Thermally induced viscosity-decreasing meshed protective film

A protective film, thermally induced technology, applied in the direction of adhesive types, ester copolymer adhesives, polymer adhesive additives, etc., can solve the problems of residual glue, affecting product quality, affecting product quality and aesthetics, etc. Achieving good effect, low cost and best use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

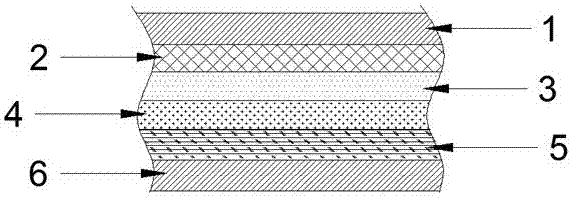

Image

Examples

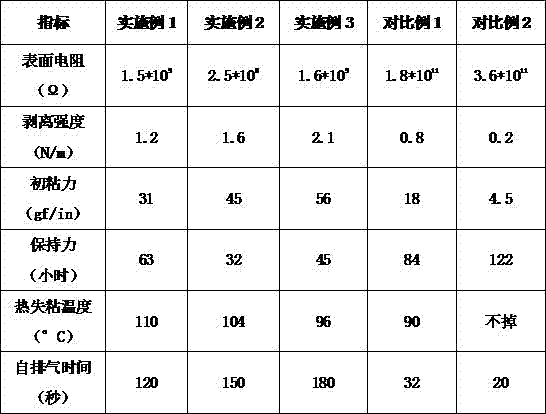

Embodiment 1

[0034] Step 1: Prepare modified polyacrylate glue:

[0035] Weighing by weight: modified polyacrylate: 40 parts, ethyl acetate: 49.6 parts, isocyanate: 6 parts, polyaniline: 0.4 parts, polymerized rosin ester: 4 parts, heat-induced viscosities: 6 parts. Stir and mix the above raw materials for 30 minutes at a rotation speed of 400 rpm, then filter through a pore size of 50-100 mesh, let stand for 60 minutes, and detect that the solid content is 24.4 parts, and set aside;

[0036] Step 2: Preparation of heat-induced non-adhesive textured protective film:

[0037] Unwind the PET film, the unwinding tension is 50N, and then brush the polyaniline antistatic liquid on both sides of the PET film, and the brushing amount is 0.005g / cm 2 , then dry, and then apply the modified polyacrylate glue prepared in the first step on the PET film coated with antistatic liquid, the thickness of the glue layer is 20 μm, dry at low temperature, and the drying temperature gradient is: 40°C , 50°C,...

Embodiment 2

[0039] Step 1: Prepare modified polyacrylate glue:

[0040] Weighing by weight: modified polyacrylate: 35 parts, ethyl acetate: 43.7 parts, isocyanate: 5 parts, polythiophene: 0.3 parts, polymerized rosin ester: 8 parts, heat-induced viscosities: 8 parts. Stir and mix the above raw materials for 30 minutes at a rotation speed of 400 rpm, then filter through a pore size of 50-100 mesh, let stand for 60 minutes, and detect that the solid content is 23.8 parts, and set aside;

[0041] Step 2: Preparation of heat-induced non-adhesive textured protective film:

[0042] Unwind the PET film, the unwinding tension is 50N, and then brush the polyaniline antistatic liquid on both sides of the PET film, and the brushing amount is 0.005g / cm 2 , then dry, and then apply the modified polyacrylate glue prepared in the first step on the above-mentioned PET film coated with antistatic liquid. The thickness of the glue layer is 16 μm, and dry at low temperature. The temperature gradient of dry...

Embodiment 3

[0044] Step 1: Prepare modified polyacrylate glue:

[0045] Weighing by weight: modified polyacrylate: 30 parts, ethyl acetate: 45.7 parts, isocyanate: 4 parts, polybenmidazole: 0.3 part, polymerized rosin ester: 10 parts, heat-induced viscosities: 10 parts. Stir and mix the above raw materials for 30 minutes at a rotation speed of 400 rpm, then filter through a pore size of 50-100 mesh, let stand for 60 minutes, and detect that the solid content is 23.3 parts, and set aside;

[0046] Step 2: Preparation of heat-induced non-adhesive textured protective film:

[0047] Unwind the PET film, the unwinding tension is 50N, and then brush the polyaniline antistatic liquid on both sides of the PET film, and the brushing amount is 0.005g / cm 2 , then dry, and then apply the modified polyacrylate glue prepared in the first step on the PET film coated with antistatic liquid, the thickness of the glue layer is 14 μm, dry at low temperature, and the drying temperature gradient is: 40° , 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com