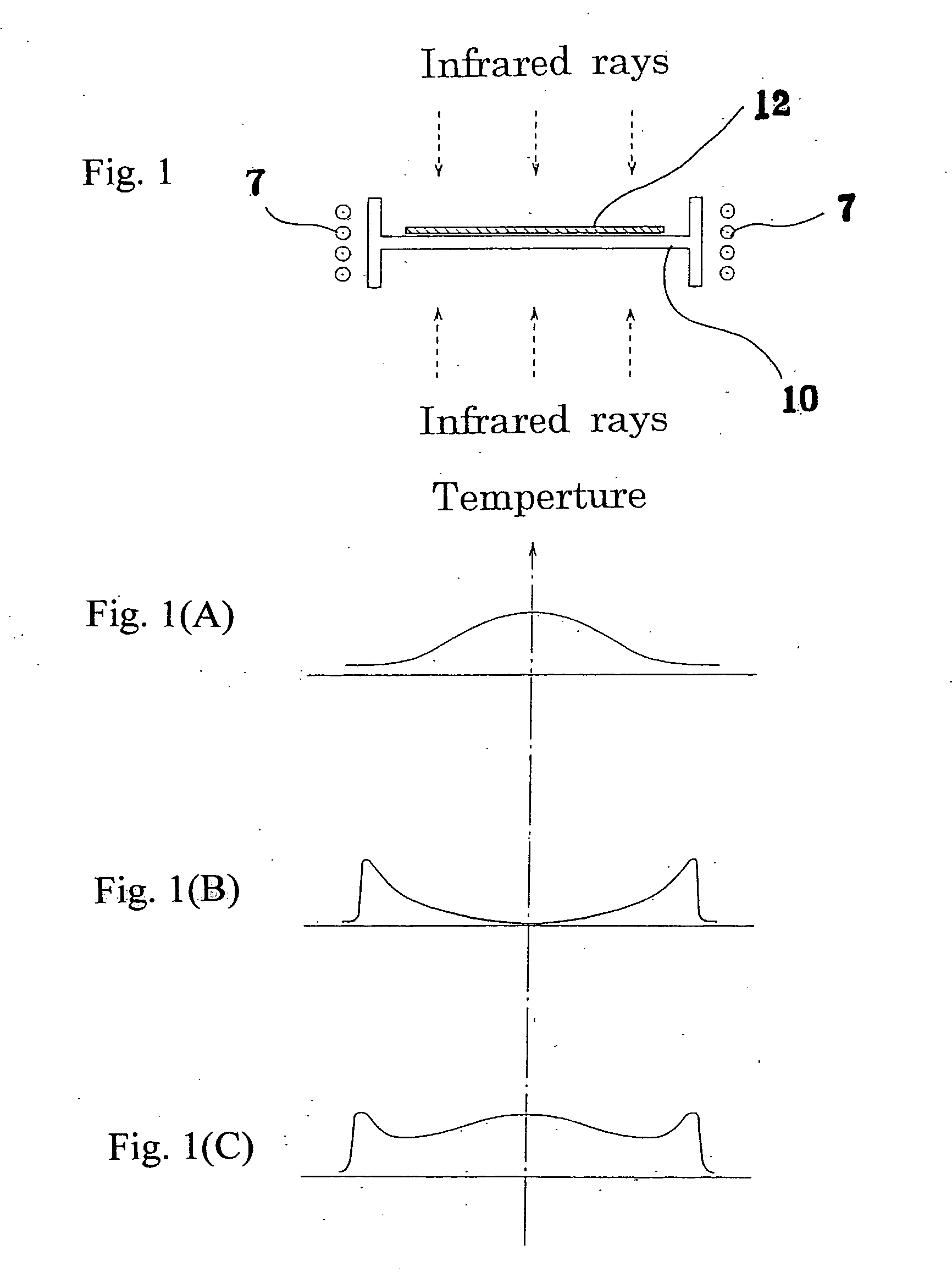

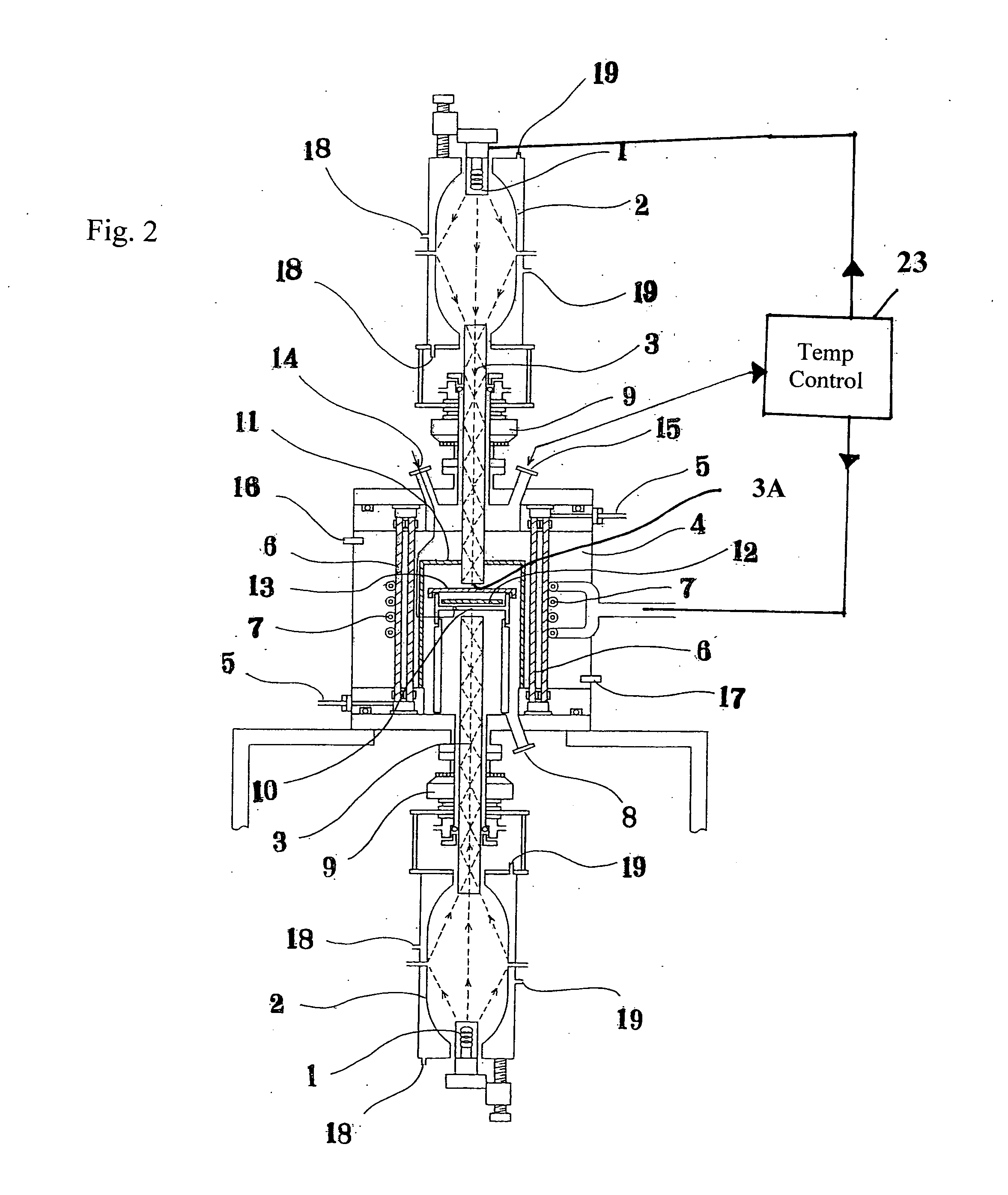

Thermal treatment equipment

InactiveUS20050183820A1Quality improvementAvoid uneven surfacesMuffle furnacesSemiconductor/solid-state device manufacturingIn planeInfrared lamp

Thermal treatment equipment for rapidly heating a SiC substrate having a diameter of several inches or larger to a temperature as high as 1200° C. or higher with a high in-plane evenness by heating a peripheral zone of a substrate using high frequency induction and by heating a central zone of the substrate using infrared lamps while the substrate and a stage thereof are covered with a shield plate.

Owner:NAT INST OF ADVANCED IND SCI & TECH +2

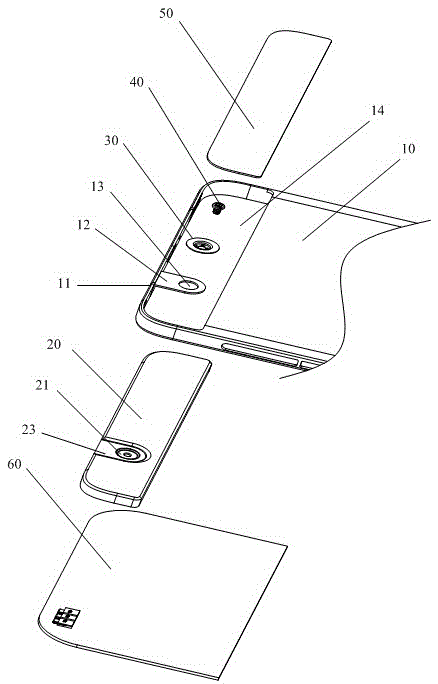

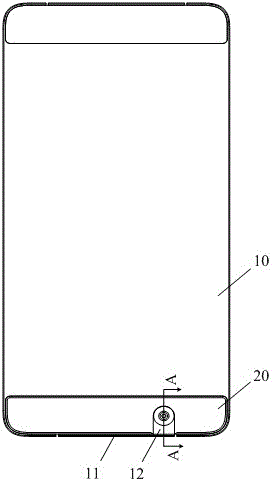

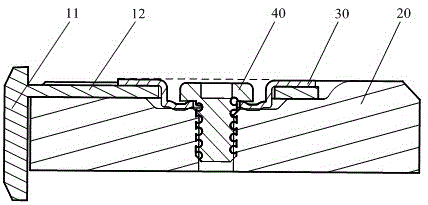

Mobile terminal

ActiveCN105576345AAchieve conductionAvoid uneven surfacesAntenna supports/mountingsAntenna equipments with additional functionsElectrical connectionEngineering

The invention discloses a mobile terminal, and relates to the structure technical field of mobile terminals. The mobile terminal solves the problem in the prior art that after the thinning process of a metal frame, during the conduction process of the metal frame and the antenna of an antenna bracket by a bolt, the bolt is raised out of a plastic rear cover so as to cause the non-flush phenomenon of the plastic rear cover and a metal rear cover. The mobile terminal comprises a casing metal frame, a conduction piece and an antenna bracket. The casing metal frame is provided with an electrical connection part. The electrical connection part is provided with a through hole. The region of the antenna bracket, corresponding to the through hole, is provided with an accommodating groove. The antenna bracket is provided with a threaded hole in communication with the accommodating groove. A bolt passes through the through hole to be inserted into the threaded hole so as to be in contact with an antenna in the threaded hole. The nut of the bolt is positioned in the through hole and the accommodating groove. The conduction piece is used for the conduction of the electrical connection part with the nut.

Owner:QINGDAO HISENSE MOBILE COMM TECH CO LTD

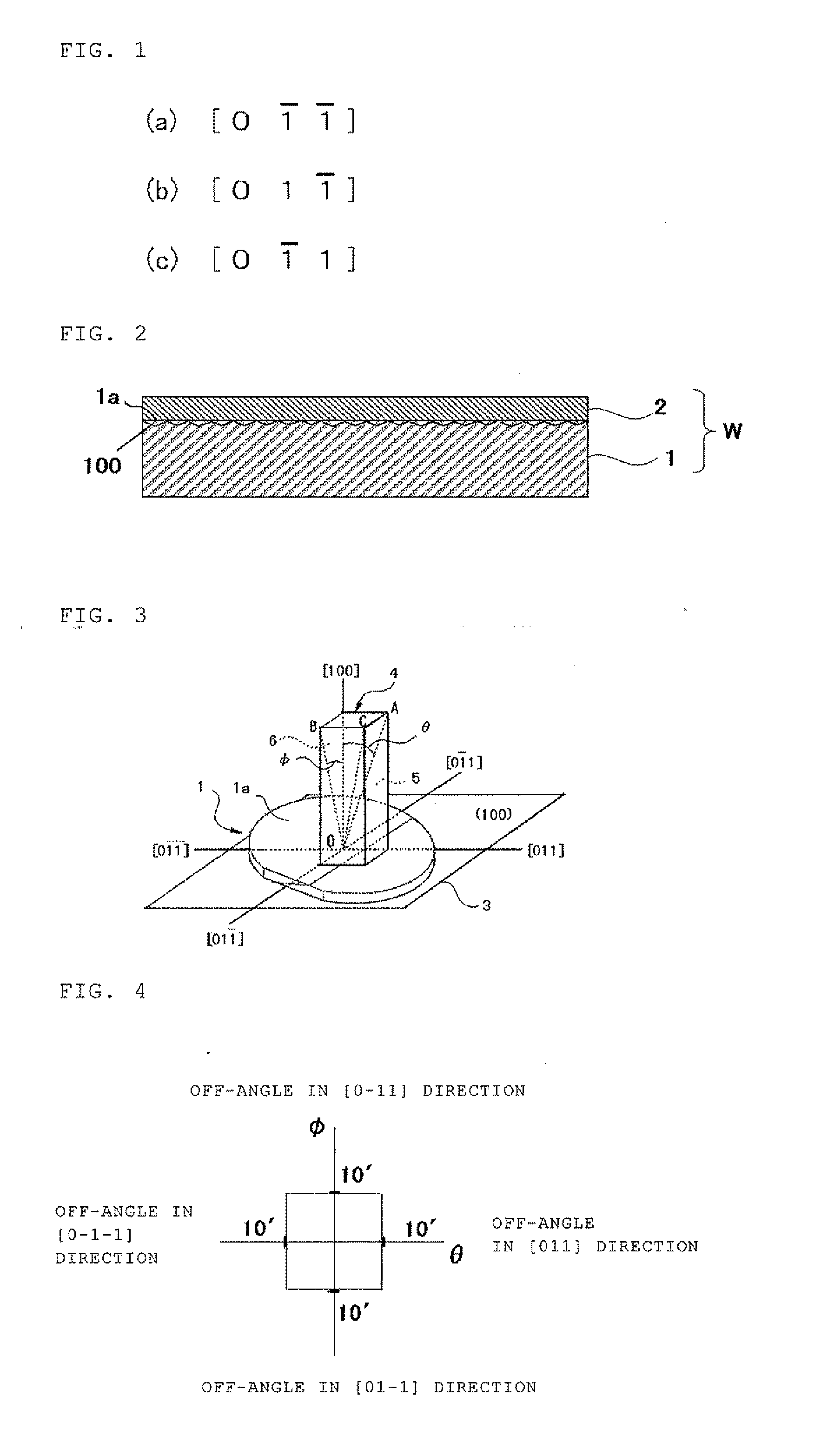

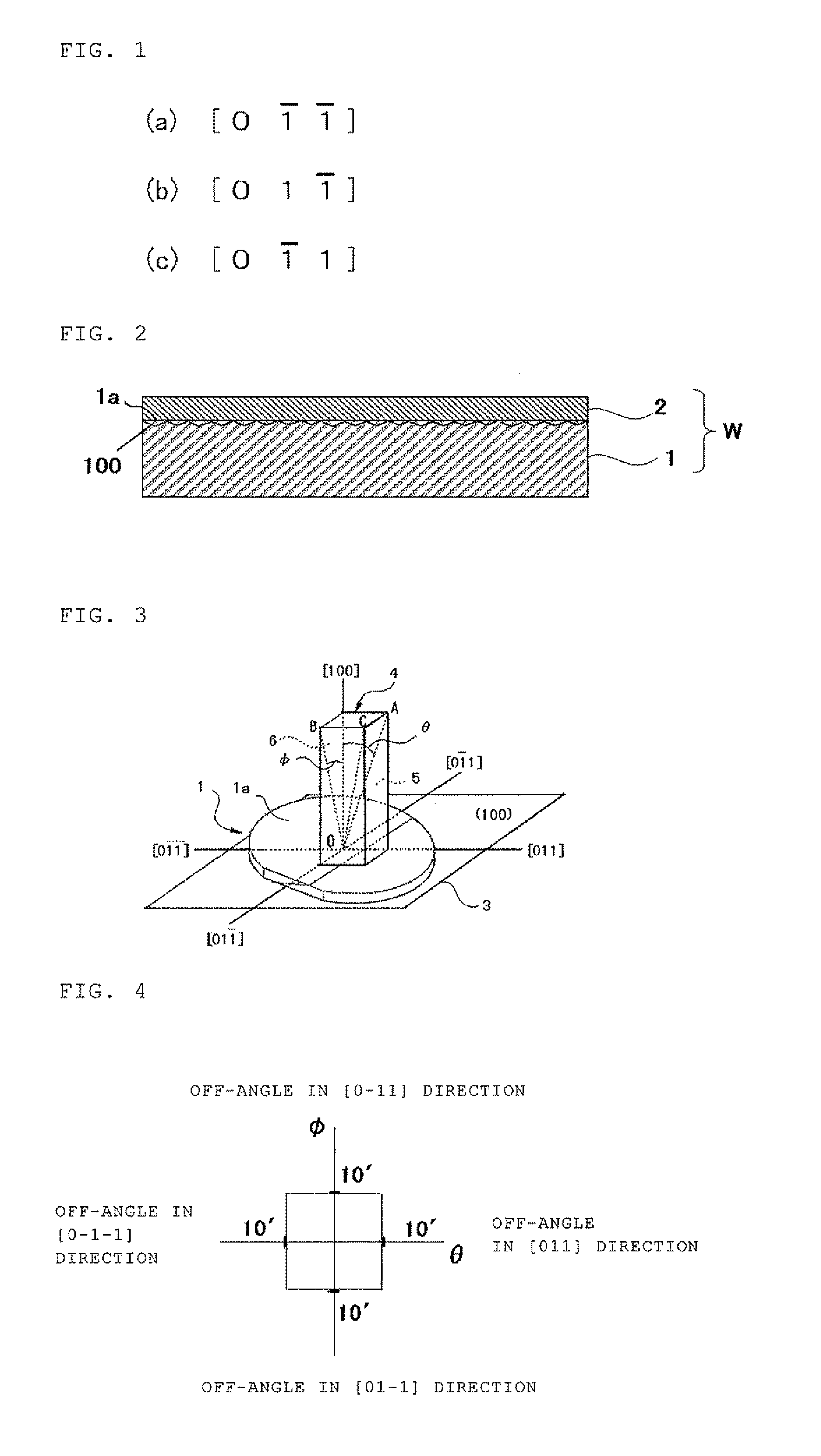

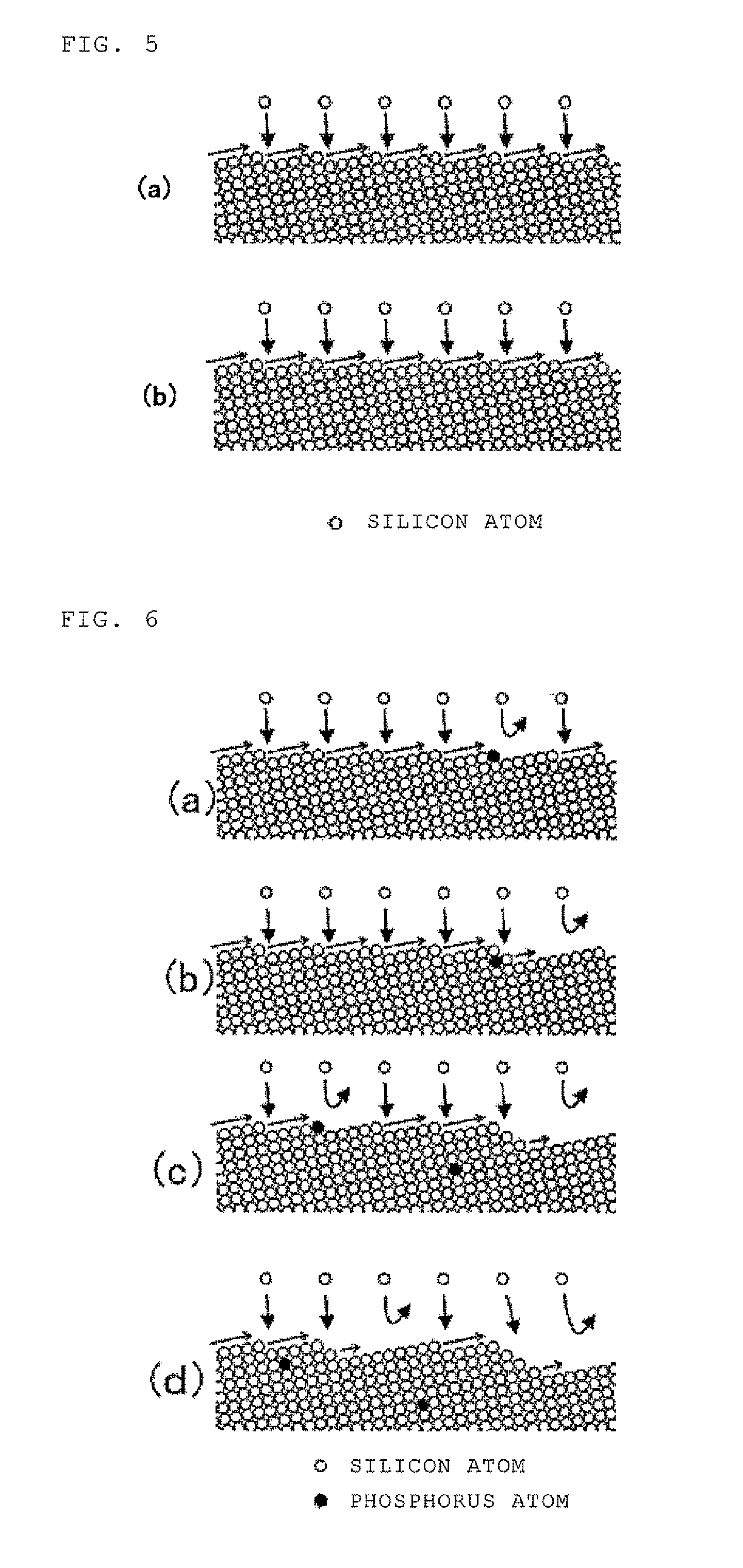

Silicon epitaxial wafer, method for manufacturing the same, bonded soi wafer and method for manufacturing the same

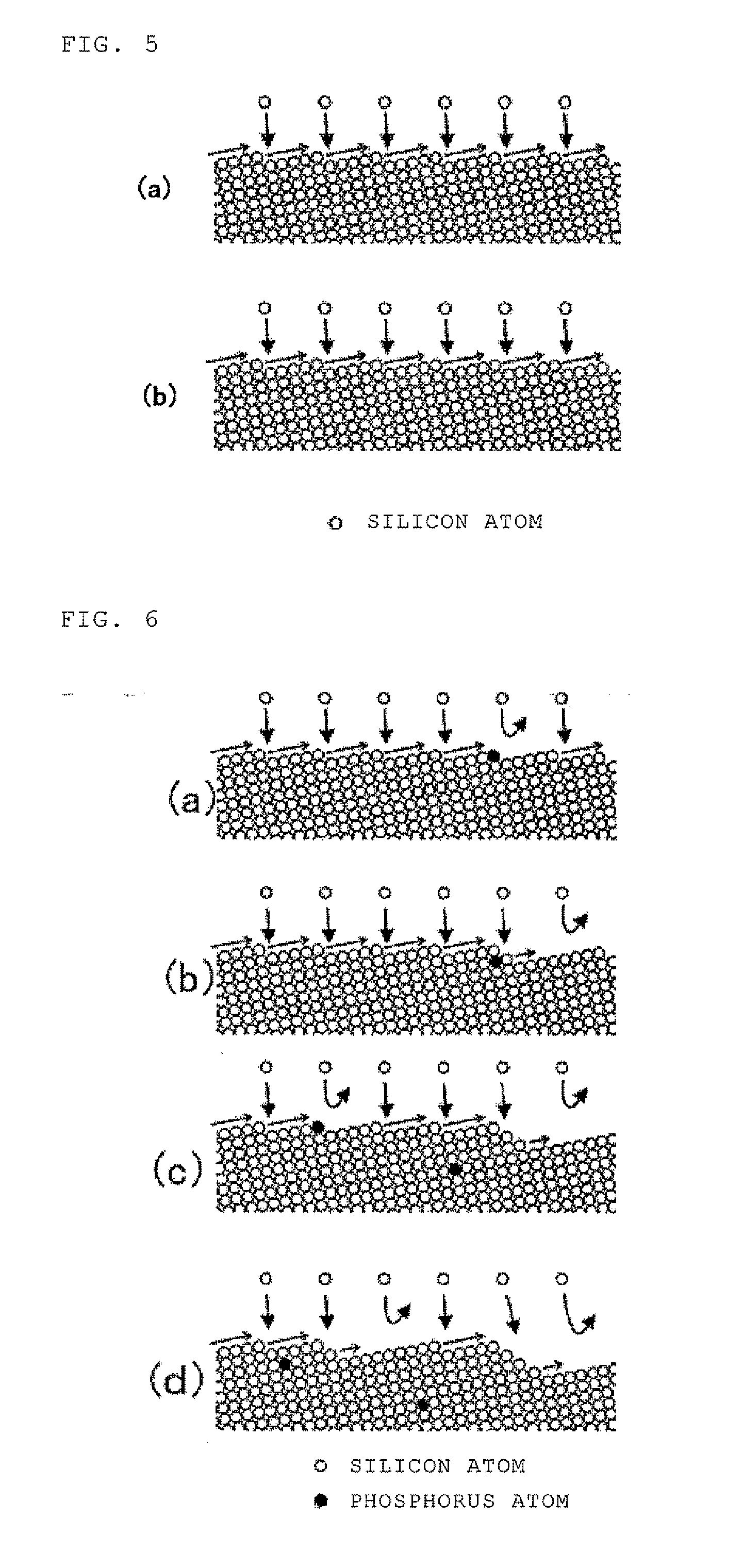

ActiveUS20120326268A1Quality improvementImprove bonding interfaceSemiconductor/solid-state device manufacturingSemiconductor devicesDopantSingle crystal substrate

A silicon epitaxial wafer having a silicon epitaxial layer grown by vapor phase epitaxy on a main surface of a silicon single crystal substrate, wherein the main surface of the silicon single crystal substrate is tilted with respect to a [100] axis at an angle θ in a [011] direction or a [0-1-1] direction from a (100) plane and at an angle Φ in a [01-1] direction or a [0-11] direction from the (100) plane, the angle θ and the angle Φ are less than ten minutes, and a dopant concentration of the silicon epitaxial layer is equal to or more than 1×1019 / cm3. Even when an epitaxial layer having a dopant concentration of 1×1019 / cm3 or more is formed on the main surface of the silicon single crystal substrate, stripe-shaped surface irregularities on the epitaxial layer are inhibited.

Owner:SHIN-ETSU HANDOTAI CO LTD

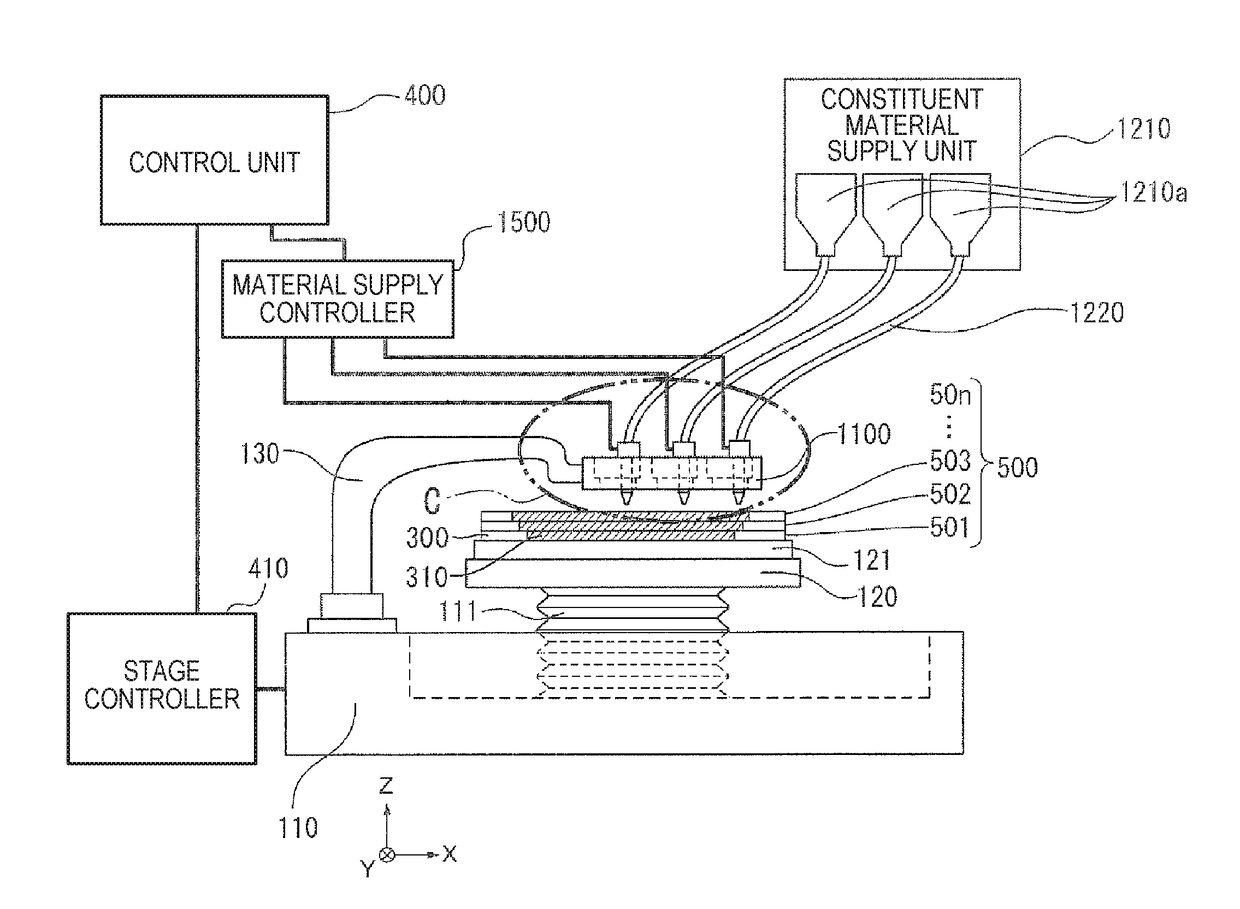

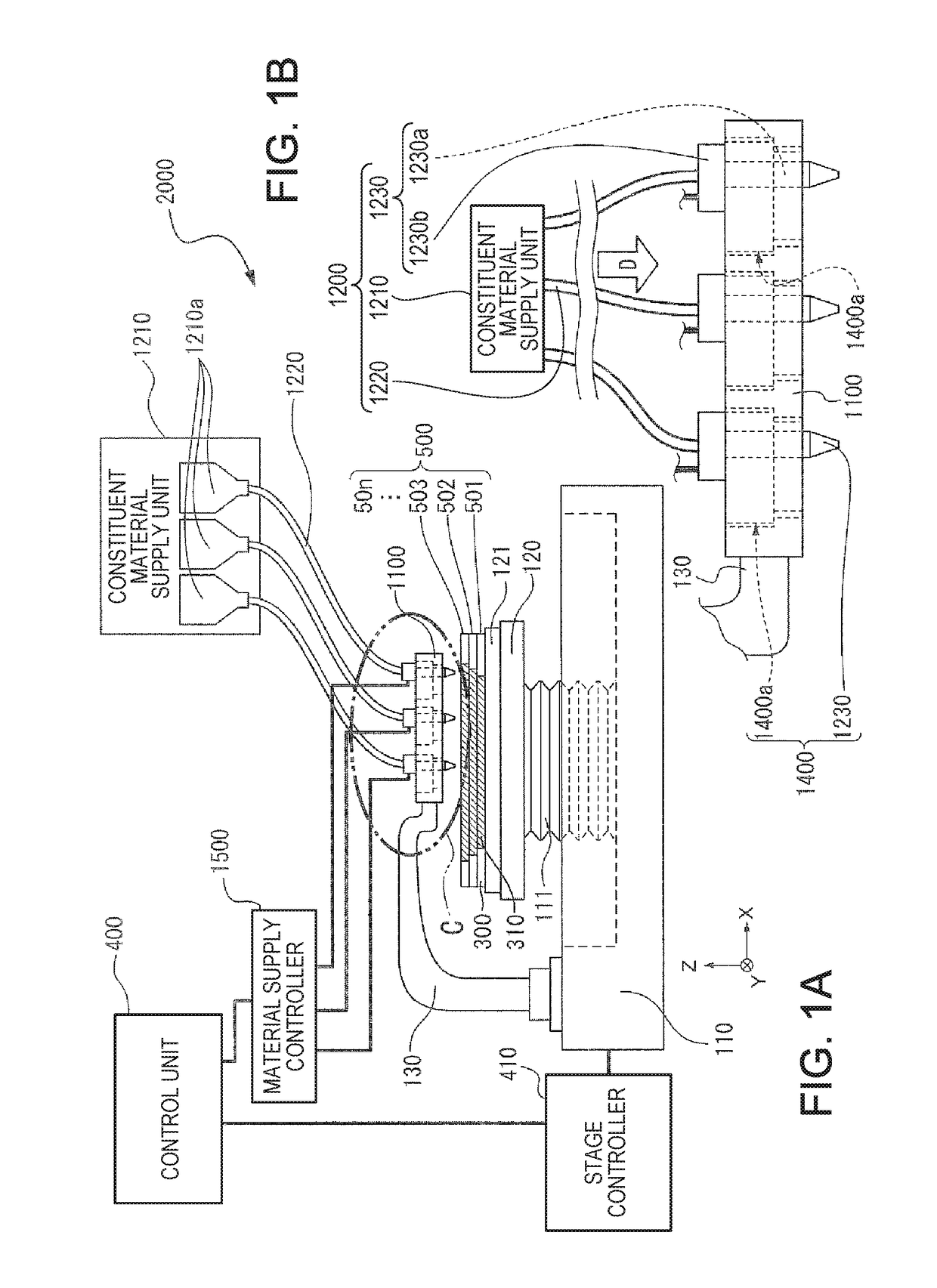

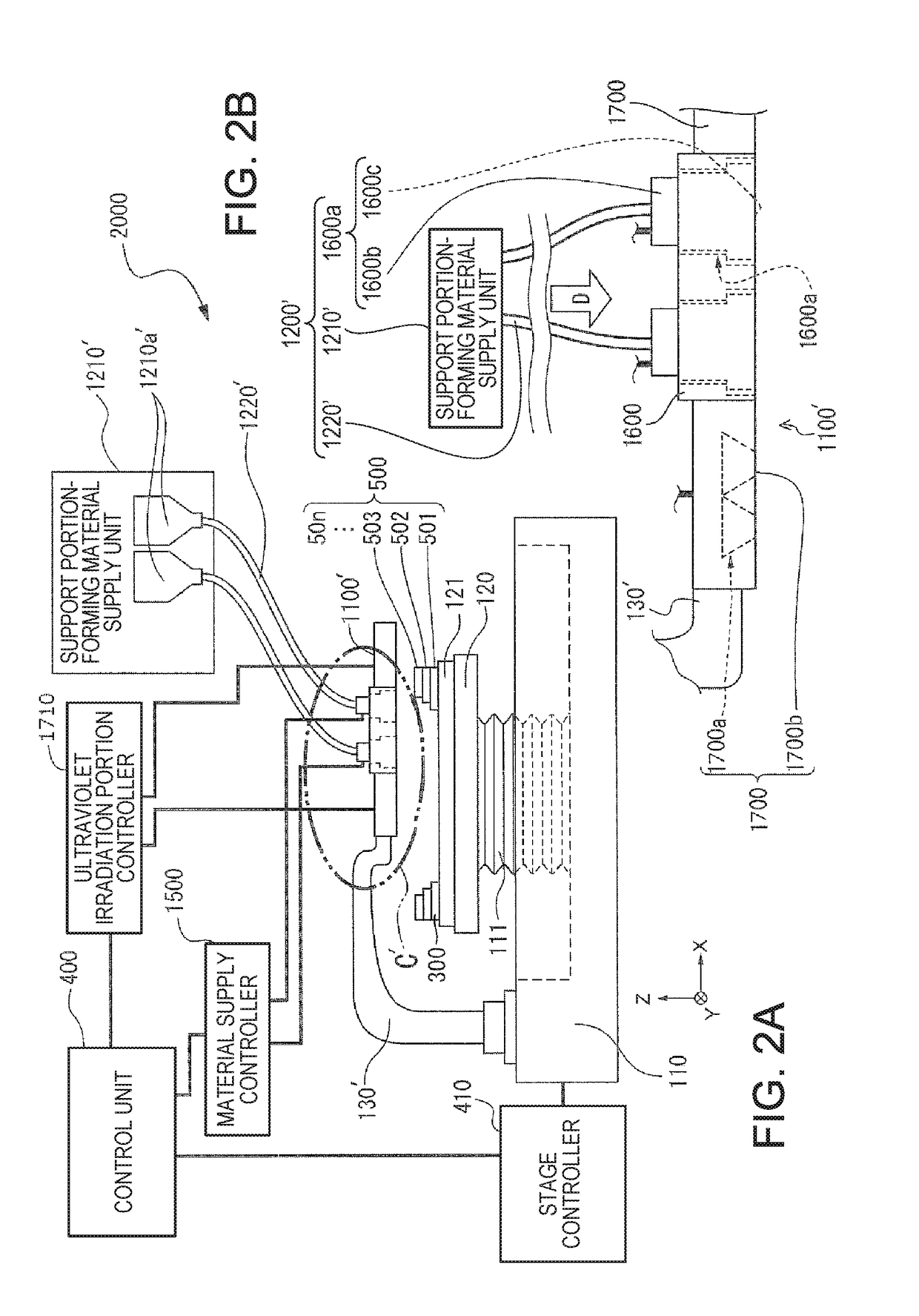

Method of manufacturing three-dimensionally formed object

ActiveUS20170136693A1Fast preparationImprove accuracyAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringLiquid drop

A method of manufacturing a three-dimensionally formed object in which the three-dimensionally formed object is manufactured by laminating layers to forma laminate, includes: forming a constituent layer corresponding to a constituent region of the three-dimensionally formed object; forming a support layer which is in contact with the constituent layer and supports the constituent layer by ejecting a flowable composition including a resin from an ejecting portion in the form of liquid drops; solidifying the support layer; and heating the laminate which is formed in the formation of the constituent layer, the formation of the support layer, and the solidification of the support layer.

Owner:SEIKO EPSON CORP

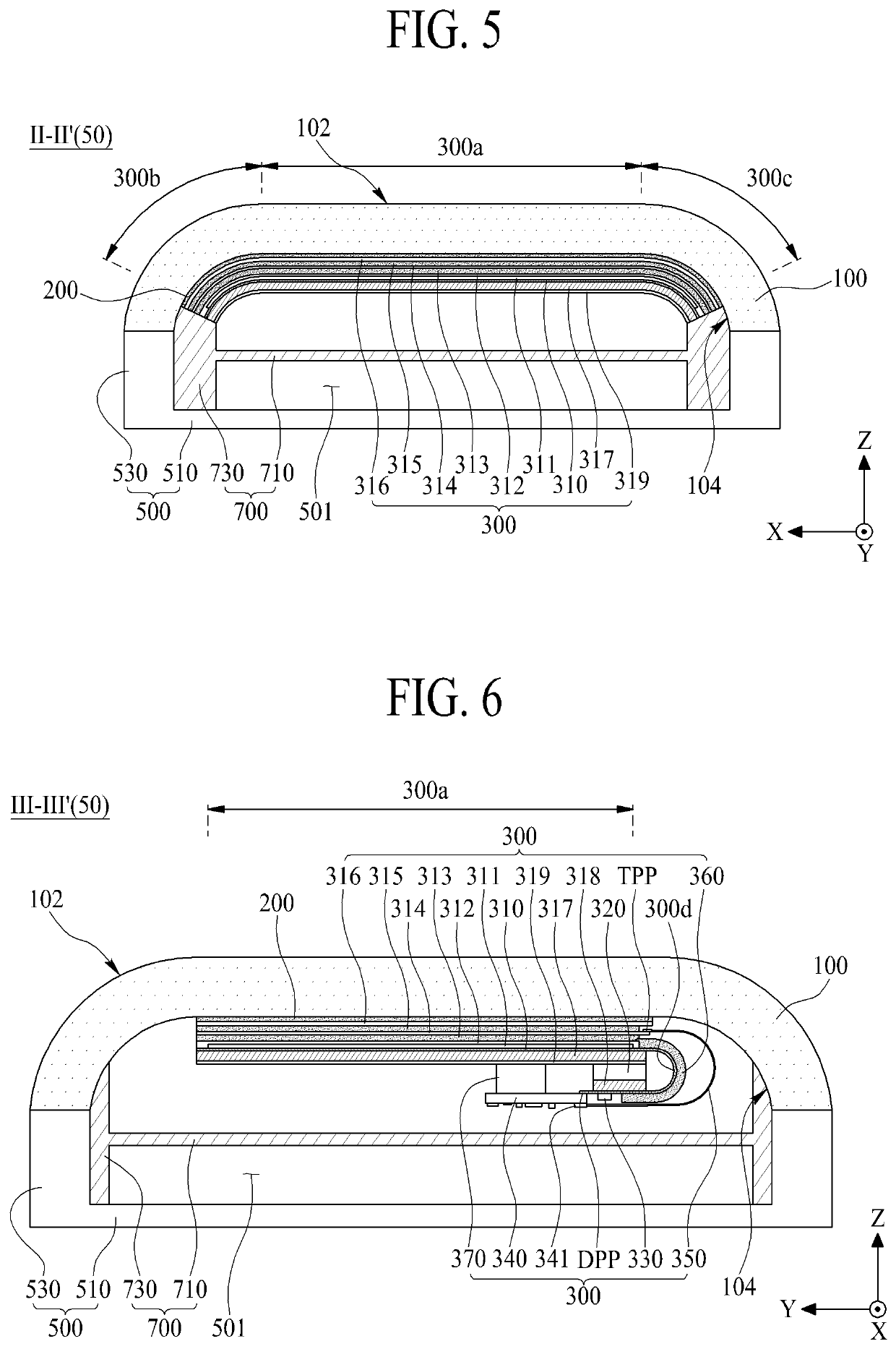

Flexible circuit film and electronic device comprising the same

ActiveUS20200137890A1Avoid uneven surfacesLittle strengthCircuit bendability/stretchabilityInsulating substrate metal adhesion improvementFlexible circuitsThin membrane

A flexible circuit film, which is capable of preventing broken portions during an assembly process, and an electronic device comprising the same is disclosed. The flexible circuit film comprises a bonding pad portion, a body portion, and a film bending portion between the bonding pad portion and the body portion, wherein at least some portion of the film bending portion has a thickness that is less than a thickness of the body portion.

Owner:LG DISPLAY CO LTD

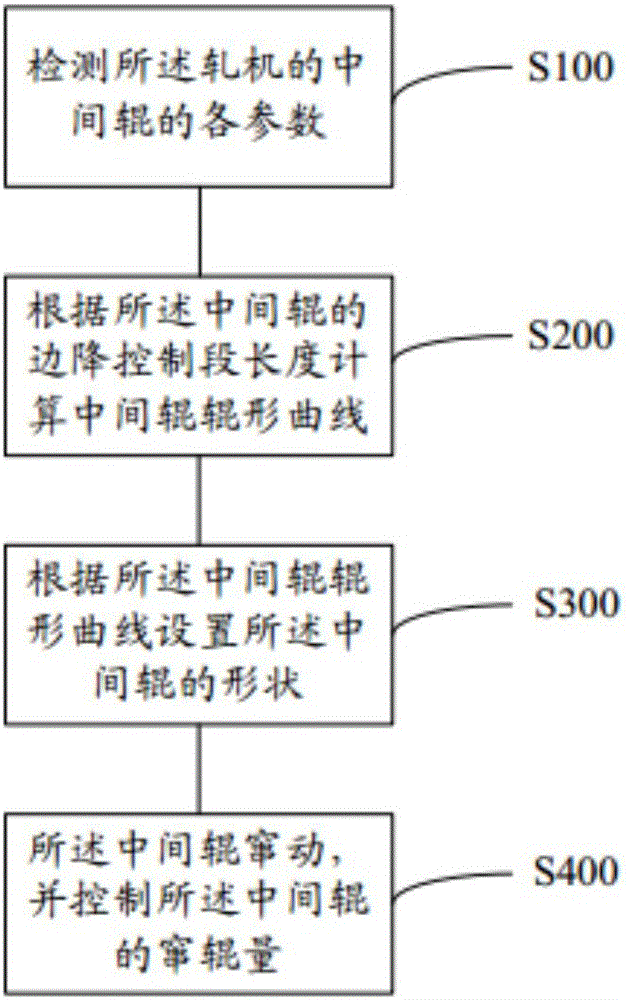

Method for lowering edge drop of tin plate

ActiveCN106111708AImproved edge controlUniform thickness distributionRollsMetal rolling arrangementsTinningEngineering

The invention discloses a method for lowering the edge drop of a tin plate. The method for lowering the edge drop of the tin plate is applied to a rolling mill and comprises the steps that all the parameters of an intermediate roll of the rolling mill are detected, wherein all the parameters of the intermediate roll of the rolling mill comprise the length LIEDC of an edge drop control section of the intermediate roll and the full length LIMR of a roll body of the intermediate roll; according to the length of the edge drop control section of the intermediate roll, a roll shape curve of the intermediate roll is calculated; according to the roll shape curve of the intermediate roll, the shape of the intermediate roll is set; and the roll shifting amount S1 of the intermediate roll is controlled. The method for lowering the edge drop of the tin plate solves the technical problems that in the prior art, the control capacity of the strip steel edge drop of the tin plate is poor and edge waves are difficult to control and achieves the technical effects of improving the control capacity of the edge drip of the tin plate and enabling the thickness distribution of the tin plate to be uniform.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

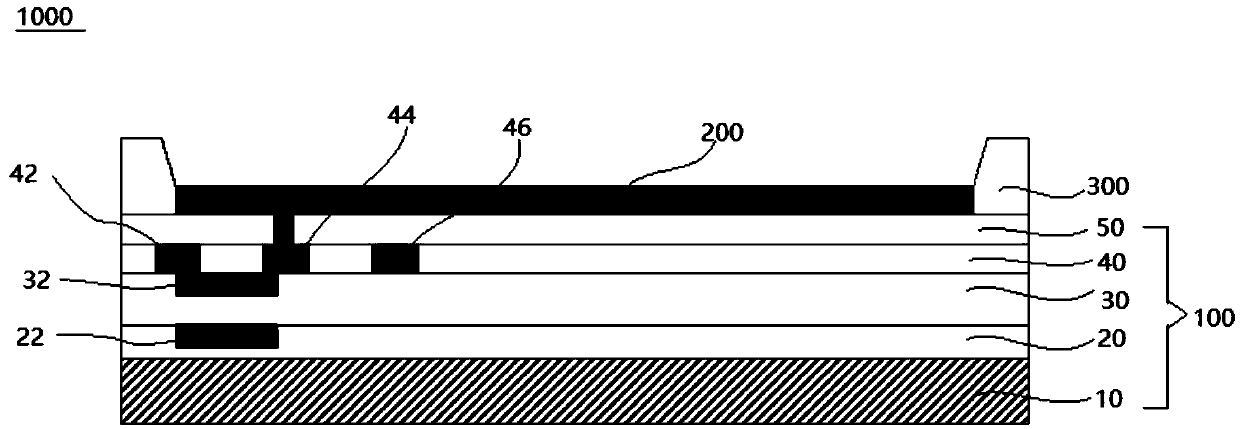

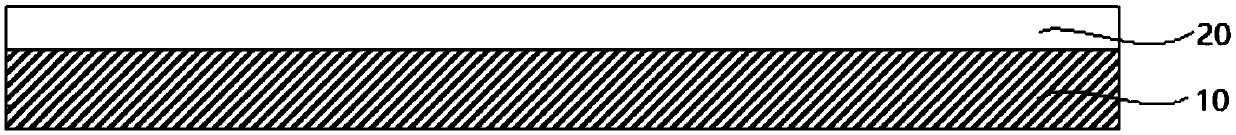

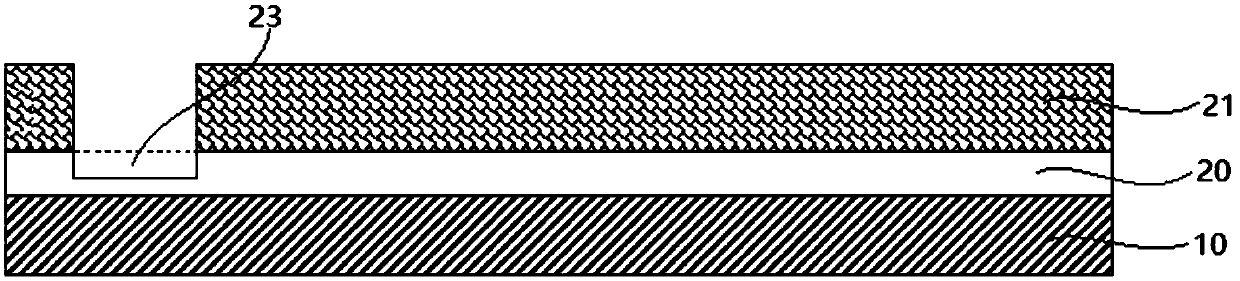

Display panel back plate structure and preparation method thereof, and top emission type display panel

InactiveCN110416257AImprove uniformity of light emissionAvoid uneven surfacesSolid-state devicesSemiconductor devicesAuxiliary electrodeEngineering

The invention relates to a top emission type display panel; the top emission type display panel comprises a substrate, a buffer layer, a grid electrode, an insulating layer, an active layer, a protective layer, a source electrode, a drain electrode, an auxiliary electrode, a flat layer, a pixel electrode and a pixel definition layer. According to the top emission type display panel, the grid electrode is embedded in the buffer layer and forms a flat surface with the buffer layer; the active layer is embedded in the insulating layer and forms a flat surface with the insulating layer; the sourceelectrode, the drain electrode and the auxiliary electrode are embedded in the protective layer and form a flat surface with the protective layer, so that a flat surface is formed on the surface of the whole substrate after a TFT driving circuit is manufactured, the problem that the surface of the pixel electrode is uneven due to the driving circuit of the top emission type display panel is avoided, the luminous uniformity of the top emission display panel is effectively improved, and the display effect is improved.

Owner:GUANGDONG JUHUA PRINTING DISPLAY TECH CO LTD

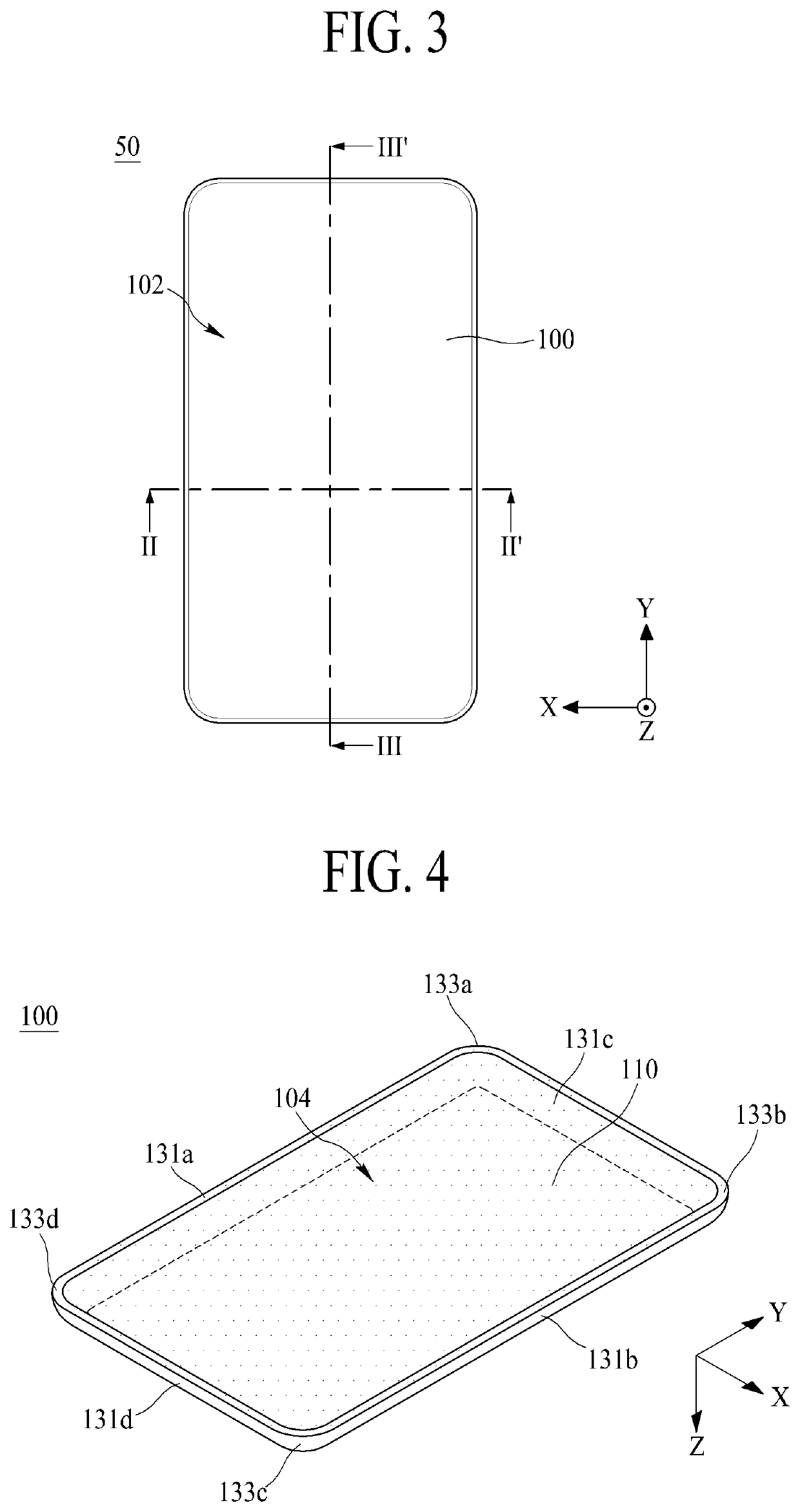

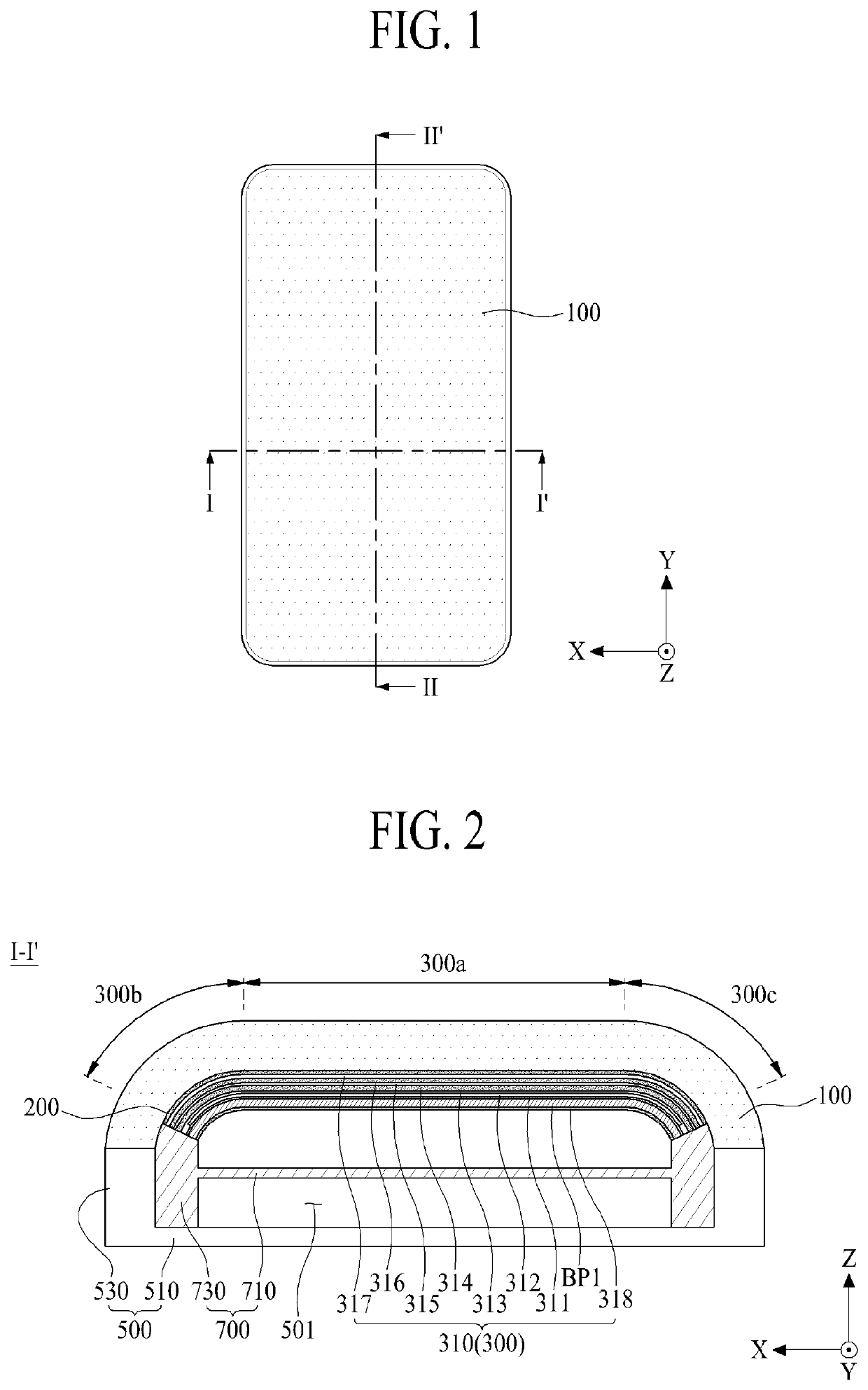

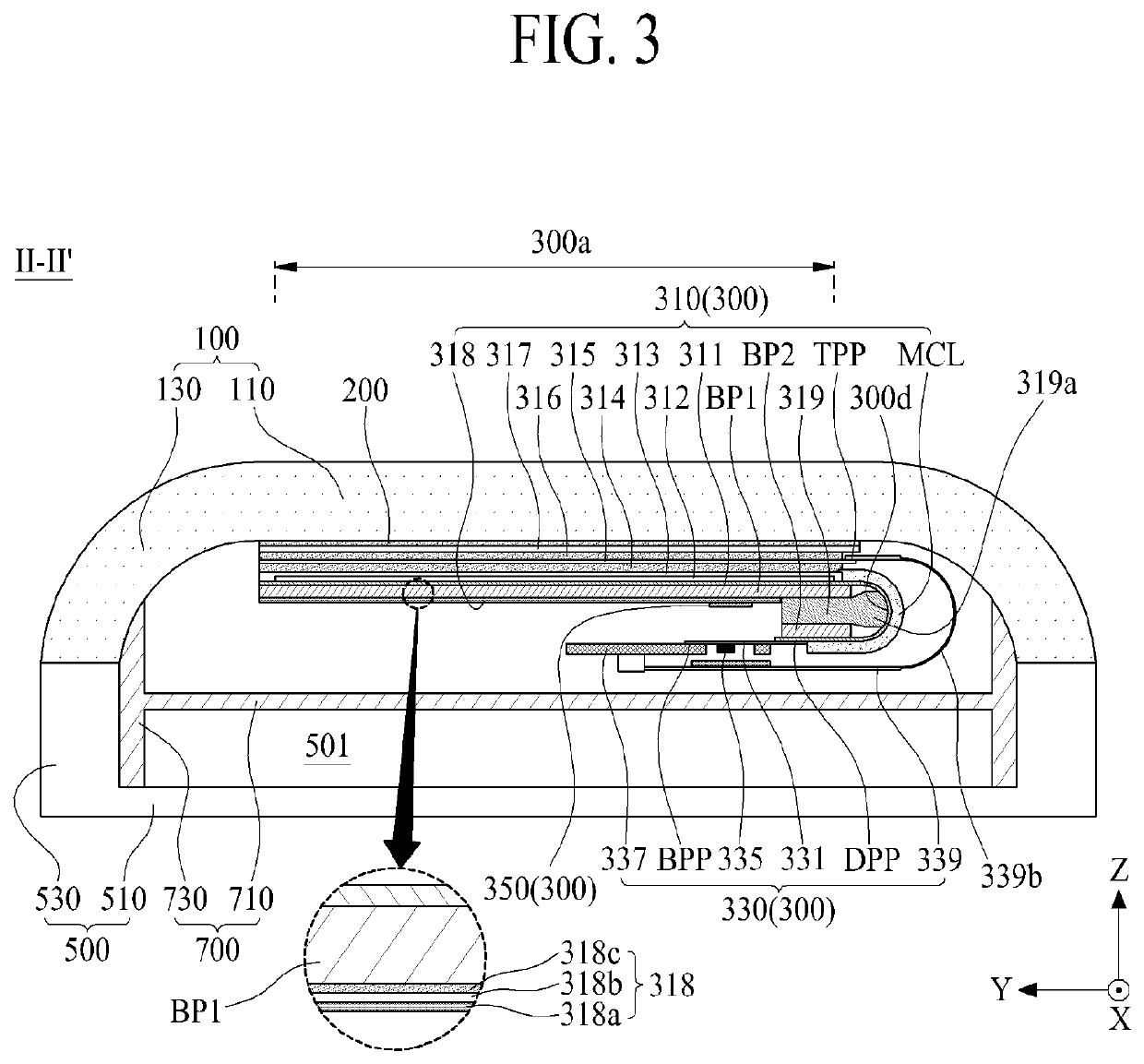

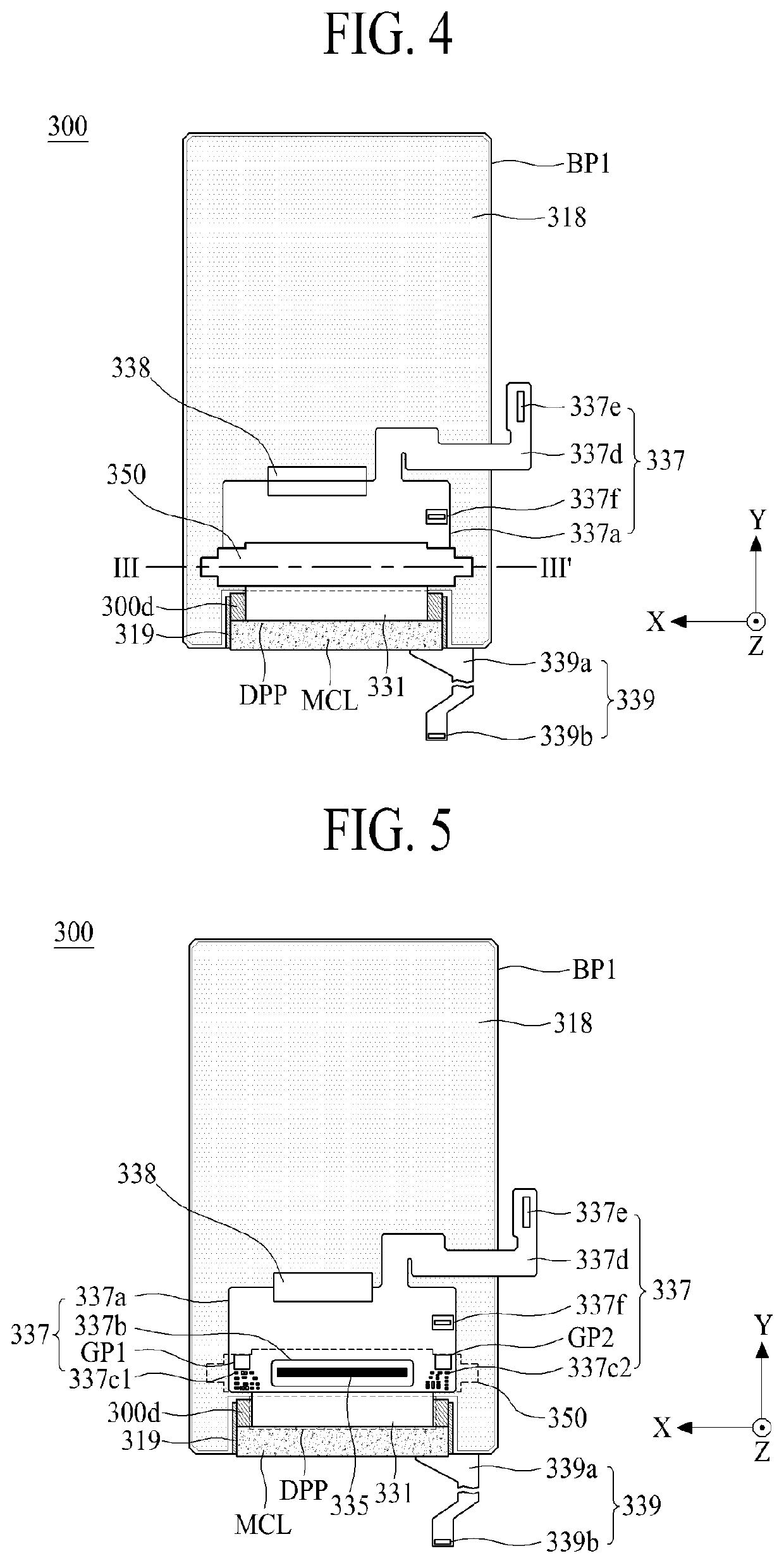

Flexible Display Module and Electronic Device Comprising the Same

ActiveUS20200192431A1Avoid uneven surfacesDigital data processing detailsFilm/foil adhesivesComputer hardwareFlexible circuits

A flexible display module and an electronic device comprising the same are disclosed, wherein the flexible display module covers uneven surface portions of a flexible circuit board, and protecting circuit components mounted on the flexible circuit board. The flexible display module comprises a flexible display panel including a display portion and a display pad portion disposed on a flexible substrate, a flexible circuit board connected with the display pad portion and arranged in a rear surface of the flexible display panel, and a cover member attached to the rear surface of the flexible display panel and configured to cover uneven surface portions of the flexible circuit board, wherein the cover member includes a cover body portion overlapped with the flexible circuit board, and an adhesion portion connected with both sides of the cover body portion and attached to the rear surface of the flexible display panel.

Owner:LG DISPLAY CO LTD

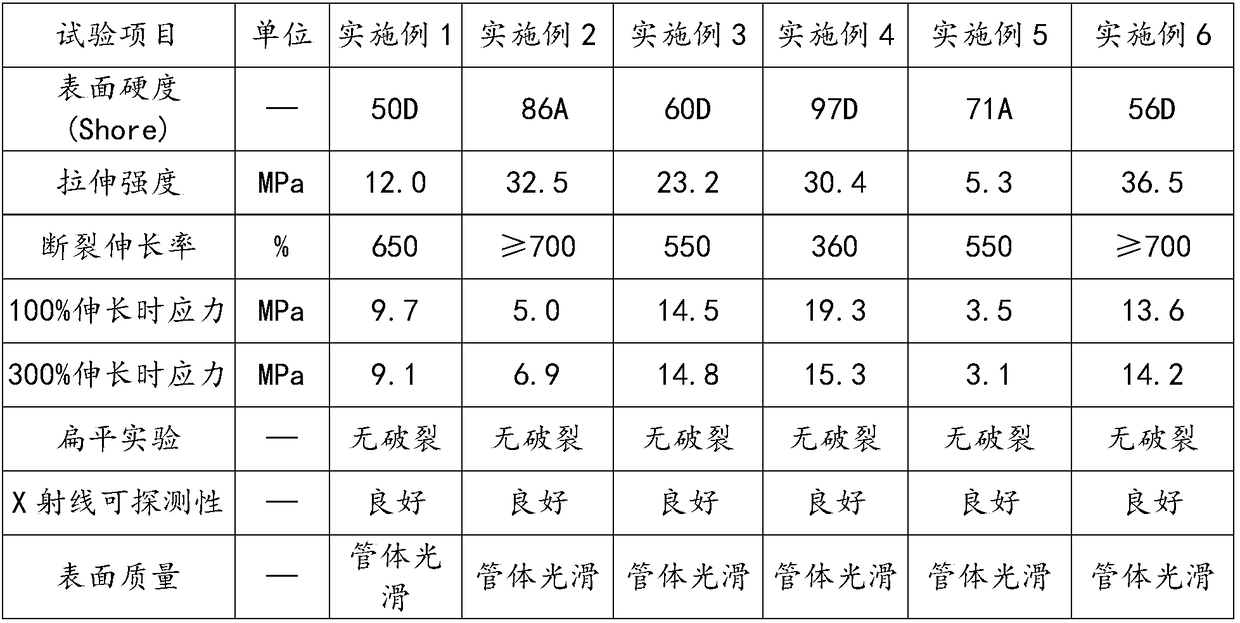

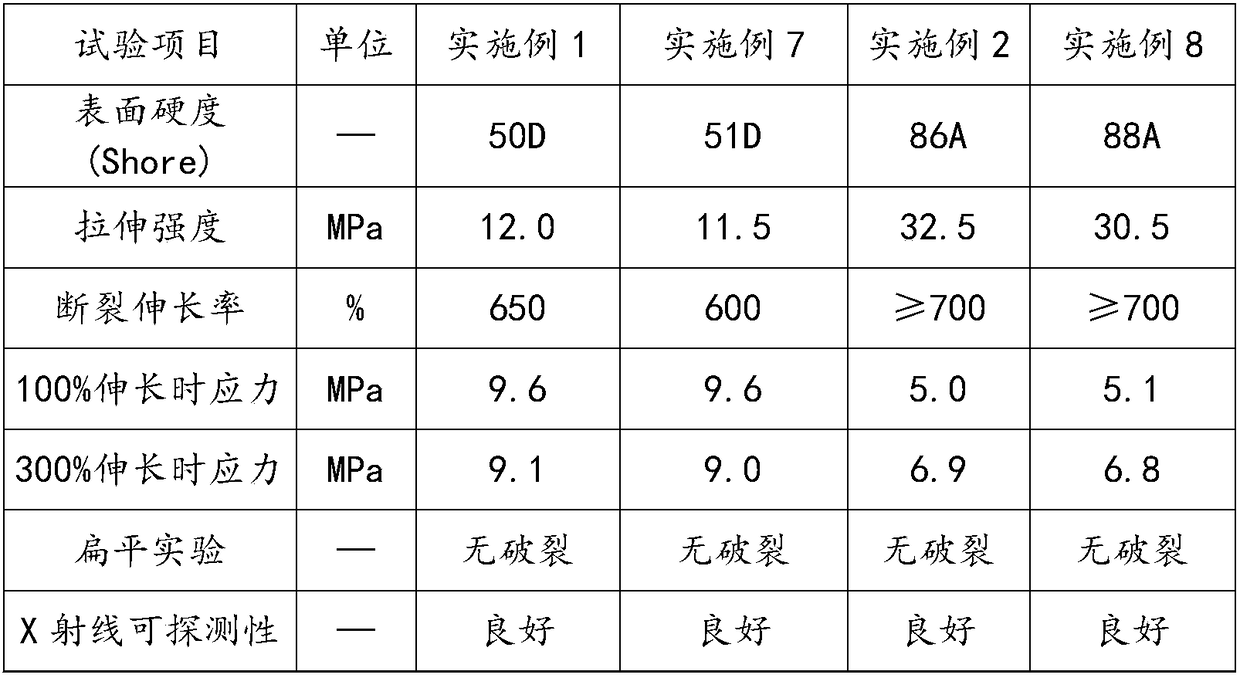

Tubular material with X ray developing function, and preparation method thereof

InactiveCN108276638AQuality improvementImprove smoothnessSynthetic resin layered productsMedical devicesMedicineX-ray

The invention belongs to the technical field of medicine, and especially relates to a tubular material with X ray developing function, and a preparation method thereof. The tubular material comprisesa core layer, an external skin layer, and an internal skin layer; the core layer is arranged between the external skin layer and the internal skin layer; the external skin layer and the internal skinlayer are prepared from a basic resin; the core layer comprises the basic resin and a developing agent. The external skin layer and the internal skin layer are basic resin layers, and contain no or little developing agent, so that excellent internal surface and external surface quality and smoothness are provided for the tubular material, and defects such as surface irregularity, burrs, pits, andparticles caused by direct adding of a large amount of the developing agent into the tubular material are avoided.

Owner:SHENZHEN POLYTECHNIC +1

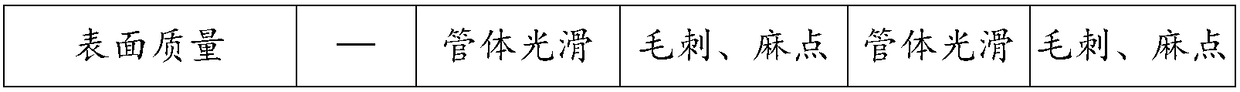

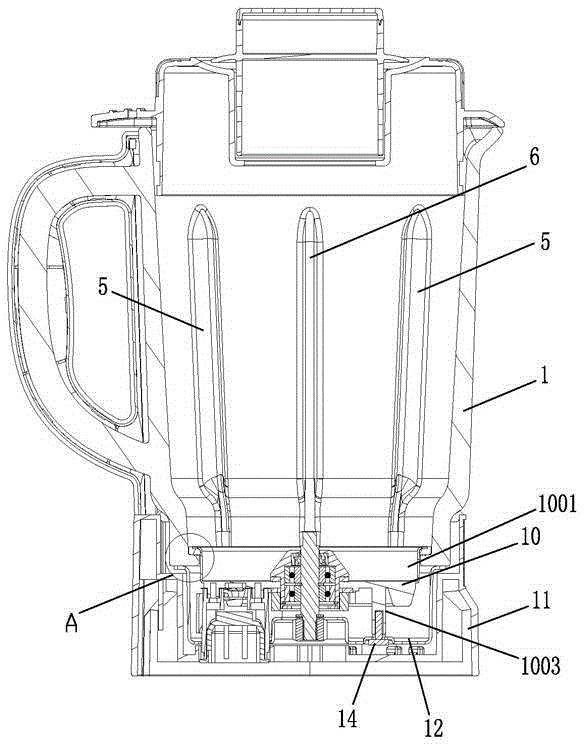

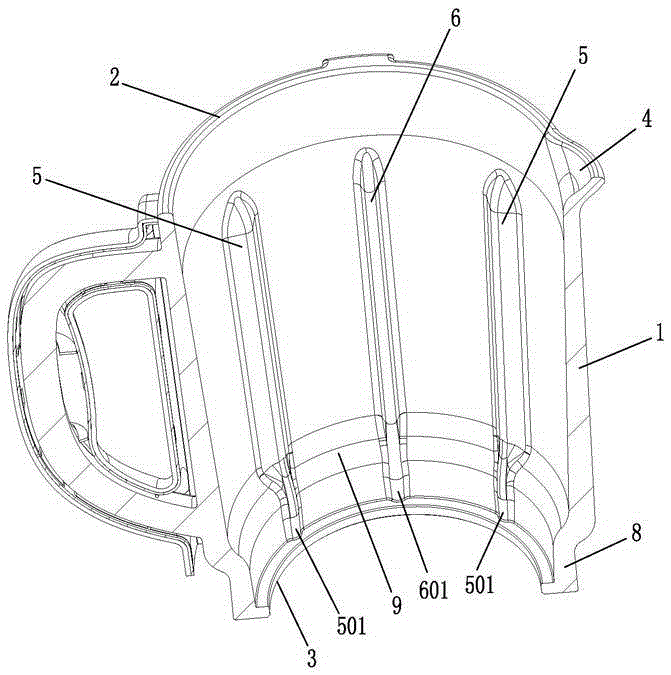

Novel food processer

Owner:广东昌盛电器有限公司

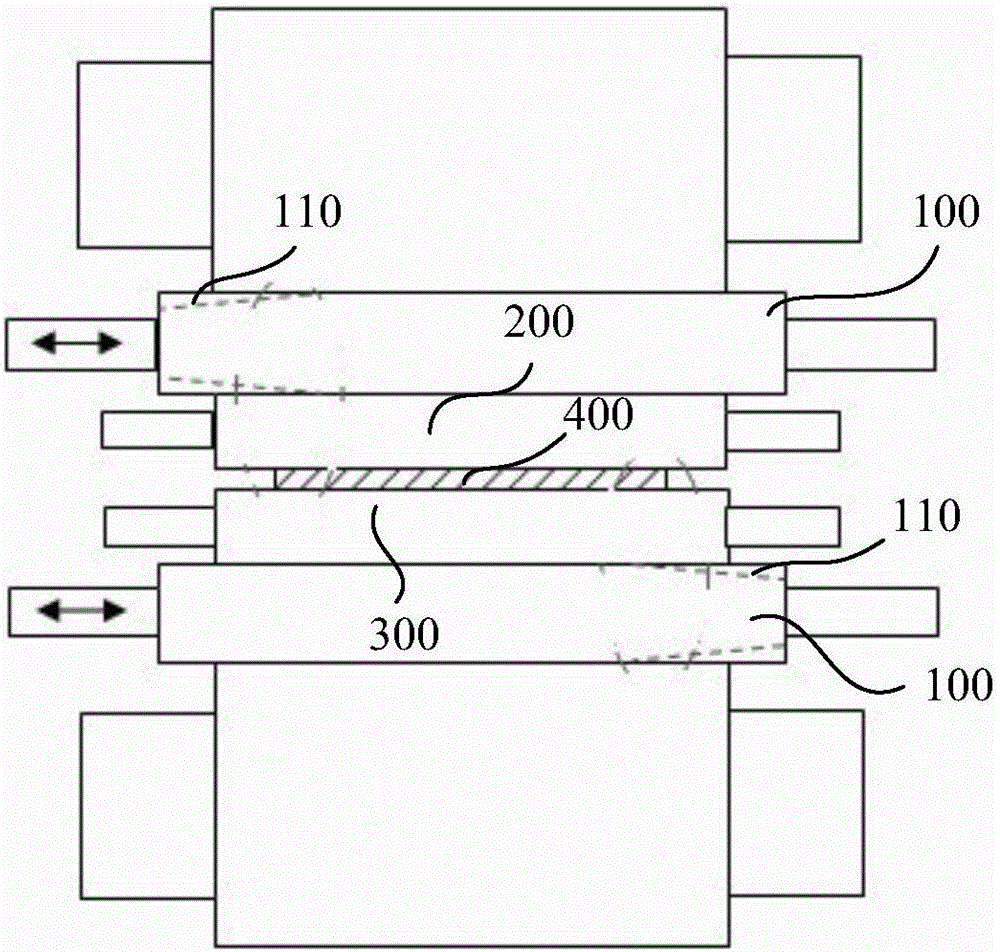

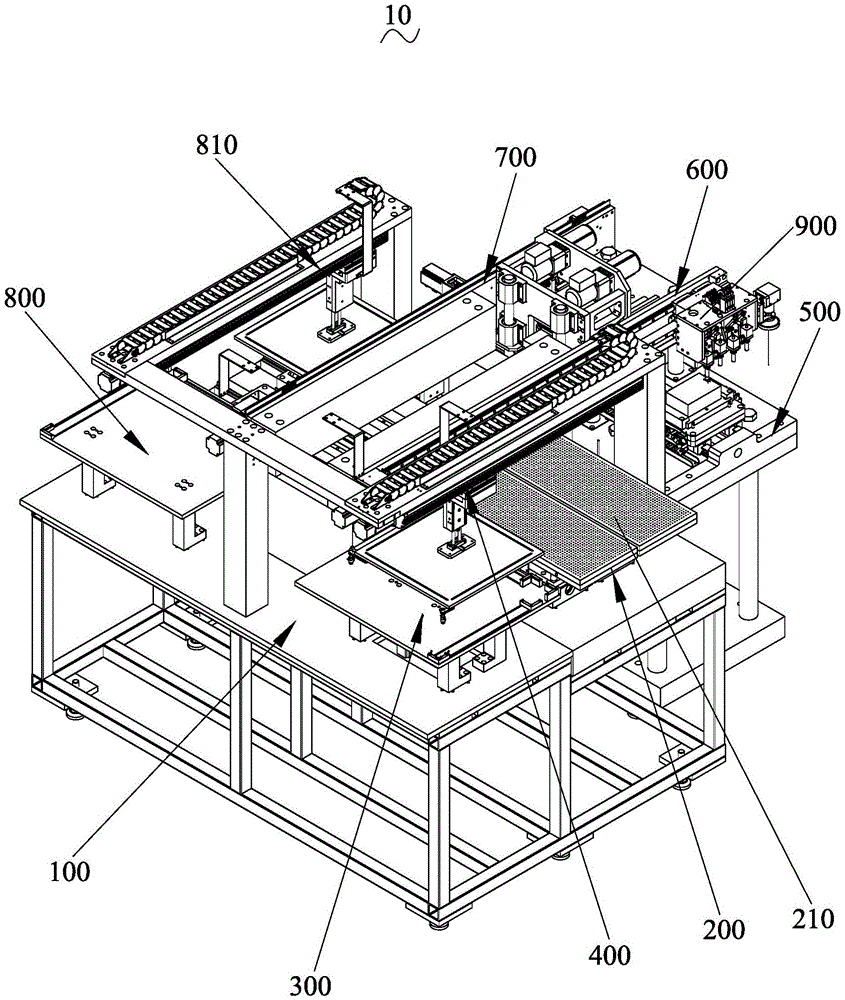

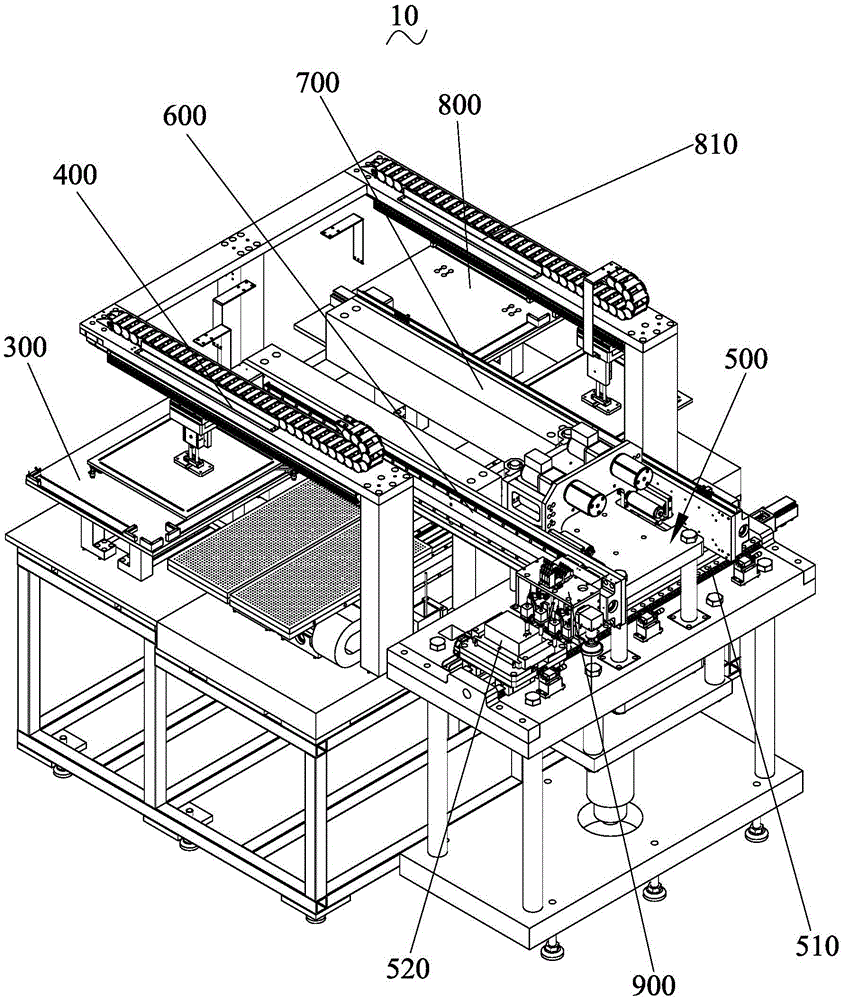

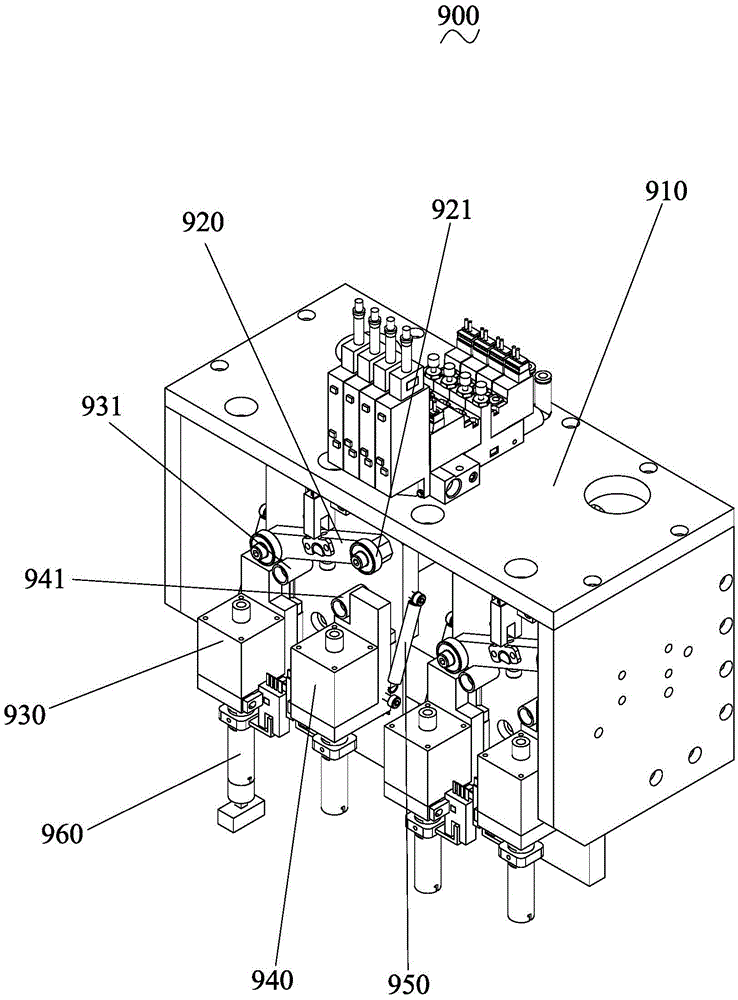

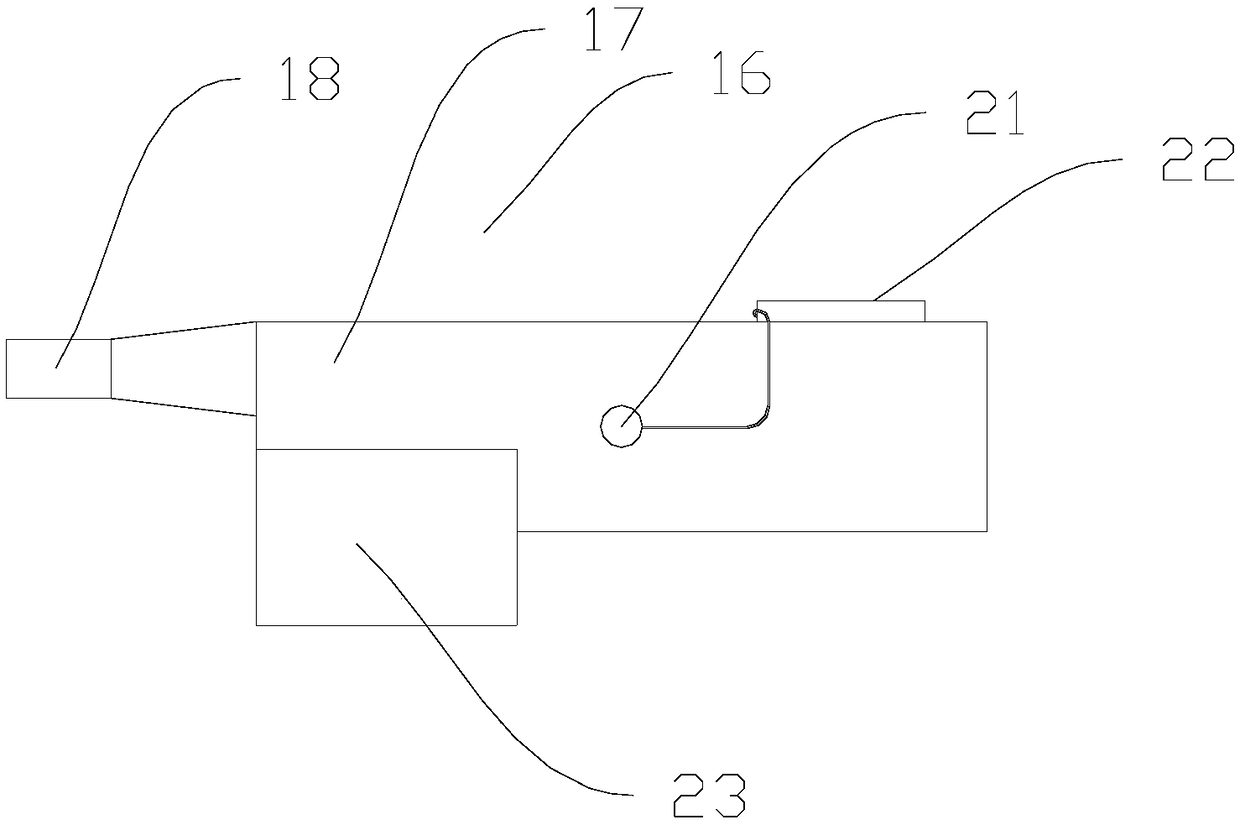

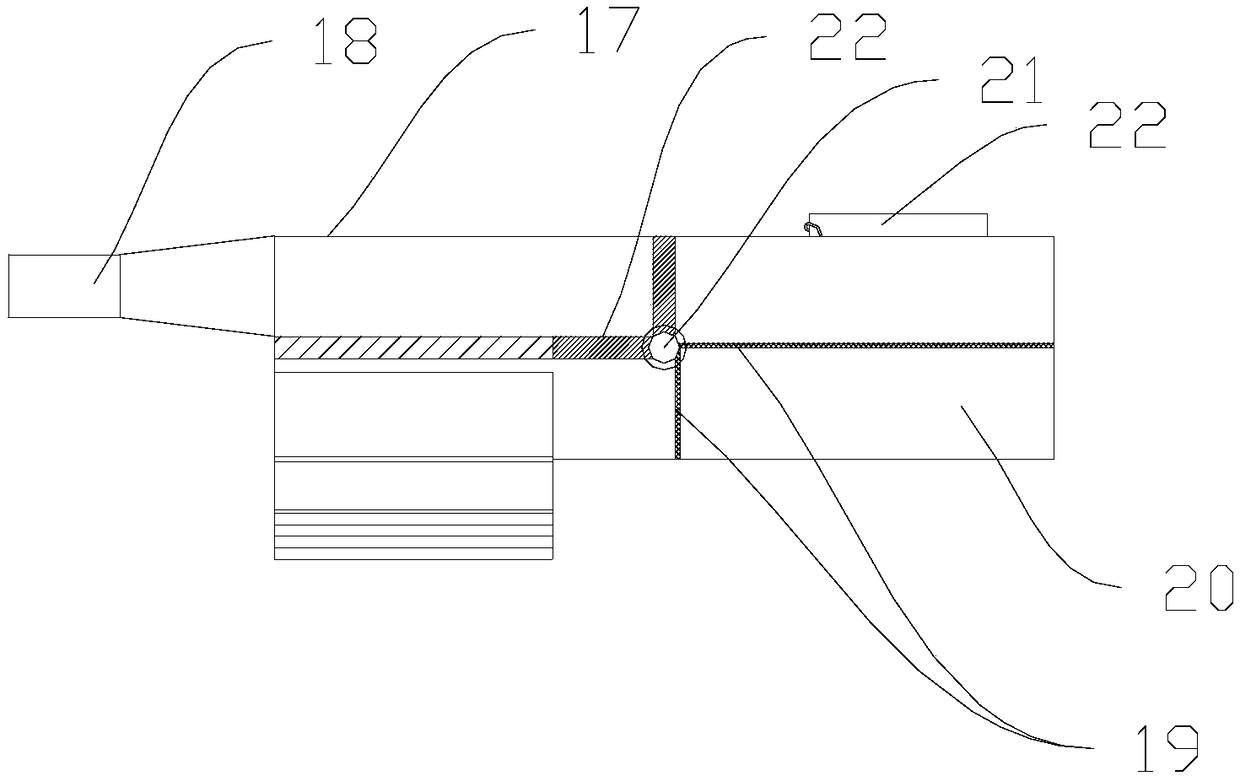

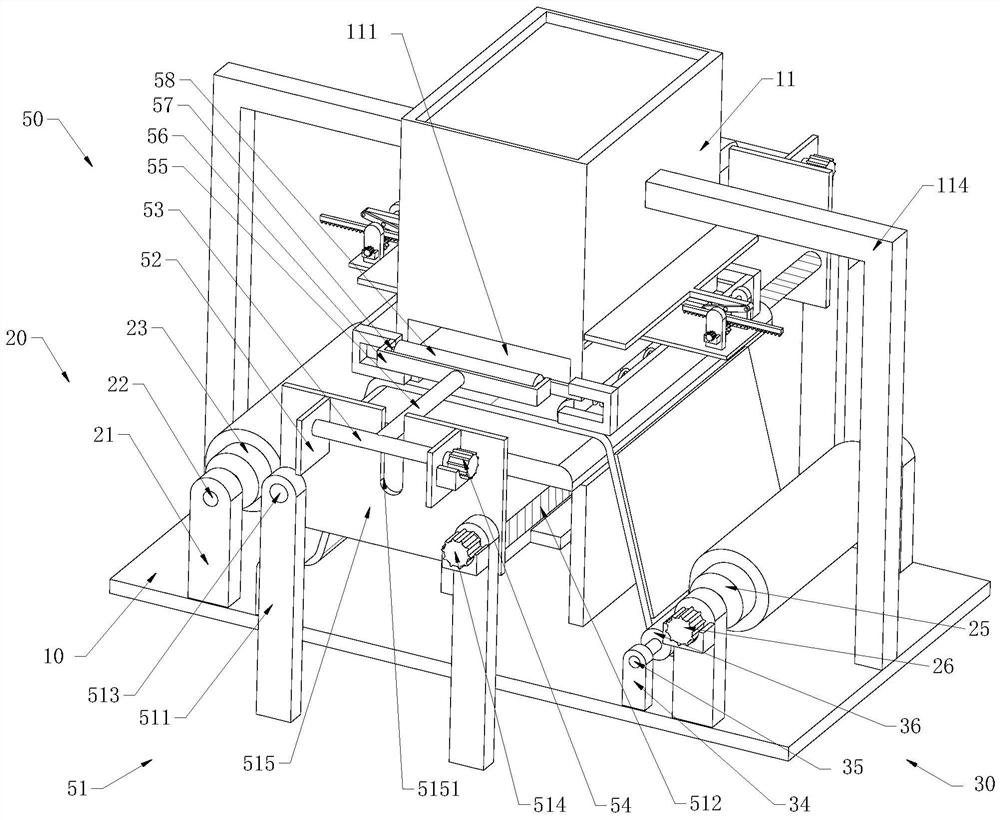

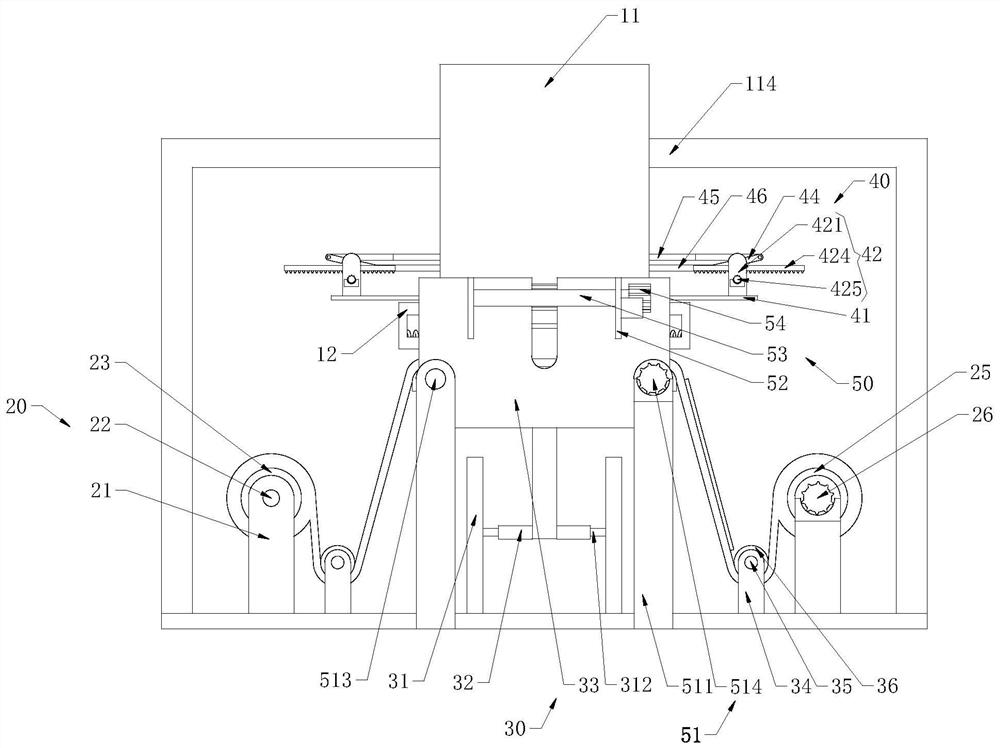

Automatic stamping and laminating equipment of PI reinforcement plates for FPC

ActiveCN105530759AImprove work efficiencyAvoid uneven surfacesCircuit bendability/stretchabilityPrinted circuit manufactureEngineeringManipulator

The invention discloses automatic stamping and laminating equipment of PI reinforcement plates for an FPC. The automatic stamping and laminating equipment comprises a work bench, a transit transfer station, an FPC storage tray, an FPC feeding manipulator, a PI reinforcement plate stamping device, a first PI reinforcement plate laminating manipulator, a second PI reinforcement plate laminating manipulator, a finished product receiving tray and a finished product receiving manipulator, wherein the transit transfer station comprises a transit transfer plate which slides in a reciprocating manner along the work bench; the first PI reinforcement plate laminating manipulator and the second PI reinforcement plate laminating manipulator are provided with suction laminating devices; each suction laminating device comprises a bracket, a driving lever, a first lifting part and a second lifting part; the driving lever is rotationally arranged on the bracket; the first lifting part is vertically arranged on the bracket in a sliding manner; the second lifting part is vertically arranged on the bracket in the sliding manner; and two ends of the driving lever are propped against or separated from the first lifting part and the second lifting part respectively. According to the automatic stamping and laminating equipment, automatic stamping and laminating work of the PI reinforcement plates on the FPC is achieved; the overall process is smooth and fast; and the production working efficiency is greatly improved.

Owner:SANKYO PRECISION HUIZHOU

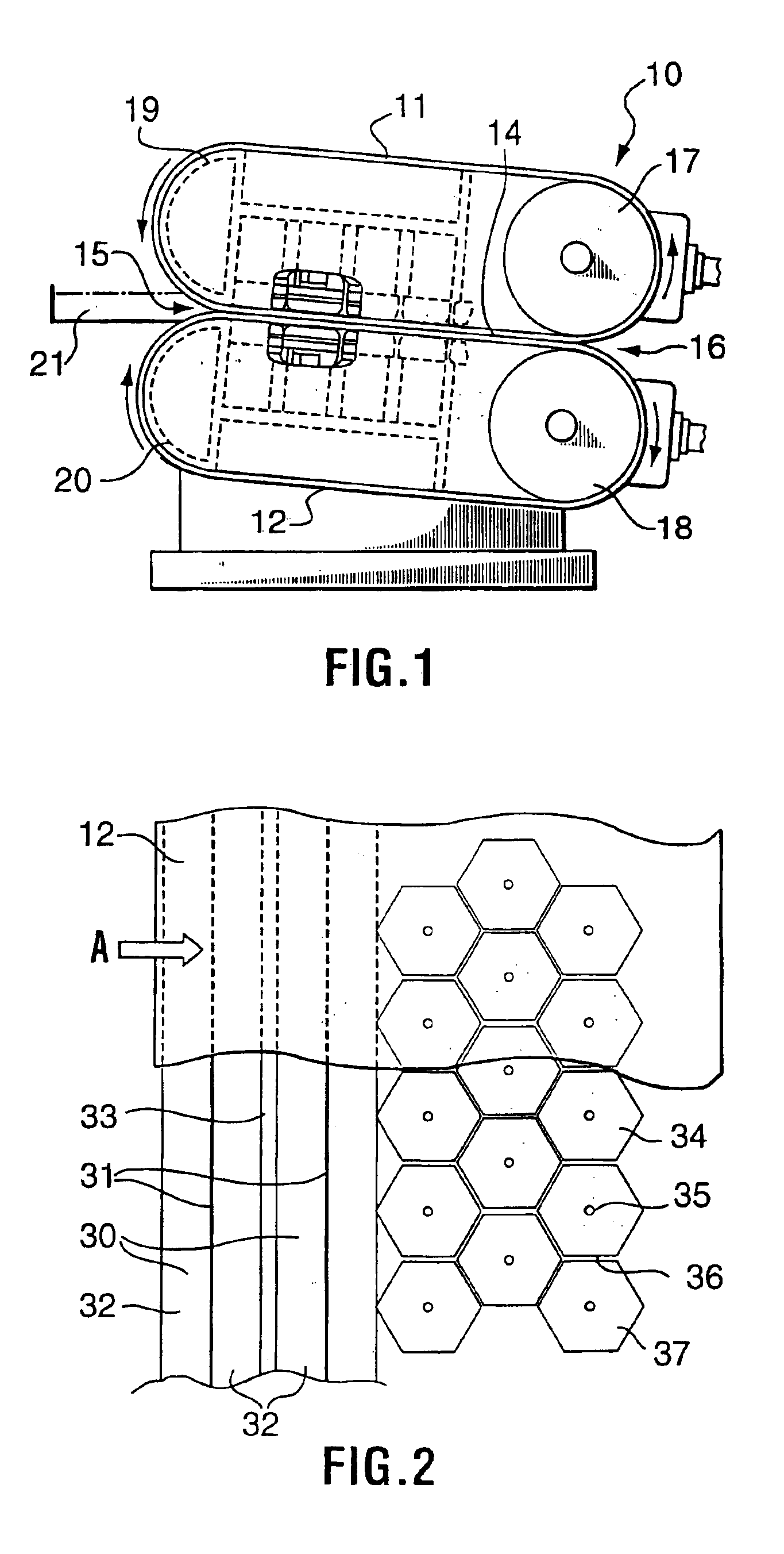

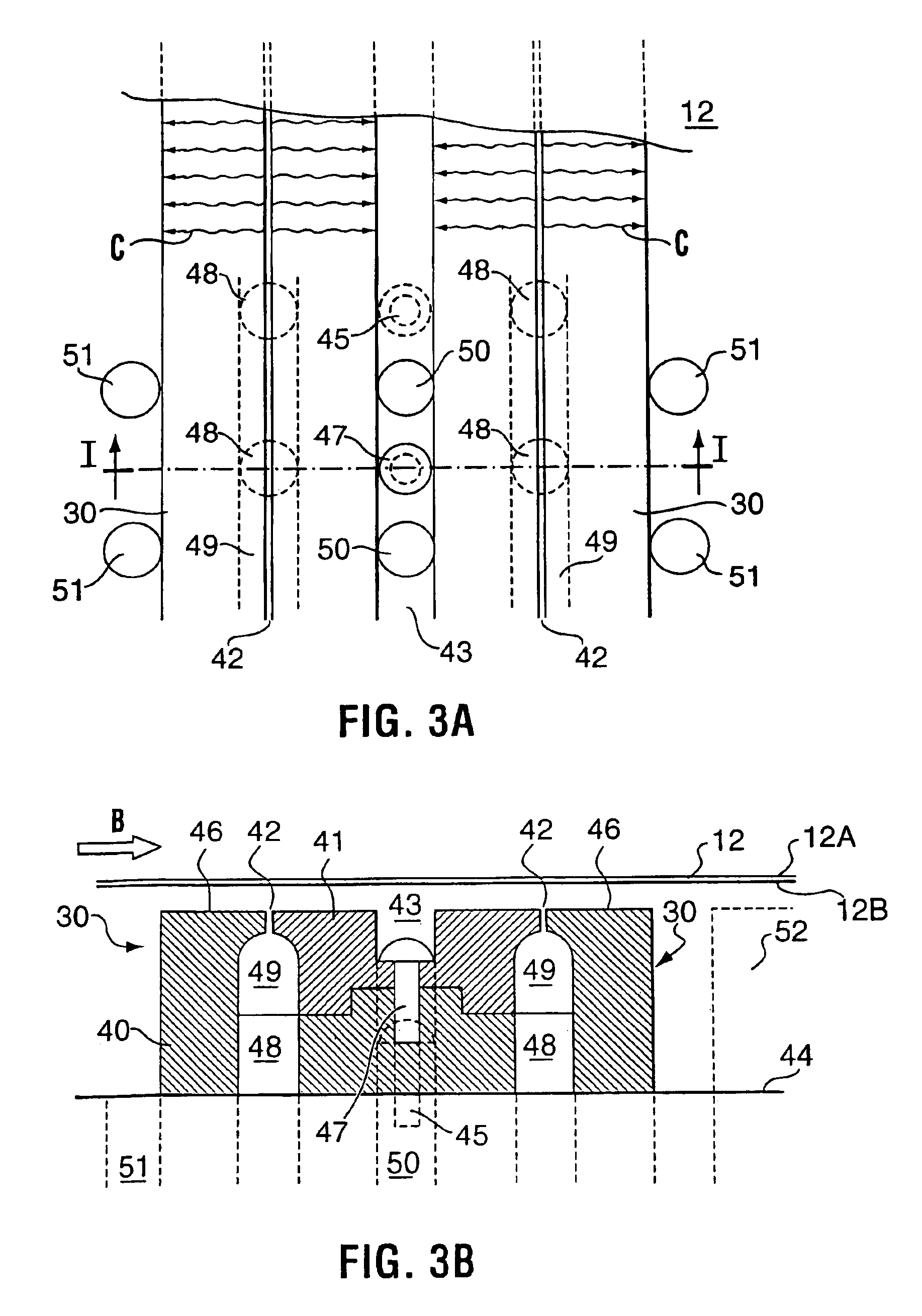

Belt-cooling and guiding means for continuous belt casting of metal strip

A belt cooling and guiding apparatus for a casting belt of a twin belt caster. The cooling and guiding apparatus includes at least one nozzle having a support surface facing a reverse surface of the casting belt (a surface opposite to a casting surface in the casting mold), provided with a continuous slot in the support surface arranged transversely substantially completely across the casting belt. The slot allows for delivery of cooling liquid to the reverse surface of the belt in the form of a continuous film having uniform thickness and velocity of flow when considered in the transverse direction of the belt. This allows for even cooling transversely of the belt. The nozzle arrangement is also provided with a drainage opening for removal of cooling liquid downstream from the continuous slot, and a vacuum system associated with the drainage opening for applying suction to the drainage opening. One or more such cooling nozzles is provided at the entrance of the casting mold where uniform cooling is critical to the characteristics of the cast strip article.

Owner:NOVELIS INC

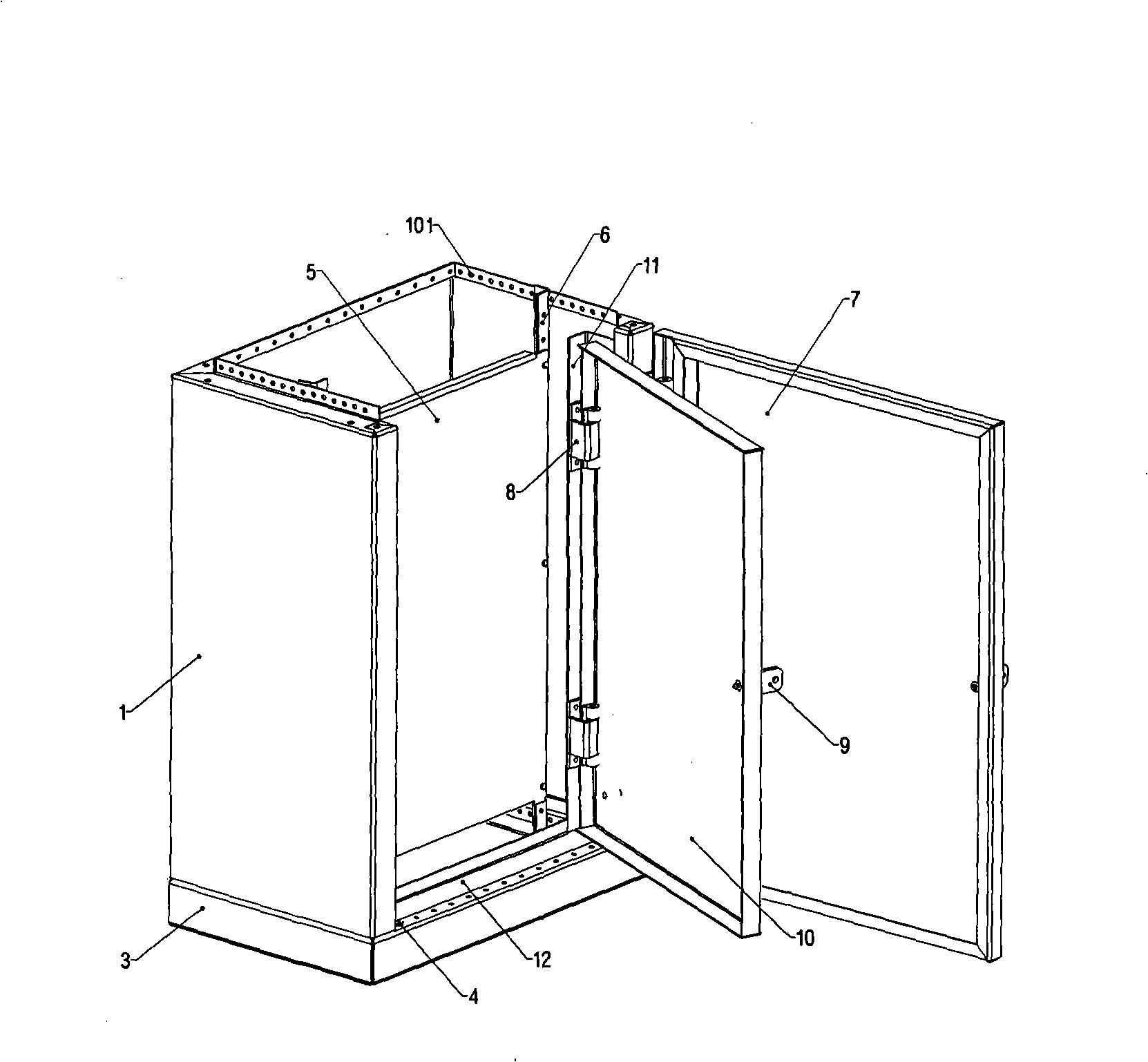

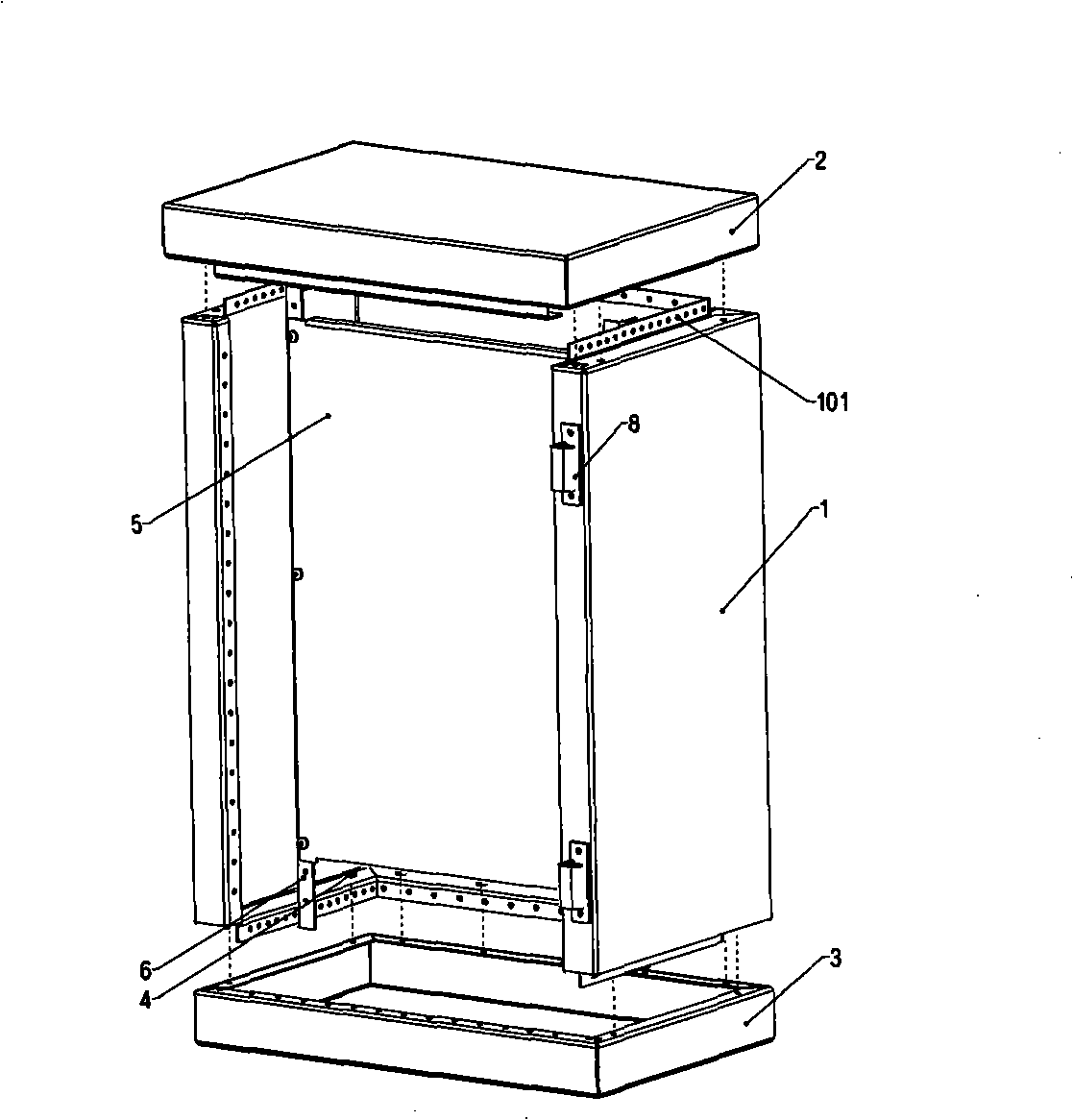

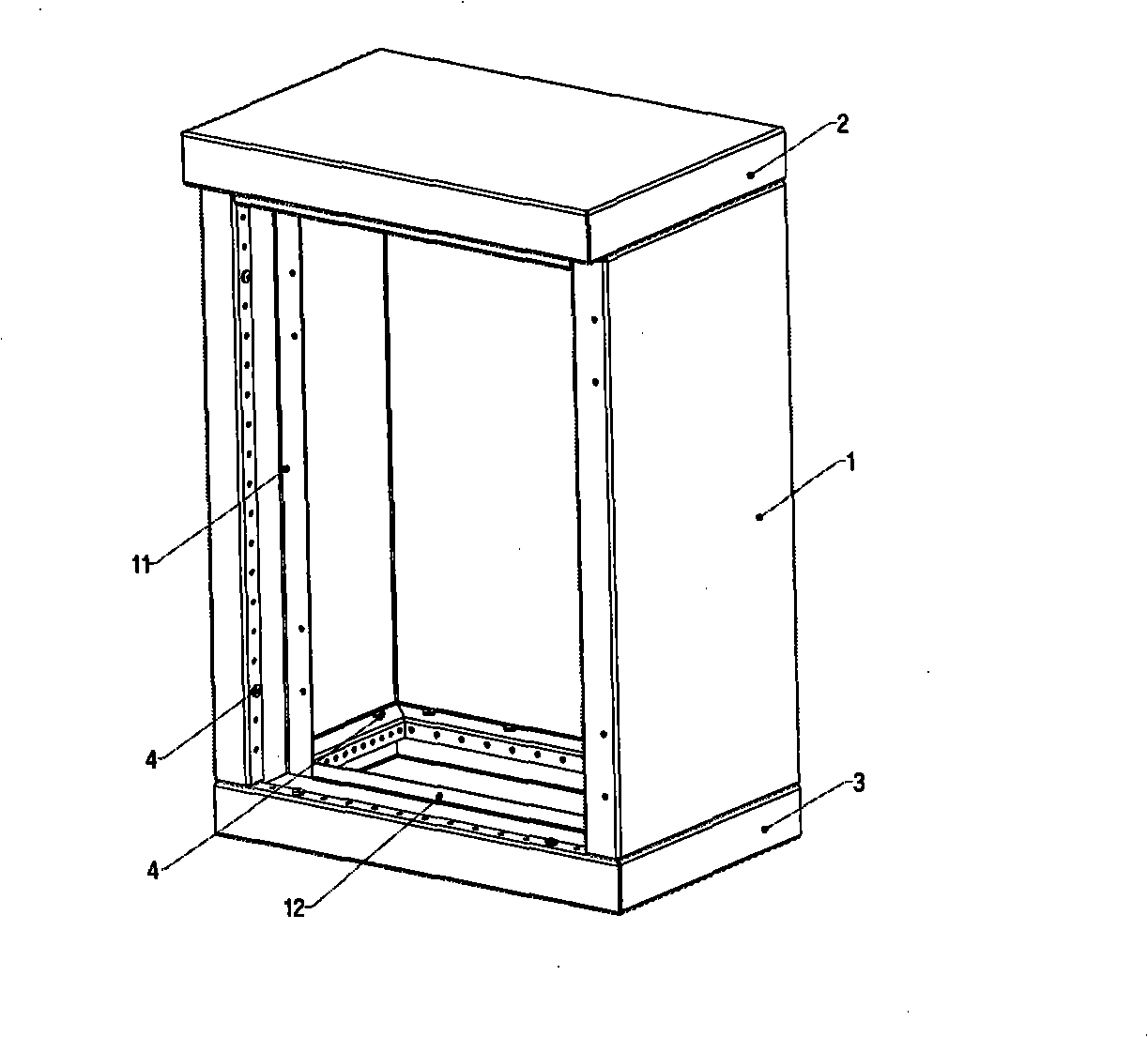

Assembled distribution box

InactiveCN101320888AEasy to installNice appearanceSubstation/switching arrangement casingsEngineeringDistributor

The invention provides a assembled distributor case, comprising a shell, an upper cover, a lower cover, an installing plate in the shell, an inner door plate and an outer door plate fixedly-connected to the shell; the upper and lower covers are respectively connected on the upper and lower ends of the shell via the tapping screws. The invention has a convenient installation, simple production and beautiful appearance.

Owner:XIANGRONG ELECTRIC GRP

Silicon epitaxial wafer, method for manufacturing the same, bonded SOI wafer and method for manufacturing the same

ActiveUS8823130B2Quality improvementImprove bonding interfaceTransistorSemiconductor/solid-state device manufacturingSingle crystal substrateSingle crystal

A silicon epitaxial wafer having a silicon epitaxial layer grown by vapor phase epitaxy on a main surface of a silicon single crystal substrate, wherein the main surface of the silicon single crystal substrate is tilted with respect to a [100] axis at an angle θ in a [011] direction or a [0-1-1] direction from a (100) plane and at an angle φ in a [01-1] direction or a [0-11] direction from the (100) plane, the angle θ and the angle φ are less than ten minutes, and a dopant concentration of the silicon epitaxial layer is equal to or more than 1×1019 / cm3. Even when an epitaxial layer having a dopant concentration of 1×1019 / cm3 or more is formed on the main surface of the silicon single crystal substrate, stripe-shaped surface irregularities on the epitaxial layer are inhibited.

Owner:SHIN-ETSU HANDOTAI CO LTD

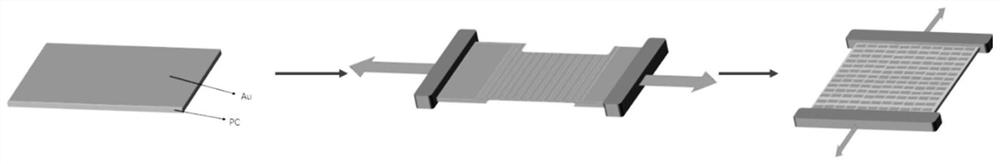

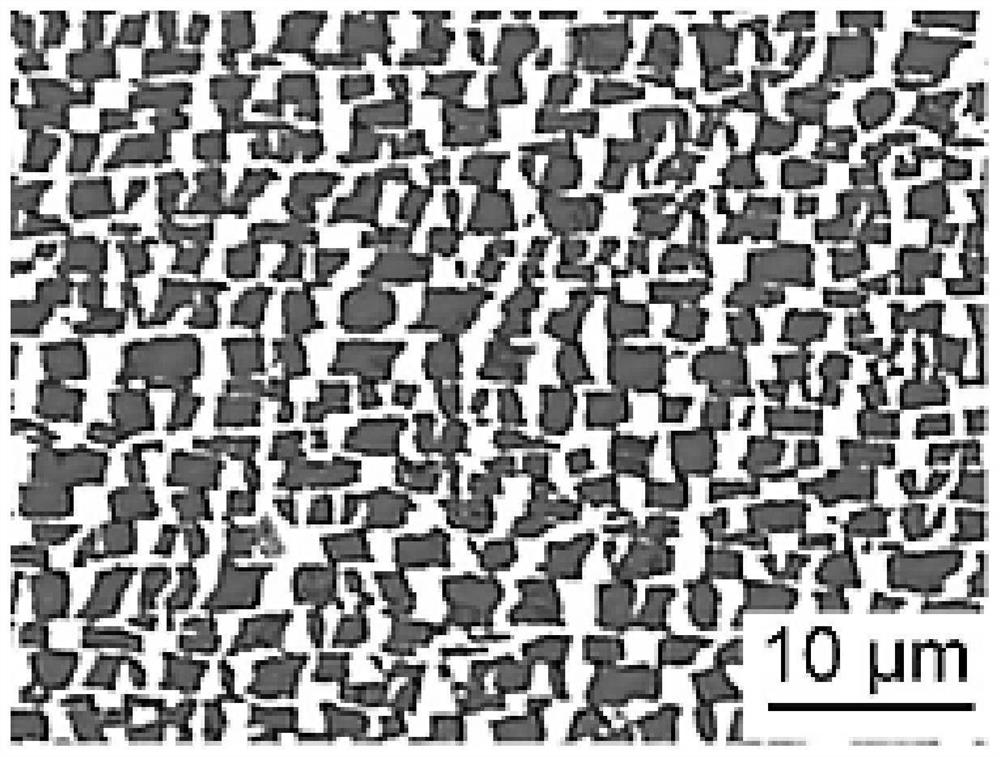

Surface enhanced Raman scattering substrate and preparation method thereof

ActiveCN113296176AReduce sizeEnhancement effect is goodDiffusing elementsVacuum evaporation coatingCrazingPolymer substrate

The invention discloses a surface enhanced Raman scattering substrate and a preparation method thereof. The method comprises the following steps: firstly, growing a layer of gold nano film on a flexible polymer substrate, and enabling the gold film to generate regular and uniform cracks along with the extension of a polymer through adoption of a two-way mechanical stretching method; and then, transferring the gold film with the stretched microstructure to a clean glass substrate, and a layer of uniform and compact SnSe2 nanosheets grow on the gold film. The structure combines the advantages of a traditional metal SERS substrate, that is, a metal tip has a hot spot, and a local electric field is enhanced; and the two-dimensional material SnSe2 has the advantages that the two-dimensional material SnSe2 and the semiconductor SERS substrate are combined, surface non-uniformity caused by agglomeration due to weak adsorption capacity of the metal SERS substrate can be avoided, in addition, the two-dimensional material SnSe2 is large in specific surface area, the structure has a light limiting effect, and light can be limited in the structure. The advantages of a semiconductor SERS substrate and a traditional metal substrate are combined, and the effect of enhancing Raman scattering is achieved.

Owner:江苏度微光学科技有限公司

Method for repairing flexible tube

ActiveUS8365774B2Avoid uneven surfacesSurface irregularities of the repaired flexible tube are preventedEndoscopesPipe elementsRepair materialEngineering

Around a damaged area of a jacket of a flexible tube, a top coat layer whose adhesion to a polymer layer is weak is peeled off with an adhesive tape. The damaged area and its immediate surrounding area are sanded, and then wiped with ethanol for cleaning. A main agent and a hardening agent are heated and defoamed while being mixed to prepare a repair material. The repair material is applied to the damaged area and the immediate surrounding area. A heat shrink tube is opened along slits in an end portion and covers the flexible tube. The heat shrink tube is shrunk with hot air, pressing the repair material and making it flush with a surface of the jacket. The flexible tube is heated with an electric hot plate to harden the repair material. Thereafter, the heat shrink tube is peeled off from the flexible tube.

Owner:FUJIFILM CORP

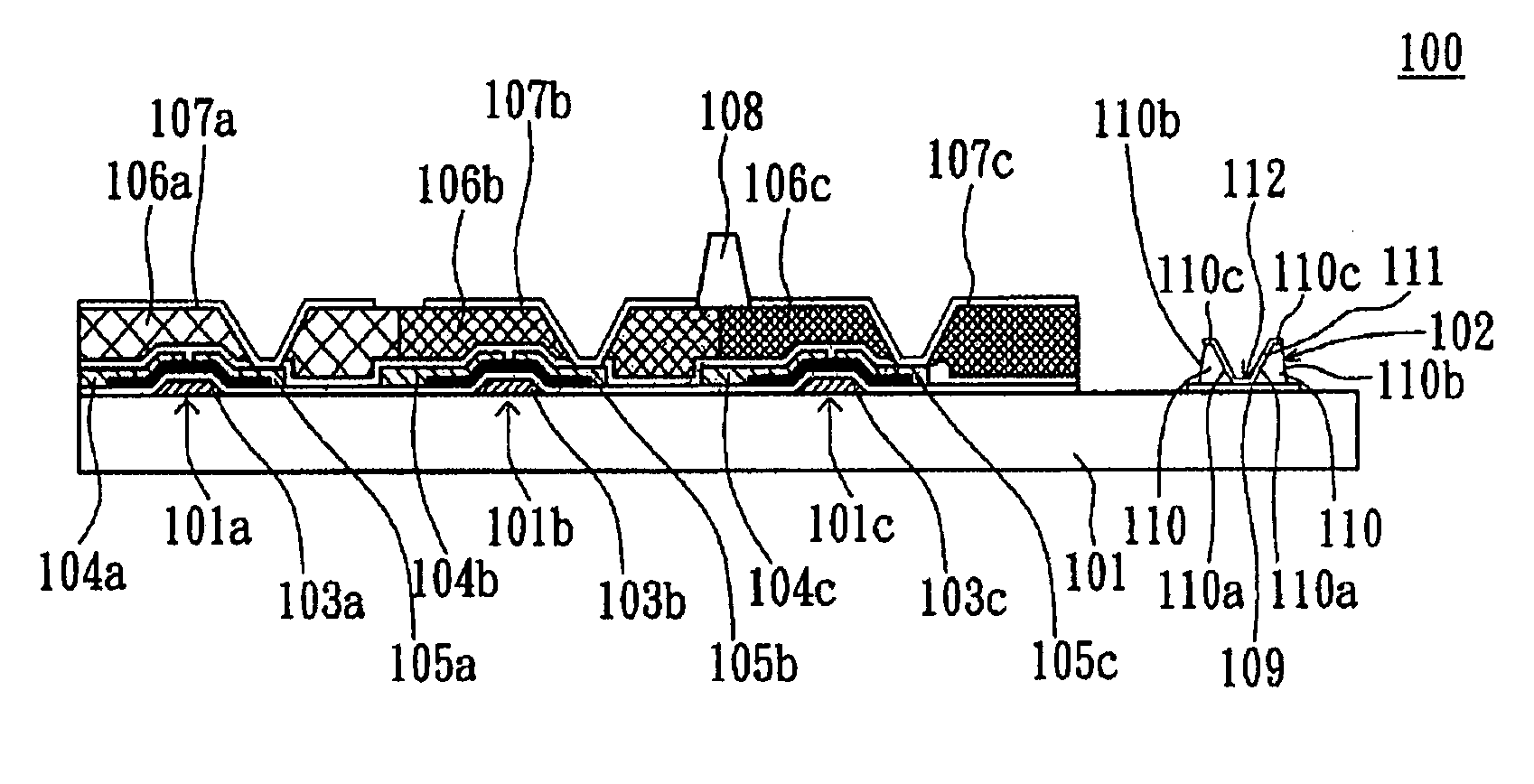

Thin film transistor substrate and manufacturing method thereof

ActiveUS7245012B2Avoid uneven surfacesQuality improvementTransistorSemiconductor/solid-state device detailsOptoelectronicsTransistor

A thin film transistor (TFT) substrate includes a glass substrate, a thin film transistor, an electrode pad, and a conductive bump. The TFT and the electrode pad are formed on the glass substrate, and the electrode pad is used for electrically connecting with the thin film transistor. The conductive bump includes several insulating bumps and a conductive layer. The insulating bumps are formed on the electrode pad dividedly, and the conductive layer covers the top surfaces of the insulating bumps, the inward surfaces of the insulating bumps, and the electrode pad between the insulating bumps for electrically connecting with the electrode pad. The outward side surfaces of the insulating bumps are exposed out of the conductive layer.

Owner:AU OPTRONICS CORP

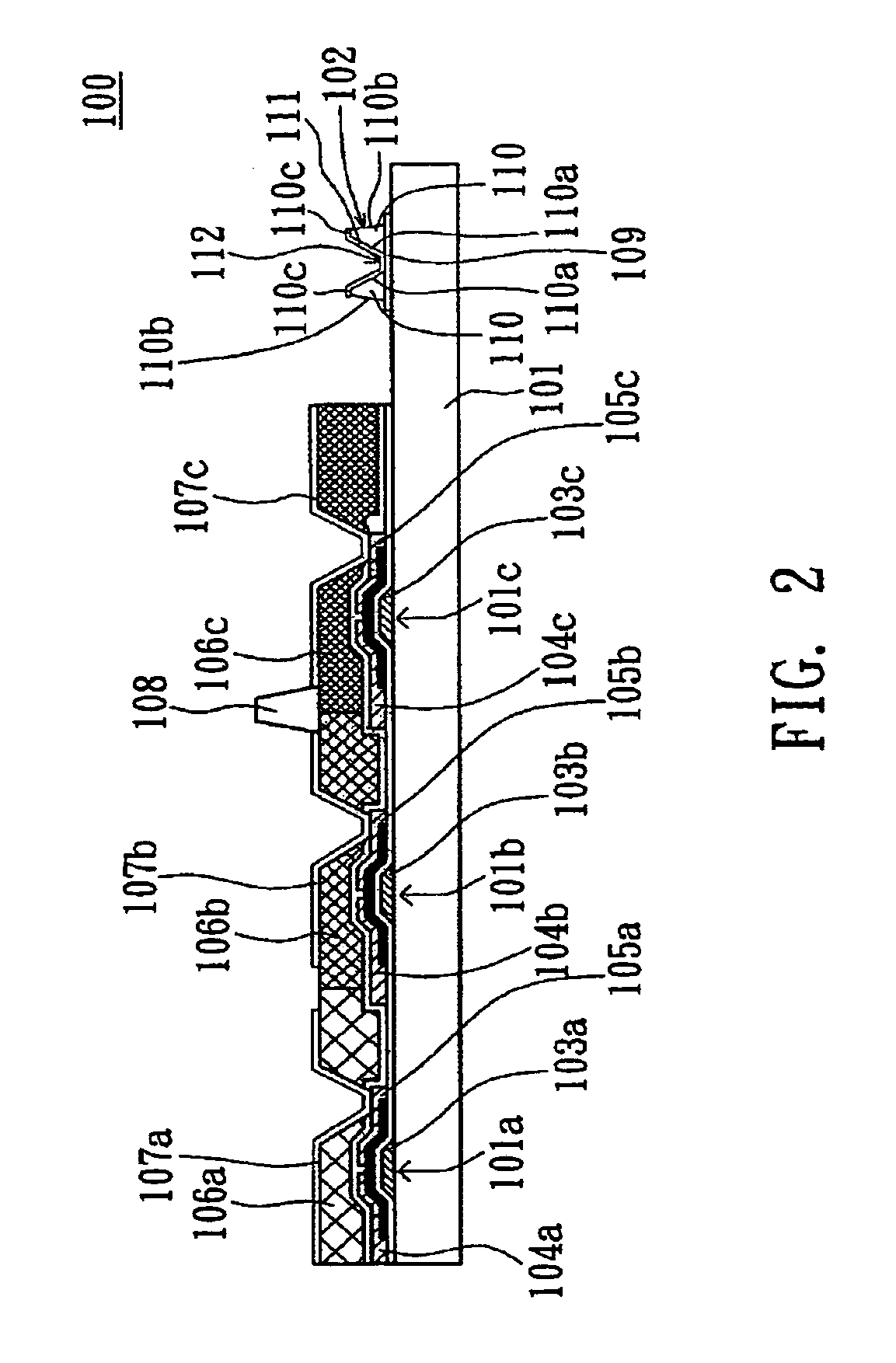

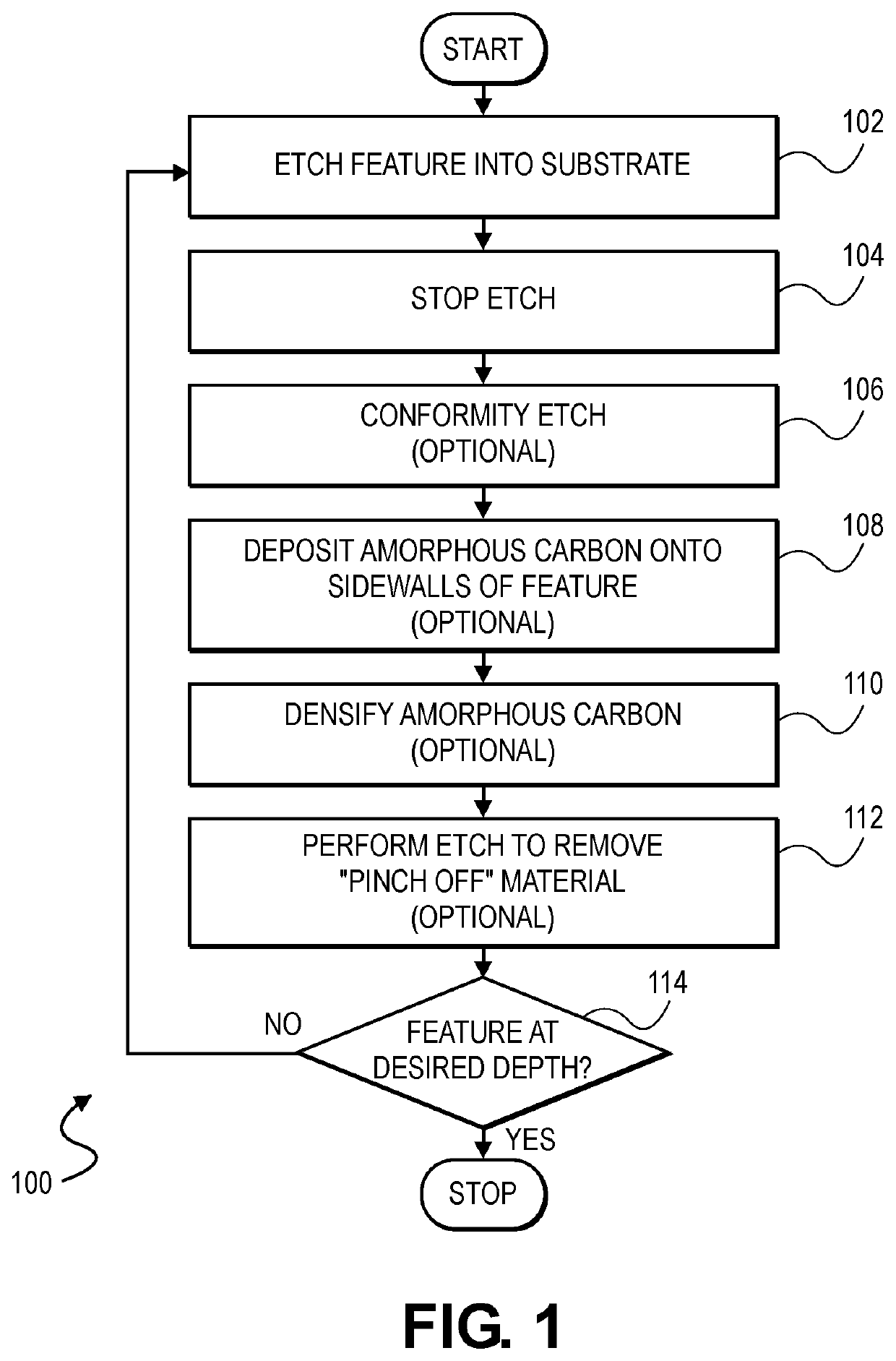

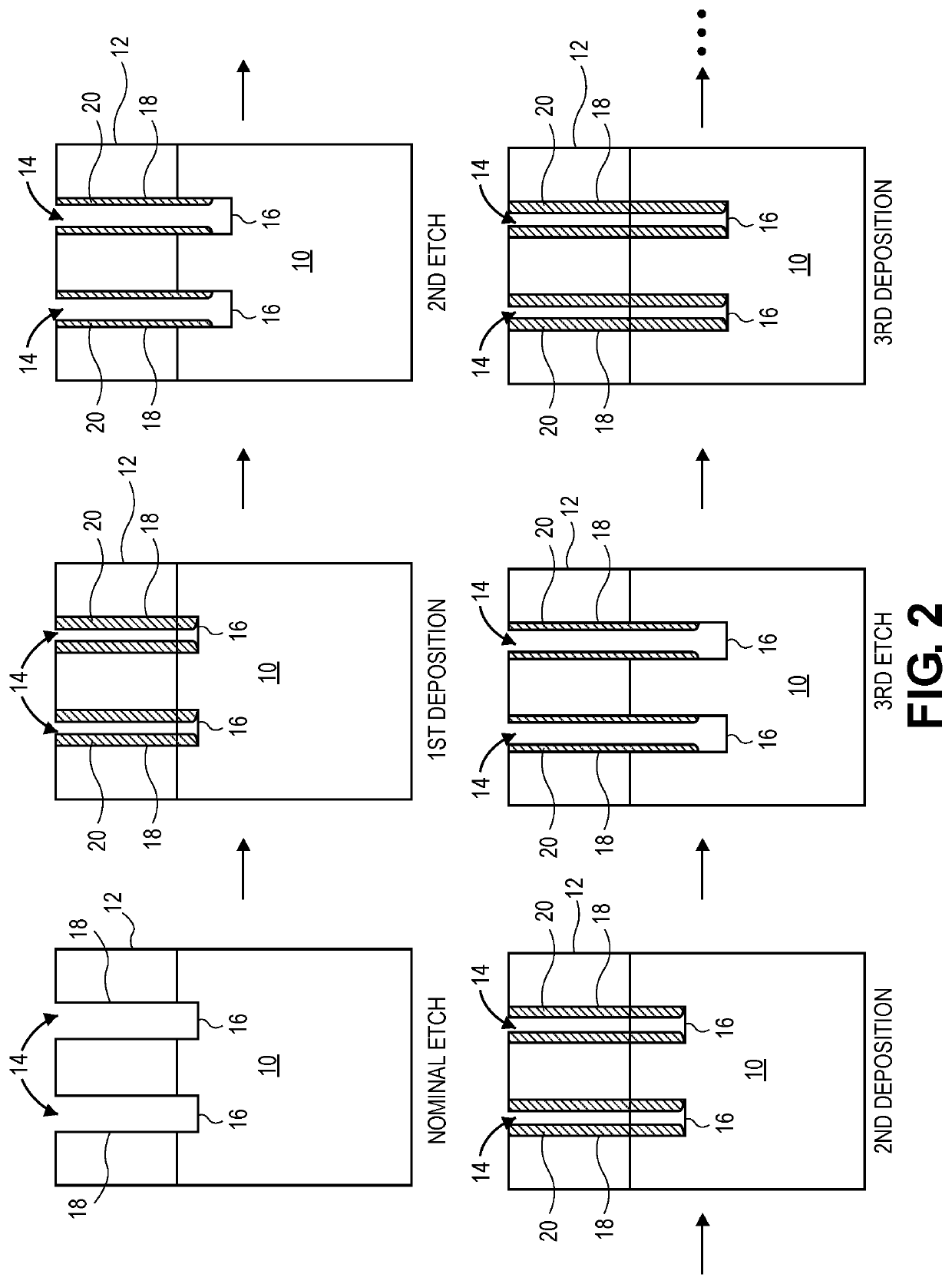

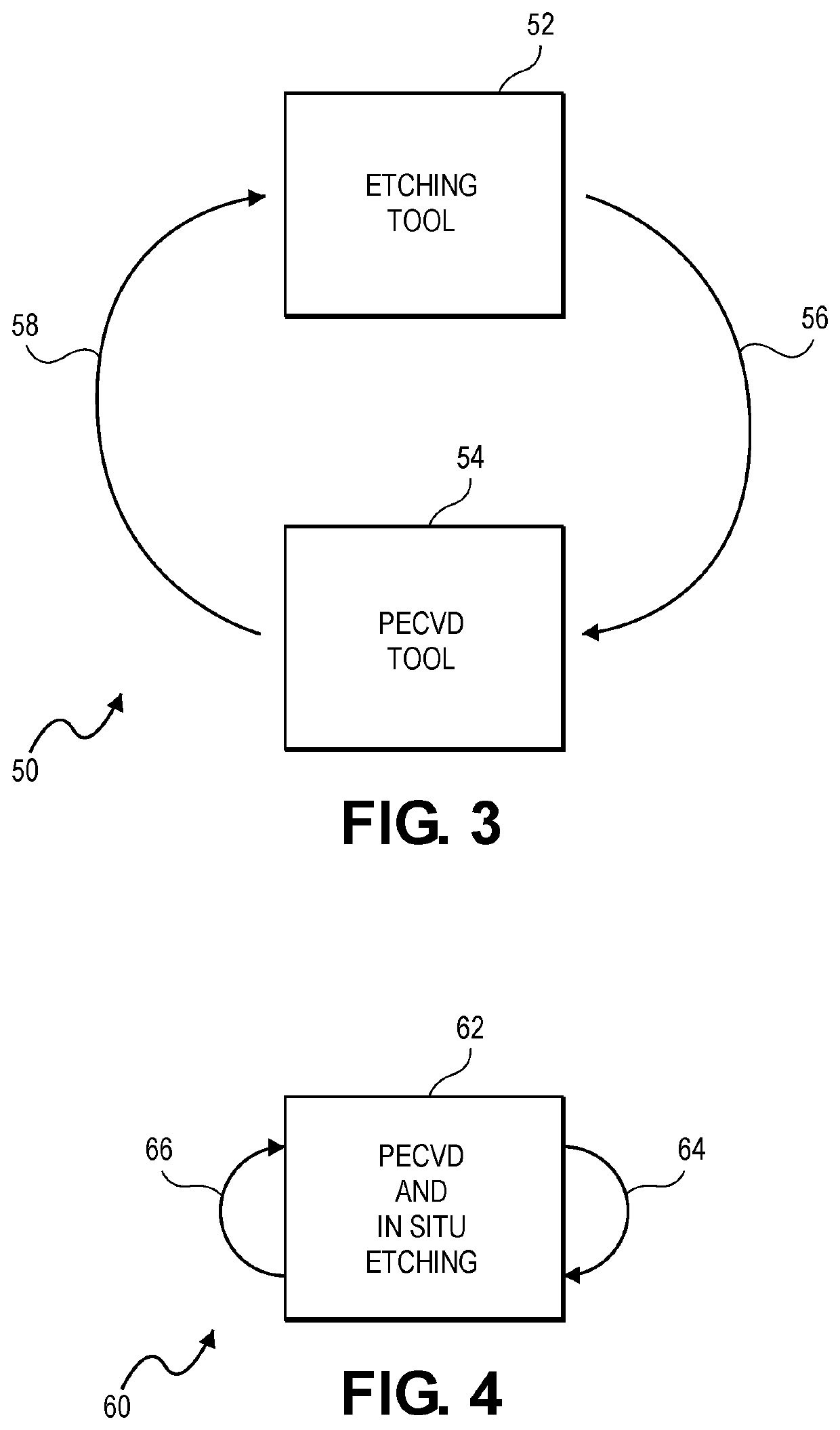

Carbon based depositions used for critical dimension control during high aspect ratio feature etches and for forming protective layers

PendingUS20220199417A1Speed up the flowTight CD controlElectric discharge tubesSemiconductor/solid-state device manufacturingEtchingEngineering physics

Fabricating a semiconductor substrate by (a) vertical etching a feature having sidewalls and a depth into one or more layers formed on the semiconductor substrate and (b) depositing an amorphous carbon liner onto the sidewalls of the feature. Steps (a) and optionally (b) are iterated until the vertical etch feature has reached a desired depth. With each iteration of (a), the feature is vertical etched deeper into the one or more layers, while the amorphous carbon liner resists lateral etching of the sidewalls of the feature. With each optional iteration of (b), the deposited amorphous carbon liner on the sidewalls of the feature is replenished.

Owner:LAM RES CORP

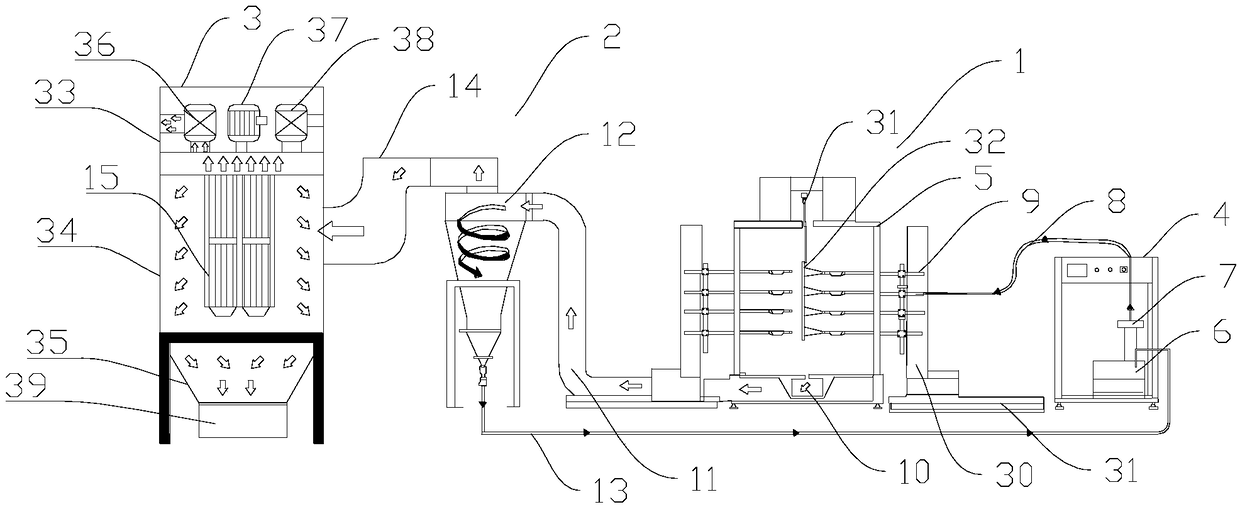

Operation method for quick magic powder replacing system

ActiveCN108787265ANo wasteTake advantage ofCombination devicesSpraying apparatusEngineeringFilter effect

The invention relates to the field of coating equipment, in particular to an operation method for a quick magic powder replacing system. The operation method can achieve self filtering on inferior powder and quick magic powder replacing of tail powder. The operation method comprises the steps of (1) early-stage preparation, (2) workpiece spraying, (3) primary recovering, (4) secondary recovering and the like. The operation method has the following beneficial effects that a thin filter screen can filter powder doped into the spraying powder and having the large grain size, the spraying homogeneity is improved, and the sprayed coating smoothness is improved; (2) a recovering bin can quickly and conveniently recover the tail powder, and waste caused by idle spraying and adverse effects on thework environment are avoided; and (3) a candle filter can automatically clean dust accumulated on a filter element of the filter, the filtering effect is greatly improved, and the production efficiency is effectively improved.

Owner:ZHEJIANG HUIER COATING ENVIRONMENTAL PROTECTION EQUIP

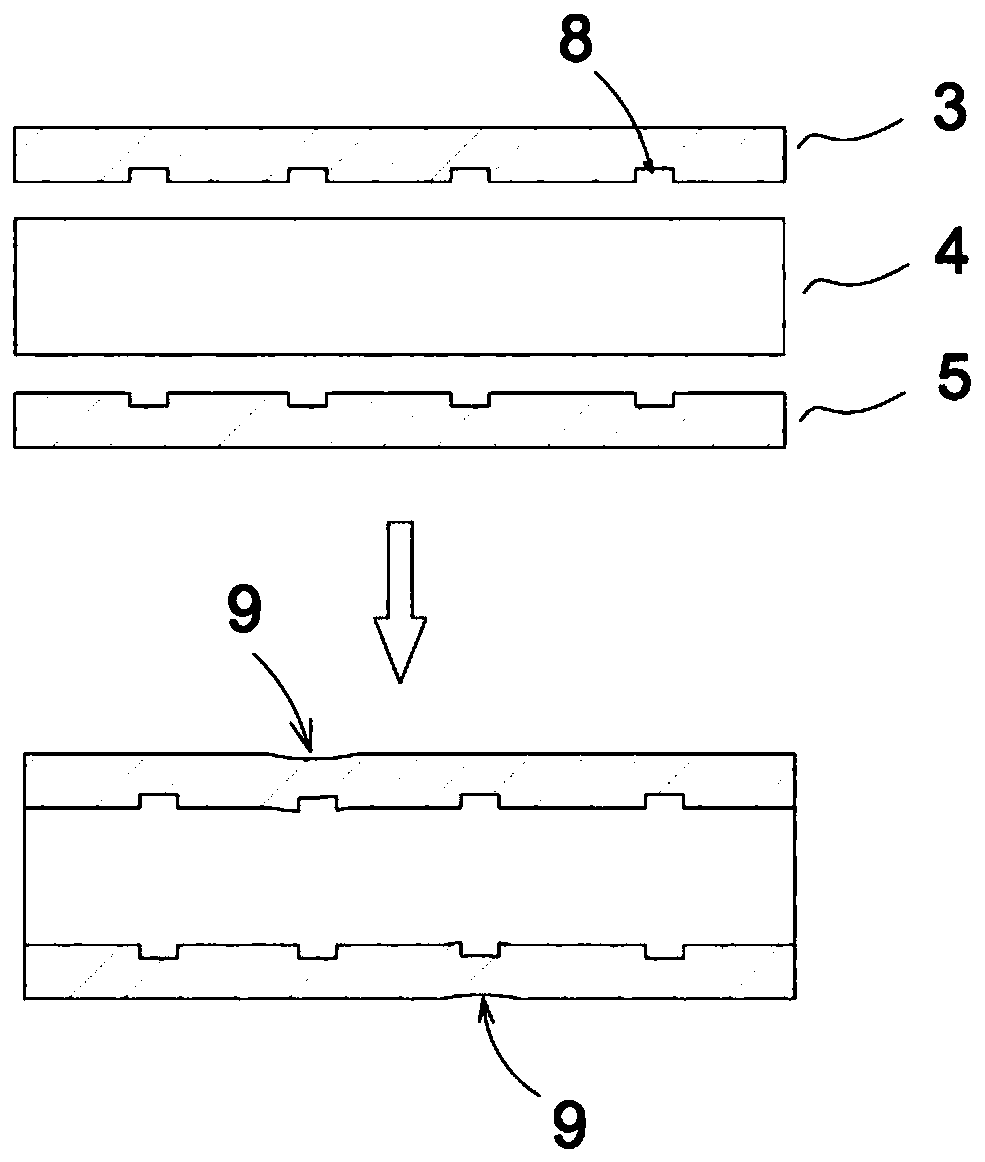

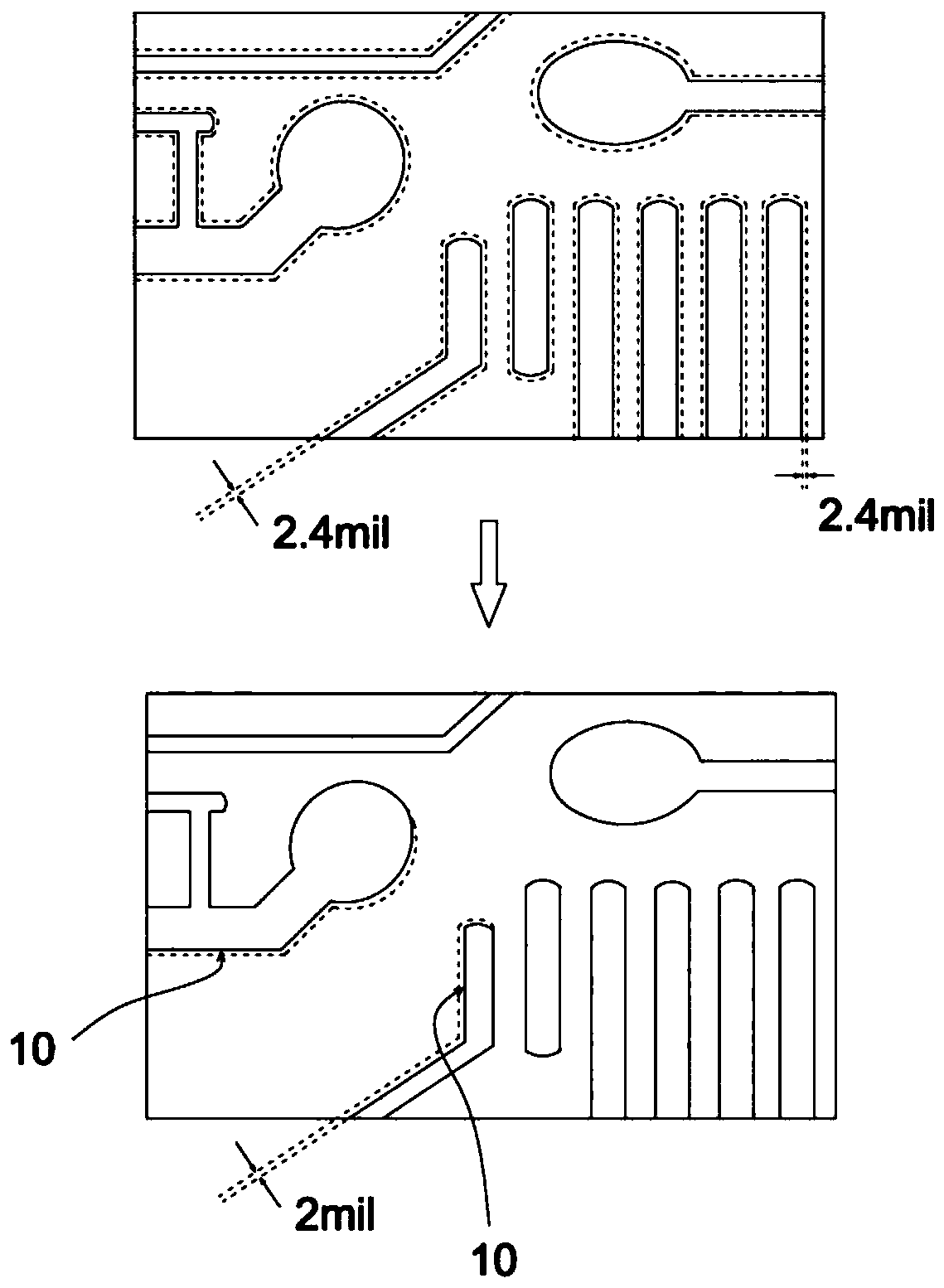

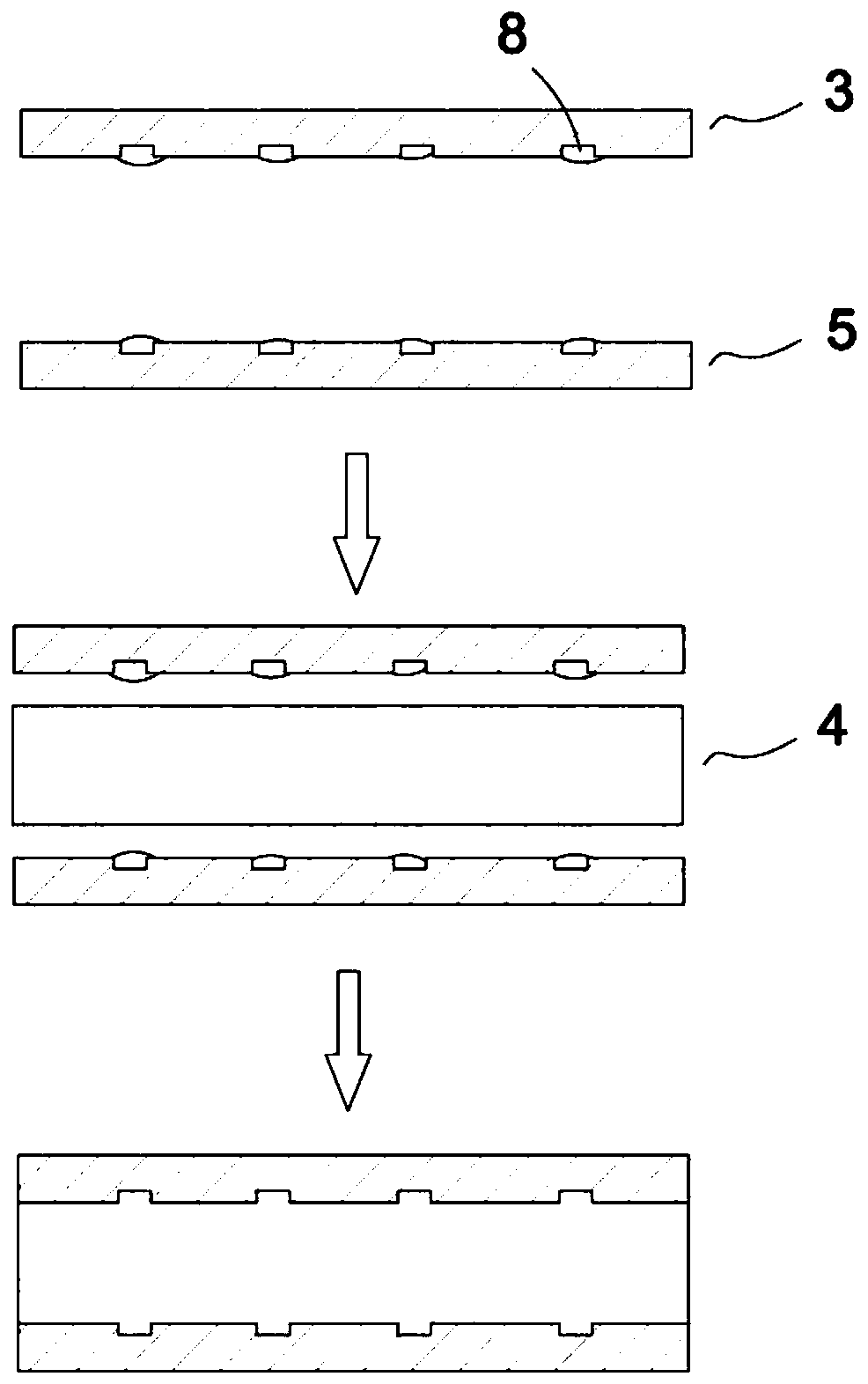

Manufacturing method of high-flatness multilayer circuit board

PendingCN111586985AIncrease the caulking processAvoid uneven surfacesPrinted circuit liquid treatmentConductive material chemical/electrolytical removalEtchingTin plating

The invention provides a manufacturing method of a high-flatness multilayer circuit board. The manufacturing method comprises the following steps of material preparation, first copper substrate processing, second copper substrate processing, primary resin joint filling, primary press fit, inner layer board processing, secondary resin joint filling, secondary press fit, drilling, copper plating, film drying, etching, tin plating, solder masking, secondary solder masking, character forming and pattern fishing. The problems of uneven surface and overlarge line etching amount of the multilayer circuit board manufactured in the prior art can be solved.

Owner:DIGITAL PRINTED CIRCUIT BOARD CO LTD

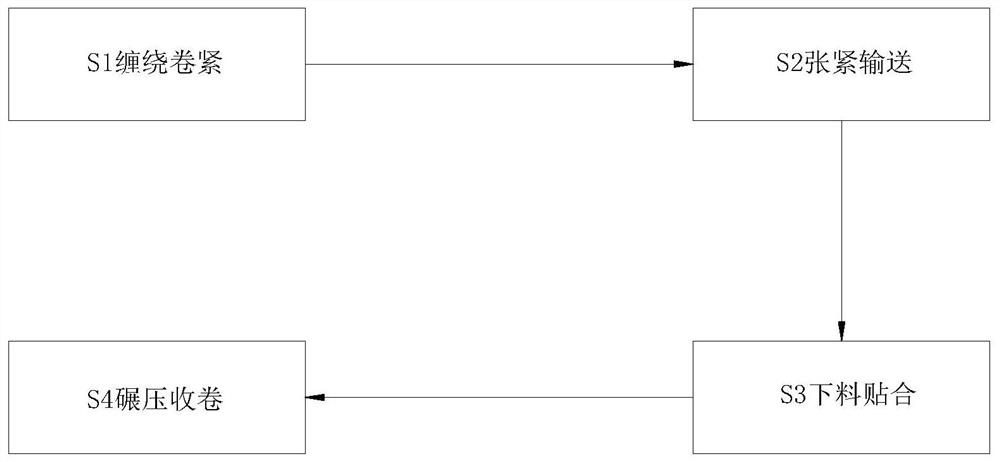

Preparation method of self-adhesive label paper

InactiveCN112373167AAvoid uneven surfacesFit flatMechanical working/deformationLamination ancillary operationsAdhesiveManufacturing engineering

The invention relates to a self-adhesive label paper preparation method, which uses self-adhesive label processing and manufacturing equipment. The equipment comprises a workbench and a winding devicearranged at the top of the workbench. A tensioning device is arranged at the top of the workbench, a feeding box is arranged over a T-shaped plate, discharging devices are arranged at the left end and the right end of the feeding box, and rolling devices are arranged at the front end and the rear end of the feeding box. A designed tensioning roller can achieve a certain tensioning effect on the surface of backing paper, the tensioning degree of the surface of the backing paper can be adjusted through a designed cross-shaped sliding groove, an electric sliding block and a T-shaped plate, the backing paper is in a tensioned state in the working process, and the situation that the surface of the backing paper is uneven, and consequently the attaching quality is reduced is prevented.

Owner:倪敏跃

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com