Installation device of counter bore gland of guide rail

A technology of installer and counterbore, which is applied in the field of guide rail counterbore gland installer, which can solve the problems that the gland is easy to be shaken or pressed over the plane of the guide rail, enters the slider, and affects the reliability or life of the guide rail pair.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

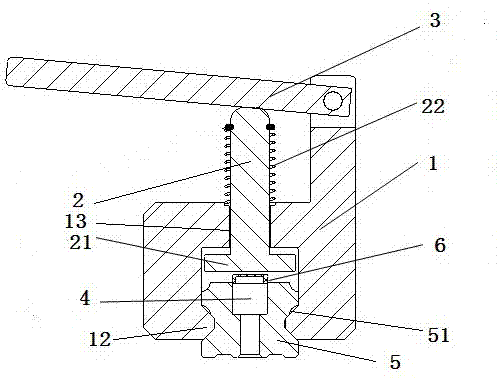

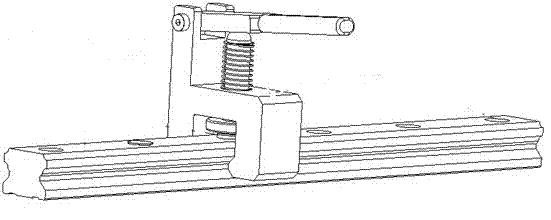

[0014] The guide rail counterbore gland installer includes a frame 1, a pressing bar 2 and a handle 3, two vertical sides of the guide rail are symmetrically provided with chute 51, counterbore holes 4 are evenly arranged on the guide rail 5, and the frame 1 The lower part is symmetrically arranged with a V-shaped slider 12, and the slider 12 is placed in the chute 11 so that the frame 1 is horizontally slid on the guide rail 5; the middle part of the frame 1 is provided with a guide hole 13, and the pressure rod 2 passes through the guide The hole 13 is slidably arranged on the frame 1 up and down, and the lower end of the pressing rod 2 is provided with a pressing plate 21 opposite to the counterbore 4 . One end of the handle 3 is hinged with the top of the frame 1, and the middle part is hinged with the upper end of the depression bar 2. A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com