Operation method for quick magic powder replacing system

An operation method and magic technology, applied in the field of tail powder quick magic powder changing system, can solve the problems of poor filtering effect, reduced production efficiency, low efficiency, etc., and achieve the effect of avoiding surface unevenness and improving uniformity and flatness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0052] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

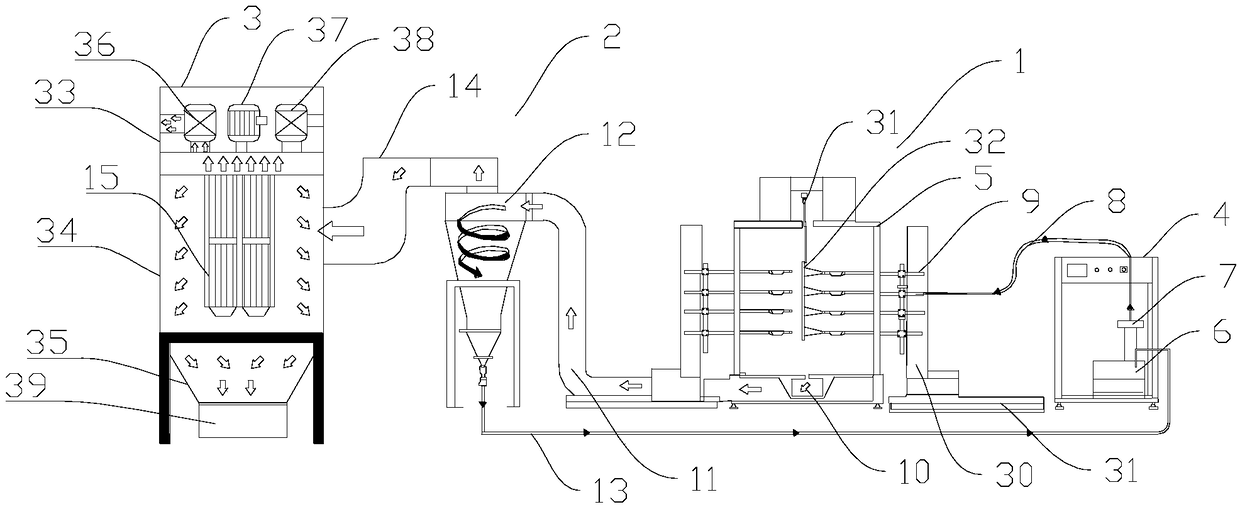

[0053] Such as figure 1 In the shown embodiment, a kind of operation method of fast magic powder changing system, described operation method comprises the following steps:

[0054] (1) Preliminary preparation: Check the performance of the powder supply system 1, the reverse blowing cyclone dust removal system 2 and the filter element filter 3, and fill the powder supply 6 inside the powder supply center 4 of the powder supply system 1 with the powder coating to be sprayed ;

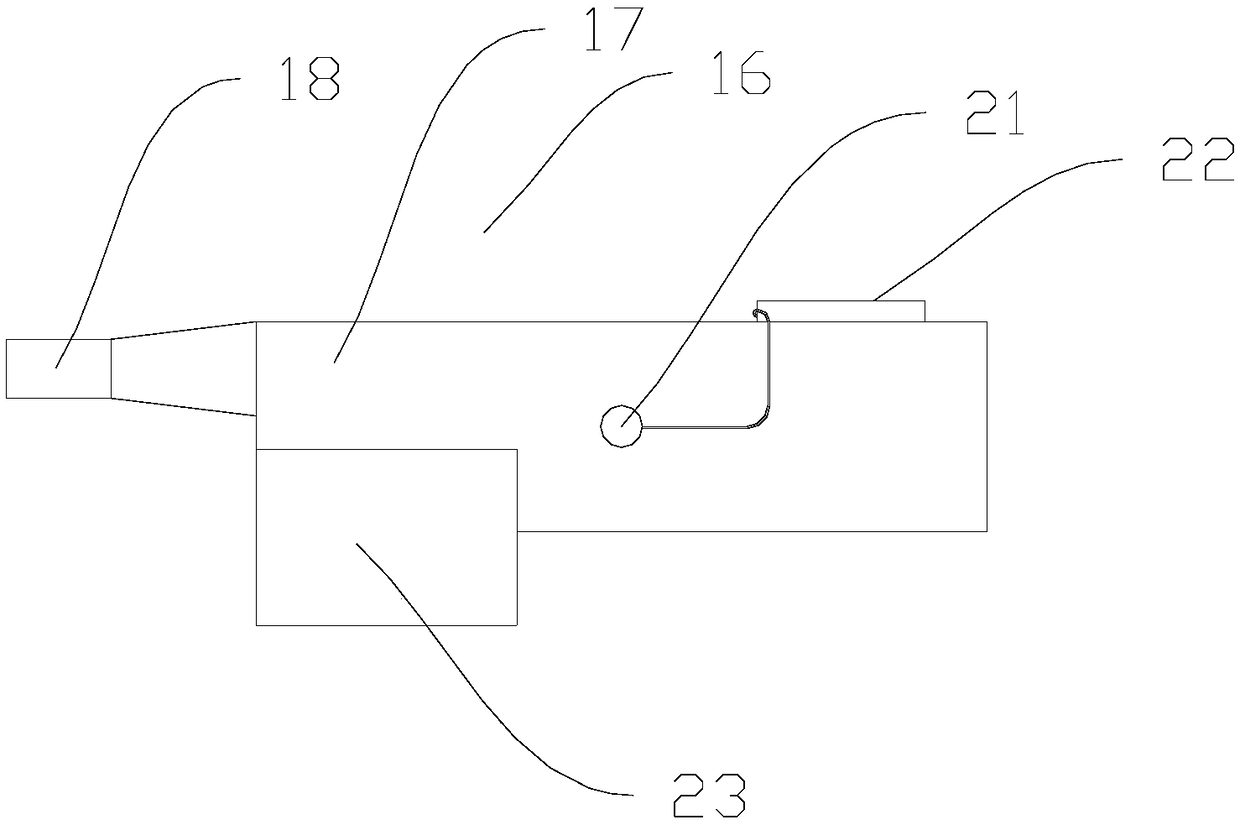

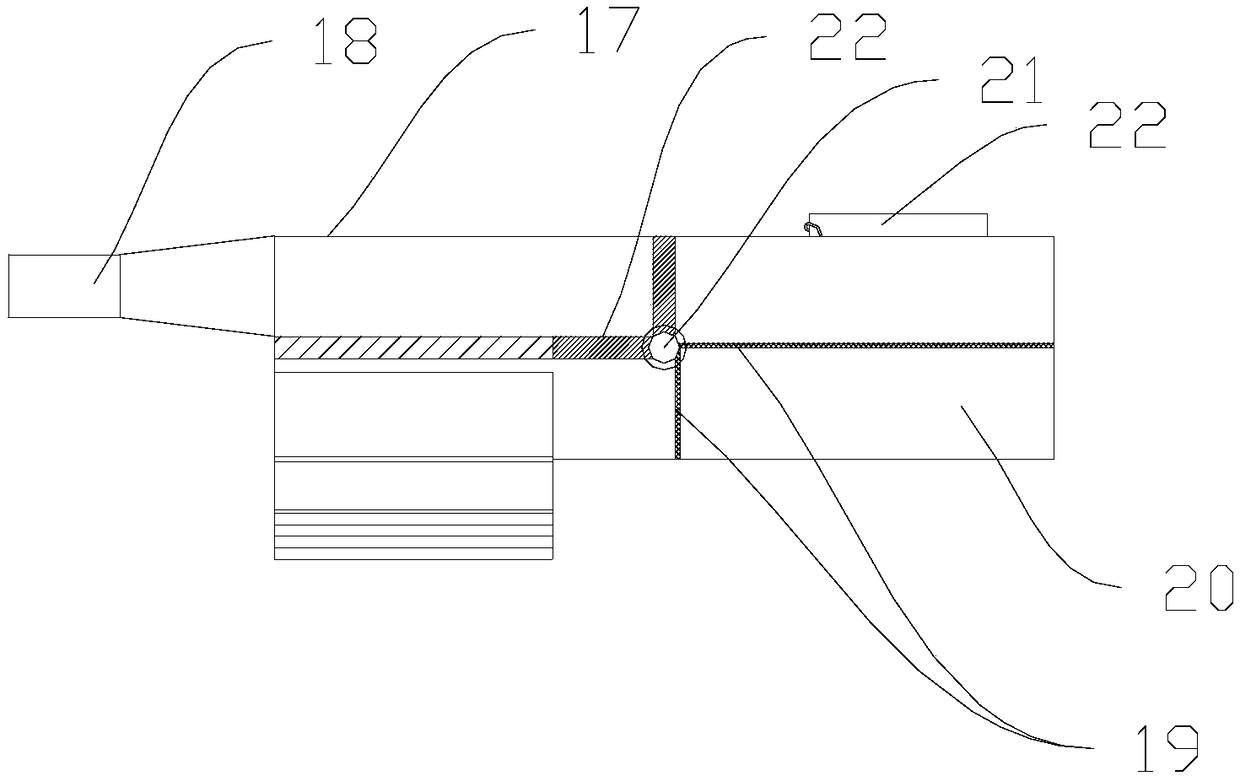

[0055] (2) Workpiece spraying: hang the workpiece 32 in the spreader 31 in the powder spraying room 5, start the Venturi powder pump 7 above the powder supply barrel 6, and transfer the powder coating to the automatic spray gun 9 through the first powder pipe 8 , then spraying to the surface of the workpiece 32 to complete the spraying, the automatic spray gun 9 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com