Patents

Literature

102results about How to "Fit flat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

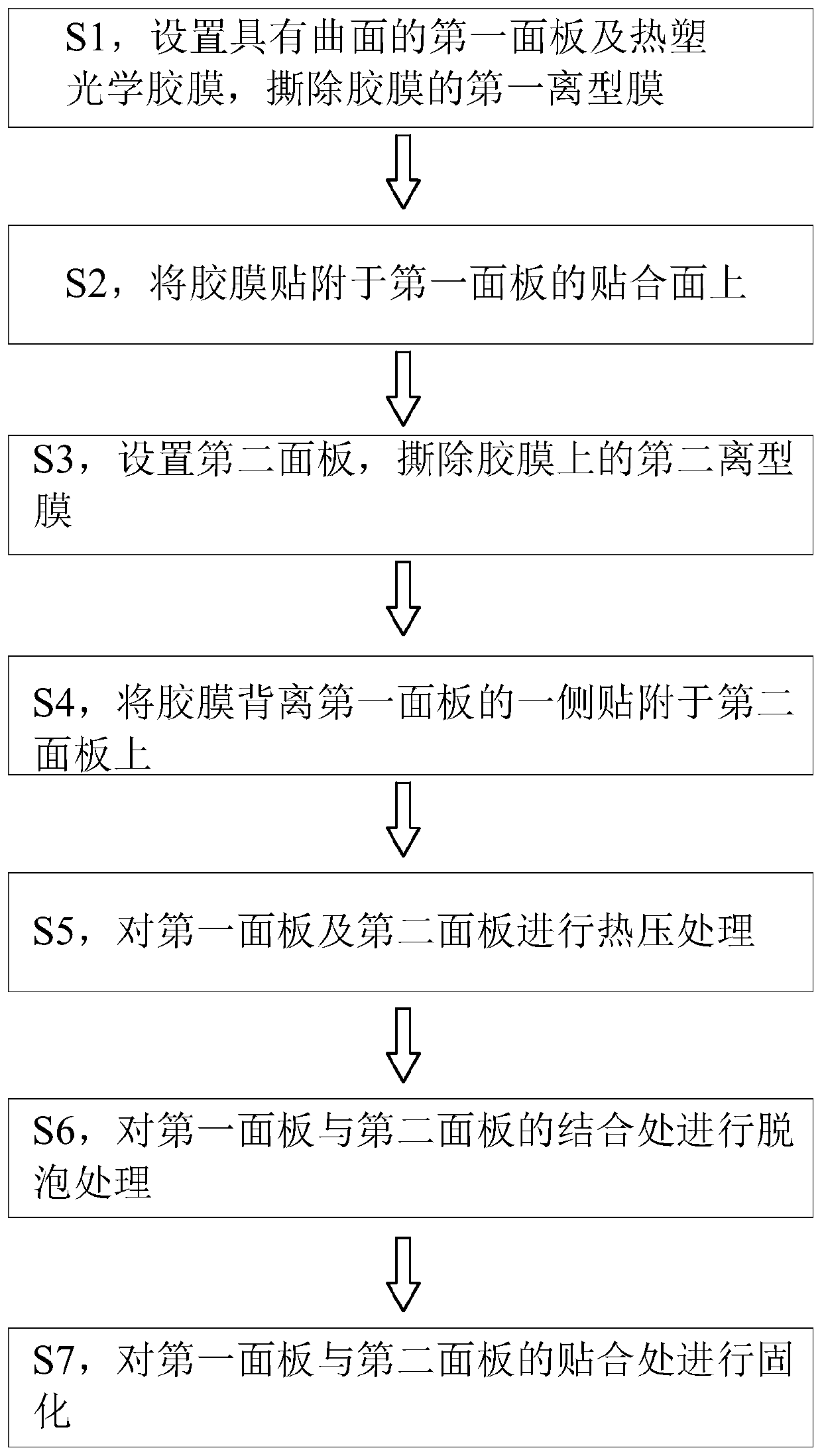

Adhesion method based on curved-surface flexible screen and display device

The invention relates to the technical field of displays and display adhesion. The invention relates to an Adhesion method based on a curved surface flexible screen. The adhesion method based on the curved surface flexible screen comprises the steps of providing a first panel with a curved surface and an optical thermoplastic adhesive film, tearing off the first release film of the adhesive film,attaching the adhesive film to the surface of the first panel, arranging a second panel, tearing off the second release film, attaching one side, opposite to the first panel, of the adhesive film to the second panel, carrying out hot pressing and defoaming treatment on the first panel and the second panel, and curing the joint of the first panel and the second panel. The display device is manufactured by the film adhesion method. The adhesive film provided by the invention can be quickly attached to the first panel and the second panel; according to the display device, bubbles generated in thehot pressing process of the adhesive film are eliminated, stress at the attaching position of the first panel and the second panel is absorbed, the adhesive film is prevented from rebounding, the first panel and the second panel are prevented from deforming, the attaching yield between the first panel and the second panel is increased, the display effect of the display device is improved, and theservice life of the display device is prolonged.

Owner:深圳一鑫新材料有限公司

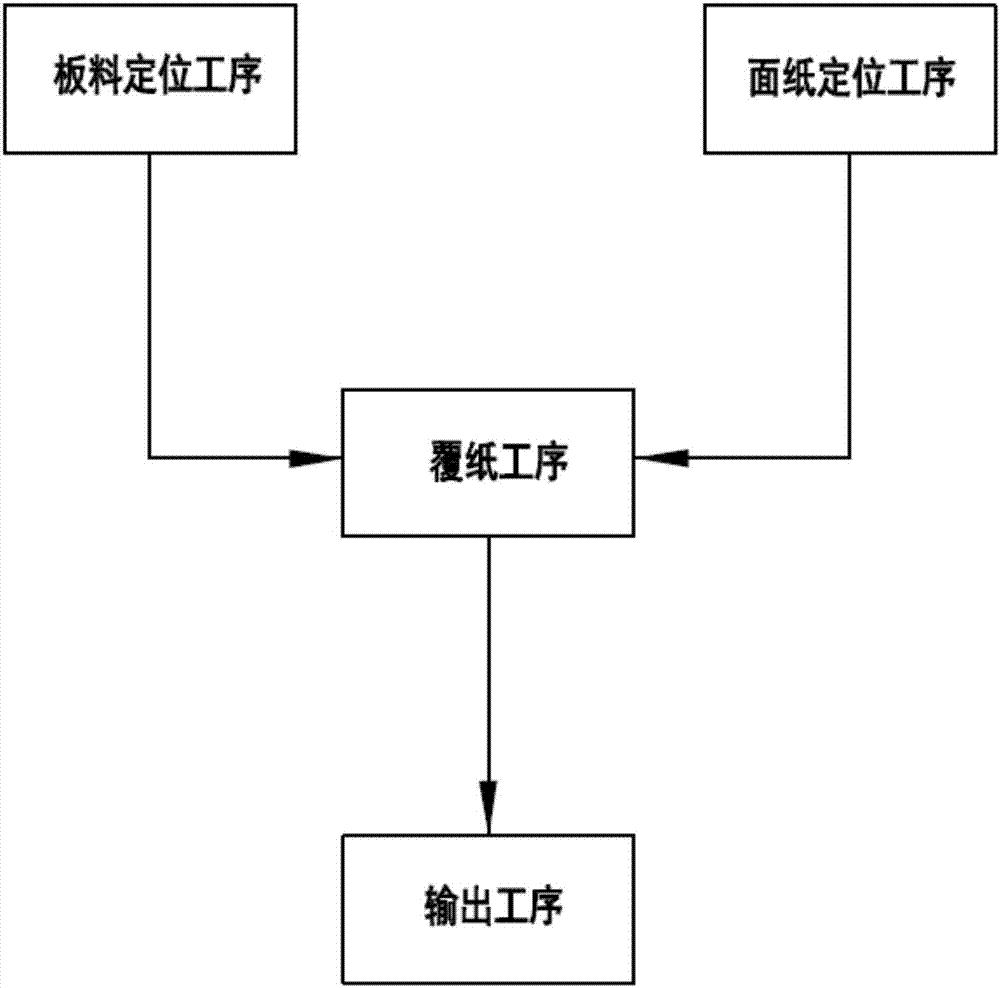

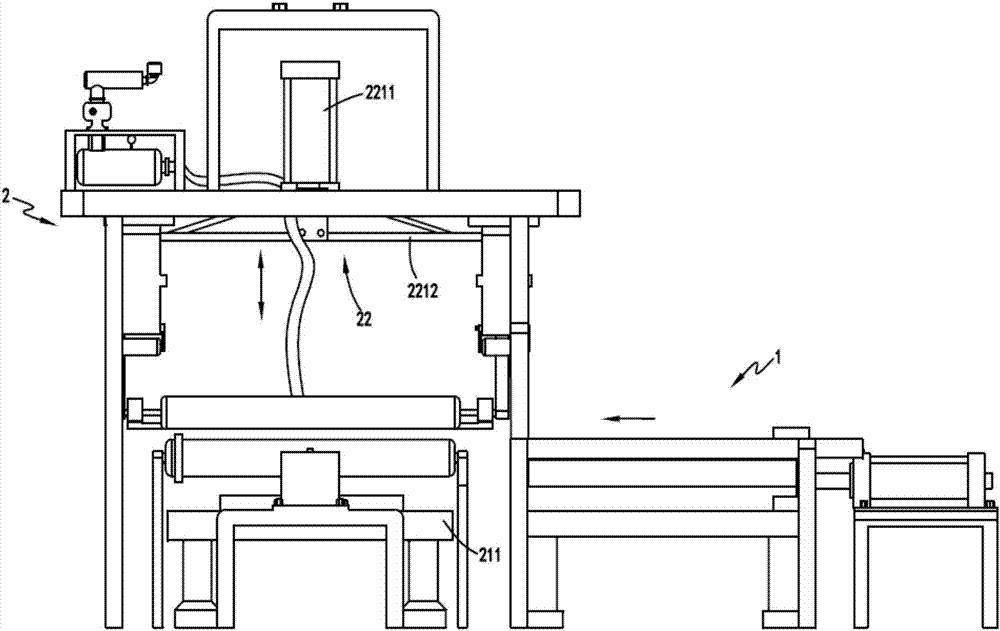

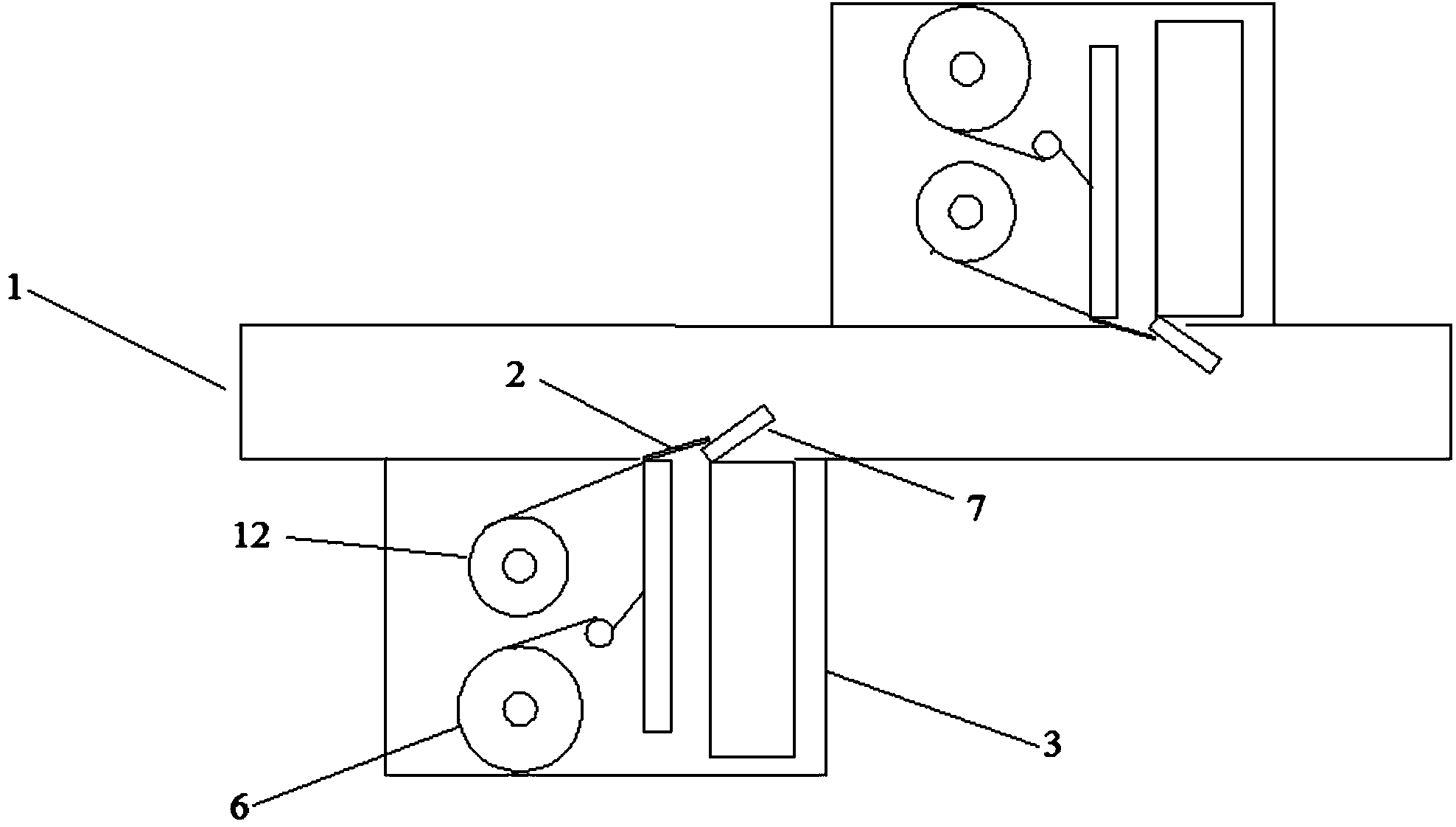

Continuous flattening and paper-attaching production line for single plates and production process thereof

InactiveCN107020790ASimple structureImprove bonding efficiencyLamination plant layoutLaminationProduction lineSingle plate

The invention relates to a veneer continuous smoothing and paper-coating production process, comprising the following steps: a. sheet positioning process, pushing the sheet coated with glue to a sheet positioning station through a linear transmission method; b. . Facial tissue positioning process, push the facial tissue to be attached to the facial tissue positioning station through a linear transmission method, and adsorb and fix the middle part of the facial tissue through negative pressure adsorption; c. Paper covering process, the facial tissue in step b Driven by the adsorption and fixing device to move down synchronously, so that the middle position is in pre-contact with the sheet material in step a, continue to move down, and the two sides of the middle position of the facial paper are completely attached to the sheet material by rolling from the inside to the outside, and the completion The surface of the sheet is covered with paper. d. Output process, pushing and outputting the sheets covered with paper in step c; the present invention overcomes the uneven bonding that exists in the bonding method from one side to the other, which is prone to bulging and The existing equipment has complex structure and unstable operation.

Owner:长兴昊太机械有限公司

Method for producing environmental-friendly glass fiber facing felt

The invention relates to a method for producing an environmental-friendly glass fiber facing felt from adhesion agent and glass fiber cut into the length according to the process requirement in the steps of forming with fiber, dipping the glue, drying and rolling. The method for producing the environmental-friendly glass fiber facing felt is characterized in that the main components of the adhesion agent are urea formaldehyde and polyacrylate. The glass fiber facing felt has good air permeability, high dry strength, strong clamate adaptability and no mirror reflection, can be adhered to the wall surface conveniently and easily to decorate the wall surface and make the wall surface attractive without blistering and cracking and is mildewproof, fireproof, attractive and durable.

Owner:泰山玻璃纤维淄博有限公司

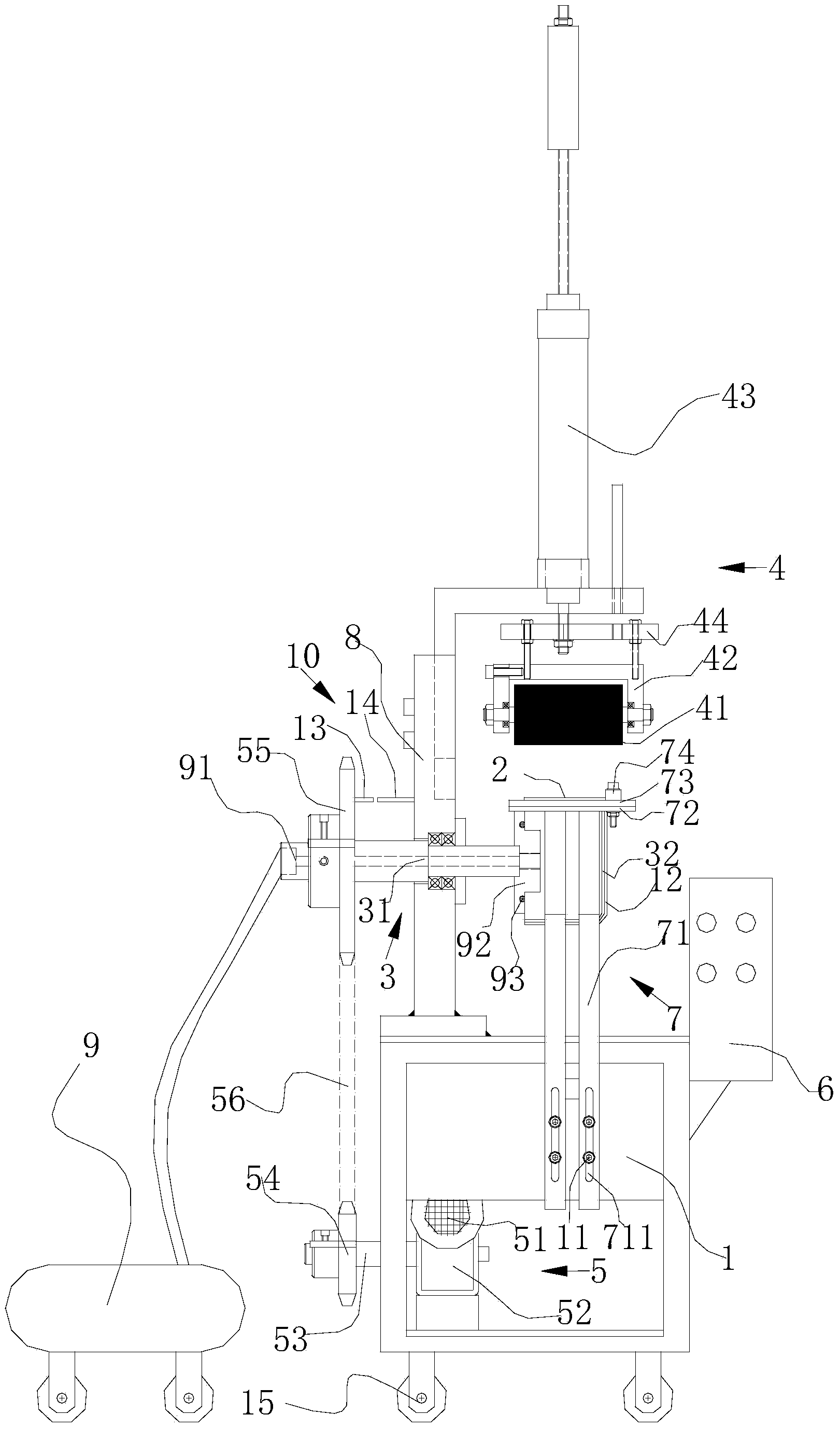

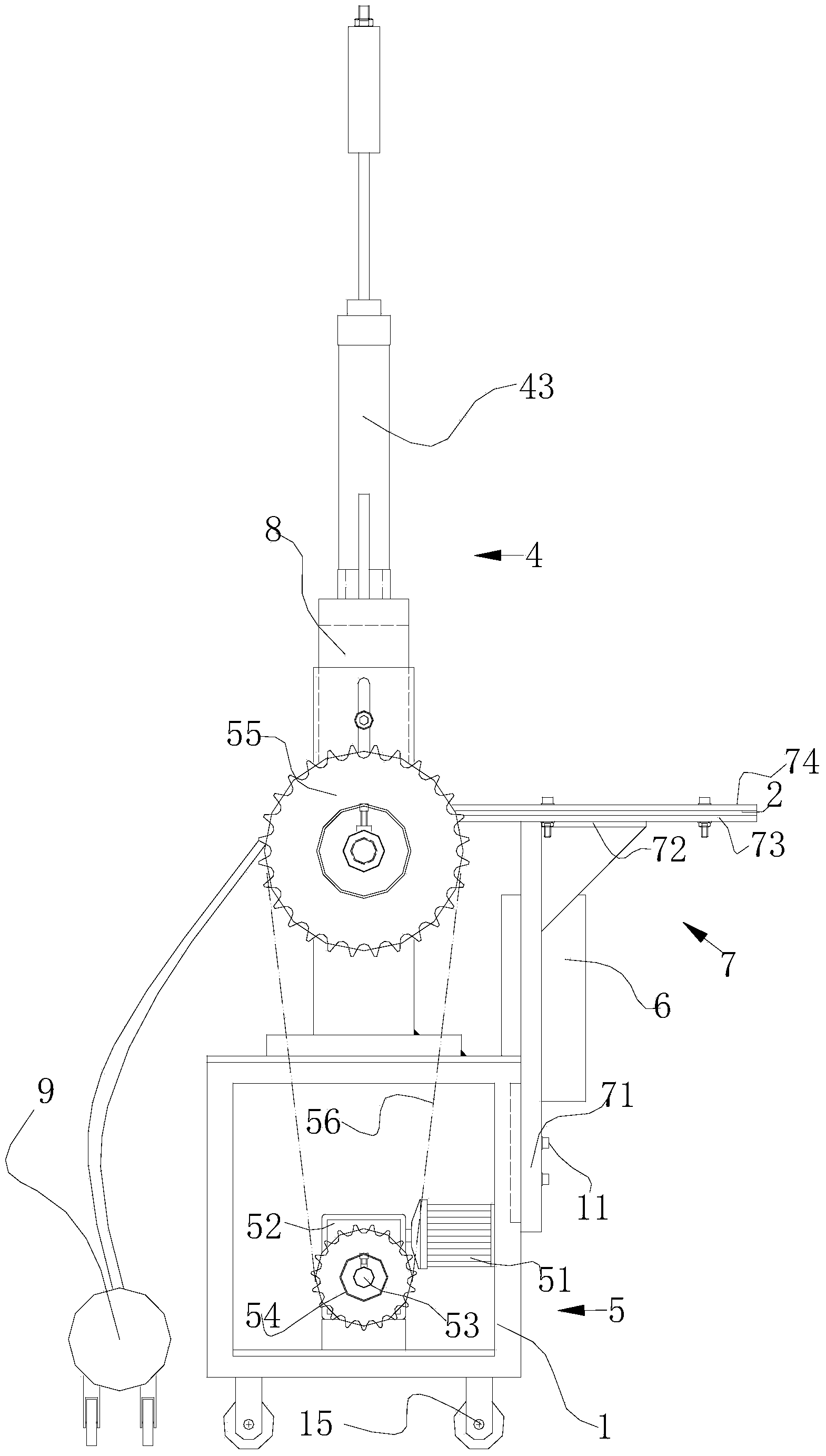

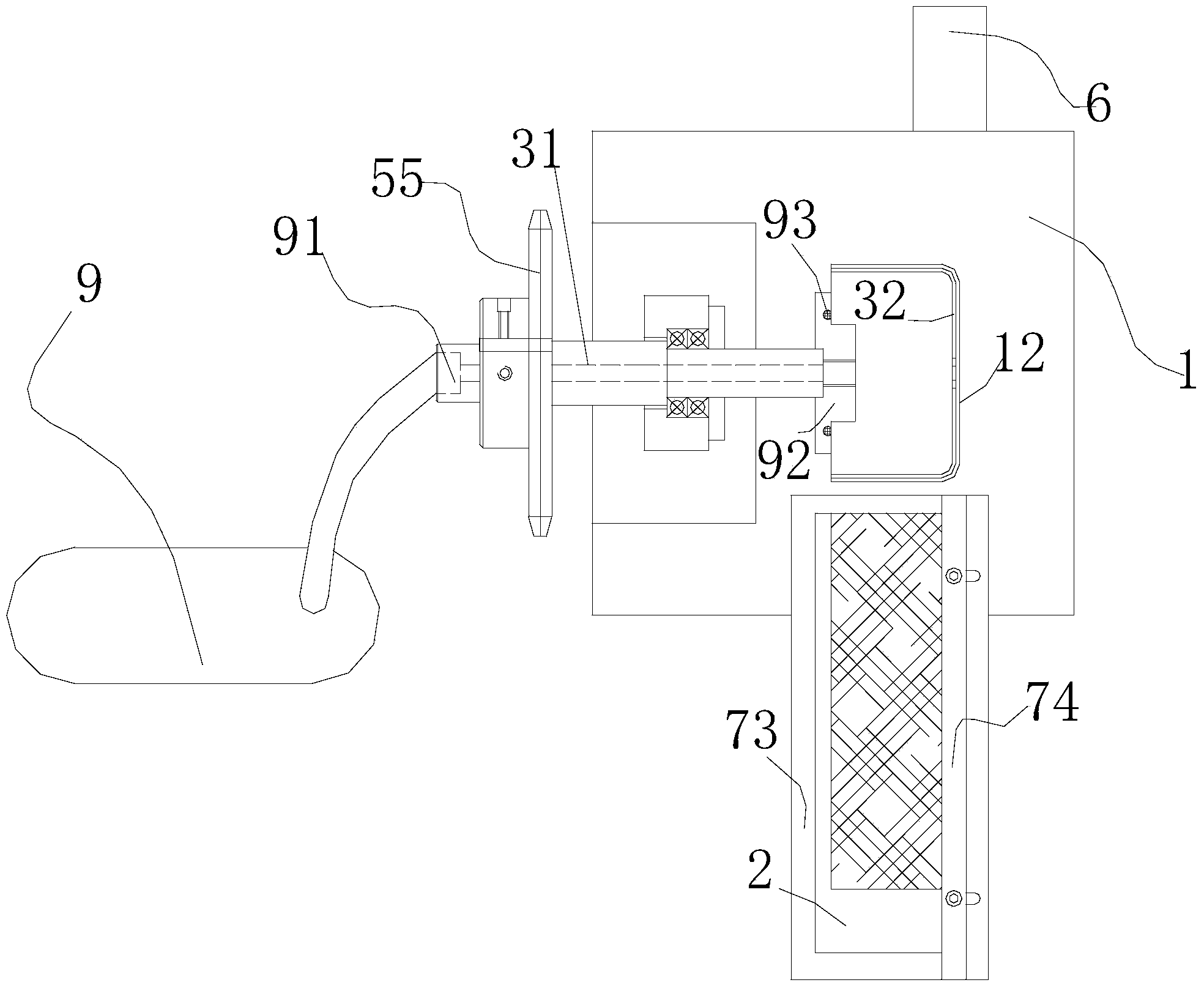

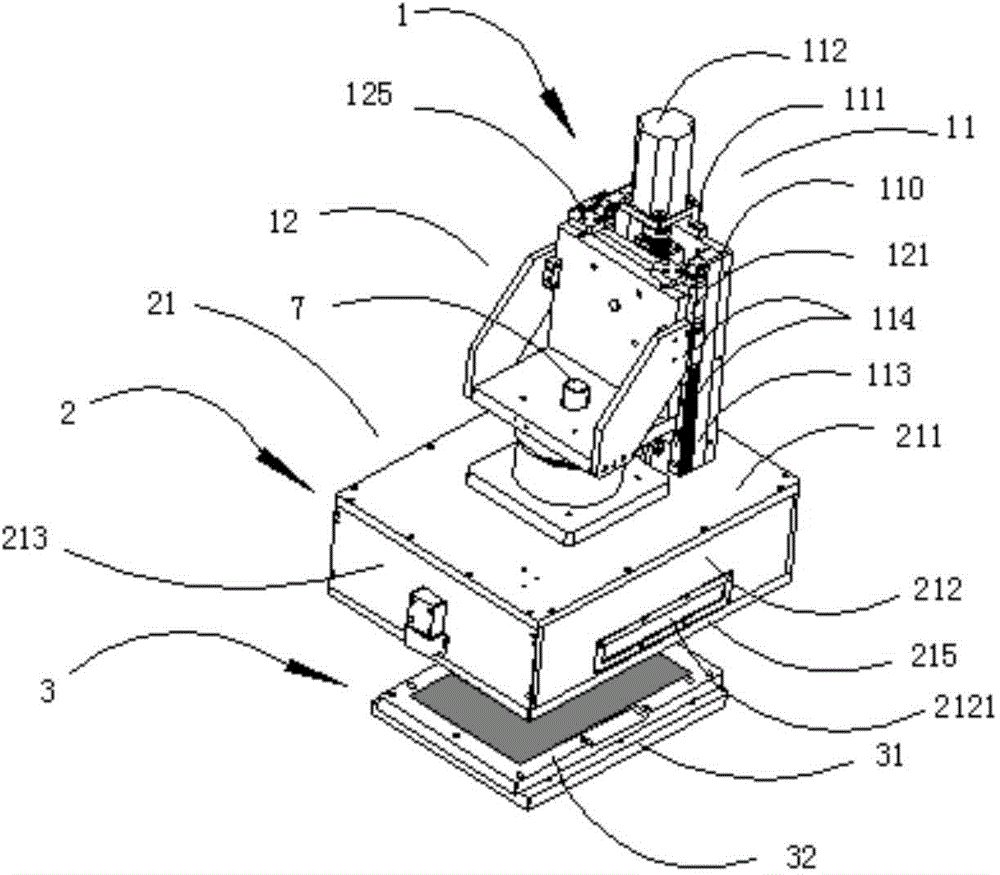

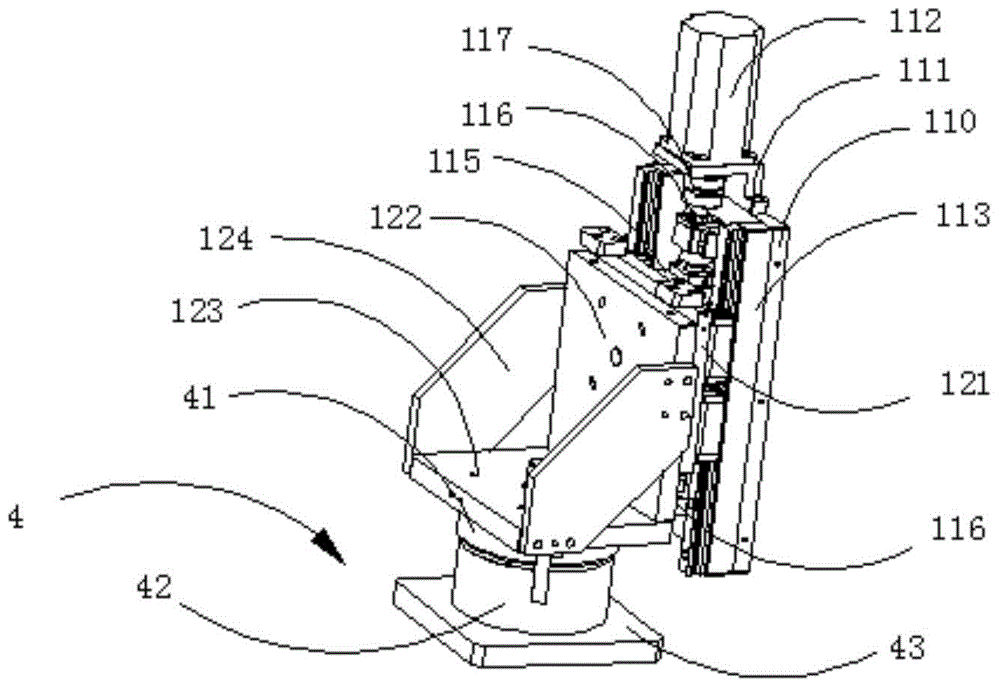

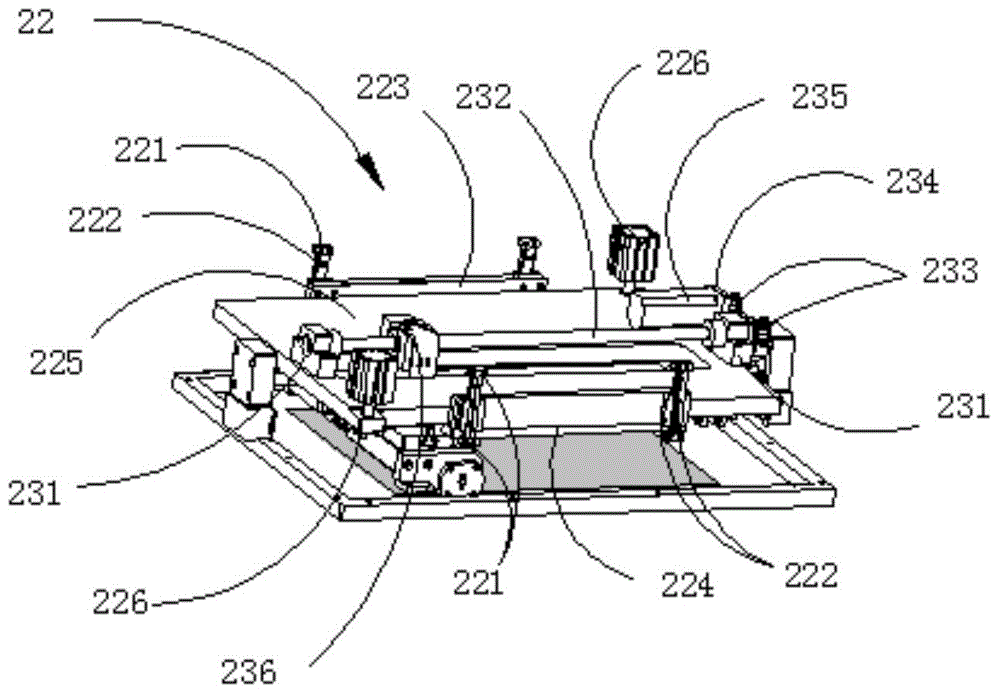

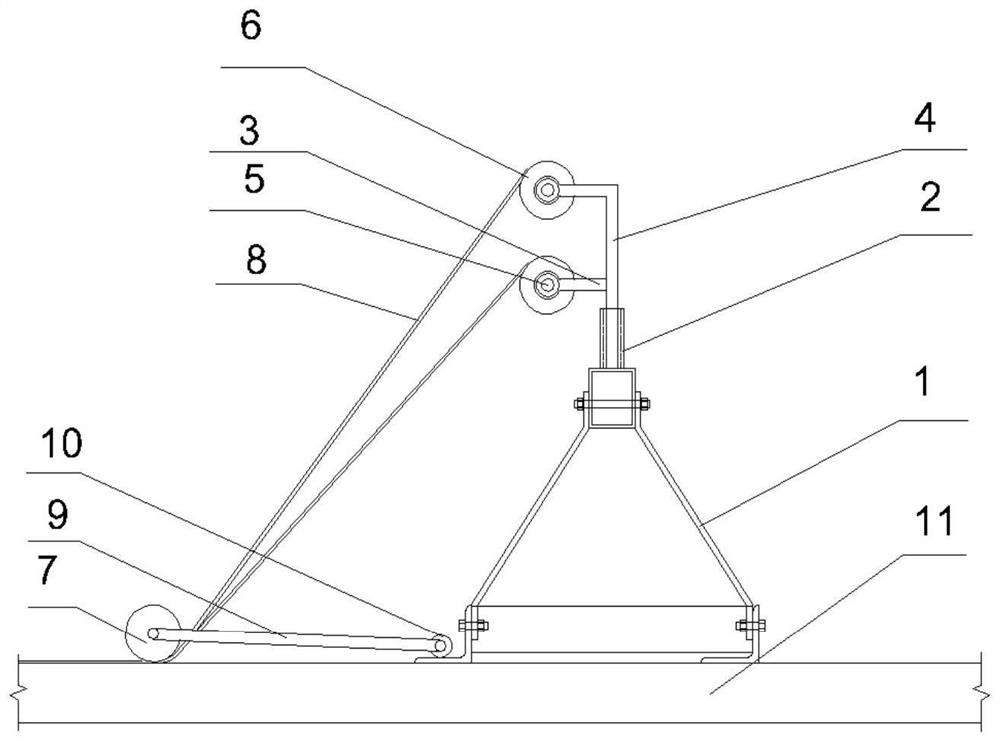

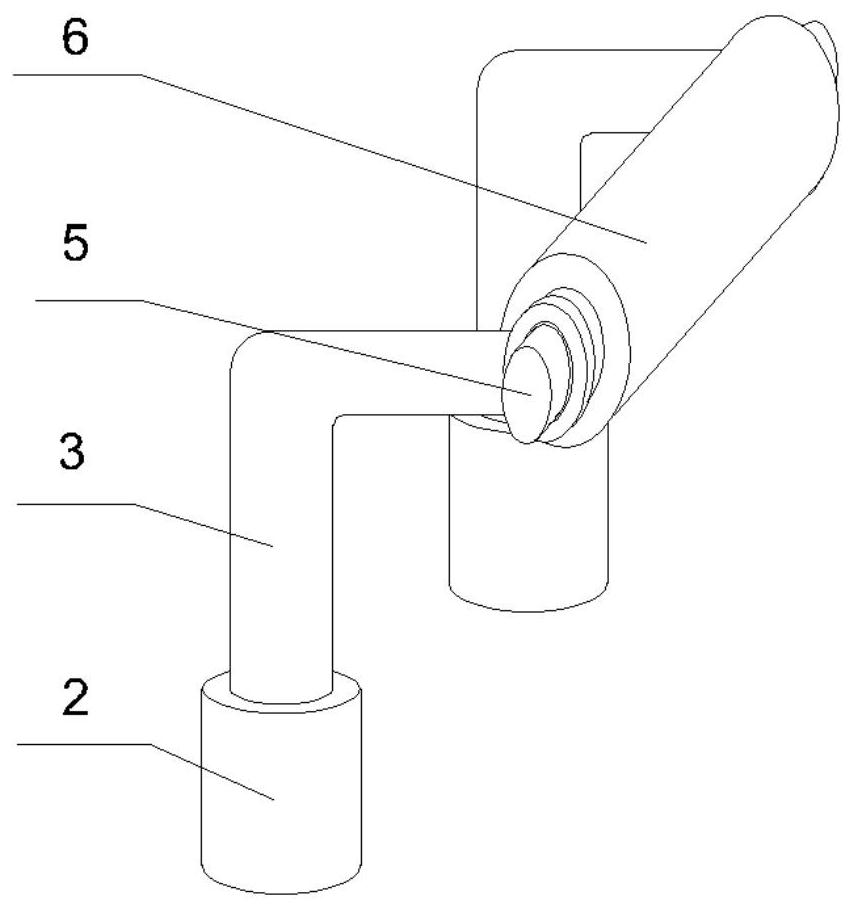

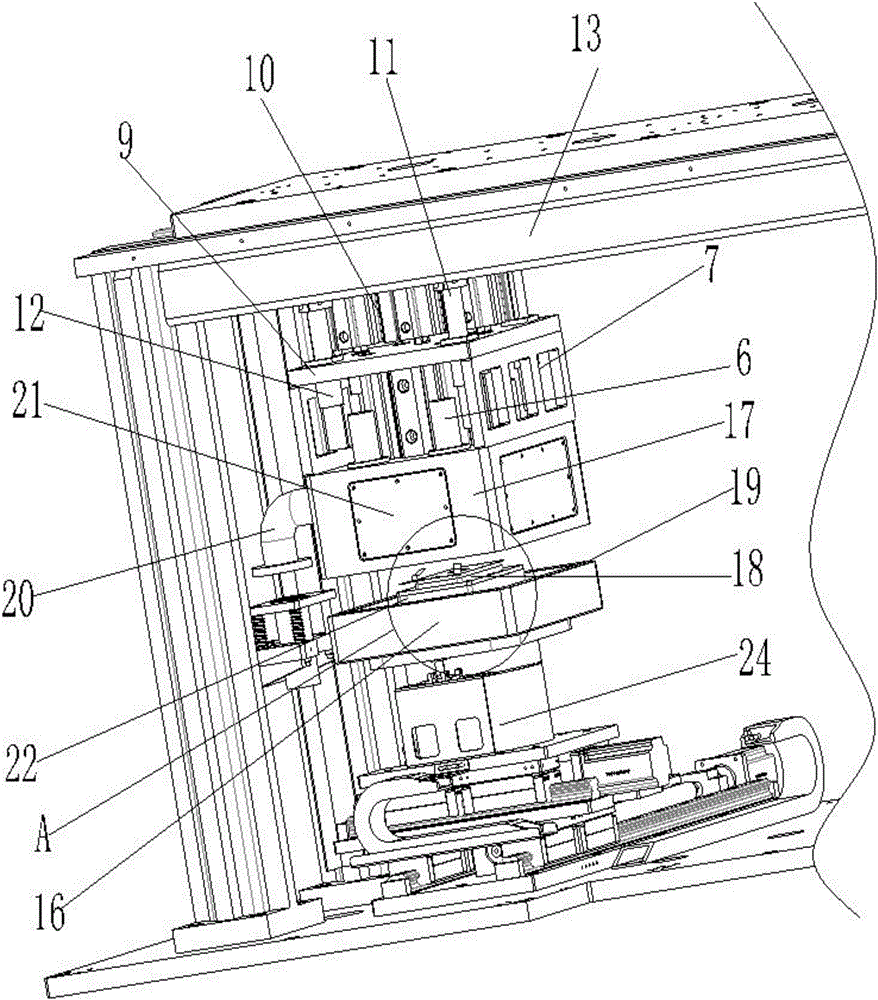

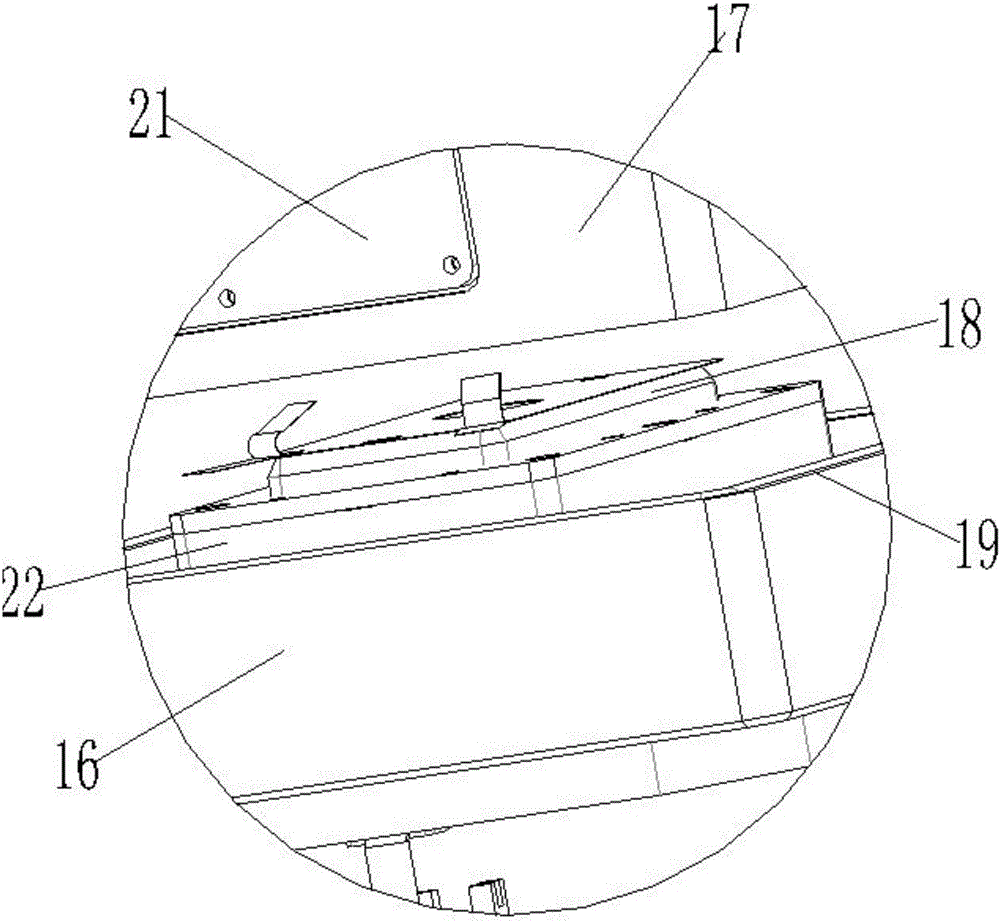

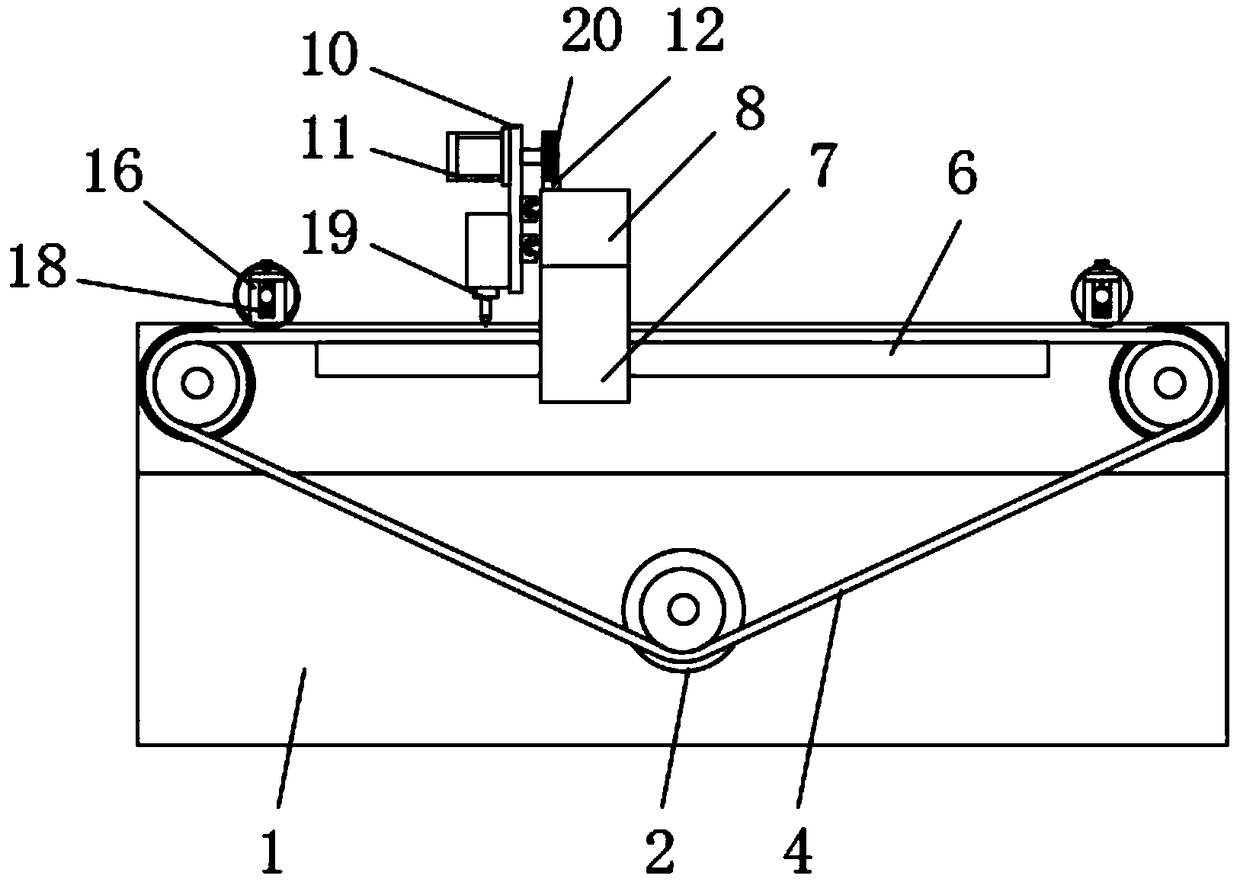

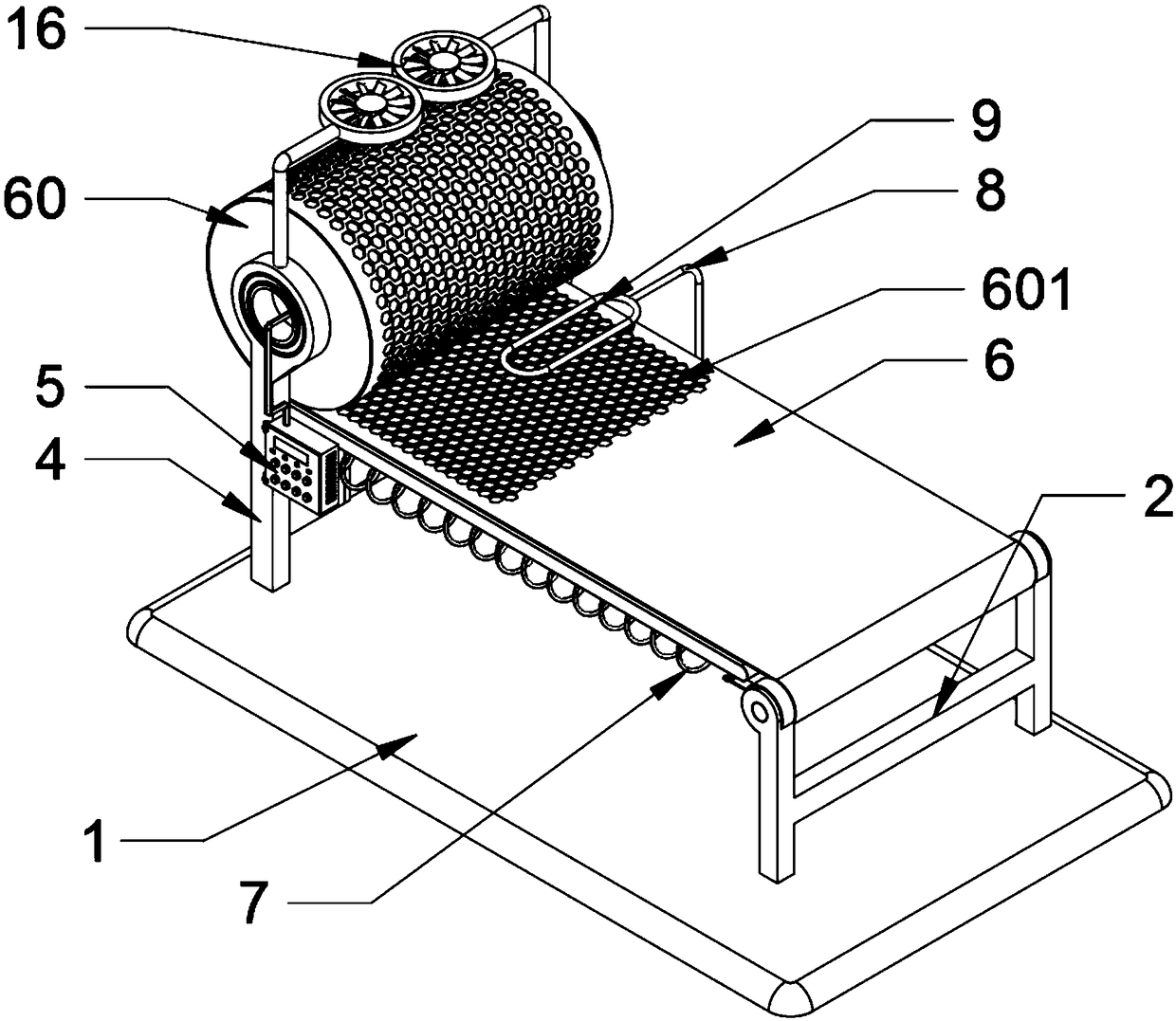

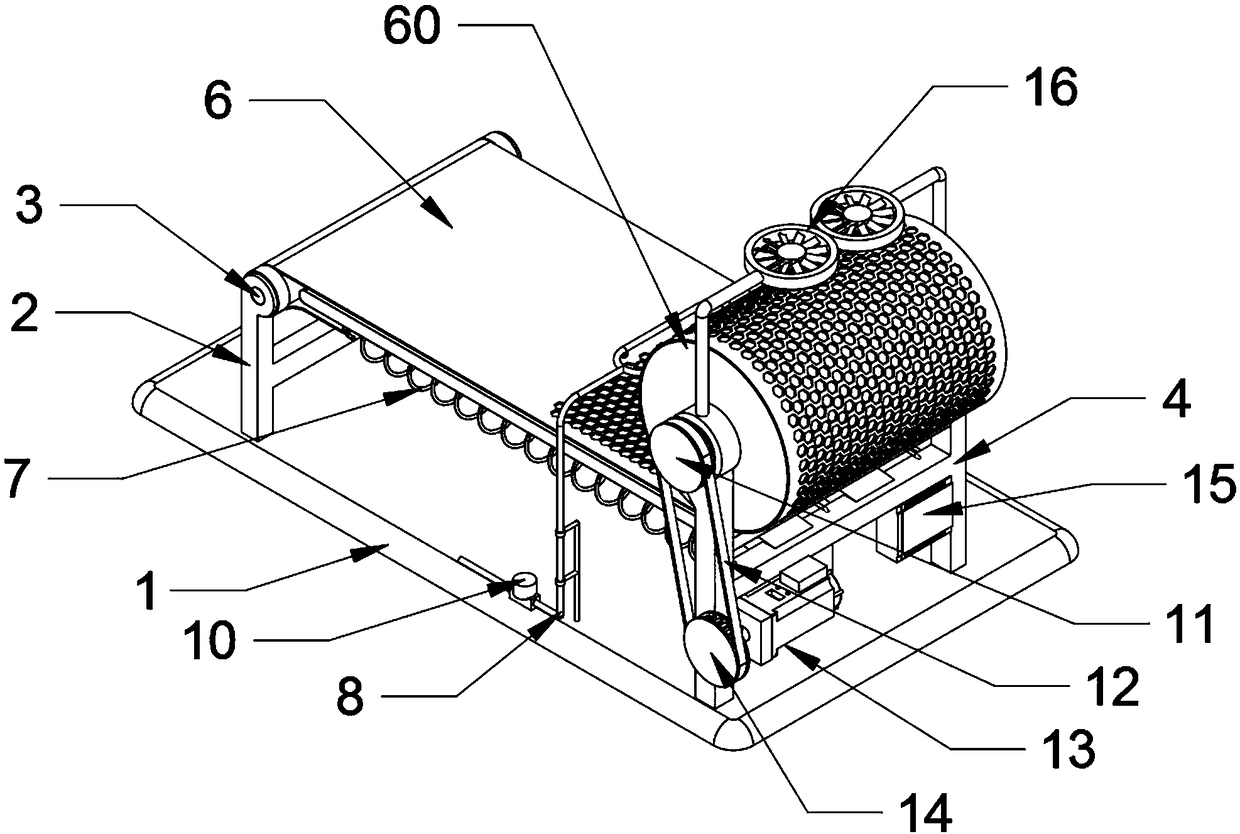

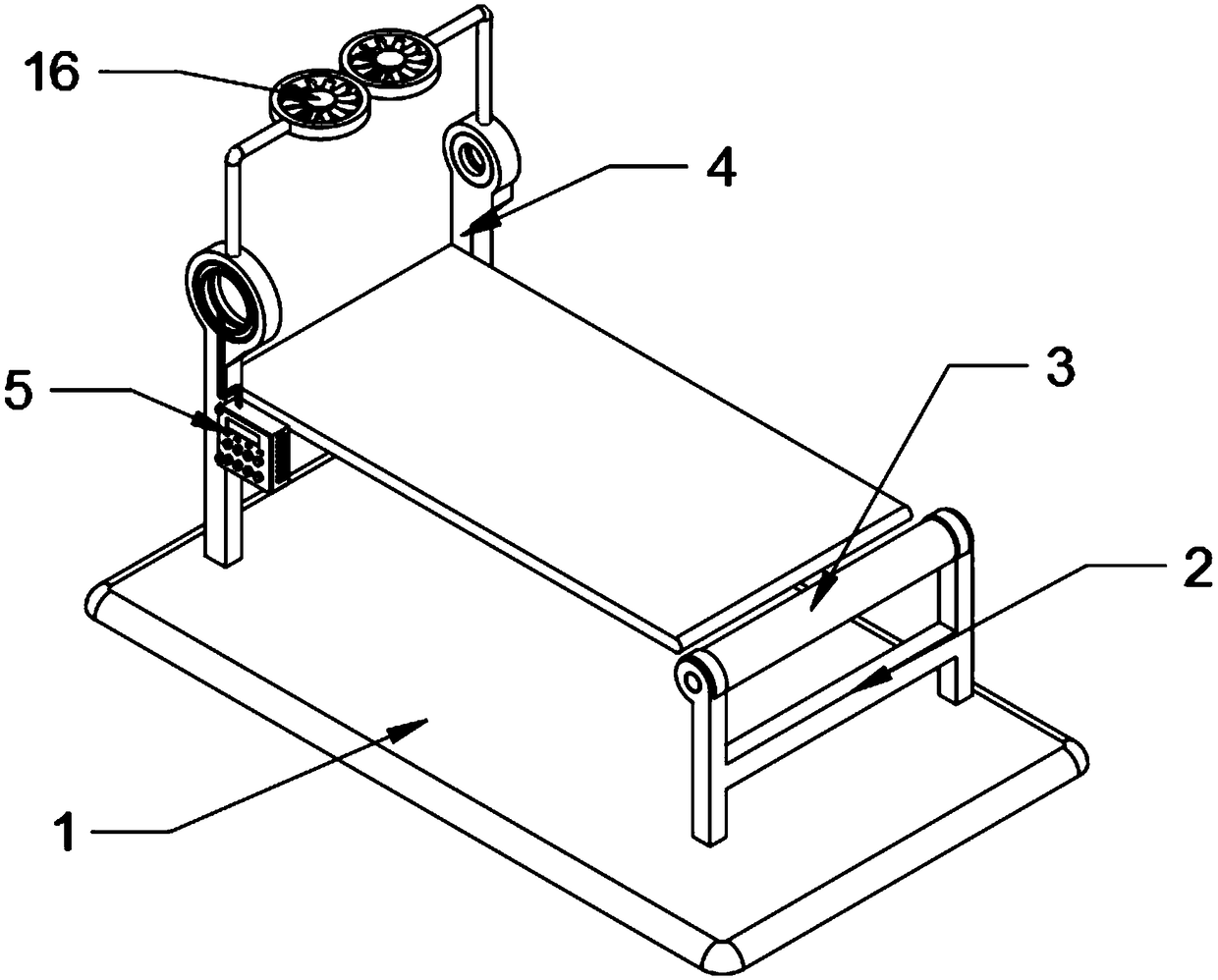

Automatic decal machine

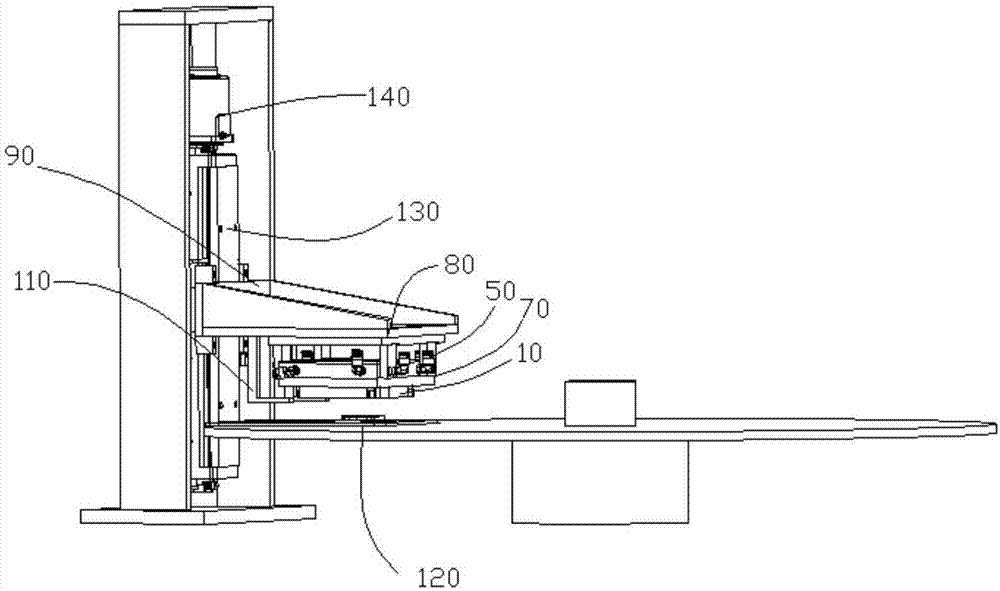

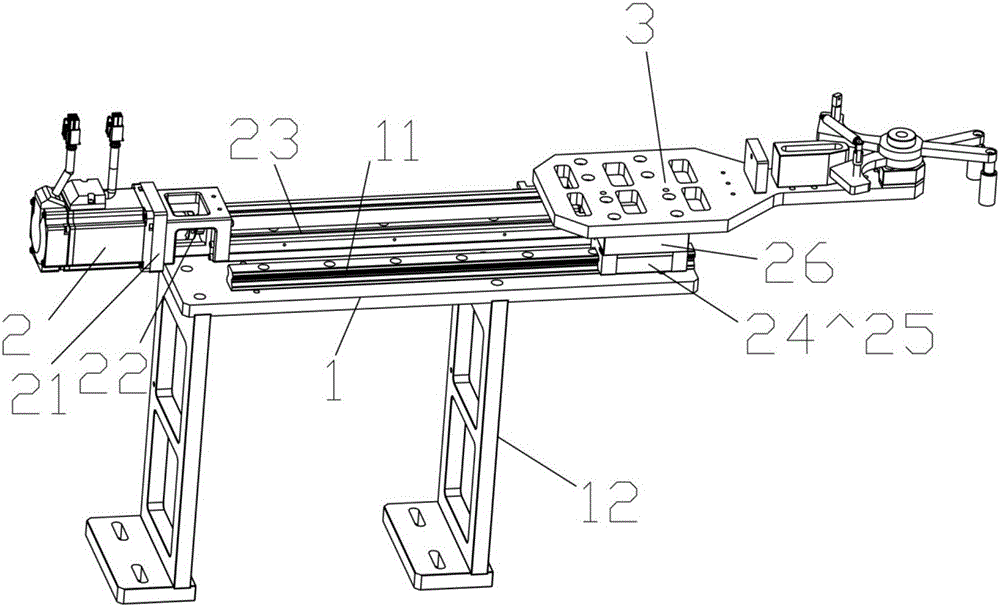

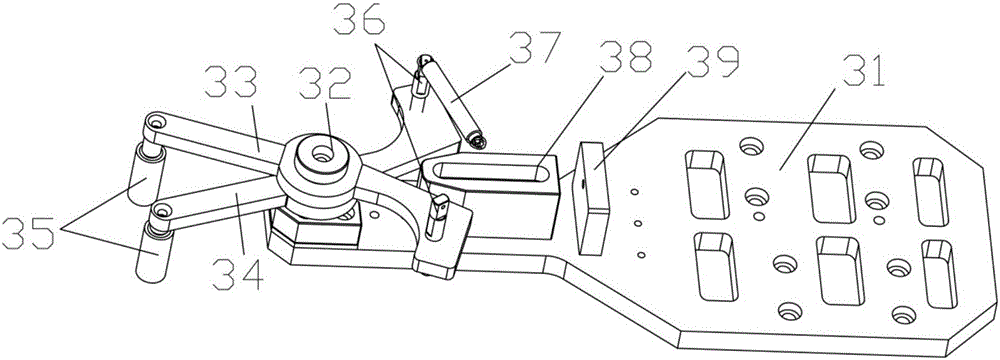

ActiveCN103625711AFit flatHigh precisionLabelling machinesLabelling short rigid containersMechanical engineeringIndustrial engineering

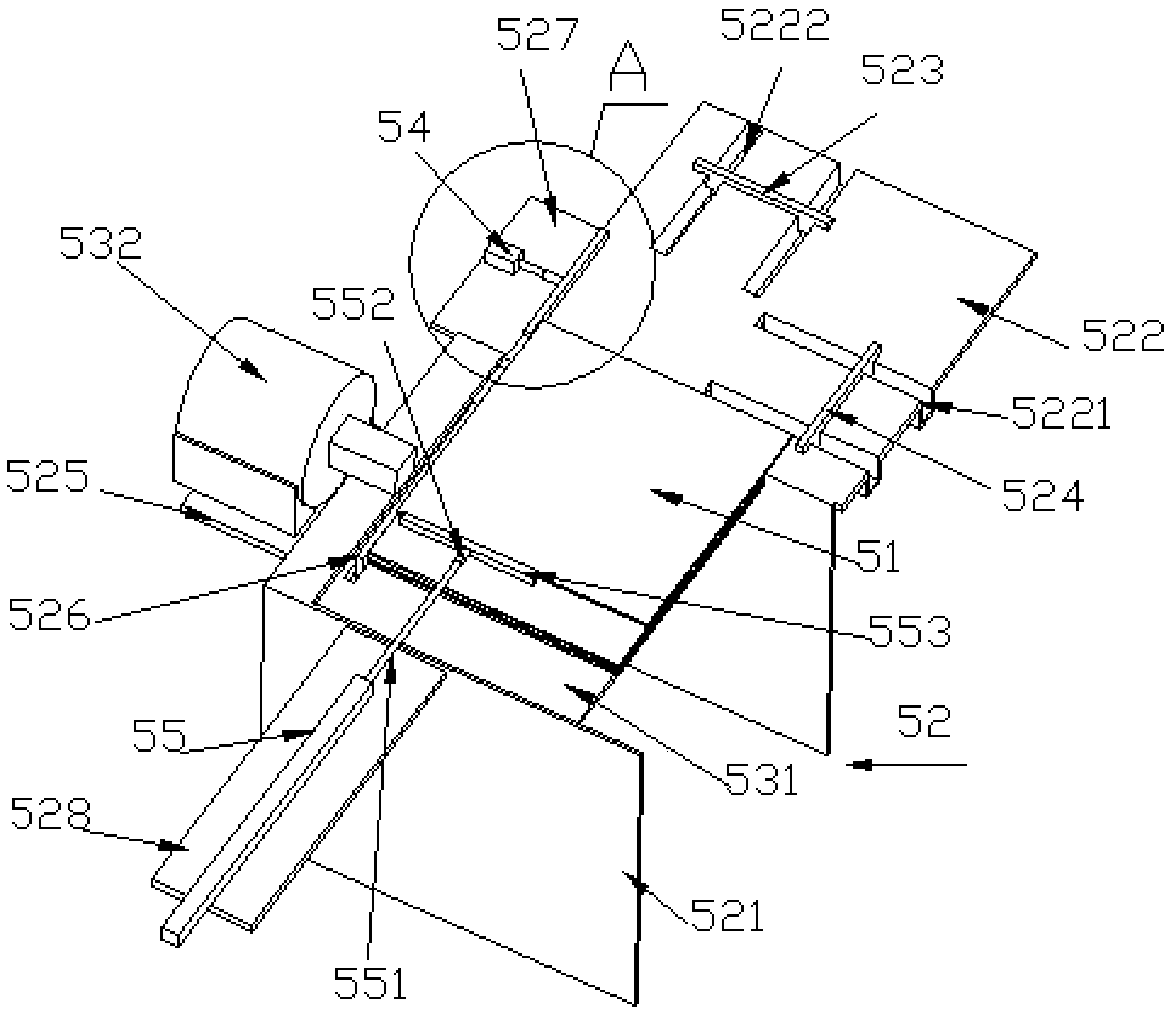

The invention relates to an automatic decal machine, which is used for pasting a piece of water transfer printing paper on the surface of an appliance. The automatic decal machine comprises a seat, a decal paper laying plate, a base plate, an appliance bracket, a rubber covered roller part, a driving part and an electronic control cabinet, wherein the appliance bracket is used for fixing the appliance; the rubber covered roller part compresses the decal paper on the surface of the appliance; the driving device drives the appliance bracket or the rubber covered roller of the rubber covered roller part to rotate; in the rotation process, the decal paper is pasted on the surface of the appliance; the driving part and the rubber covered roller part are both controlled by the electronic control cabinet. The automatic decal machine can improve the decal production efficiency, and reduce the production cost of the decal working procedure, and in the meantime the decal surface of the product is good in uniformity, more structured; the automatic decal machine is simple in operate.

Owner:KUNSHAN SHUGUANG LIGHTING EQUIP

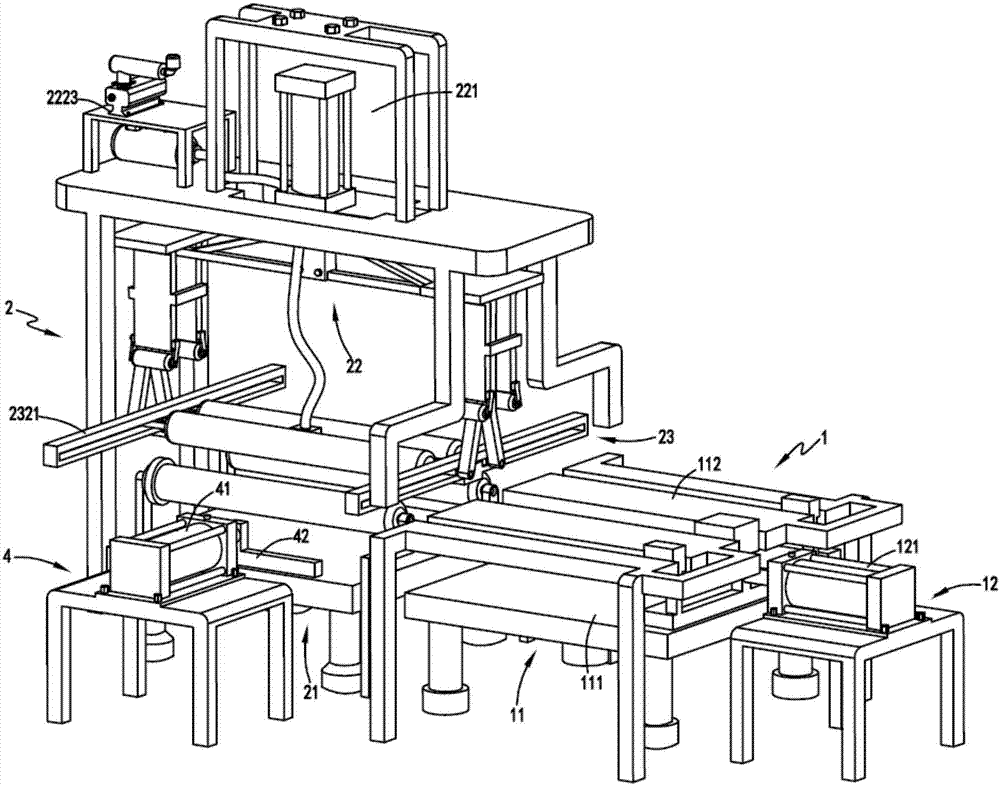

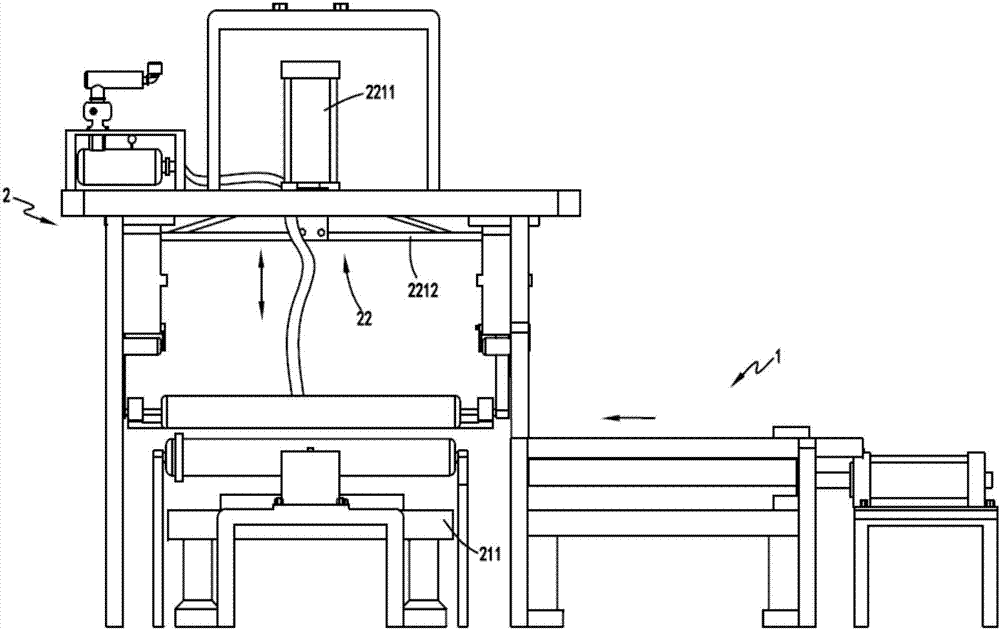

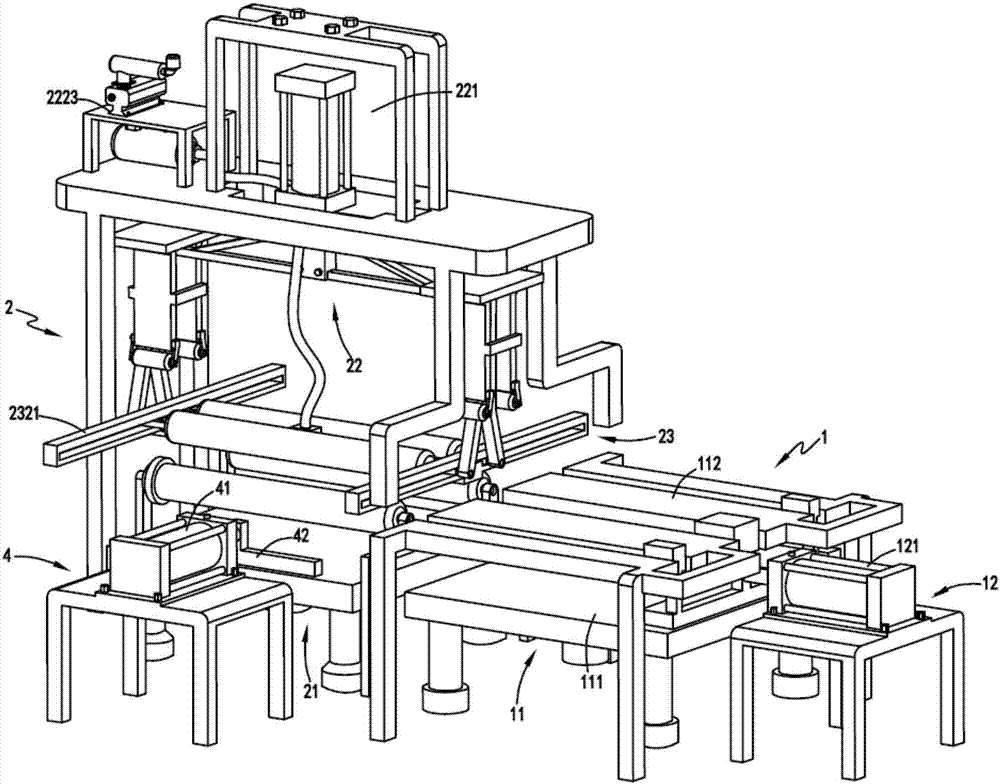

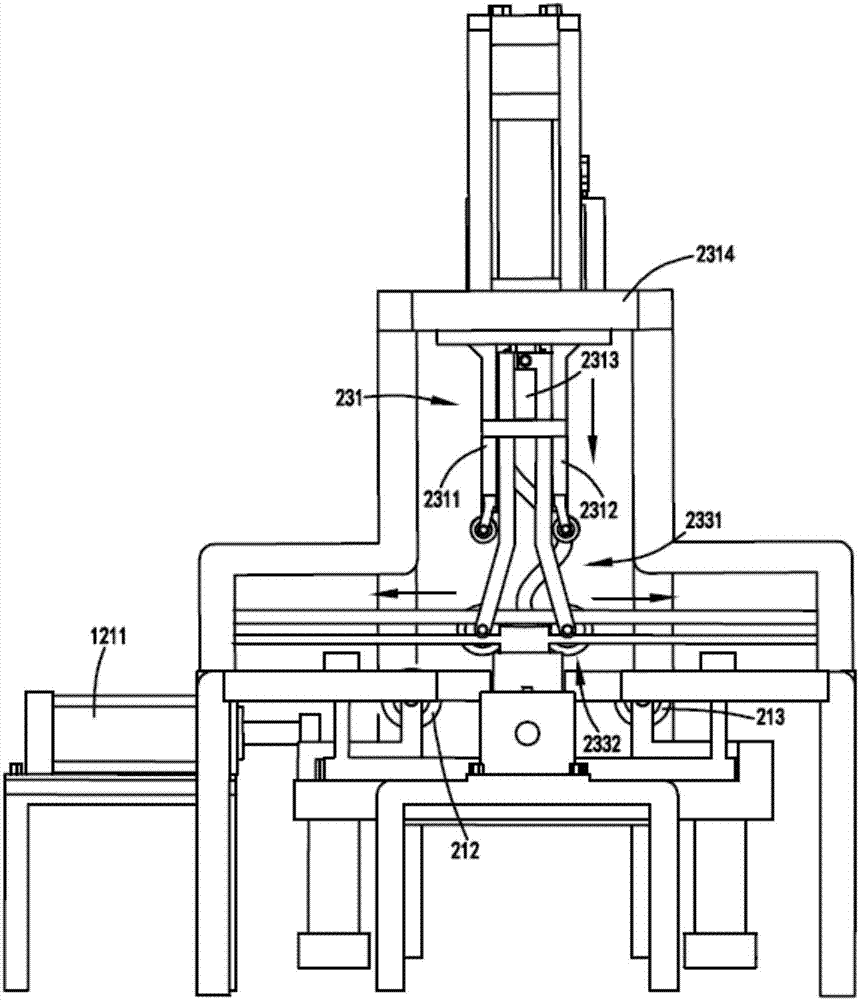

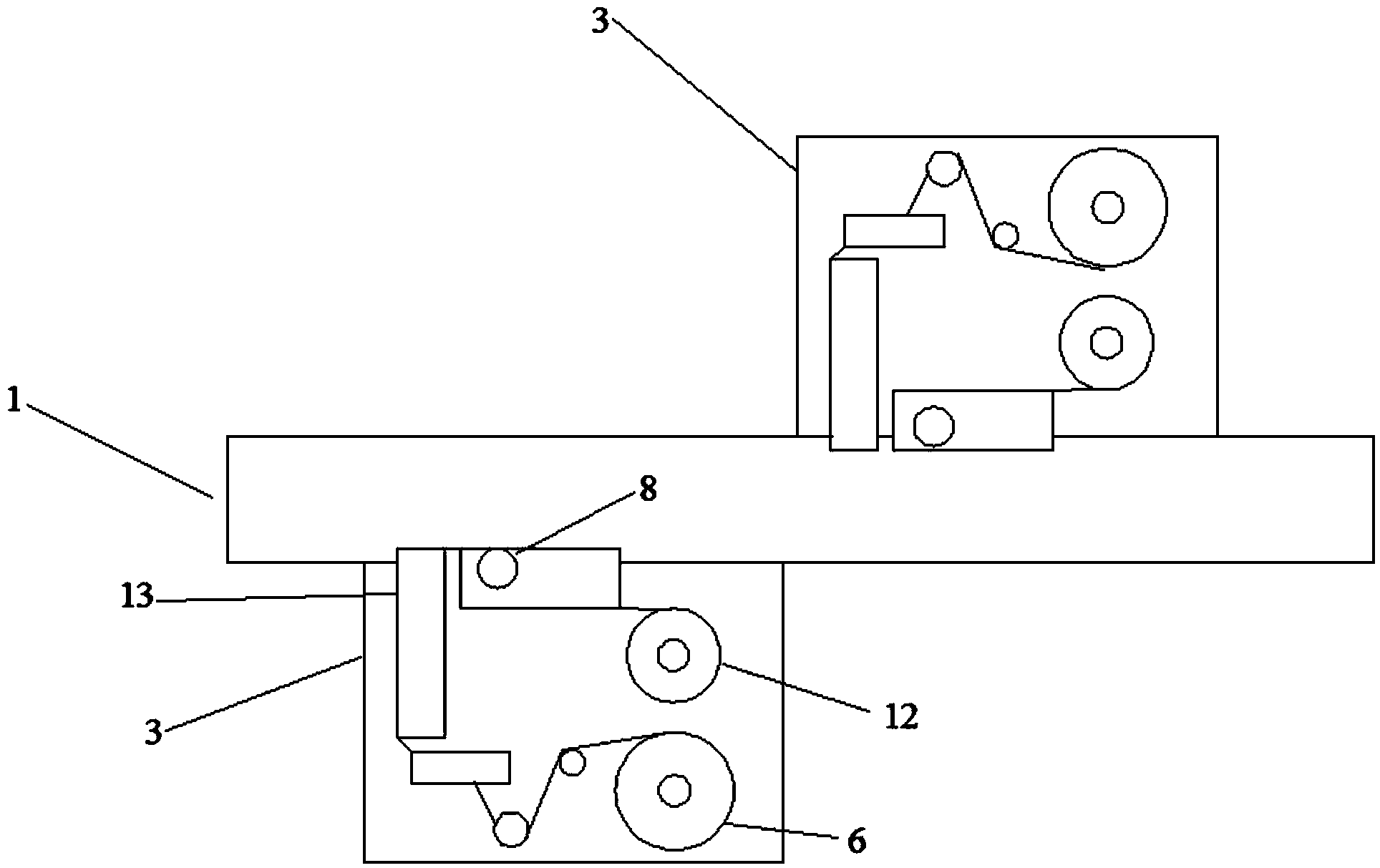

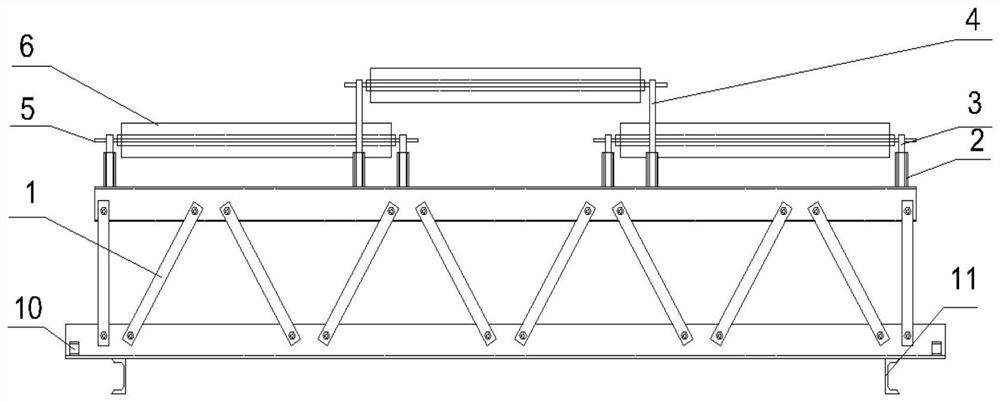

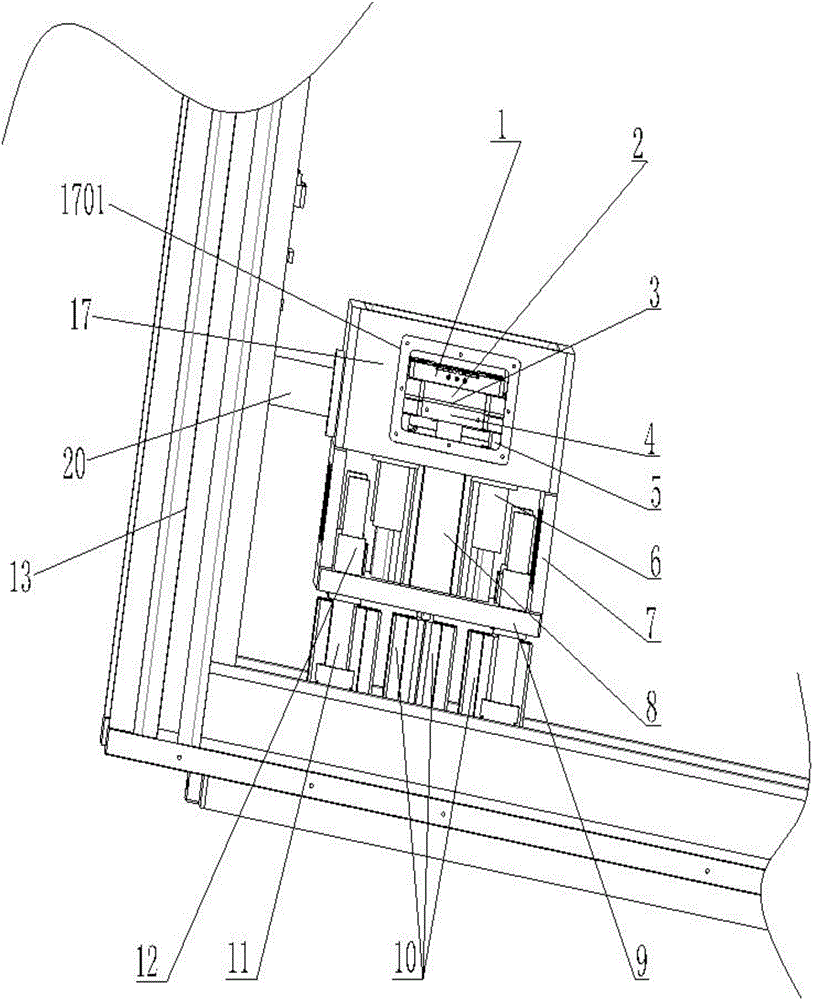

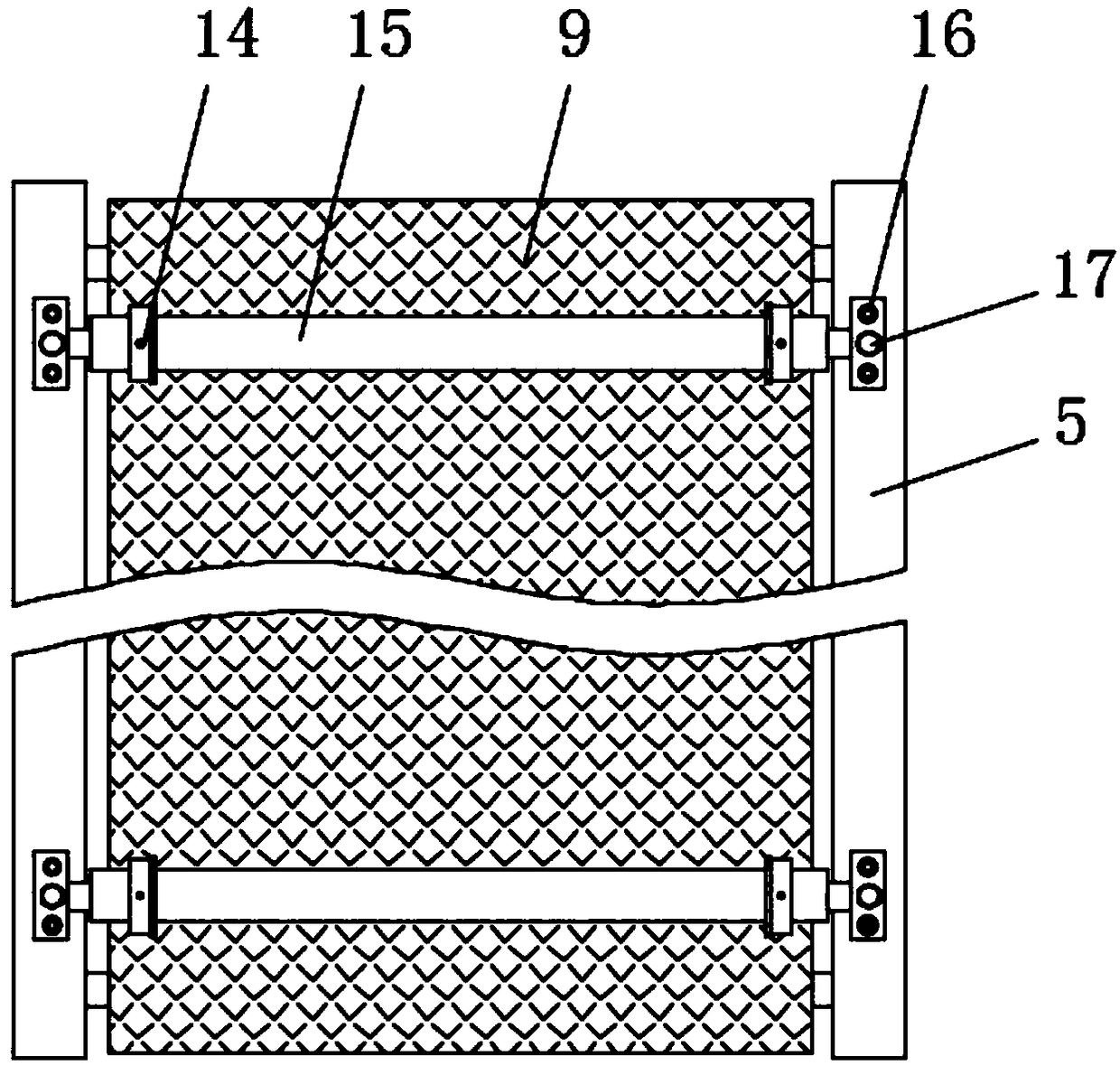

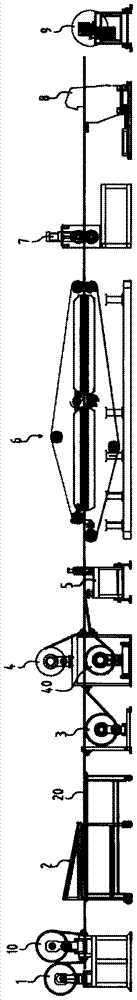

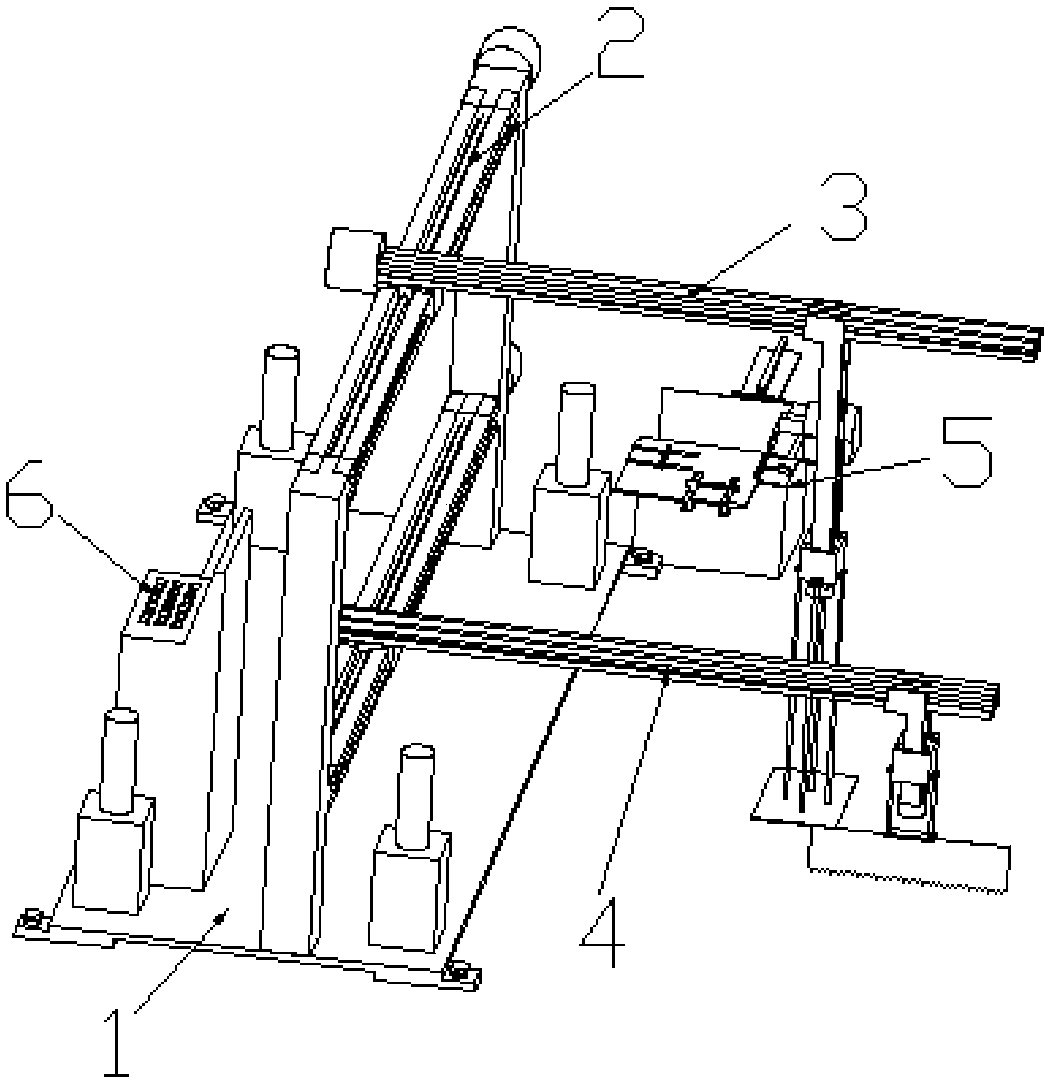

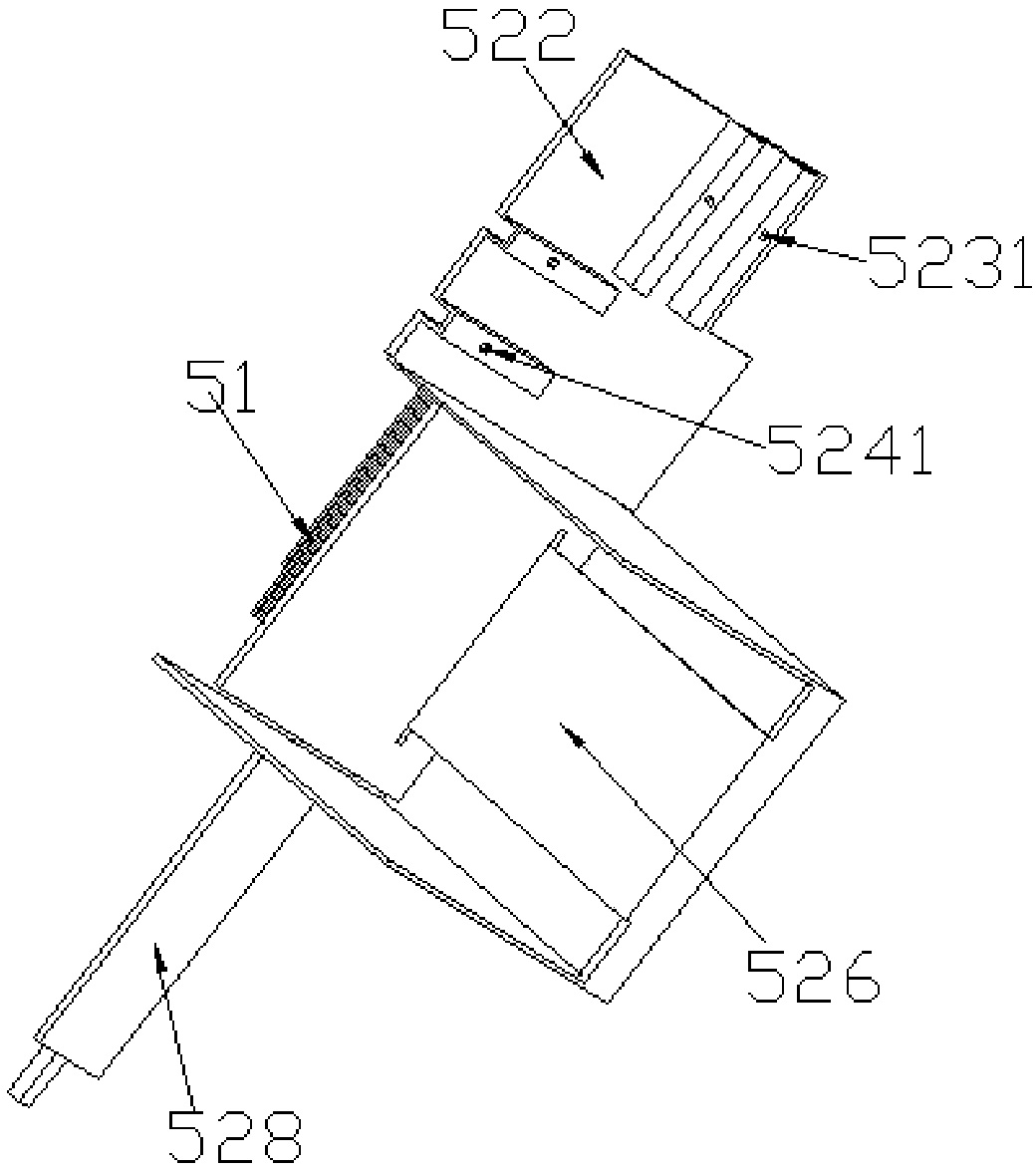

Continuous flattening and paper-attaching production line for single plates

ActiveCN107020791ASimple structureImprove bonding efficiencyLamination plant layoutLaminationProduction lineSingle plate

The invention relates to a continuous flattening and paper-attaching production line for single plates, which comprises a feeding part and an attaching part; the feeding part comprises a bearing mechanism and a feeding mechanism used for pushing a piece of surface paper and a plate with glue applied on the surface on the bearing mechanism to move together to an attaching station; and the attaching part comprises a supporting mechanism used for bearing the plate and the surface paper conveyed by the feeding mechanism, a pushing mechanism arranged upon the supporting mechanism and used for driving the surface paper to move in a direction toward the plate below, and attaching mechanisms arranged on both ends of the pushing mechanism and used for spreading the surface paper from the middle of the surface paper to both sides and attaching the surface paper to the plate. The invention overcomes the problems of uneven attaching and easy blistering existing in the method of attaching from one side to the other side and the problem of complex structure and unstable operation existing in conventional equipment.

Owner:贵港市东海木业有限公司

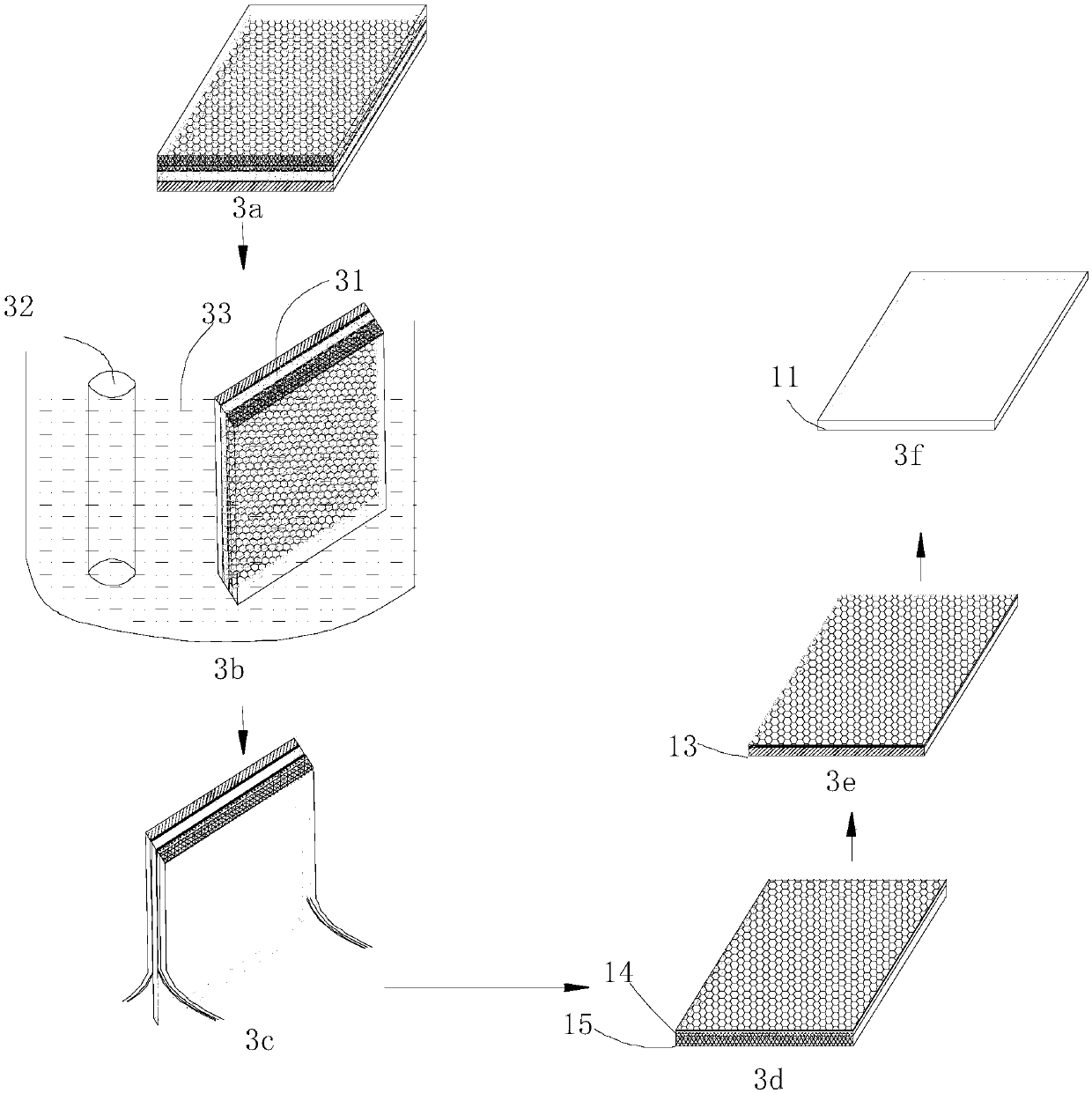

Graphene transfer and doping method

The present invention discloses a graphene transfer and doping method, which comprises: growing graphene on both surfaces of a substrate; adhering one graphene growing surface of the substrate to a transition substrate; coating a target substrate with a glue layer having a doped material; adhering the other graphene growing surface of the substrate to the target substrate coated with the glue layer; curing the glue layer; completely peeling the substrate from the graphene; adhering the graphene growing on the target substrate to the graphene growing on the transition substrate, and removing the transition substrate; and transferring the multiple graphene layers on the target substrate. According to the present invention, with the graphene transfer and doping method, the transfer of the large-sized and high-quality graphene can be achieved while the transfer and the doping are simultaneously performed without the additional doping, the graphene has advantages of uniform doping distribution and good stability, and the target substrate has good adhesion when the multi-layer graphene is transferred.

Owner:XIFENG 2D FUJIAN MATERIAL TECH CO LTD

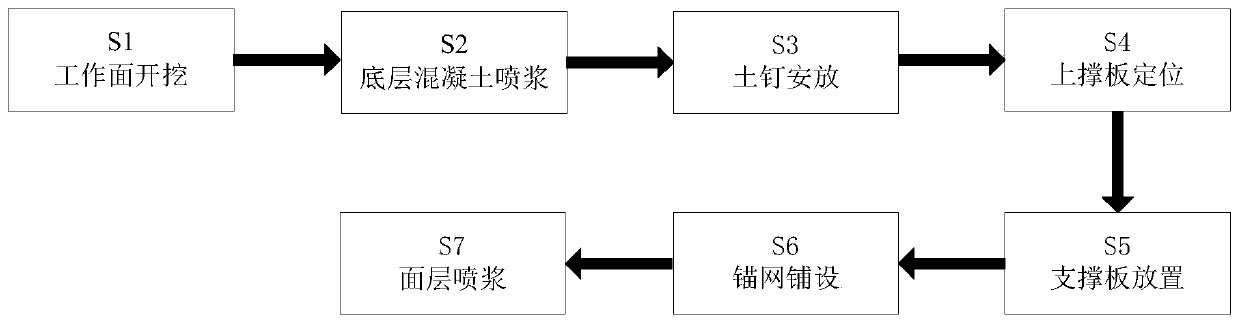

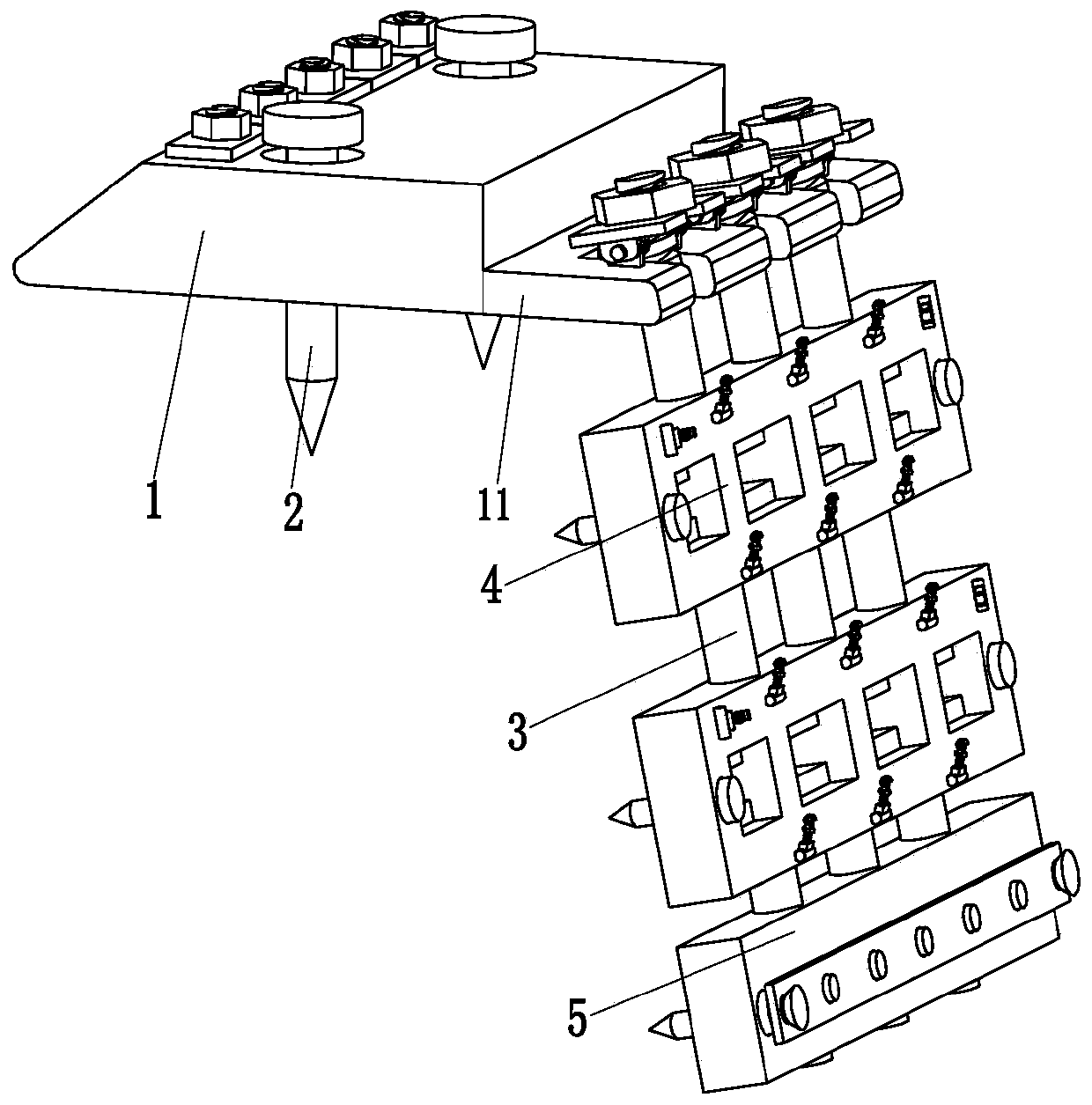

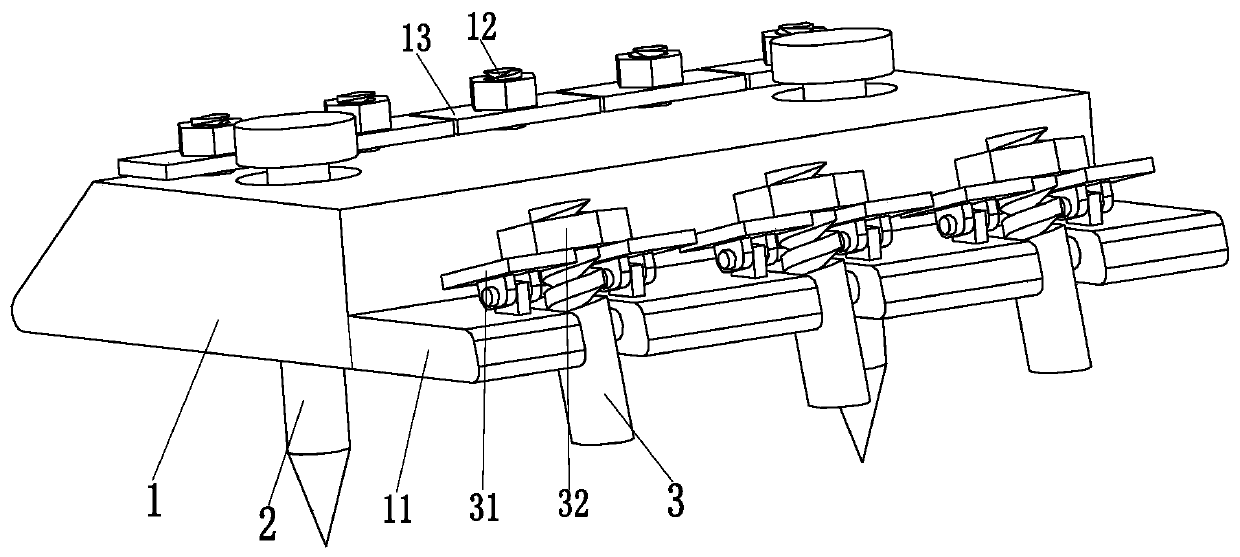

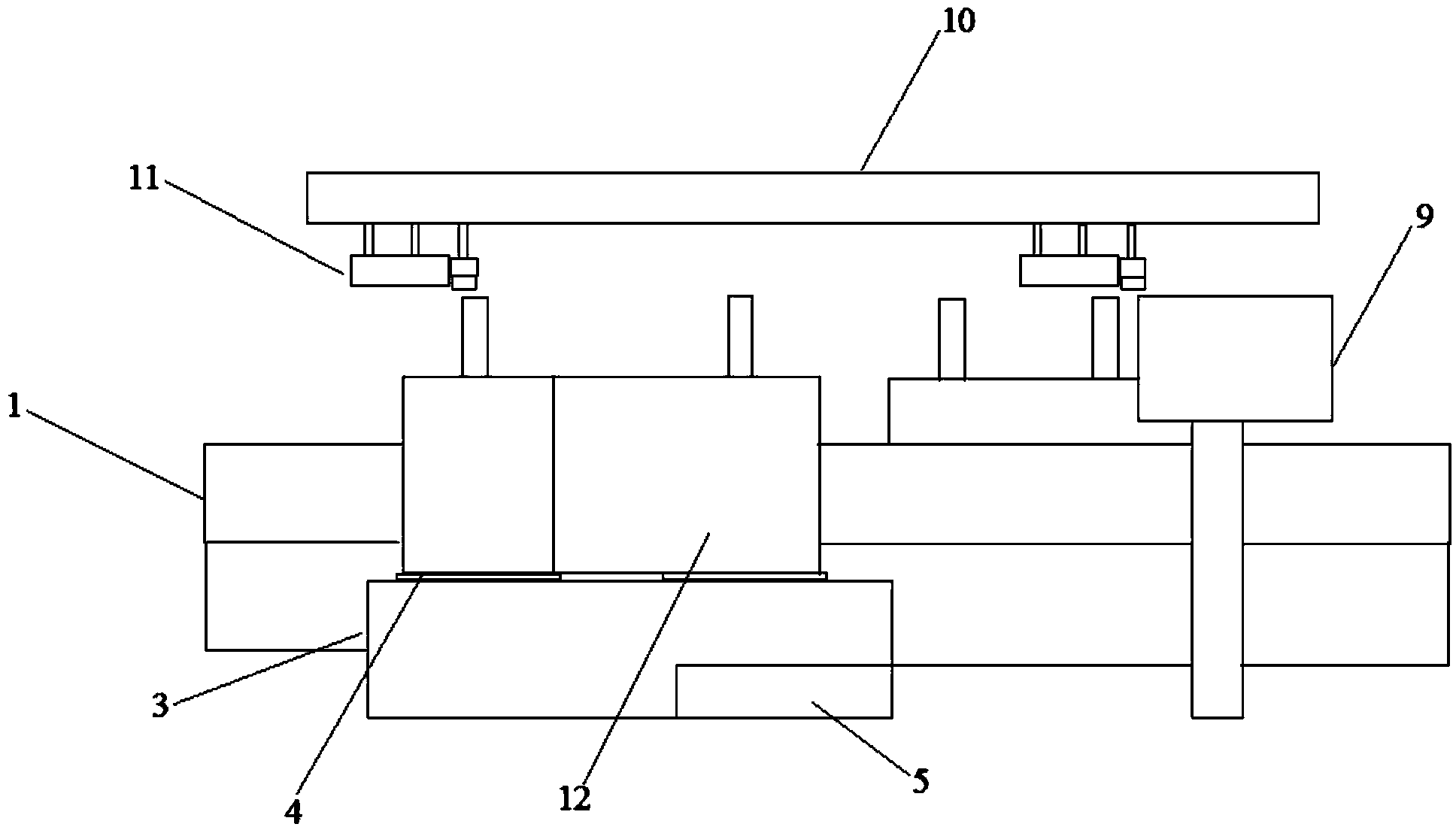

Anchoring and shotcreting support construction method in foundation pit construction

ActiveCN111155534AImprove integrityImprove the support effectExcavationsBulkheads/pilesSoil nailingArchitectural engineering

The invention relates to an anchoring and shotcreting support construction method in foundation pit construction. The anchoring and shotcreting support construction method in foundation pit construction adopts a following anchoring and shotcreting support structure in foundation pit construction. The anchoring and shotcreting support structure in foundation pit construction comprises upper supporting plates, inserting rods, inclined supporting rods, supporting mechanisms and laminated plates. The anchoring and shotcreting support construction method in foundation pit construction by adopting the anchoring and shotcreting support structure in foundation pit construction comprises the following steps that S1, a working face is excavated; S2, mortar spraying is conducted on bottom-layer concrete; S3, soil nails are placed; S4, the upper supporting plates are positioned; S5, supporting plates are placed; S6, an anchor net is laid; and S7, mortar spraying is conducted on a surface layer. Through the anchoring and shotcreting support construction method, the problems existing during existing anchoring and shotcreting support construction that the locking effect of the soil nails throughconnecting rods is poor, consequently, integrality of the soil nails is poor, the supporting effect of the anchoring and shotcreting support structure on the side wall of a foundation pit is affected,anchor net laying operation is tedious, and the anchor net is prone to folding or bending can be solved.

Owner:西北电力建设第一工程有限公司

Dual-purpose labelling machine for hollow container

InactiveCN103950604AFit tightlyFit flatTransfer printingLabelling machinesProgrammable logic controllerDual purpose

The invention discloses a dual-purpose labelling machine for a hollow container, belonging to the technical field of automation of equipment. The dual-purpose labelling machine for the hollow container comprises an automatic conveying belt, a worktable, an adhesive sticker labelling mechanism, a heat transfer printing mechanism and a PLC (programmable logic controller). The dual-purpose labelling machine has the beneficial effects that the heat transfer printing function and the adhesive sticker labelling function can be converted conveniently, the labelling precision is stable, and a label is attached to the outer surface of the hollow container tightly and flatly without folds, bubbles and warping, so that the dual-purpose labelling machine is particularly suitable for thin-wall containers and irregular products.

Owner:潘玉军 +1

Rolling and laminating device and laminating method of hot rollers

ActiveCN104608456ASolve winding, lineSolve heatingLamination ancillary operationsLaminationMechanical engineeringEngineering

Owner:SHENZHEN LIANDE AUTOMATION EQUIP

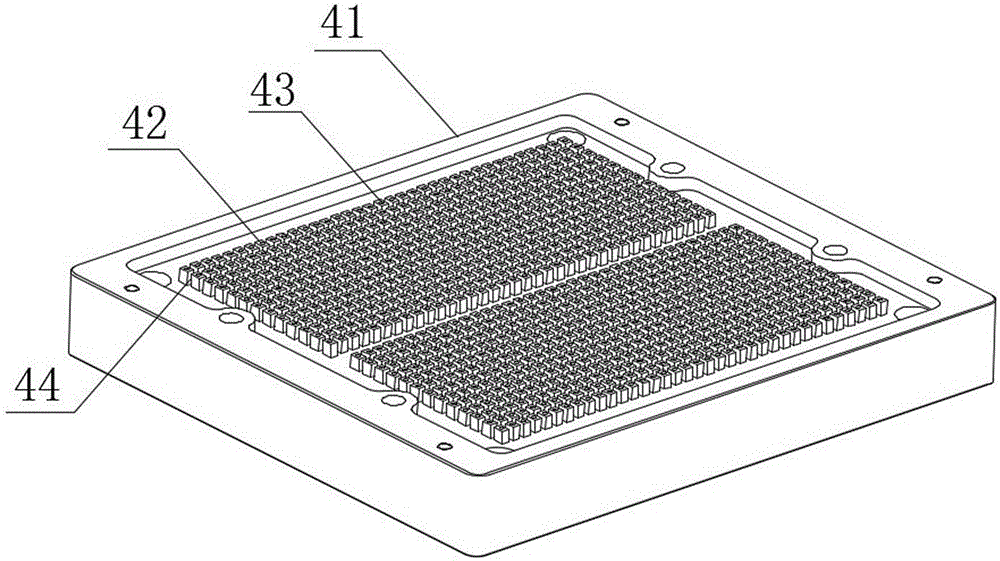

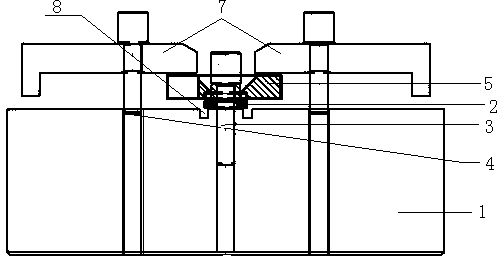

Printing mechanism for raw ceramic chip through hole wall metallization

ActiveCN106658997AFit tightlyFit flatPrinted circuit aspectsPrinted element electric connection formationSlurryComputer engineering

The present invention provides a printing mechanism for raw ceramic chip through hole wall metallization. The mechanism comprises a printing platform with a big cavity, an external negative pressure source communicated with the big cavity, a mask piece and a support plate, the mask piece is movably arranged at the upper portion of the support plate along the vertical direction, and the mask piece is provided with a through hole being consistent to a raw ceramic chip; the support plate is arranged on the printing platform, a venthole corresponding to the through hole on the mask piece is arranged on the support plate, and absorption holes are arranged at other positions of the support plate; and one way of negative voltage of the negative pressure source is communicated with the venthole, and the other way of the negative voltage of the negative pressure source is communicated with the absorption holes. The printing mechanism improves the slurry uniformity at the raw ceramic chip through hole wall metallization and alleviates the phenomenon of slurry obstructing the through hole.

Owner:西北电子装备技术研究所

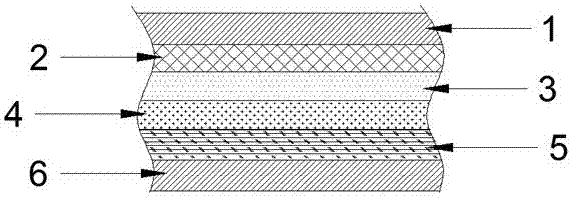

Thermally induced viscosity-decreasing meshed protective film

ActiveCN107160746AThermally induced viscosity loss hasPaste evenlySynthetic resin layered productsMacromolecular adhesive additivesTectorial membranePolyethylene terephthalate

The invention discloses a thermally induced viscosity-decreasing meshed protective film which comprises a PET (Polyethylene Terephthalate) film layer, a PE (Polyethylene) spraying film mesh layer, a silicone oil layer, a glue layer, a conductive layer and a PET base material layer which are arranged from top to bottom, wherein the glue layer is a modified polyacrylate glue layer. The protective film disclosed by the invention has a function of automatic dropping after heating and does not need to be stripped manually or by a robot. In addition, the protective film has a network structure, the mesh surface has an automatic exhaust effect during use, the protective film can be completely flushed, and residual glue is avoided after the film is stripped.

Owner:惠州市科域新材料科技有限公司

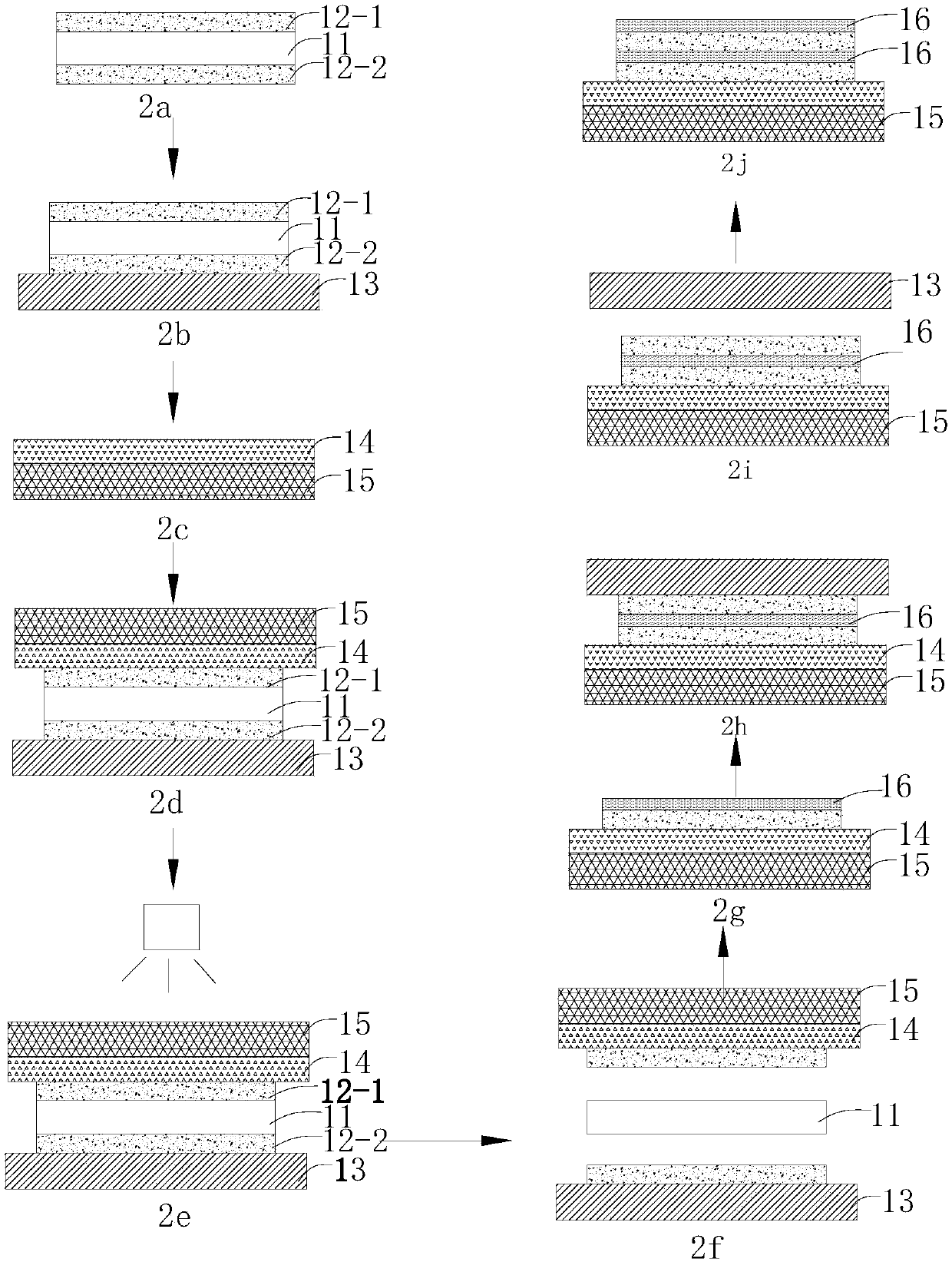

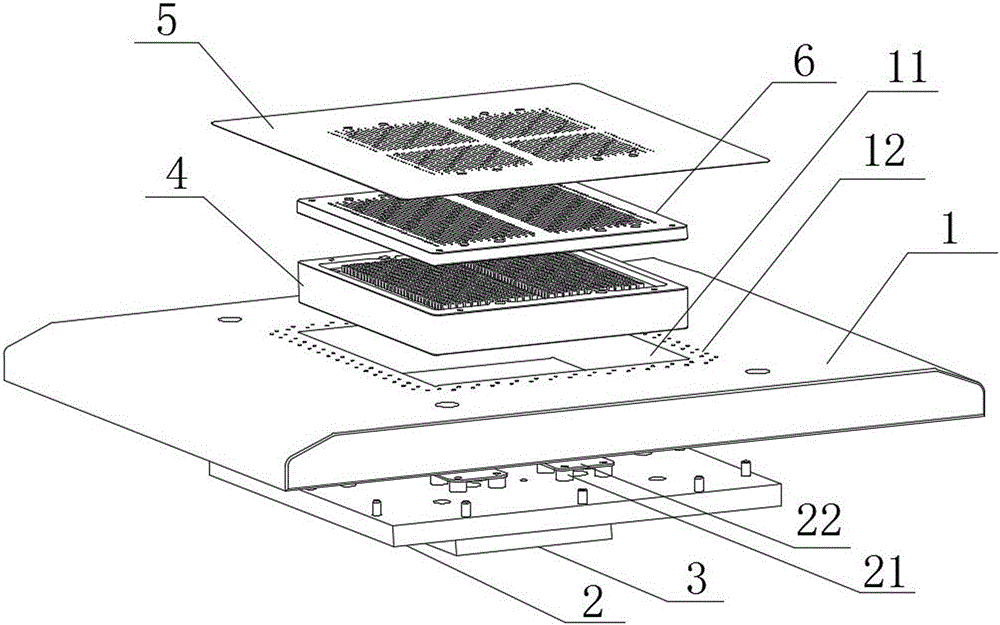

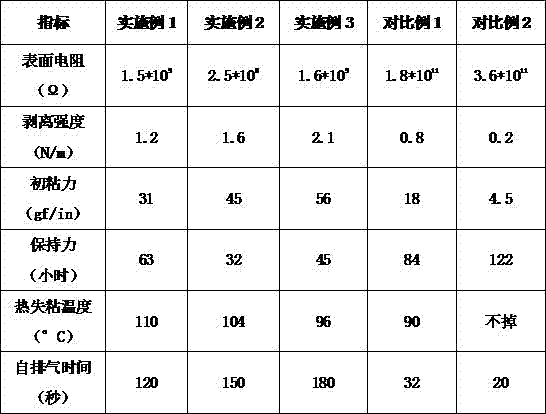

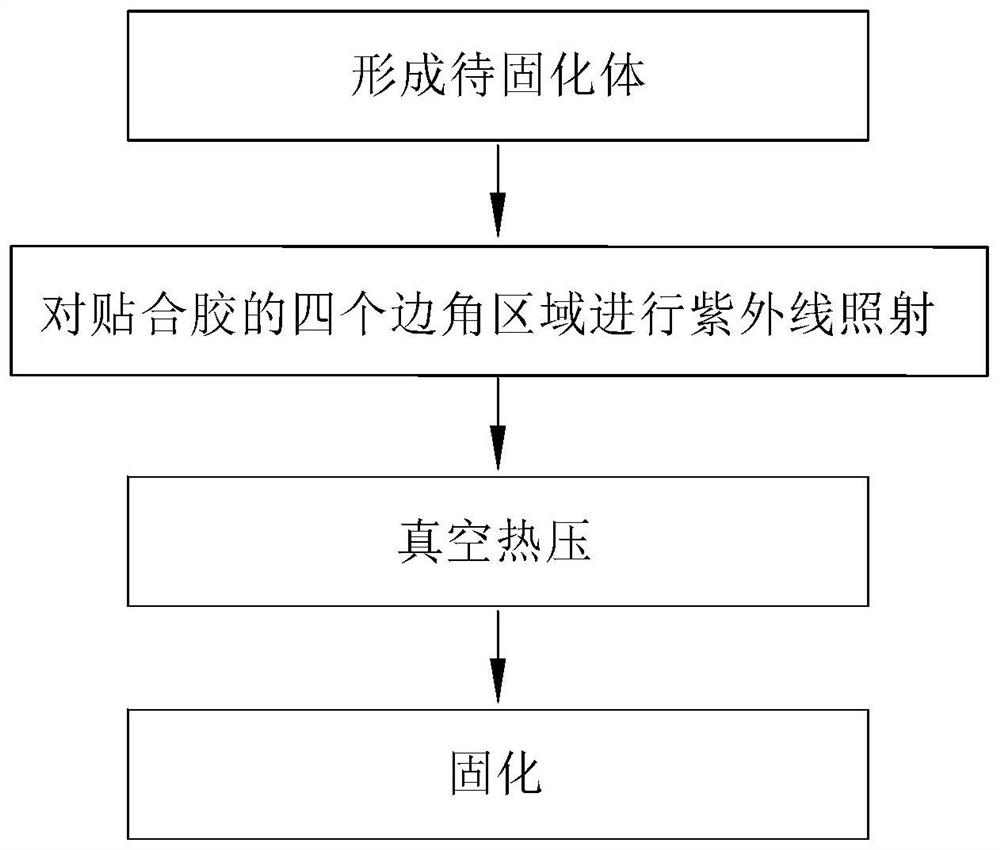

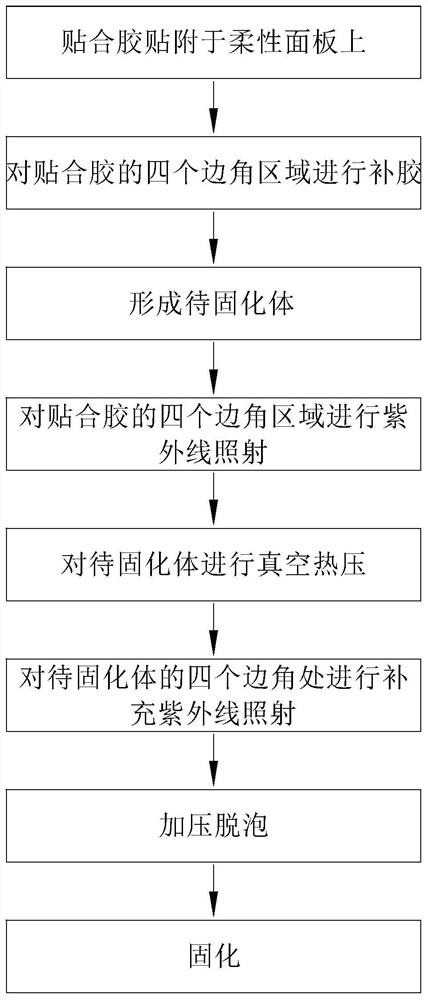

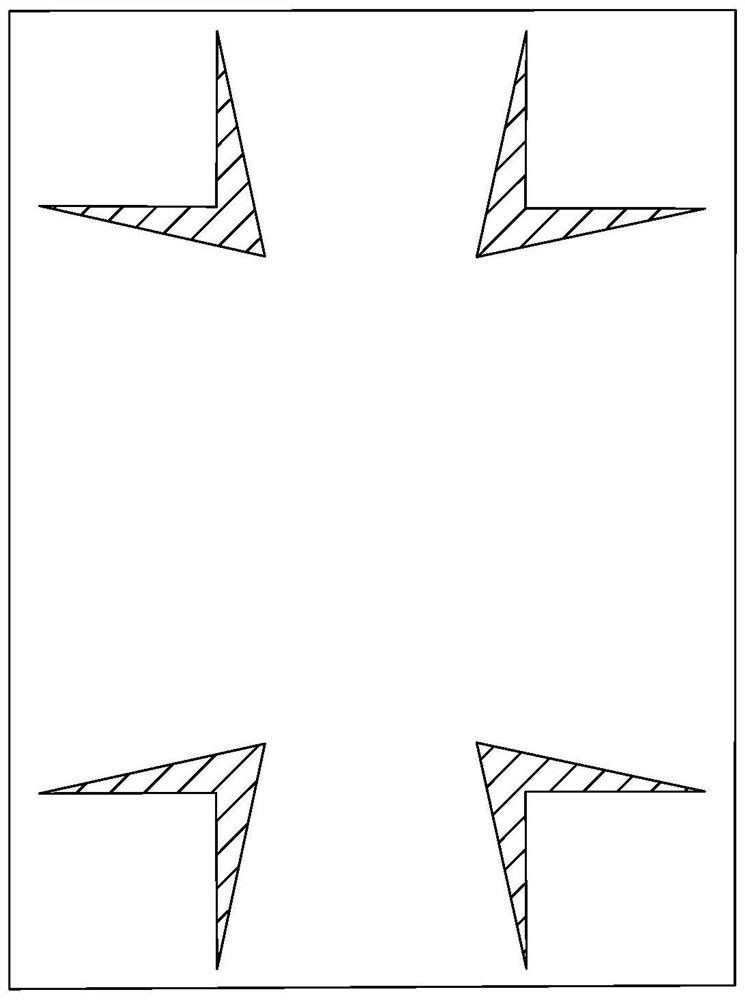

Four-side curved display screen laminating process

ActiveCN112652243AImprove fit qualityImprove the display effectIdentification meansAdhesiveMechanical engineering

The invention discloses a four-side curved display screen laminating process which comprises the following steps: attaching a flexible panel and a protective panel to two sides of a laminating adhesive to form a to-be-cured body, and before vacuum hot pressing of the to-be-cured body, carrying out ultraviolet irradiation on four corner areas of the laminating adhesive to cure the to-be-cured body. According to the four-side curved display screen laminating process, before vacuum hot pressing, ultraviolet irradiation is carried out on the four corner areas of the laminating adhesive firstly, so that the laminating adhesive in the areas has certain bonding force, rebound of the laminating adhesive is avoided, the flowability of the laminating adhesive in the areas after melting is reduced, and the laminating glue in other areas continuously flows and fills the four corners to discharge bubbles at the corners, so that the flexible panel and the protective panel are laminated more smoothly, and the laminating quality and the display effect of a four-sided curved display screen are improved.

Owner:深圳一鑫新材料有限公司

Simple automatic laminating device on vibrating beam

PendingCN112392278AAvoid confictFree rotationBuilding material handlingLap jointMechanical engineering

The invention discloses a simple automatic laminating device on a vibrating beam. The simple automatic laminating device comprises the vibrating beam, a support base is arranged at the upper end of the vibrating beam, a low support is arranged at the upper end of the support base, a high support is arranged on one side of the low support, a rotating shaft is arranged in the low support and the high support in a penetrating mode, a film roll is arranged on the outer side of the rotating shaft in a penetrating mode, a laminating rolling bar is arranged on the side, close to the film roll, of thevibrating beam, a film is arranged between the film roll and the laminating rolling bar, and a rolling bar traction rod is arranged on the side, close to the vibrating beam, of the laminating rollingbar. According to the device, by arranging the low support and the high support, film lap joint can be facilitated, and the maintenance quality of film covering is ensured. By arranging the laminating rolling bar, the film can be evenly, flatly and tightly attached to the surface of concrete, and the frequency of manual rework is reduced. By arranging the support base, the low support and the high support can be mounted and dismounted more conveniently.

Owner:CHINA CONSTR SEVENTH ENG DIVISION CORP LTD

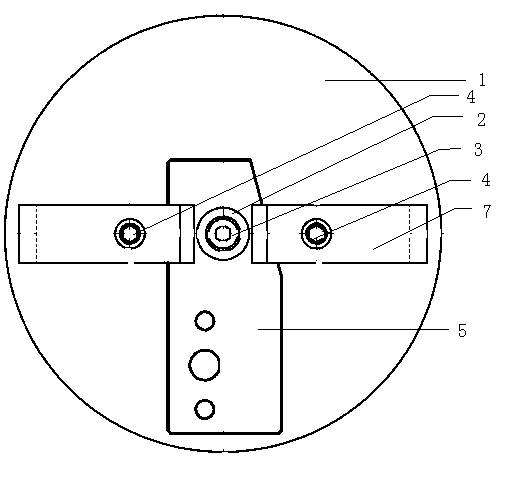

Gluing device for processing front baffle

InactiveCN103527587AFit tightlyImprove work efficiency and product qualityFastening meansEngineering

The invention relates to a gluing device for processing a front baffle. The gluing device comprises a substrate and a circular ring, wherein the substrate is cylindrical, a main threaded hole is longitudinally formed in the center of the substrate, the two sides of the main threaded hole are respectively provided with an auxiliary threaded hole, the circular ring is placed above the main threaded hole of the substrate, and the contact face between the circular ring and the substrate is coated by a layer of glue. A gasket is arranged on the circular ring and connected with the main threaded hole in a fastened mode through bolts, two press sheets are arranged on the gasket and connected with the auxiliary threaded holes in a fastened mode through bolts, finally, the circular ring is attached to the substrate, installing is firmer, attachment is flatter, and working efficiency is improved.

Owner:扬中市方正天瑞电子科技有限公司

Silica-gel cavity structure

The invention relates to the technical field of bent glass films, in particular to a silica-gel cavity structure. The silica-gel cavity structure is characterized in that a sliding mechanism is fixedly arranged at the bottom of the inner chamber of a frame body; press-fitting silica gel is arranged on the upper surface of a silica gel fixing plate; the lower surface of a sealing upper cavity takes the shape of an opening; a glass profile jig is fixed in the inner chamber of the sealing upper cavity, and the inner chamber of the sealing upper cavity is communicated with a vacuum tube; a lifting mechanism is arranged at the top of the inner chamber of the frame body; a cantilever fixing seat is arranged on the lifting mechanism and fixedly connected with the sealing upper cavity through a side connecting plate; a hold-down mechanism is arranged on the cantilever fixing seat and fixedly connected with an upper cantilever press-fit baseplate after extending into the sealing upper cavity; an upper cantilever heating plate and a thermal baffle are fixedly arranged between the glass profile jig and the upper cantilever press-fit baseplate in sequence. When the silica-gel cavity structure is in use, even press-fitting of a bent glass film can be realized, and a bubble-free, fold-free and layer-break-free perfect press-fitting effect is achieved.

Owner:SHENZHEN FUHEDA AUTOMATION CO LTD

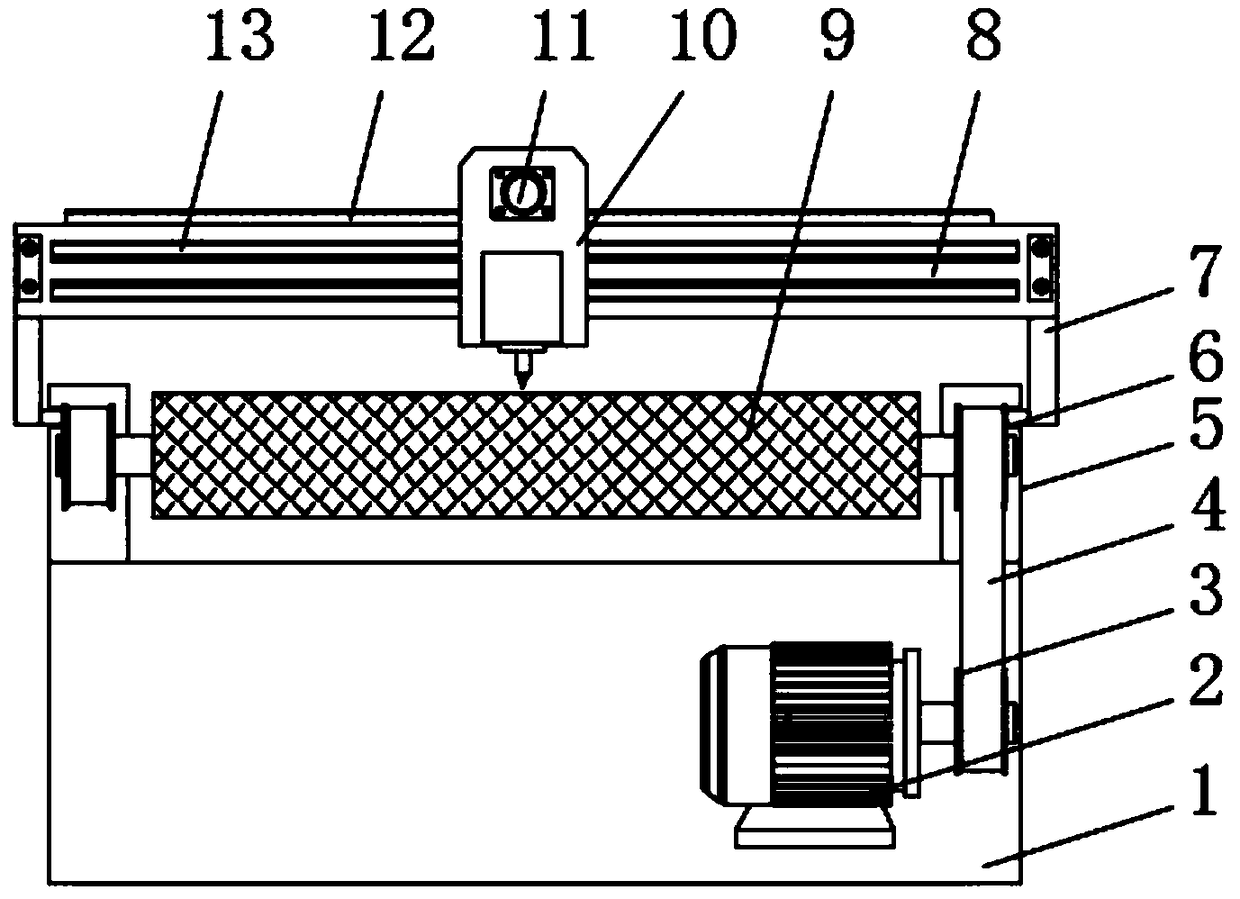

Cutting device convenient to fix for processing microfiber leather

The invention discloses a cutting device convenient to fix for processing microfiber leather. The cutting device comprises a base and a driving motor, the driving motor is mounted on one side of the interior of the base, and a synchronous belt pulley is mounted at one end of the driving motor; a synchronous belt is transmission connection with the surface of the synchronous belt pulley, and a conveyor net is arranged on one side of the upper portion of the synchronous belt; a supporting sectional material is arranged on one side of the upper portion of the base, a sliding slot is formed in oneside of the upper portion of the supporting sectional material, and a supporting leg is slidingly connected to one side of the sliding slot. According to the cutting device for processing the leather, an arranged cutting knife can achieve linkage of two axes and cut the leather in any shape, the driving motor drives the synchronous belt in transmission connection with the surface of the synchronous belt pulley to rotate, a cross beam on the supporting leg moves along the sliding slot, and the cutter can be moved in a Y-axis direction; at the same time, a moving motor drives a gear to rotate on a rack, so that the cutting knife below a mounting plate moves along a linear guide in an X-axis direction.

Owner:YANGZHOU XIANGBEI MACHINERY

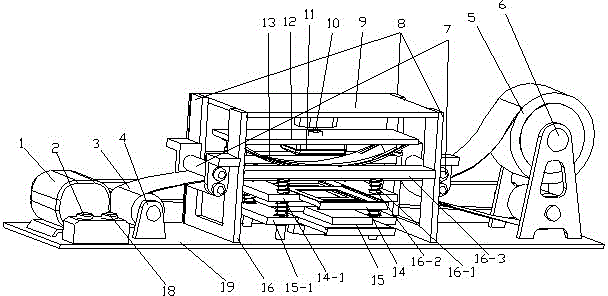

Disposable attaching fixture for foam rubber protective film of touch screen

InactiveCN104354437AImprove efficiencyLow costLaminationLamination apparatusTectorial membranePaper recycling

The invention relates to a disposable attaching fixture for a foam rubber protective film of a touch screen. The disposable attaching fixture comprises a motor, a control switch, a base paper recycling roller wheel, a roller wheel contracting bracket, a protective film releasing roller wheel, a roller wheel releasing bracket, a protective film operation limiting roller wheel, a main bracket, a hydraulic system fixing plate, a hydraulic column, a silica gel plate, a silica gel plate fixing plate, a bow spring piece, a touch screen positioning plate, a foam rubber positioning plate, a positioning plate bracket, a base plate and a hydraulic column switch. The disposable attaching fixture has the technical effects of improving efficiency, lowering cost and being capable of attaching the film flatly without bubbles.

Owner:中环高科(天津)股份有限公司

Layer-by-layer self-assembly film, preparation method and application thereof

ActiveCN107929810AShorten the timeImprove efficiencyTissue regenerationProsthesisLayer by layer self assemblyInjury wounds

The invention discloses a layer-by-layer self-assembly film, a preparation method and application thereof. The layer-by-layer self-assembly film is formed by laying polymer layers with opposite electrical properties and dropwise adding charged therapeutic drugs; the distribution and rearrangement time of polymer in a mode of sucking unreacted solution through a vacuum extractor to produce flowingliquid phase is reduced, a step of washing with clear water is avoided, formed negative and positive ionic polymer layers are smoothly fitted, and the film can be applied to various wound surfaces through design of dies; a 100 to 20000nm ultrathin film can be formed, materials in contact with organisms are obviously reduced, and foreign body rejection reaction is reduced. The film is wide in material selection and drug selection ranges. Types and dosages of drugs can be selected, the effects of antibacterial property, anti-inflammatory property and promotion of wound healing are achieved; thefilm has flexible and convenient processibility, is suitable for the requirements of repairing of various injury wound surfaces, and is stable in product quality and good in reproducibility.

Owner:ZHEJIANG UNIV

Crease removal shaping apparatus for producing clothing

ActiveCN109355886AEasy to sprayEase of heating and smoothingIroning machinesTextiles and paperEngineeringBreathing

The invention provides a crease removal shaping apparatus for producing clothing. The crease removal shaping apparatus comprises a servo controller and a guide fan; the bottom of a right supporting frame is installed on the right end of the top end surface of a base, and a rotating shaft is installed on the top of the right supporting frame; the bottom of a left supporting frame is installed on the left end of the top end surface of the base, and a clothing flatting cylinder is installed on the top of the left supporting frame; a power supply control box is installed on the front end surface of the left supporting frame, and the power supply control box is connected with an external power supply circuit by virtue of a power supply wire; the clothing which is humidified around the apparatuscan be heated and flatted, and the crease on the clothing in the processing can be removed, so that the clothing is more flatly fit onto the outer end surface of the apparatus, and the clothing crease removal shaping effect can be improved; and moreover, by virtue of vent holes inside a clothing transfer belt and the guide fan, when the clothing is heated, the ventilation on the outer side of theclothing can be ensured, so that the hot vapor produced inside the clothing when being heated can be automatically discharged by virtue of a permeation apparatus, and the drying efficiency of the clothing can be improved.

Owner:嘉兴瑞美时装有限公司

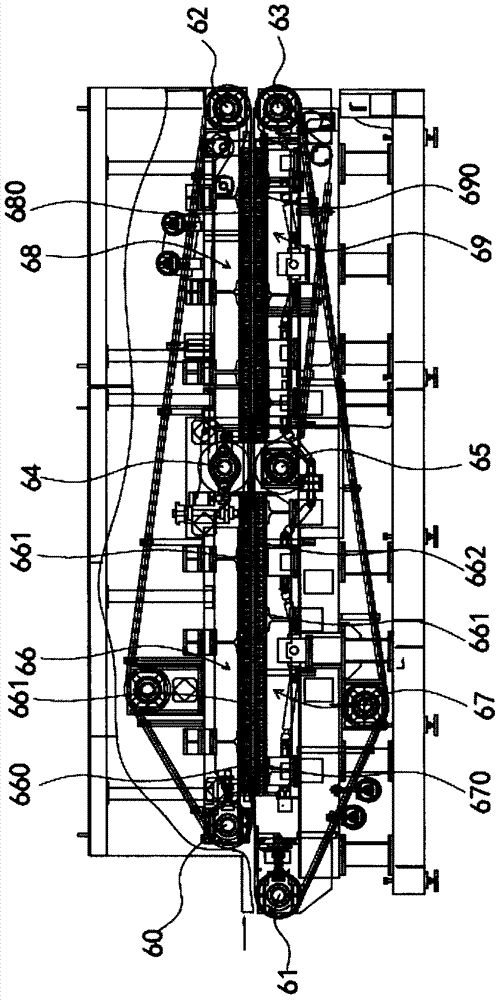

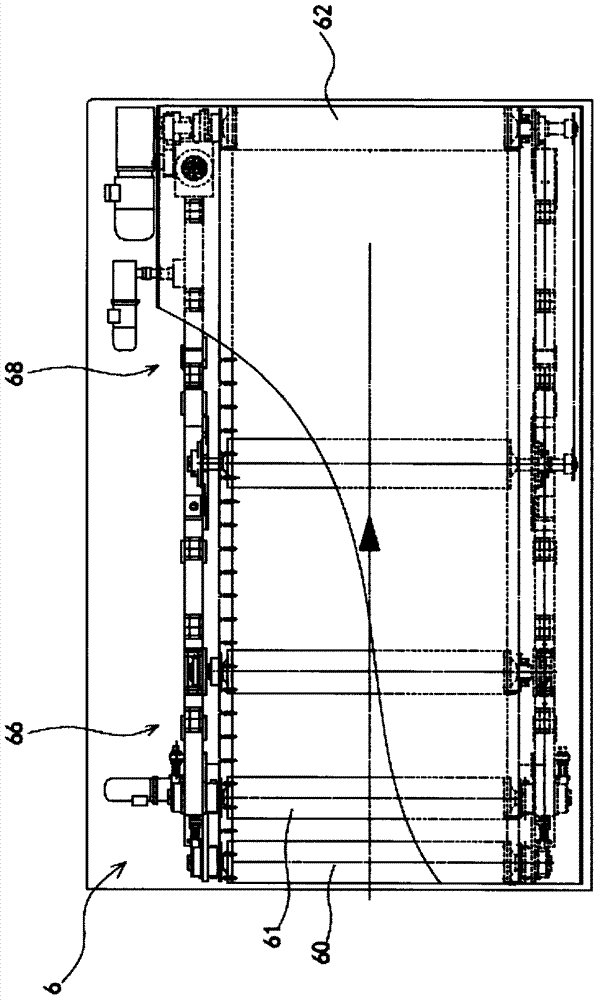

A continuous fiber plane hot-press composite equipment

ActiveCN105751663BImprove yieldReduce power consumptionLaminationLamination apparatusFiberEngineering

The invention discloses a continuous fiber plane hot-pressing compound device.The continuous fiber plane hot-pressing compound device comprises a combined unreeling machine, a transverse feeder, a high-low unreeling machine, a roll-in compound machine, a traction cutting machine, a transverse trimming machine and a reeling machine, all of which are sequentially connected.The operating direction of a composite material serves as reference, an upper heating region is arranged in the region, between an upper inlet roller and an upper pressure roller, of the roll-in compound machine, and an upper cooling region is arranged in the region, between the upper pressure roller and an upper outlet roller, of the roll-in compound machine.A lower heating region is arranged in the region between a lower inlet roller and a lower pressure roller, a lower cooling region is arranged in the region between the lower pressure roller and a lower outlet roller, heating bodies are arranged in the heating regions, and cooling bodies are arranged in the cooling regions.The continuous fiber plane hot-pressing compound device is reasonable in structural arrangement, good in reliability, high in yield and better in compound effect, by means of the assembly line arrangement, the working efficiency of the hot-pressing compound device is greatly improved, the device is suitable for high-strength continuous fiber plant hot-pressing compound operation, and operation of the mechanical device is simple and user-friendly.

Owner:常州贝弗勒机械有限公司

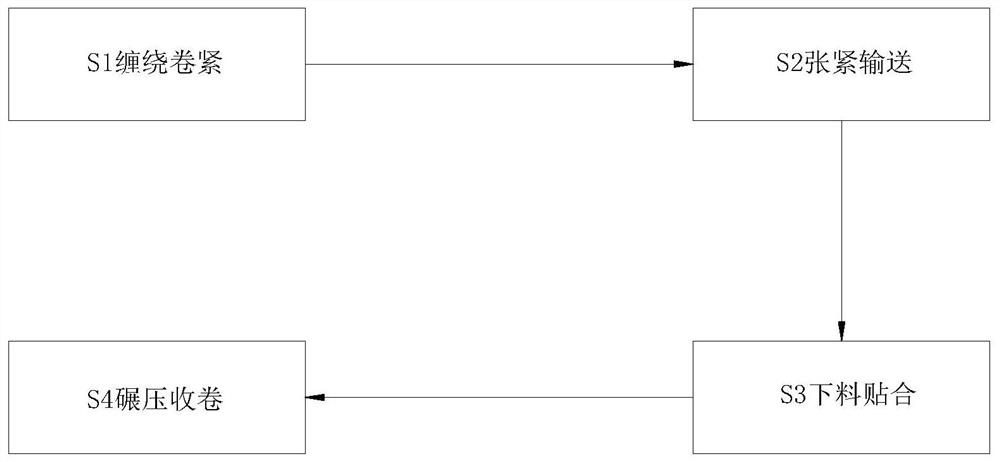

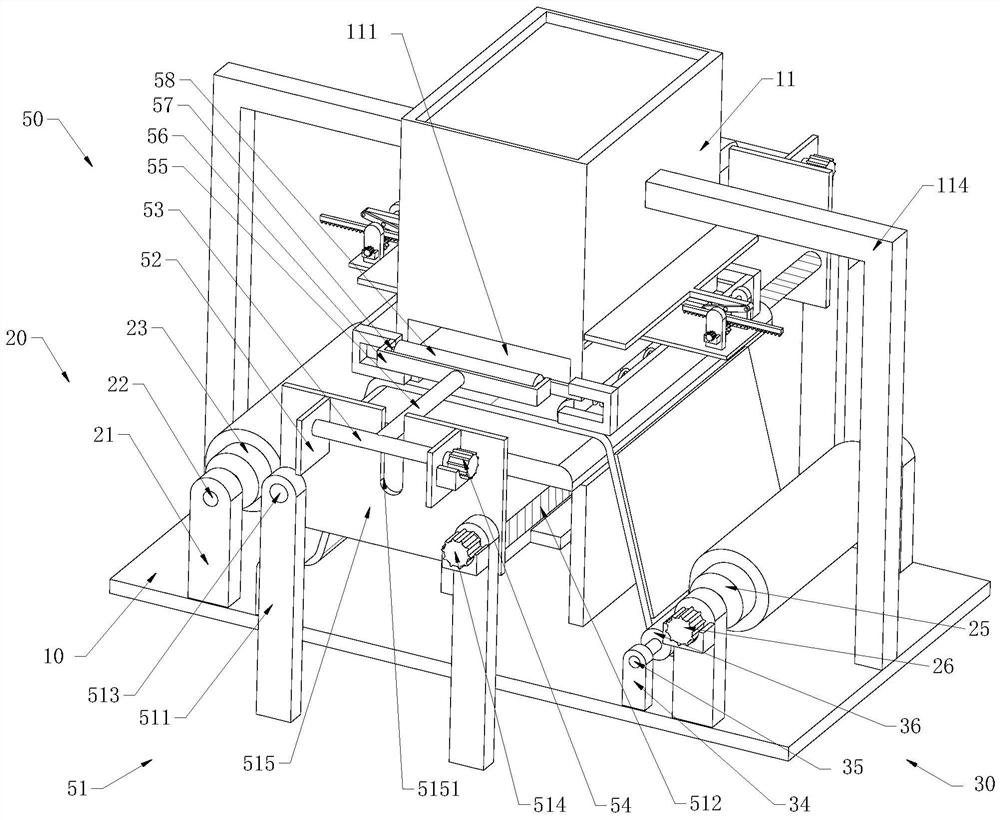

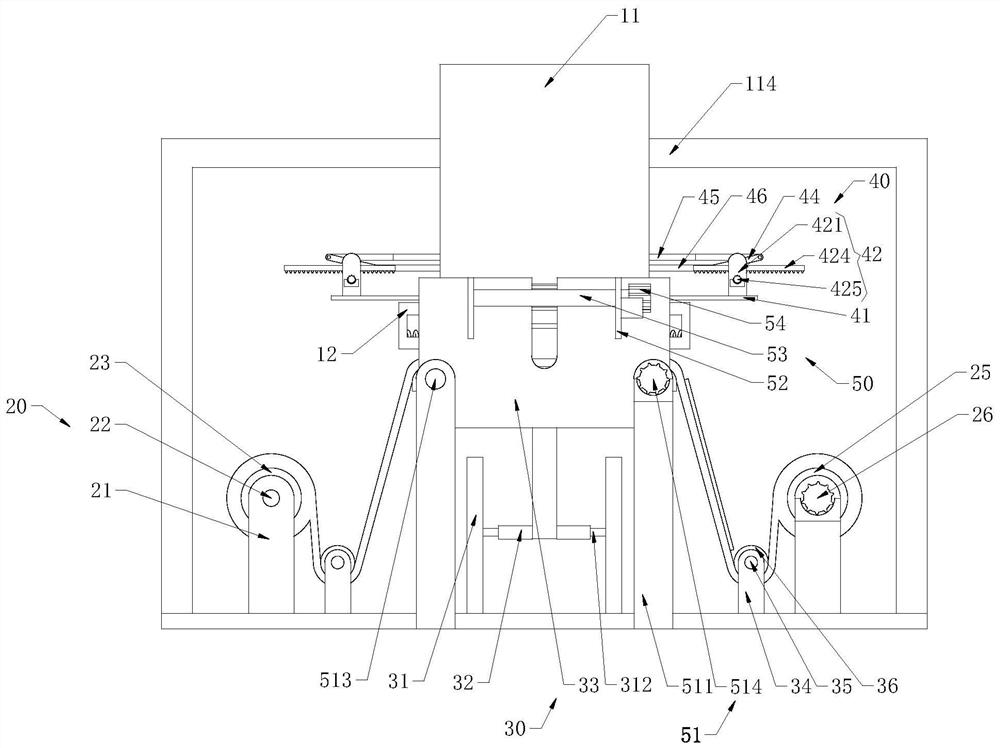

Preparation method of self-adhesive label paper

InactiveCN112373167AAvoid uneven surfacesFit flatMechanical working/deformationLamination ancillary operationsAdhesiveManufacturing engineering

The invention relates to a self-adhesive label paper preparation method, which uses self-adhesive label processing and manufacturing equipment. The equipment comprises a workbench and a winding devicearranged at the top of the workbench. A tensioning device is arranged at the top of the workbench, a feeding box is arranged over a T-shaped plate, discharging devices are arranged at the left end and the right end of the feeding box, and rolling devices are arranged at the front end and the rear end of the feeding box. A designed tensioning roller can achieve a certain tensioning effect on the surface of backing paper, the tensioning degree of the surface of the backing paper can be adjusted through a designed cross-shaped sliding groove, an electric sliding block and a T-shaped plate, the backing paper is in a tensioned state in the working process, and the situation that the surface of the backing paper is uneven, and consequently the attaching quality is reduced is prevented.

Owner:倪敏跃

Novel transparent spiral water suction pipe production process

InactiveCN109676981AFit flatHigh fluid viscosityTubular articlesPulp and paper industryProduct processing

The invention discloses a novel transparent spiral water suction pipe production process. PVC resin and auxiliary materials are put into a stirring device for mixing; the mixture is put into a screw extruder; a bonding layer, an outer framework layer and a lining layer are respectively extruded through mouth molds of the screw extruders; a pressurizing wheel, a flat pressing roller and an auxiliary heating device are additionally arranged on a core rod, so that the lining layer, the bonding layer and the outer framework layer are directly compounded and formed once under the action of heat and pressure while being wound and formed on the core rod; the lining layer, the bonding layer and the outer framework layer are compounded by adopting a one-step forming process, the edges of extrusionparts can be smoothly bonded without adding an additional bonding and compacting process, the processing process is simple, and the product processing quality is excellent.

Owner:ZHONG YU HOSES TECH CO LTD

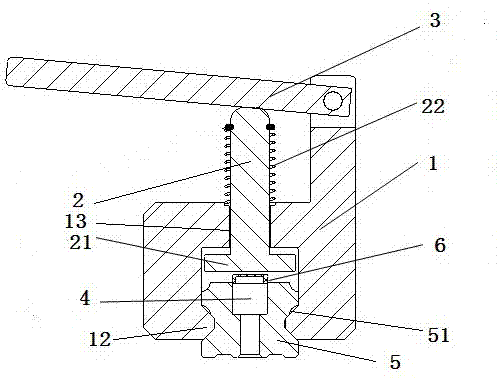

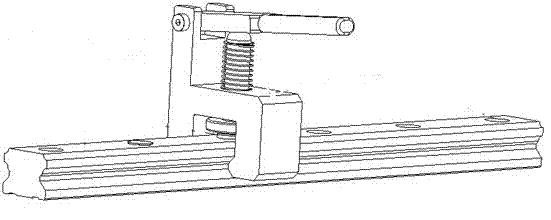

Installation device of counter bore gland of guide rail

The invention relates to an installation device of a counter bore gland of a guide rail. The installation device of the counter bore gland of the guide rail comprises a machine frame, a pressing rod and a handle, wherein the machine frame is arranged on the guide rail and can slide on the guide rail horizontally, the pressing rod is arranged on the machine frame and can slide vertically on the machine frame, one end of the handle is hinged to the upper portion of the machine frame, and the middle of the handle is hinged to the upper end of the pressing rod. According to the installation device of the counter bore gland of the guide rail, the lever principle is adopted, the gland is pressed into a counter bore through the pressing rod with relatively even force and speed, damage, caused by impact to the upper surface of the guide rail, of the guide rail is avoided, and the gland can be attached to the upper surface of the guide rail more smoothly.

Owner:NANJING TECHN EQUIP MFG

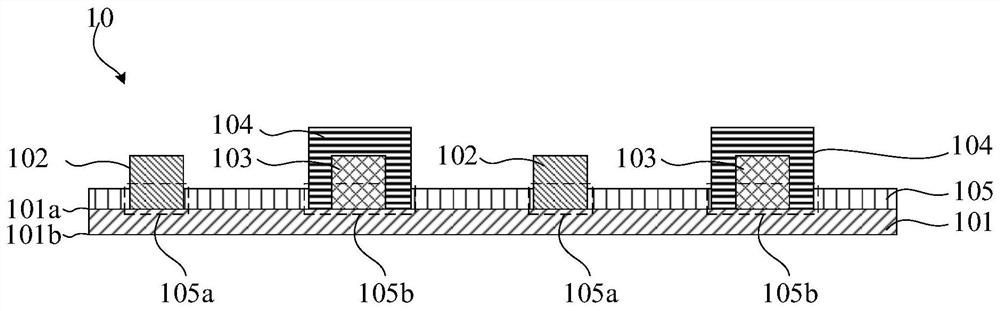

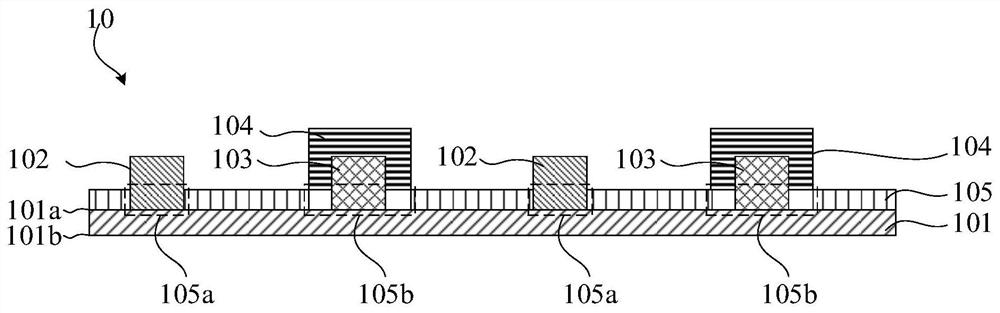

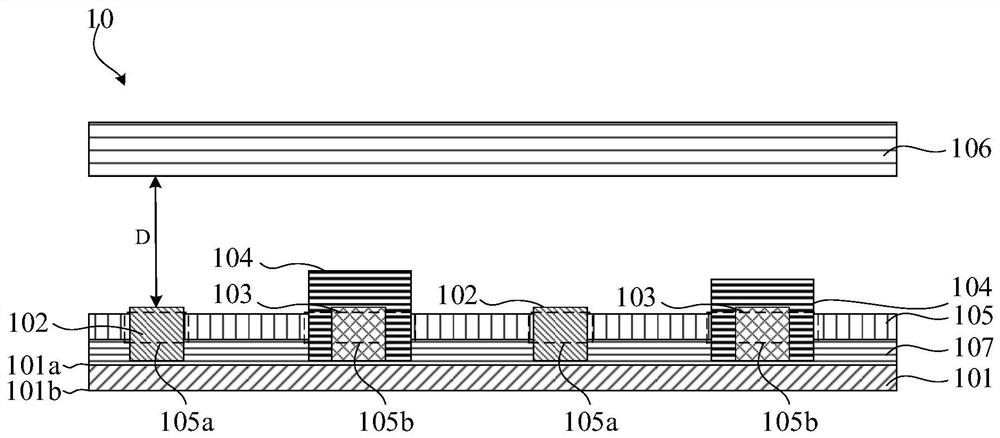

Backlight module, backlight module manufacturing method and display panel

The embodiment of the invention provides a backlight module, a backlight module manufacturing method and a display panel. The backlight module comprises an array substrate, a light emitting diode, a driving switch, a reflection packaging glue and a reflection layer. According to the invention, a reflecting layer is provided with a first through hole and a second through hole at a light emitting diode and a driving switch respectively, and a reflecting packaging adhesive is adopted at the driving switch for packaging, so that the driving switch can be further reinforced so as to improve the reliability of the driving switch, the reflectivity of the reflection packaging adhesive is high, and light reflected by the driving switch can be reflected back so as to avoid display dark spots; and when the reflecting layer is attached, the first through hole and the second through hole are formed in the light-emitting diode and the driving switch respectively, so that the light-emitting diode andthe driving switch are completely exposed, attachment is smoother, the attachment difficulty of the reflecting layer is reduced, and the attachment reliability of the reflecting layer is enhanced.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Production technology of smudging wood floor

InactiveCN108393994AGuaranteed tightnessGuaranteed waterproof performanceRosin coatingsWood treatment detailsAdhesiveWear resistance

The invention relates to a production technology of a smudging wood floor. A base material preparing technology, a smudging ammonia water technology and a veneering preparing technology are included,wood raw materials with large chromatic aberrations can be even in color, mountain-shaped wood grains are formed on the surface, the wood raw material toughness is increased, light wooden fragrance can be emitted from the wood raw materials, meanwhile, the production technology guarantees that the manufactured floor has leakproofness, waterproofness and moth repellency, the floor appearance coloris much mellow and glossy, the wood skin on the surface of the floor is smooth and flat in attachment, a chemical adhesive is not used, environmental protection is better achieved, the abrasive resistance is good, and the production technology is suitable for meeting modern home decoration requirements.

Owner:湖州市南浔广达木业有限公司

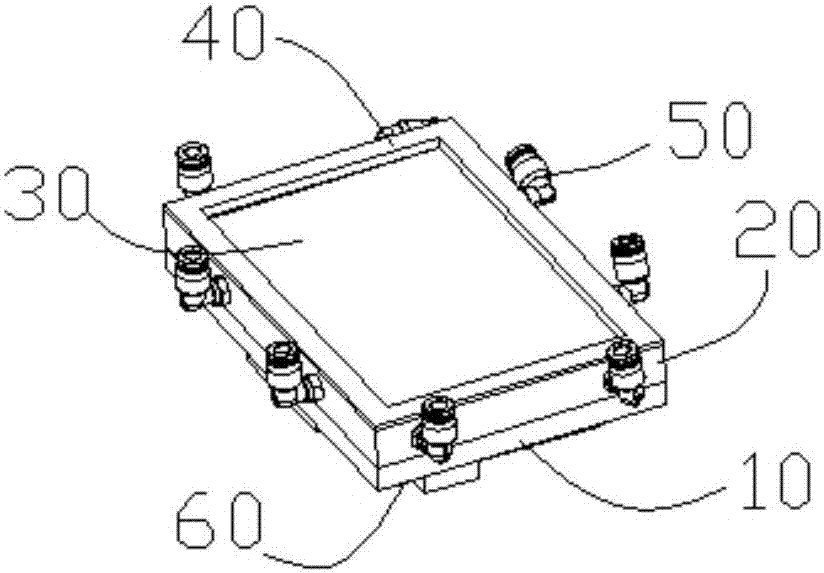

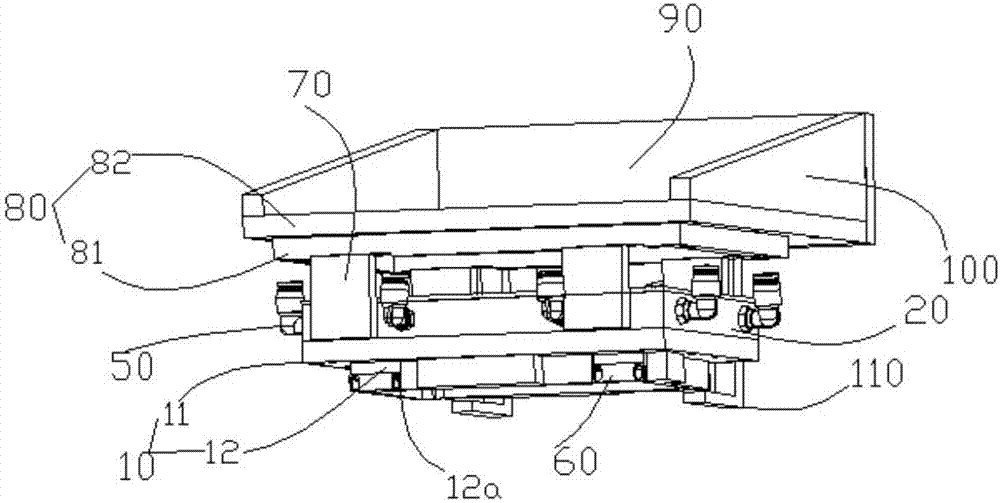

Pressure apparatus for assisting backlight module checking fixture

PendingCN107367852ABlemish highlightsFit flatNon-linear opticsFixed frameElectrical and Electronics engineering

The invention provides a pressure apparatus for assisting a backlight module picture checking fixture. The pressure apparatus comprises an air cover, wherein the air cover comprises a storage board, a connector fixing block connected with the storage board and a transparent board capable of being embedded onto the connector fixing board, a side edge of the storage board is provided with an adjusting check block, a side edge of the connector fixing block is provided with an air pipe connector, and the pressure apparatus also comprises a movable structure connected with a connector fixing frame and capable of adjusting the air cover. According to the pressure apparatus, the stable air pressure in the air cover is realized by virtue of inflation and deflation between the air pipe connector and the adjusting check block on the air cover, and an upper surface of a backlight module is pressed, so that backlight module components are kept flatly laminated; for a backlight module of a different model numbers and a corresponding checking fixture, the air cover can be adjusted by the movable structure to move in a front-rear direction and a left-right direction, so that the air cover can be better matched with the checking fixture; and the pressure apparatus has the advantages of simple structure, low production cost, high practicability and high automation degree.

Owner:博讯光电科技(合肥)有限公司

Label rolling mechanism

The invention provides a label rolling mechanism. The label rolling mechanism comprises a driving assembly and a label rolling assembly connected to the driving assembly. The label rolling assembly comprises a base plate, a rotary shaft, a left driving rod, a right driving rod, label rolling wheels, restoration struts and an elastic restoration piece, wherein the initial end of the base plate is connected to the driving assembly; the rotary shaft is arranged at the tail end of the base plate; the middle portion of the left driving rod and the middle portion of the right driving rod are arranged on the rotary shaft in a crossed mode, and the left driving rod and the right driving rod are used in cooperation; the label rolling wheels are arranged at the tail end of the left driving rod and the tail end of the right driving rod correspondingly; the restoration struts are arranged at the initial end of the left driving rod and the initial end of the right driving rod correspondingly; and the two ends of the elastic restoration piece are connected to the restoration struts arranged at the initial end of the left driving rod and the initial end of the right driving rod correspondingly. According to the label rolling mechanism, a label attached to the surface of an arc-surface product can be rolled, and bubbles are eliminated after the label is attached to an arc surface, so that the label is attached more smoothly, and accordingly the outgoing quality of the product is improved.

Owner:BOZHON PRECISION IND TECH CO LTD

Floor tile fitting device with tile supply function

InactiveCN108468422AGuaranteed tidyNo height differenceBuilding constructionsCivil engineeringEngineering

The invention relates to the field of building decoration, in particular to a floor tile fitting device with a tile supply function. The device comprises a base component, a supporting frame component, a tile fitting component, a bonding material scraping component, a tile supply assembly and an operation and control platform. Not only are the functions of automatic fitting, aligning and positioning of tiles achieved, but also the device is provided with the tile supply assembly. The device has the advantage that the tile supply position is accurate and stable.

Owner:HUZHOU ZHONGCHEN CONSTR

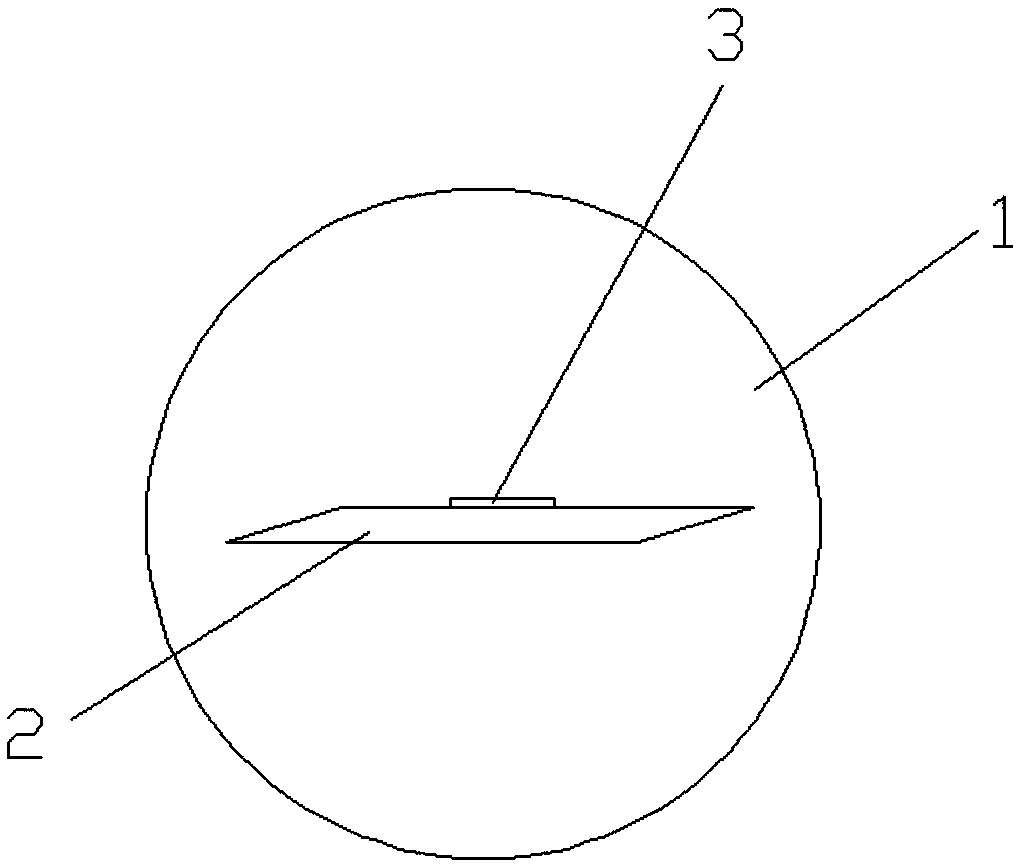

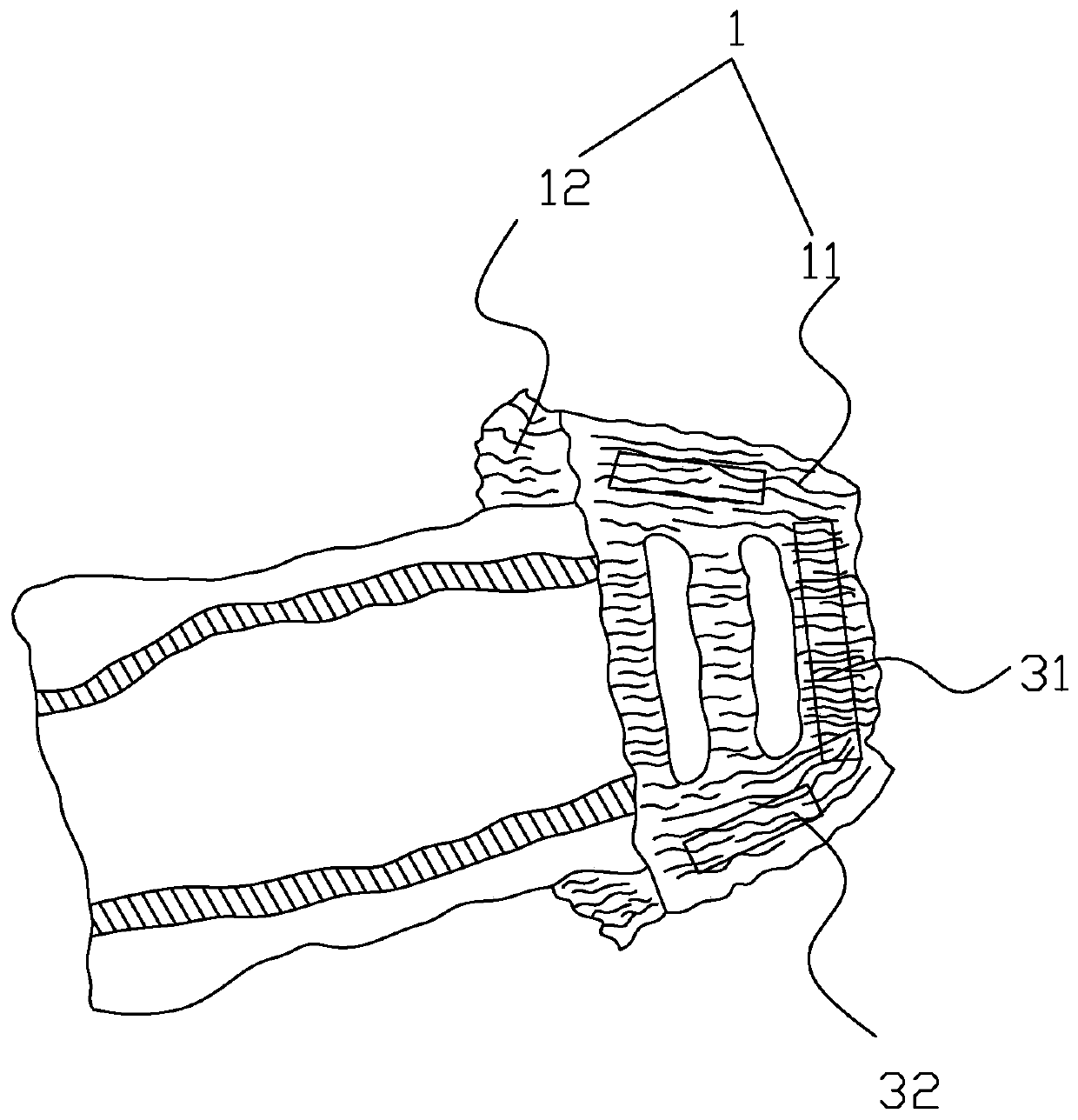

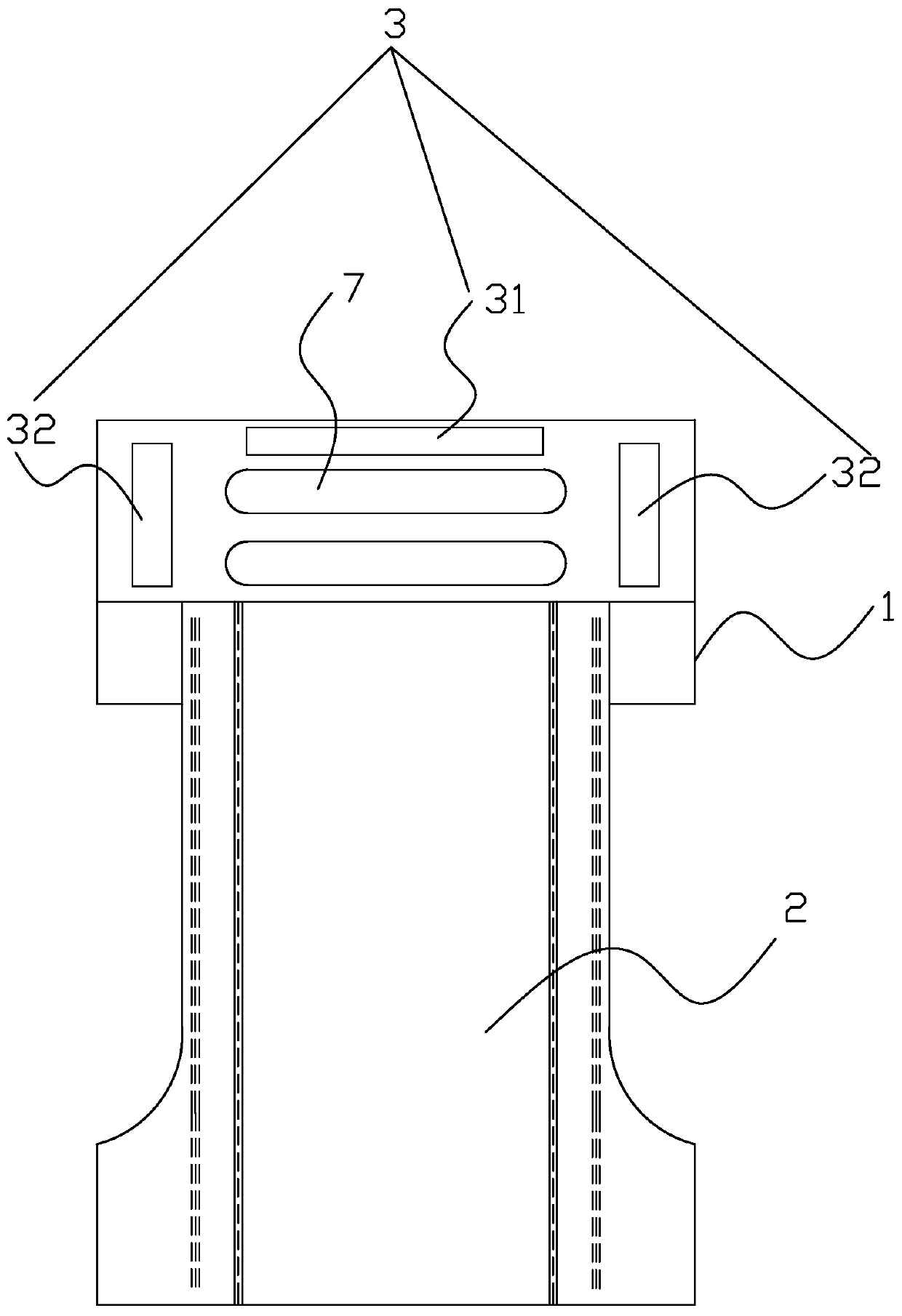

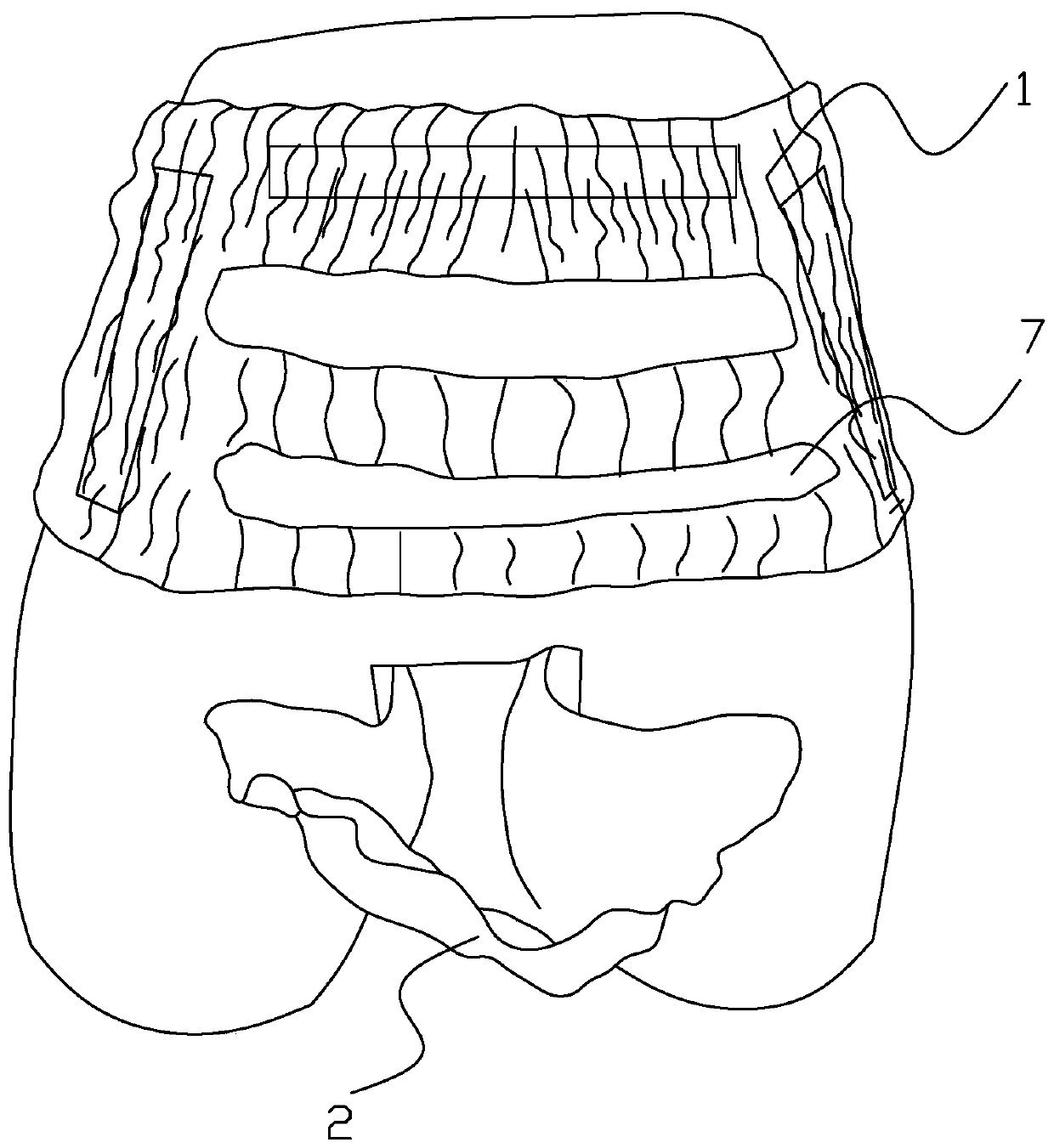

Easy-to-wear-and-take-off absorptive article and preparation method therefor

The invention relates to the field of sanitary accessories and provides an easy-to-wear-and-take-off absorptive article and a preparation method therefor. The easy-to-wear-and-take-off absorptive article is used for solving the problem in the prior art that whether an infant defecates or not is inconvenient to check due to the fact that an absorptive article is not skintight and can only be worn by completely taking off trousers. The easy-to-wear-and-take-off absorptive article comprises a waistline elastic component 1, an absorber 2 and a connecting member 3, wherein the absorber 2 is definedto have a longitudinal direction along a length direction and a transverse direction along a width direction, one end of the longitudinal direction of the absorber 2 is fixedly connected with the waistline elastic component 1, the other end of the longitudinal direction of the absorber 2 is detachably connected with the waistline elastic component 1 through the connecting member 3, the waistlineelastic component 1 is composed of a first non-woven fabric 4, a second non-woven fabric 5 and an elastic ribbon 6 arranged between the first non-woven fabric 4 and the second non-woven fabric 5 and comprises a front elastic member 11 and a back elastic member 12, and two transverse ends of the front elastic member 11 and two transverse ends of the back elastic member 12 are welded to form a closed type structure.

Owner:FUJIAN HENGAN HLDG CO LTD +2

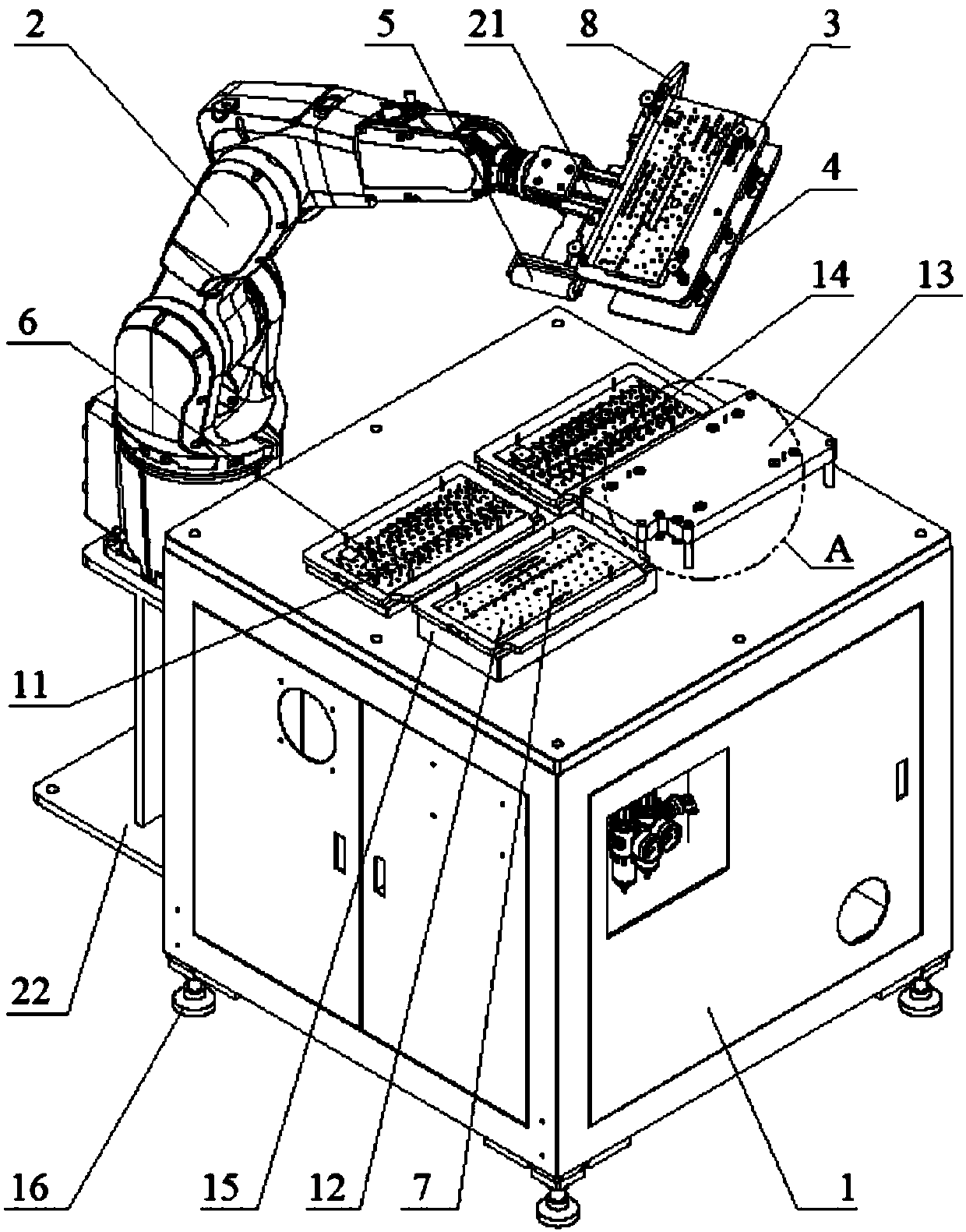

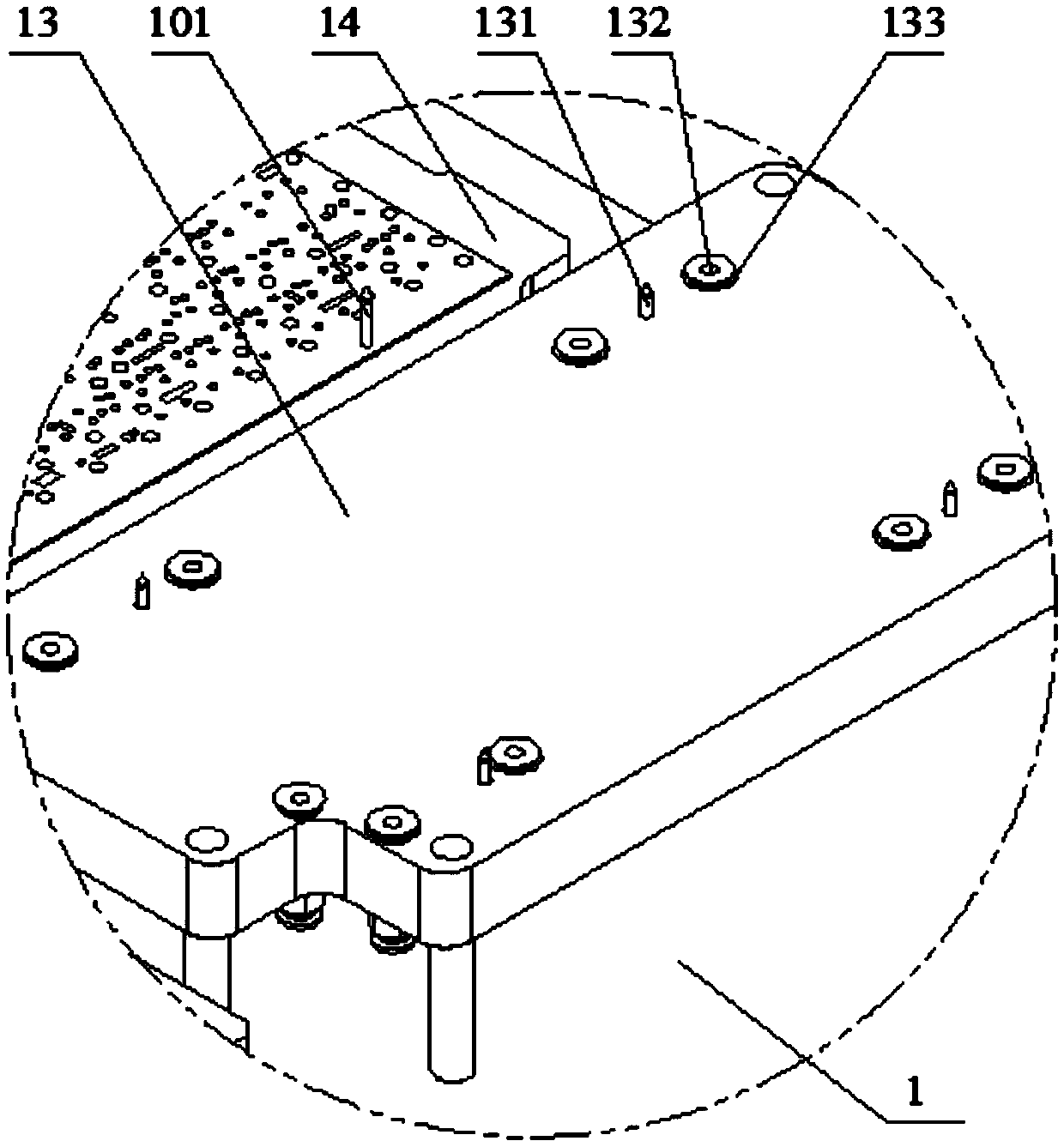

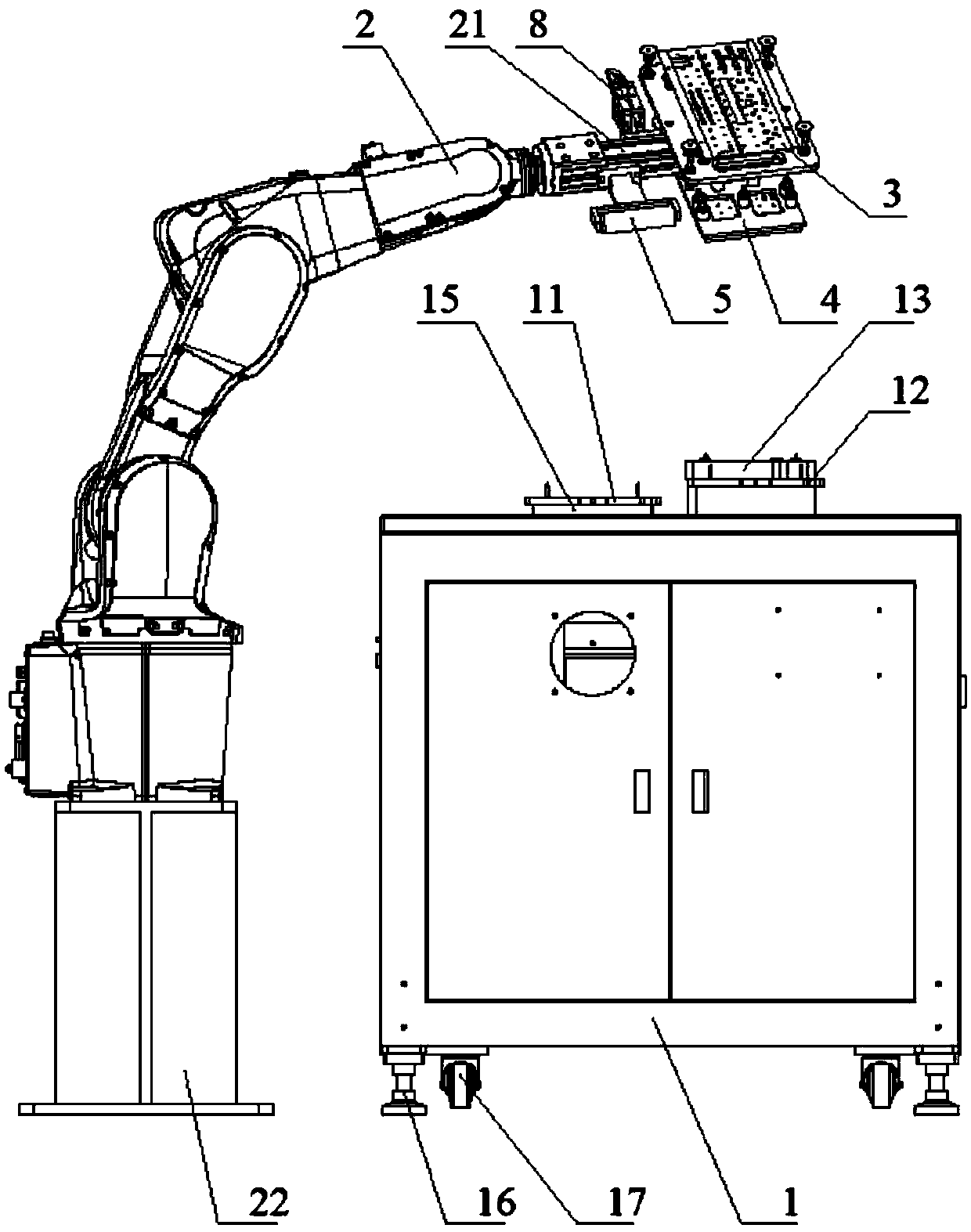

Keyboard adhesive product automatic assembly equipment and assembly process adopting same

PendingCN109623732AEasy to operateImprove assembly accuracyGripping headsElectric switchesFilm materialManipulator

The invention discloses keyboard adhesive product automatic assembly equipment. The keyboard adhesive product automatic assembly equipment comprises a machine table. A first jig used for placing a first film material, a second jig used for placing a second film material, a laminating assembly table and a discharge jig are arranged on a table board of the machine table. A plurality of first locating pins and a plurality of first vacuum cups are arranged on a table board of the laminating assembly table. A mechanical arm is arranged on one side of the machine table. The front end of the mechanical arm is provided with a mounting frame. The mounting frame is provided with a first taking device, a second taking device and a rolling assembly. Meanwhile, the invention further provides an assembly process adopting the keyboard adhesive product automatic assembly equipment. The adhesive product automatic assembly equipment realizes automatic laminating assembly of a keyboard adhesive product,is easy and convenient to operate, high in assembly precision and good in stability, improves the product yield and the production efficiency, shortens the manufacturing cycle of products, reduces themanpower demands, saves resources and lowers the cost.

Owner:LINGSHENGCHENG TECH JIANGSU CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com