Bracing wire warning tube reflective film pasting method

A technology of reflective film and pipe material, applied in copying/marking methods, printing, etc., can solve the problems of automatic peeling off of reflective film pasting of warning tubes, manual pasting of reflective film pasting, etc., achieve better reflective effect, neat pasting, and improve service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

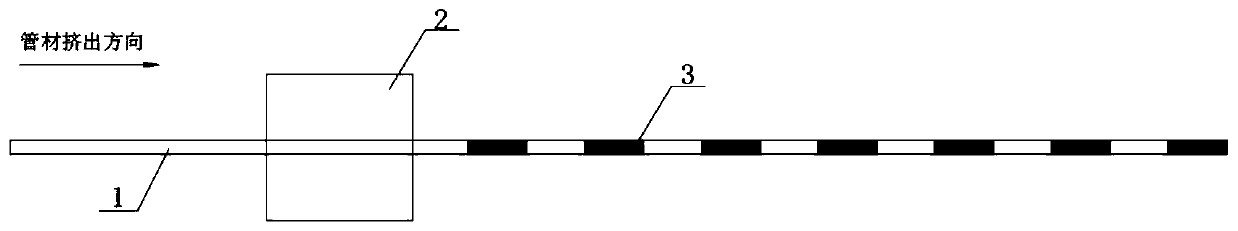

[0029] Such as figure 1 As shown, a method for sticking reflective film of a pull wire warning tube, including a heat transfer machine 2, the heat transfer machine 2 is placed in front of the cutting machine of the pipe extrusion production line, when the pipe 1 is extruded along the pipe on the production line When the direction passes through the heat transfer machine 2, the heat transfer machine 2 can print the reflective film 3 on the pipe 1 through the heat transfer technology, and the pipe 1 with the reflective film 3 can be directly cut out to the required length by the cutting machine. Can be used as a pull wire warning tube.

[0030] Among them, the heat transfer machine 2 can be used to adjust the distance between the reflective film 3 printed on the pipe 1, and the film distance on the pipe 1 can be set on the heat transfer machine 2, so that the distance between the printed film is appropriate and the reflective effect is better. good.

[0031] In this embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com