Method for preparing thermal protection rain boots made from plastic or mixed rubber and plastic

A technology of rain boots, rubber and plastics, applied in the direction of shoe-making machinery, clothing, footwear, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

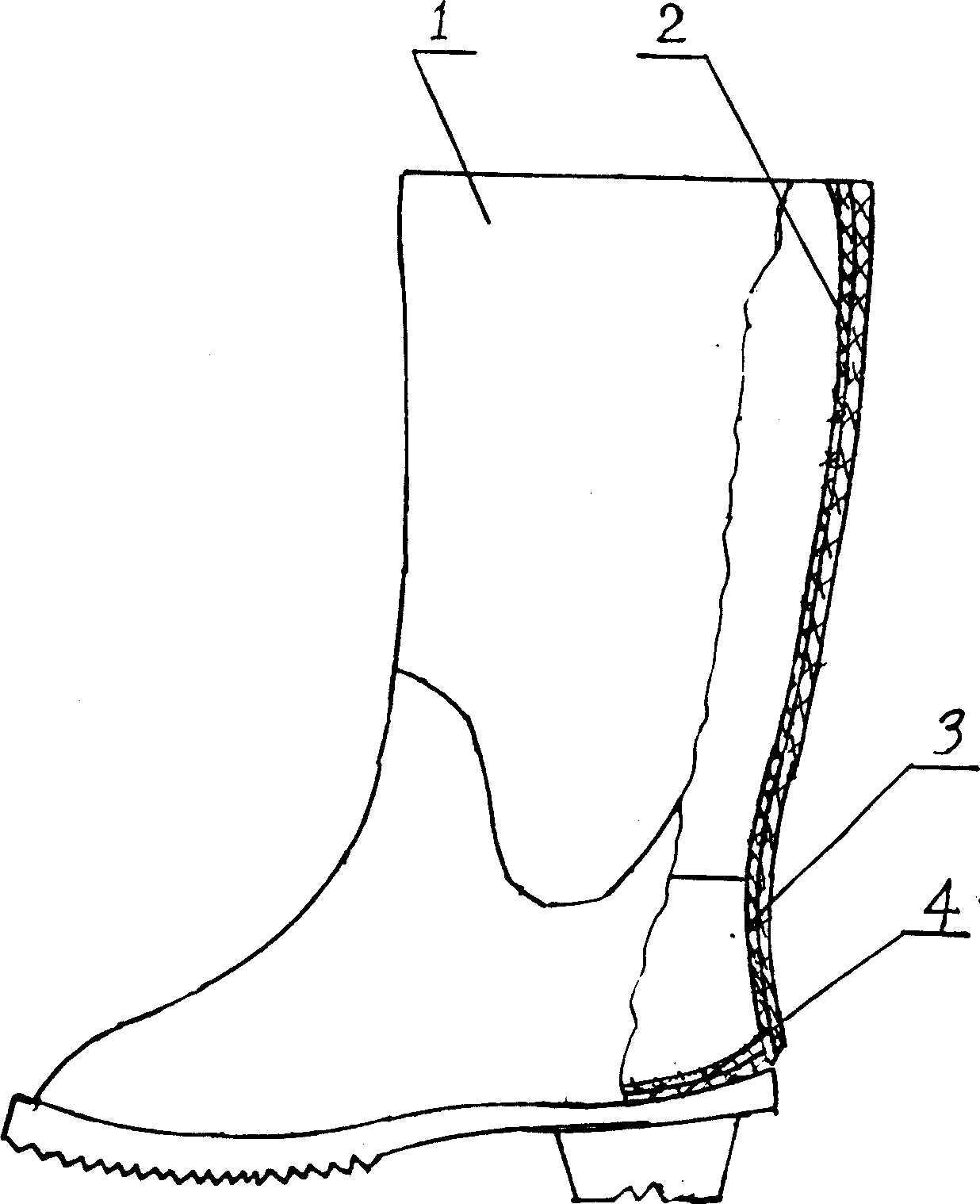

[0032] exist figure 1 Among them, the plastic warm rain boots are composed of a boot blank 1, a boot tube piece 2, a left piece under the ankle bone 3, a sole piece 4, and a right piece under the ankle bone. The geometric shape of the right sub-ankle bone piece and the left sub-ankle bone piece 3 is exactly the same. The upper end of the left piece 3 under the ankle bone is sewn together, and the right piece under the ankle bone is sewn together with the lower end of the left piece 3 under the ankle bone and the bottom of the foot piece 4 to make a thermal inner cover, the thermal inner cover and the boot blank 1 Paste the link.

[0033] The preparation process steps of the above-mentioned plastic warm rain boots are as follows:

[0034] 1. Making boot blanks 1

[0035] Make boot base 1 with plastics by conventional scale injection molding process step.

[0036] 2. Make a warm inner jacket

[0037] According to the model of rain boots, the artificial imitation fur is cut ...

Embodiment 2

[0053] In this embodiment, air is injected into the boot-shaped inflatable inner mold, and the air pressure is 0.00606 MPa. In the baking and pasting step, the boot with a thermal inner sleeve and a boot-shaped inflatable inner mold is placed inside the thermal inner sleeve. Blank 1 was put into an oven and baked at 60°C for 20 minutes. Other processing steps are identical with embodiment 1.

Embodiment 3

[0055] In this embodiment, air is injected into the boot-shaped inflatable inner mold, and the air pressure is 0.01515 MPa. In the baking and pasting step, a boot with a thermal inner sleeve and a boot-shaped inflatable inner mold is placed inside the thermal inner sleeve. Blank 1 was put into an oven and baked at 100°C for 12 minutes. Other processing steps are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com