Central gunite spraying system for multiple pig iron casting machine production lines

A cast iron machine and production line technology, applied in casting molding equipment, surface coating liquid devices, metal processing equipment, etc., can solve the problems of low slurry utilization rate, complicated operation and maintenance, unsatisfactory demoulding, etc., and achieve slurry High material utilization rate, uniform slurry coating, good spraying and mold release effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

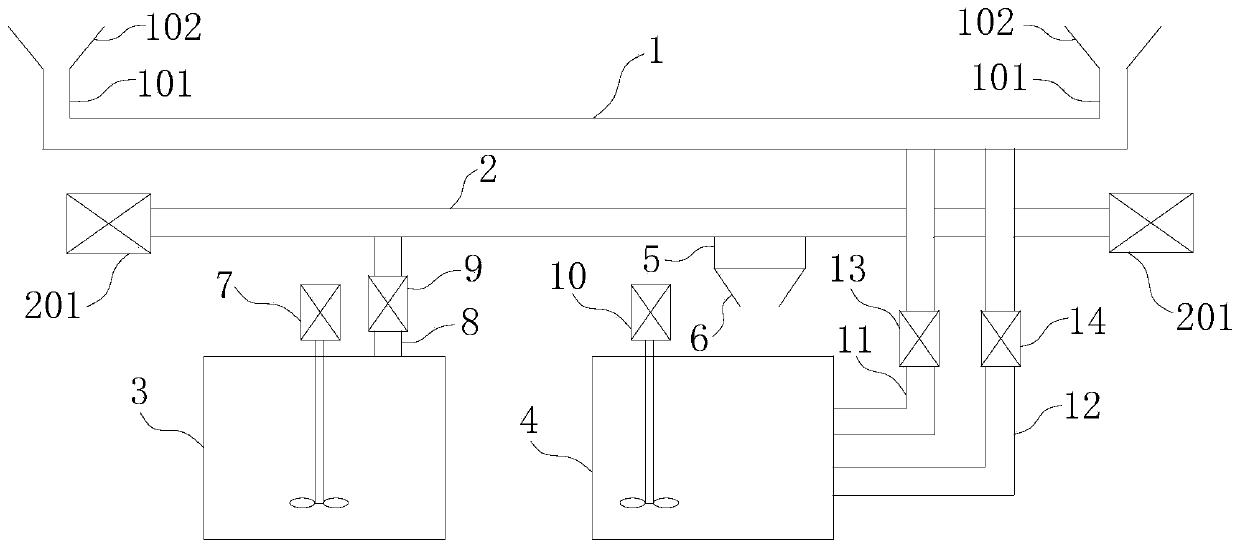

[0018] Such as figure 1 As shown, the central spraying system used for multiple cast iron production lines includes a main spraying pipeline 1, a slurry return channel 2 is provided under the main spraying channel 1, and a slurry mixing channel is provided below the return channel 2 Tank 3 and slurry storage tank 4;

[0019] The two ends of the spraying main pipe 1 are provided with several spraying branch pipes 101 leading to different cast iron machines, the spraying branch pipes 101 are provided with nozzles 102, and the slurry in the spraying branch pipes 101 passes through the nozzles 102 to The mold cavity of the cast iron chain belt is sprayed, and the slurry return channel 2 is suitable for receiving excess slurry flowing down from the mold cavity of the cast iron belt belt and the nozzle 102. The lower end of the slurry return channel 2 is provided with a high frequency screen 5, and the high frequency The screen 5 is set directly above the slurry storage tank 4, and...

Embodiment 2

[0023] Based on the structure of Example 1, in Example 2, both the slurry storage tank 4 and the slurry mixing tank 3 are of cement concrete structure, and the capacity of the slurry storage tank 4 and the slurry mixing tank 3 is relatively large.

Embodiment 3

[0025] Based on the structure of Embodiment 1, in Embodiment 3, two spraying branch pipes 101 are provided, and they are arranged symmetrically at both ends of the main spraying pipe 1 .

[0026] When working, the slurry in the slurry mixing tank 3 is sent to the slurry return channel 2 through the slurry replenishing pump 9 in the slurry mixing tank 3 after the first stirring reducer 7 performs the first slurry stirring, and then the slurry is sent to the return channel 2 by the high frequency The sieve 5 vibrates to separate the pure slurry in the slurry, and the pure slurry enters the slurry storage tank 4 from the slurry return tank 6 at the lower part of the high-frequency sieve 5, and the slurry storage tank 4 performs the second stirring under the operation of the second stirring reducer 10. Stir evenly for the first time, and the viscosity is moderate, then the slurry in the slurry storage tank 4 is pumped into the main pipeline 1 of the slurry by the slurry pump 14, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com