Manufacturing method of high-flatness multilayer circuit board

A technology of multilayer circuit board and manufacturing method, which is applied in the direction of multilayer circuit manufacturing, printed circuit manufacturing, printed circuit, etc., can solve the problems of uneven surface of multilayer circuit board, large amount of line erosion, etc., and prevent the problem of uneven surface , the effect of reliable conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below with reference to the examples and drawings, but the implementation of the present invention is not limited thereto.

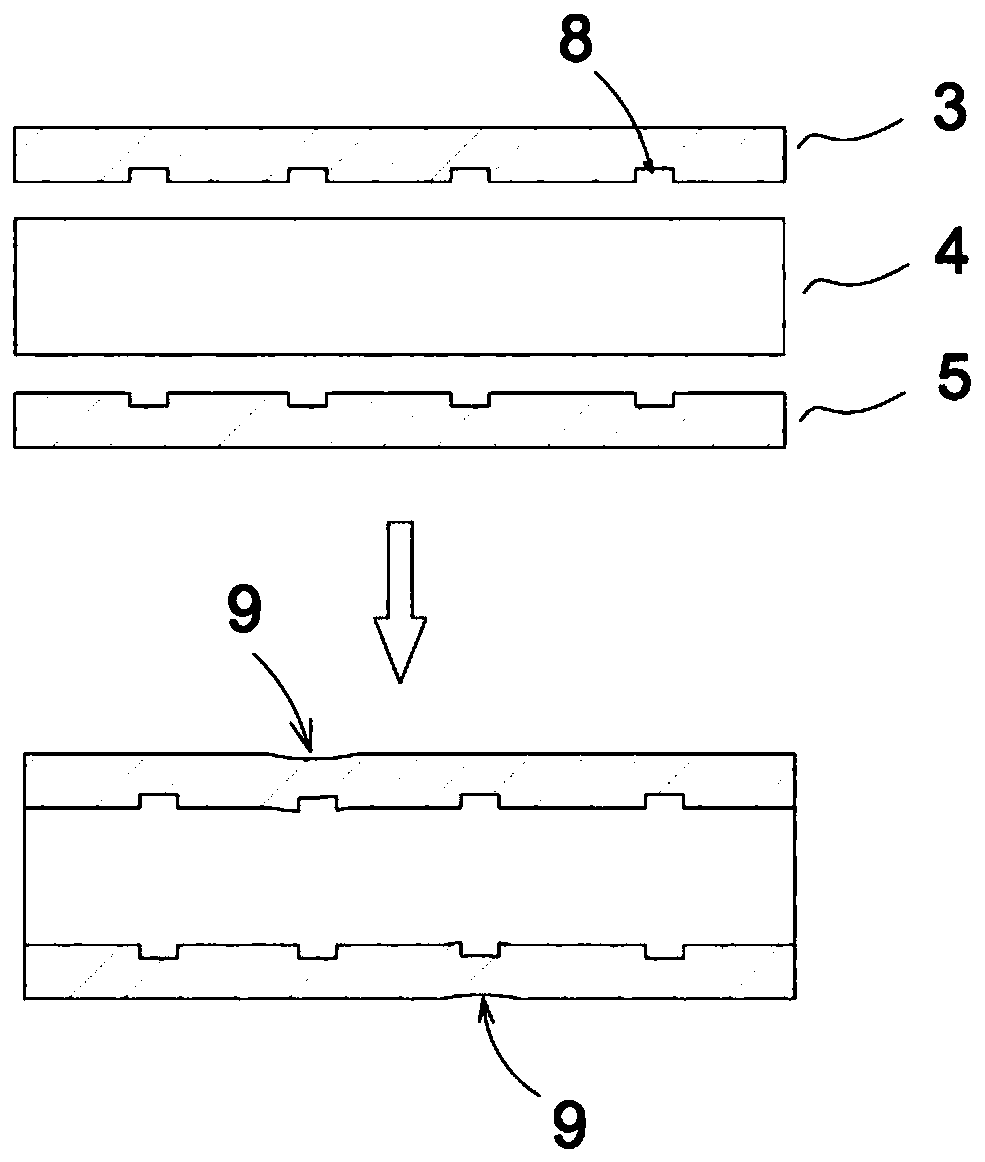

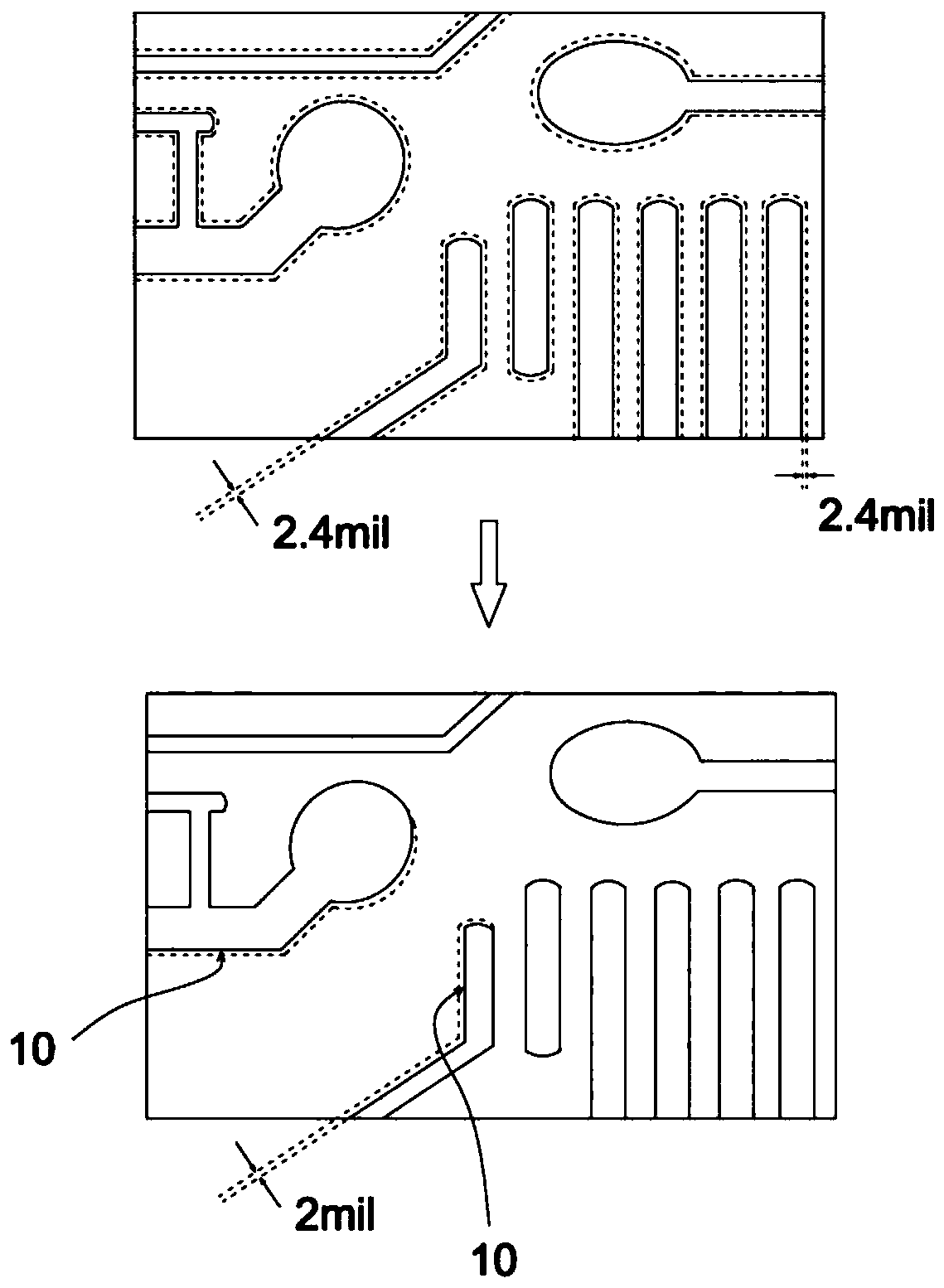

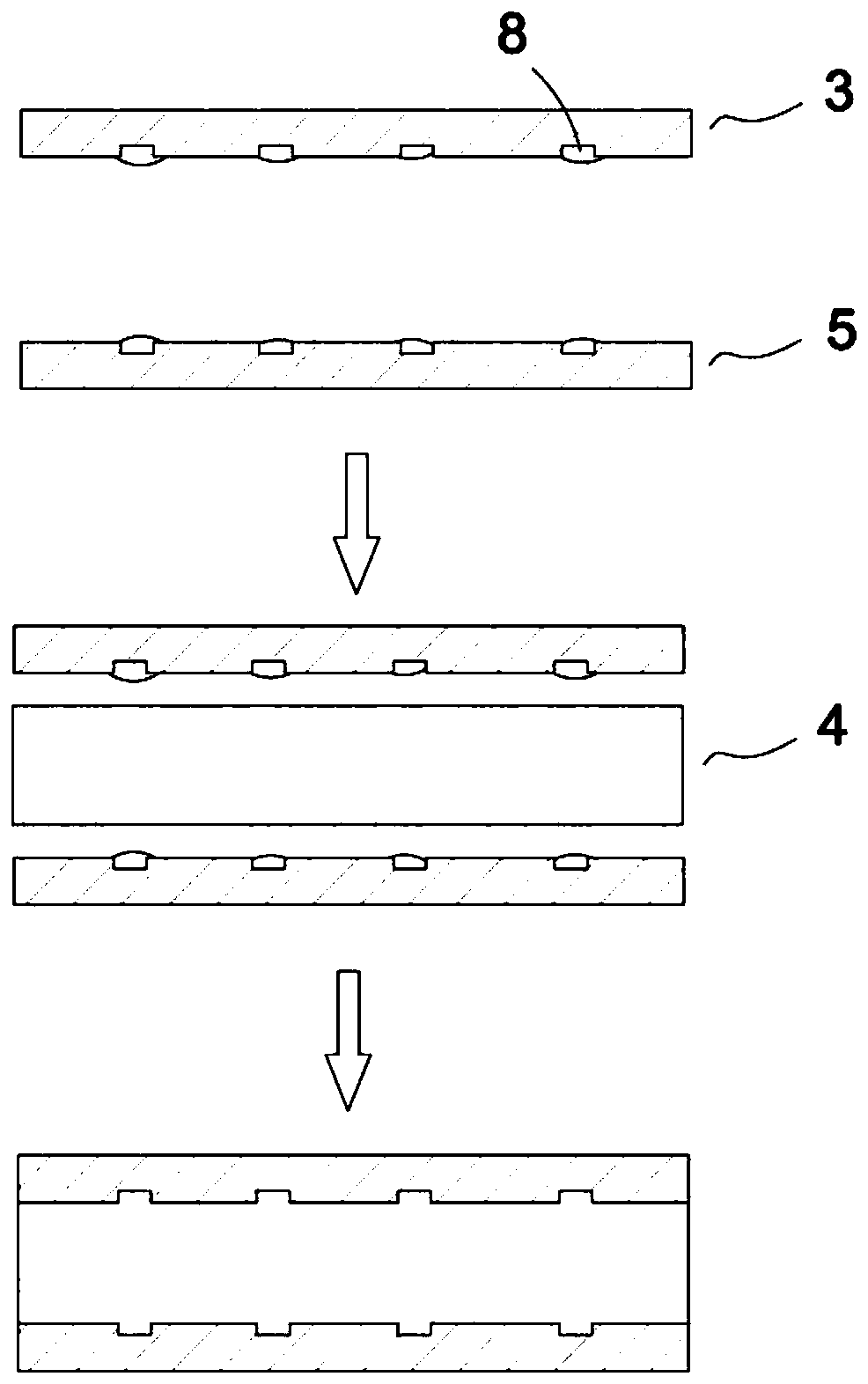

[0039] refer to Figure 3-5 Shown:

[0040] A method for manufacturing a multilayer circuit board with high flatness, comprising the following steps:

[0041] S1 material preparation: prepare the upper layer board 1, the first prepreg board 2, the first copper substrate 3, the second prepreg board 4, the second copper substrate 5, the third prepreg board 6, and the lower board 7;

[0042] S2 First copper substrate treatment: apply film, develop, expose, and etch the lower end surface of the first copper substrate 3, and obtain the hollowed-out first inner layer circuit after removing the film, and make target holes on the first copper substrate 3 for target shooting After the holes are made, target holes are made on the first copper substrate 3. Since the first copper substrate 3, the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com