Assembled distribution box

A distribution box, assembled technology, applied in the substation/distribution device shell, electrical components, substation/switch layout details, etc., can solve the problems of irregular distribution box box, inconvenient installation, difficult operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

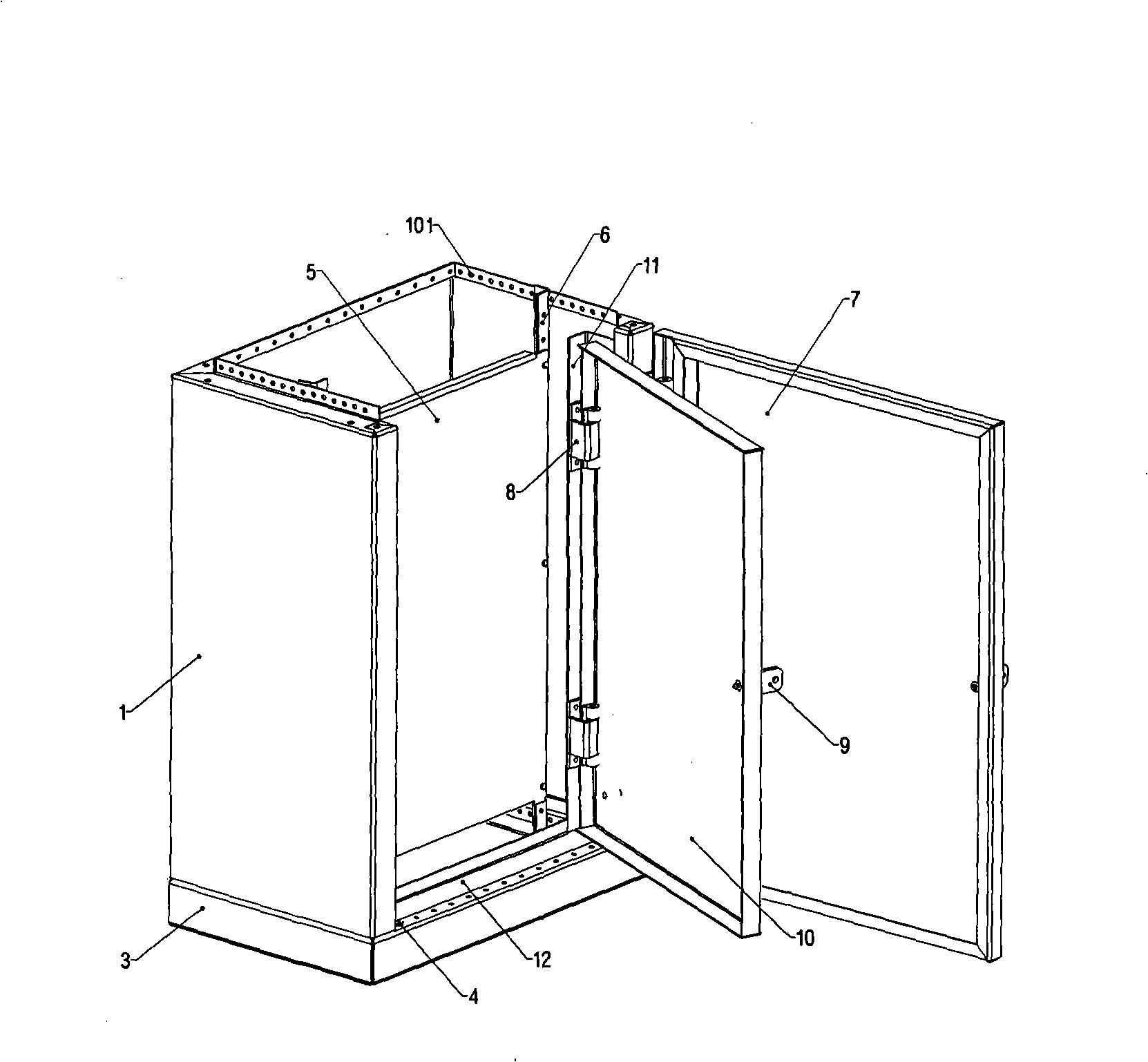

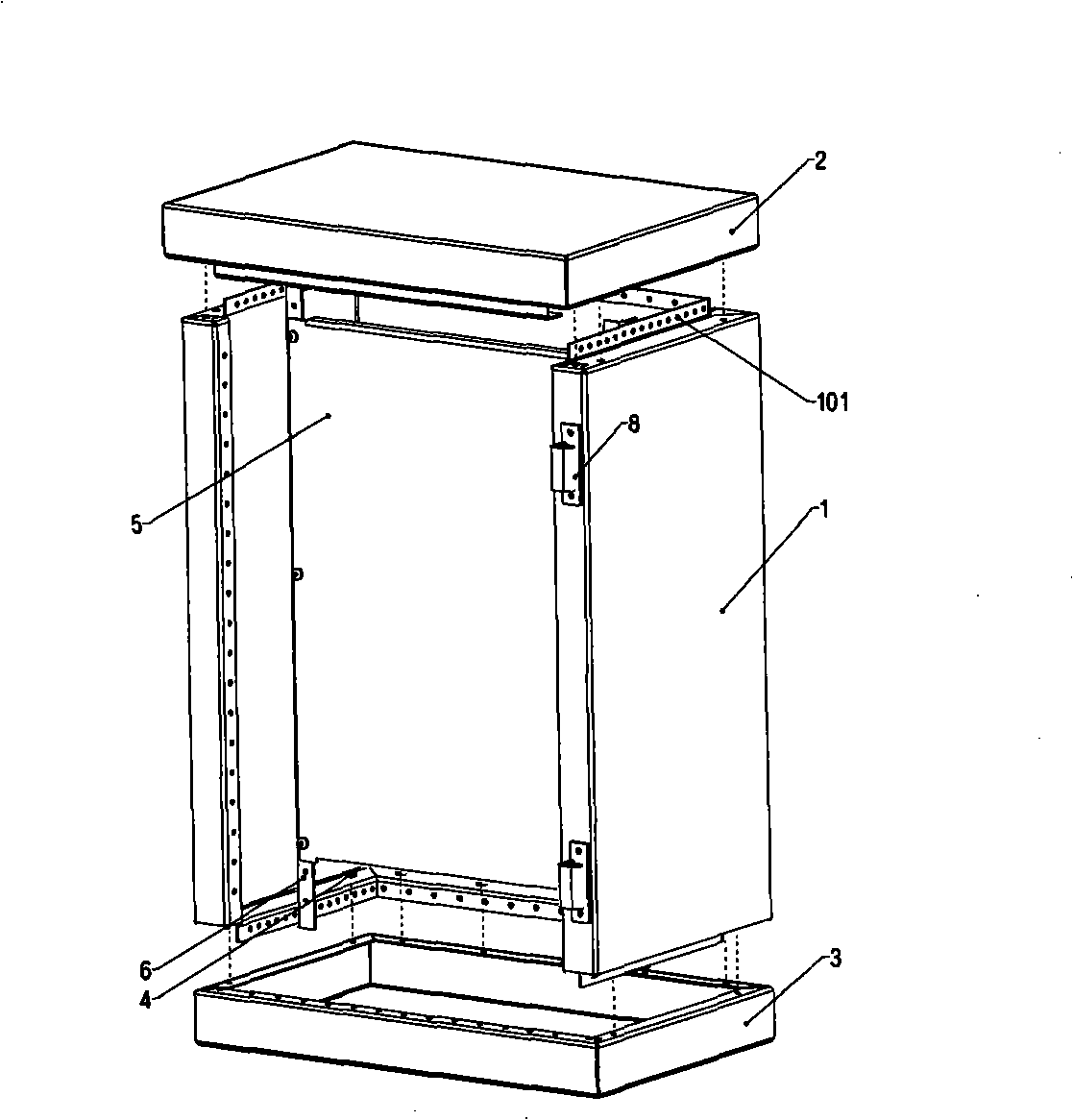

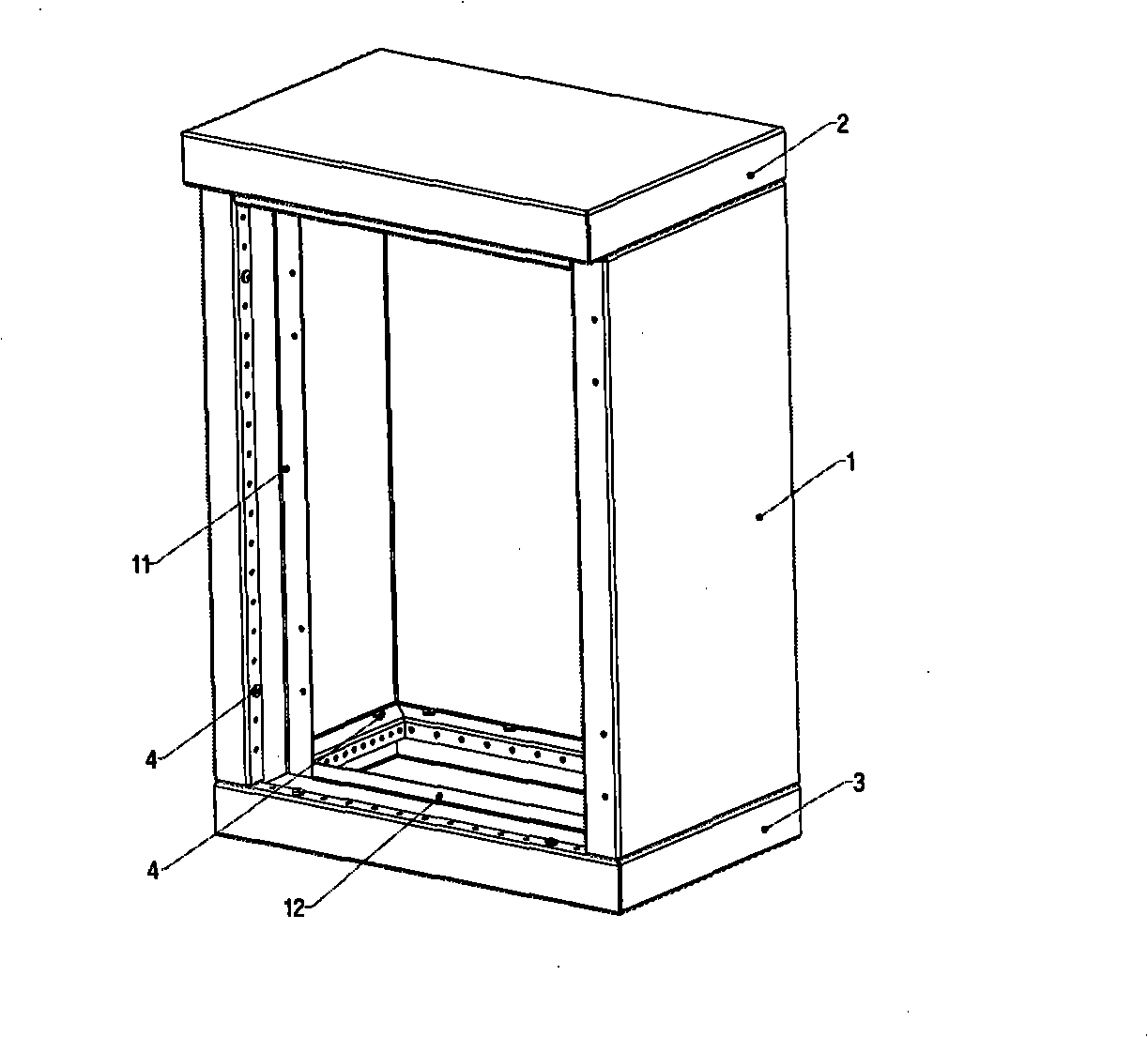

[0014] In order to solve the above technical problems, an assembled distribution box of the present invention includes a housing 1, an upper cover 2, a lower cover 3, a mounting plate 5, a door 7 and an inner door 10, wherein the housing 1 The upper and lower ends are provided with notches 13, the inner sides of the upper and lower cover plates 2, 3 contain the notches 13, the mounting plate 5 is arranged in the housing 1, the inner door panel 10 and the door panel 7 are connected with the housing The body 1 is fixedly connected, and the upper and lower cover plates 2 and 3 are respectively connected to the upper and lower ends of the housing 1 by self-tapping screws 4. The housing 1, the upper cover plate 2 and the lower cover plate 3 are made of steel plates It is processed by multiple forming and bending, and the steel plate has the advantages of high strength and good s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com