Rolling and laminating device and laminating method of hot rollers

A technology of lamination device and hot roller, applied in lamination device, chemical instrument and method, lamination and other directions, can solve the problems of uneven lamination, easy occurrence of air bubbles, etc., and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to make the above features and beneficial effects of the present invention more obvious and understandable, the present invention will be described in detail below in conjunction with the embodiments. It should be noted that the terms "first", "second", and "third" used herein ", "vertical", "horizontal", "above", "below" and similar expressions are for illustrative purposes only and do not represent the only implementation.

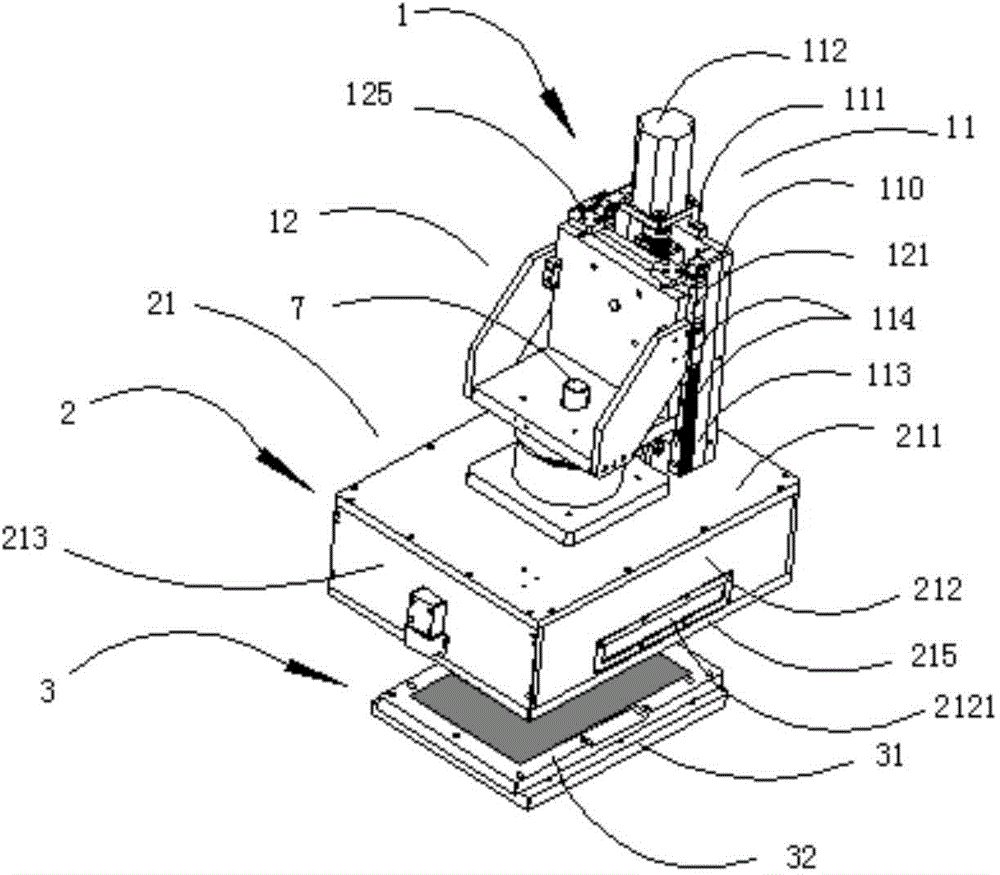

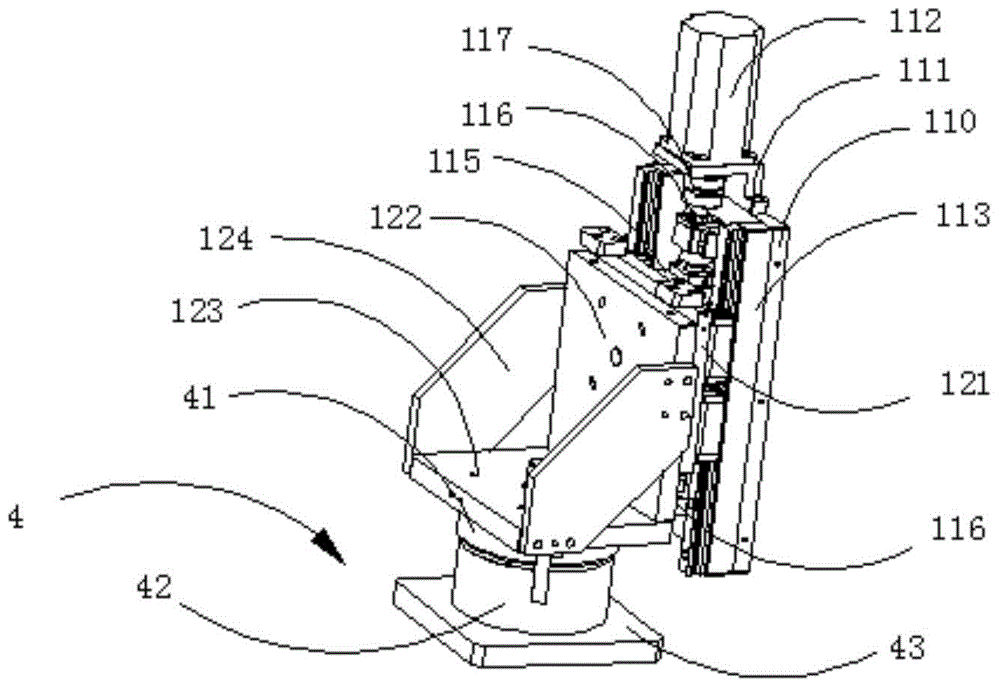

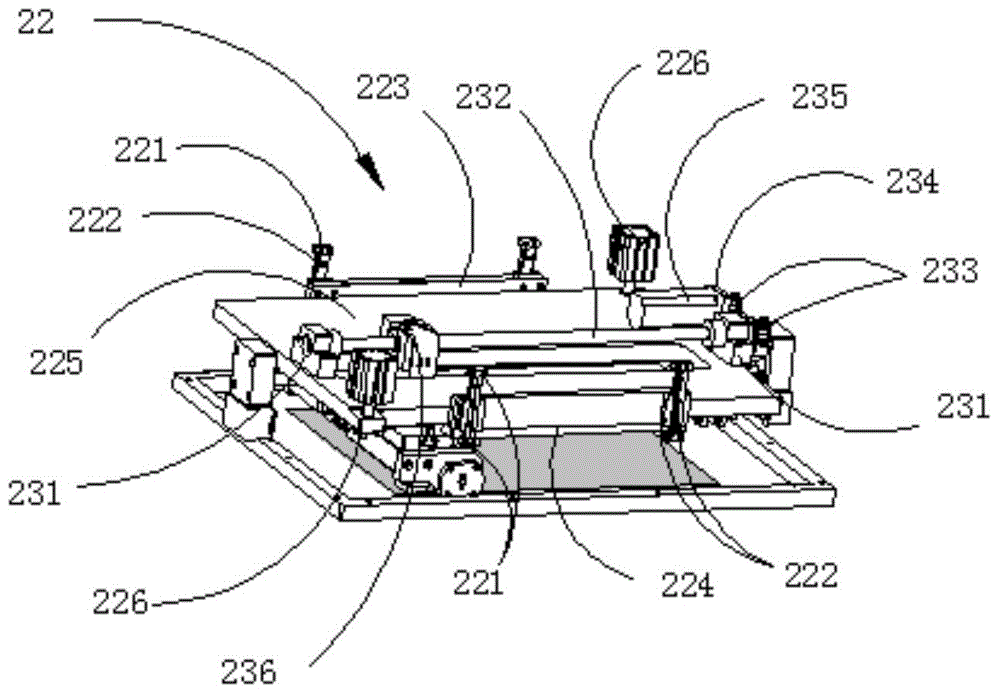

[0051] see figure 1 , is a structural schematic diagram of the bonding device in the embodiment. The pasting device is used for pasting a soft base material and a hard base material or a soft base material and another soft base material. The bonding device includes a driving device 1, a first bonding mechanism 2, an upper end connected to the driving device 1, a lower end connected to the rotating member 4 of the first bonding mechanism 2, and a second bonding mechanism 3 located below the first bonding mechanism 2. , the soft substrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com