Patents

Literature

60results about How to "Paste evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

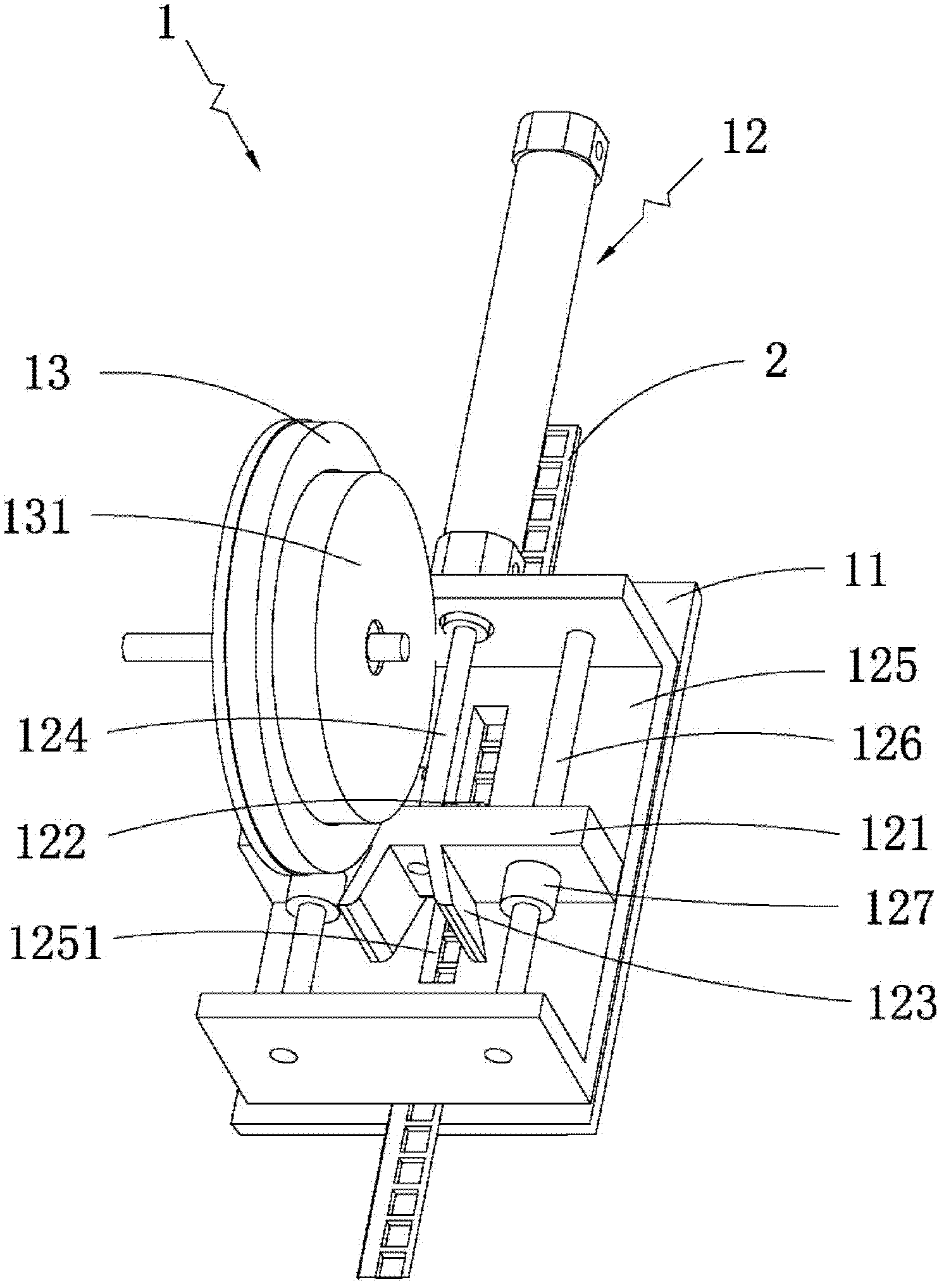

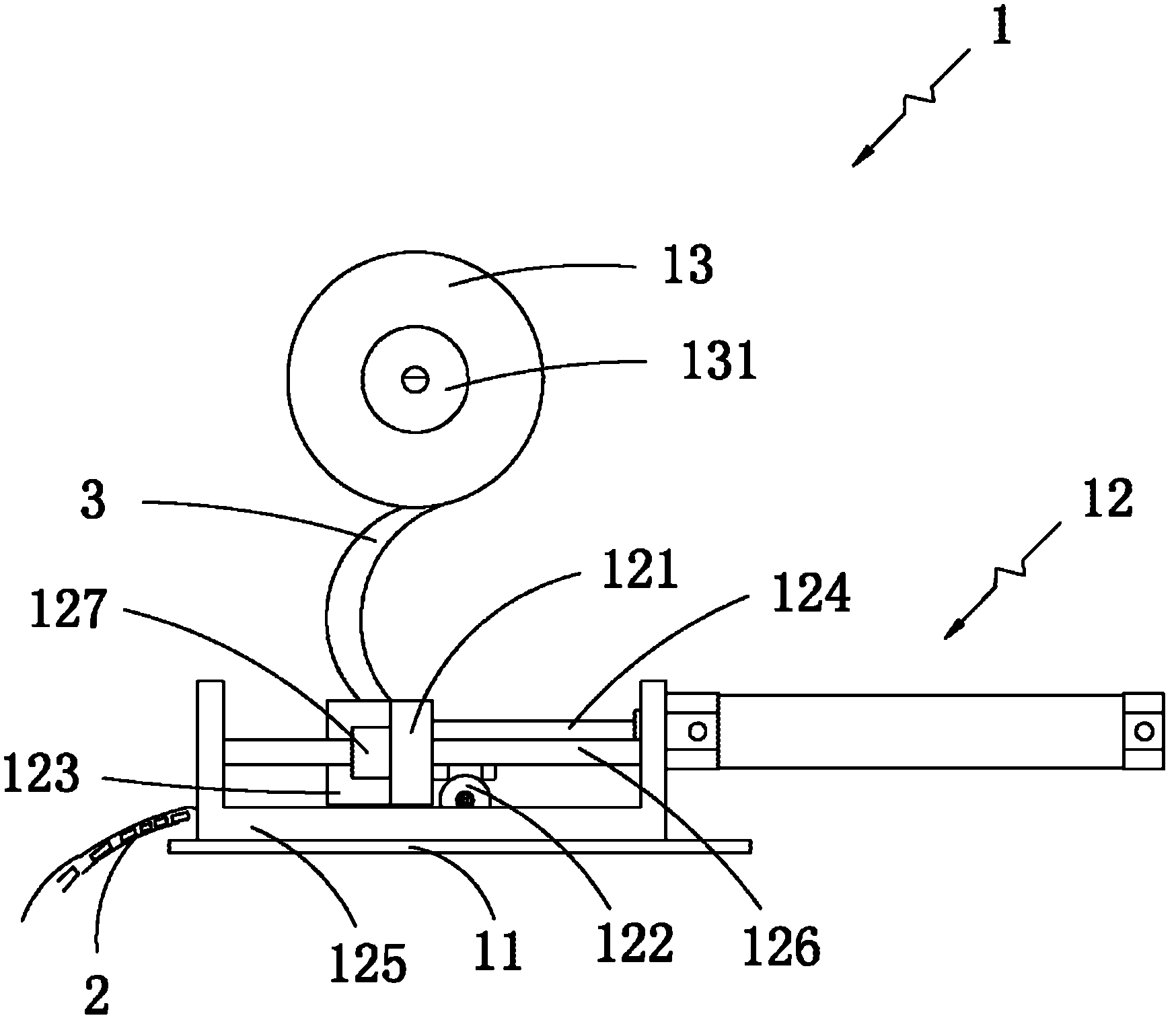

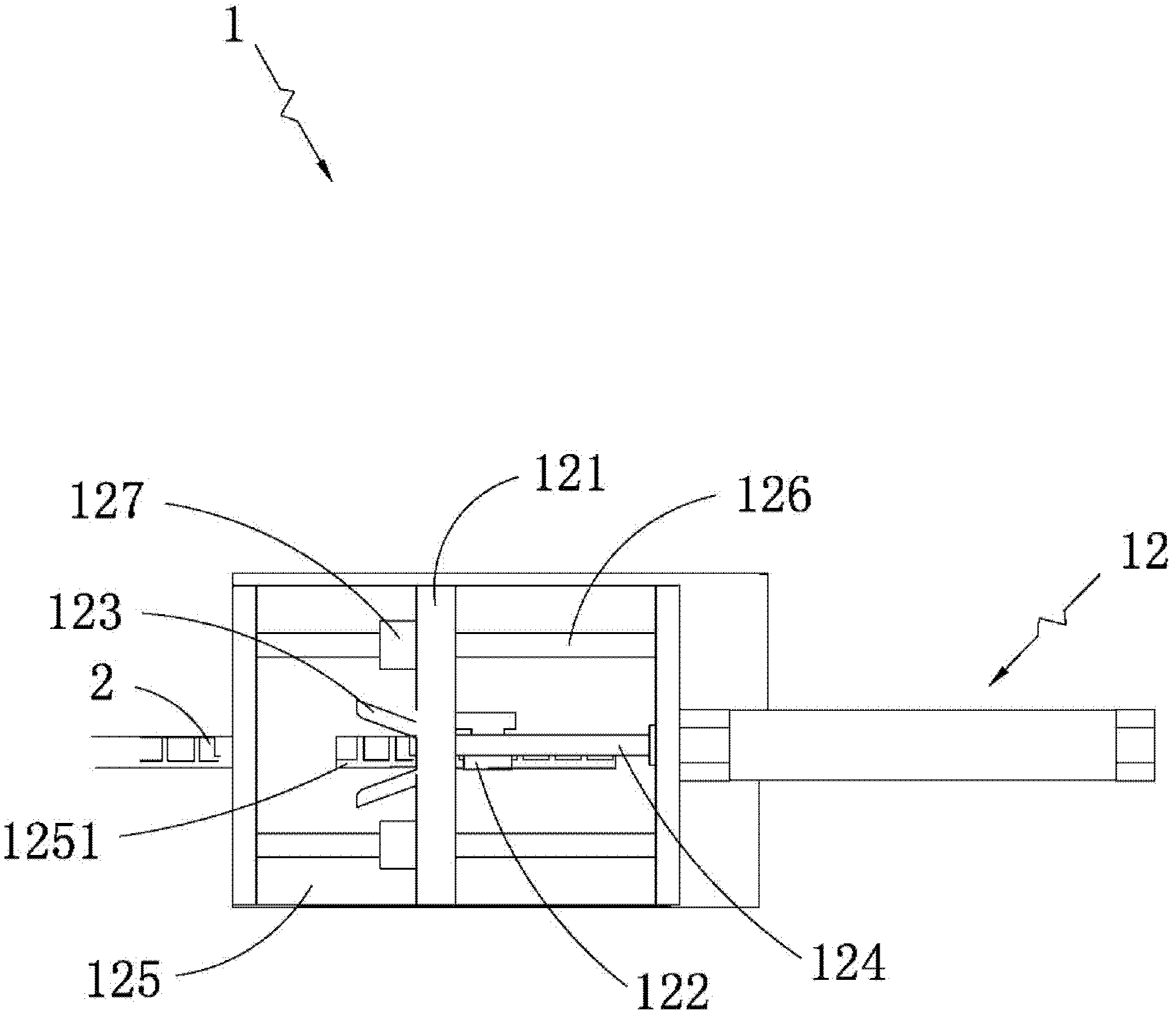

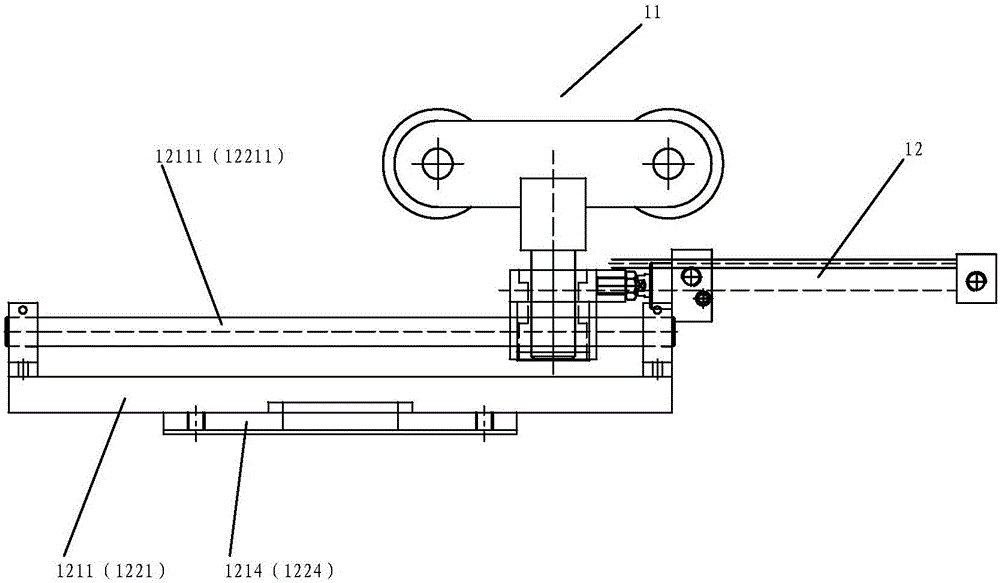

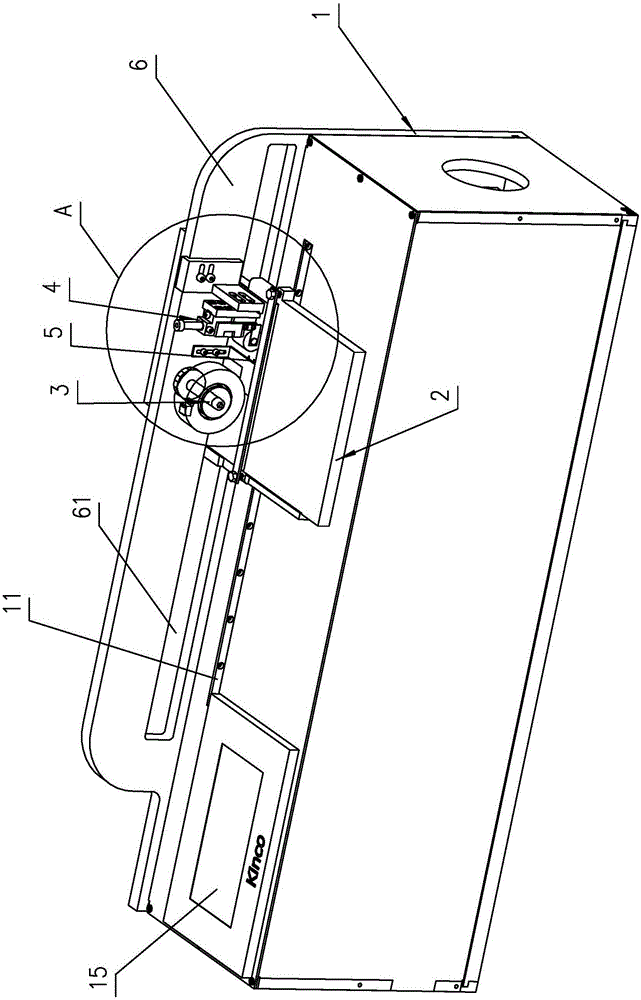

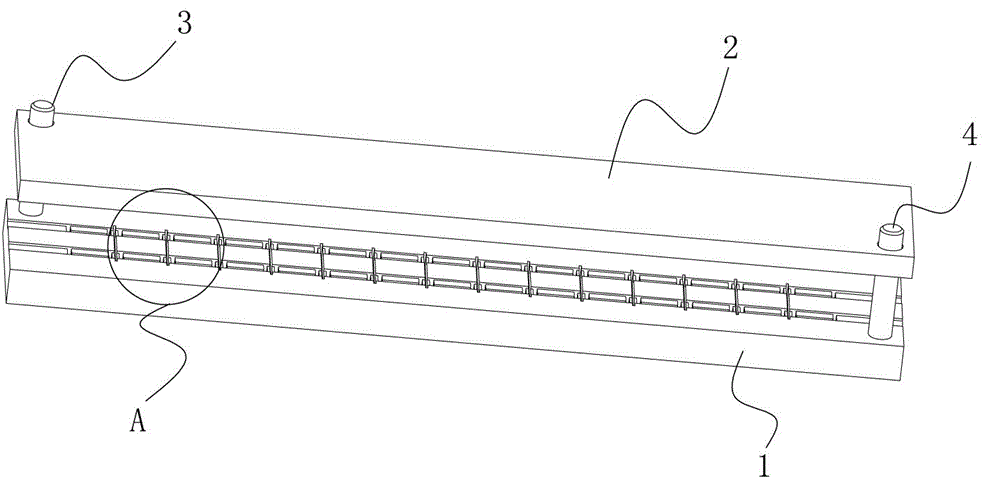

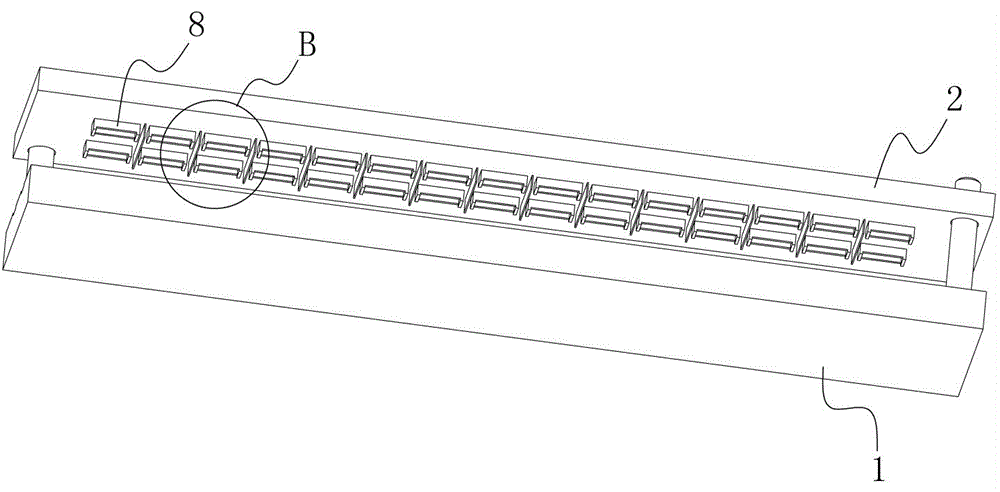

Automatic adhering device of transparent adhesive tape

ActiveCN102305228ASmooth transmissionAutomatic paste evenlyFastening meansMechanical engineeringAir bubble

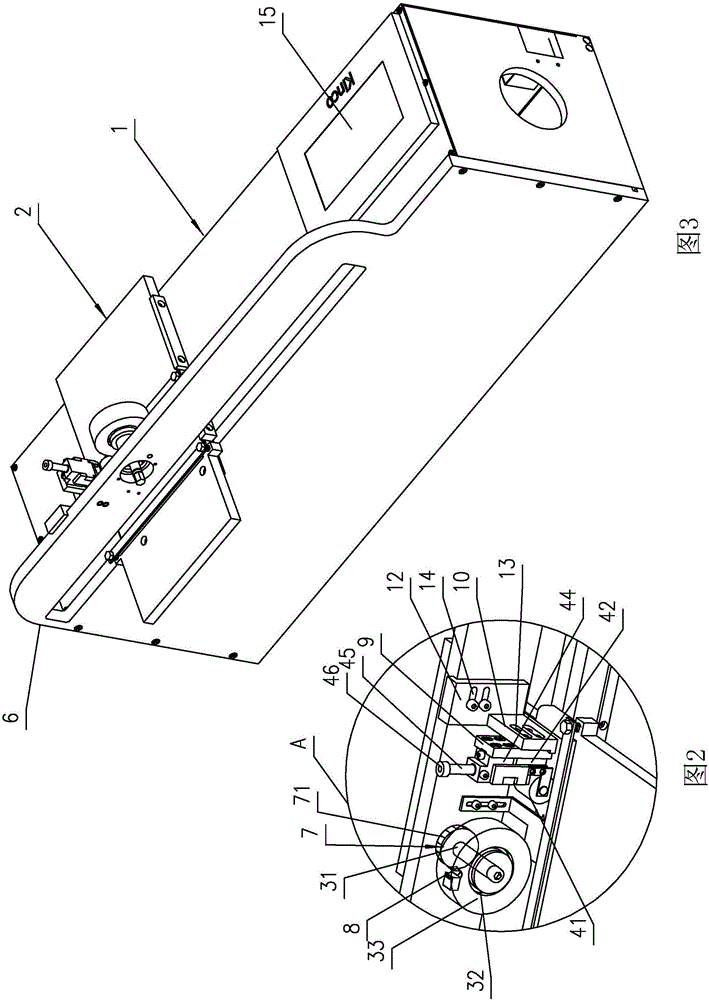

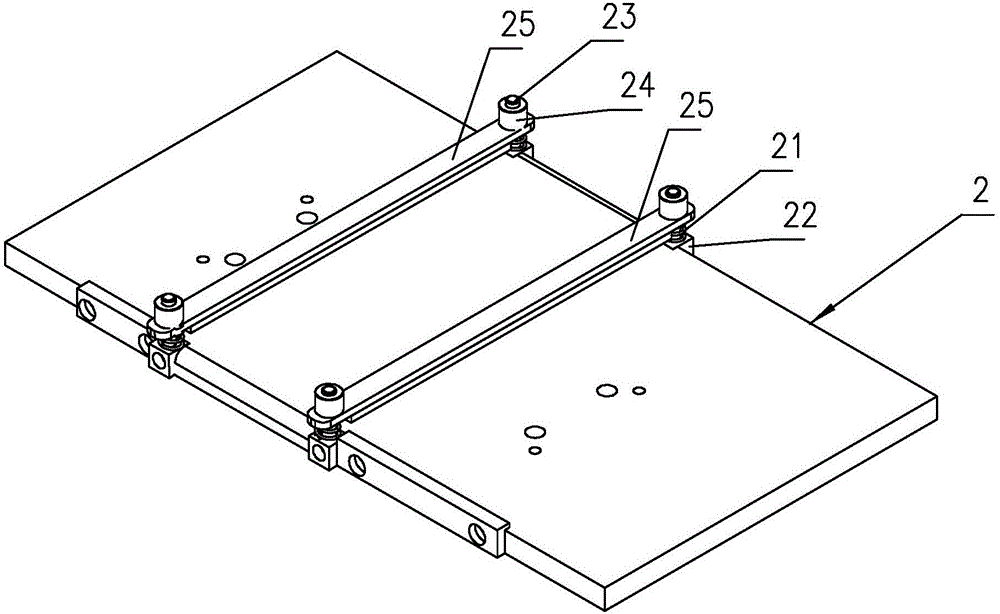

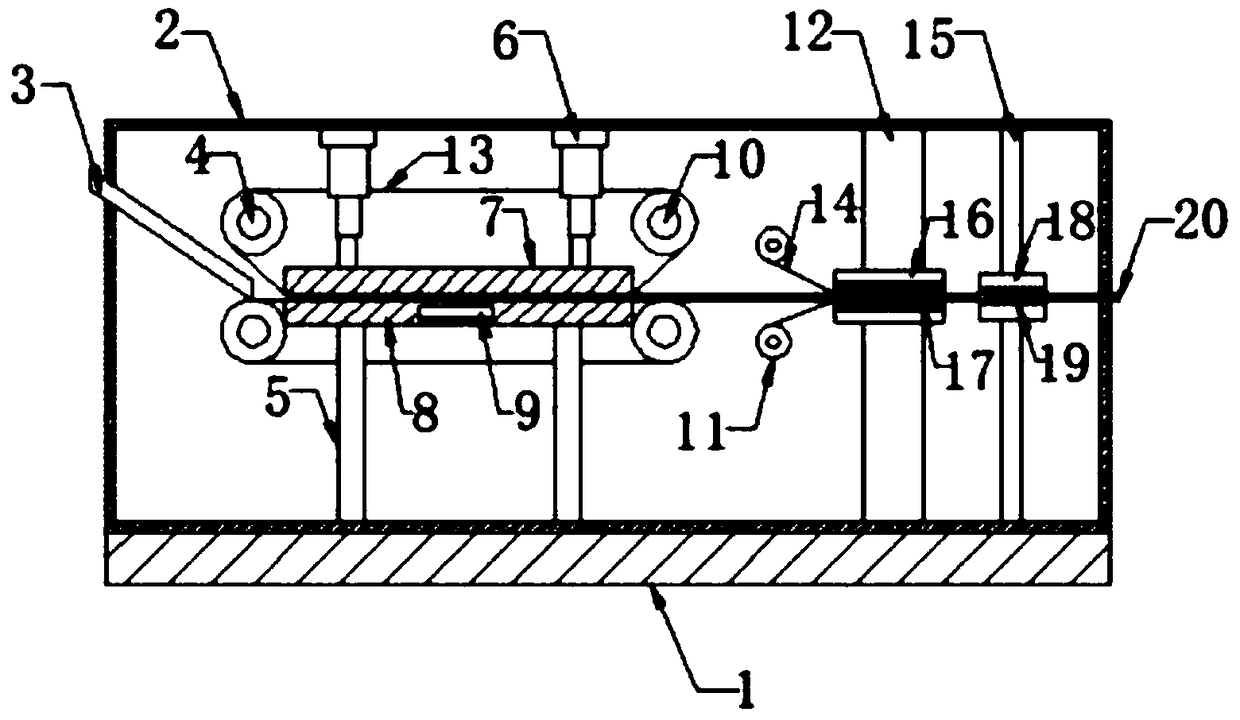

The invention provides an automatic adhering device of a transparent adhesive tape. The automatic adhering device adheres to an object to be adhered by utilizing the transparent adhesive tape and comprises a driving mechanism. The driving mechanism is arranged on a base plate, the base plate is provided with a guiding slot through which the object to be adhered passes, the driving mechanism drives a sliding block to carry out sliding displacement on the base plate, a rolling wheel is arranged on one side of the sliding block and can roll on the object to be adhered, and a locating structure is arranged on the other side of the sliding block and is used for locating the transparent adhesive tape. The transparent adhesive tape is suspended above the rolling wheel, the head of the transparent adhesive tape is firstly adhered on the object to be adhered, and the driving mechanism drives the rolling wheel to roll and drives the transparent adhesive tape to roll and automatically press the object to be adhered, thus the adhesion is ensured to be more uniform, firmer and better quality, and no bubbles or adhesion misalignment generates in the adhering process; the transparent adhesive tape is located by utilizing the locating structure so as to ensure that the transparent adhesive tape can stably convey without interruption; in addition, the automatic adhering device further has the advantages of simple structure and low cost, and the labor and the time are saved due to manual adhesion replaced by the automatic adhesion.

Owner:SHENZHEN SKYWORTH RGB ELECTRONICS CO LTD

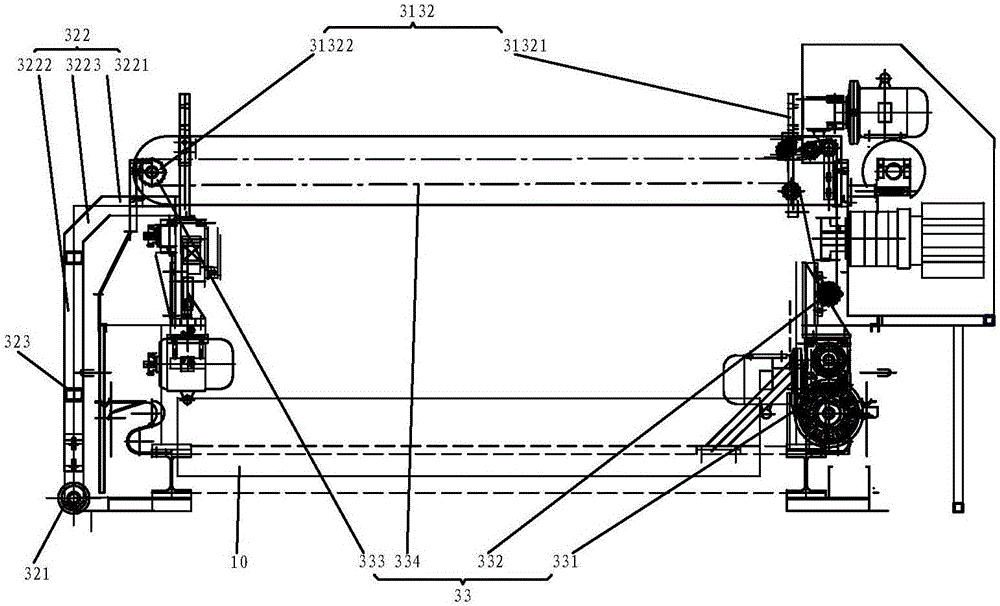

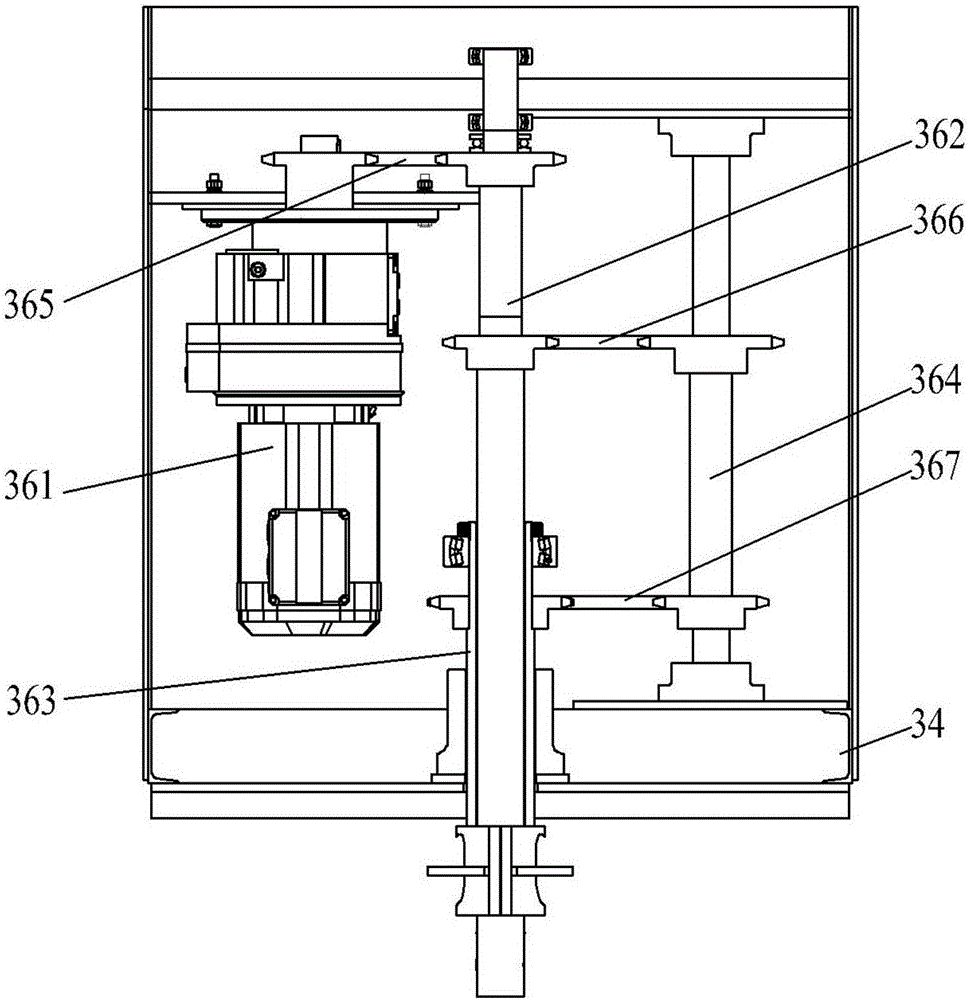

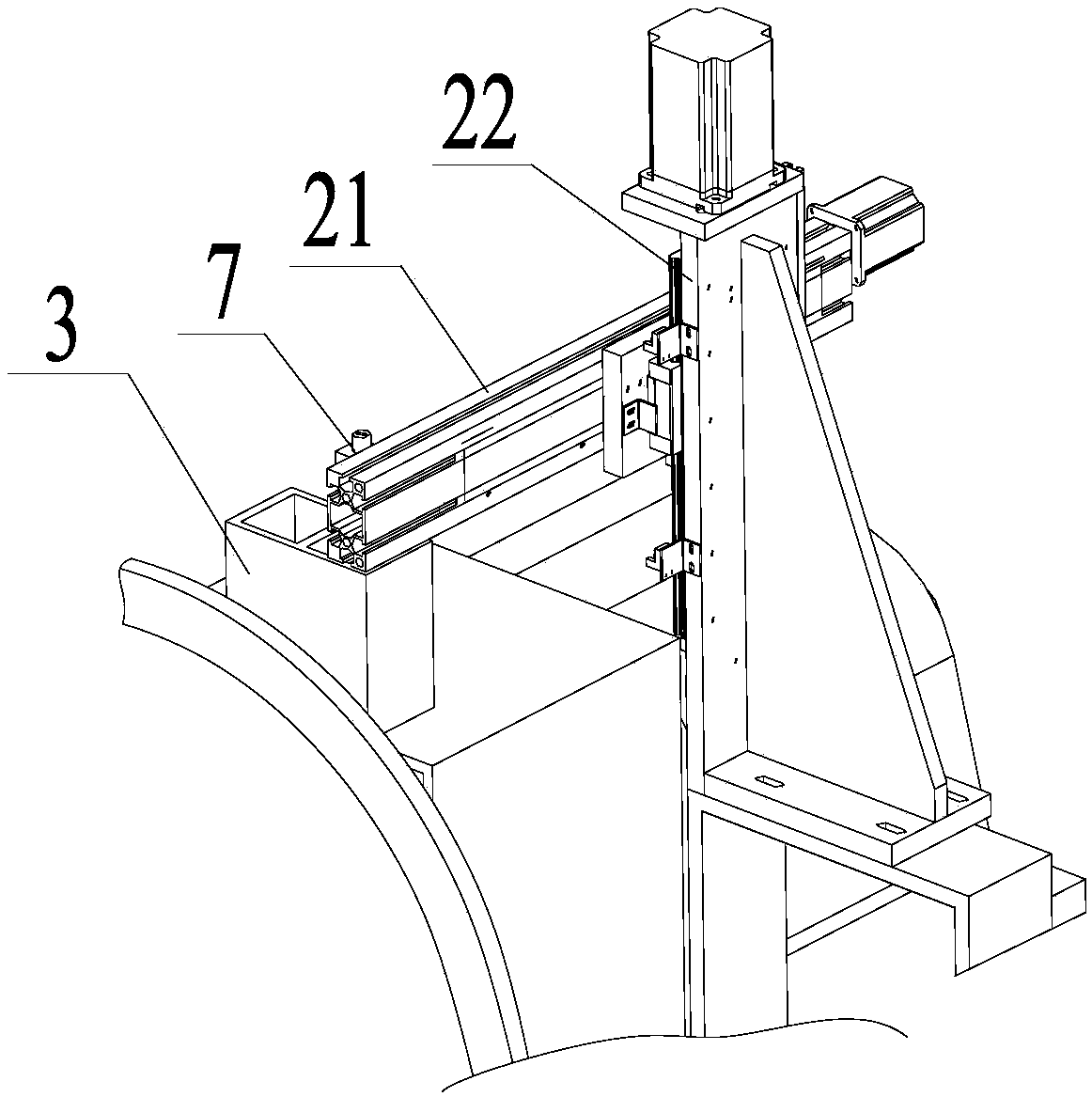

Cloth printing system

PendingCN106739478AAchieve corrective effectPromote repairLiquid surface applicatorsRotary pressesEngineeringBrush device

The invention provides a cloth printing system which comprises a machine frame, a cloth correcting device, a plurality of printing devices, a plurality of printing supports, a printing correction device, a scraper device, a plurality of cloth spreading drying devices, a conveying belt for driving cloth, a glue brushing device for brushing glue on the conveying belt, an ink scrubbing mechanism for scrubbing ink on the conveying belt and a conveying belt cleaning device for cleaning the conveying belt. The cloth printing system can efficiently correct the cloth, ink is added to printing rollers efficiently, working state conversion of a printing component is facilitated, the cloth printing system is flexible to operate and convenient to maintain, the printing rollers are independently driven in each direction, printing deviation in each direction is overcome, efficient and uniform ink scraping is performed on the printing rollers, the cloth is efficiently and fully dried before printing, glue is evenly smeared on the conveying belt, oil stain on the conveying belt is efficiently scrubbed, the conveying belt is efficiently cleaned, printing quality is greatly improved, and the practicality is high.

Owner:泉州市西格玛智能工业机械有限公司

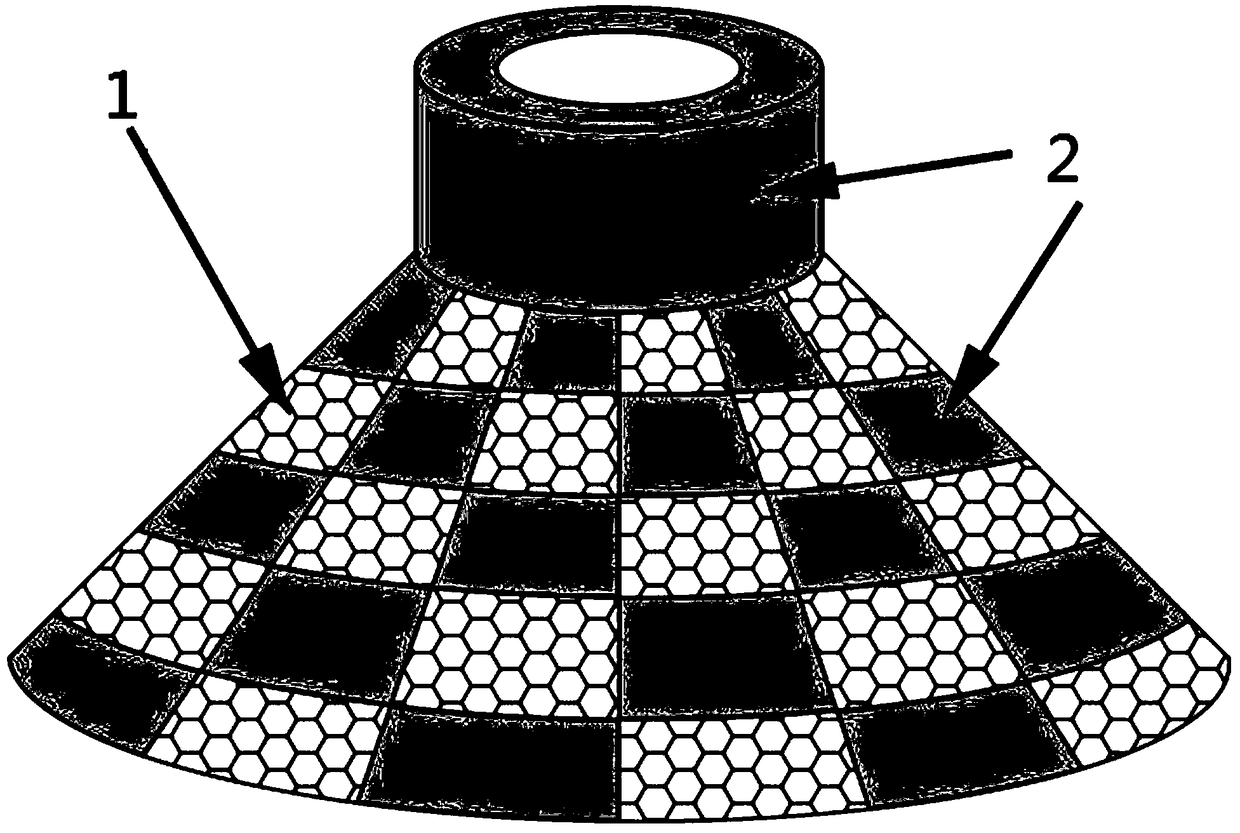

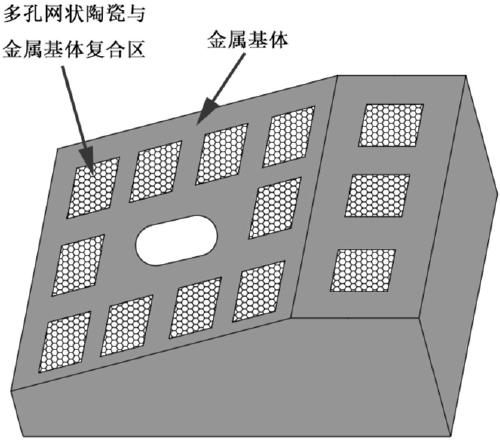

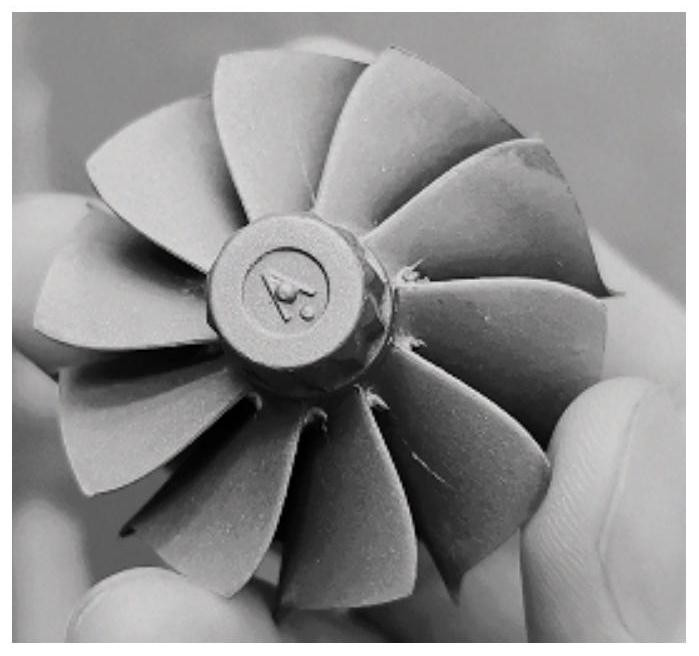

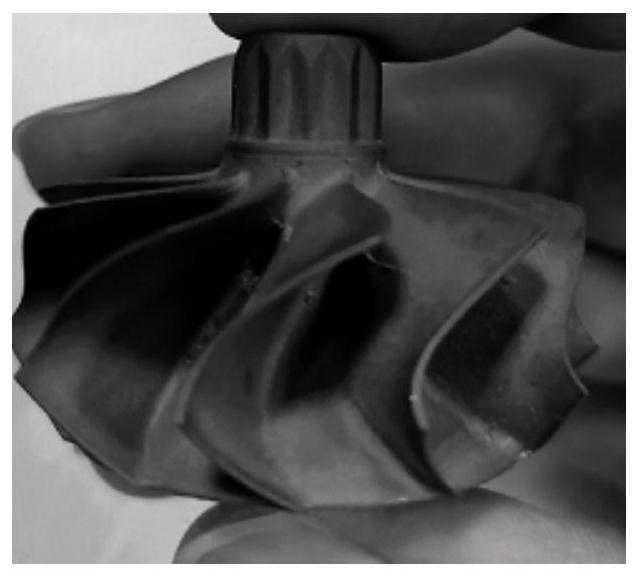

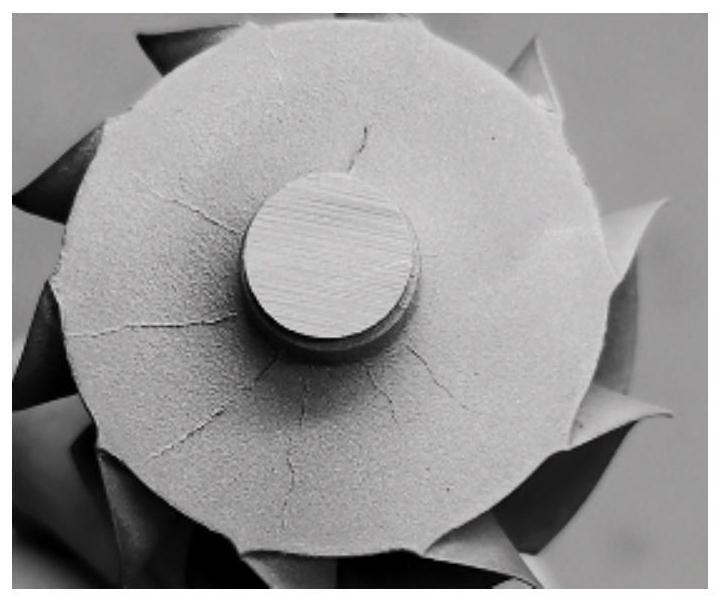

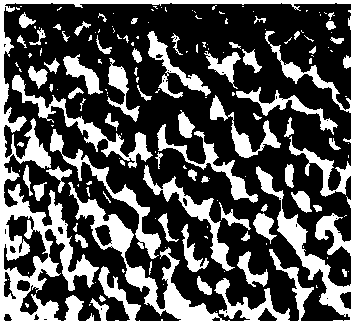

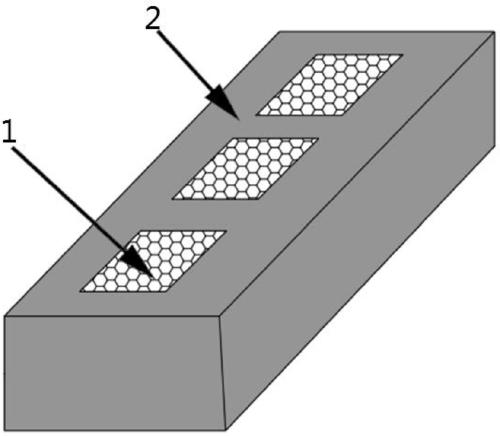

Preparation method of porous meshed ceramic-reinforced steel-based compound broken wall

The invention discloses a preparation method of a porous meshed ceramic-reinforced steel-based compound broken wall. The preparation method comprises the steps that TiB2 powder and an additive are mixed and then added into deioned water to be sufficiently stirred, so that a ceramic pulp suspension is obtained; organic foam is soaked in ceramic pulp, then dried and sintered at high temperature, sothat a porous meshed TiB2 prefabricated part is obtained; finally, a molten steel base material is poured to the prepared porous meshed TiB2 prefabricated part through a cast-penetration process, andcooling and demoling are carried out, so that the porous meshed ceramic-reinforced steel-based compound broken wall is obtained. The compound broken wall prepared according to the method has higher friction resistance and high-temperature resistance, enhanced strength and toughness and longer service life, and the strength of bonding between a reinforcement phase and a matrix is high.

Owner:XI AN JIAOTONG UNIV +1

Preparation method of porous netty ceramic reinforced steel and iron base composite lining plate

The invention discloses a preparation method of a porous netty ceramic reinforced steel and iron base composite lining plate. After mixing of TiB2+Ti(C, N) powder and additives, de-ionized water is added for fully stirring to prepare ceramic pulp suspension; organic foam bodies are dipped in ceramic pulp; then, the dipped organic foam bodies are dried; porous netty TiB2+Ti(C, N) precast bodies areobtained after high-temperature sintering; finally, steel and iron matrix material metal liquid is cast in the prepared porous netty TiB2+Ti(C, N) precast bodies by adopting a casting permeation process; and the porous netty ceramic reinforced steel and iron base composite lining plate is obtained after cooling and demolding. The friction coefficient of the composite lining plate prepared throughthe method is improved; reinforcement phases are uniformly distributed in a basal body; the strength and the toughness are improved; and the service life is prolonged.

Owner:XI AN JIAOTONG UNIV +1

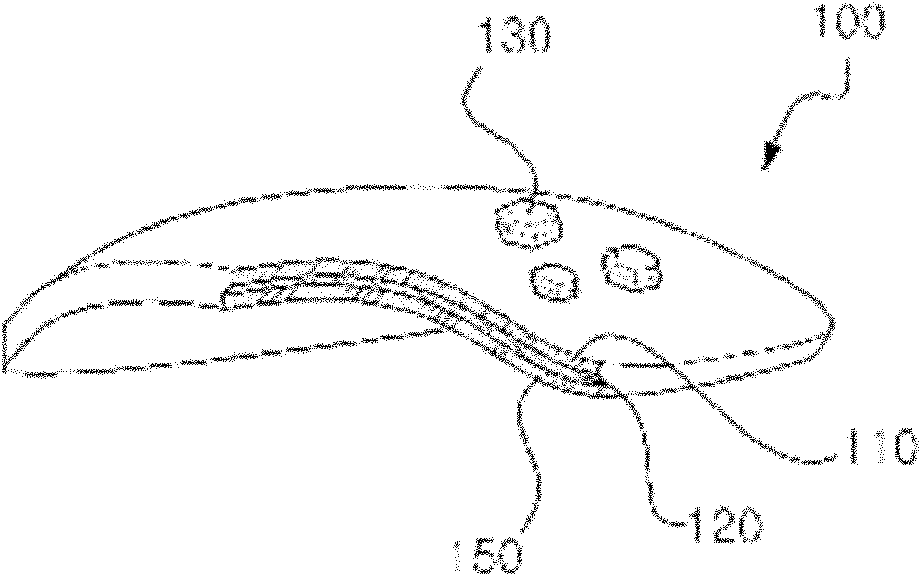

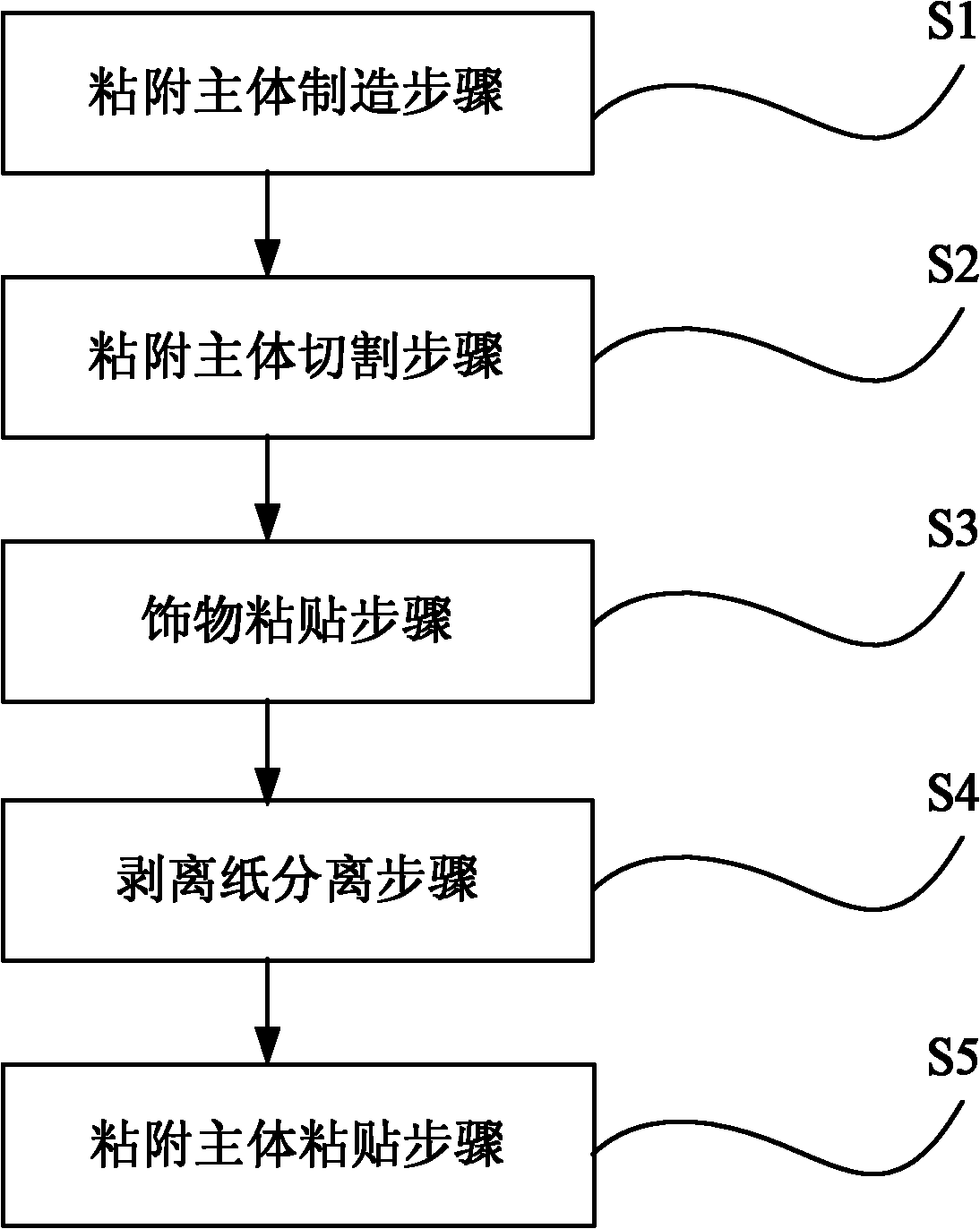

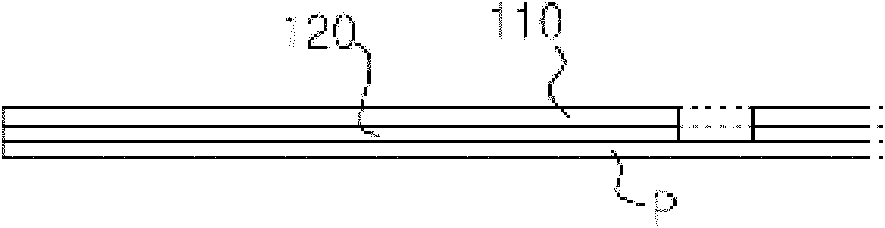

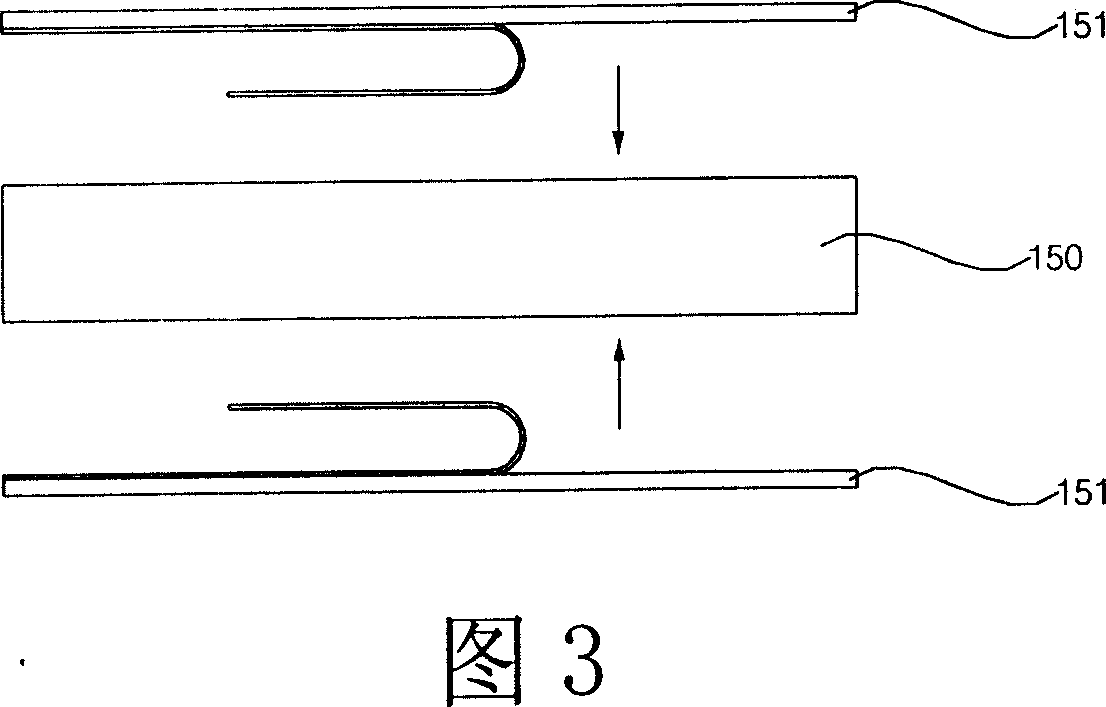

Artificial nail and fabrication method thereof

InactiveCN102068106AShorten the timeShorten production timeManicure/pedicureAdditive ingredientUltimate tensile strength

The invention relates to an artificial nail on which stereoscopic decorations are struck. According to the invention, the artificial nail consists of an adhesive body, the stereoscopic decorations and a basal artificial nail body; the adhesive body consists of a flexible flat film layer and an adhesive layer with adhesive ingredient on both sides, and the adhesive layer is stuck on the lower surface of the film layer; the stereoscopic decorations are stuck on the upper surface of the adhesive body by a decoration-sticking device operating according to a set track; and the basal artificial nail body is shaped like a nail, and the flat adhesive body with the stereoscopic decorations is stuck on the upper surface of the curved basal artificial nail body. The stereoscopic decorations are stuck on the basal artificial nail body of the artificial nail with the stereoscopic decorations with constant adhesive strength, and moreover, the sticking positions are in consistency. Compared with manual operation, the invention can shorten the stereoscopic decoration-sticking time, so that the fabrication time of the artificial nail with the stereoscopic decorations can be shortened. The invention also relates to a fabrication method for the artificial nail.

Owner:天津珍熙美容实业有限公司

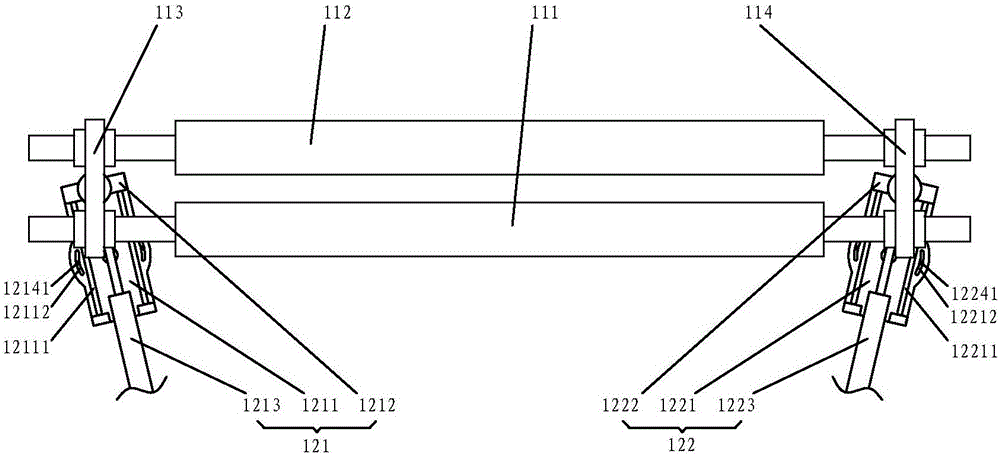

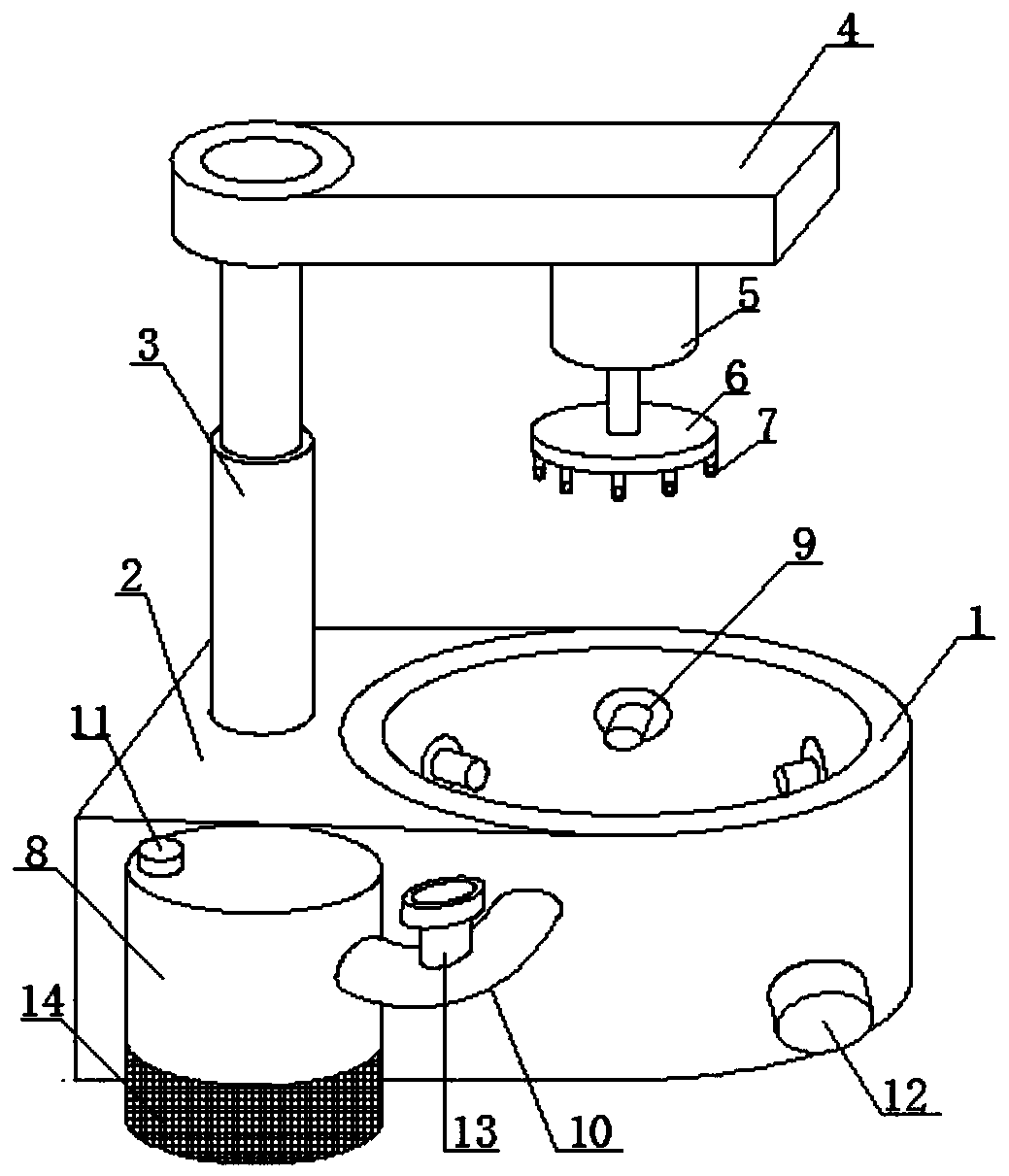

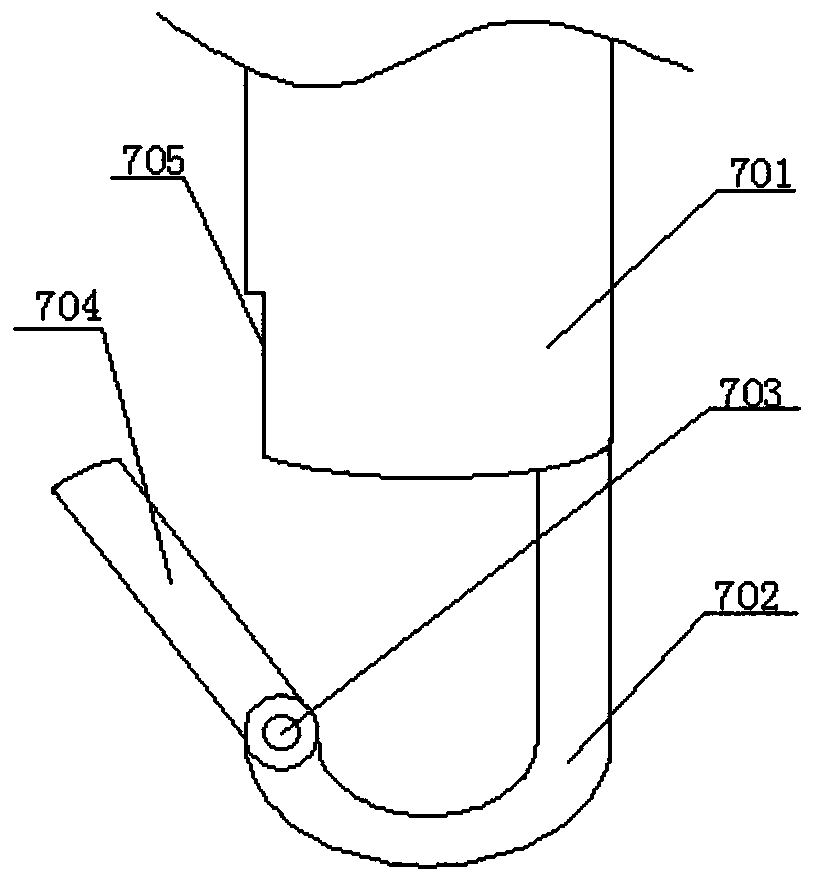

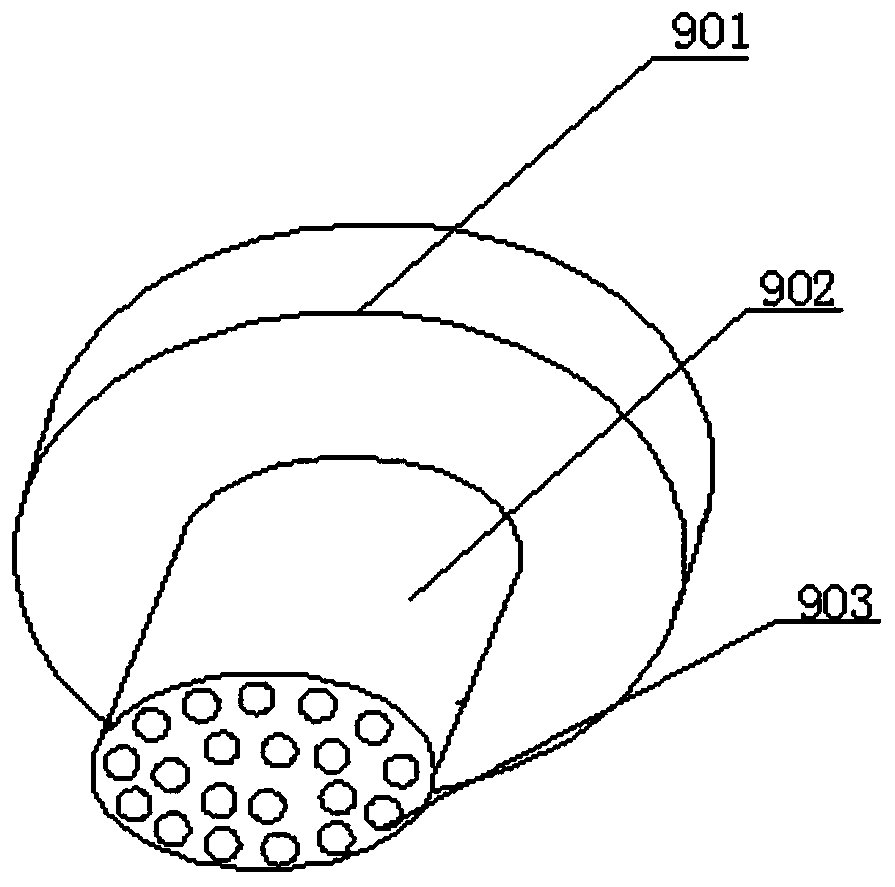

Full-automatic crystalline silicon solar cell quality testing machine

ActiveCN106328553ANo pollutionQuality assuranceSemiconductor/solid-state device testing/measurementSilicon solar cellElectric control

The invention discloses a full-automatic crystalline silicon solar cell quality testing machine. The full-automatic crystalline silicon solar cell quality testing machine includes a machine table, an electric control device, a driving mechanism, a detection table, an adhesive tape fixing device, an adhesive tape pressing wheel mechanism and a cutter; the top surface of the machine stage is provided with a mounting plate; an elongated through hole is formed in the mounting plate; the detection table passes through the elongated through hole; an elongated hole is formed in the top surface of the machine table; the driving mechanism is connected with the bottom surface of the detection table through the elongated hole so as to drive the detection table to move on the machine table; the adhesive tape fixing device, the cutter and the adhesive tape pressing wheel mechanism are all fixed on the mounting plate; the adhesive tape fixing device is mainly composed of a rotation shaft and a rotation wheel; the adhesive tape pressing wheel mechanism comprises a lifting pressing wheel; a gap is left between the pressing wheel and the detection table; the height of the gap is adjustable; and the cutter is located between the rotation wheel and the pressing wheel. With the full-automatic crystalline silicon solar cell quality testing machine of the invention adopted, automatic detection of the printing effect of silicon wafer grid lines to be detected can be realized; detection results are accurate; detection efficiency can be improved; time and effort can be saved; and the quality of silicon wafers can be ensured.

Owner:JA SOLAR

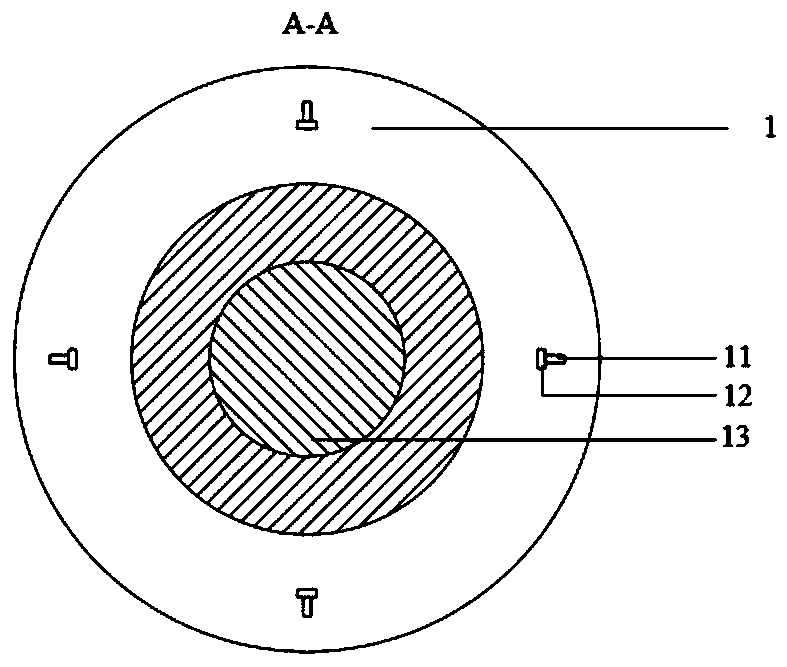

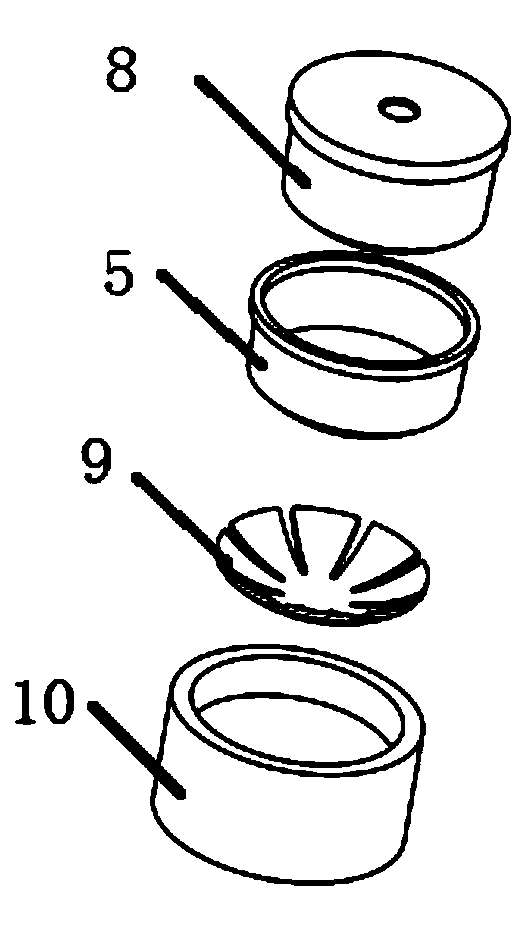

Static cracking agent radial expansion pressure test method

InactiveCN109900409AEasy to pastePaste evenlyApparatus for force/torque/work measurementMeasuring instrumentEngineering

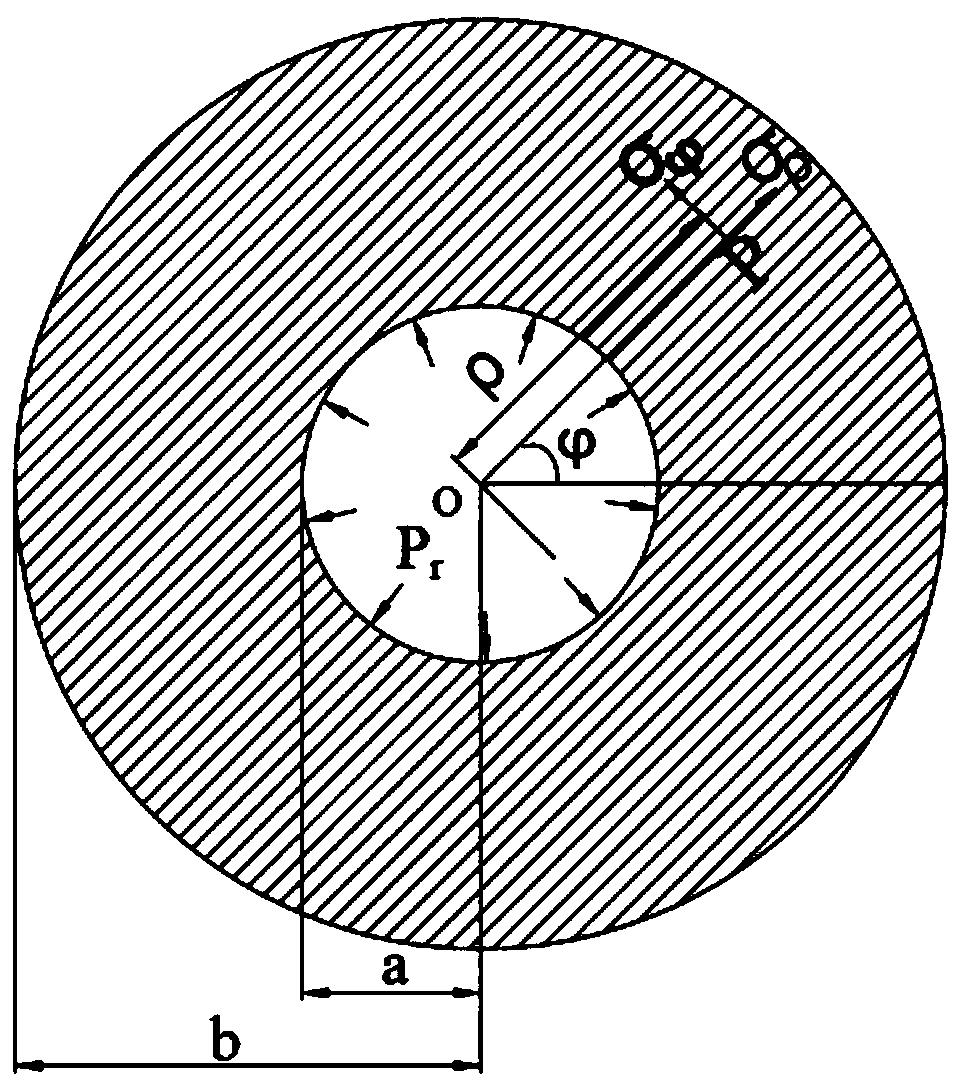

The invention relates to a static cracking agent radial expansion pressure test method. According to the method, a metal material is adopted to make a metal cylinder with a reversed-T-shaped upper end; four measuring points are symmetrically calibrated on the mesa of the cylinder; a radial strain gauge, a tangential strain gauge and a temperature sensor are bonded to each measuring point, whereinthe strain gauges and the temperature sensor are connected with a strain measuring instrument through a wire; the cylinder is filled with a static cracking agent and thereafter is sealed with an upperend cover and a lower end cover; the radial strain and tangential strain of the four measuring points are recorded through an offline and on-line collection mode; after collection is performed for 24hours, and the radial strain and tangential strain measured by the four measuring points are averaged respectively; and maximum average values, together with the outer radius, inner radius, elastic modulus and Poisson's ratio of the metal cylinder, is substituted into a given formula, so that the radial expansion pressure of the static cracking agent is calculated. According to the static cracking agent radial expansion pressure test method of the invention, the mesa of the metal cylinder is adopted to test expansion pressure, the strain gauges can be evenly bonded easily, and therefore, measurement error can be reduced; the temperature of the measuring points is low, so that normal-temperature strain gauges with low cost can be used; and the measured radial expansion pressure used as theexpansion pressure of the static cracking agent at a production site, is more accurate.

Owner:NORTHEASTERN UNIV

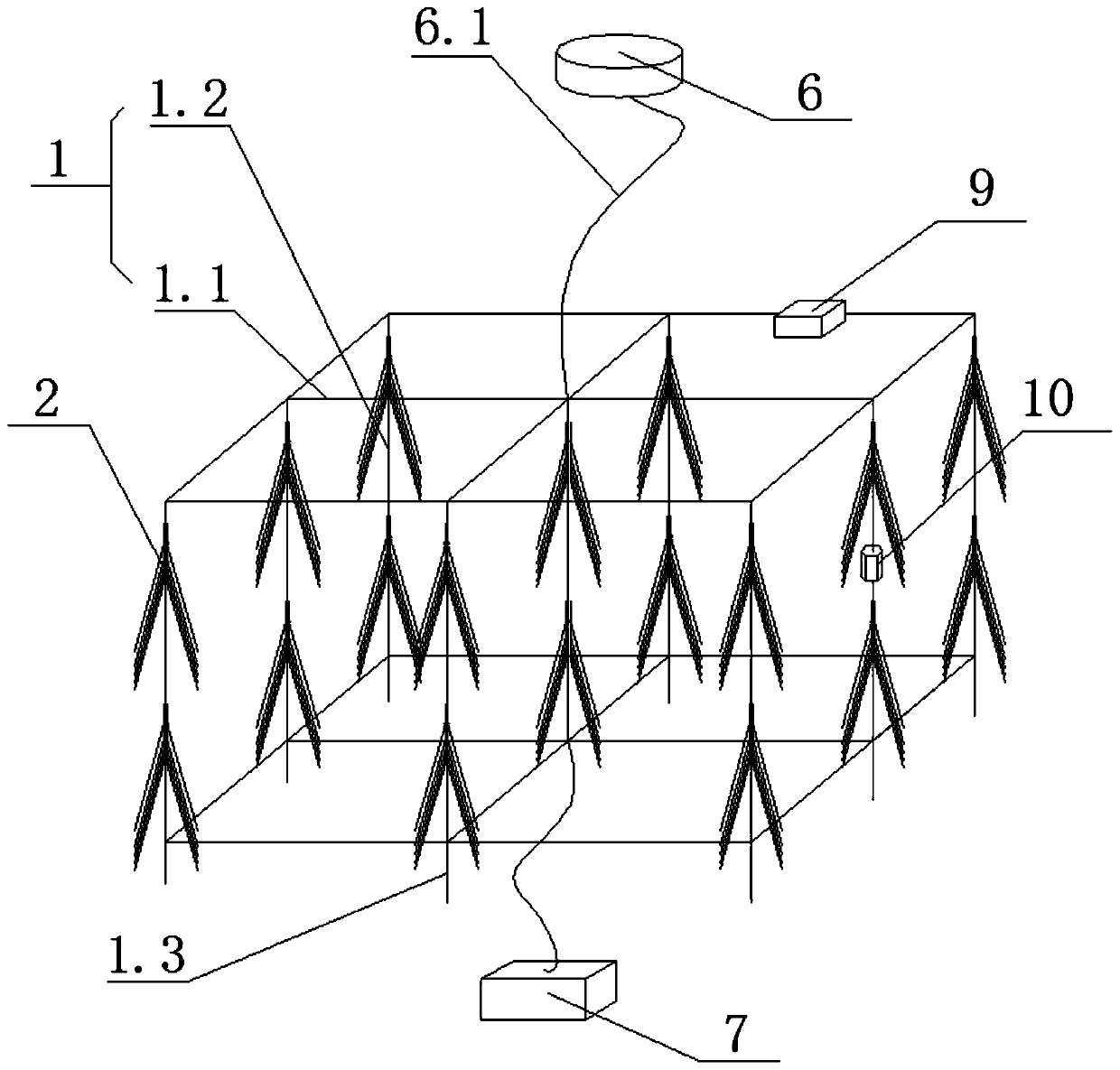

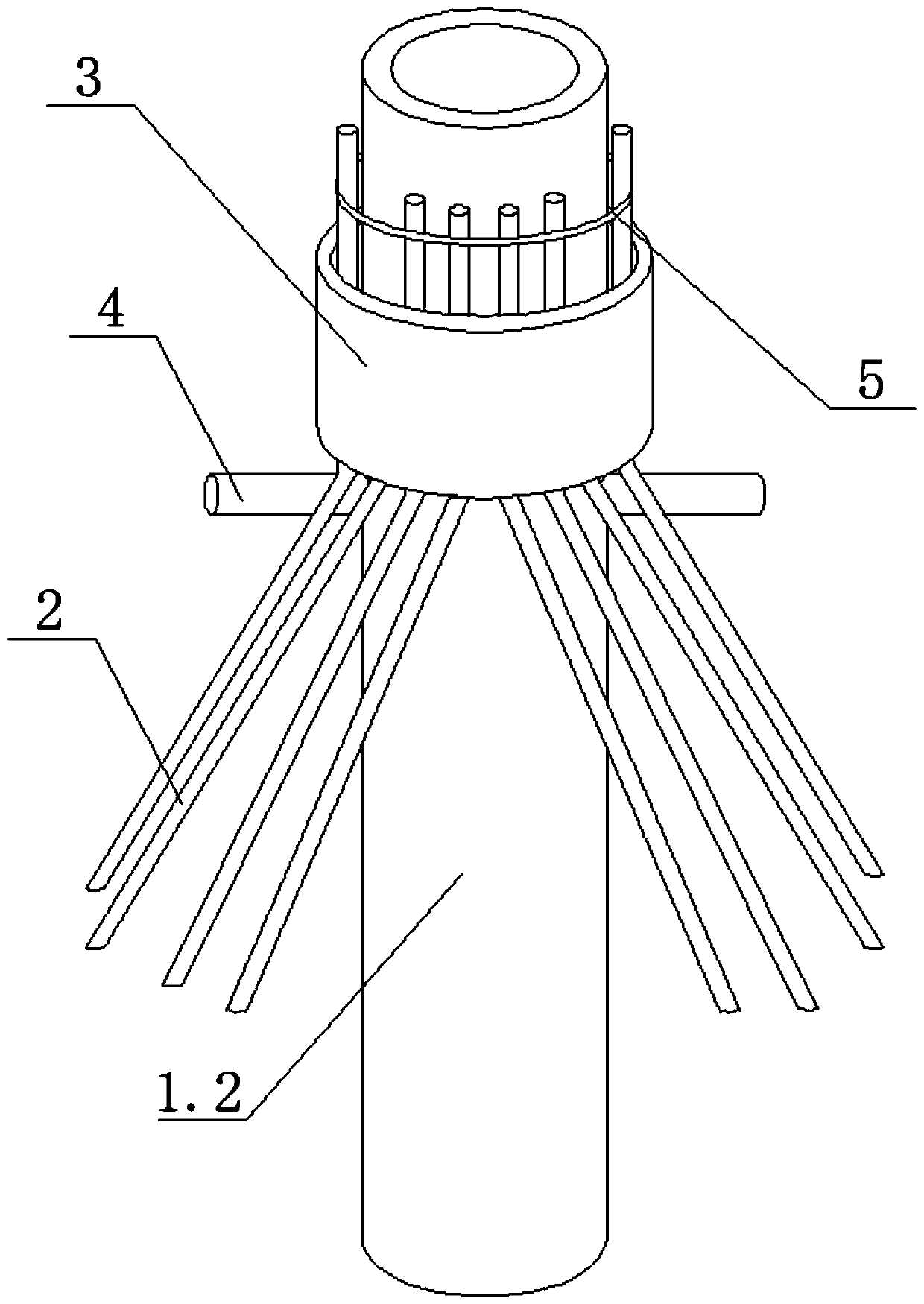

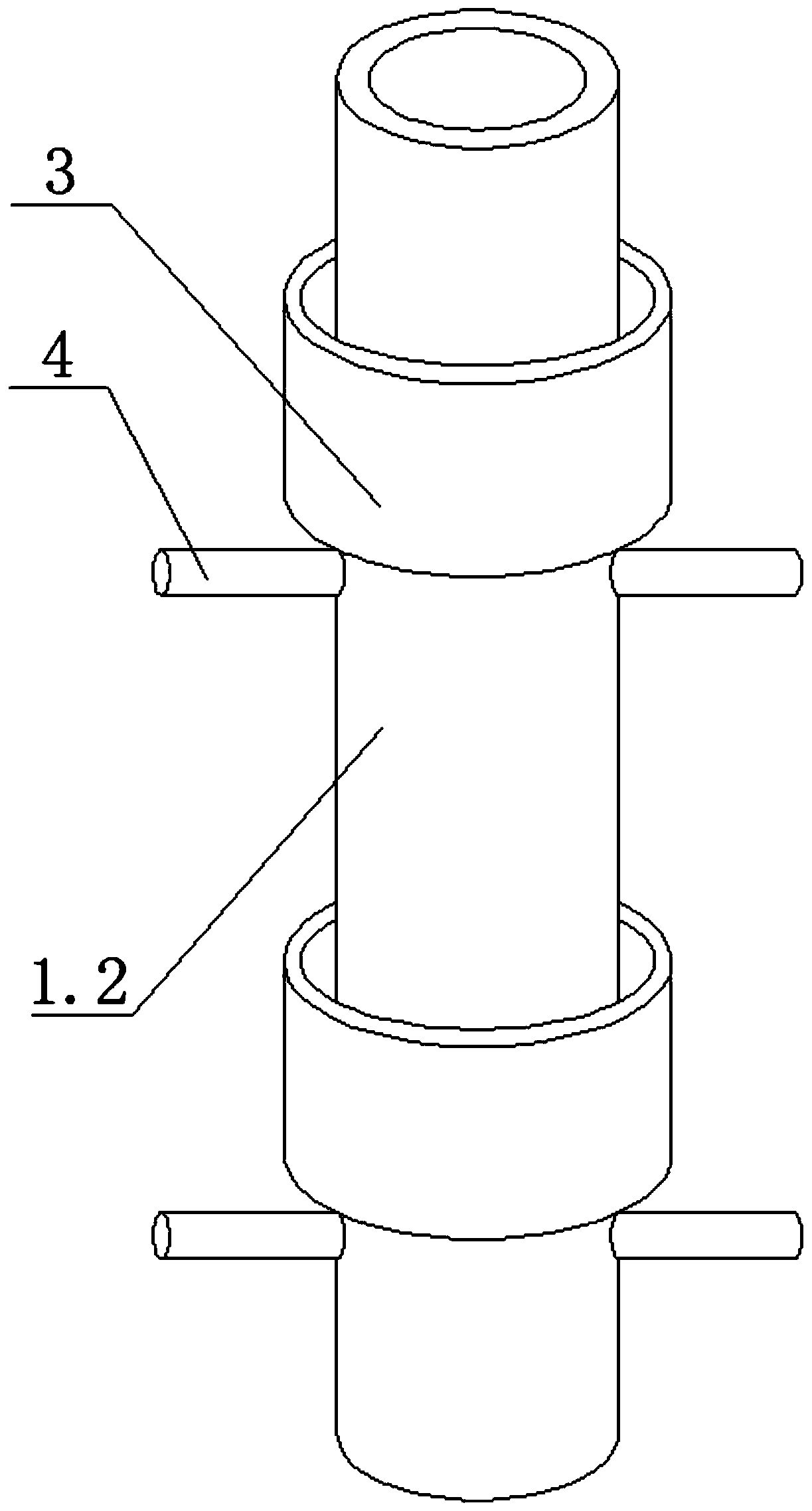

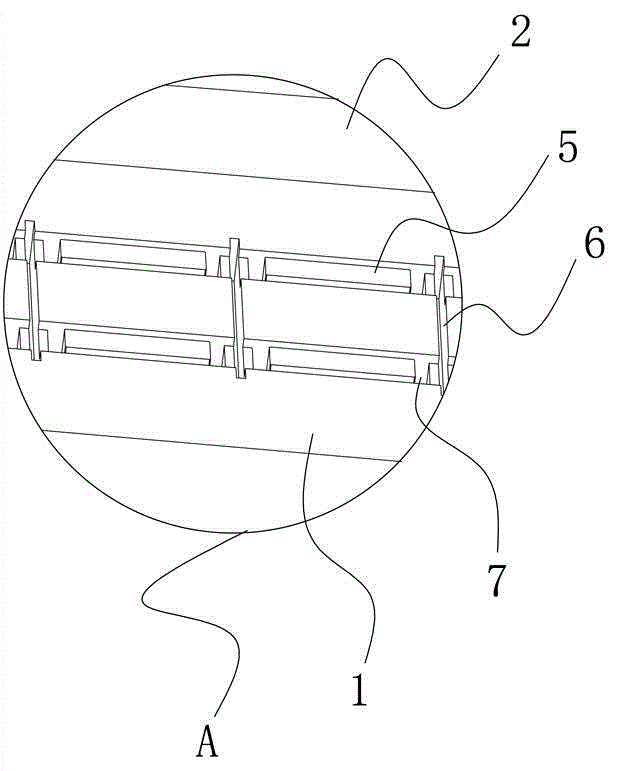

Straw fish shelter and preparing method thereof

PendingCN110250067AImprove corrosion resistanceImprove crack resistanceClimate change adaptationReed/straw treatmentContact timeEngineering

The invention discloses a straw fish shelter and a preparing method thereof. The fish shelter comprises a frame and straw arranged on the frame. The frame comprises a cuboid or cubic frame body. The frame body is composed of a plurality of beams and stand columns perpendicularly connected with one another. The straw is rolled on the stand columns. Each stand column is provided with multiple bundles of straw sequentially arrayed in the length direction of the stand column. One end of each bundle of straw is bound to the corresponding stand column, and the other end of the bundle of straw is naturally dispersed around. The nutrients and effective area of the straw are sufficiently used; since one end of each bundle of straw is dispersed in space, the occupied space is large, more algae and shells can be attached, and the unit benefits are improved; meanwhile, due to the structure, the ocean current of an ocean can be changed, the flow velocity of the ocean is reduced in the structure, and therefore the contact time between the fish shelter and the straw is prolonged, and the fish shelter is low in weight, simple in structure and easy to repair.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG +1

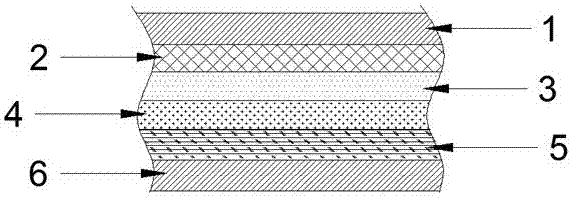

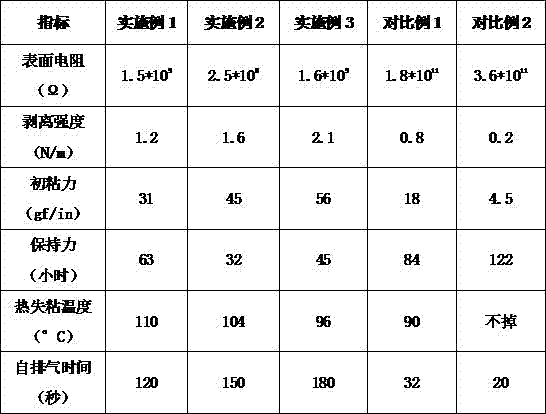

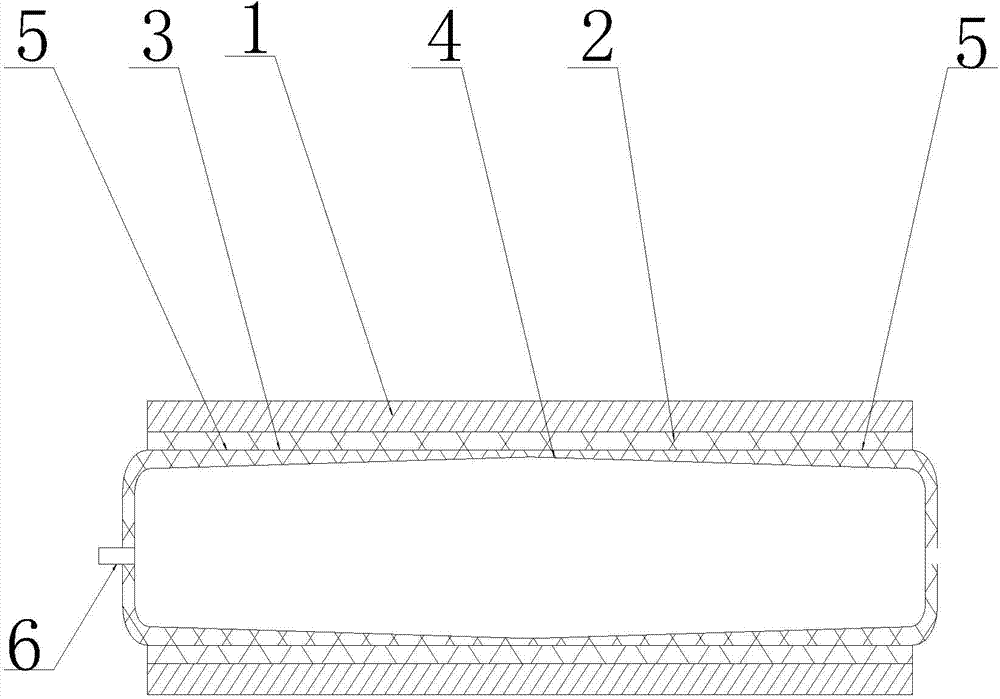

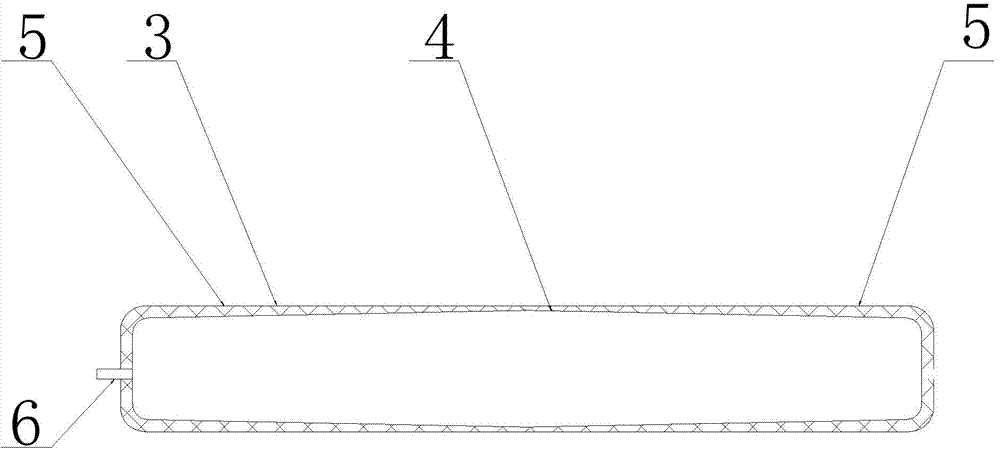

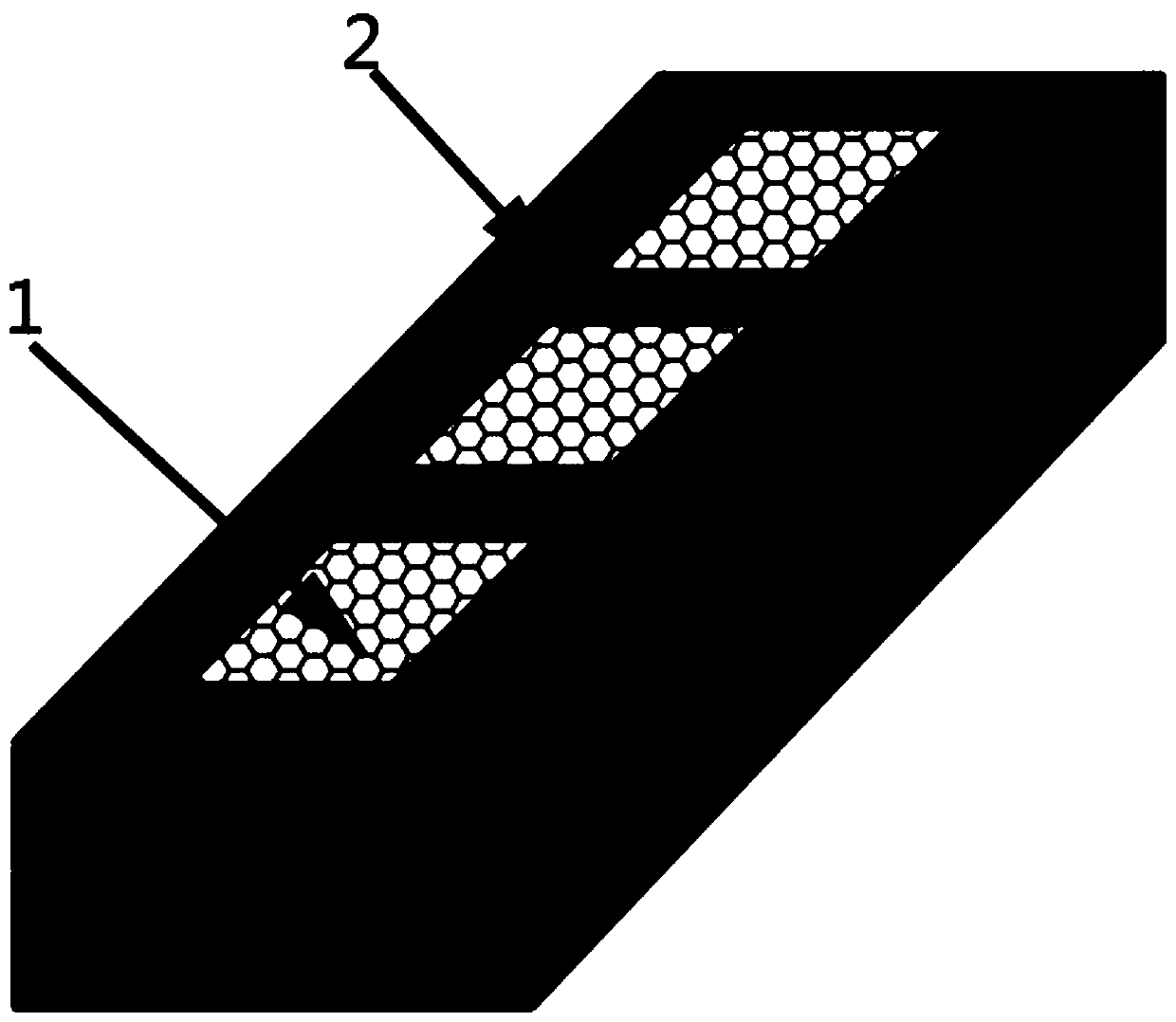

Thermally induced viscosity-decreasing meshed protective film

ActiveCN107160746AThermally induced viscosity loss hasPaste evenlySynthetic resin layered productsMacromolecular adhesive additivesTectorial membranePolyethylene terephthalate

The invention discloses a thermally induced viscosity-decreasing meshed protective film which comprises a PET (Polyethylene Terephthalate) film layer, a PE (Polyethylene) spraying film mesh layer, a silicone oil layer, a glue layer, a conductive layer and a PET base material layer which are arranged from top to bottom, wherein the glue layer is a modified polyacrylate glue layer. The protective film disclosed by the invention has a function of automatic dropping after heating and does not need to be stripped manually or by a robot. In addition, the protective film has a network structure, the mesh surface has an automatic exhaust effect during use, the protective film can be completely flushed, and residual glue is avoided after the film is stripped.

Owner:惠州市科域新材料科技有限公司

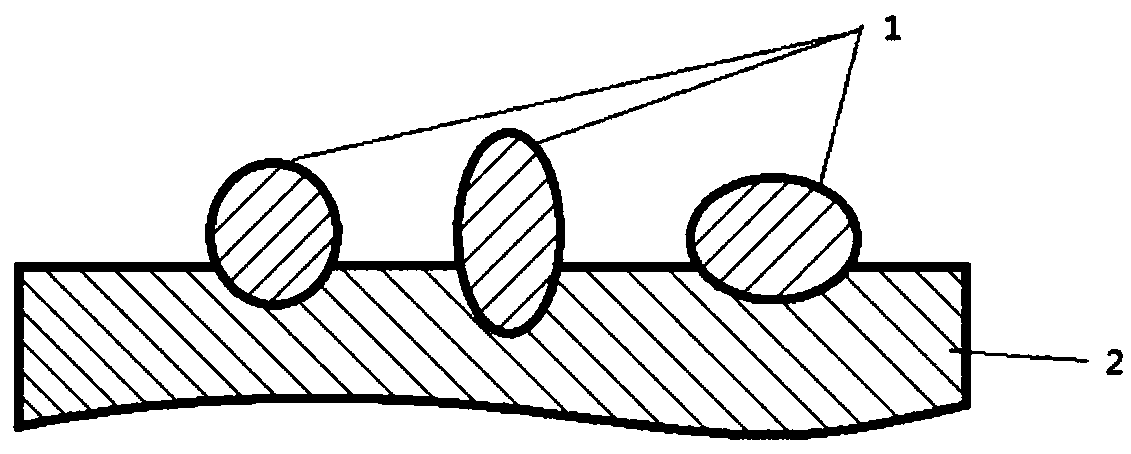

Process for bonding metal circular tube rubber lining

The invention relates to a process for bonding a metal circular tube rubber lining. The process for bonding the metal circular tube rubber lining comprises the following steps of carrying out sand blasting on the inner wall of a metal circular tube; brushing base gel on the inner wall, drying and then brushing a binding agent; placing a prefabricated cylindrical rubber plate into the metal circular tube; placing a cylindrical air bag with two sealed ends into the cylindrical rubber plate, wherein the wall thickness of the air bag from a middle thin-wall part to the walls at two ends is gradually increased, and one end is connected to an air valve nozzle; inflating air in the air bag through the air valve nozzle, wherein the air bag is expanded, and the diameter of the middle thin-wall part is increased firstly to tightly press the cylindrical rubber plate and the metal circular tube; and gradually expanding to press two ends of the metal circular tube through the air bag along with the inflating process. Through the process for bonding the metal circular tube rubber lining, the air bag having two sealed ends and the wall thickness which is gradually increased from the middle to two ends is adopted; after the air valve nozzle connected to one end is inflated, a process of applying pressure to the rubber plate from the middle to two sides and from inside to outside is realized, so that the rubber plate is evenly bonded to the inner wall of a steel tube; the bonding quality is improved; the labor efficiency is improved.

Owner:YANTAI XINHAI MINING MACHINERY

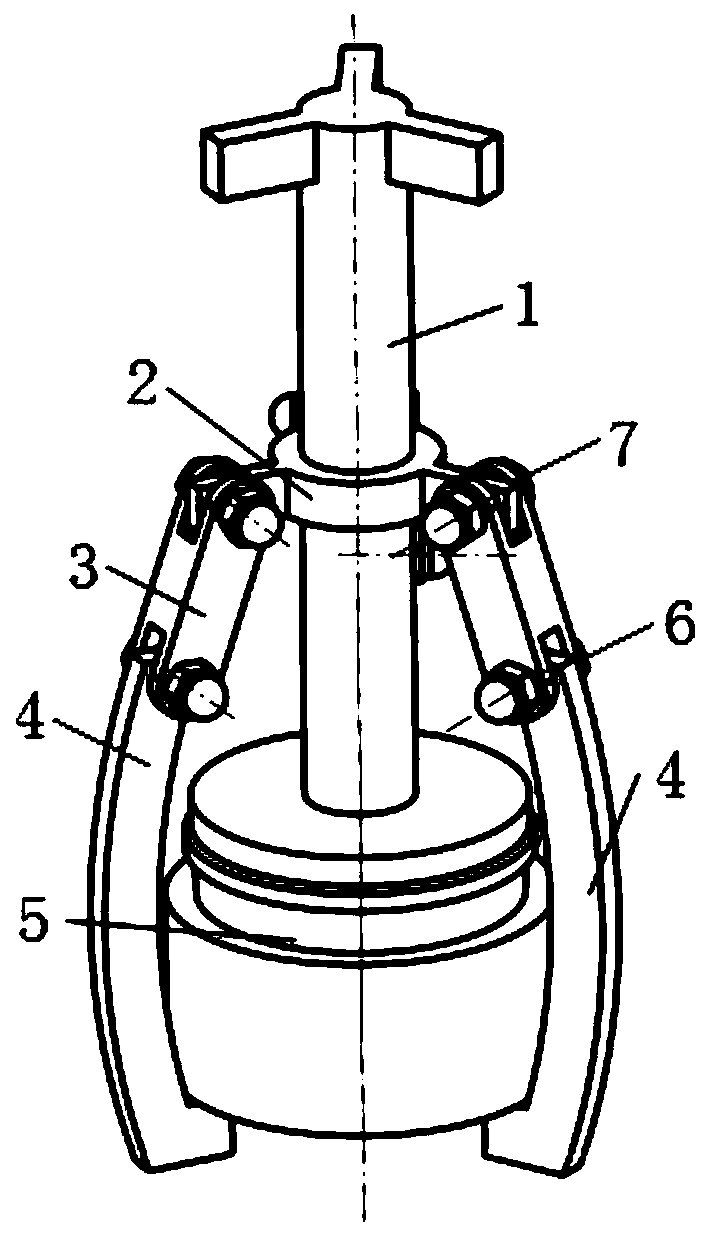

Auxiliary pasting device for polishing pad

InactiveCN110900416APaste evenlyImproved noodle qualityGrinding machine componentsPolishing machinesPolishingMaterials science

The invention discloses an auxiliary pasting device for a polishing pad. The device comprises a jacking piece and a fixing seat, wherein a jacking head used for sleeving a polishing head is arranged at one end of the jacking piece, the fixing seat is used for being sleeved with an outer wall of the polishing head and positioning the polishing pad, an outer wall of the jacking piece is sleeved witha positioning piece, the positioning piece is used for being matched with the fixing seat to limit movement of the fixing seat in the direction perpendicular to the axis of the jacking piece, the fixing seat comprises a clamping face used for being matched with the polishing head, and the clamping face makes contact with the polishing pad to be extruded when the jacking head is jacked, so the polishing head and the polishing pad are extruded and pasted. The device is advantaged in that when the jacking piece drives the jacking head to move in the axial direction, the polishing pad makes contact with the clamping face of the fixing seat to be extruded, pasting of the polishing pad and the polishing head is achieved, the polishing pad is extruded and pasted through cooperation of the clamping face and the polishing head, pasting is uniform, the surface quality is improved, moreover, continuous pressing with two hands is not needed, and pasting efficiency is improved.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Device for propelling and extruding patching of strain sheet and using method thereof

Owner:济源市超光传感器系统工程有限公司

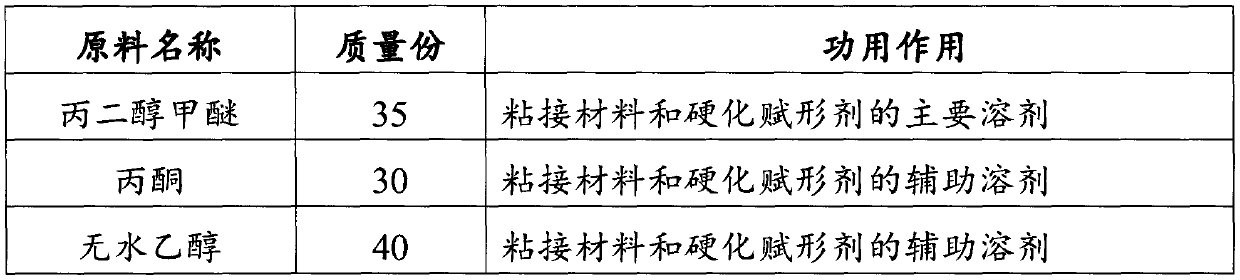

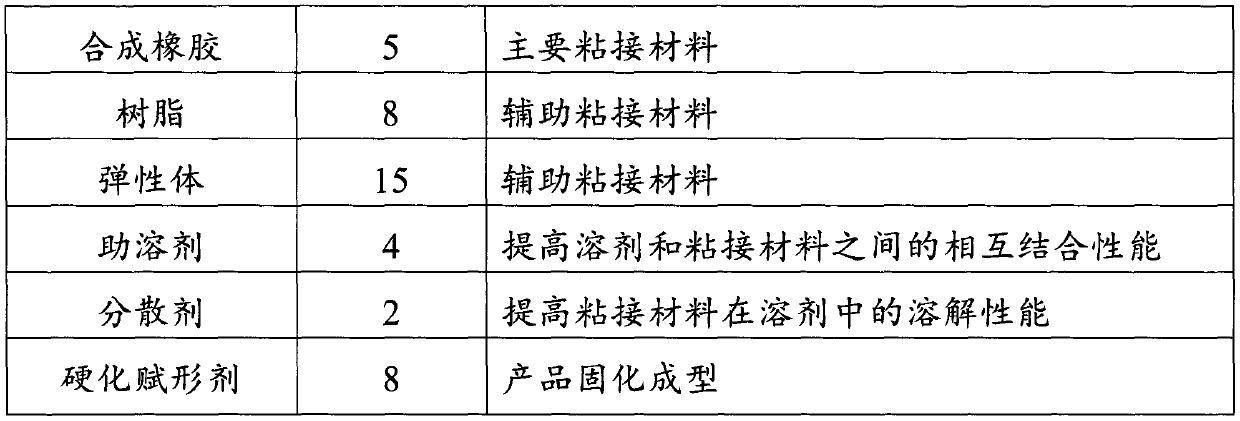

Preparation method of all-purpose glue stick

InactiveCN107556939AWide range of usesPaste evenlyNon-macromolecular adhesive additivesEster polymer adhesivesSolventChemistry

The invention discloses a preparation method of an all-purpose glue stick. The all-purpose glue stick comprises the following raw materials in parts by mass: 25 to 40 parts of propylene glycol methylether; 25 to 35 parts of acetone; 30 to 50 parts of absolute ethyl alcohol; 2 to 8 parts of synthetic rubber; 3 to 10 parts of resin; 10 to 20 parts of elastomers; 1 to 5 parts of a cosolvent; 1 to 3parts of a dispersing agent; 5 to 10 parts of hardening excipient. The raw materials are prepared into the all-purpose glue stick in a certain way. Compared with the prior art, the preparation methodhas the advantages that the all-purpose glue stick is extensive in use, environmentally friendly, innocuous, uniform for gluing and multipurpose, and has no waste.

Owner:JIANGSU XINGDA STATIONERY GRP

Cloth processing device

InactiveCN106758427AImprove processing qualityEffective smear distributionTextile decorationMechanical engineeringEngineering

The invention discloses a cloth processing device. The cloth processing device comprises a feeding mechanism, a flattening mechanism, a processing mechanism and a material receiving mechanism, wherein the processing mechanism comprises a compressing assembly, a gluing assembly, a processing platform, a roller seat, an inner roller and an outer roller; the inner roller is arranged in the outer roller and the inner roller and the outer roller coaxially rotate at a differential speed; the flattening mechanism comprises a flattening base, a first flattening roller and a second flattening roller; the feeding mechanism comprises a feeding base, a fifth feeding rolling wheel and a feeding roller; the material receiving mechanism comprises a material receiving base, a material receiving roller and a material receiving motor; the material receiving base is provided with a dust collection motor; an air suction hole of the dust collection motor is aligned to the material receiving roller. The cloth processing device is compact in structure and convenient to use, can be used for rapidly and effectively smearing bright sand powder on cloth, and has high processing efficiency and good processing quality.

Owner:JIAXING WANYUAN FASHION

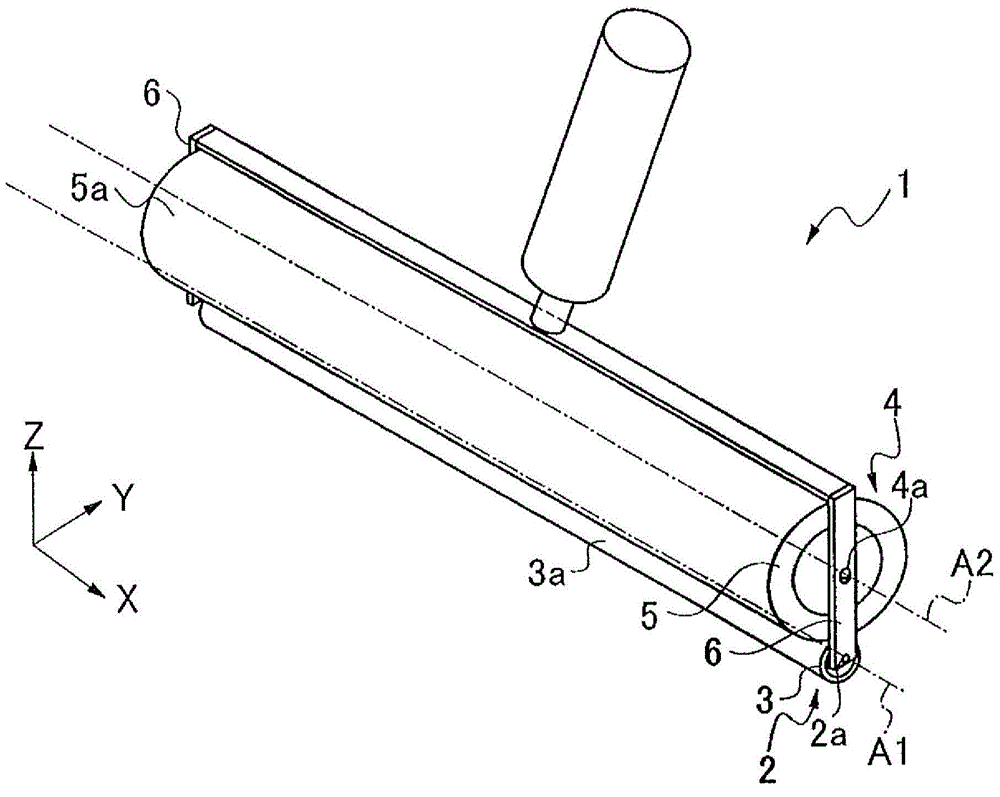

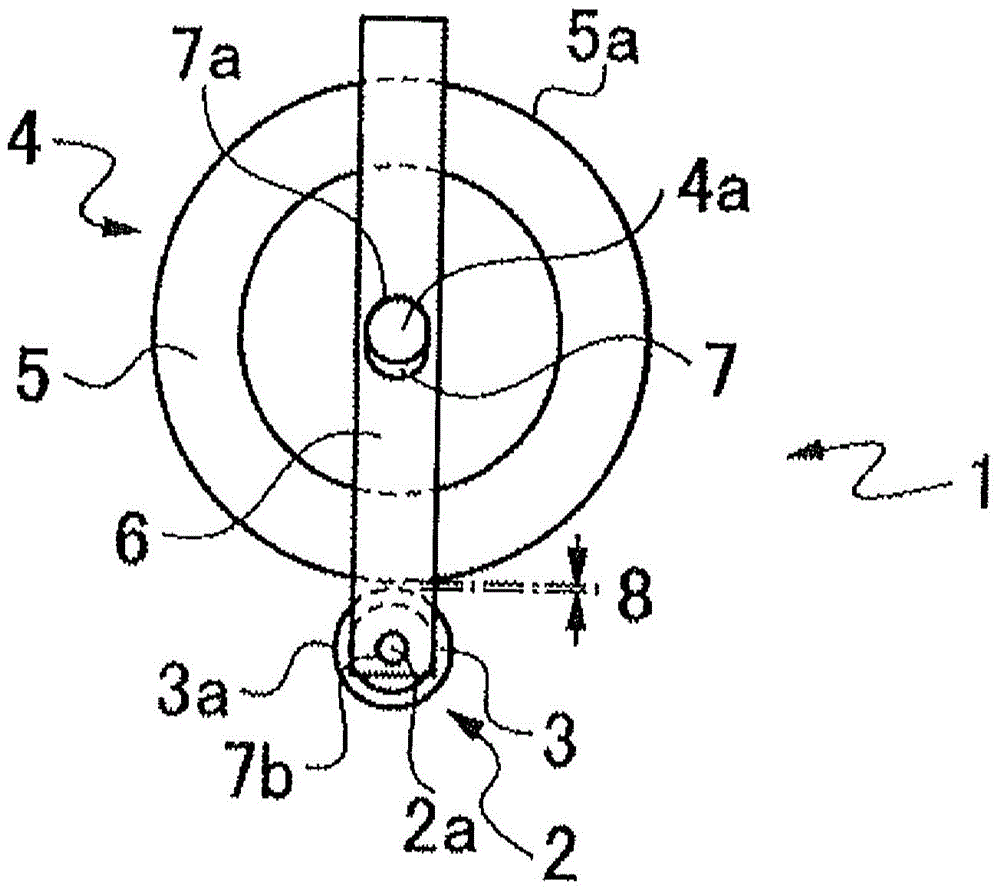

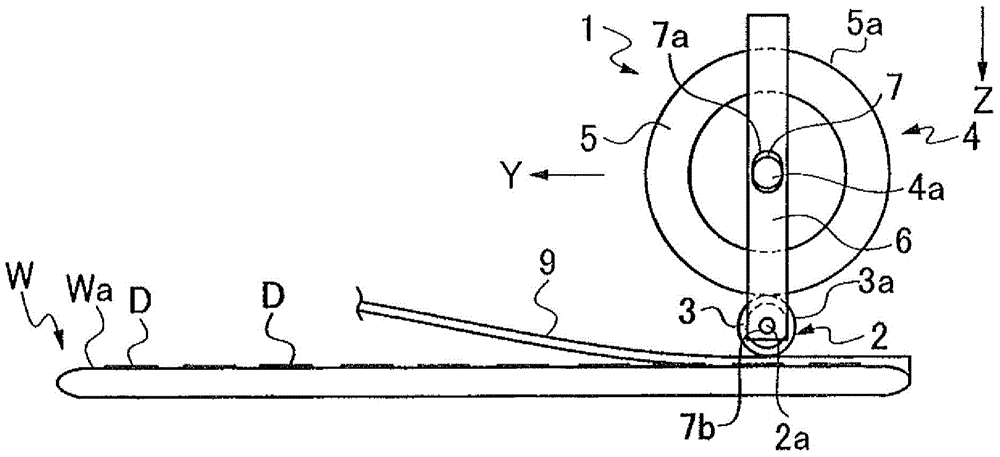

Rollers

InactiveCN103943566AWon't crashAvoid deflectionSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

The invention provides rollers which apply a pressing force uniformly on an object. The rollers comprise a pressing roller (2), a flexible prevention roller (4) having an axial center (A2) in parallel with an axial center (A1) of the pressing roller (2) and having a diameter larger than that of the pressing roller (2), and a connection part (6). The flexible prevention roller (4) is configured to be adjacent to the pressing roller (2) and can press the pressing roller (2) in a state that the periphery (5) of the flexible prevention roller (4) is abutted against the periphery (3) of the pressing roller (2). The connection part (6) connects the pressing roller and the flexible prevention roller. Thus, compared with one roller, the rollers are improved in rigidity and prevent slight flexure of the pressing roller. The pressing roller can apply a pressing force on a bonding belt, so that a bonding belt (9) can be adhered to a plate-shaped object (W) when bubbles are formed between the bonding belt (9) and a plate-shaped object (W).

Owner:DISCO CORP

Mirror frame pulp wrapping machine

PendingCN110743726APaste evenlyIncrease the speed of solidificationPretreated surfacesLiquid spraying apparatusEngineeringRotating disc

The invention provides a mirror frame pulp wrapping machine, and relates to the technical field of mirror frame processing. The mirror frame pulp wrapping machine comprises a pulp wrapping bath, an equipment table is fixedly welded to the left side of the pulp wrapping bath, the upper surface of the equipment table is fixedly provided with a telescopic rod in a welded mode, the upper end of the telescopic rod is fixedly connected with a servo motor through a rotating plate, the output end of the servo motor is fixedly connected with a hook through a rotating disc, a pulp barrel is arranged onthe side face of the equipment table, a booster pump is arranged on the lower surface of the pulp barrel, the pulp barrel communicates with the pulp wrapping bath through a material guiding pipe, anda nozzle is fixedly connected to the inner wall of the pulp wrapping bath. According to the mirror frame pulp wrapping machine, the booster pump and the servo motor are started, so that a pulp machinesends pulp to a material feeding pipe, the pulp is finally sprayed out from the nozzle through the material guide pipe, and pulp wrapping is carried out on the surface of a mirror frame; and moreover, the rotating disc starts to rotate, so that the pulp is uniformly wrapped around the outer surface of the mirror frame, the mirror frame moves relative to air in the rotating process, then the solidification speed of pulp wrapping is accelerated, and the pulp wrapping efficiency is improved.

Owner:江苏森宝节能材料有限公司

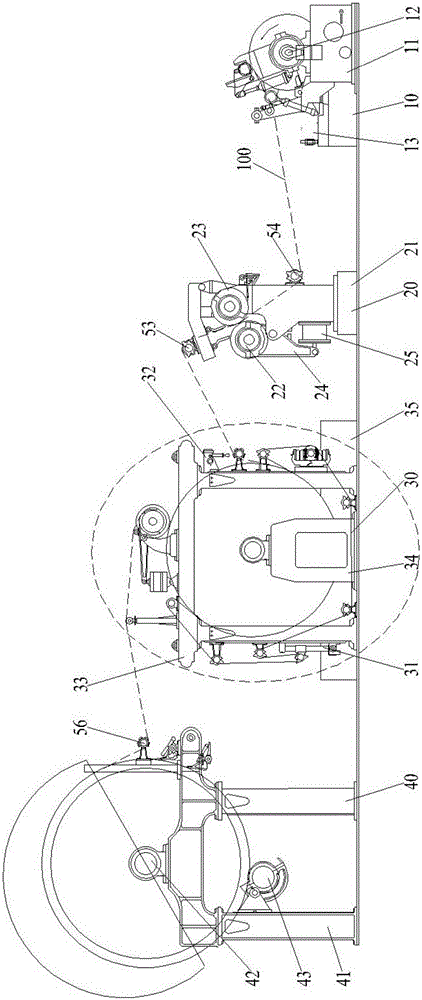

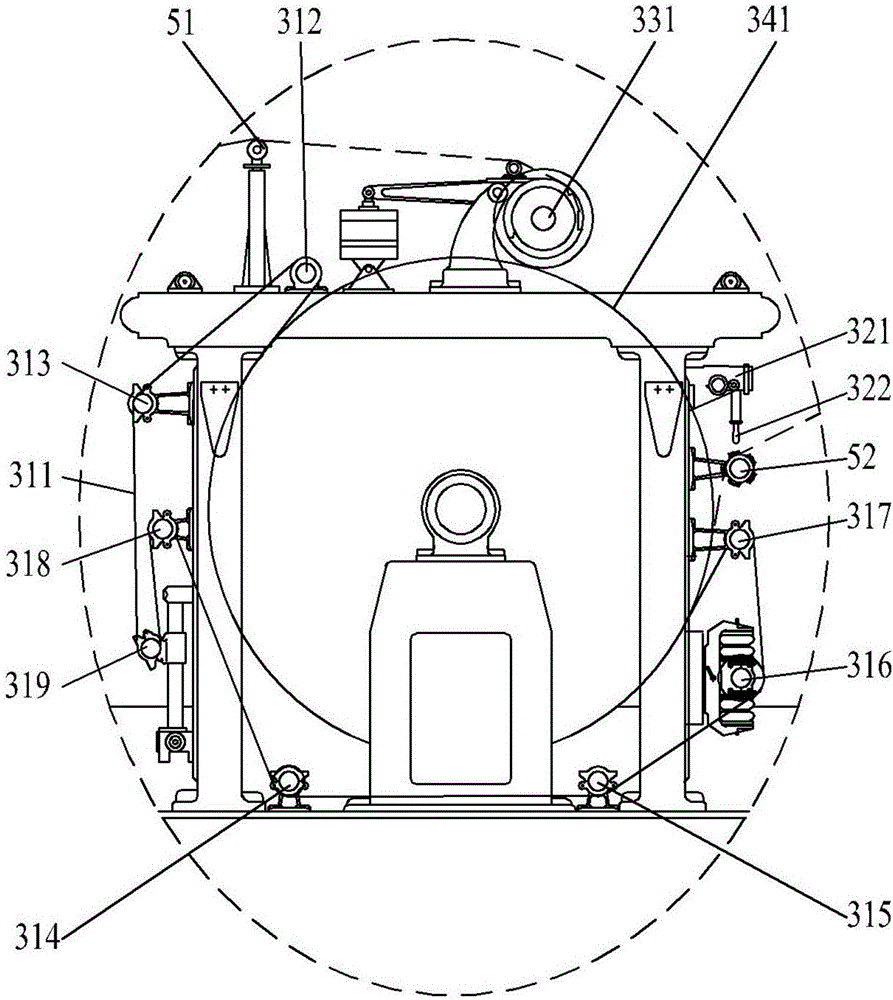

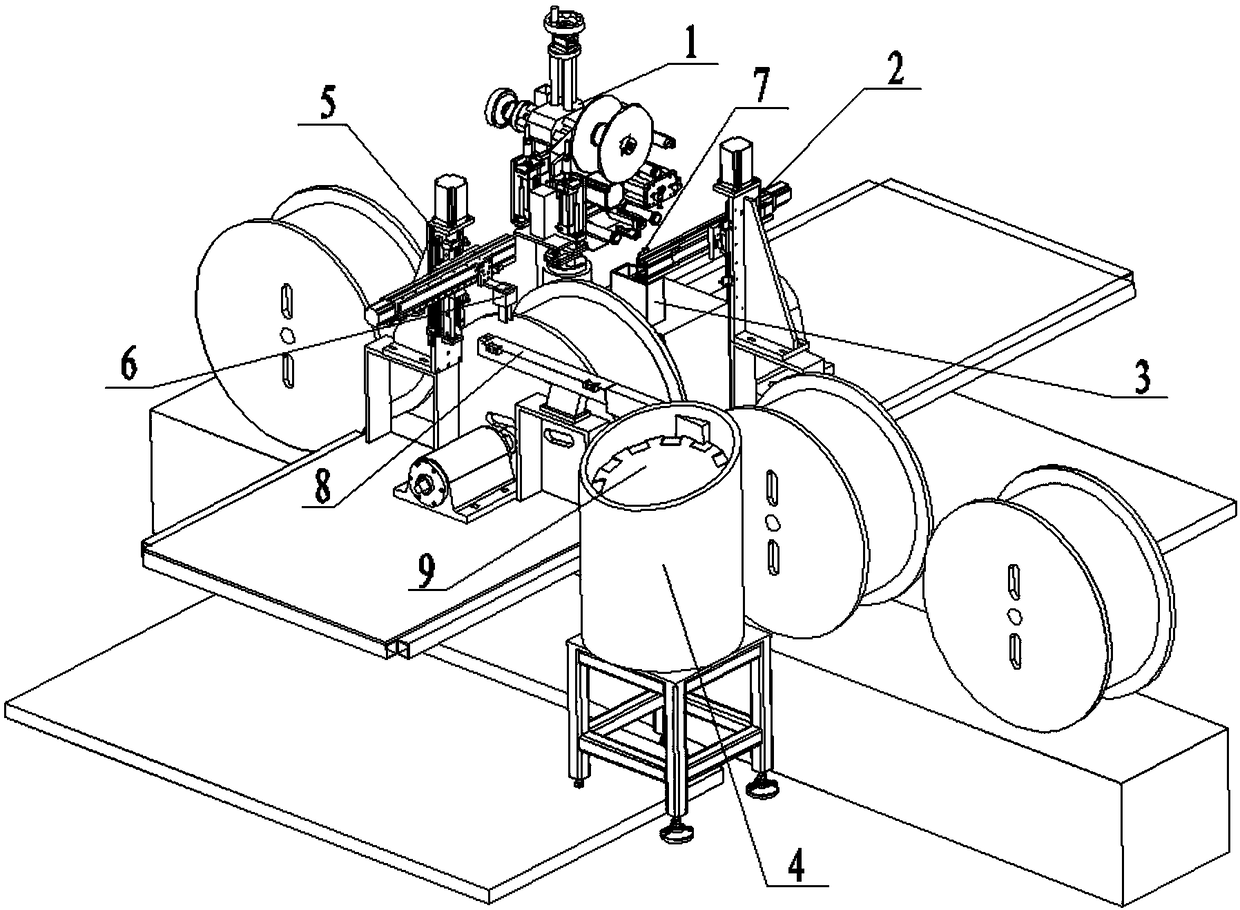

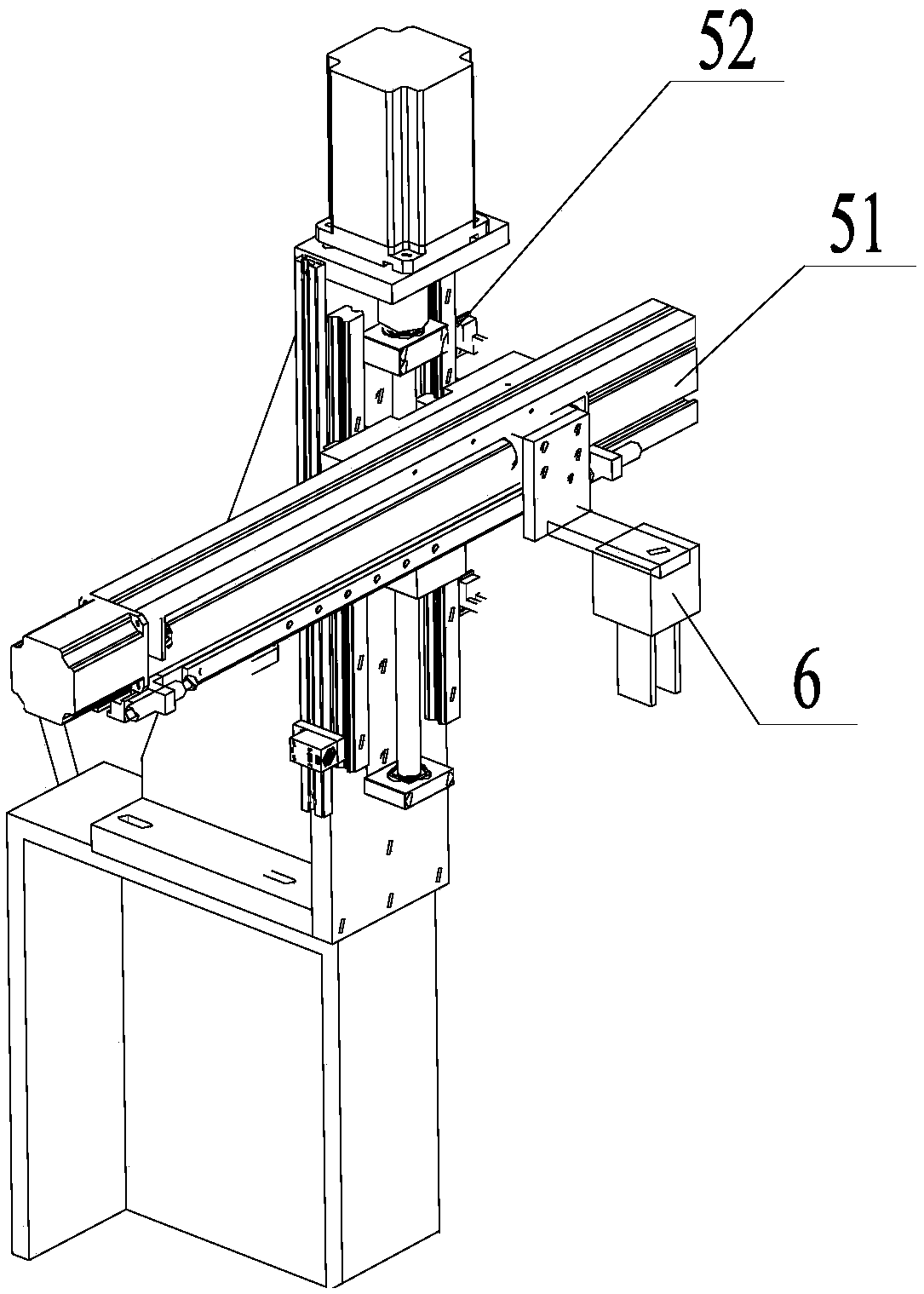

Device and method for feeding and pasting drying agents and humidity indicators to spools

PendingCN108328025AIncrease productivityReduce labor costsPackagingBio-packagingEngineeringDesiccant

The invention discloses a device and method for feeding and pasting drying agents and humidity indicators to spools, and relates to the technical field of pasting drying agents and humidity indicatorsto spools. The device comprises a humidity indicator feeding device, a drying agent feeding device and gluing equipment, the humidity indicator feeding device is used for feeding the humidity indicators onto the spools, the drying agent feeding device is used for feeding the drying agents onto the spools, and the gluing equipment is used for pasting the fed drying agents and the fed humidity indicators to the spools. The method comprises the following steps that the drying agents are fed and pasted, specifically, the drying agent feeding device feeds the drying agents onto the spools, and thegluing equipment presses adhesive tape on the fed drying agents; and the humidity indicators are fed and pasted, specifically, the humidity indicator feeding device feeds the humidity indicators ontothe spools, and the gluing equipment presses the adhesive tape on the fed humidity indicators. According to the device and the method, the drying agents and the humidity indicators can be automatically pasted to the spools, and therefore the production efficiency can be greatly improved.

Owner:SHANDONG DAYE

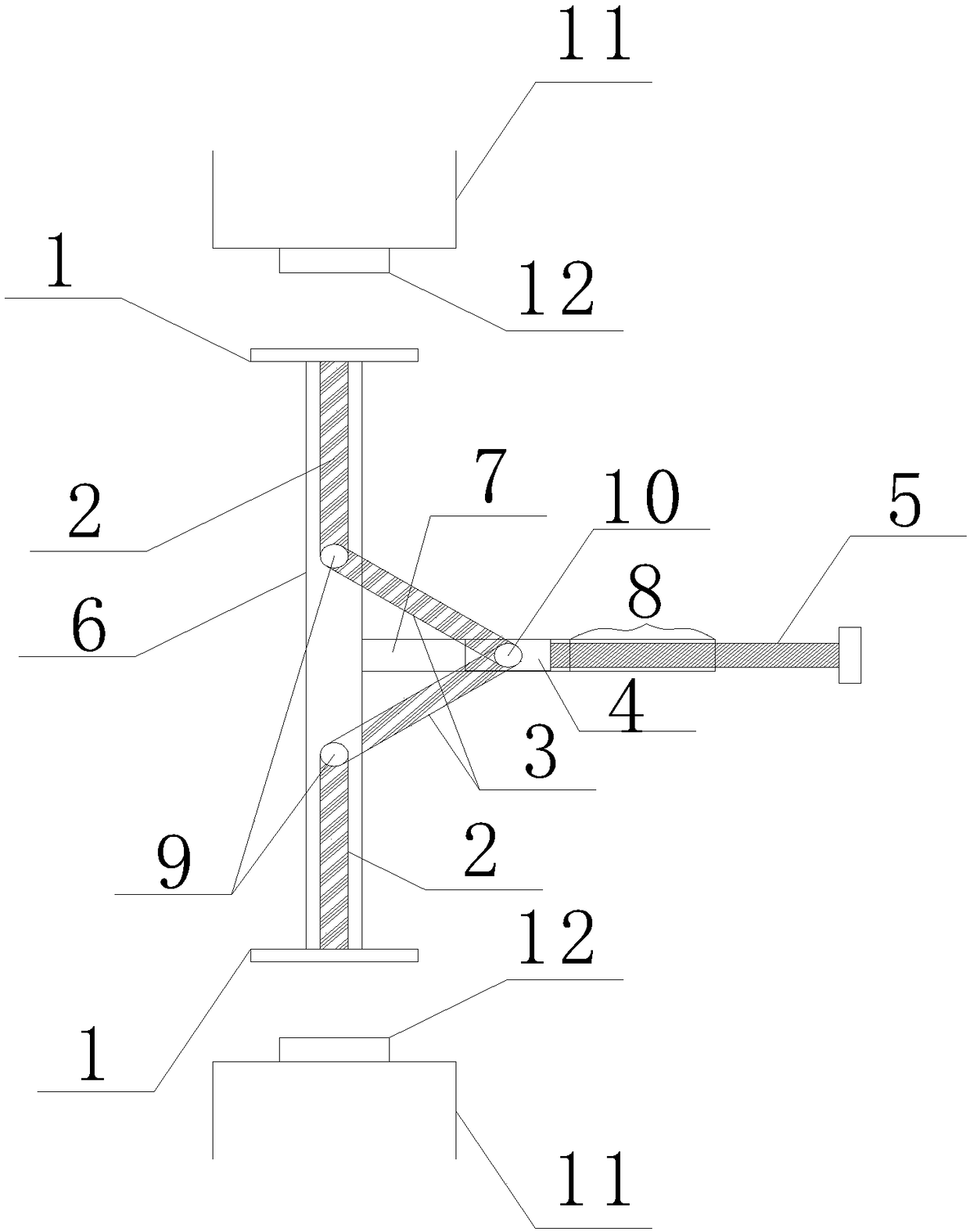

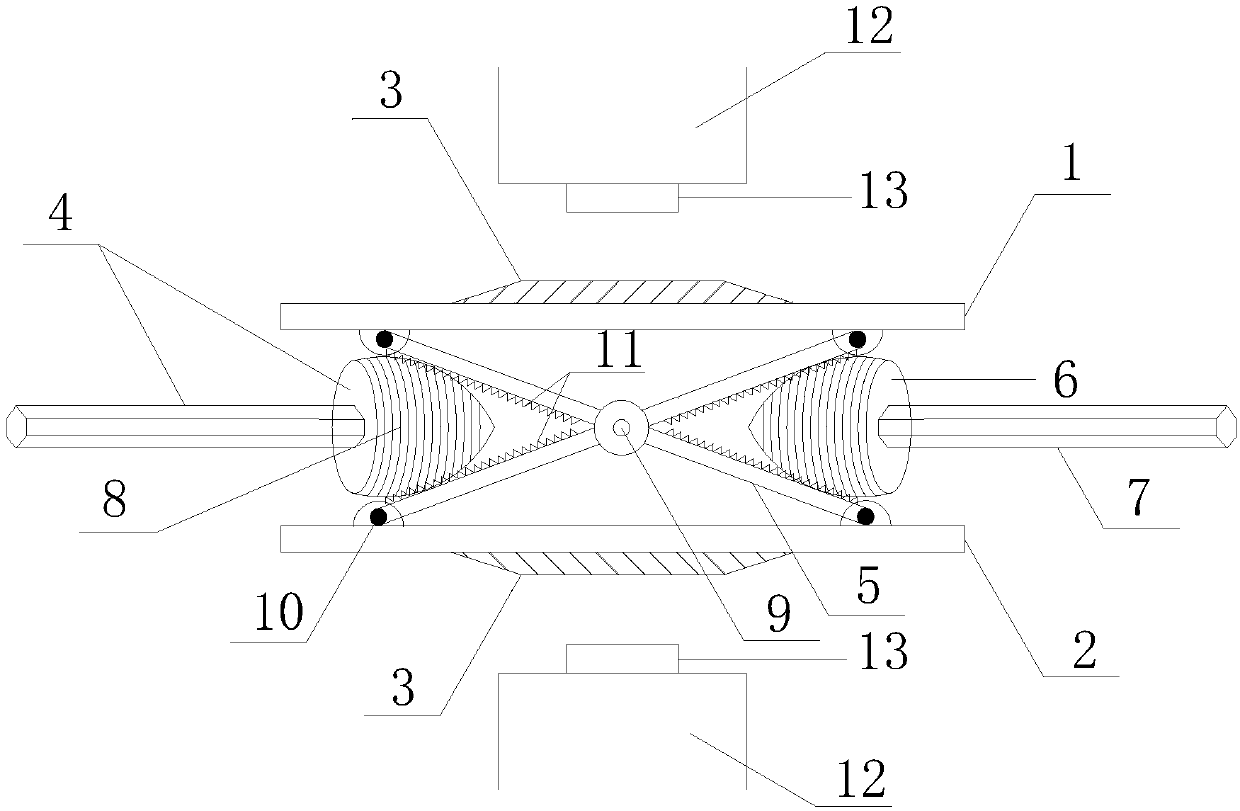

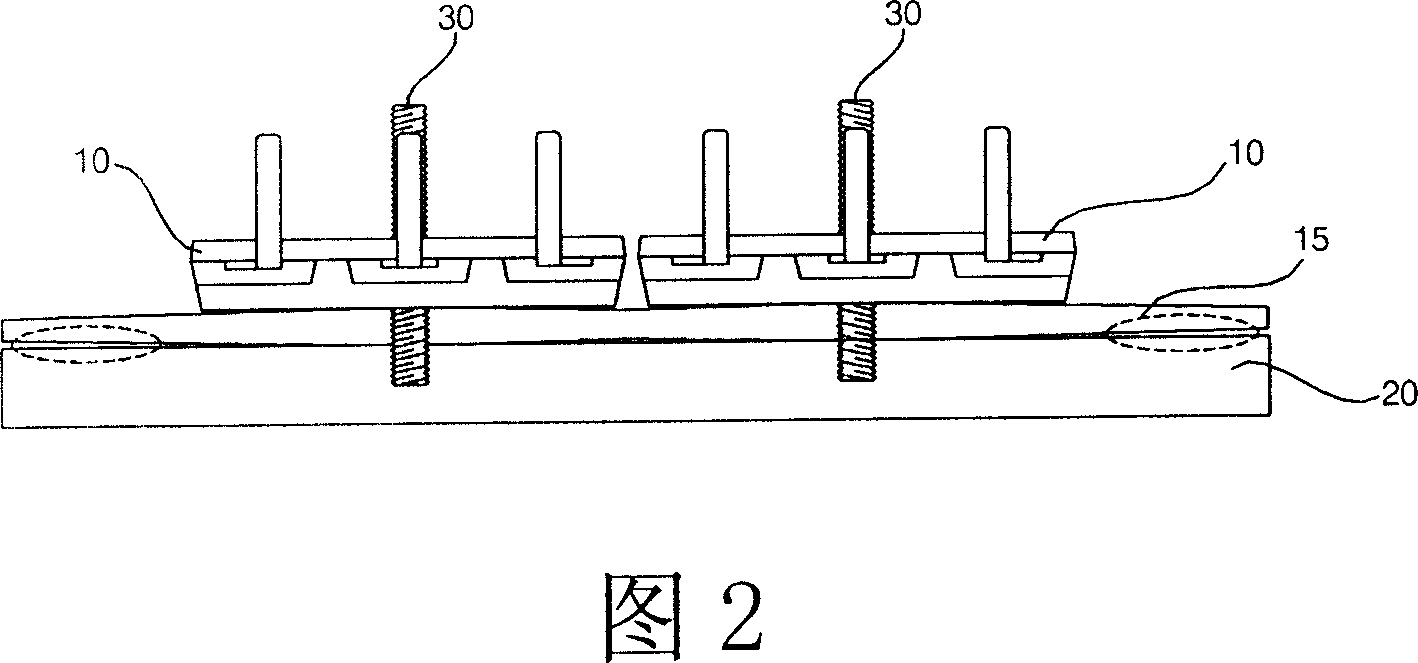

Screw-extrusion attaching device for strain gauge patching

The invention belongs to the technical field of sensor detection, and particularly relates to a screw-extrusion attaching device for strain gauge patching. The device comprises an upper plate, a lowerplate, a platform, threaded push rods and support rods. The strain gauge is glued to the surface of the object to be tested, then two objects to be tested are symmetrically clamped by a clamp, and the attaching device is placed between the two objects. The threaded push rods are rotated, a threaded taper gradually pushes inward under the meshing of internal and external threads, the two support rods are extended at an angle, and the upper and lower plates gradually move away, so that the raised platform abuts against and gradually presses the strain gauge. Finally, a certain pressure is maintained so as to solidify and stabilize the strain gauge. The device can make the strain gauge stick more uniformly, and can eliminate air bubbles in the glue, so that the measurement precision of the strain gauge is higher.

Owner:济源市超光传感器系统工程有限公司

High-strength and easy-to-clean silica sol shell making process

ActiveCN112808935AImprove breathabilityHigh strengthFoundry mouldsFoundry coresCrazingPhysical chemistry

The invention discloses a high-strength and easy-to-clean silica sol shell making process which specifically comprises the following steps of coating the surface of a wax mold with surface layer slurry, spraying zircon sand, drying at 40-60 DEG C for 3-6 hours, coating with back layer slurry, and finally sealing the slurry. The surface of a casting manufactured through the shell making process is smoother and has no cracks, burrs or bumps, various mechanical properties of the casting are superior to those of a casting prepared through an existing method, and the compactness and hardness are higher.

Owner:JIANGYIN UNI POL

E-shaped magnetic core gum application tool

InactiveCN104533904AReduce stressAvoid tearingFastening meansEngineeringElectrical and Electronics engineering

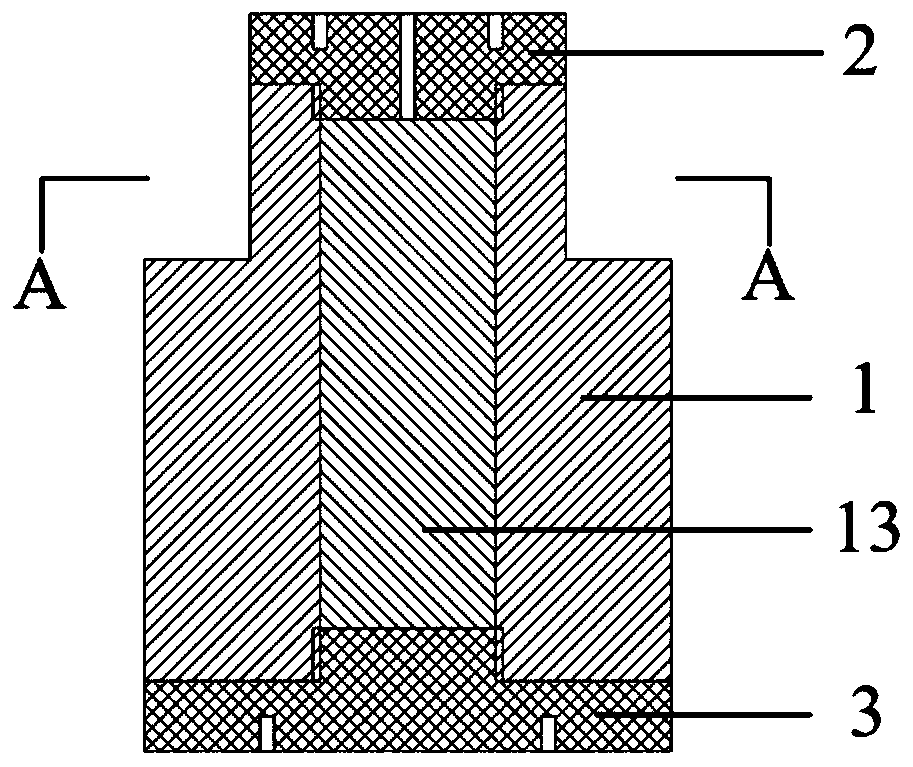

The invention provides an E-shaped magnetic core gum application tool. The E-shaped magnetic core gum application tool comprises a magnetic core installation mold provided with multiple magnetic core containing grooves. Positioning columns are arranged in the magnetic core containing grooves. A cutting groove is formed between every two adjacent magnetic core containing grooves. At least two guide columns are arranged on the magnetic core installation mold. An upper mold cover penetrates through the guide columns in a sliding mode. Multiple extrusion pieces are arranged on the lower surface of the upper mold cover. The extrusion pieces are provided with inner cavities matched with E-shaped magnetic cores in an inserted mode and outer circumferential surfaces matched with the corresponding magnetic core containing grooves in an inserted mode, a cutting tool matched with the corresponding cutting groove in a cutting mode is arranged between every two adjacent extrusion pieces, and the blade portions of the cutting tools are lower than the bottoms of the extrusion pieces. The guide columns are arranged on the magnetic core installation mold, the upper mold cover penetrates through the guide columns in the sliding mode, the extrusion pieces are arranged on the lower surface of the upper mold cover, and through the tool, one person can apply gum to the E-shaped magnetic cores at a time, and work efficiency is improved dozens of times and even hundreds of times.

Owner:河南普照光电科技有限公司

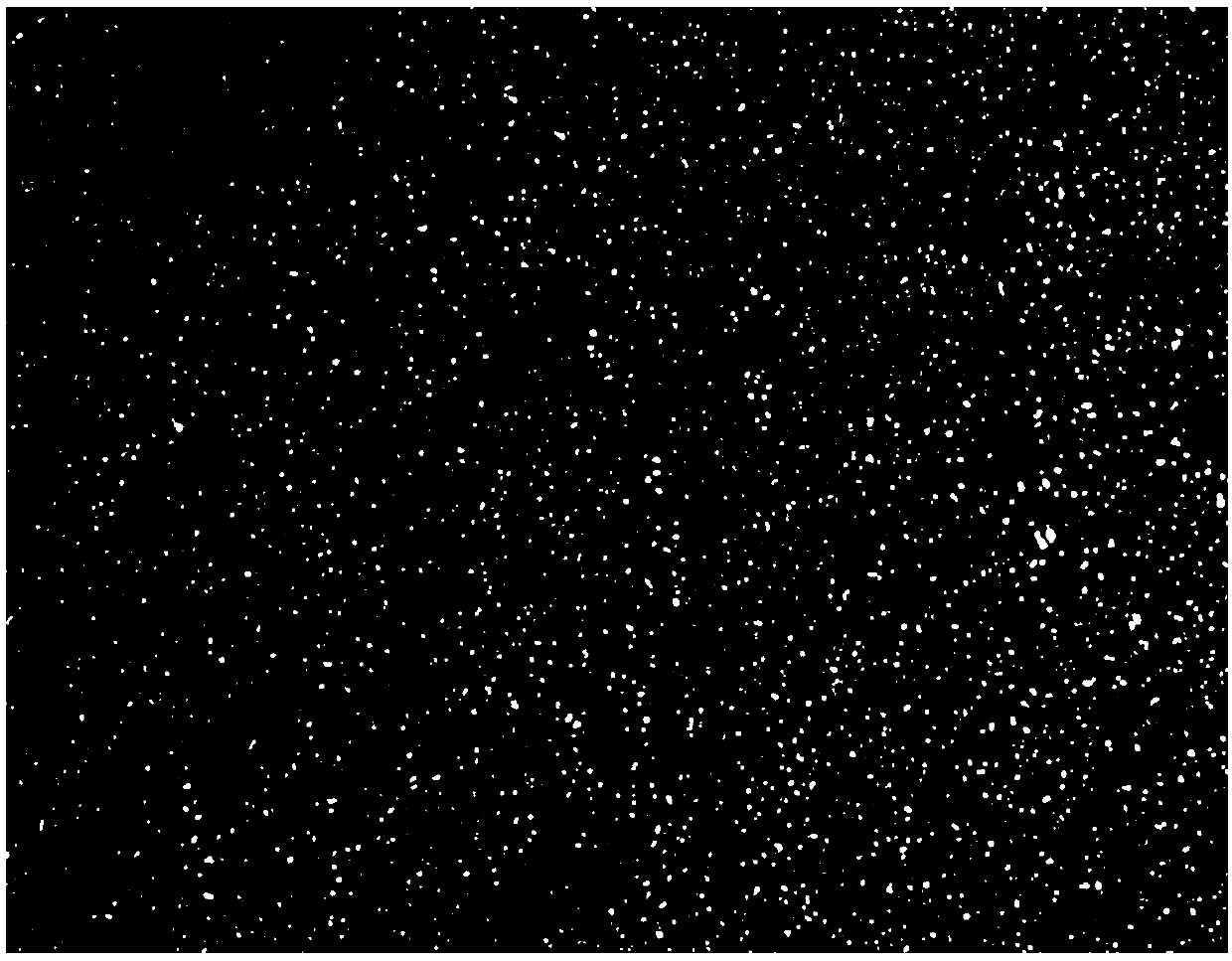

TiO2 photocatalyst and preparation method thereof

ActiveCN110871059AExcellent photocatalytic degradation performanceCatalyst performance is stableGas treatmentPhysical/chemical process catalystsPhoto catalysisTitanium oxide

The invention discloses a TiO2 photocatalyst and a preparation method thereof. The catalyst is TiO2 photocatalyst supported by a foam alumina-based supporter having a porous foam structure. The preparation method includes: preparing the alumina-based supporter, impregnating the supporter in titanium sol, and performing thermal treatment to prepare the photocatalyst. The photocatalyst has high photocatalytic activity and is very suitable for a catalytic reaction process under the effect of ultraviolet light.

Owner:中科粤能净(山东)新材料有限公司

Preparation method of porous reticulated ceramic enhanced steel-based compound brake block

The invention discloses a preparation method of a porous reticulated ceramic enhanced steel-based compound brake block. The method includes the steps: mixing TiB2 powder and additives, and adding mixture into deionized water to sufficiently stir the mixture to prepare ceramic slurry suspension liquid; soaking organic foam bodies into ceramic slurry, drying soaked organic foam bodies, and sinteringthe dried organic foam bodies at high temperature to obtain porous reticulated TiB2 prefabricated bodies; casing the prepared porous reticulated TiB2 prefabricated bodies with metal solution by the aid of a cast-penetration process, and performing cooling and de-molding to obtain the porous reticulated ceramic enhanced steel-based compound brake block. The prepared compound brake block is high infriction coefficient and low in heat expansion coefficient, inter stress of the brake block is uniform, strength and toughness are enhanced, and the service life of the brake block is prolonged.

Owner:XI AN JIAOTONG UNIV +1

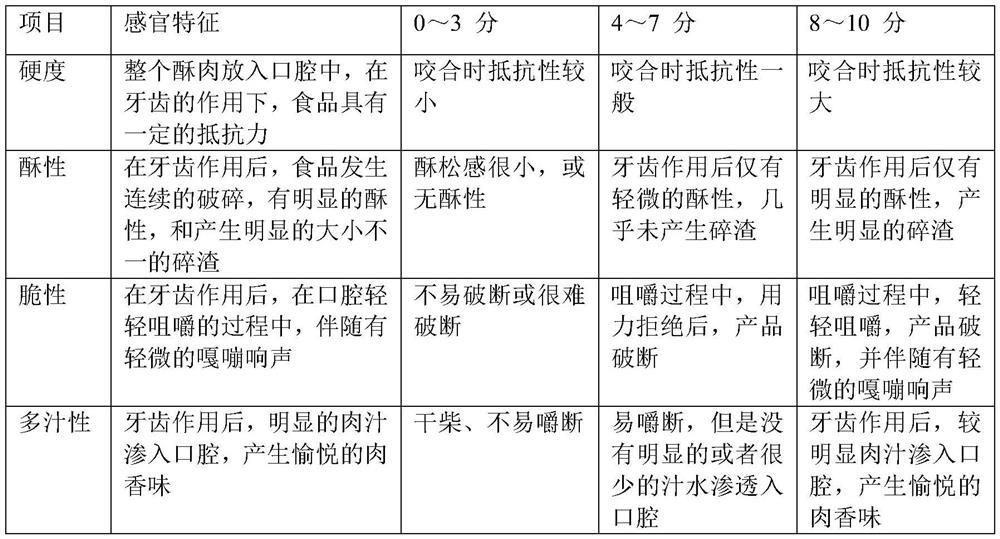

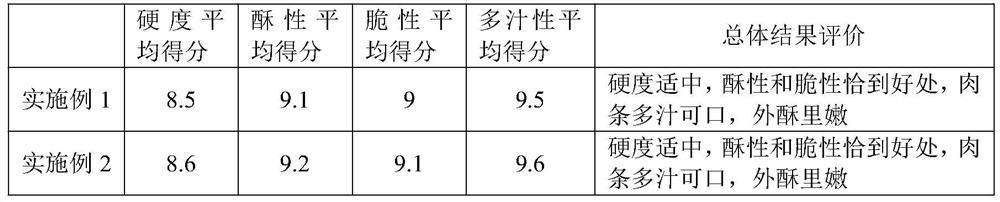

Sichuan-style pepper spicy flavor pre-fried meat product and preparation method thereof

ActiveCN112704195APaste evenlyRich flavorClimate change adaptationFood scienceBiotechnologyVegetable oil

The invention belongs to the technical field of food processing, and particularly relates to a Sichuan-style pepper spicy flavor pre-fried meat product and a preparation method thereof. The technical problem to be solved by the invention is to provide a pre-fried meat product being pure in pepper spicy flavor and crisp and a preparation method of the pre-fried meat product. The method comprises the following steps: A, cutting pork: cutting the pork into pork pieces and then cutting the pork pieces into pork strips; B, performing rolling: adding water of 0-4 DEG C into rolling auxiliary materials, performing rolling, adding the meat strips of which the temperature is 10 DEG C or below, performing rolling until moisture is completely absorbed by the meat strips, and performing pickling; C, performing sizing: preparing slurry from whole egg liquid of 0-4 DEG C, compound starch and Chinese prickly ash in a weight ratio of (15-18): (20-23): (0.2-0.22), and coating the pickled meat strips with the slurry according to a weight ratio of (50-65): (35-40); and D, performing frying: heating vegetable oil to 170-175 DEG C, adding the meat strips coated with the slurry in the step C, and performing frying to obtain the product. The product provided by the invention is crisp in taste, juicy and pure in Sichuan pepper spicy flavor.

Owner:CHENGDU XIWANG FOOD

Graphene prepreg preparation equipment

ActiveCN108790372AEasy to useReduce manufacturing costLaminationLamination apparatusEpoxyDrive wheel

The invention discloses graphene prepreg preparation equipment. The graphene prepreg preparation equipment comprises a base, wherein a box body is fixedly arranged at the top end of the base; one sideof the box body is provided with a material inlet, the other side of the box body is provided with a material outlet, and two support columns are fixedly arranged at the bottom end of the interior ofthe box body; a lower grinding plate is fixedly arranged at the top ends of the two support columns; a horizontal scale is fixedly arranged in the middle part of the lower grinding plate; two electric telescopic rods are fixedly arranged at the top end of the interior of the box body; the telescopic ends of the two electric telescopic rods are fixedly connected with the top end of an upper grinding plate. The graphene prepreg preparation equipment has the advantages that a release paper strip is rotated between a driving wheel and a driven wheel, so that the repeated use effect of the releasepaper strip is enhanced, and the manufacturing cost is reduced; the upper grinding plate is driven by the electric telescopic rods to ascend and descend, so that the graphene powder can be uniformlyground; a spray head is arranged in a laminating sheet and is connected with an external refrigerator, so that the heated semi-curing epoxy resin rubber film can be effectively cooled.

Owner:绍兴纤逸纺织科技有限公司

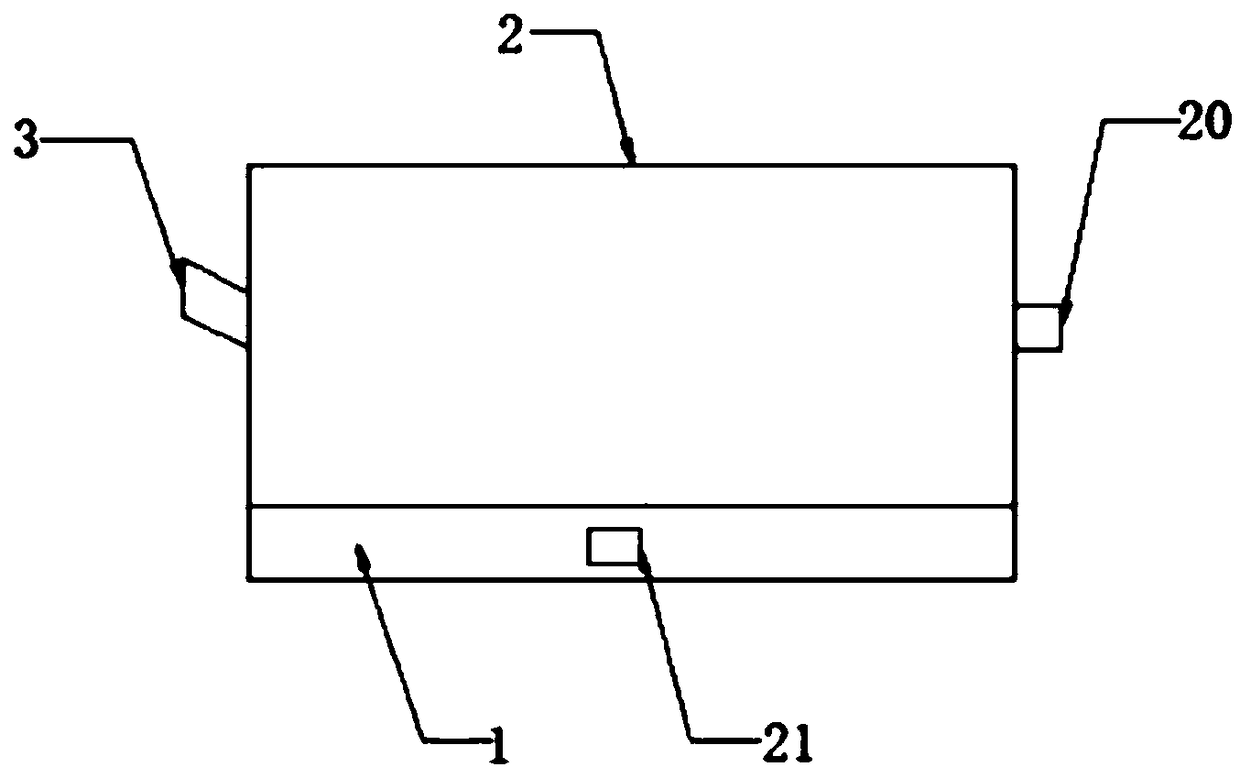

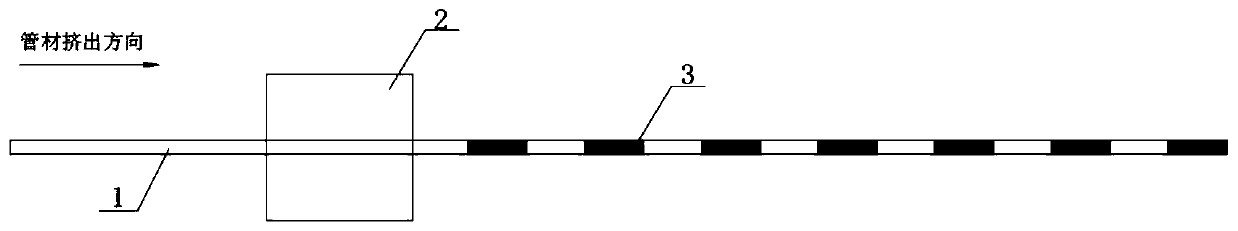

Bracing wire warning tube reflective film pasting method

InactiveCN110126498AExtend the life cycleSave human resourcesDuplicating/marking methodsEngineeringManufacturing line

The invention belongs to the technical field of PVC wire tubes, and particularly relates to a bracing wire warning tube reflective film pasting method. The method comprises a heat transfer machine, the heat transfer machine is placed in front of a cutting machine of a pipe extrusion production line, when a pipe passes through the heat transfer machine in the pipe extruding direction on the production line, the heat transfer machine can print a reflective film on the pipe through a heat transfer technology, the pipe where the reflective film is pasted is directly cut through the cutting machineaccording to the needed length, and then the pipe can be used as a bracing wire warning tube. The purpose is to avoid the inconvenience caused by the fact that an existing warning tube reflective film can automatically fall off after being pasted and used for a long time and manual pasting is required when the reflective film is pasted, and the method capable of prolonging the use time of the reflective film and achieving automatic pasting is provided.

Owner:HENAN LIANSU IND

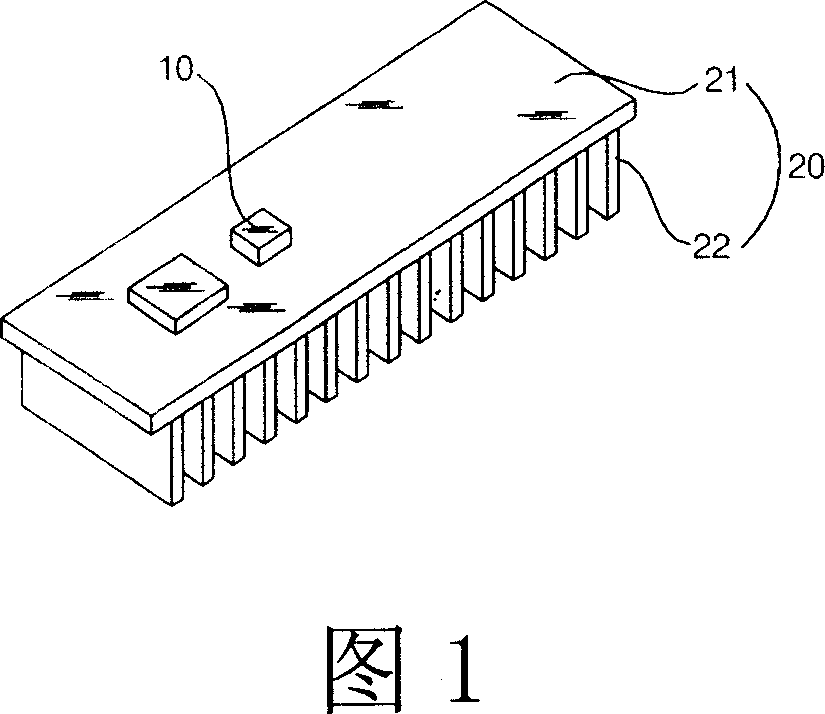

Heat radiation structure of air conditioner

InactiveCN101080155APaste evenlyLighting and heating apparatusSpace heating and ventilation detailsEngineeringElectron

This invention relates to a heat-discharge structure of an air-conditioner including: more than one electronic heating parts set in the outdoor or the indoor machine, heat discharge plates set adjacent to the parts for radiating heat generated by them, heat discharging pads for insulation and set between the electronic parts and the heat discharge plates, in which, double-face adhesive tapes are adhered on both sides of the pads contacted with the parts and the plates, and the heat discharge plate is made of Al and composed of a chassis adjacent to the electronic parts and multiple heat discharge pins vertical to the surface of the chassis.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

A preparation method of porous network ceramic reinforced steel-based composite brake block

The invention discloses a preparation method of a porous reticulated ceramic enhanced steel-based compound brake block. The method includes the steps: mixing TiB2 powder and additives, and adding mixture into deionized water to sufficiently stir the mixture to prepare ceramic slurry suspension liquid; soaking organic foam bodies into ceramic slurry, drying soaked organic foam bodies, and sinteringthe dried organic foam bodies at high temperature to obtain porous reticulated TiB2 prefabricated bodies; casing the prepared porous reticulated TiB2 prefabricated bodies with metal solution by the aid of a cast-penetration process, and performing cooling and de-molding to obtain the porous reticulated ceramic enhanced steel-based compound brake block. The prepared compound brake block is high infriction coefficient and low in heat expansion coefficient, inter stress of the brake block is uniform, strength and toughness are enhanced, and the service life of the brake block is prolonged.

Owner:XI AN JIAOTONG UNIV +1

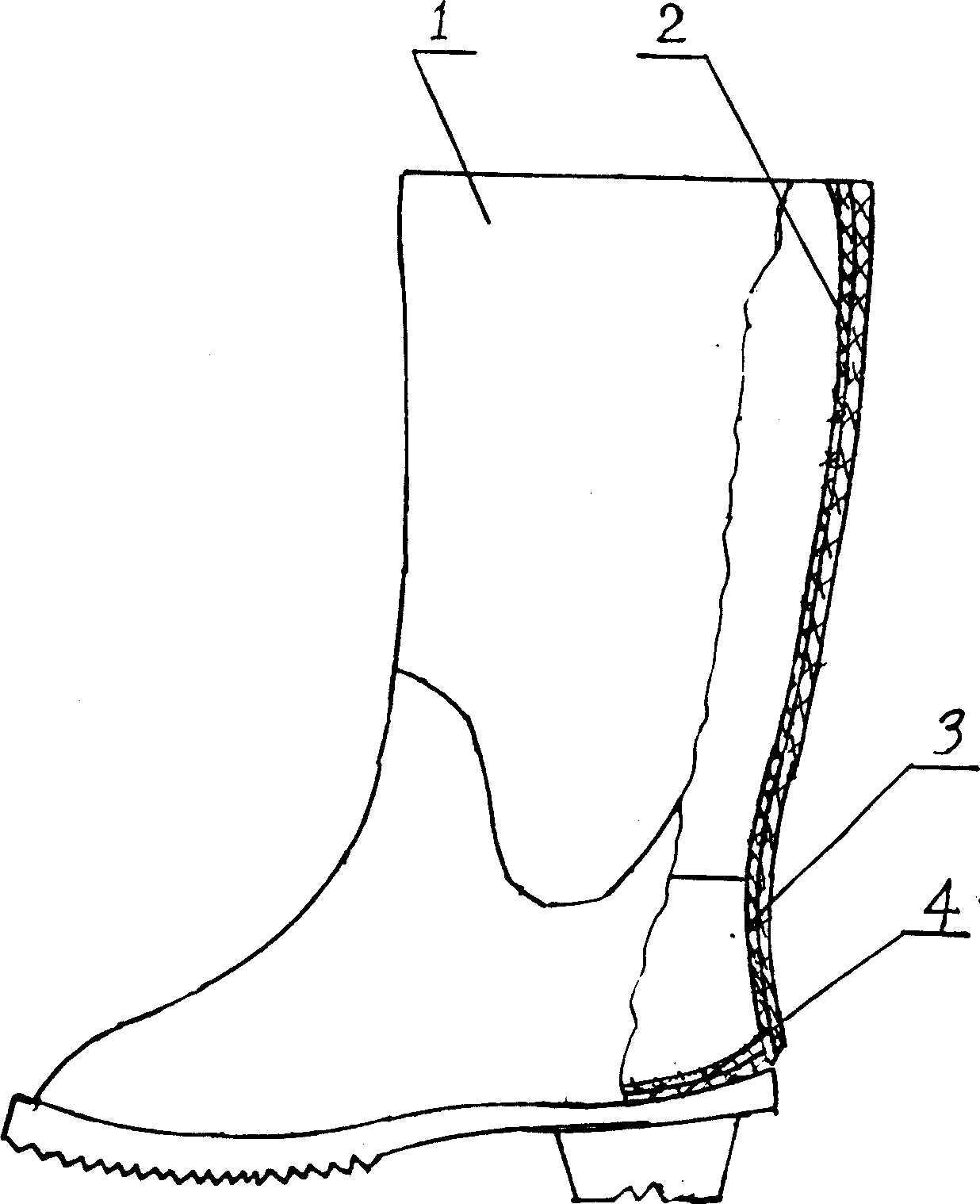

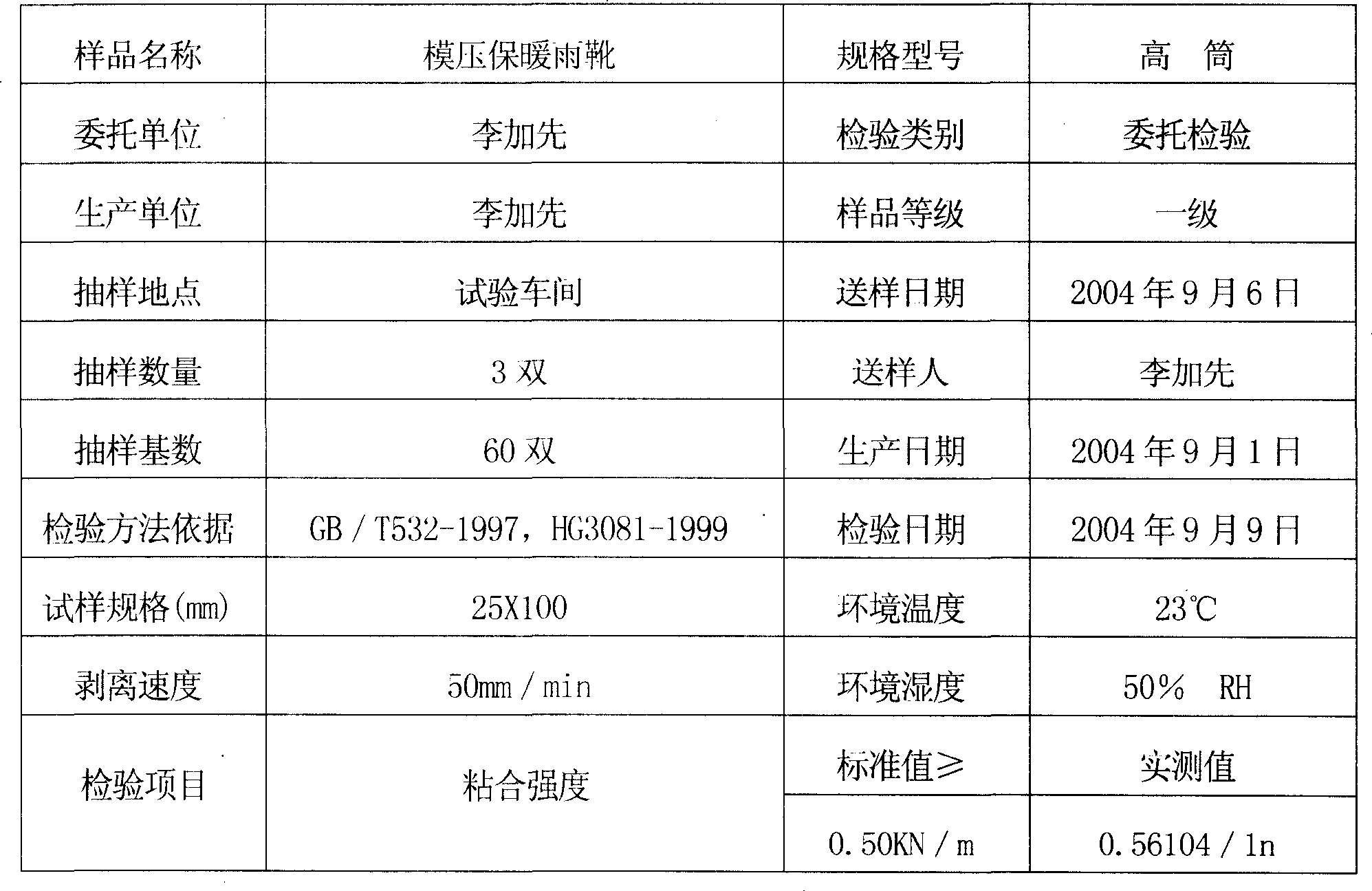

Method for preparing thermal protection rain boots made from plastic or mixed rubber and plastic

A method for preparing plastic or rubber warm boots includes preparing boot base and warm endotheca; processing inner surface of boot base; preparing viscose layer; erecting warm endotheca, air charged inner membrance of boot shape; sticking warm endotheca inner surface with boot base surface; baking; quality controlling and packing.

Owner:李加先

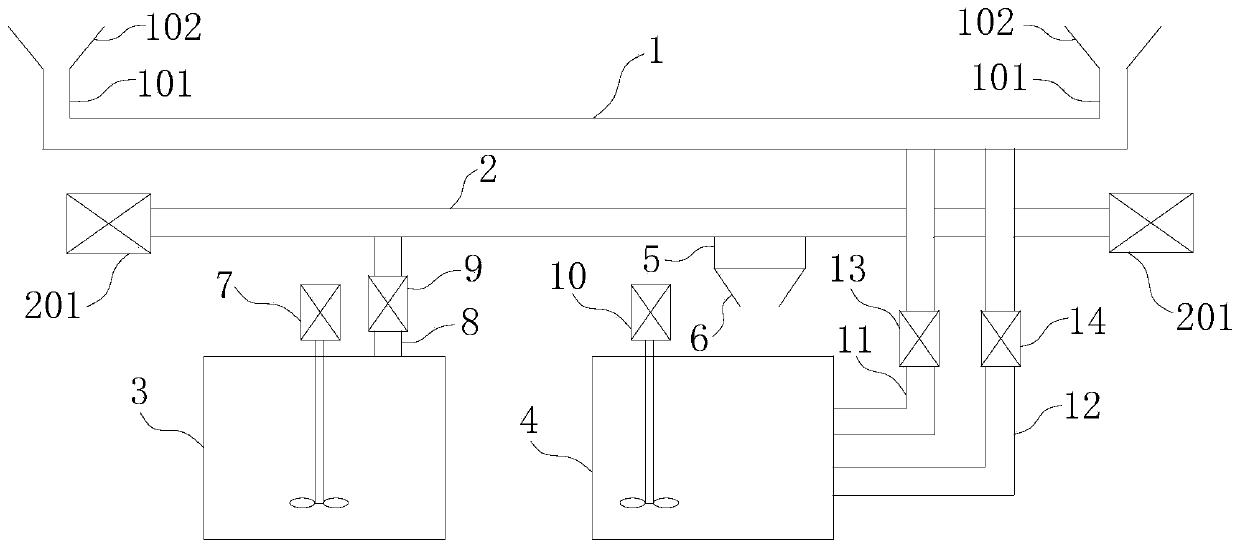

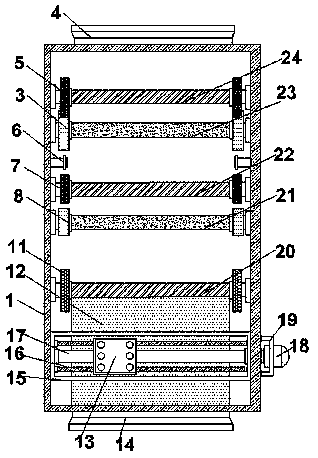

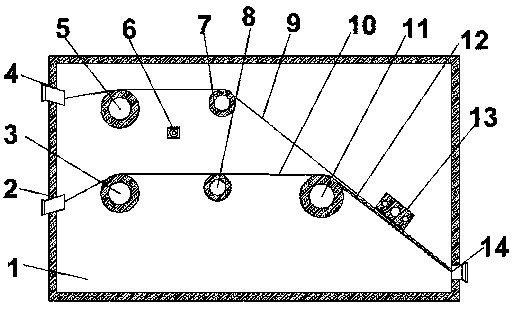

Central gunite spraying system for multiple pig iron casting machine production lines

PendingCN111347013AIncrease profitNo impuritiesLiquid surface applicatorsMoulding toolsProduction lineReducer

The invention discloses a central gunite spraying system for multiple pig iron casting machine production lines. The central gunite spraying system comprises a gunite spraying main pipeline, wherein agunite return channel is arranged below the gunite spraying main pipeline, and a gunite storage pool and a gunite mixing pool are arranged below the gunite return channel; a plurality of gunite spraying branch pipes are arranged at the two ends of the gunite return channel, a high-frequency screen is arranged at the lower end of the gunite return channel, blow-down valves are arranged at the twoends of the gunite return channel, and a gunite return groove is connected to the lower portion of the high-frequency screen; a first stirring speed reducer is arranged in the gunite mixing pool, wherein the upper end of the gunite mixing pool is connected with a first gunite pipe, a gunite supplementing pump is arranged on the first gunite pipe, and the other end of the first gunite pipe communicates with the gunite return channel; and a second stirring speed reducer is arranged in the gunite storage pool, the side end of the gunite storage pool is sequentially connected with a second gunitepipe and a third gunite pipe from top to bottom, a pressure regulating valve is arranged on the second gunite pipe, a gunite spraying pump is arranged on the third gunite pipe, and the other end of the second gunite pipe and the other end of the third gunite pipe communicate with the gunite spraying main pipeline. The central gunite spraying system is convenient to maintain, high in gunite utilization rate, free of impurities, good in spraying effect and low in power consumption and equipment cost.

Owner:山西建邦集团铸造有限公司

Dustless PE bag integrated shaping device

InactiveCN109049850ARealize one-time moldingPaste evenlyBag making operationsPaper-makingProduction ratePulp and paper industry

The invention discloses a dustless PE bag integrated shaping device. The dustless PE bag integrated shaping device comprises a box body, a stitching lower shift and a moving device. While the dustlessPE bag integrated forming device is in use, a PE film is led in through an upper inlet, and further the PE film is led onto a second guide pulley and a third guide pulley; a paper film is led in through a lower inlet, and further the paper film is led onto a fourth guide pulley and a first guide pulley; in the course that the paper film and the PE film pass through, spray nozzles jet pasting gluetowards a place between the paper film and the PE film, and the paper film and the PE film can be adhered and stuck through an overall guide pulley; after being adhered and stuck by the overall guidepulley, the paper film and the PE film can become an integral structure; further the paper film and the PE film enter a stitching sloping plate, then are subjected to reciprocating stitching by a pressing block driven by the moving device, further the paper film and the PE film are subjected to pressing, covering and adhering, and pasting is more uniform; and through an outlet, pulling out for shaping is performed, and finally, cutting-out processing is performed so that PE bag one-time shaping is realized. The productivity is increased, artificial errors are reduced, and the dustless PE bagintegrated shaping device is convenient and quick to operate in use and high in practicality.

Owner:孙立强

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com